Reducing screw displacement pile drilling tool and construction method thereof

A technology of variable-diameter piles and auger bits, which can be used in earth drilling, drilling without stripping topsoil, and drill pipes. It can solve problems such as broken piles, construction quality problems, and difficulties in hole formation, and improve pile side friction. , Good construction quality and fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. First of all, it should be pointed out that what is described in this section is only a preferred embodiment for implementing the present invention. Those skilled in the art can make modifications to the technical solutions described here, and these modifications will also fall within the scope of the present invention.

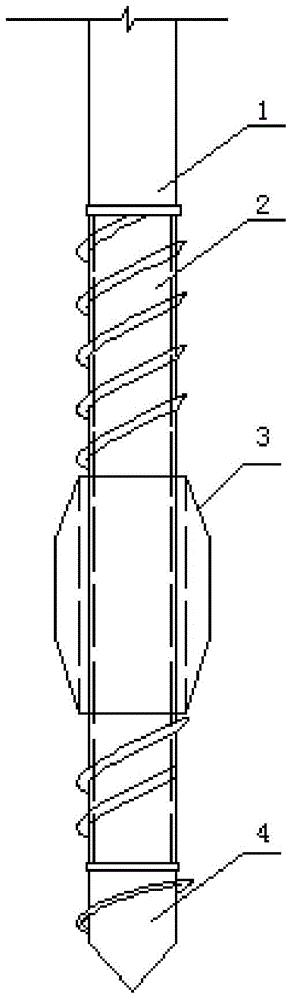

[0030] Reference attached figure 1 , a helical soil-squeezing variable-diameter pile drilling tool, comprising a hollow inner drill rod 2, the inner drill rod 2 is a cylinder with an external thread on the outer wall, and the outer part of the inner drill rod 2 is connected with a soil-squeezing body 3 with an internal thread through threads , the extruded soil body 3 is a spindle body with two thin ends and a thick middle.

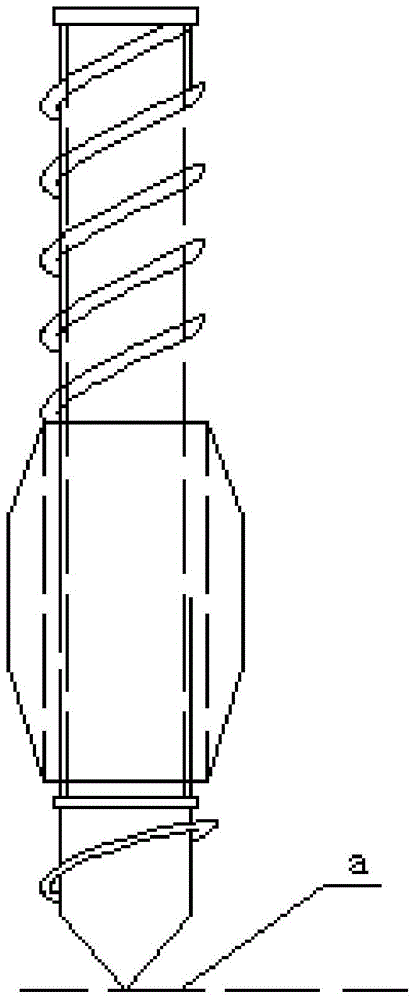

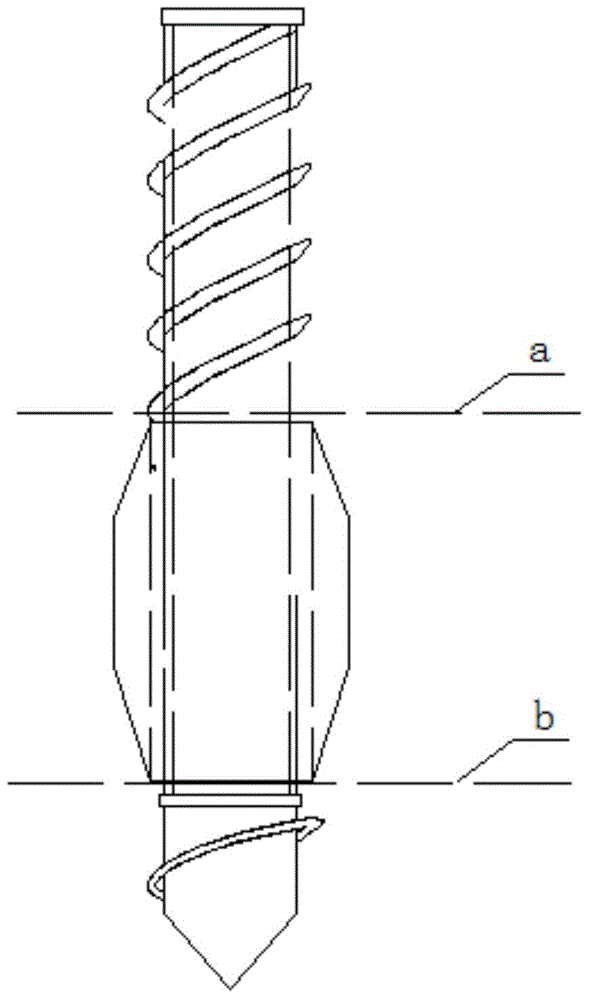

[0031] Reference attached Figure 2 to Figure 6 , a method for constructing by using the scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com