Walnut shell based ecological composite structure material and preparation method thereof

A composite structure and walnut shell technology, which is applied in the field of walnut shell-based ecological composite structural materials and its preparation, can solve the problems of complex process and high investment cost of technology implementation, and achieve the effect of simple process, wide application range and reliable strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of step that prepares mobile phone frame with walnut shell-based ecological composite material is as follows:

[0036] Step 1. According to the material texture design plan, cut the walnut into four parts along the direction parallel to the central axis, and remove the kernels;

[0037] Step 2, placing the cut walnut shells evenly and densely in the mold with the cut section facing upwards;

[0038] Step 3: Heat the alicyclic epoxy resin with a volume ratio of 1:3 to the walnut shell to 155°C, and pour it evenly into the mold;

[0039] Step 4. Apply a positive pressure of 35 MPa to the mold to remove air holes and cool to form;

[0040] Step 5. Machine the plate according to the drawing, polish the edges and corners around it, and cut out the groove for placing the mobile phone, such as figure 1 .

Embodiment 2

[0042] A kind of cubic type walnut shell handicraft prepared with walnut shell-based ecological composite material as the main body is as follows:

[0043] Step 1. According to the material texture design plan, cut the walnut into four parts along the direction parallel to the central axis, and remove the kernels;

[0044] Step 2, placing the cut walnut shells evenly and densely in the mold with the cut section facing upwards;

[0045] Step 3: Heat the plexiglass with a volume ratio of 1:2 to the walnut shell to 240°C, and pour it into the mold evenly;

[0046] Step 4. Apply a positive pressure of 25 MPa to the mold to remove air holes and cool to form;

[0047] Step 5, machine the plate according to the drawings to form an outer frame;

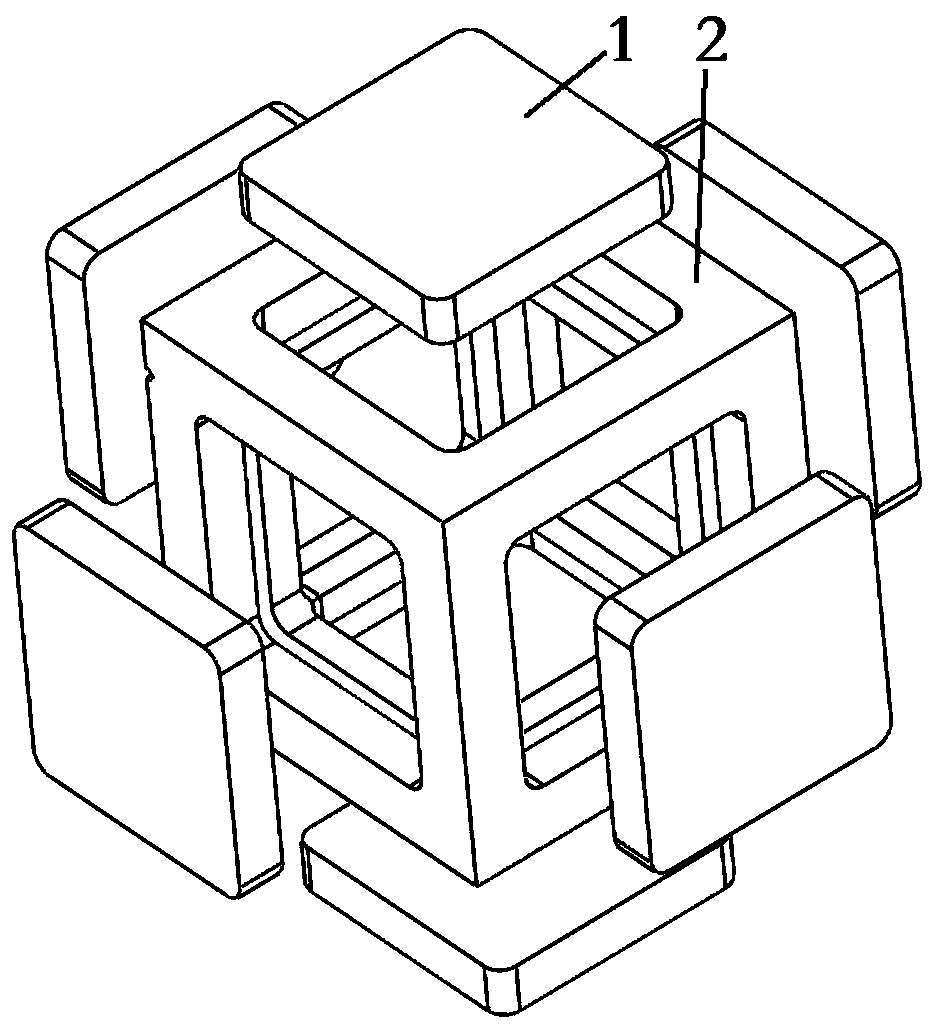

[0048] Step 6. Inlay activated carbon blocks in the outer frame, and connect tassels to the outside, such as figure 2 and Figure 2a , 2b , 2c, the handicraft component includes a frame 2 and a mosaic block 1 conforming to the shape of ...

Embodiment 3

[0051] A walnut-shell-based ecological composite material is a pier-shaped walnut-shell handicraft prepared as a main body. The steps are as follows:

[0052] Step 1. According to the material texture design plan, cut the walnut into the required shape and remove the kernel;

[0053] Step 2, place the cut walnut shells in the mold;

[0054] Step 3: Heat the rosin with a volume ratio of 1:1 to the walnut shell to 180°C, pour it into the mold evenly, and stir;

[0055] Step 4. Apply a positive pressure of 10MPa to the mold, remove air holes, and cool and form;

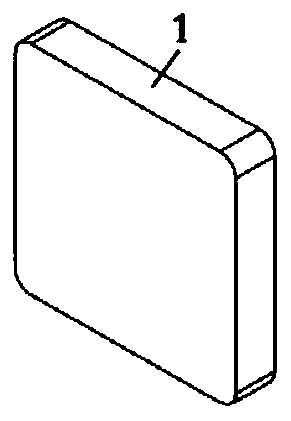

[0056] Step 5: Inlay crystal blocks on walnut shells, such as image 3 and Figure 3a , 3b , 3c, the handicraft component includes a frame 2 and a mosaic block 1 conforming to the shape of the frame 2; the material of the mosaic block 1 is crystal, and the quantity is two, which are cast in a mould. The frame 2 is in the shape of a pier, and its material is a walnut shell-based ecological composite material, which i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com