Fabricated bridge double-column pier with triple energy dissipation system

A prefabricated and systematic technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of complex construction and easy damage and damage, and achieve the effects of short construction period, controllable earthquake damage, and good energy consumption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

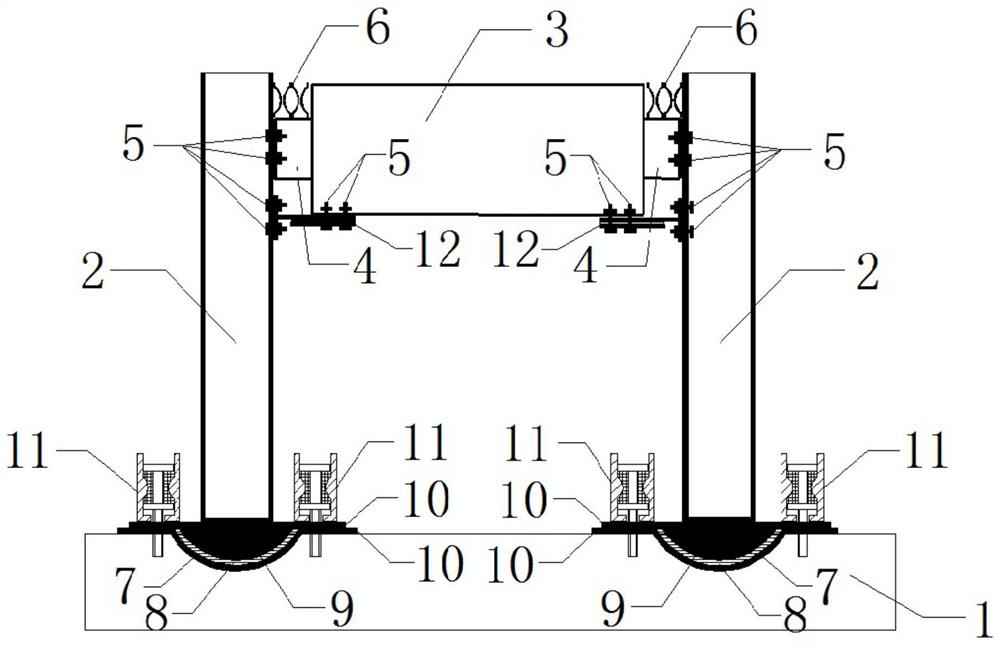

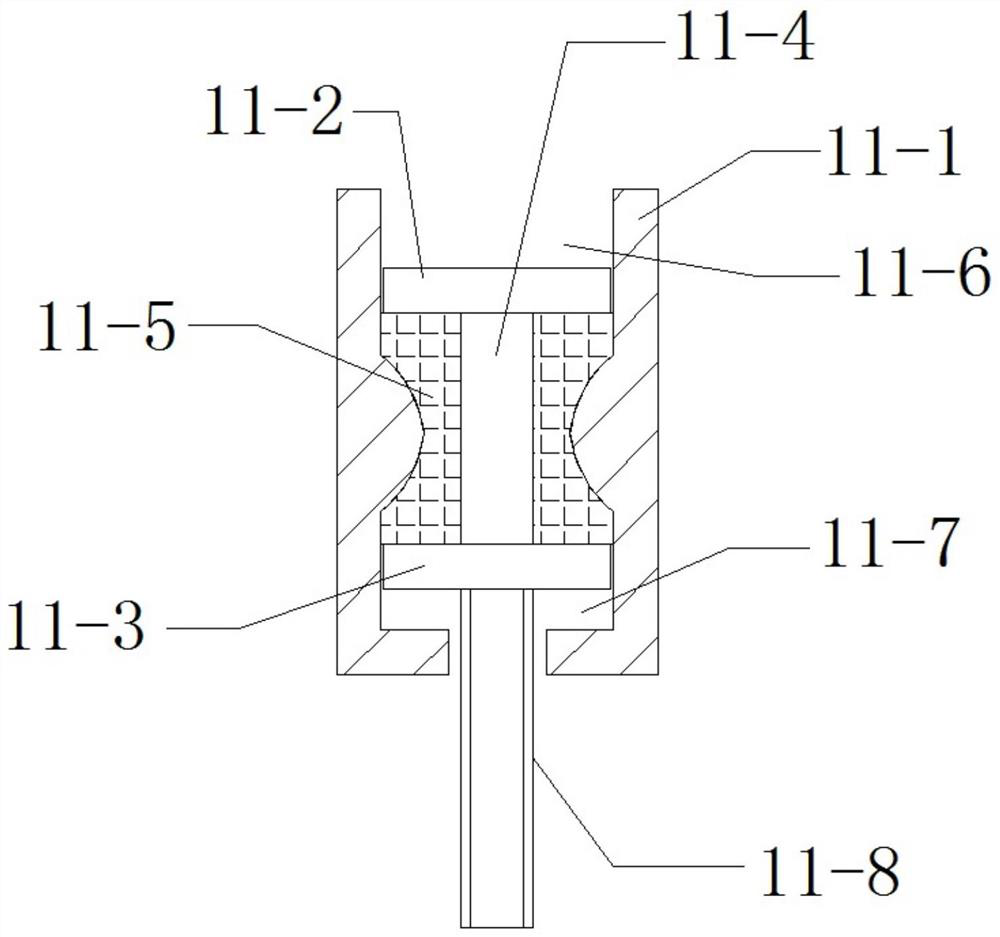

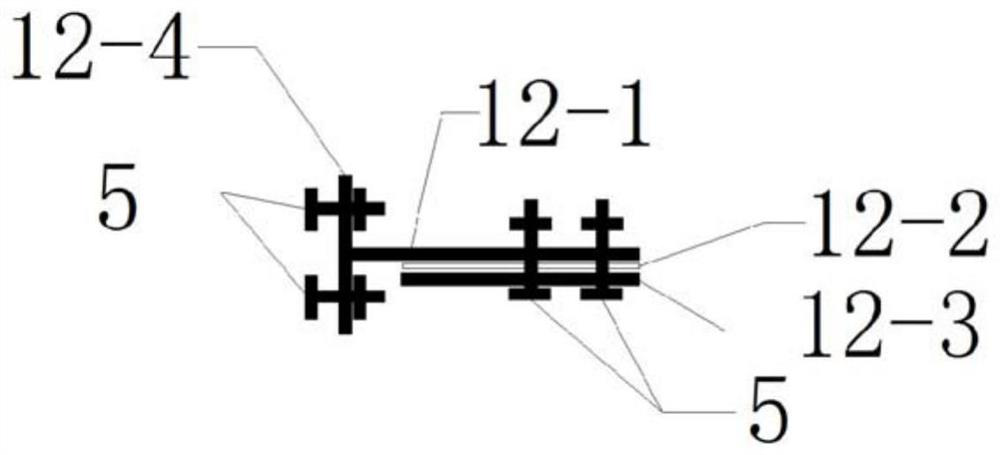

[0036] This embodiment provides a prefabricated bridge double-column pier with triple energy dissipation system, such as figure 1As shown, it includes a cap 1, a CFST pier 2 is installed on the upper left and right sides of the cap 1, and a squeeze damper 11 is arranged between the CFST pier 2 and the cap 1; A concrete-filled steel tube cover beam 3 is installed between the two ends of the steel tube. One end is fixedly connected with the concrete-filled steel tube pier 2 through the bolt 5; the top of the steel shear ear plate 4 is provided with a cymbal-shaped disc reed 6, and the cymbal-shaped disc reed 6 is located between the concrete-filled steel tube pier 2 and the concrete-filled steel tube cover beam 3; An anti-buckling plate assembly 12 is arranged below the steel shear lug plate 4 . One end of the anti-buckling plate assembly 12 is fixedly connected to the CFST pier 2 through bolts 5 , and the other end is fixedly connected to the CFST cover beam 3 through bolts 5 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com