Double beam floor structure

A technology for cover structure and floor covering, which is applied to floor slabs, building components, building structures, etc., can solve the problems of inability to standardize the production of main components in factories, poor ductility of beamless slabs, etc., and achieve easy processing and installation, reduce beam height, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

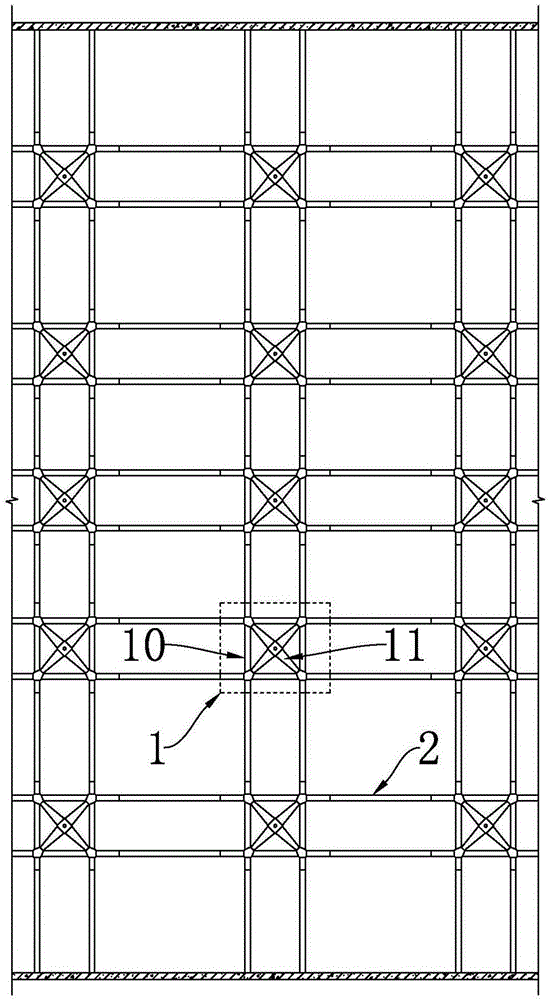

[0037] Such as figure 1 , 2 As shown in, 3, 4, and 10, the present invention provides a double-beam floor structure, which includes several supporting units 1 that play a supporting role. The number and density of the supporting units 1 are determined according to the actual needs of the floor. , Adjacent support units 1 are connected by two parallel vertical and horizontal beams 2, and then a square-hole mesh structure with the supporting unit 1 as the node and the vertical and horizontal beams 2 as the link is formed; this kind of square-hole mesh support The structure is easy to process and install, with fewer types of components and strong standardization, which improves installation efficiency.

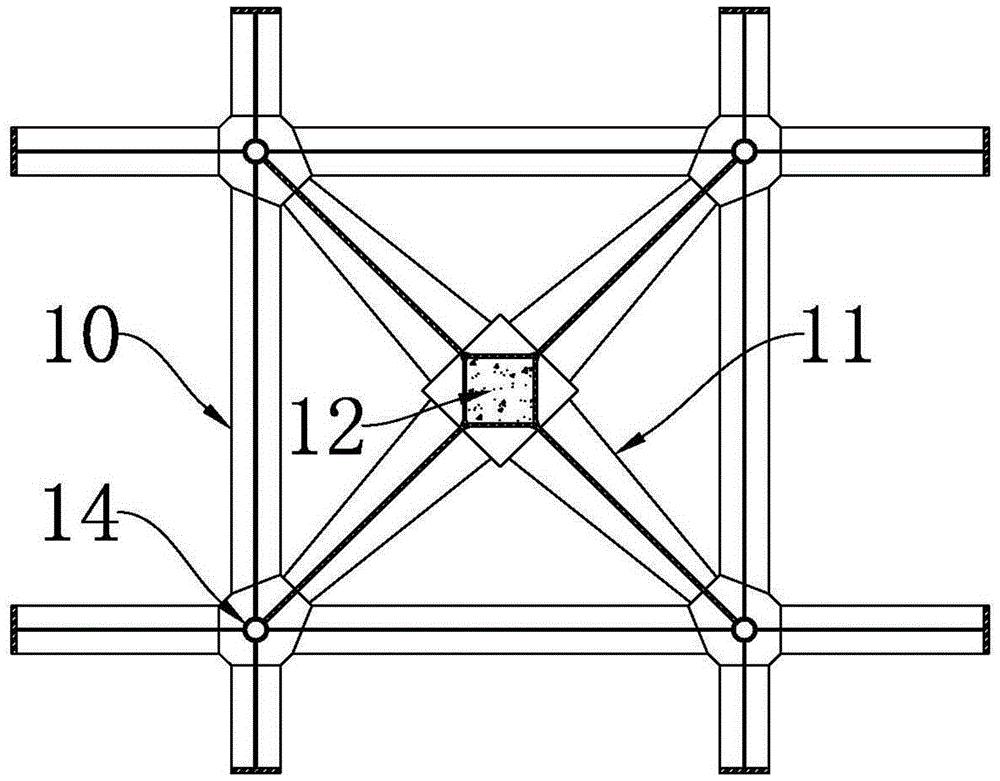

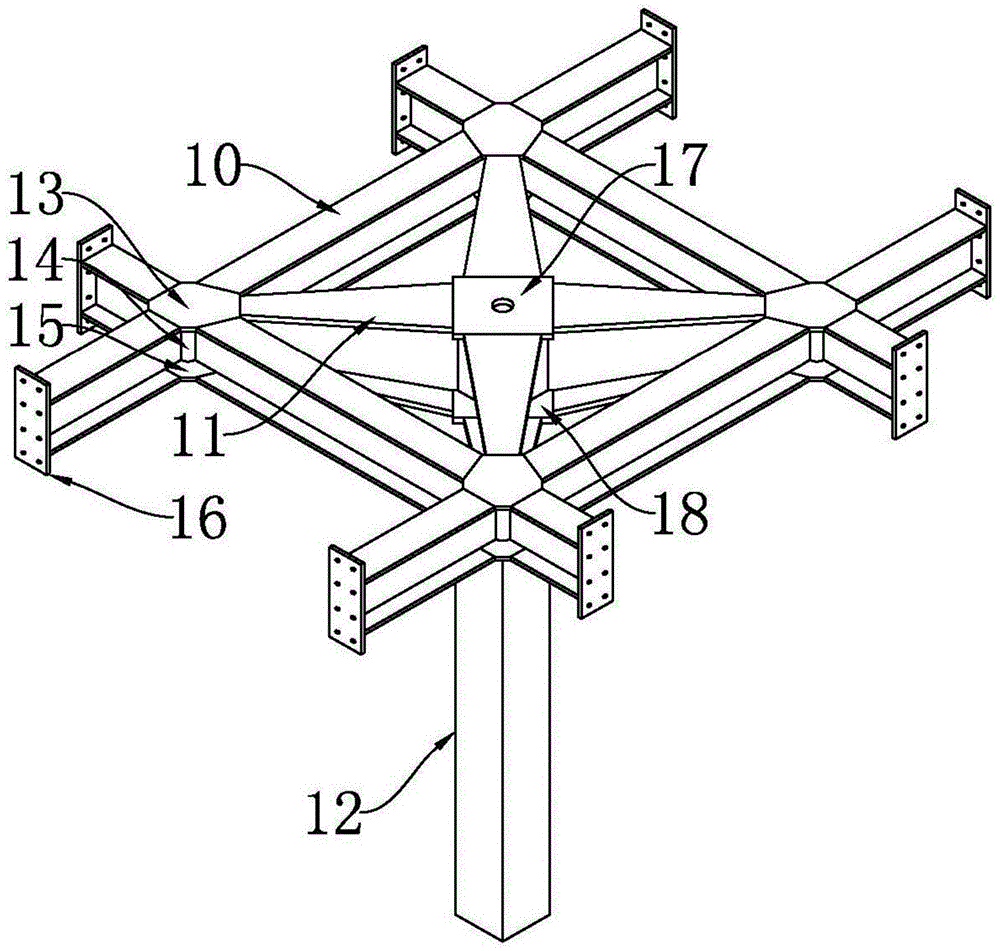

[0038] More specifically, such as figure 1 , 2 , 3, and 4, the support unit 1 of this embodiment includes a cross beam 10, a cross beam 11, and a support column 12. In the present invention, the supporting beams are all on the side of the support column 12, and the cross beam 11 is p...

Embodiment 2

[0041] The double-beam floor structure of the second embodiment is basically the same as that of the first embodiment, and the difference lies in that the structure of the tic-shaped beam 10 and the connection mode between the supporting units 1 of the present embodiment are different from those of the first embodiment.

[0042] Specifically, such as Figure 5 , 6 As shown in, 7, 8, 9, 10, the well-shaped beam 10 includes H-shaped steel A20, H-shaped steel B21 and H-shaped steel C22. Two H-shaped steels B21 and two H-shaped steels B21 are welded between two H-shaped steels A20 arranged in parallel. The distance between the two H-shaped steels A20 is the same. The H-shaped steel B21 is perpendicular to the H-shaped steel A20; the H-shaped steel C22 is welded to the outside of the H-shaped steel A20 and is in a straight line with the H-shaped steel B21. The above-mentioned H-shaped steel A20 , H-shaped steel B21 and H-shaped steel C22 form the Tic-Tac-beam 10 structure; the end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com