Circular knitting method of composite material high-pressure container

A technology of high-pressure containers and composite materials, which can be used in knitting, weft knitting, textiles and papermaking, etc., and can solve problems such as insufficient hoop strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

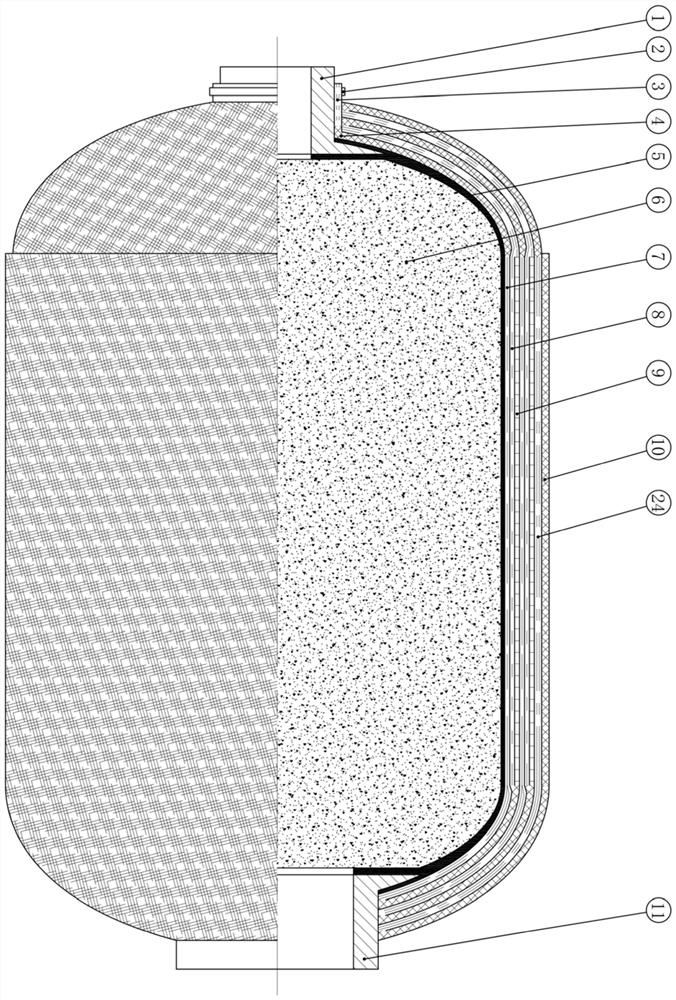

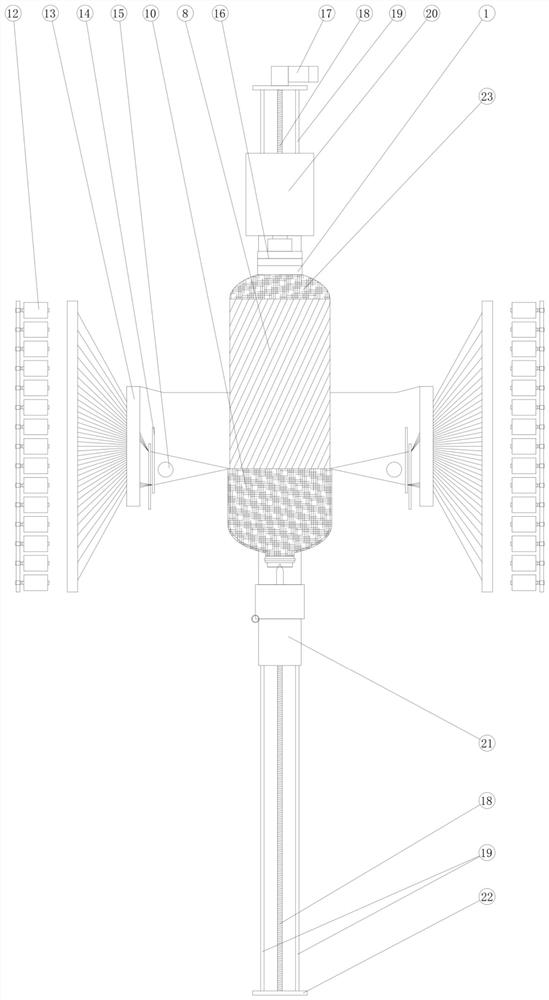

[0030] see figure 1 , the present invention proposes a circular weaving method for the shell of a composite solid rocket combustion chamber, using a circular loom to replace the meal winding machine to weave the load-bearing structure of the high-pressure vessel, and controlling the opening of the warp yarn of the loom and the shaft of the mandrel through a software program Change the fabric structure and weft density, so that the strength of each part of the fabric in any direction can meet the requirements; install the mandrel on the axial movement mechanism, and firstly distribute the ends of the warp yarns evenly on the root of the head at one end of the mandrel Tighten the warp with cable ties, and then start circular weaving. The diameter of the circular fabric increases as the diameter of the mandrel increases. After weaving a layer of cylindrical surface, the main shaft stops rotating, and the shedding mechanism and weft insertion mechanism stop working. 1. The mandrel...

Embodiment 2

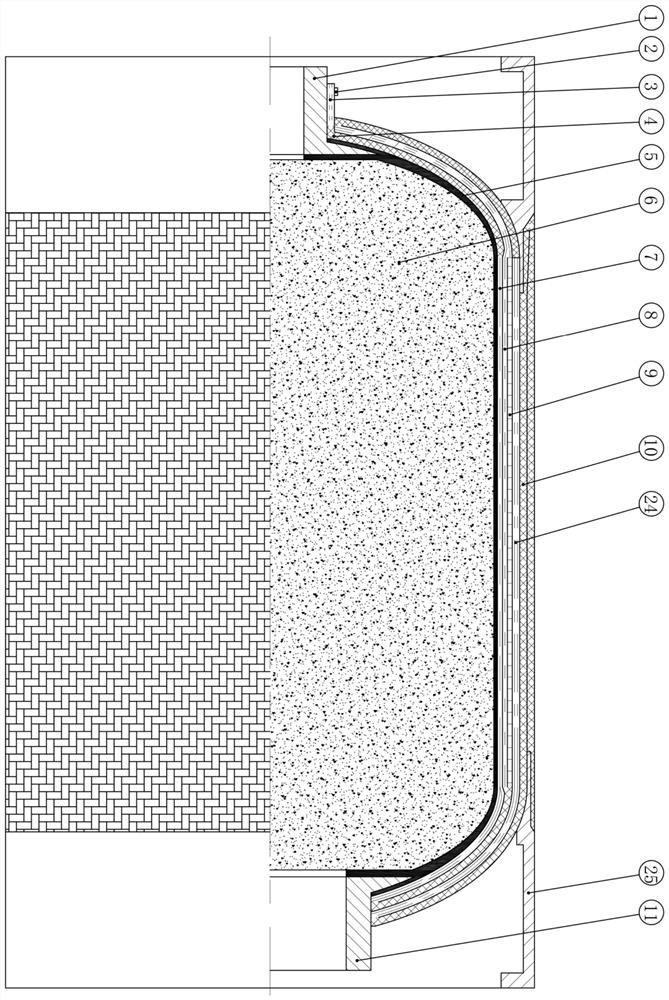

[0035] see figure 1 with image 3 , the present embodiment is a connection method between the composite material solid hair combustion chamber and the front and rear skirts 25 using a weaving process. After the weaving of the shell is basically completed by the method described in Example 1, when the weaving cylinder is woven by the loom about halfway, the front and rear skirts are respectively pressed onto the front and rear heads of the shell, and then Continue to weave cylindrically to hold the front skirt firmly, then reverse circular knit to hold the rear skirt firmly.

[0036] The oblique laying of the warp yarn layer on the surface of the cylindrical section can make the shell have torsion resistance, while the warp yarn parallel to the axis can make the shell have sufficient bending resistance.

[0037] The main axis direction of ordinary circular looms is perpendicular to the ground. In order to facilitate the weaving of products with relatively large length and dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com