A Two-way Inverted T Beam Composite Floor Slab

A technology for combining floors and webs, applied in floors, walls, buildings, etc., can solve problems such as complex setting of shear parts, large floor thickness, and inability to ensure the combined effect of steel beams and concrete, and achieve good technical and economical results Benefits, lower storey height, favorable for flexible arrangement and free separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

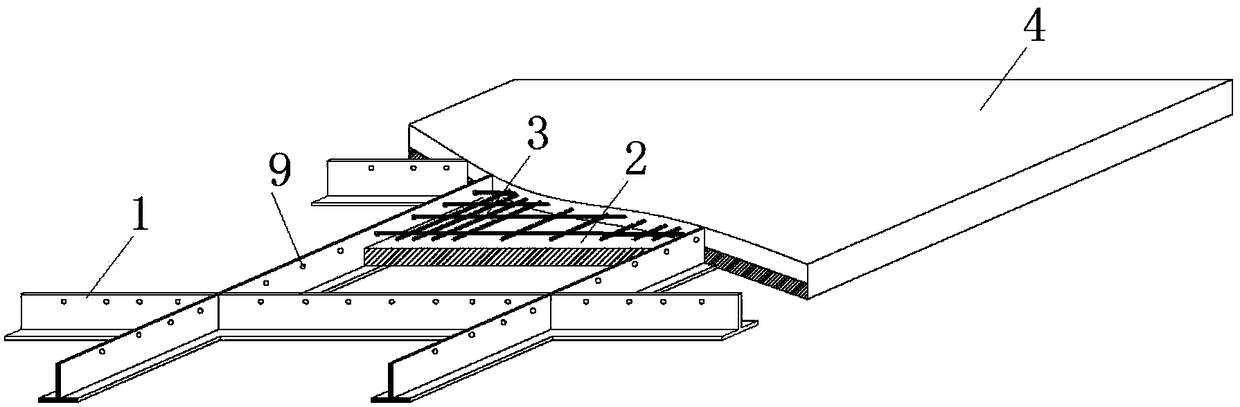

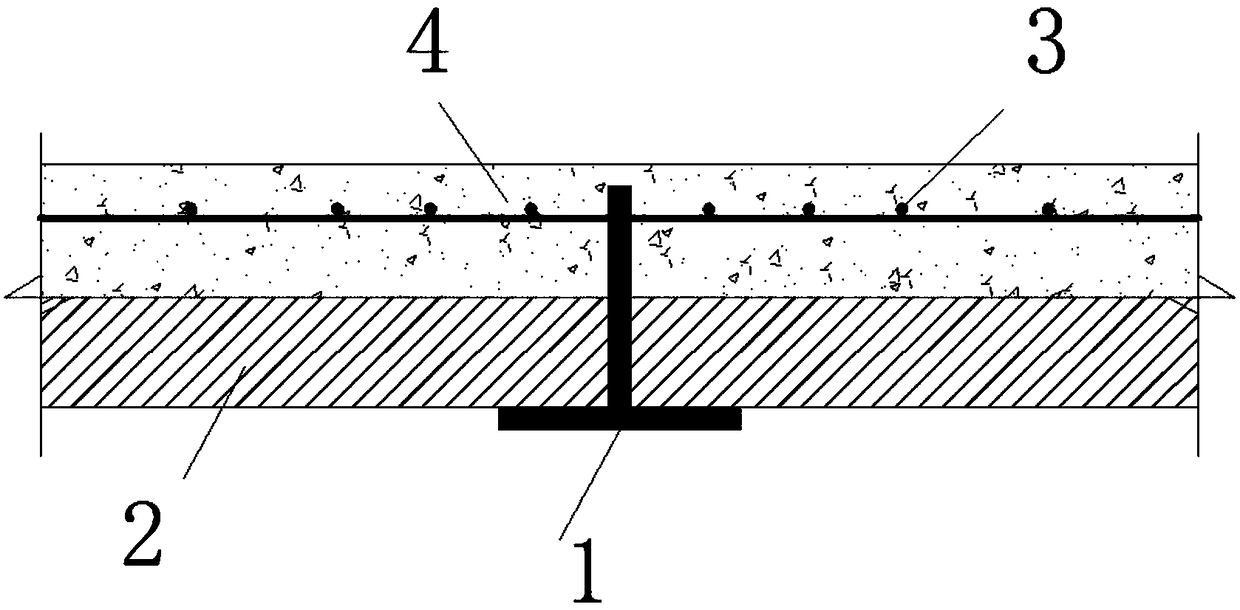

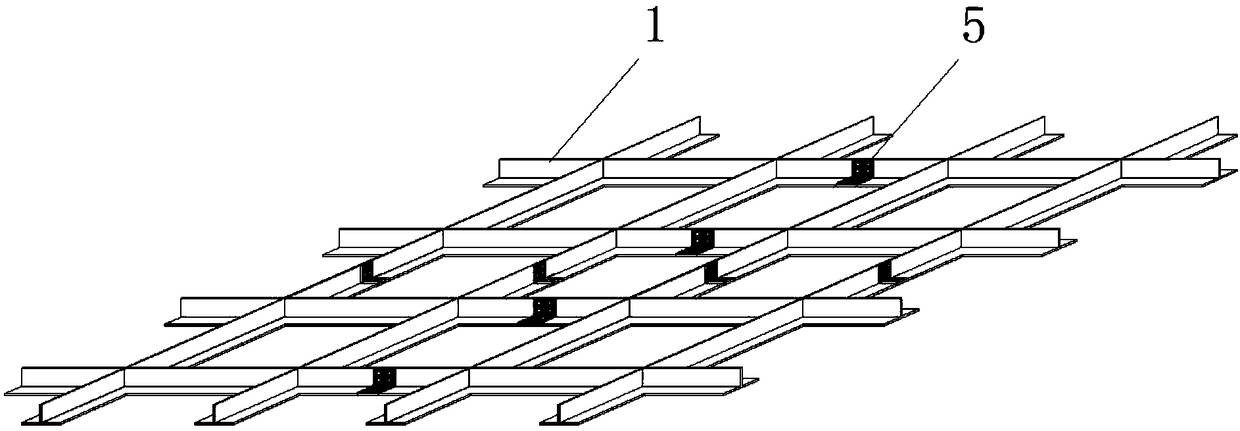

[0024] Such as figure 1 , figure 2 , image 3 As shown, the two-way inverted T-beam composite floor of the present invention adopts a two-way flat beam form, including a well-shaped member composed of a plurality of inverted T-shaped steel beams 1, and the inverted T-shaped steel beam 1 web of the well-shaped member A plurality of small holes 9 are sequentially opened on the top, and steel bars 3 are intersected between the small holes 9 on the web plate of the inverted T-shaped steel beam 1. The diameter of the small holes 9 is larger than that of the steel bars 3, and the edge of the well-shaped member There is a splicing node 5 at the place, and a two-way steel rib structure that acts as a force during construction is formed through the splicing node 5 between multiple well-shaped components, such as Figure 4 and Figure 5 As shown, the splicin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com