Cup production process

A production process and cup technology, which is applied in the field of bra cups, can solve the problems of poor material viscosity and the cups cannot meet the demand, etc., and achieve the effect of improving the gathering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

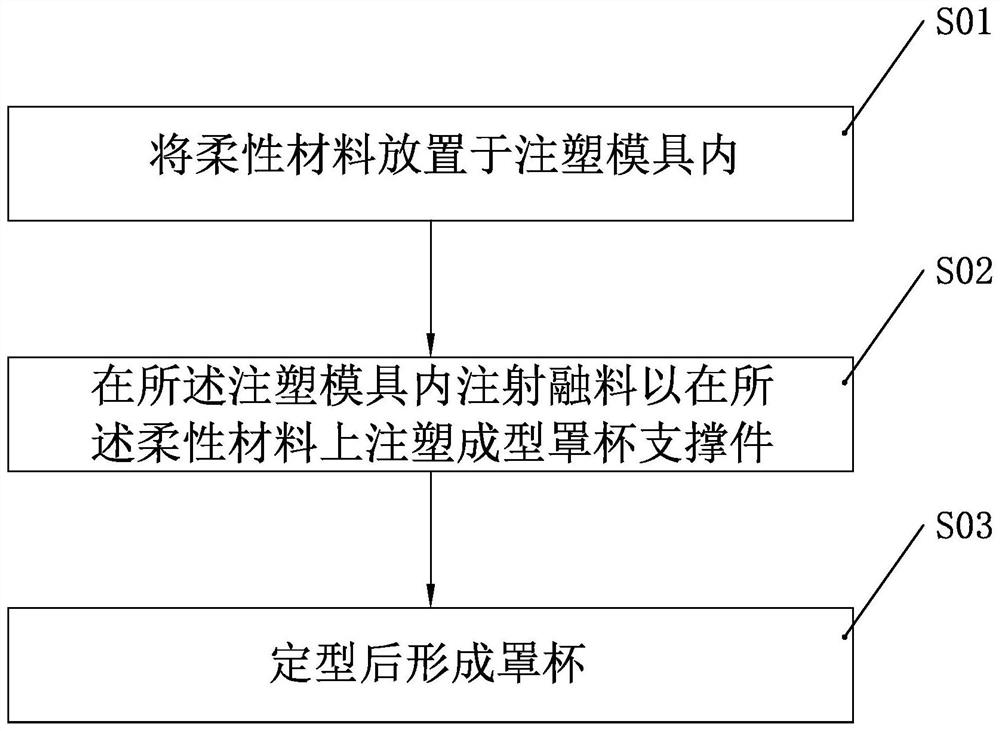

[0032] Embodiment 1: as figure 1 As shown, the present embodiment provides a production process for breast cups, comprising the following steps:

[0033] S01: placing the flexible material in the injection mold;

[0034] S02: Injecting molten material into the injection mold to injection-mold a cup support on the flexible material;

[0035] S03: Form a cup after shaping.

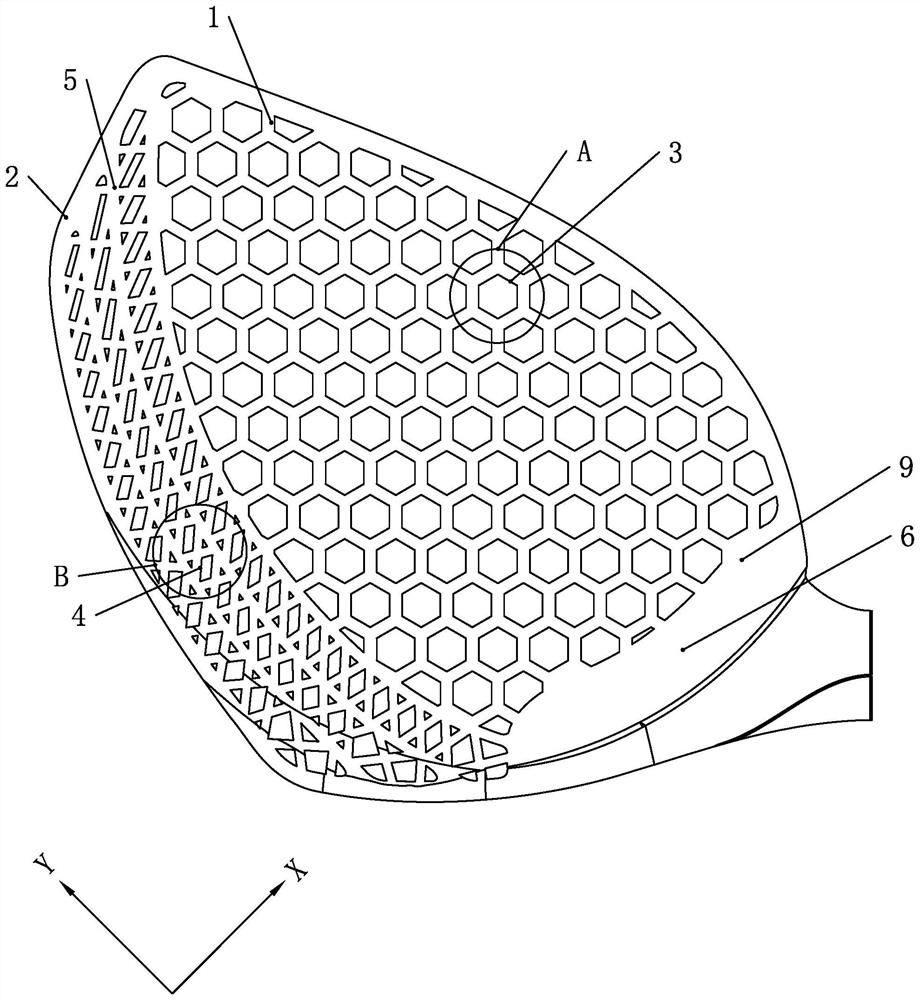

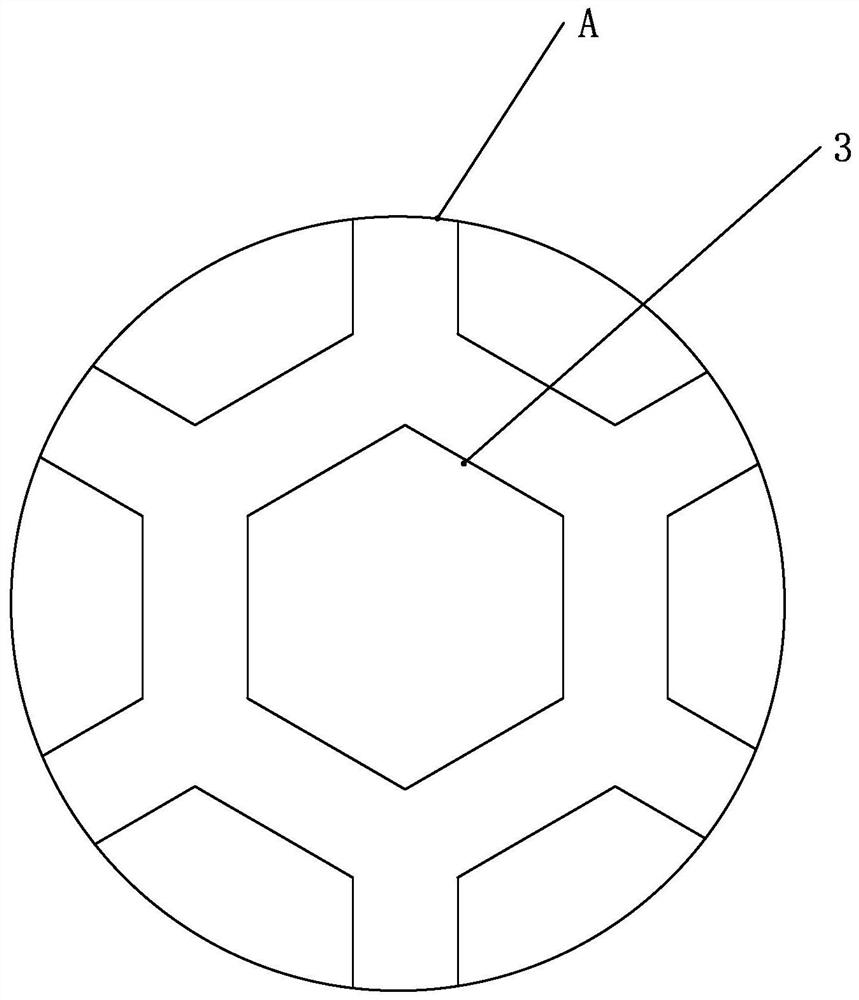

[0036] Before the injection molding process, the flexible material is placed in the injection mold, that is, between the fixed mold and the movable mold of the injection mold; then the fixed mold and the movable mold are locked, and a cavity suitable for a cup shape is formed between the fixed mold and the movable mold ; Heat the molten material to the molten state and inject it into the cavity. During the cooling process of the molten material, it will be bonded and bonded with the flexible material. After cooling to a certain temperature, the molten material will solidify and shape to form a cup. The pr...

Embodiment 2

[0045] Embodiment 2: as Image 6 As shown, the present embodiment provides a production process for breast cups, comprising the following steps:

[0046] S11: placing the flexible material in the injection mold;

[0047] S12: placing the chicken heart in the injection mold;

[0048] S13: Injection-molding the cup support on the flexible material, and forming a cladding layer connecting the two cup supports in the mould, on the outer side of the chicken heart at the same time, by melting the material;

[0049] S14: Form a cup after shaping.

[0050] The difference between this embodiment and embodiment 1 is that step S12 is added before step S02 of embodiment 1: placing the chicken heart in the injection mold; in step S02 of embodiment 1, the following steps are also included: melting the material at the same time The outer side of the chicken heart forms a cladding layer connecting the two cup supports in the mould.

[0051] like Figure 7-9 As shown, before the injection...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com