Rotation type segregation-preventing device

An anti-segregation and rotary technology, which is used in mixing operation control devices, unloading devices, clay preparation devices, etc., can solve the problems affecting the durability and safety performance of concrete, affecting the mixing performance of concrete, and the quality of concrete cannot be guaranteed. Good economical practicability, enhanced market competitiveness, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following will clearly and completely describe the technical solutions in the embodiments of the present invention in conjunction with the accompanying drawings in the embodiments of the present invention:

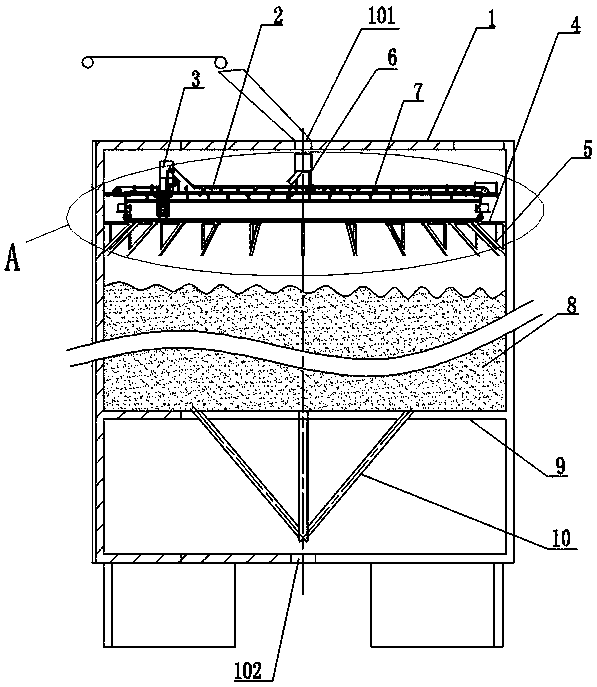

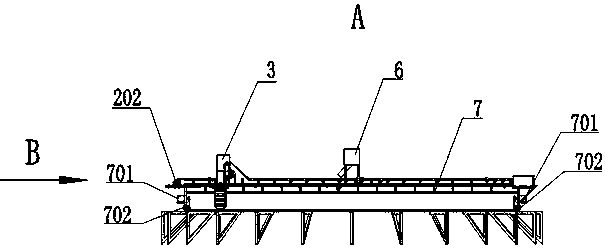

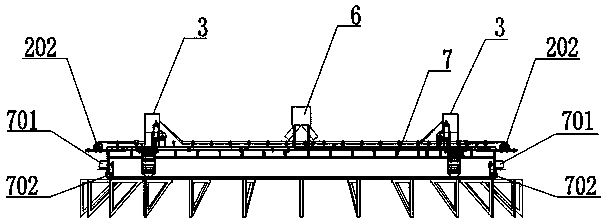

[0040] like Figure 1~Figure 14 As shown, a rotary anti-segregation device includes a silo 1, a feed port 101 is provided at the top axis of the silo 1, and one or more discharge ports 102 are provided at the bottom. 101 below is provided with a belt conveyor 2 and a rotary drive mechanism that controls the rotation of the belt conveyor 2 around the bin axis 1, and the belt conveyor 2 is provided with a distributing device 3 that reciprocates along the belt conveyor 2, and the belt conveyor 2 The machine 2, the rotary drive mechanism and the material distribution device 3 are all connected with a PLC control system that controls their mutual cooperation.

[0041] The PLC control system is an existing PLC control.

[0042] The belt conveyor 2 includes a fabric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com