Quick dismounting type flexile bionic finger

A finger and flexible technology, applied in the field of quick-release flexible bionic fingers, can solve the problems of easy wear, limited service life and compressive strength, low safety, etc., to prevent excessive wear and tear, improve lateral locking strength, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

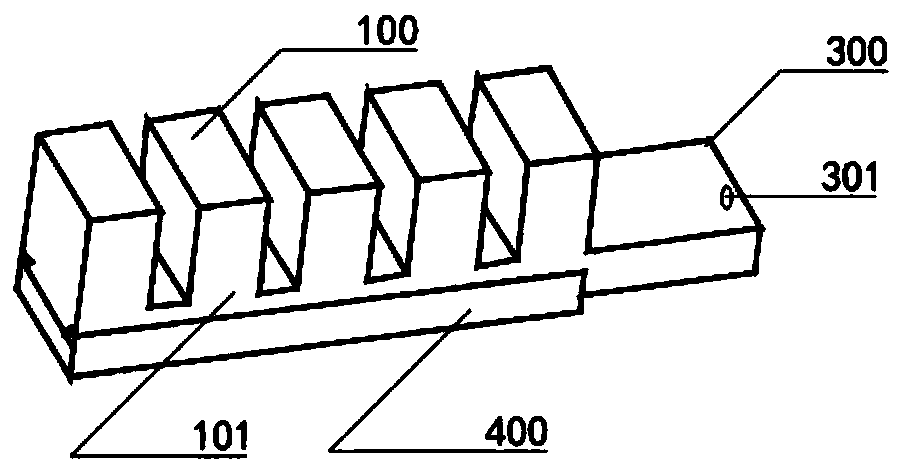

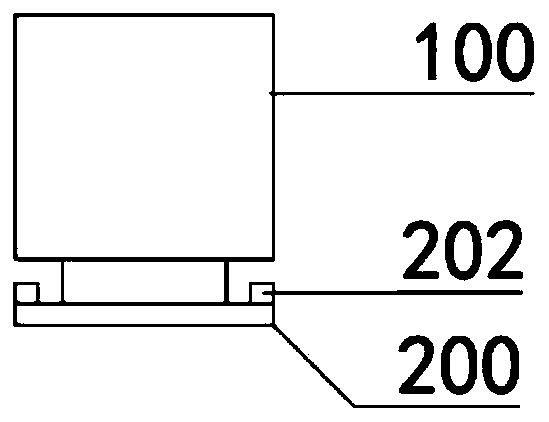

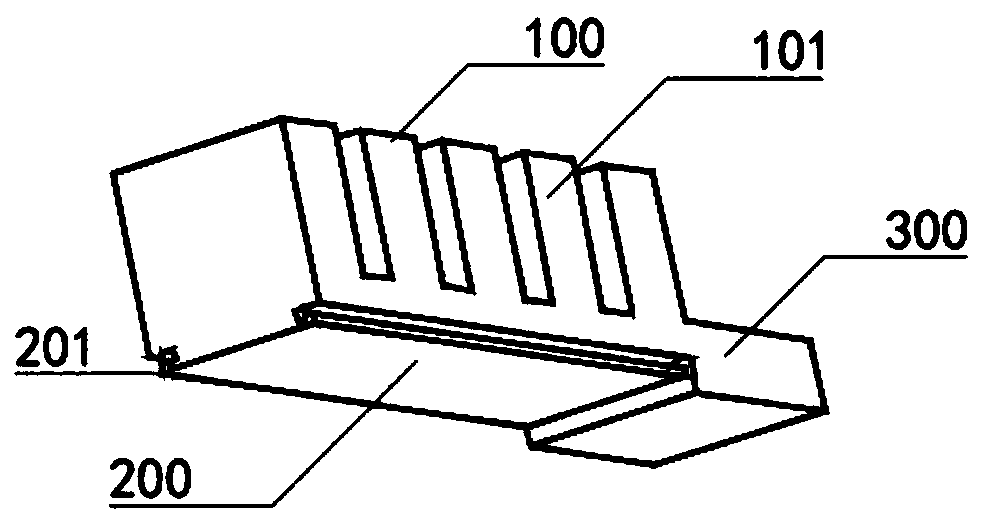

[0049] Such as figure 1 , 3 As shown, the present invention provides a quick-release flexible bionic finger, which includes a finger surface 100 that drives the flexible bionic finger to deform to clamp or release fruits and vegetables through its own deformation, and is arranged on the bottom of the finger and is connected to the finger surface. The inner cavity constitutes the finger base plate 200 of the bending deformation driving cavity 101, and a section of the finger surface 100 and the end of the finger base plate 200 extend backwards for a movable insertion into the mechanical arm to connect the air circuit to inflate and deflate the bending deformation driving cavity 101 The root of the finger 300 and the soft elastic quick-release pad 400 that is slidably connected to the bottom of the bottom of the finger bottom and directly contacts the outer surface of the fruit and vegetable; figure 2 , 4 As shown, wherein, a quick-change slot 201 including a horizontally pro...

Embodiment 2

[0055] On the bionic finger in embodiment 1, a soft elastic quick release pad clamping mechanism is set, such as Figure 11 , 12 As shown, it includes a bottom plate spring slot 203 opened on the finger bottom plate 200 close to the root of the finger, a spring 204 fixed in the bottom plate spring slot and free to expand and contract in and out of the bottom spring slot 203, and the bottom spring slot 203 Corresponding to the quick-release pad spring slot 404 provided on the flexible elastic quick-release pad.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com