Vibration stirrer special for construction of large-particle-size drainage bituminous stabilized macadam base layer

A technology for stabilizing the gravel base and draining asphalt, which can be used in roads, road repair, roads, etc., and can solve the problems of high asphalt content, poor control of oil-to-stone ratio, and undrained water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

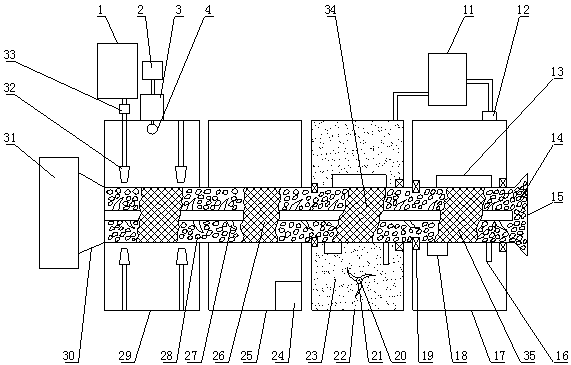

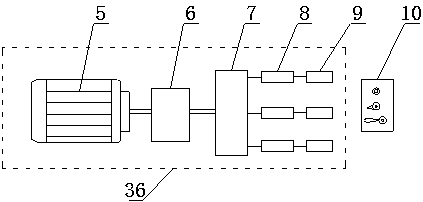

[0017] Such as Figure 1-2 As shown, the special vibrating mixer for large-diameter drainage asphalt stabilized gravel base construction includes a screw conveyor 27, and the outside of the screw conveyor 27 is sequentially provided with a washing bin 29 and a drying bin 25 from left to right. , the mixing bin 22, the mixture processing bin 17, the first steel wire cage 26 is arranged between the described washing bin 29, the drying bin 25 and the screw feeder 27, and the described mixing bin 22 and the screw feeder 27 A second wire cage 34 is arranged between them, a third wire cage 35 is arranged between the mixture processing bin 17 and the screw conveyor 27, and a feed inlet is arranged on the left side of the screw conveyor 27 30, the left side of the feed inlet 30 is provided with a storage bin 31, and the water washing bin 29 is provided with a nozzle 32 and a water outlet 4, and the nozzle 32 is connected to a water pump 33 through a pipeline. The water pump 33 is con...

Embodiment 2

[0021] Such as Figure 1-2 As shown, the special vibrating mixer for large-diameter drainage asphalt stabilized gravel base construction includes a screw conveyor 27, and the outside of the screw conveyor 27 is sequentially provided with a washing bin 29 and a drying bin 25 from left to right. , the mixing bin 22, the mixture processing bin 17, the first steel wire cage 26 is arranged between the described washing bin 29, the drying bin 25 and the screw feeder 27, and the described mixing bin 22 and the screw feeder 27 A second wire cage 34 is arranged between them, a third wire cage 35 is arranged between the mixture processing bin 17 and the screw conveyor 27, and a feed inlet is arranged on the left side of the screw conveyor 27 30, the left side of the feed inlet 30 is provided with a storage bin 31, and the water washing bin 29 is provided with a nozzle 32 and a water outlet 4, and the nozzle 32 is connected to a water pump 33 through a pipeline. The water pump 33 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com