Attitude motion simulation device with two degrees of freedom

A motion simulation, degree of freedom technology, used in measuring devices, static/dynamic balance tests, instruments, etc., can solve the problems of small carrying capacity, low degree of automation, low precision, etc., and achieve strong longitudinal carrying capacity and shorten the test. The effect of time, ease of operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

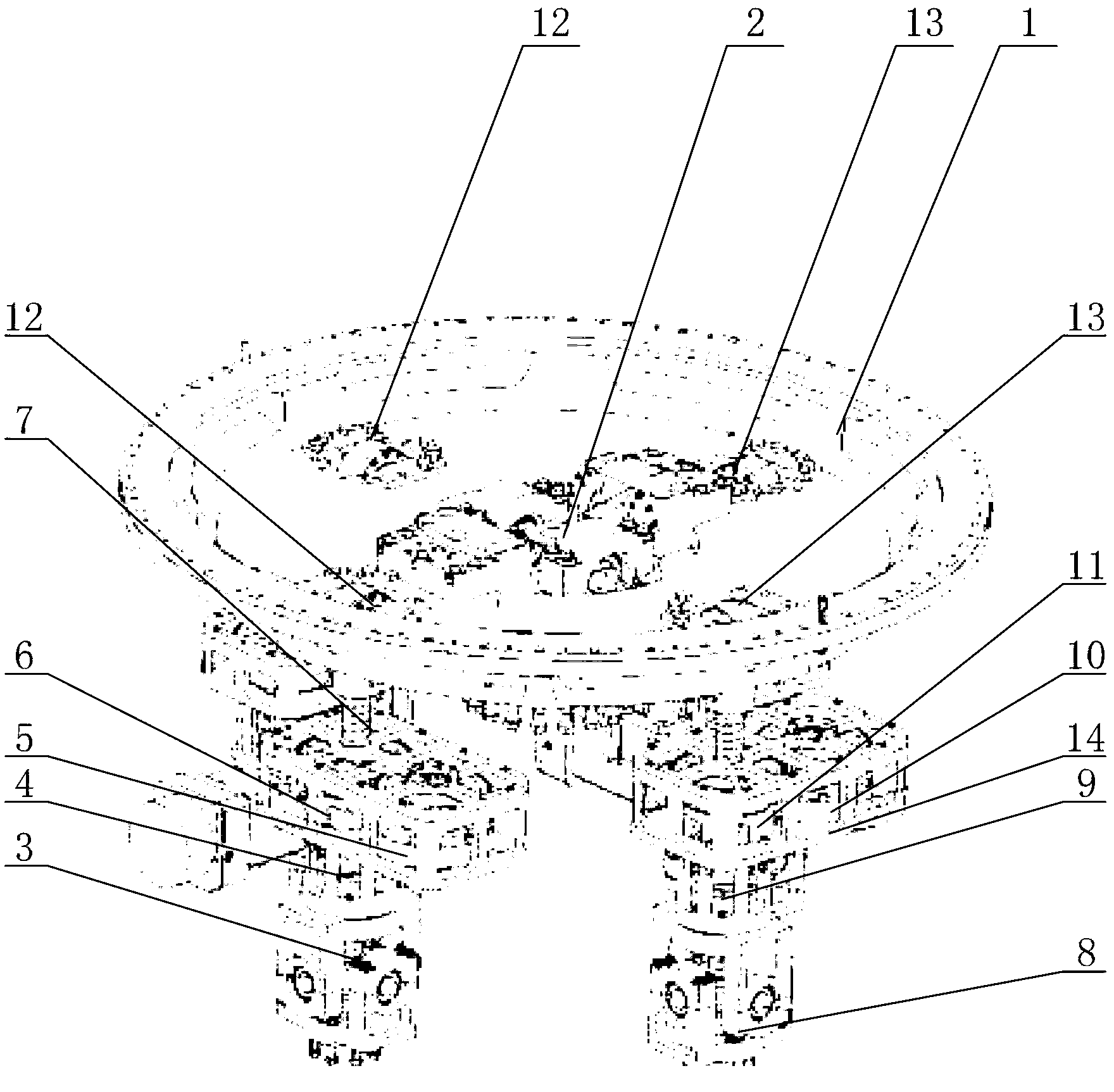

[0007] Specific implementation mode one: combine figure 1 Describe this embodiment. A two-degree-of-freedom attitude motion simulation device described in this embodiment includes a mechanical mounting plate 1 for passive components, a pitch and yaw universal joint 2, two pitch and yaw drive mechanisms, and two pitch and yaw brakes. Mechanisms, two pitching and yaw driving mechanisms and two pitching and yaw braking mechanisms are arranged symmetrically under the mechanical mounting plate 1 of the passive component, and the pitching and yaw universal joints 2 are installed in the middle of the mechanical mounting plate 1 of the passive component, each The pitching and yaw driving mechanism includes a motor 3, a coupling 4, an electromagnetic clutch 5, a gear reducer 6 and a driving ball spline screw 7. The output shaft of the motor 3 is connected to the electromagnetic clutch 5 through the coupling 4, and the electromagnetic clutch 5 passes through The gear reducer 6 is connec...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination figure 1 To illustrate this embodiment, each pitch and yaw driving mechanism of a two-degree-of-freedom attitude motion simulation device in this embodiment also includes a drive joint ball bearing 12, and the upper end of each drive ball spline screw 7 passes through the drive joint ball bearing 12 is connected with the lower surface of the mechanical installation plate 1 of the passive component.

[0010] The technical effect of this embodiment is: such arrangement reduces the wear on the upper end of each driving ball spline screw 7 and the lower surface of the mechanical mounting plate 1 of the passive component, prolongs the service life of each driving ball spline screw 7, and improves the sensitivity of the entire device.

[0011] Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0012] Specific implementation mode three: combination figure 1 To illustrate this embodiment, each pitching and yaw braking mechanism of a two-degree-of-freedom attitude motion simulation device described in this embodiment also includes a braking joint ball bearing 13, and the upper end of each braking ball spline screw 9 passes through the braking mechanism. The dynamic joint ball bearing 13 is connected with the lower surface of the mechanical mounting plate 1 of the passive component.

[0013] The technical effect of this embodiment is: such arrangement reduces the wear on the upper end of each brake ball spline screw 9 and the lower surface of the mechanical mounting plate 1 of the passive component, prolongs the service life of each brake ball spline screw 9, At the same time, the sensitivity of the whole device is improved.

[0014] Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com