Concrete-filled steel tube column with ECC reinforced protective layer and FRP confined concrete core column and construction method and application of concrete-filled steel tube column

A technology for concrete-filled steel tubular columns and restrained concrete, which is applied in chemical instruments and methods, columns, buildings, etc., can solve the problems of steel tube buckling failure, insufficient corrosion resistance and fire resistance, and achieve local buckling suppression and enhancement of strength and deformation capacity. , make full use of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

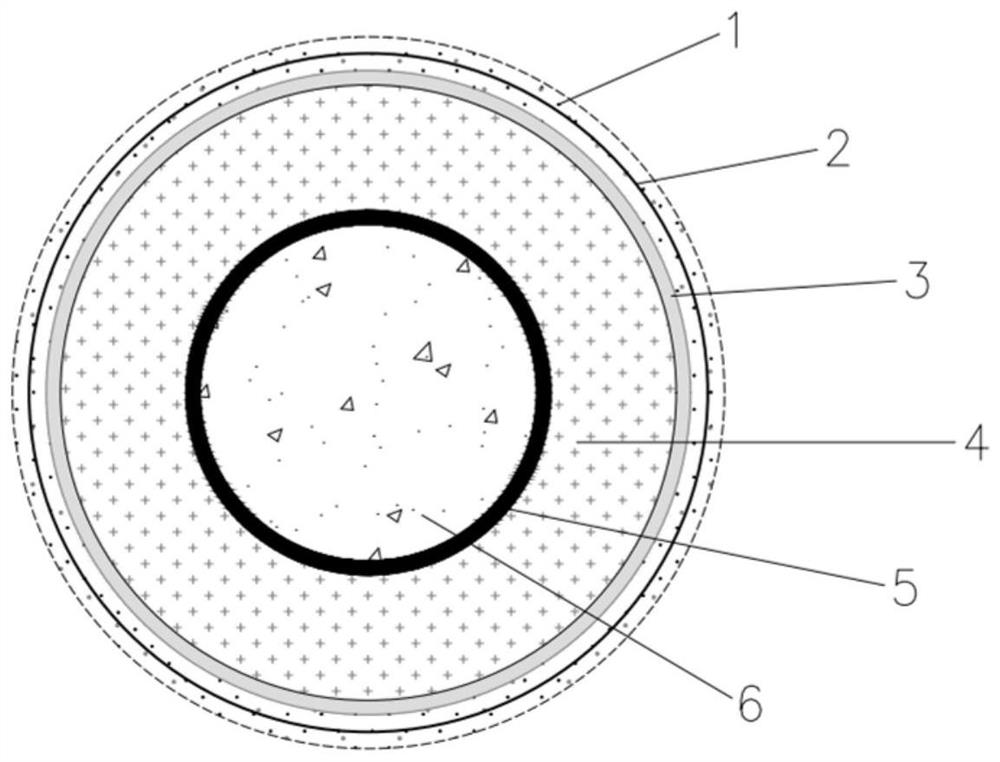

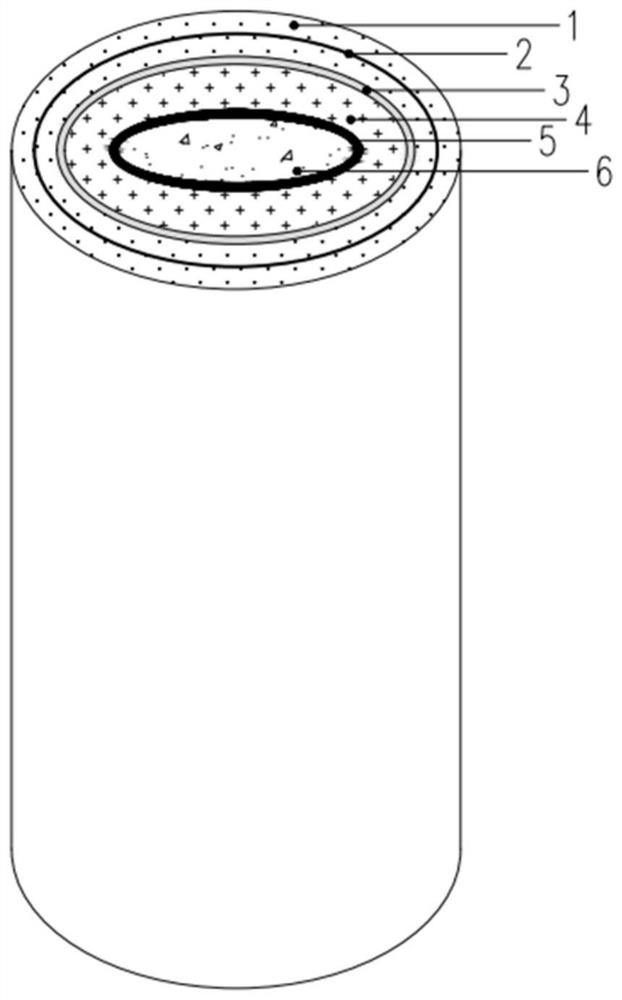

[0031] The concrete-filled steel tube column with ECC reinforced protective layer and FRP-confined concrete core column includes ECC layer, steel tube layer, concrete layer, FRP tube layer, and core concrete core column arranged in sequence from outside to inside.

[0032] The thickness of the ECC layer is 5-50mm, the thickness of the steel pipe layer is 2-30mm, the thickness of the concrete layer is 20-200mm, the thickness of the FRP pipe layer is 1-20mm, and the outer diameter of the core concrete core column is 50-1000mm. In this embodiment, the thickness of the ECC layer is 25mm, the thickness of the steel pipe layer is 15mm, the thickness of the concrete layer is 100mm, the thickness of the FRP pipe layer is 15mm, and the outer diameter of the core concrete core column is 500mm.

[0033] The material of the concrete layer is ordinary concrete, high-strength concrete, expansive concrete, fly ash concrete, lightweight aggregate concrete, recycled aggregate concrete, fiber co...

Embodiment 2

[0050] The concrete-filled steel tube column with ECC reinforced protective layer and FRP-confined concrete core column includes ECC layer, steel tube layer, concrete layer, FRP tube layer, and core concrete core column arranged in sequence from outside to inside.

[0051] In this embodiment, the material of the concrete layer is ordinary concrete, and the material of the core concrete core column is high-strength concrete; the reinforced grid is an FRP (Fiber reinforced polymer) grid; Three times, the edges of adjacent reinforced grids overlap each other, and the overlapping length is 3-4 times the grid spacing of the reinforced grid; the ECC layer is wrapped in the outside of the steel pipe layer with variable thickness; the cross section of the steel pipe layer is square, The cross-section of the FRP tube layer is circular, the cross-section of the ECC layer is square, and the geometric centroids of the three coincide.

[0052] The parts not mentioned in this embodiment are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com