Powder solid waste granulation baking-free brick and preparation method thereof

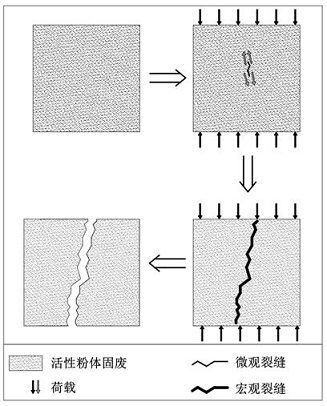

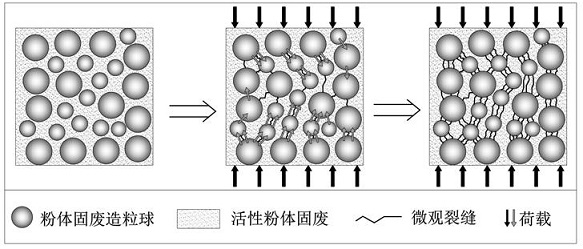

A technology of unburned bricks and powders, which is applied in the field of resource utilization of solid waste building materials, can solve the problems that the real mechanical properties are not fully exerted and the strength of powder solid waste unburned bricks is low, so as to improve the strength and solve the problem of brittleness. , the effect of improving ductility and crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

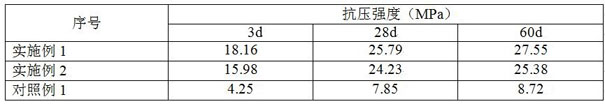

Embodiment 1

[0026] (1) Preparation of red mud aggregate particles

[0027] Taking the Bayer process red mud produced by the aluminum plant as the treatment object, by weight percentage, take 80% of the Bayer process red mud, 20% of P.O42.5 ordinary Portland cement, add water and water reducer to granulate, and obtain granules Solid waste particles with a diameter of 1~30mm; (2) Preparation of cementitious materials

[0028] In terms of weight percentage, take 80% of Bayer process red mud and 20% of P.O 42.5 ordinary portland cement, and mix them uniformly to obtain a cementitious material;

[0029] (3) Preparation of unburned bricks

[0030] In terms of weight percentage, take 20% of the cementitious material, 40% of the solid waste particles with a particle size of less than 5mm, and 40% of the solid waste particles with a particle size of greater than 5mm, add water and water reducer to mix, and use a brick making machine to press and form it. To avoid burning bricks.

Embodiment 2

[0032] (1) Preparation of red mud aggregate particles

[0033] The Bayer red mud produced by the aluminum plant is used as the processing object, and its particle size is less than 200 microns. In terms of weight percentage, take 90% of Bayer red mud, 10% of P.O 42.5 ordinary Portland cement, add water and water reducer to granulate, and make solid waste particles with a particle size of 1~30mm;

[0034] (2) Preparation of gelling material

[0035] In terms of weight percentage, take 70% of Bayer process red mud and 30% of P.O 42.5 ordinary Portland cement, and mix them uniformly to obtain a cementitious material;

[0036] (3) Preparation of unburned bricks

[0037] In terms of weight percentage, take 30% of the cementitious material, 20% of the solid waste particles with a particle size of less than 5mm, and 50% of the solid waste particles with a particle size of greater than 5mm, add water and water-reducing agent to mix, and use a brick making machine to press and form i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com