FRP (fiber reinforced plastic)-steel bone reinforced composite column structure

A technology of combining columns and steel frames, applied in the directions of columns, piers, pillars, etc., can solve the problems such as the difficulty in fully exerting the tensile properties of FRP, poor corrosion resistance and fire resistance, and achieve the avoidance of local buckling problems and compressive strength. The effect of increasing and reducing the need for temporary support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

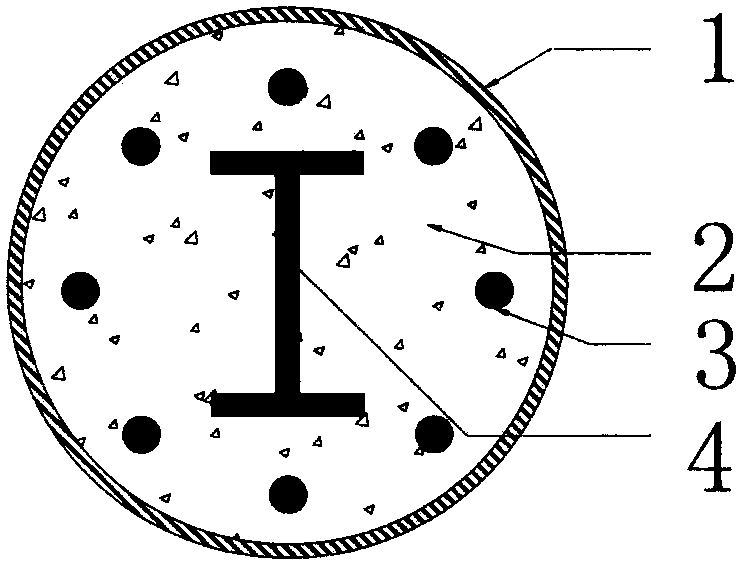

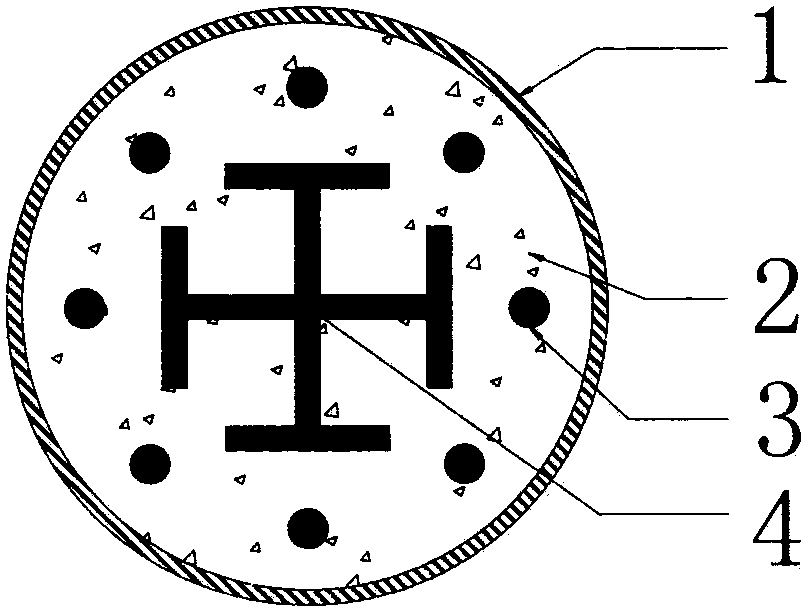

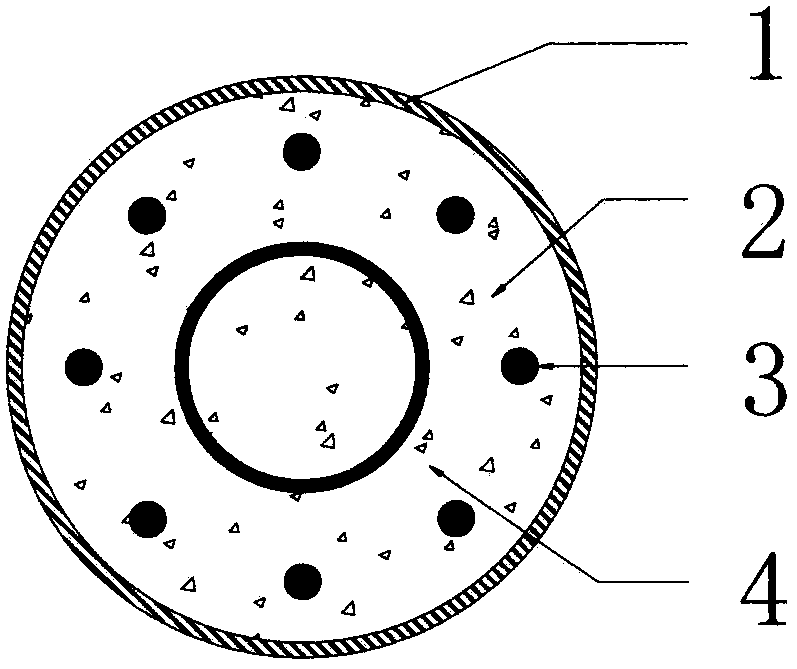

[0028] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings. The present invention provides an FRP-steel reinforcement composite column structure, which is characterized in that the structure comprises four parts: FRP layer 1, concrete 2, reinforcement 3 and steel reinforcement 4; wherein, reinforcement 3 and steel reinforcement 4 The direction is along the axial direction of the composite column structure and is wrapped by concrete 2. The steel frame 4 is located in the center of the section, the reinforcement 3 is evenly arranged around the inner side of the section edge, and the FRP layer 1 surrounds the concrete 2 at the outermost periphery.

[0029] The FRP-steel reinforcement composite column structure described above has a cross-sectional form including a circle and a rectangle with ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com