Three-dimensional printing method of metal-based composite material

A composite material and three-dimensional printing technology, applied in the field of composite material molding, can solve problems such as high cost, difficult interface reaction control, complex process, etc., and achieve the effect of less defects, excellent overall performance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

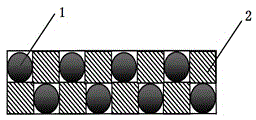

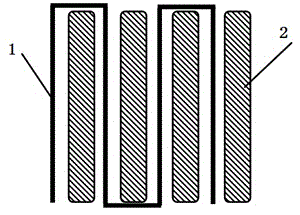

[0029] Example 1: The metal matrix composite material includes 0° direction yarns, 45° direction yarns, 90° direction yarns and 135° direction yarns, and has a square cross section. The yarns are all made of 12K nickel-plated carbon fiber yarns, and the metal materials are made of aluminum. The thickness of the metal matrix composite is 4 mm.

[0030] Specific implementation steps:

[0031] (1) Layer the metal matrix composite CAD model along the Z direction to generate section profile information;

[0032] (2) Apply a layer of release agent on the abutment;

[0033] (3) According to the cross-sectional profile information, print liquid metal on the abutment along the direction of 0° to form a metal groove, then lay the reinforcement material in the metal groove along the direction of 0°, and then place the reinforcement material along the direction of 0° The liquid metal is printed in the direction of 0°, the liquid metal penetrates into the reinforcement material and form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com