Patents

Literature

80results about How to "Reduce dead load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

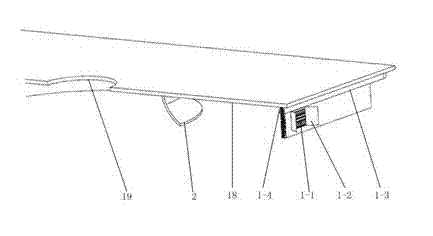

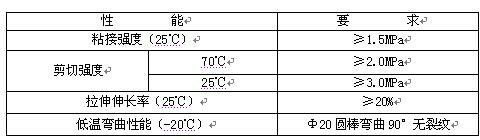

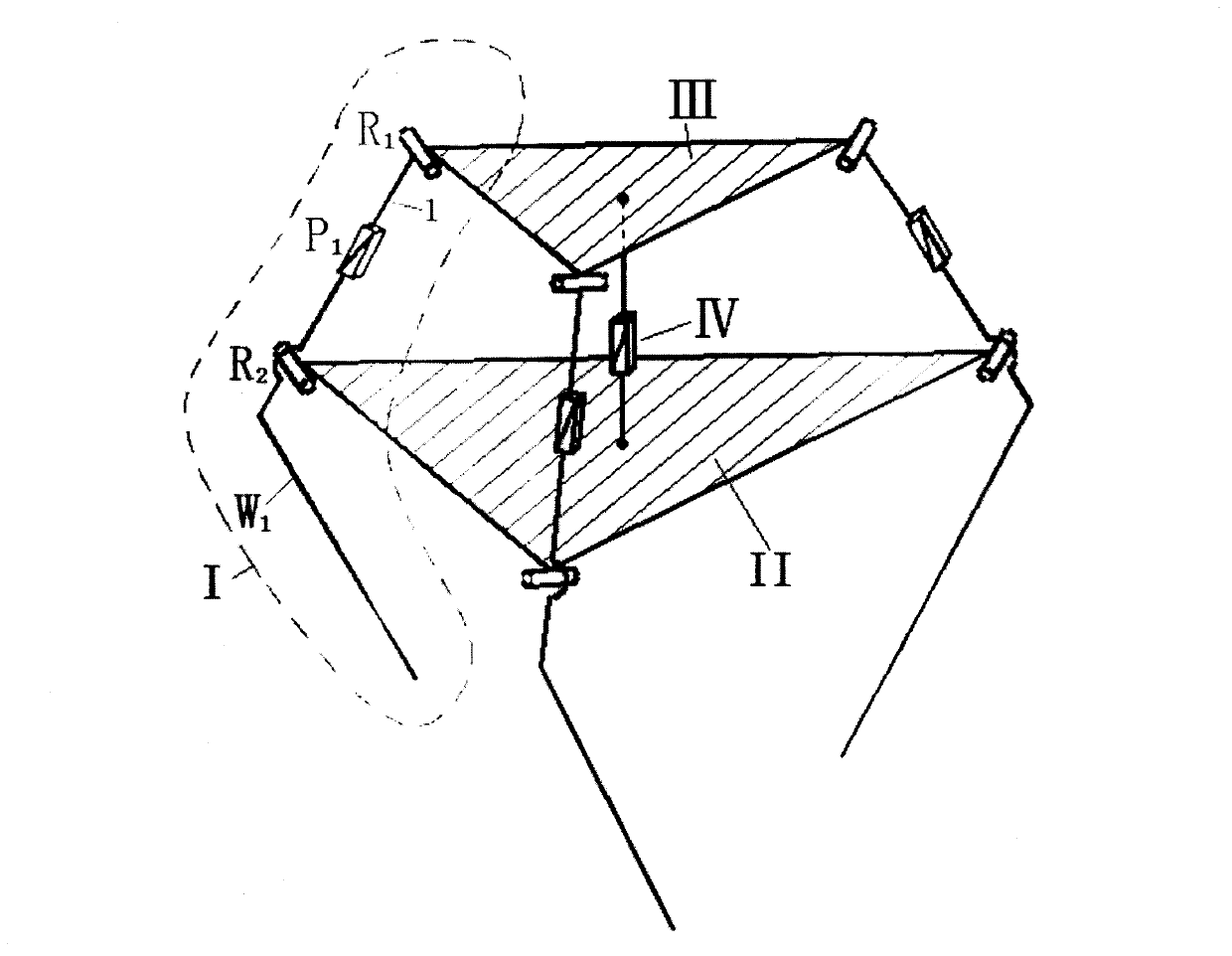

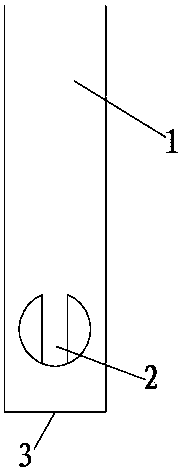

Reconfigurable wall climbing robot and collaborative obstacle-detouring method thereof

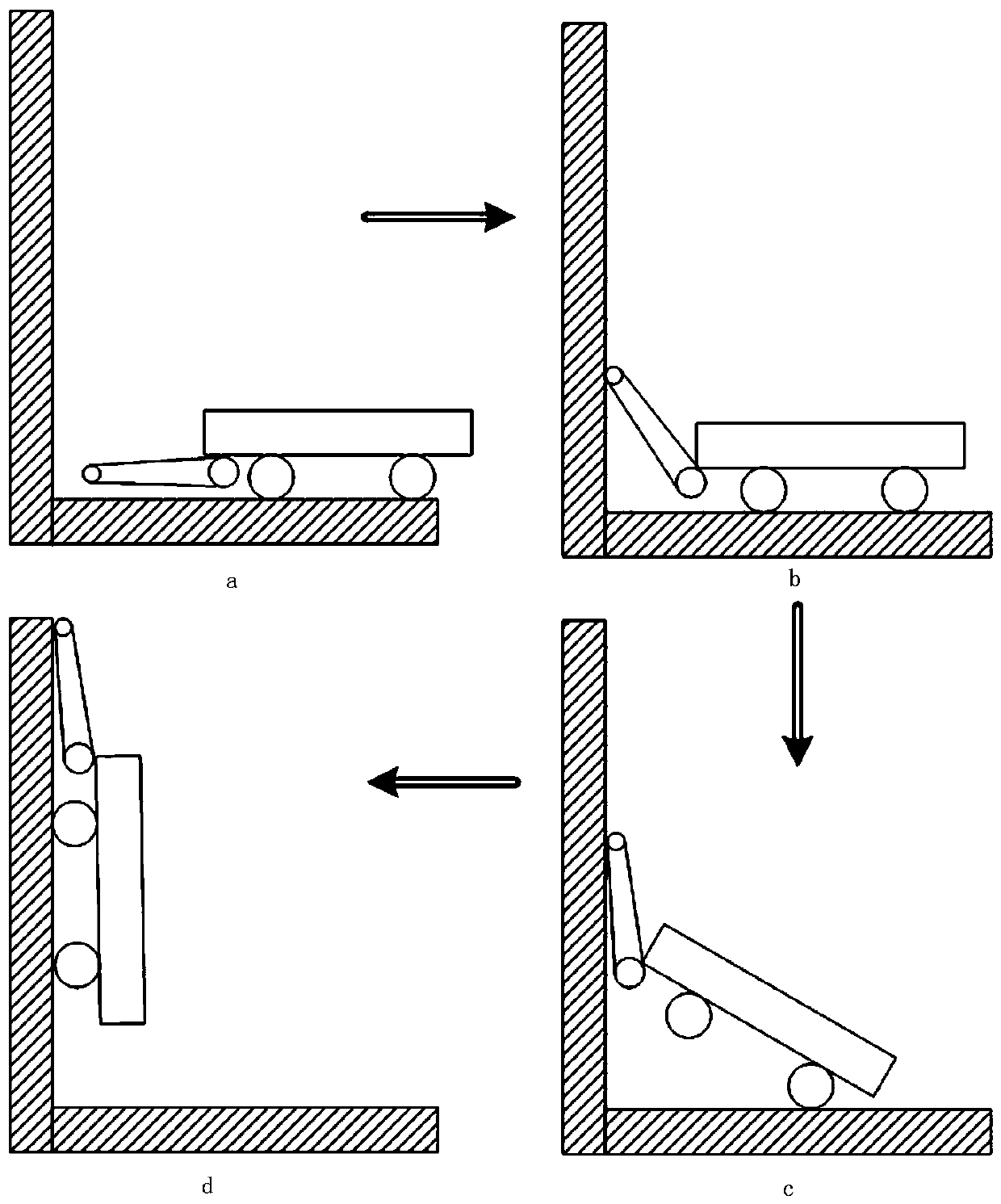

The invention discloses a reconfigurable wall climbing robot and a collaborative obstacle-detouring method thereof. The reconfigurable wall climbing robot comprises an adaptive seal skirt, a sealing lining, a centrifugal pump, a centrifugal pump motor, a centrifugal pump motor driver, a robot body, and the like, wherein the seal skirt is vertically fixed on the periphery of the lower bottom surface of the robot body; the robot body is provided with a through hole, the air inlet of the centrifugal pump is corresponding to the through hole of the robot body and fixedly arranged on the robot body, and an output shaft of the centrifugal pump motor is connected with the centrifugal pump; and the sealing lining is arranged on the lower bottom surface of the robot body and located between the through hole and the seal skirt. In the invention, each reconfigurable wall climbing robot is an independent individual, and can independently complete tasks such as reconnaissance and the like under the condition of no barrier; and when a certain wall climbing robot is required to detour an obstacle, two independent reconfigurable wall climbing robots can collaboratively complete an obstacle-detouring task through being combined to be a whole.

Owner:NANJING UNIV OF SCI & TECH

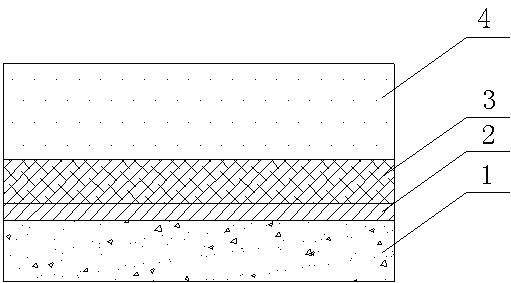

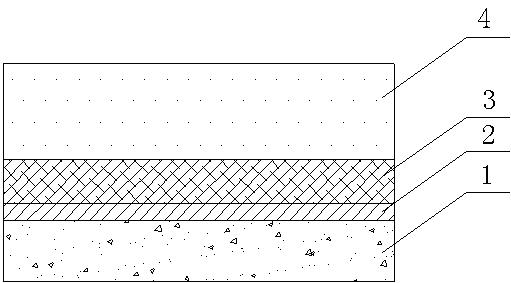

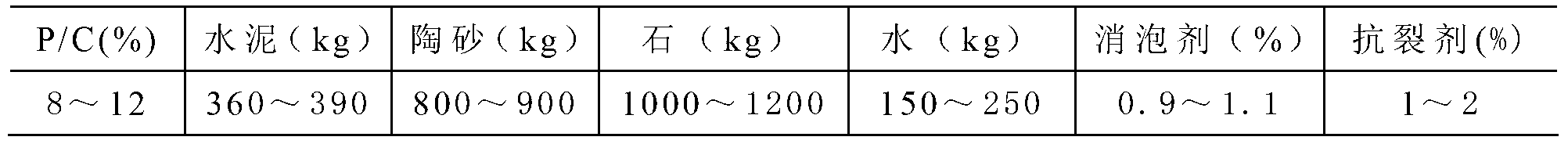

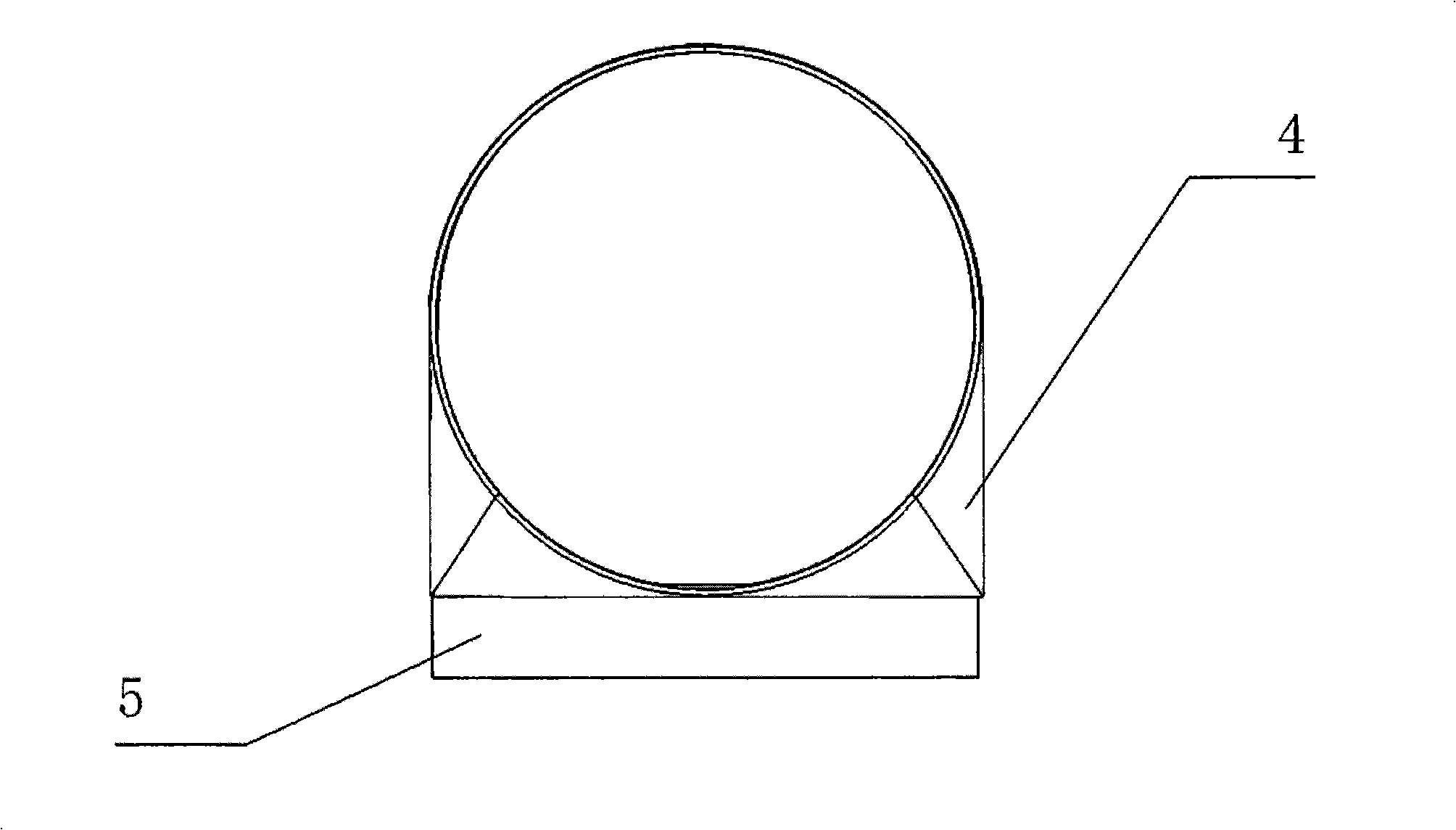

Pavement structure for cement concrete bridge deck and pavement method thereof

InactiveCN102002909AEfficient removalImprove interlayer adhesionBridge structural detailsEpoxyBridge deck

The invention relates to the technical field of traffic engineering, in particular to a pavement structure directly paved on a cement concrete bridge deck and a pavement method thereof. The pavement structure for the cement concrete bridge deck comprises a waterproof bonding layer, a stress absorption layer and a road surface layer, which are sequentially paved on the cement concrete bridge deck from bottom to top, wherein the waterproof bonding layer comprises a basalt gravel layer bonded on the cement concrete bridge deck through epoxy resin and a reactive waterproof binding agent layer coated on the basalt gravel layer. The invention also discloses a pavement method for the pavement structure. The pavement structure and the pavement method thereof enhance the bonding and shearing action between a pavement layer and a cement concrete slab, improve the using effect and service life of the pavement layer, reduce the temperature of mixing, transporting and paving, save energy and reduce environmental pollution; and the total thickness of the bridge deck pavement system is only 30 to 40 mm, so that the dead load of the bridge deck is greatly reduced, the pavement materials are saved and the construction cost is reduced.

Owner:CHONGQING JIAODA ROAD BRIDGE TECH RES

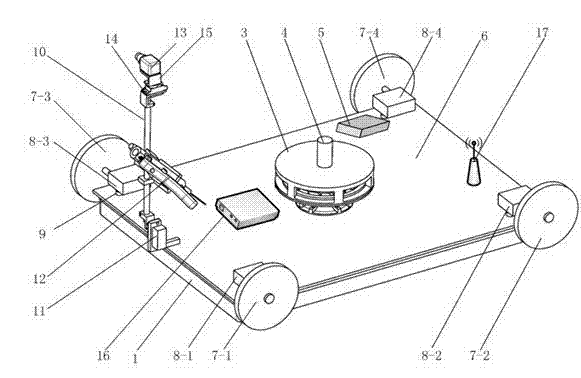

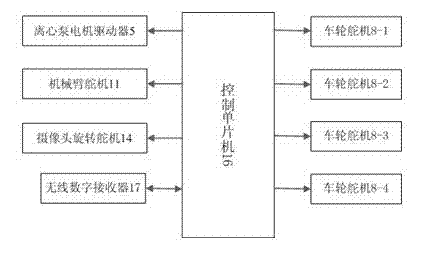

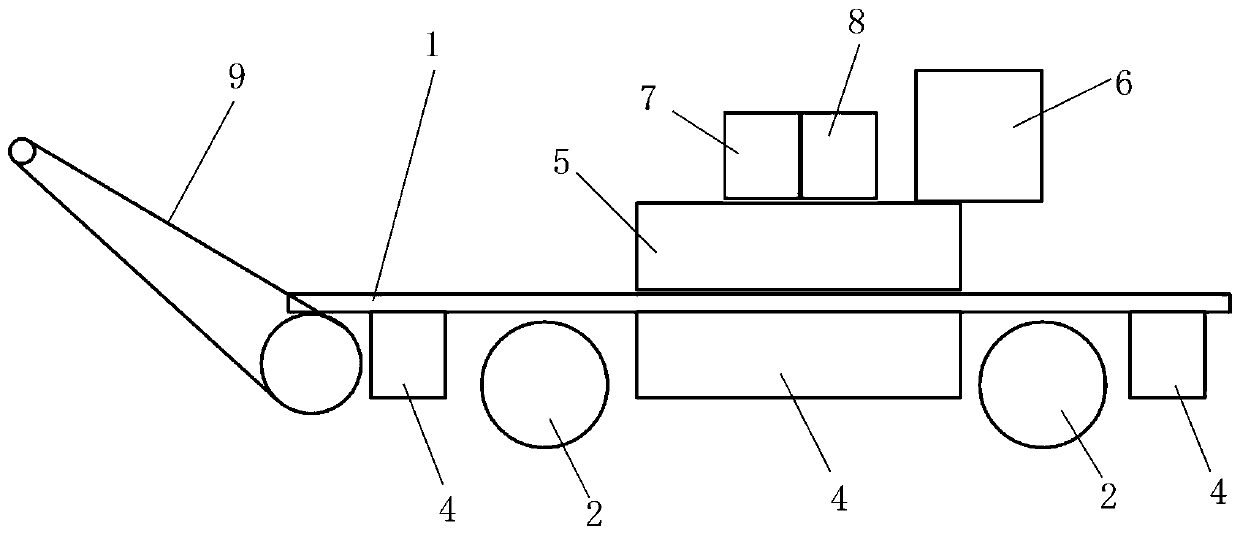

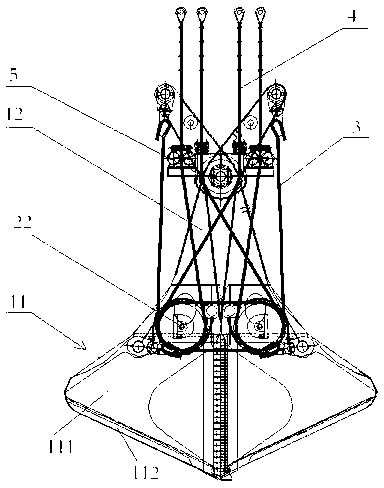

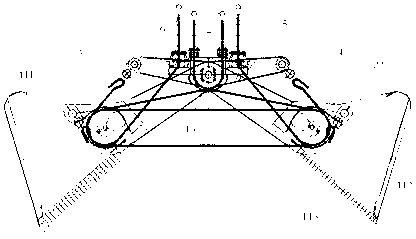

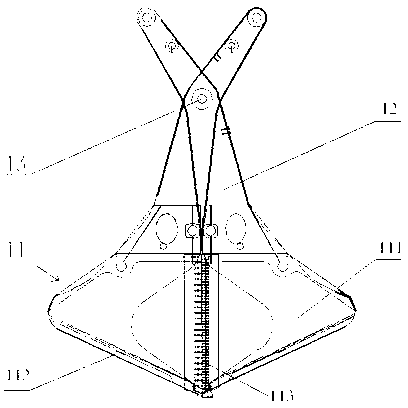

Omni-directional mobile wall-climbing robot for ship

ActiveCN110667719AAchieve omnidirectional movementPrevent fallingVehiclesVehicle frameElectric machinery

The invention provides an omni-directional mobile wall-climbing robot for a ship. The omni-directional mobile wall-climbing robot for the ship comprises a frame, wheels, wheel motors, a two-axis electric control holder and a front arm assisting mechanism and is characterized in that permanent magnets generating adsorption magnetic forces to a steel plate on the ship are arranged in the positions,around the frame, at the bottom of the frame; ducted propellers for counteracting the gravity of the wall-climbing robot are fixed on the two-axis electric control holder; propeller motors used for driving the ducted propellers to rotate are fixed on the two-axis electric control holder; the front arm assisting mechanism is arranged at the front end of the frame through a connecting shaft; and caterpillar tracks are arranged on the two sides of the front arm assisting mechanism. According to the omni-directional mobile wall-climbing robot for the ship, under the action of the adsorption magnetic forces between the permanent magnets and the steel plate of the ship, the counteracting of the ducted propellers to the gravity and the fitting of the front arm assisting mechanism to the next wallsurface or obstacle, the omni-directional movement, obstacle crossing and climbing wall surface switching of the wall-climbing robot can be realized, the detection, cabin sweeping or welding operation of any wall surface of the ship are realized, the labor finishing cost is reduced, and the beneficial effect is obvious.

Owner:SHANDONG JIAOTONG UNIV

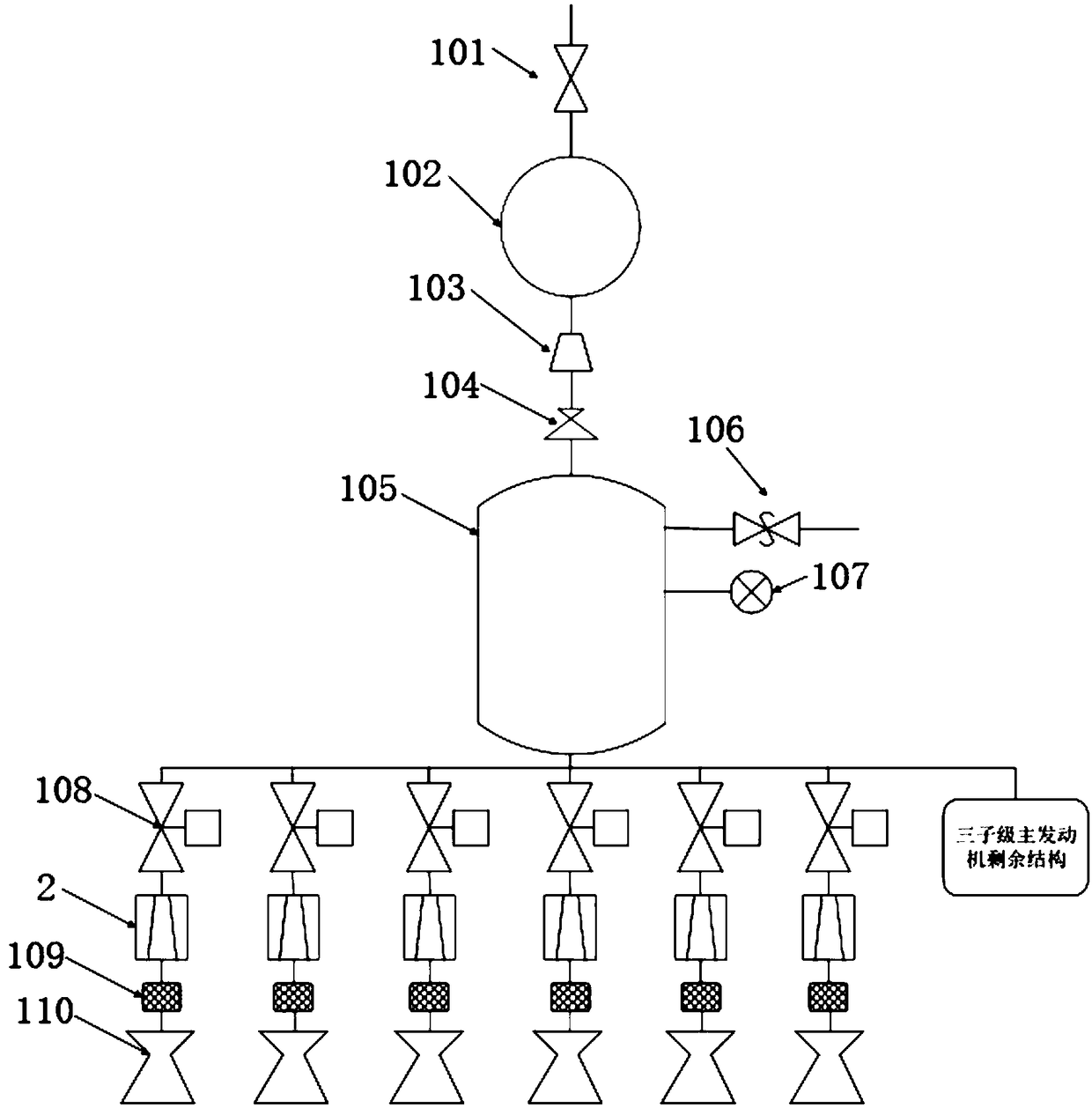

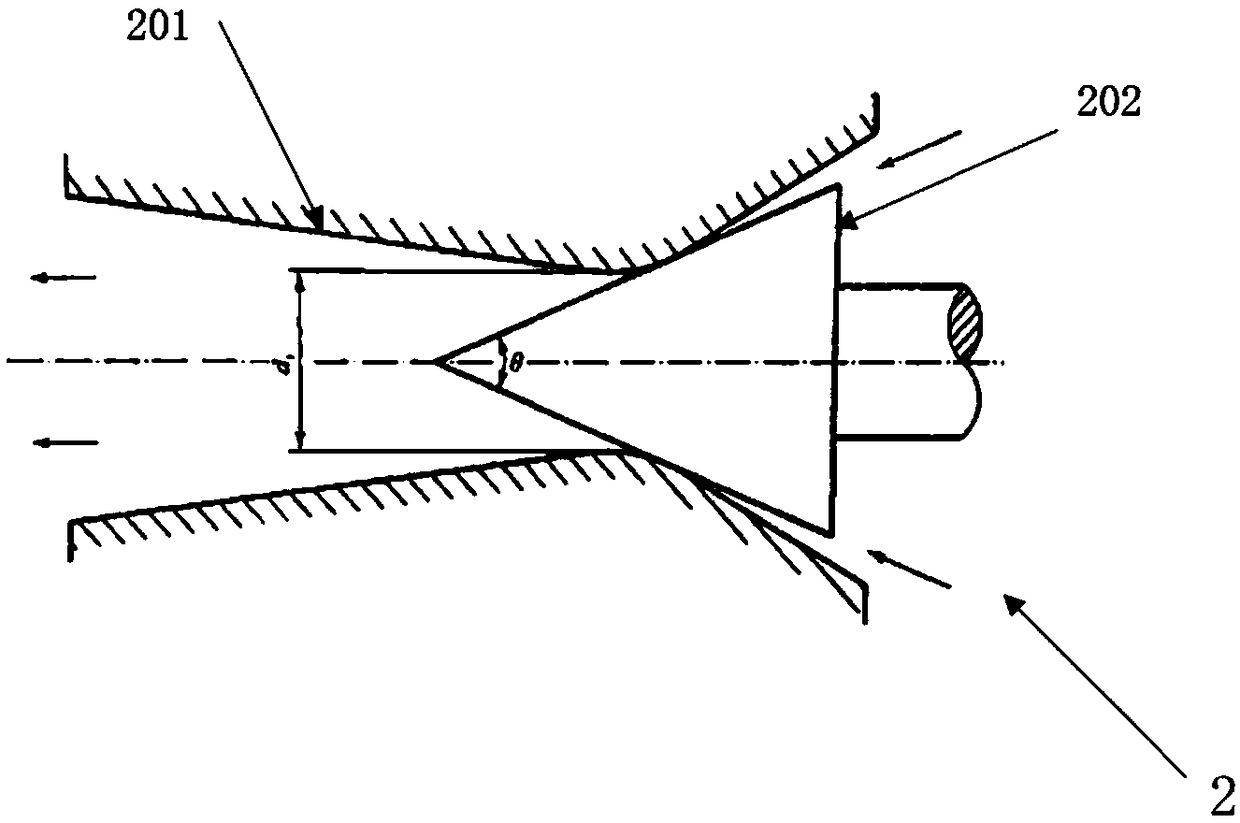

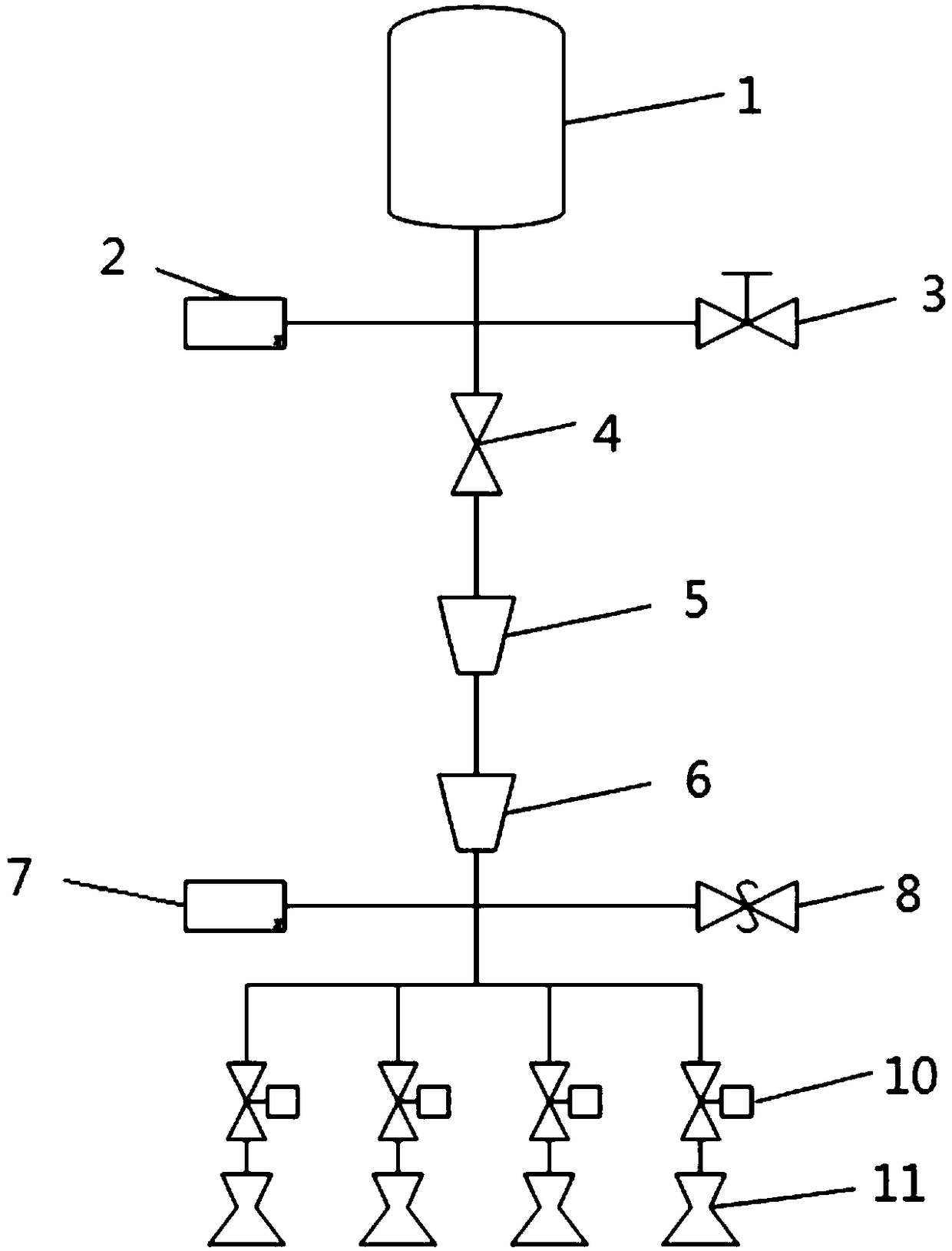

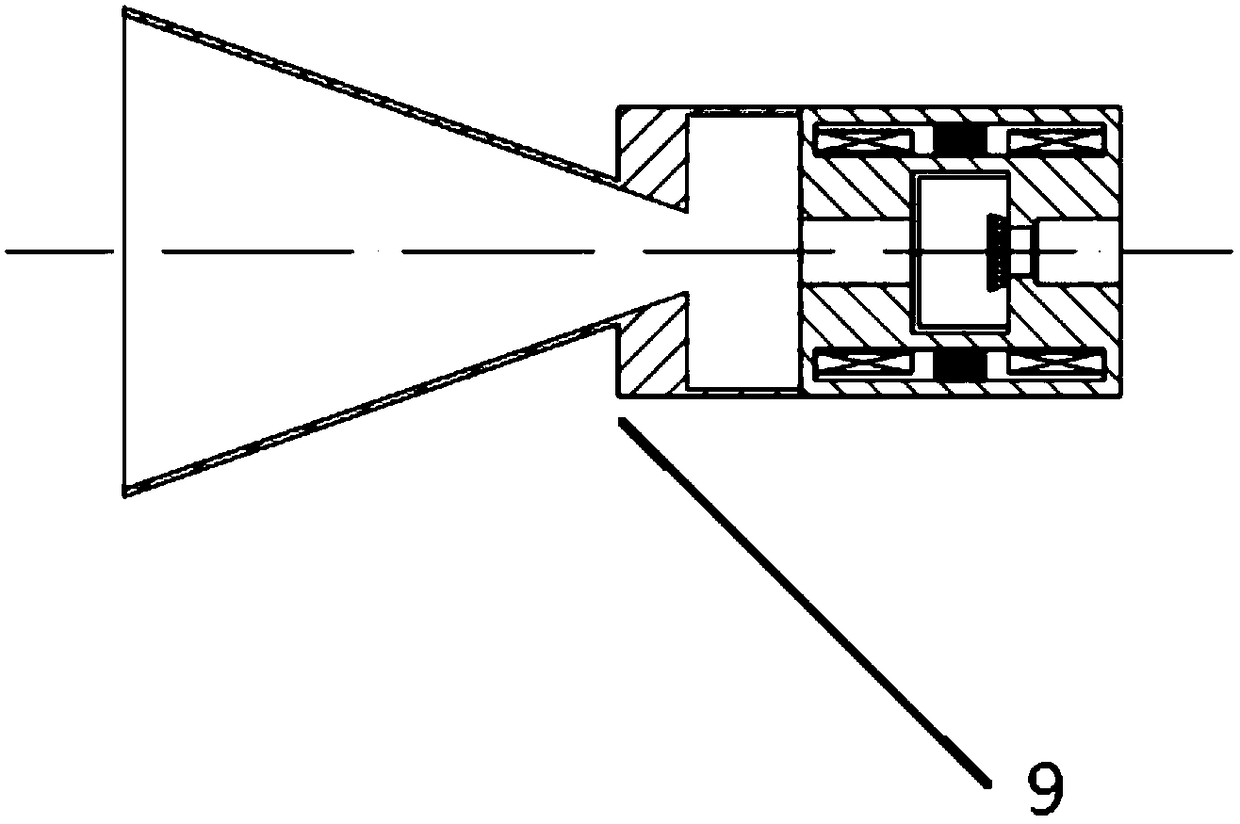

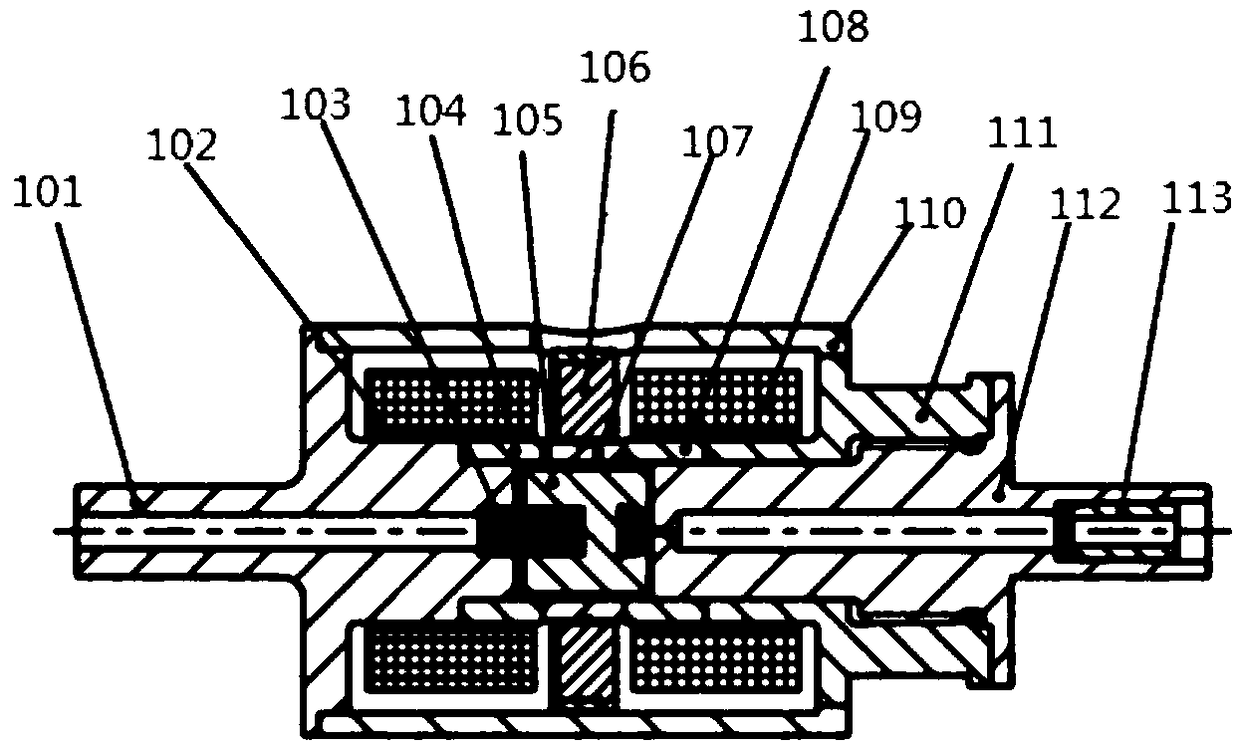

Hydrogen peroxide posture control system applied to solid-liquid hybrid power carrier rocket

InactiveCN108895921AReduce in quantityImprove transportation capacityRocket engine plantsProjectilesFailure rateControl system

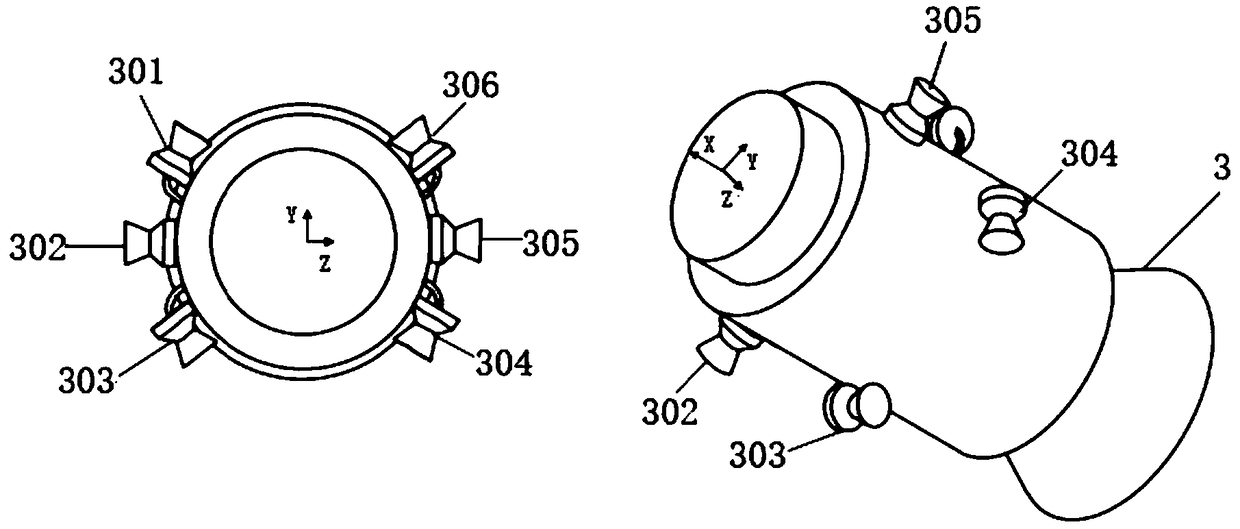

The invention relates to the field of carrier rocket posture control systems, in particular to a hydrogen peroxide posture control system applied to a solid-liquid hybrid power carrier rocket. The system includes four pitching rolling posture control engines and two yawing posture control engines; the two yawing posture control engines are arranged in the positive and negative directions of a Z axis of the outer side of a rocket three-sublevel main engine separately; the first pitching rolling posture control engine is installed on the surface of the main engine, and a 40-degree included angleis formed between the first pitching rolling posture control engine and the negative direction of the Z axis; the fourth pitching rolling posture control engine is installed on the surface of the main engine, and a 40-degree included angle is formed between the fourth pitching rolling posture control engine and the positive direction of the Z axis; the other two pitching rolling posture control engines are installed symmetrically on the surface of the main engine relatively to an XZ plane. According to the scheme, six posture control engines are adopted as propelling force, the number of thrusters is small, invalid loads can be reduced to a great extent, and the conveying capability of the whole carrier rocket is improved. Meanwhile, the failure rate of the posture control system is decreased, and the stability and safety of the system are improved.

Owner:BEIHANG UNIV

Attitude control system and small rocket launcher

The invention provides an attitude control system and a small rocket launcher, and relates to the technical field of rockets. The technical problems of low carrying capacity and high cost of an existing small rocket launcher are solved. The attitude control system comprises a high-pressure nitrogen bottle, a first pressure sensor, a second pressure sensor, an electric explosion valve, a pressure reduction device, a safety valve and a cold air thruster, wherein the first pressure sensor is arranged between the high-pressure nitrogen bottle and the electric explosion valve and is used for detecting pressure of the nitrogen which flows out of the high-pressure nitrogen bottle; the pressure reduction device is connected with the electric explosion valve; the second pressure sensor is arrangedbetween the pressure reduction device and the safety valve and is used for detecting the pressure of the nitrogen which flows out of the pressure reduction device; and the safety valve is connected with the cold air thruster. The device has the advantages of simple structure and low cost, and the provided thrust force just meets a control requirement of the small rocket launcher, and therefore, waste is avoided.

Owner:BEIHANG UNIV

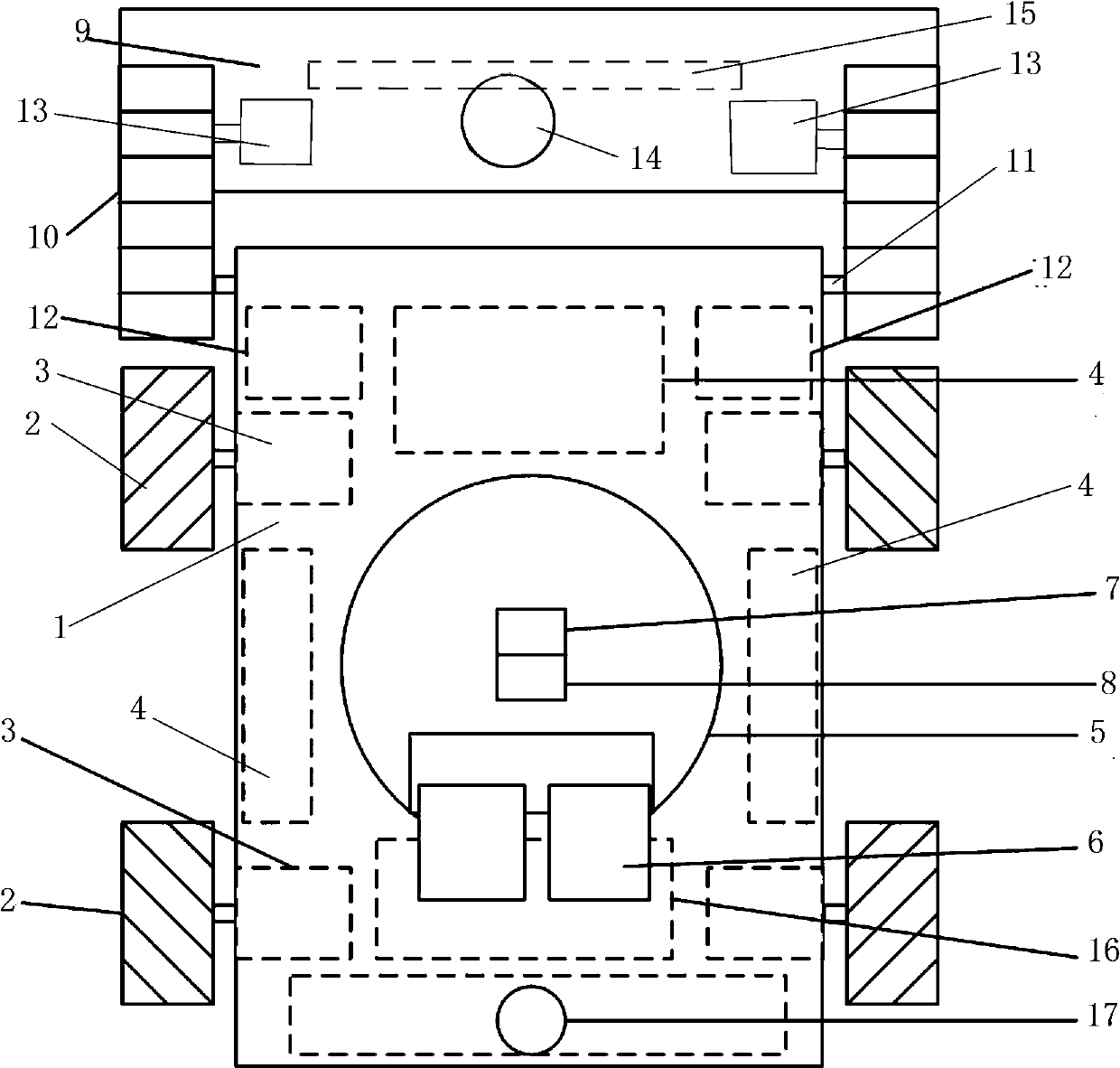

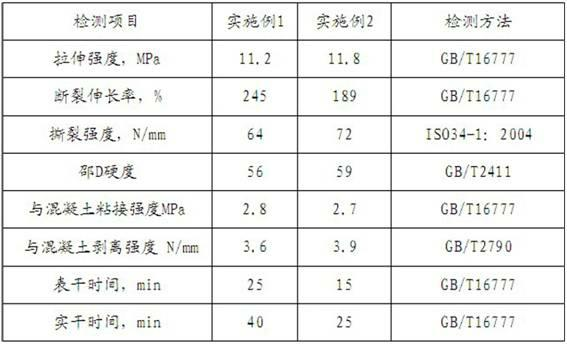

Modified polyurethane waterproof paint as well as preparation method and construction method thereof

ActiveCN101974289AFast curingStrong adhesionPolyurea/polyurethane coatingsUrethane acrylatePrepolymer

The invention relates to a modified polyurethane waterproof paint as well as a preparation method and a construction method thereof. The waterproof paint mainly comprises three components A, B and C as follows by weight: the raw materials of the components A and B mainly comprise 25-45 parts of polyurethane acrylate prepolymer, 30-50 parts of active diluent, 15-30 parts of anti-seepage filler and 1-8 parts of auxiliaries, and the component C comprises 2-5 parts of peroxide initiator. The modified polyurethane waterproof paint has high physical mechanics performance and excellent ultraviolet-resistant performance, can be directly used for waterproof treatment of passenger special lines, and a protective layer is not needed on the surface of a waterproof layer. The preparation method of the waterproof paint is simple and environmental-friendly by using a double-component spraying device for construction, and comprises the steps of adding 2-5% of the component B of the component C into the component B, stirring evenly, proportioning according to the volume ratio of the component A to the mixture of the component B and the component C to be 1:1 during construction. The construction is simple and convenient without heating the materials.

Owner:HUNAN NAISSANT PLASTIC ENGINEERING MATERIALS CO LTD

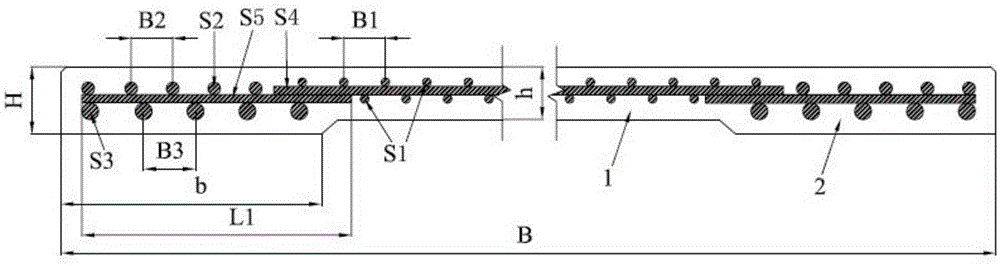

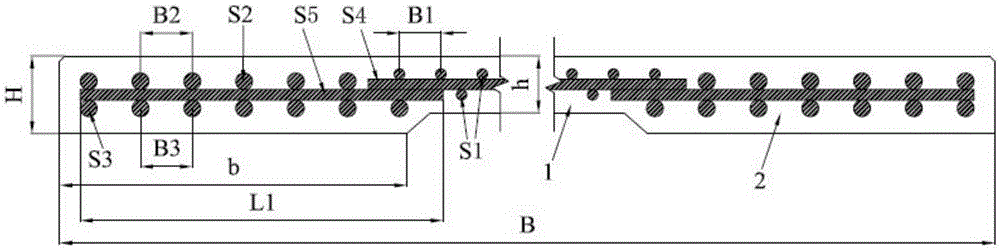

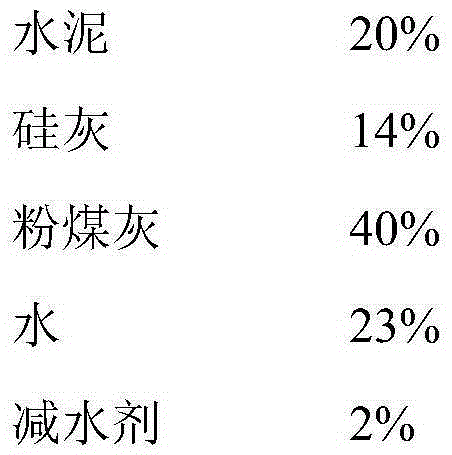

Ultra-high-performance cement-based bridge deck slab poured with ultra-high-performance cement-based composite materials

InactiveCN105254249ALight weightEasy to manufactureBridge structural detailsBridge materialsReinforced concreteBridge deck

The invention relates to an ultra-high-performance cement-based bridge deck slab poured with ultra-high-performance cement-based composite materials. The cement-based bridge deck slab meets the conditions that H / B<=0.03, h / B<=0.025, H>=h+15 mm, 1<=L / B<=4, B1, B2 and B4>=30 mm, B3>=40 mm, b / B=0.05-0.15, b<=L1<=b+B1, the reinforcement ratio of the middle section of the bridge deck slab is 1%-10%, the reinforcement ratio of the reinforcing sections on the two sides of the bridge deck slab is 5%-15%, the rib material yield strength is larger than or equal to 400 MPa, and the self weight is smaller than or equal to 240 kg / m<2>. According to the ultra-high-performance cement-based bridge deck slab poured with the ultra-high-performance cement-based composite materials, due to the fact that the cement-based composite materials with the ultra-high strength and high-strength rib materials are adopted, not only is the high bearing capacity achieved, but also the advantages that the self weight is small (only accounts for 20%-40% of that of an ordinary reinforced concrete bridge deck slab), the fatigue resistance, the corrosion resistance and the long life (the theoretical life can be more than 150 years) are achieved, installation is quick, time and labor are saved (the construction amount and the construction period are both reduced by 50%-70% than those of the ordinary reinforced concrete bridge deck slab) are achieved, and the cement-based bridge deck slab can be applied to new projects of small-medium bridges or existing bridge upgrading projects in the fields of roads, railways and the like.

Owner:浙江宏日泰耐克新材料科技有限公司

Building outer wall high-altitude spraying unmanned aerial vehicle and operating method thereof

InactiveCN107554772AAdapt to spraying needsFacilitate real-time operation controlAircraft componentsRotocraftMotor driveSpray nozzle

The invention relates to the technical field of building construction, in particular to a high-altitude spraying drone for building exterior walls, including a multi-rotor drone and a spraying device. The spraying device includes a paint delivery pipe interface, a spraying pipeline, an electromagnetic control valve and a directional spray head. The high-pressure paint boosted by the booster pump is sprayed out from the external delivery pipe through the paint delivery pipe interface, spray pipe, electromagnetic control valve and directional nozzle; the multi-rotor UAV is equipped with a counter rotor on the other side of the directional nozzle; The drive power of the machine is an external power supply. The high-altitude spraying drone on the exterior wall of the building of the present invention uses the drone as a carrier, through directional side spraying and hedging balance, and all the paint storage device and the driving power of the drone are externally installed to minimize the invalid load of the drone , can not only realize high-altitude spraying safety operation, but also realize continuous operation, and improve the efficiency of UAV operation.

Owner:宿松县佳宜装饰有限公司

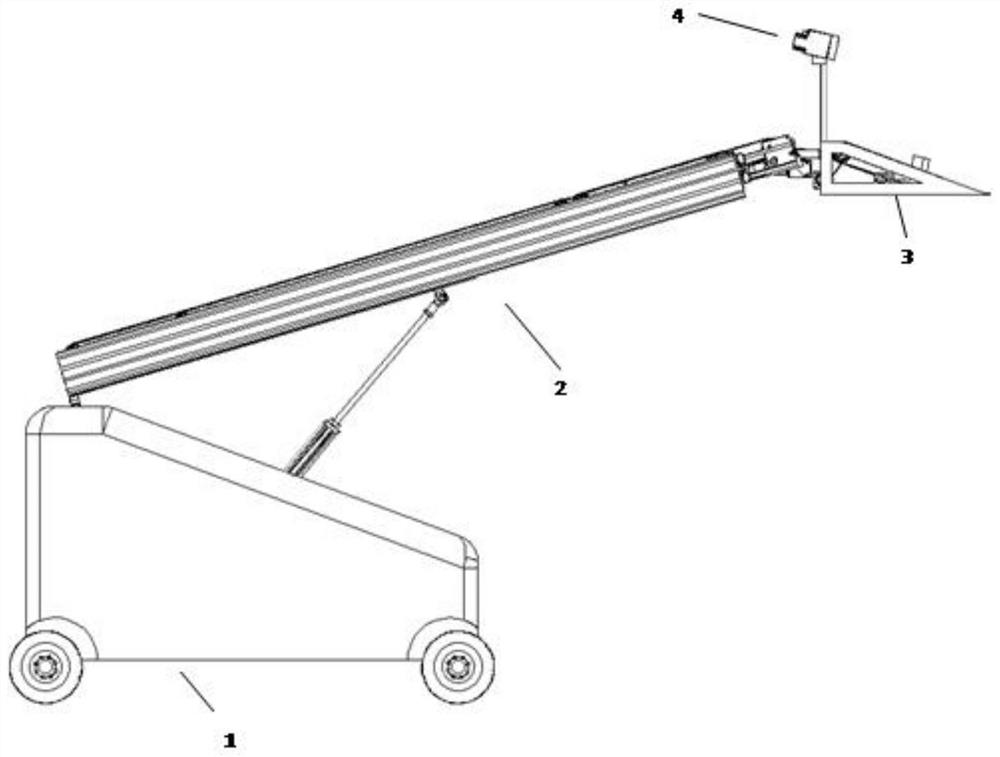

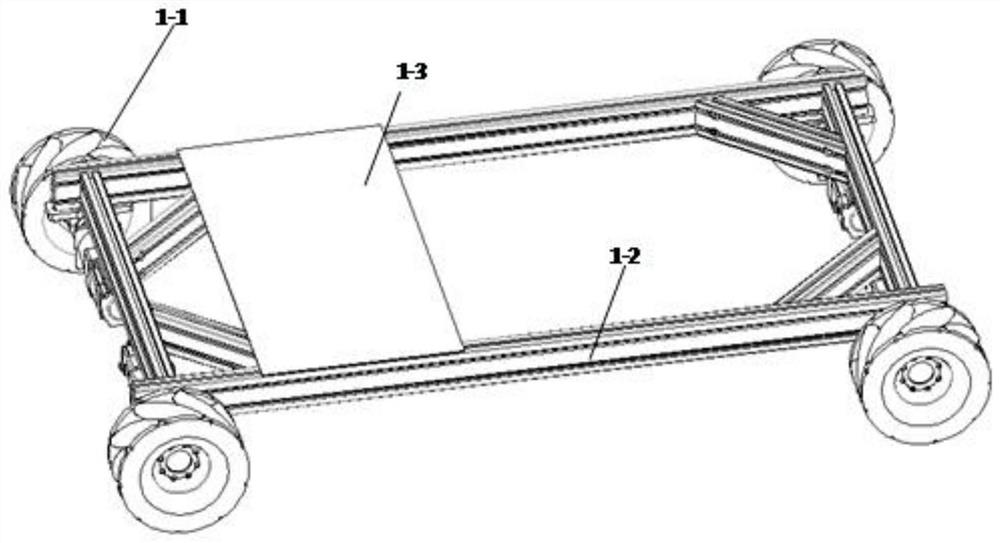

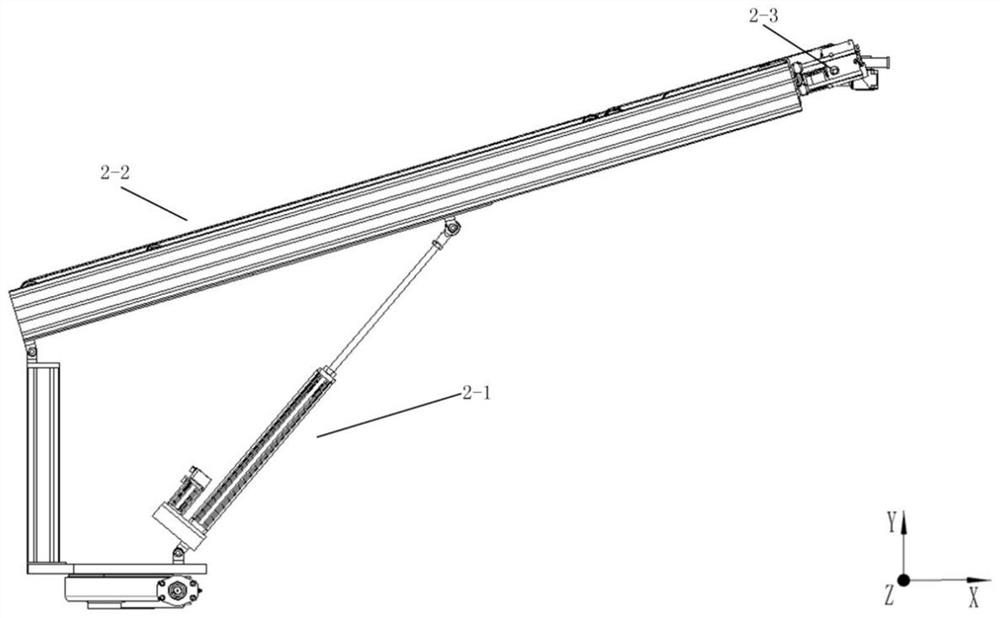

Intelligent loading and unloading vehicle system based on visual servo

PendingCN111847004ACompact structurePrecise positioningConveyorsControl devices for conveyorsVisual servoingPalletizer

The invention discloses an intelligent loading and unloading vehicle system based on visual servo, and belongs to the technical field of intelligent loading and unloading vehicle robots. The intelligent loading and unloading vehicle system comprises an unstacking and stacking mechanism, a conveying mechanism and an AGV loading and unloading mechanism, wherein the two ends of the conveying mechanism are connected to the unstacking and stacking mechanism and the AGV loading and unloading mechanism correspondingly; the AGV loading and unloading mechanism comprises an AGV trolley capable of achieving front-back, left-right and rotation displacement, a pose adjusting device arranged on the AGV trolley, a flexible grabbing device arranged on the pose adjusting device, and a first image obtainingmechanism arranged on the flexible grabbing device; and the unstacking and stacking mechanism comprises a movable carrying platform, a three-coordinate machine arranged on the carrying platform, anda second image obtaining mechanism arranged on the three-coordinate machine. The intelligent loading and unloading vehicle system solves the problem that an unstacking and stacking machine is not suitable for narrow space and space needing to be moved, full-automatic loading and unloading of goods in limited space such as a van are achieved, and manpower replacement is achieved.

Owner:李宏亮

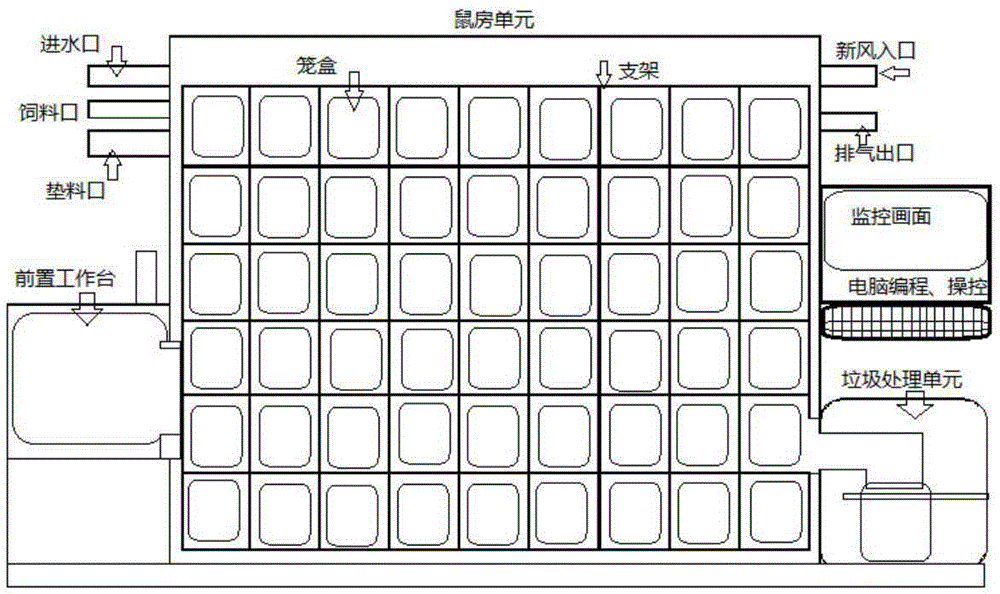

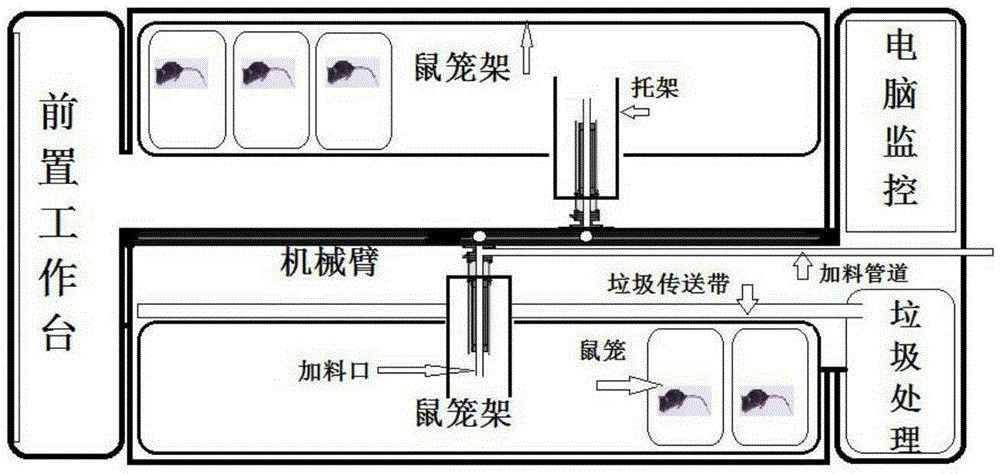

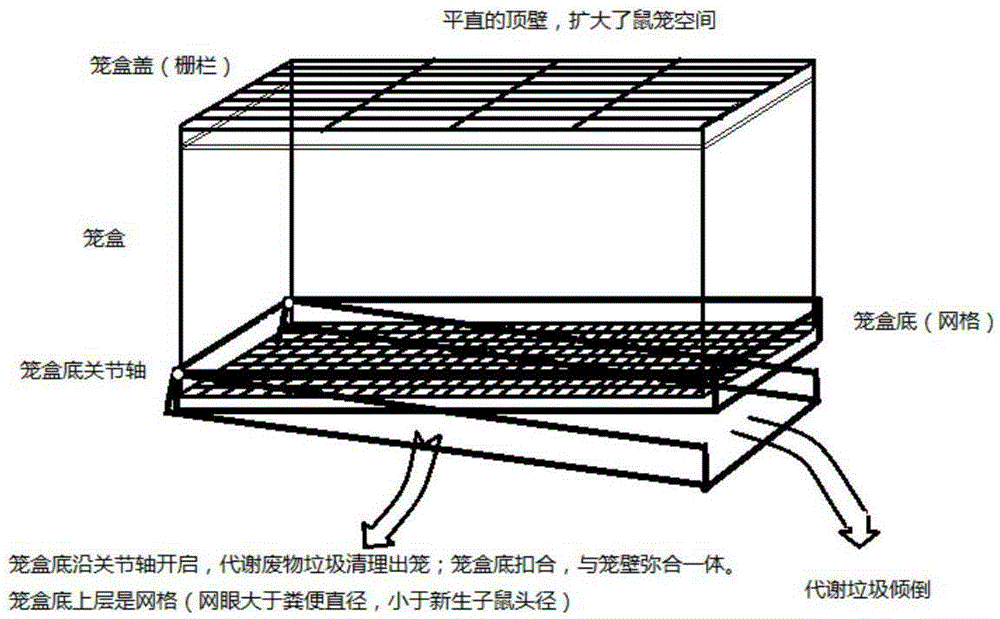

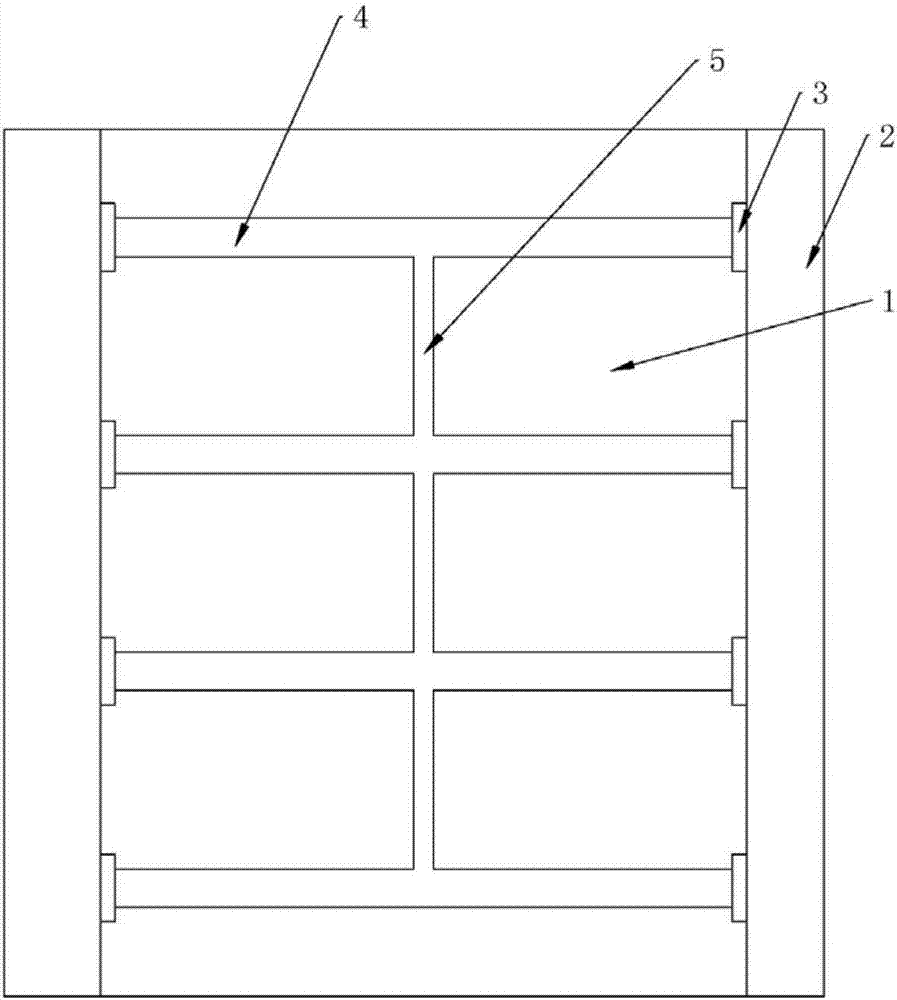

Intensive combined-cage type animal house

ActiveCN106550898AImprove the effective utilization of spaceReduce dead loadAnimal watering devicesAnimal feeding devicesAnimal cageManipulator

The present invention relates to the field of animal feeding and discloses an intensive combined-cage type animal house. The animal house comprises a shell that forms a confined space isolated from the outside, a bracket, a three-dimensional manipulator, a plurality of animal cages, and a plurality of through-holes through which the confined space is connected with the outside, wherein the bracket, the three-dimensional manipulator and the animal cages are all arranged in the shell, and the through-holes include a feed port, a padding port, a water inlet, an air inlet, an exhaust port and a garbage outlet. The animal cages are disposed on the bracket and are provided with pipes connected to the through-holes, respectively. The manipulator is controlled by a computer and can automatically take and place the animal cages and replace paddings. The plurality of the through-holes are controlled by the computer to provide materials for the animal house and transport waste from the animal house. The shell of the animal house forms the confined space that is isolated from the outside ,and the confined space is connected with the outside through the through-holes, and the operator does not need to enter the animal house, so the space is saved, air and light control is limited to the animal house, so that people are free from direct contact with animals during feeding, therefore the effective control volume is reduced, and the control system is simplified, thereby reducing the equipment investment and reducing the energy consumption of the system operation.

Owner:魏佑震

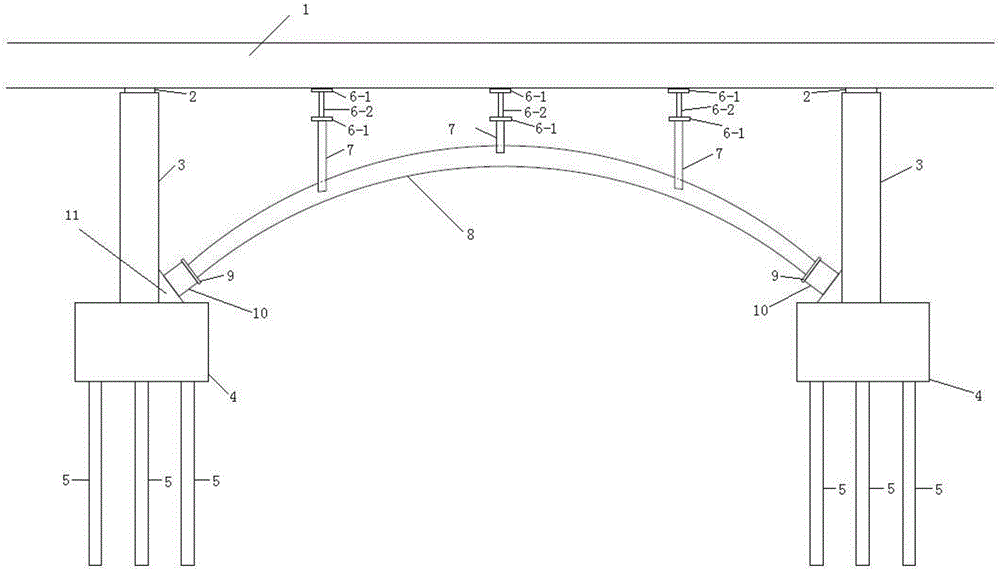

Beam bridge reinforcing structure and reinforcing method

ActiveCN106149572AImprove the forceReduce dead loadBridge erection/assemblyBridge strengtheningBridge deckRebar

The invention provides a beam bridge reinforcing structure and reinforcing method. The beam bridge reinforcing structure comprises an arched steel pipe component, I-beams and steel inclined struts. The two ends of the arched steel pipe component are fixed to two adjacent piers of a bridge body. A middle section of the arched steel pipe component is fixedly connected with the steel inclined struts. The steel inclined struts are fixedly connected with the I-beams. The bottom of a bridge deck of a beam bridge is continuously supported through upper flanges of the I-beams. By the adoption of the reinforcing structure, stress of an original beam bridge is optimized, the bending moment of the beam bridge is remarkably reduced, the situation that the beam bridge further cracks under the overloading effect is effectively prevented, part of cracks can be partially closed, stressed reinforcing steel bars in the beam bridge are protected against exposure and corrosion, the load burdens and operation risks of the beam bridge are remarkably reduced, the structure anti-bending and anti-shearing bearing capacity and the durability performance of the beam bridge are improved, and the service life of the bridge is effectively prolonged.

Owner:JIANGSU UNIV OF SCI & TECH

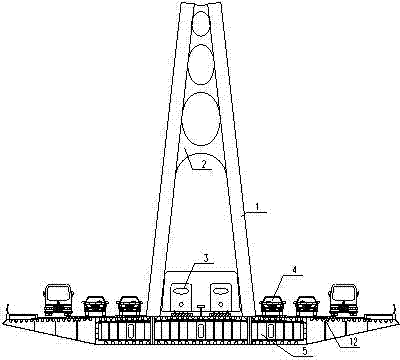

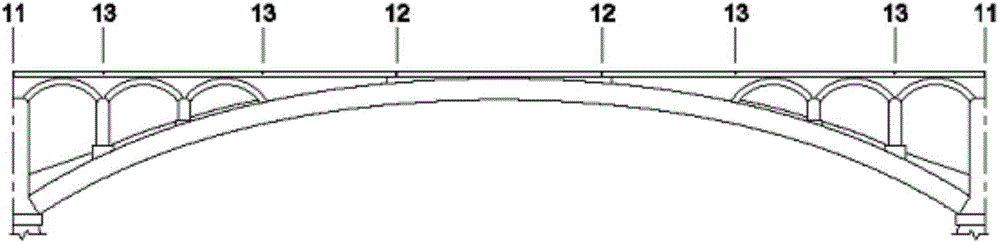

Half-through bowstring arch bridge with vehicle and light rail on same layer and construction method thereof

InactiveCN104846733AShorten the lengthRaising the bar for linear technologyBridge structural detailsBridge erection/assemblyPre stressArchitectural engineering

The invention relates to a half-through bowstring arch bridge with a vehicle and a light rail on the same layer. A main beam of the arch bridge adopts a mixed structure; a side span main beam adopts a prestressed concrete structure; and a mid-span main beam adopts a steel box girder structure. The arch bridge is characterized by having a combined arch force transfer system; and the force transfer system comprises a lifting basket type steel box main arch and a back stay rope. As a novel structural design of a bridge building is adopted, the same-layer arrangement of improving the linear technology standard and reducing the manufacturing cost is realized, and the beauty and structure unification of the bridge building is realized.

Owner:GUANGDONG PROVINCE COMM PLANNING & DESIGN INST

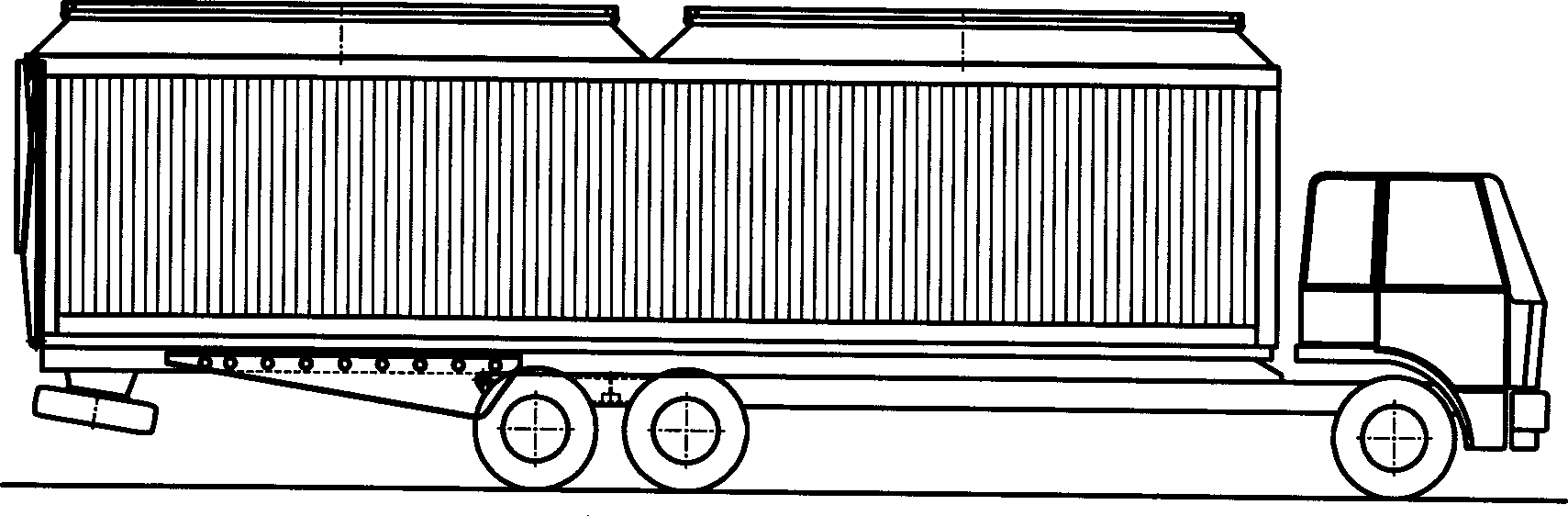

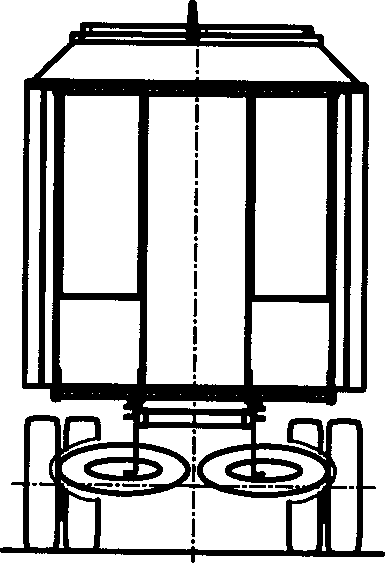

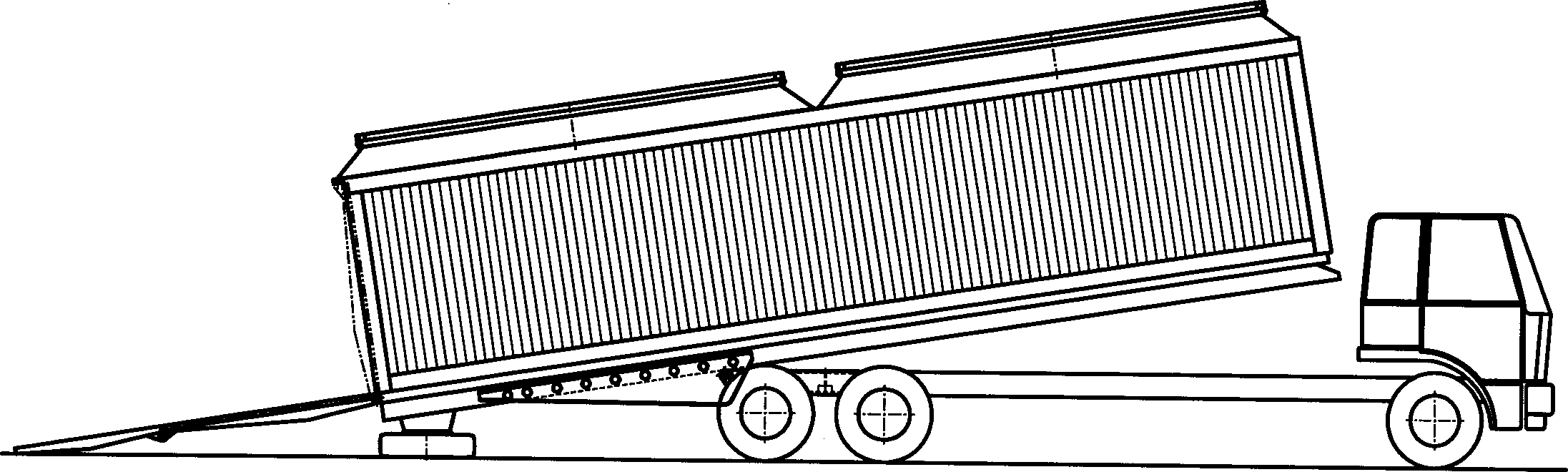

Forklift through, top loading and unloading van

InactiveCN1341525AReduce dead loadHigh strengthVehicle with tipping movementTransportation itemsCoalCar door

The present invention relates to a wagon-type truck capable of allowing fork lifter to directly come into wagon body to make loading and unloading operation, and is characterized by that its back wagon door can be turned, and its one end can be put downand on the ground to form a transition bridge, and when its engine is being in cut-off state, the fork lifter can be passed through the transitionbridge and come onto the platform to make loading and unloading operation, its wagon top can be designed into multi-stage cover hopper form so as to raise top strength, said top portion is equipped with inlet and outlet, so that the crane, belt conveyer or mechanical loader can load and unload goods from wagon top. Its inlet and outlet are equipped with top cover respectively for raintight and preventing coal powder from leaking out, so that it is favorable for environmental protection.

Owner:张玉玺

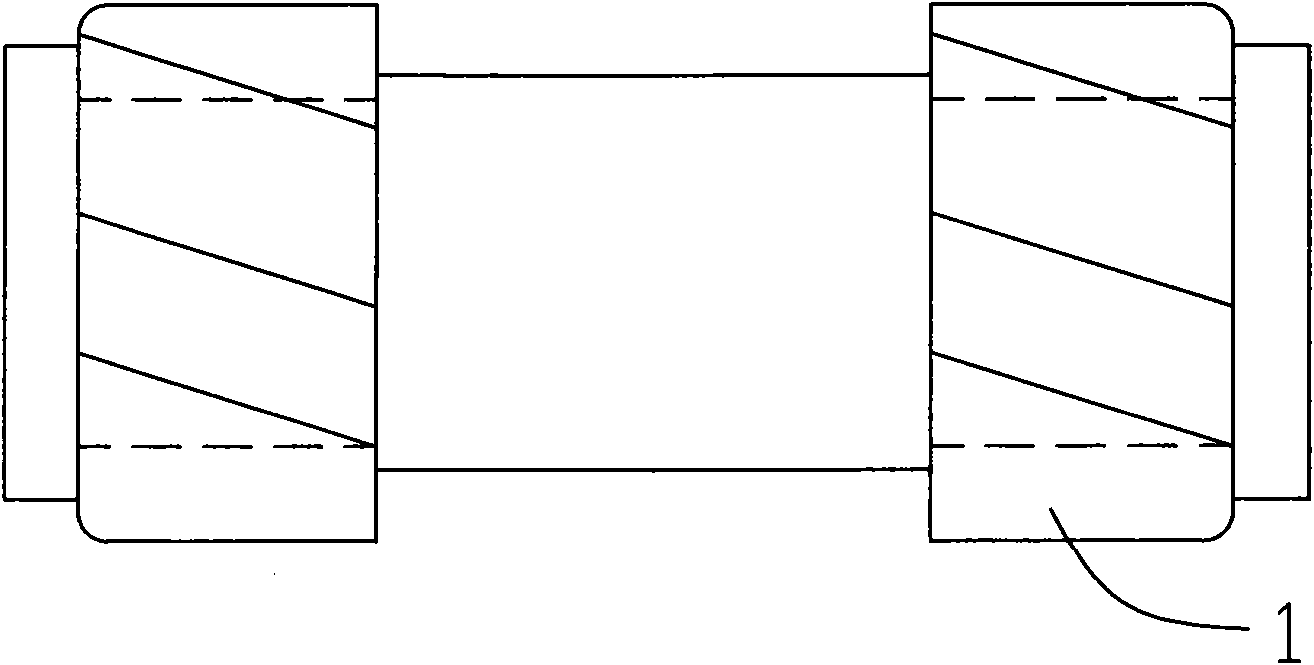

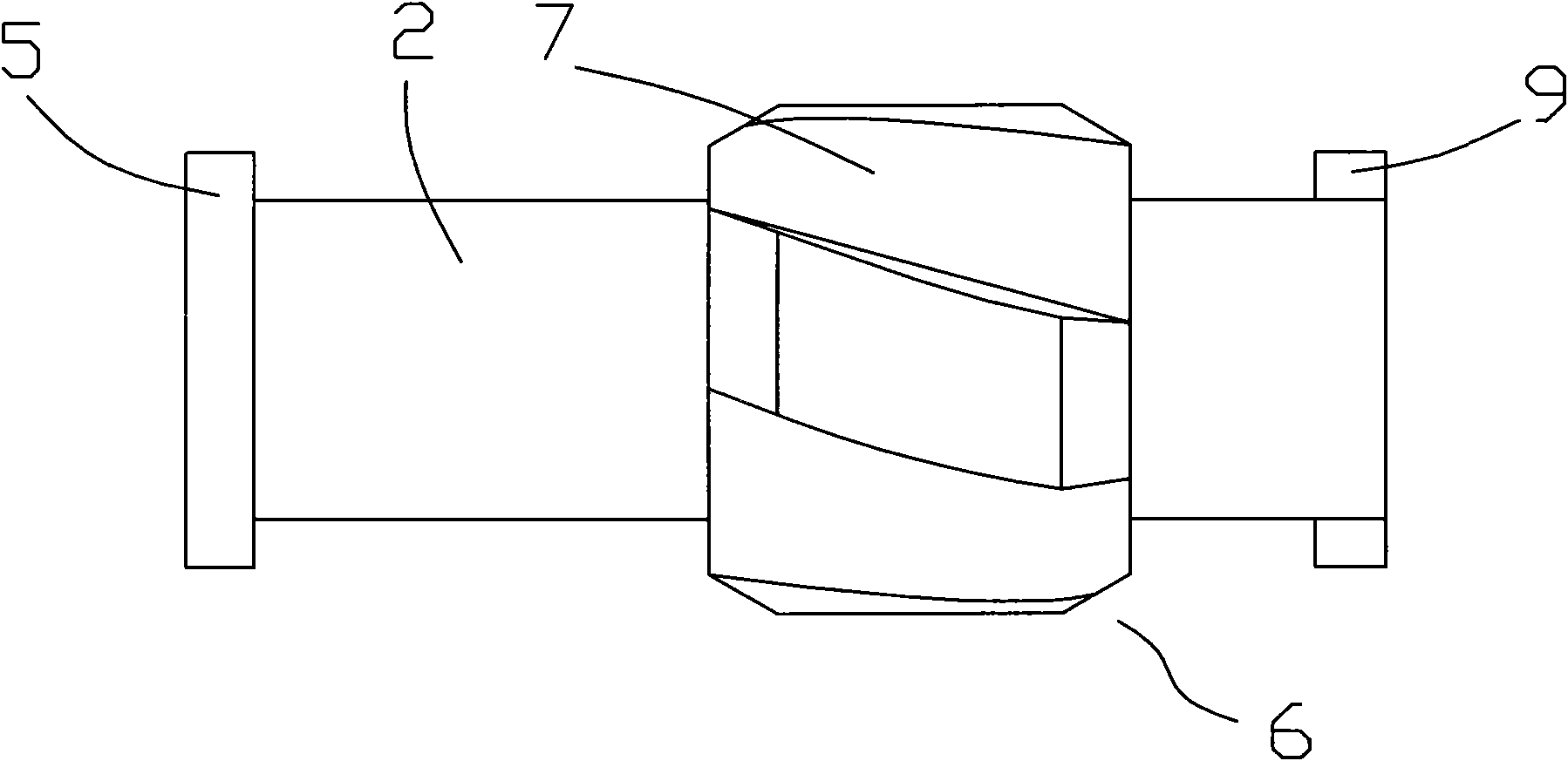

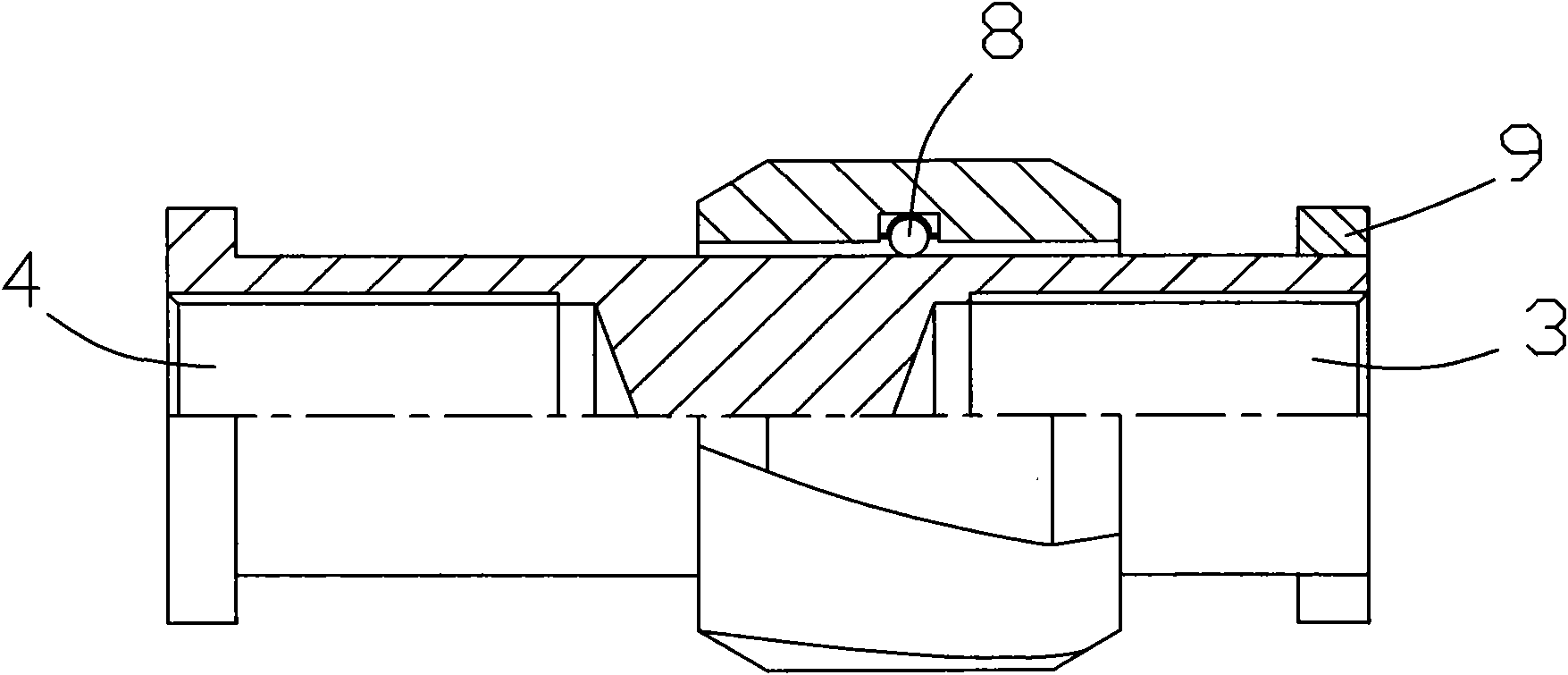

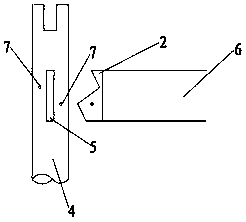

Bi-directionally sliding pup-joint coupling centralizer

InactiveCN101832111AImprove passabilityReduce in quantityDrilling rodsDrilling casingsCouplingEngineering

The invention discloses a bi-directionally sliding pup-joint coupling centralizer, which comprises a centralizer body serving as the coupling of a sucker rod. A radial positioning boss is arranged at two ends of the main body respectively; a sleeve-shaped centralizing block is sleeved on the centralizer body between two positioning steps; a helical guide slot is formed on the outer surface of the centralizing block; a rolling bearing is arranged between the inner surface of the centralizing block and the centralizer body; the length of the centralizing block is smaller than the space between the two positioning steps; and the centralizing block can axially move along the centralizer body and axially rotate around the centralizer in the length range limited by the two positioning steps. The number of the centralizing blocks in the coupling centralizer is reduced. Therefore, the ineffective load in the oil extraction process in the oil fields is reduced, the flow area between the coupling centralizer and an oil pipe is increased, and the annular circulation resistance is reduced. Due to the arrangement of the rolling bearing between the centralizing block and the centralizer body, the friction between the coupling centralizer and the oil pipe is reduced, and the passing-through capacity of the coupling centralizer in the oil pipe is improved.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

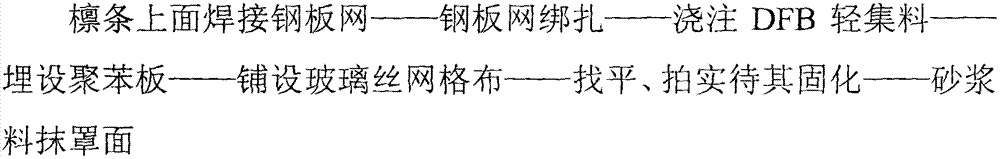

Method for producing cast-in-situ insulation roof

InactiveCN102787698AReduce dead loadChange the construction processRoof covering using sealantsRoof covering insulationsMesh gridFiberglass mesh

The invention discloses a method for producing a cast-in-situ insulation roof, which comprises the technological process that a steel screen is welded on a purline, the purline is bound with the steel screen, then DFB lightweight aggregates are poured, blocks of polyphenyl plates are embedded in the DFB lightweight aggregates side by side, fiberglass meshes are respectively laid between the DFB lightweight aggregates on the upper and lower surfaces of the polyphenyl plates, after the DFB lightweight aggregates are completely poured, a trowel for levelling up is used for beating the DFB lightweight aggregates to solidify, and finally, mortar is used for plastering an anti-cracking layer top facing. According to the method, an outer building envelop and energy-saving insulation engineering are integrated to be completed at one step, the technology is simple, the application scope is wide, and the construction progress is accelerated. The method can be used for manufacturing an insulation roof which is light, has high-strength and good integral fire proofing, and is low in comprehensive cost.

Owner:张云麟 +1

Parallel type mechanical grabbing arm mechanism

A parallel type mechanical grabbing arm mechanism comprises three identical grabbing branch chains, a moving platform, a static platform and an auxiliary vertical moving branch chain. The tail end of a mechanical arm is fixedly connected with the static platform, and two ends of the auxiliary vertical moving branch chain are fixedly connected with the center of the static platform and the center of the moving platform respectively. Three grabbing branch chains are distributed between the static platform and the moving platform symmetrically and evenly, one end of a rod 1 in the three grabbing branch chains is connected with the static platform through a rotating pair, the other end of the rod 1 is connected with a grabbing arm through a moving pair, and the grabbing arm is connected with the moving platform through a rotating pair. The grabbing arm can perform the grabbing action when driven by the moving branch chain. The parallel type mechanical grabbing arm mechanism is simple in structure, easy to control, low in additional load at the tail end of the mechanical arm and high in working efficiency.

Owner:CHANGZHOU UNIV

Method for pasting face bricks in prefabrication of concrete floor and concrete wallboard

The invention provides a method for pasting face bricks in prefabrication of a concrete floor and a concrete wallboard, and belongs to the technical field of construction engineering. The method includes the steps that a bottom mold for the prefabricated concrete floor or concrete wallboard is manufactured, a single-sided adhesive plastic film is laid on the bottom mold for the prefabricated concrete floor or concrete wallboard, a face brick positioning grid and the face bricks are placed on the bottom mold, laid with the single-sided adhesive plastic film, for the prefabricated concrete floor or concrete wallboard, and hot paraffin liquid is poured onto the bottom mold; and a side mold for the prefabricated concrete floor or concrete wallboard is mounted, steel bar materials of the prefabricated concrete floor or concrete wallboard are bound, concrete of the prefabricated concrete floor or concrete wallboard is poured, and after the needed strength is achieved through curing, construction is completed. By means of the method, the pasting quality of the face bricks for a wall surface or a building surface can be remarkably improved, pasting materials are saved, manpower is reduced, and the construction cost of construction engineering is lowered. According to the method, the production process and equipment are simple, operation is easy, the bonding strength is high, finished product protection is facilitated, and the face bricks are flat and clean in appearance; the method has positive significance to development of prefabricated and assembled type concrete buildings.

Owner:江苏亿科博建筑科技有限公司

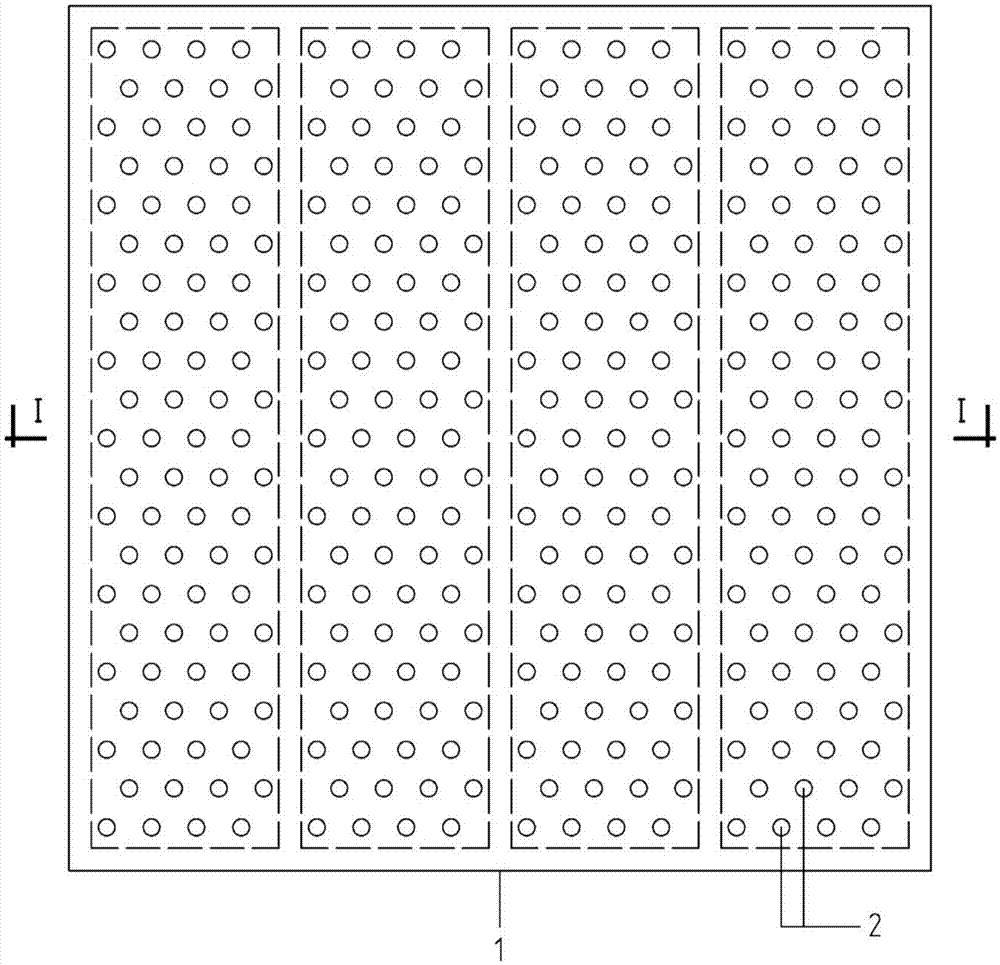

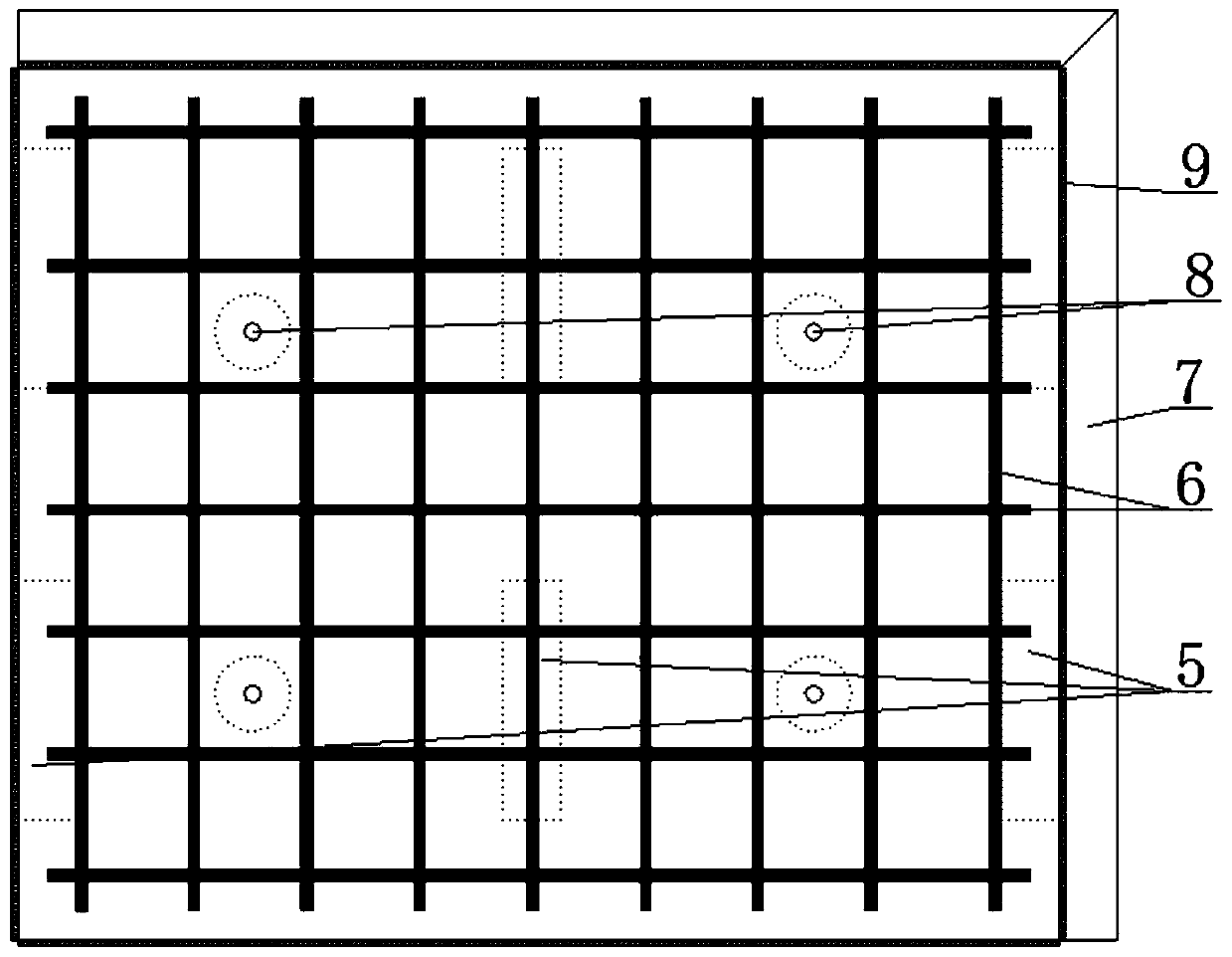

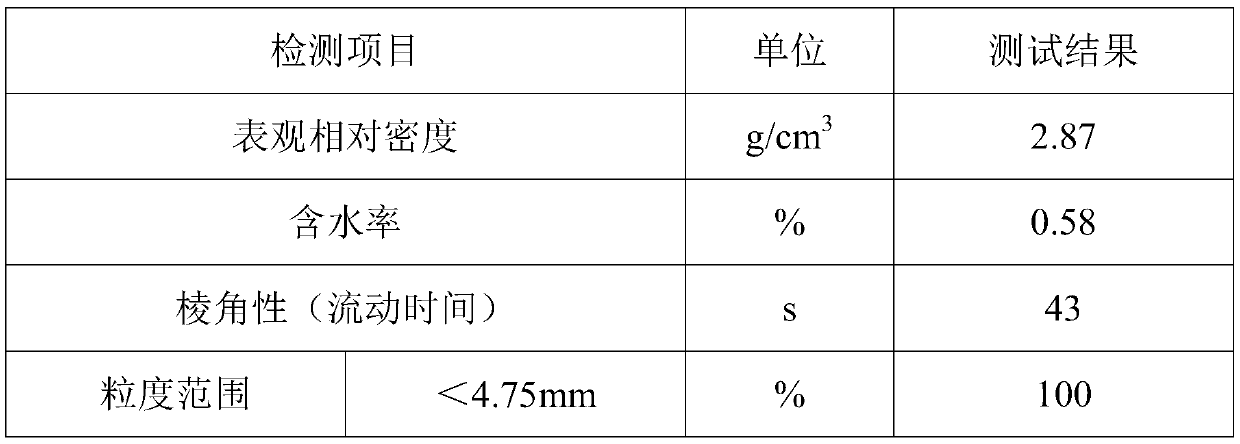

Precast ultra-high-performance concrete steel bridge deck pavement structure and preparation method

ActiveCN110714408AReduce labor intensityReduce constraintsNon-macromolecular adhesive additivesMacromolecular adhesive additivesFiberMesh reinforcement

The invention relates to the technical field of steel bridge deck pavement, in particular to a precast ultra-high-performance concrete steel bridge deck pavement structure and a preparation method. The precast ultra-high-performance concrete steel bridge deck pavement structure sequentially comprises, from bottom to top, a steel slab base layer, a high-toughness resin waterproof bonding layer withthe thickness of 5-10 mm, a high-density fiber concrete precast pavement layer with the thickness of 4-6 cm and an epoxy gravel antiskid wearing layer with the thickness of 3-5 mm. The high-density fiber concrete precast pavement layer consists of high-density fiber concrete precast slabs; the high-density fiber concrete precast slabs internally comprise sparsely-distributed reinforcing mesh; each of the high-density fiber concrete precast slabs is provided with grouting holes and hole bottom dispersion openings in advance; opposite sides of each of the high-density fiber concrete precast slabs are equipped with a locking groove and a locking fastener; and the bottoms of the precast slabs are provided with high-elastic cushion rubber during pavement of a steel bridge deck. The precast ultra-high-performance concrete steel bridge deck pavement structure and the preparation method utilize a high-toughness resin contact surface full bonding manner, and can reinforce the steel bridge deck, thereby avoiding the stress damage to steel slabs caused by conventional welding rivet connection, improving mechanical properties of the pavement structure layer, and facilitating later maintenanceand repair of the pavement layer.

Owner:JIANGSU SINOROAD TRANSPORTATION SCI & TECH CO LTD

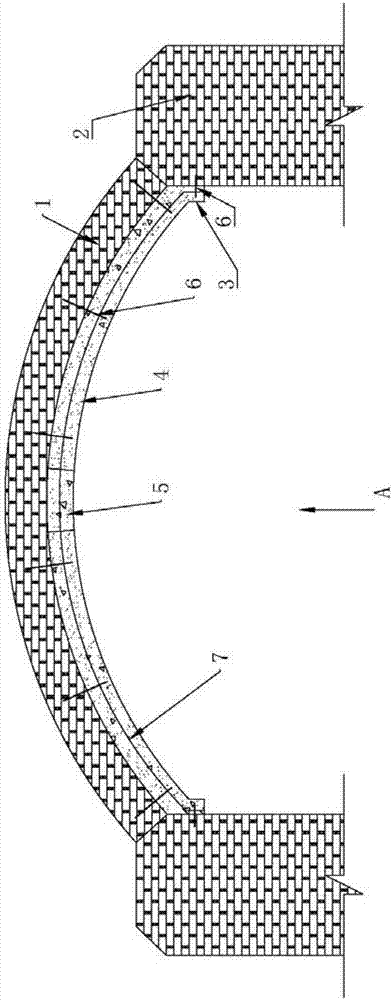

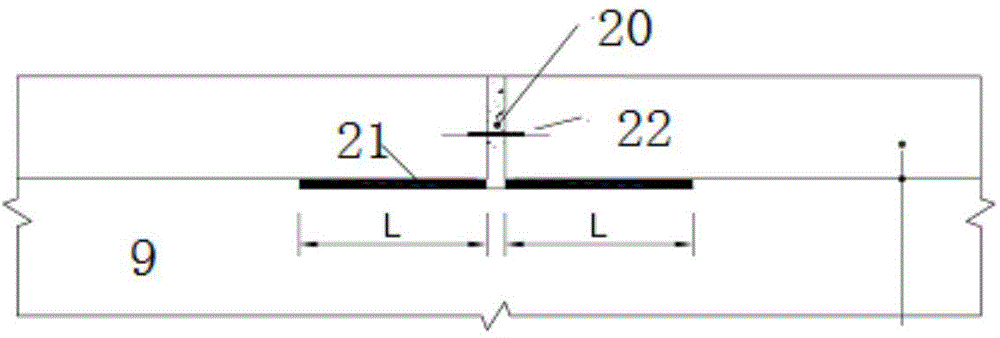

Arch bridge web arch ring reinforcing structure

PendingCN107034793AImprove carrying capacityImprove securityBridge erection/assemblyBridge strengtheningArchitectural engineeringMesh reinforcement

The invention discloses an arch bridge web arch ring reinforcing structure which comprises a web arch ring body. The two ends of the web arch ring body are both provided with supporting walls. The sides, close to each other, of the two supporting walls are each provided with a plurality of bases. The portions, between the two bases, of the opposite positions of the two supporting walls are both provided with longitudinal arch ribs. At least one cross beam is arranged between the longitudinal arch ribs. Steel pull rods are all arranged between the longitudinal arch ribs and the web arch ring body, between the cross beams and the web arch ring body as well as between the supporting walls and the bases. The longitudinal arch ribs, the cross beams and the bases are all internally provided with steel bar net racks connected with the steel pull rods. By adoption of the structure, the web arch ring body, the bases, the longitudinal arch ribs and the cross beams form a whole and are jointly stressed, the purposes of arch bridge bearing capacity improvement and safe storage are achieved, and compared with traditional structures, light-weight reinforcement is achieved, the numbers of construction sections and masonry are decreased, the construction difficulty and project cost are lowered, and damage to an arch bridge is small; and meanwhile, dead loads generated in the later period are effectively reduced, and the structure has large engineering application value.

Owner:重庆正达工程咨询有限公司

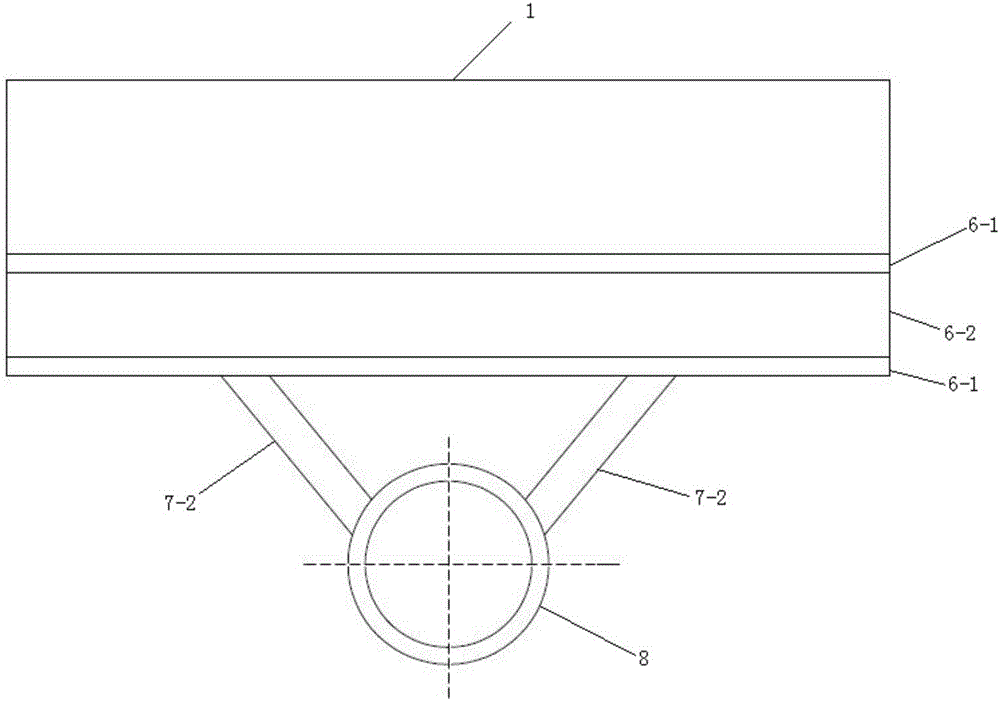

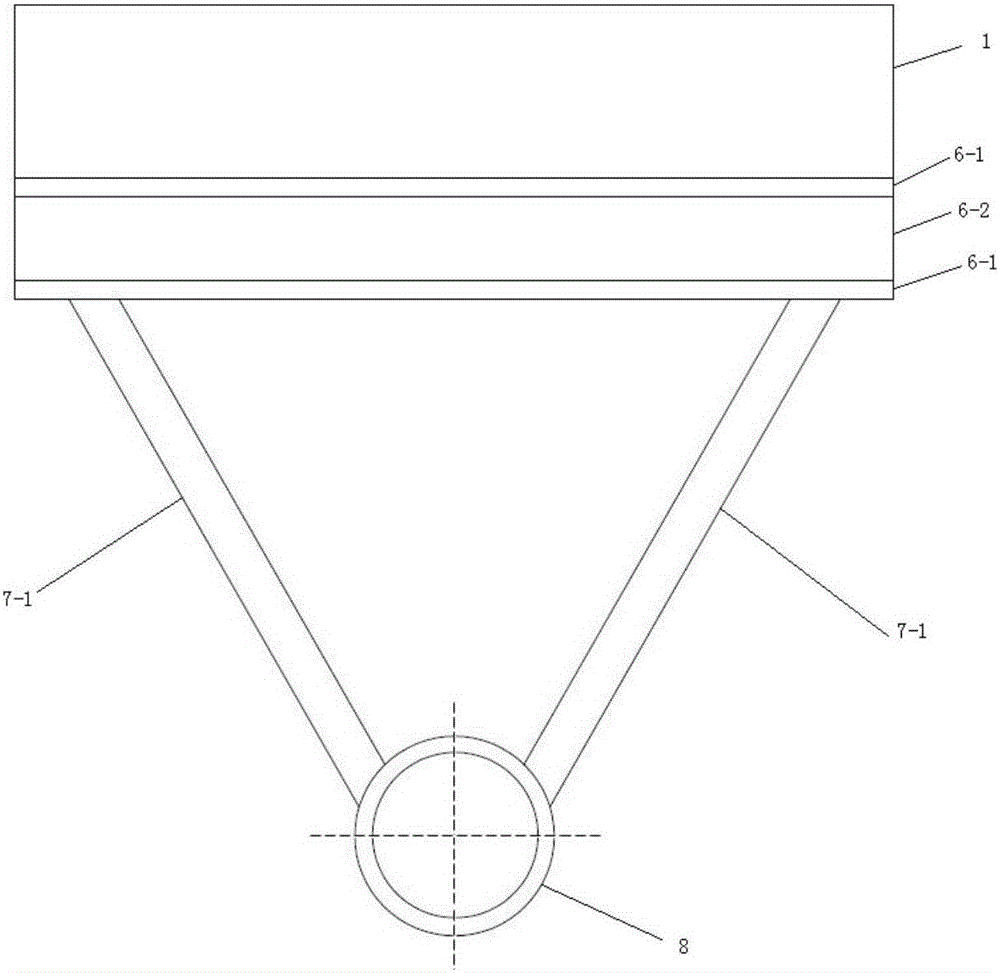

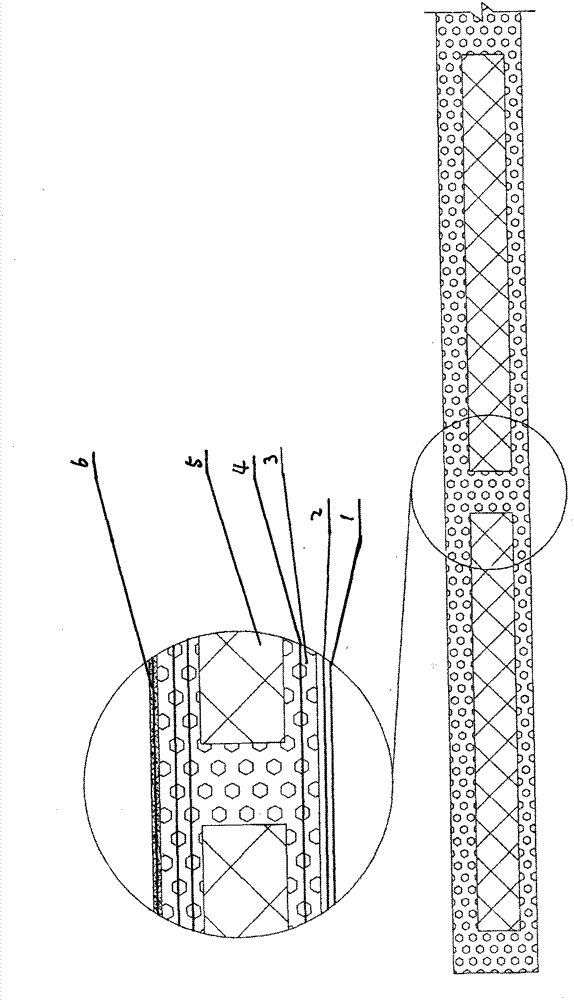

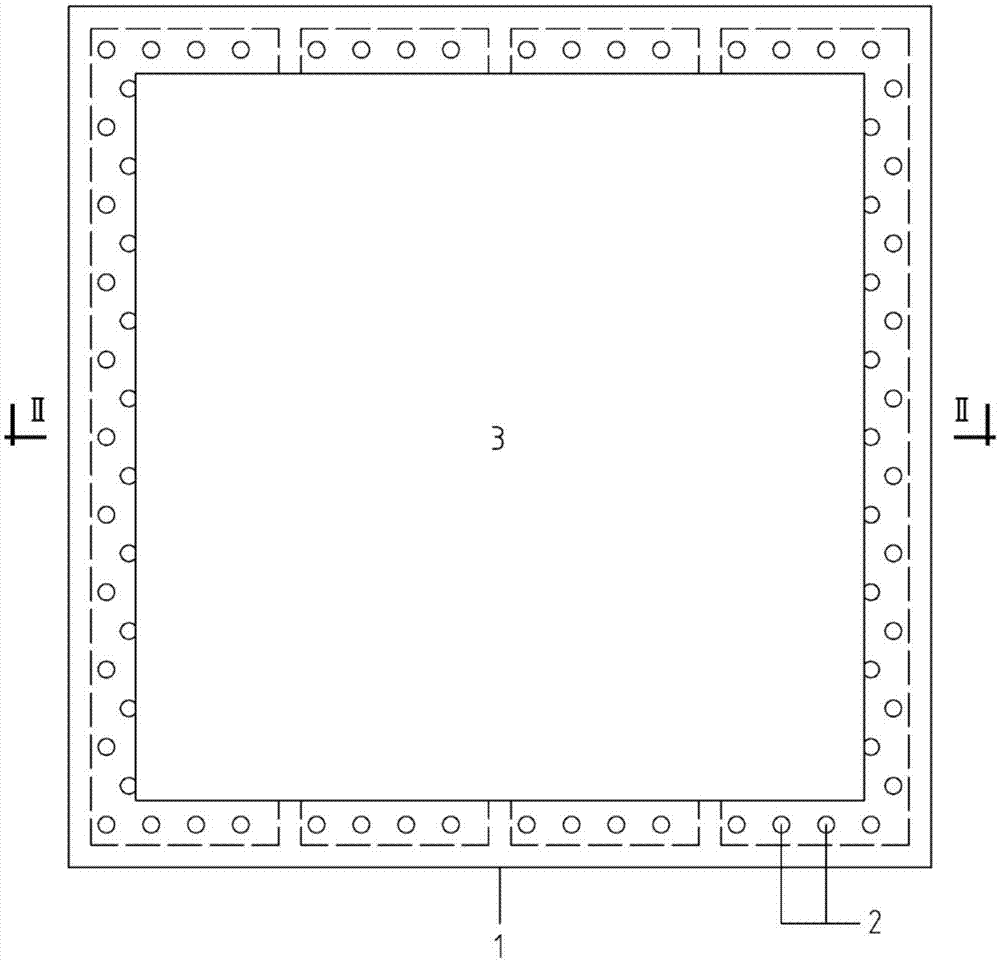

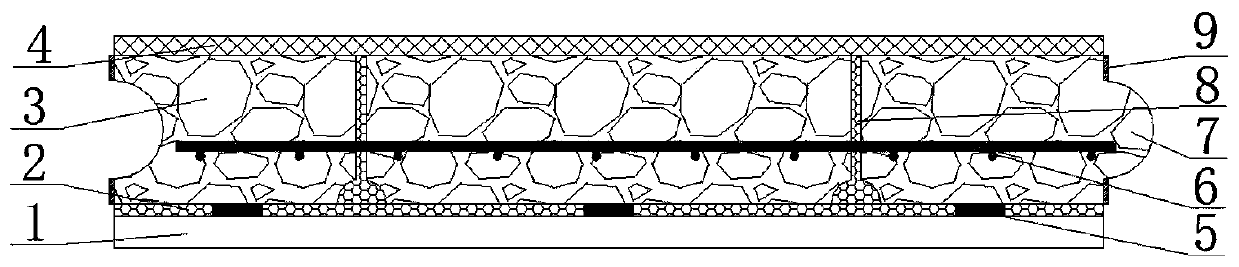

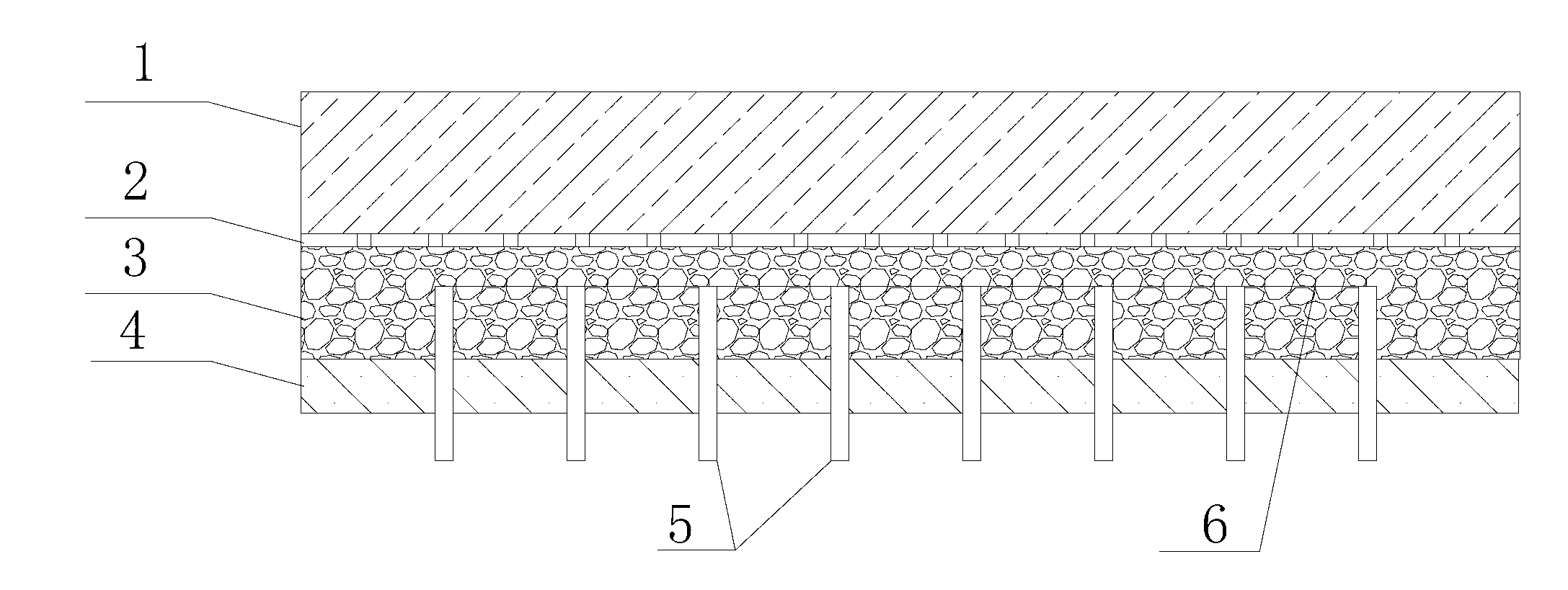

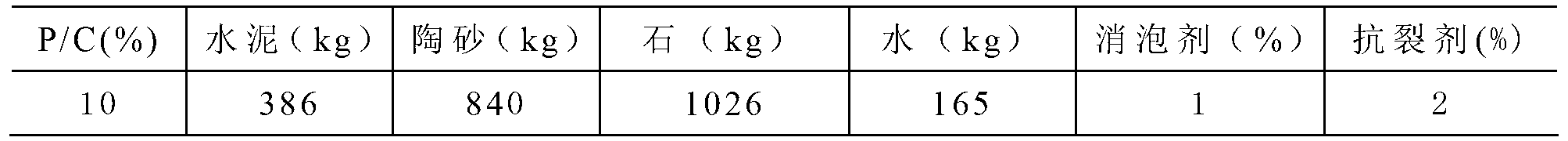

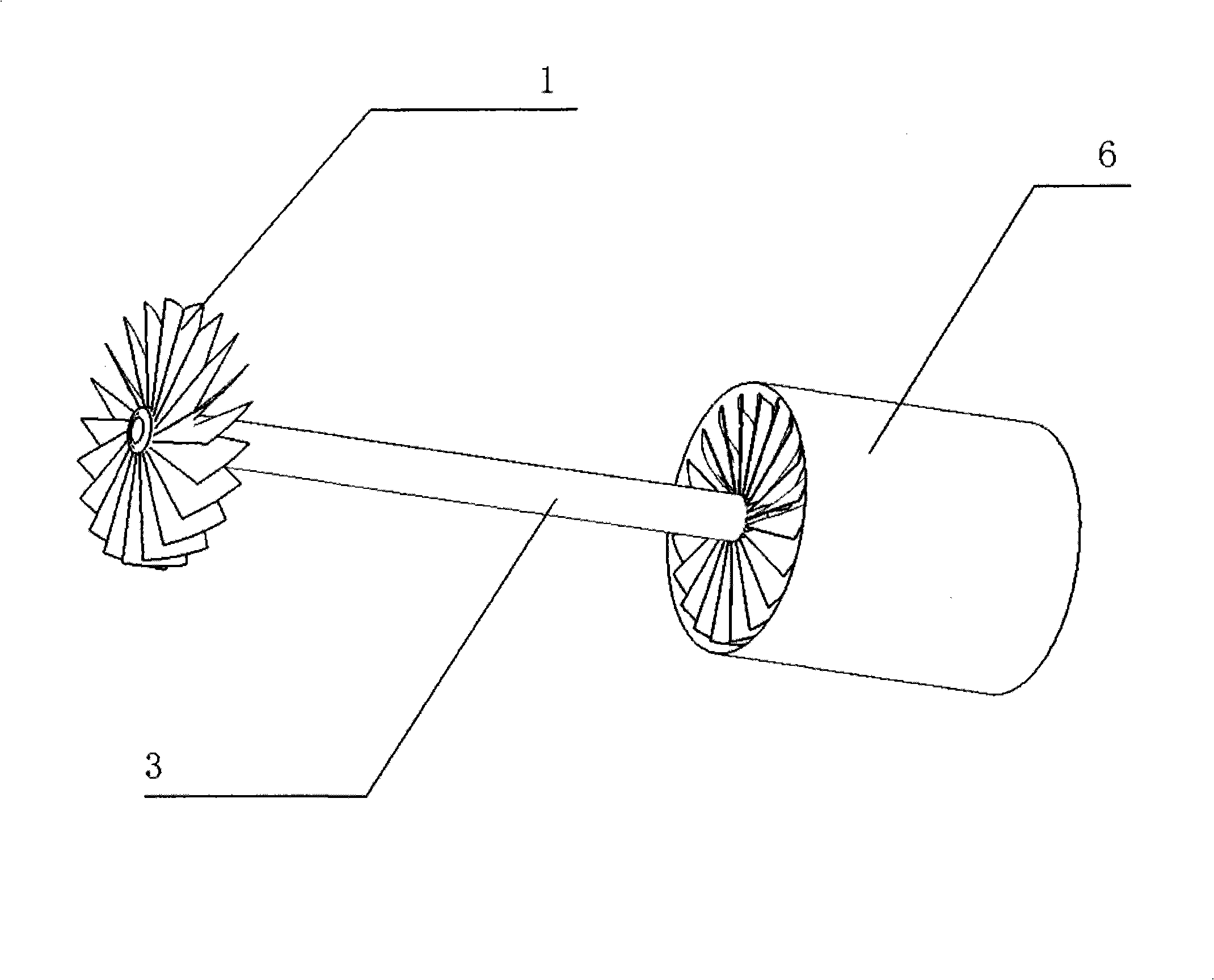

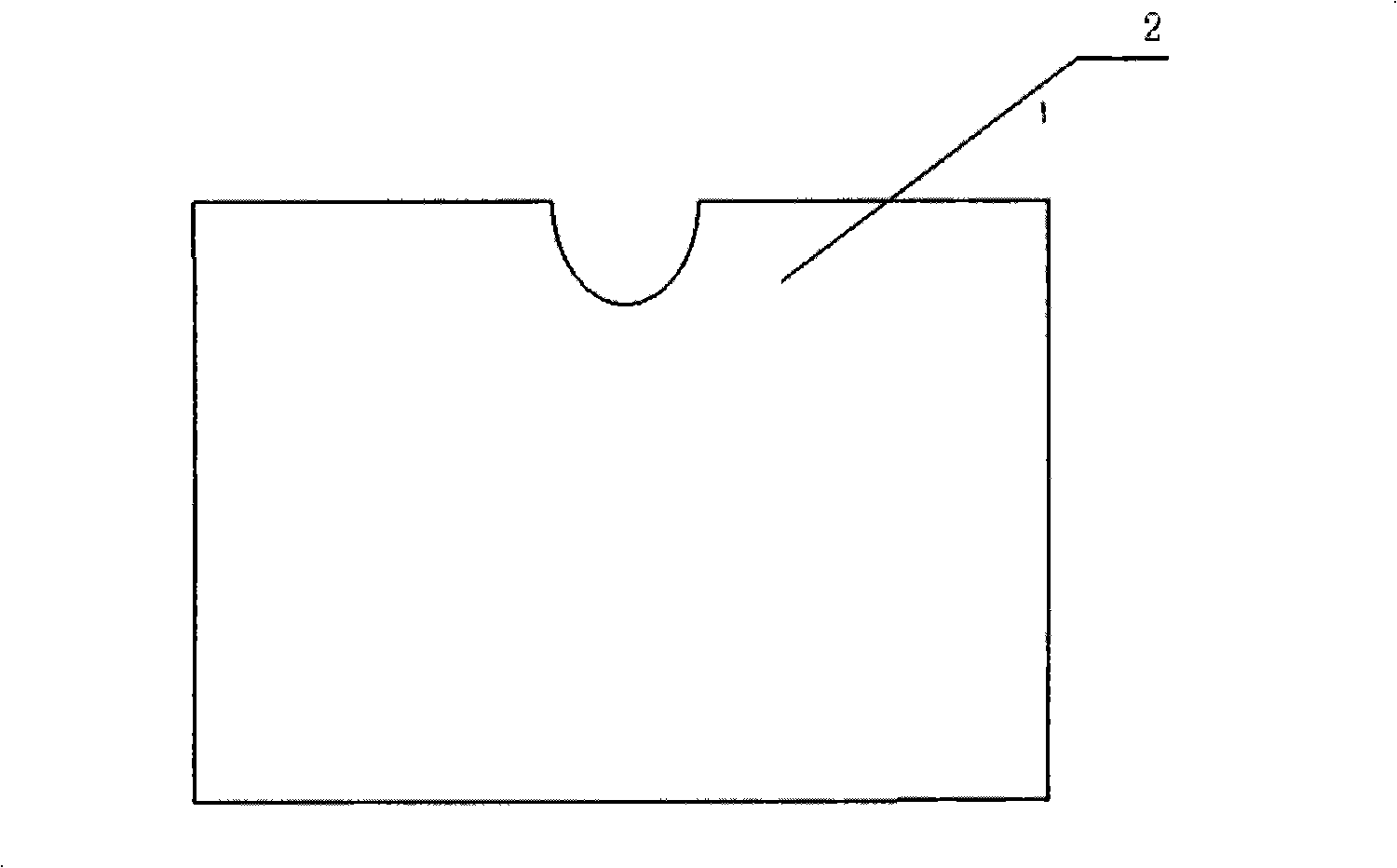

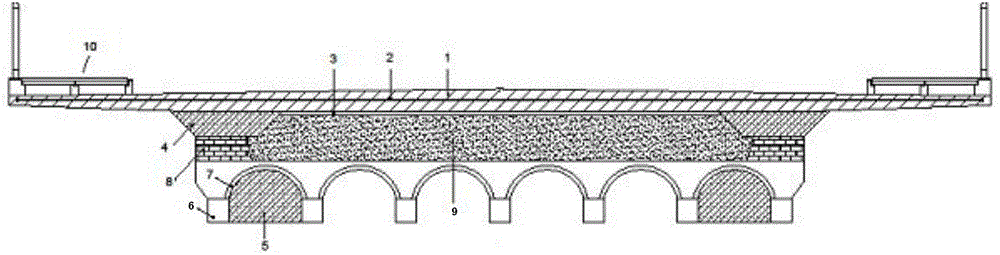

Cement concrete bridge floor composite pavement structure

The invention discloses a cement concrete bridge floor composite pavement structure. The cement concrete bridge floor composite pavement structure comprises a bridge deck slab (4), wherein erection bas (5) are erected on the bridge deck slab (4), a reinforcing steel bar screen (6) is arranged on the erection bars (5), a light polymer cement concrete transition layer (3) is poured on the bridge deck slab (4), the reinforcing steel bar screen (6) is located inside the light polymer cement concrete transition layer (3), longitudinal and horizontal anti-skidding grooves (2) are formed in the upper surface of the light polymer cement concrete transition layer (3), and a bituminous concrete pavement layer is paved on the upper surface of the light polymer cement concrete transition layer (3). The cement concrete bridge floor composite pavement structure has the advantages that the service life is prolonged.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Vertical landing lifting system of vertical landing plane

InactiveCN101850845AReduce dead loadSimple structurePower plant arrangements/mountingJet propulsion plantsLevel flightControl vector

The invention relates to a vertical landing lifting system of a vertical landing plane, and a space is generated between the front low pressure fan and the turbofan or the turbojet engine via the output shaft of the prolonged front low pressure fan. In the space, a front air channel and a vector control guide plate are arranged. Direction of a part of low pressure propelling airflow generated by the front low pressure fan is changed by changing the angle of the vector control guide plate. A gas channel and a gas vector control guide plate are arranged on the channel of jet gas airflow of the engine to change the direction of the jet gas airflow of the engine by changing the angle of the gas vector control guide plate. The angles of the vector control guide plate and the gas vector control guide plate are changed simultaneously so that the plane can achieve level flight and vertical landing state easily.

Owner:余志刚

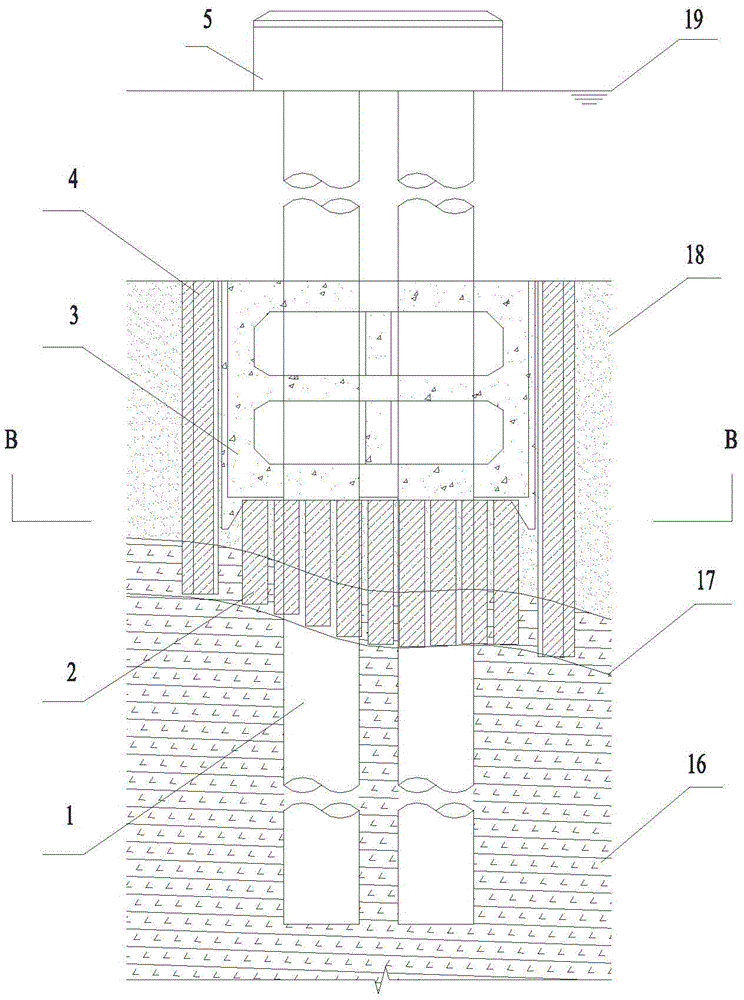

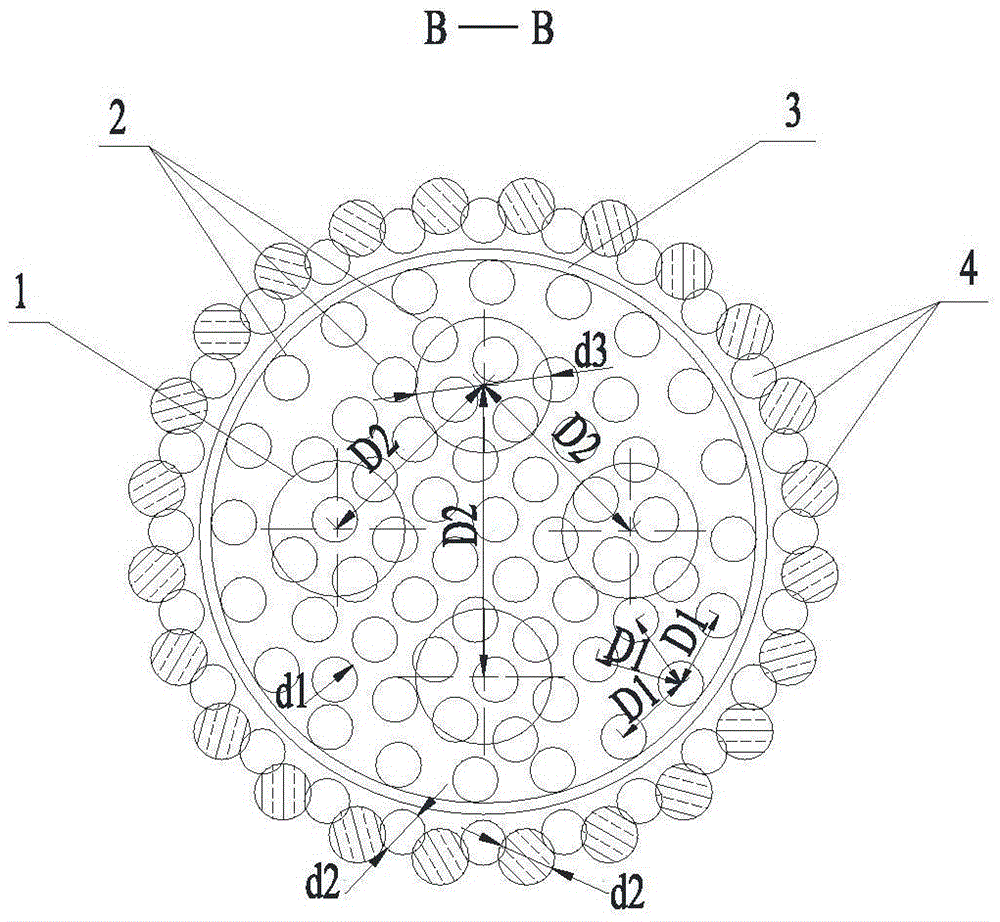

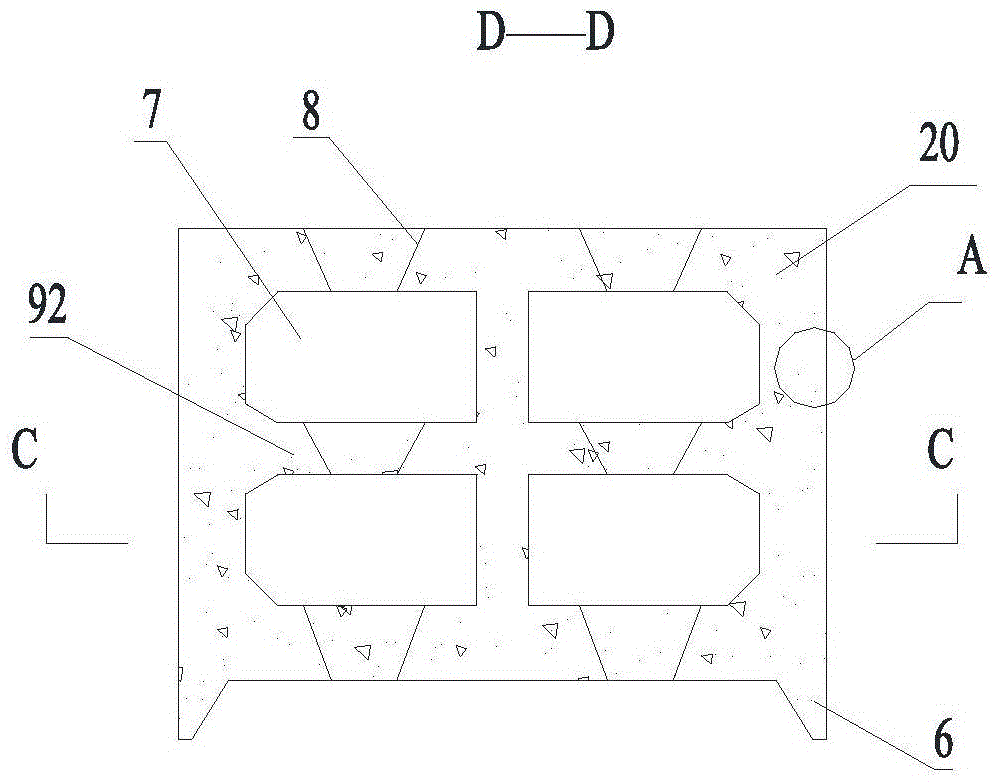

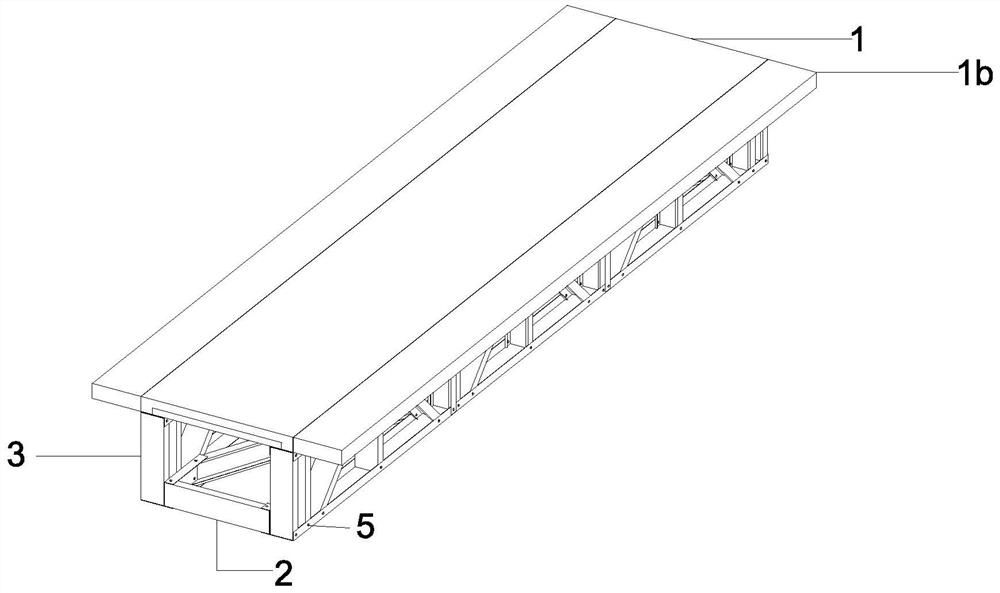

Combined foundation structure suitable for lagoon face island-reef environment and construction method thereof

ActiveCN105544597AEffective reinforcementImprove bearing capacityCaissonsBulkheads/pilesHigh pressureLarge deformation

The invention discloses a combined foundation structure suitable for a lagoon face island-reef environment and a construction method thereof, and relates to the field of geotechnical designs and island-reef development. The combined foundation structure suitable for the lagoon face island-reef environment and the construction method thereof are suitable for coral lagoon geological conditions. The combined foundation structure suitable for the lagoon face island-reef environment comprises high-pressure jet grouting stabilization piles, a prefabricated caisson, lateral restraining high-pressure jet grouting piles, prefabricated bored sinking pipe piles and a prefabricated bearing platform, wherein the prefabricated caisson is located on the high-pressure jet grouting stabilization piles and in a curtain structure formed by the lateral restraining high-pressure jet grouting piles and is in rigid connection with the prefabricated bearing platform into a whole for collaborative bearing through the prefabricated bored sinking pipe piles. The combined foundation structure suitable for the lagoon face island-reef environment and the construction method thereof not only overcome the disadvantageous engineering characteristics of a coral lagoon foundation structure such as high structural performance, low bearing capacity and large deformation, but also bring the bearing capacity of each layer of rock and earth mass of the coral lagoon foundation structure into full play, have the characteristics of large rigidity, high bearing capacity and fast, excellent and economical construction and the like, have the advantage of adapting to construction in island areas, have broad application prospects, and make it possible to build an airport and other overhead reclamation engineering on a coral lagoon foundation.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

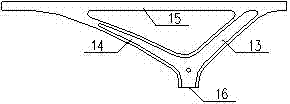

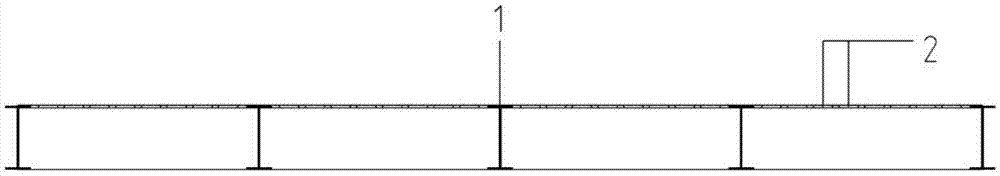

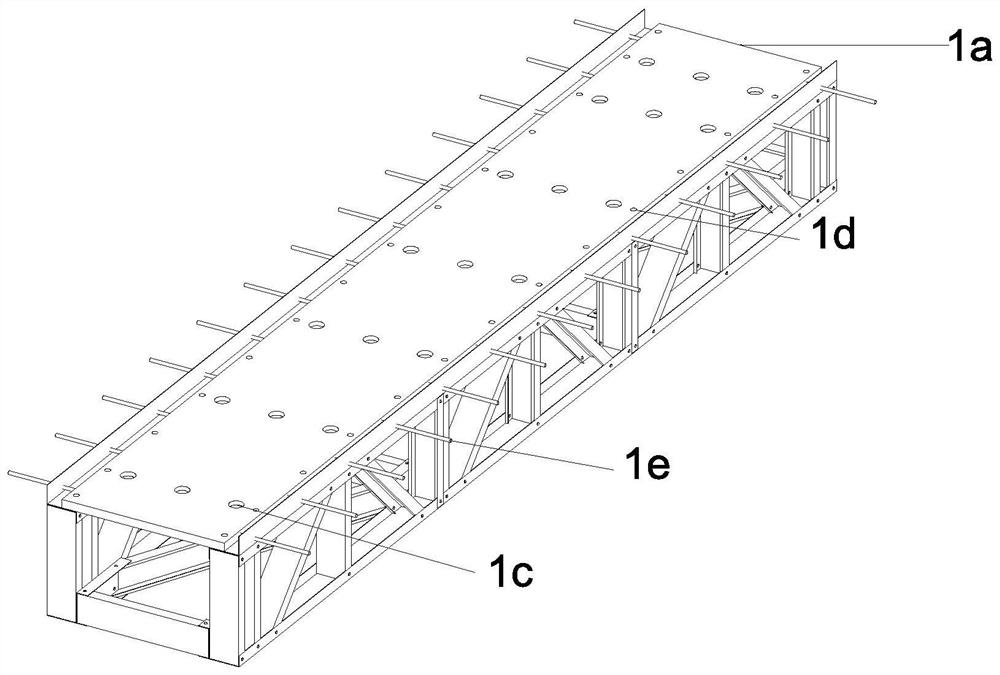

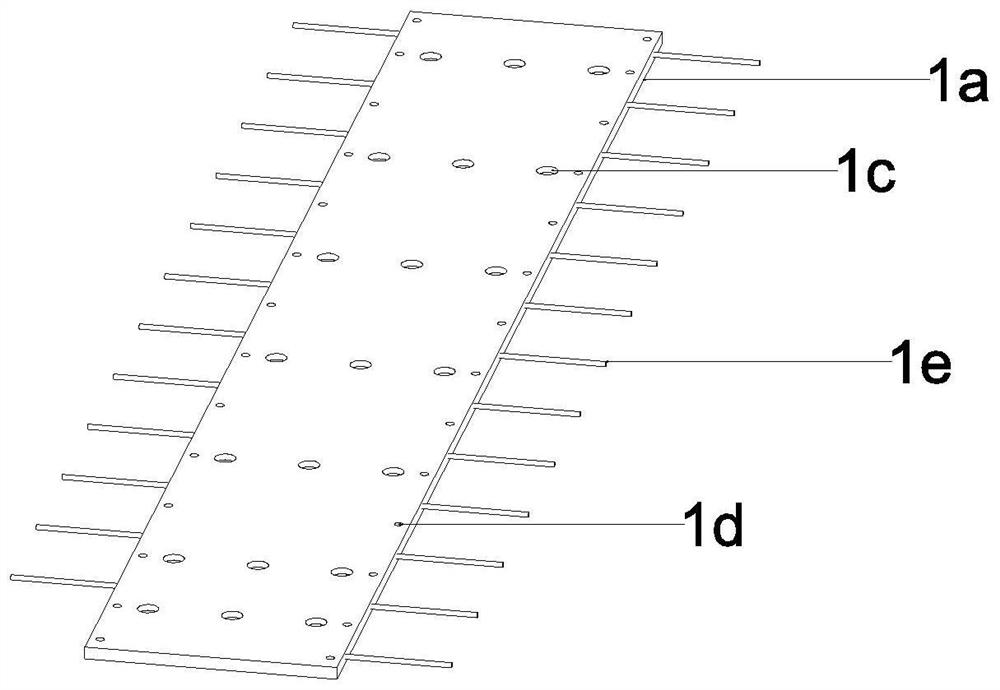

Cold-formed thin-walled steel web combined PC box girder

ActiveCN112982142ALose weightImprove mechanical propertiesBridge structural detailsBridge materialsPrestressed concrete beamCrack resistance

The invention discloses a cold-formed thin-walled steel web combined PC box girder, comprising an upper flange, a lower flange and two truss type cold-formed steel combined webs. According to the invention, the web and the lower flange are both formed by combining the cold-formed thin-walled steel, the dead weight of the girder body is reduced, and span breakthrough is achieved; the web and the lower flange are in a truss form, so the overall stability of the structure can be improved, and the problem of poor local stability of the cold-formed thin-walled steel is solved; the webs are made of the cold-formed thin-walled steel, so the problem that webs of common prestressed concrete beam bridges are prone to cracking is fundamentally solved; and factory production of the cold-formed thin-walled steel and a prefabricated laminated slab can effectively accelerate the construction progress and improve the quality of components. The box girder of the invention has the advantages of being high in assembly speed, high in standardization degree, low in manufacturing cost, light in self-weight and excellent in bending resistance and crack resistance, can effectively solve the problems that a traditional concrete box girder component is complex in construction, high in manufacturing cost, large in self-weight, prone to web cracking and the like, and is suitable for bridge structure girders or main and secondary beams and other components of a building structure.

Owner:BEIJING UNIV OF TECH

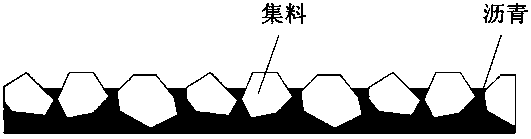

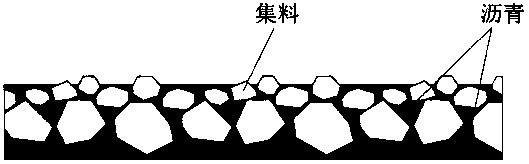

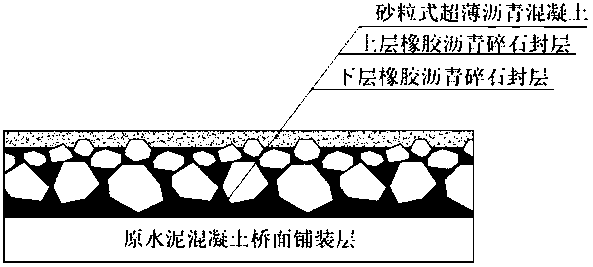

Thin-layer hood face structure for cement concrete bridge deck pavement modification and construction method thereof

InactiveCN108457179AHigh viscosityBond strength between layersBridge structural detailsChipsealStructure of the Earth

The invention discloses a thin-layer hood face structure for cement concrete bridge deck pavement modification. The thin-layer hood face structure is a combined structure which is composed of two lower rubber asphalt macadam seal layers and an upper sand-grain-type ultrathin asphalt concrete wearing layer, and the two rubber asphalt macadam seal layers are embedded and squeezed with each other; the nominal maximum particle size of sand-grain-type ultrathin asphalt concrete is 6.7 cm, and the thickness is not larger than 2.0 cm. The invention further discloses a construction method of the hoodface structure. The construction method comprises the steps of firstly, conducting fine milling on original cement concrete bridge deck pavement, wherein the milling depth is 5 mm; after cleaning is thorough, scattering the first rubber asphalt macadam seal layer, after rubber wheels grind the first rubber asphalt macadam seal layer, scattering the second rubber asphalt macadam seal layer, and after grinding, the sand-grain-type ultrathin asphalt concrete is paved and grinded on the second rubber asphalt macadam seal layer. Compared with the prior art, the thin-layer hood face structure has the advantages of being high in bonding strength, resisting to cracking and slide, and having small increased dead loads and low cost.

Owner:湖州市公路管理局

Cement concrete bridge deck pavement surface vibration reduction sealing layer and construction method

ActiveCN111377680AReduce impactReduce driving noiseIn situ pavingsBridge structural detailsBitumen emulsionFirming agent

The invention discloses a cement concrete bridge deck pavement surface vibration reduction sealing layer and a construction method. The material comprises the following components in parts by weight:10-20 parts of emulsified asphalt, 10-20 parts of water-borne epoxy resin emulsion, 10-25 parts of water-borne epoxy resin curing agent emulsion, 100 parts of sand, 3-8 parts of cement, 0.05-0.4 partof cement accelerator, 5-10 parts of waste tire rubber powder and 4-12 parts of water. The construction method sequentially comprises the following steps of designing a construction mix proportion, preparing a solid mixture, a leachate ring mixed solution and a water ring mixed solution, loading and calibrating a slurry seal paver, mixing and paving, trimming, maintaining and opening traffic. Theconstruction thickness of the surface vibration reduction sealing layer is only 3 mm, the maximum particle size of used sand is 3 mm and is the same as the thickness of the surface vibration reductionsealing layer, and therefore tracks cannot be generated. And meanwhile, the surface vibration reduction sealing layer can reduce the driving noise of cement concrete bridge deck pavement, improve thedriving comfort and reduce the impact force of the vehicle load on the bridge, namely, the vibration reduction effect is achieved.

Owner:王壹帆

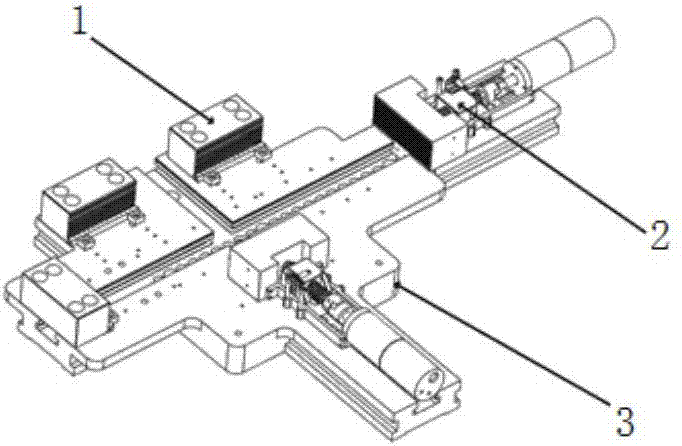

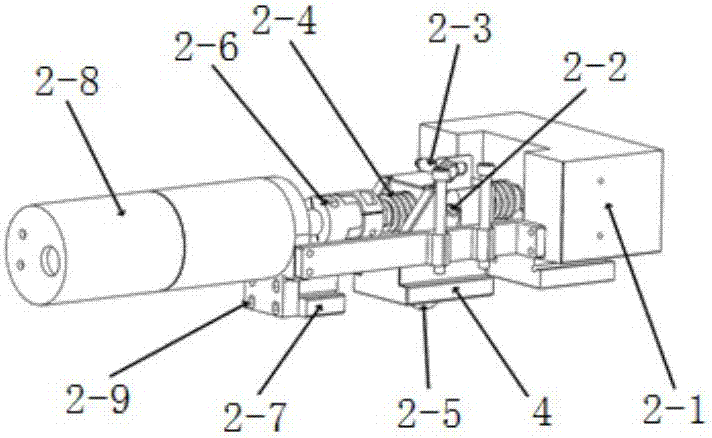

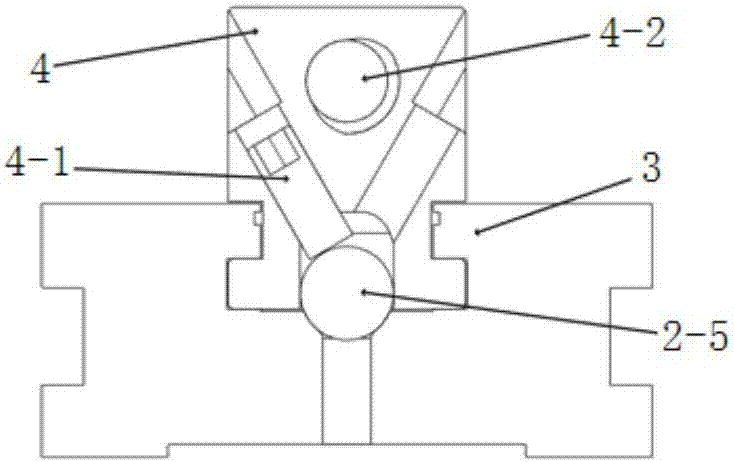

Automatic both-way positioning and clamping device

InactiveCN107253075AReduced precision requirementsReduce clamping forcePositioning apparatusMetal-working holdersPneumatic motorEngineering

The invention discloses an automatic two-way positioning and clamping device, which comprises a device body with a T-shaped structure. A positioning block is provided corresponding to each group of push-off assemblies on the side, and a clamping area for placing workpieces is formed between the push-off assemblies and the positioning blocks. Each push-off assembly is provided with a pneumatic The air motor realizes the clamping and loosening of the workpiece by controlling the ejector assembly forward and reverse, and the positioning block is used for precise positioning of the workpiece. The invention has the advantages of low cost, convenient maintenance and repair, regular-shaped workpieces can be directly clamped, no additional intermediate connection structure is required, strong versatility, large clamping force, and reliable and stable work.

Owner:西安精雕软件科技有限公司

Two-way curved arch bridge floor broadening and reinforcing process method

InactiveCN104532759AHigh strengthIncrease stiffnessBridge structural detailsBridge erection/assemblyReinforced concretePre stress

The invention discloses a two-way curved arch bridge floor broadening and reinforcing process method. The two-way curved arch bridge floor broadening and reinforcing process method comprises the steps of (a) dismounting an original bridge floor concrete road surface and then respectively dismounting a part of curved cavity padding and side walls; (b) conducting bar embedding and concrete filling on two-way curved arch tiles on two sides; (c) installing steel bar concrete cushion blocks with inverted trapezoidal structures at the upper portions of the side walls and then casting a concrete filling-leveling layer on the top face of the curved cavity padding; (d) adopting a prestressed concrete cast-in-place cantilever mode to wholly casting concrete on the concrete filling-leveling layer and meanwhile arranging multiple expansion joints and contraction joints; (e) performing bridge floor conduction including a sidewalk system. By means of the two-way curved arch bridge floor broadening and reinforcing process method, the bearing performance of a bridge can be remarkably improved, bridge floor congestion can be effectively relieved, and meanwhile the two-way curved arch bridge floor broadening and reinforcing process method has the advantages of being convenient to construct, large in bridge floor broadening proportion, capable of remarkably improving side arch bearing capacity, good in reinforcing effect and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

Novel beam, column and tiebeam structure of ancient building and manufacturing method thereof

InactiveCN108442515AIncreased durabilityStay beautifulLoad-supporting pillarsMortise and tenonArchitectural engineering

The invention provides a novel beam, column and tiebeam structure of an ancient building. The novel beam, column and tiebeam structure of the ancient building includes beam, column and tiebeam structures which are connected with each another by mortise and tenon joints, and the beam, column and tiebeam structure are all composed of hollow aluminum parts formed by punch forming and welding of aluminum alloy sheets. A mortise is arranged at the upper end of the beam structure, and an electric welding joint is arranged at one end of the mortise; a rabbit is arranged in the column structure; a mortise is arranged at one end of the tiebeam structure, and bolt holes are formed in the mortise; and bolt holes are further formed in the column structure. According to the novel beam, column and tiebeam structure of the ancient building, by adopting beam, column and tiebeam dies and beam, column and tiebeam structure base bodies which are machined by bolts and the aluminum alloy sheets, the cost of manufacturing the beam, column and tiebeam structures of the ancient building is reduced, and a lot of forest resources are saved; and in addition, the building dead load is lightened, the service life of beams, columns and tiebeams used as building units is prolonged greatly, and ancient buildings are kept attractive durably.

Owner:SUZHOU GARDEN DEV

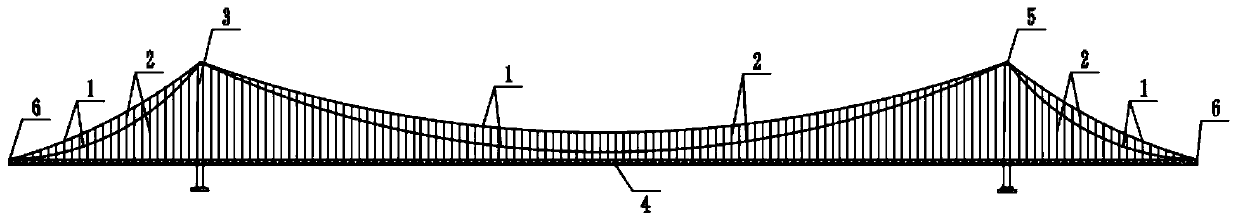

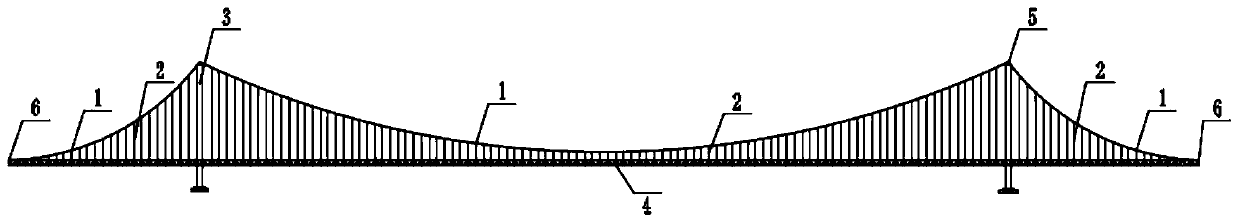

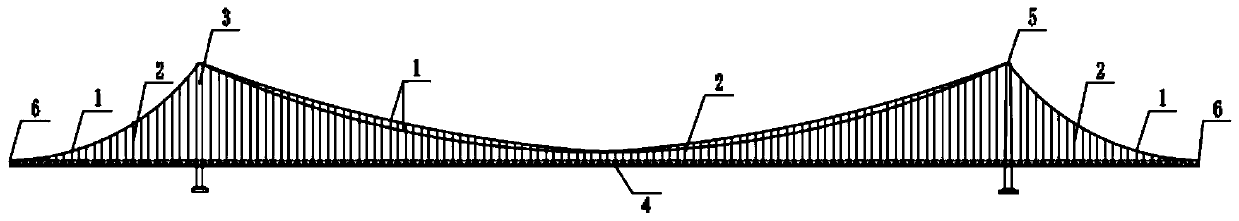

Layered suspension structure of single-side double-main-cable steel truss stiffening girder suspension bridge

InactiveCN111424561AReduce S-shaped deflectionReduce dead loadSuspension bridgeBridge structural detailsArchitectural engineeringBridge deck

The invention discloses a layered suspension structure of a single-side double-main-cable steel truss stiffening girder suspension bridge. A main cable close to the inner side of a bridge deck is connected to an upper chord of a steel truss stiffening girder through a cable clamp and a sling, and a main cable close to the outer side of the bridge deck is connected to a bracket extending out of a lower chord of the steel truss stiffening girder through a cable clamp and a sling. The single-side double main cables are arranged at different heights with one cable arranged at the upper part, and the other main cable arranged at the lower part, or the inner side main cable and the outer side main cable are arranged in parallel at the same height, or the inner side main cable and the outer sidemain cable are arranged in a double-chain manner. The bridge deck width occupied by the main cable suspension area can be reduced, so that the dead load of the stiffening girder is reduced, and the transverse width of the bridge tower is also reduced. The problem that the lifting point force is excessively concentrated on the upper (or lower) layer node can be effectively reduced by layered suspension. The inner and outer slings are different in length, so that same-frequency resonance of the slings can be avoided. The heights of the inner and outer main cables are different, so that cable vibration caused by wake flow can be avoided. If the double main cables are arranged in a double-chain form, the S-shaped deflection of the stiffening girder can be reduced.

Owner:SOUTHWEST JIAOTONG UNIV

Bulk-cargo grab bucket with high grabbing ratio

ActiveCN103010945AReduce dead loadLarger grab ratioLoad-engaging elementsDischarge efficiencyBulk cargo

The invention discloses a bulk-cargo grab bucket with high grabbing ratio. The grab bucket comprises two petals of bucket bodies arranged symmetrically, two pieces of main reinforcements which intersect at a hinging point and are connected fixedly, a conductor rope frame, a pair of movable pulleys, a pair of bucket-opening ropes and a pair of bucket-closing ropes, wherein the conductor rope frame and the two pieces of the main reinforcements are connected fixedly in the position of the hinging point; the pair of the movable pulleys are arranged inside corresponding bucket bodies and connected with bearing rods inside the corresponding bucket bodies fixedly; first ends of each bucket-opening ropes are connected with a lifting rope of an external crane respectively, and second ends of the bucket-opening ropes bypass the corresponding movable pulleys respectively and are connected with the upper part of the corresponding main reinforcements; first ends of the bucket-closing ropes are connected with an open-close rope of the external crane, and second ends are wound for a plurality of circles along two exterior common tangents of the pair of the movable pulleys and connected with the corresponding bucket bodies on the sides of the ends. The bulk-cargo grab bucket is extra large in the grabbing ratio, and the invalid load of the grab bucket is reduced greatly; and the dead weight of the grab bucket is low, the structural strength is high, and the energy consumed by overcoming the dead weight of the grab bucket is saved greatly, so that the discharging efficiency is improved greatly.

Owner:SHANGHAI MARITIME UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com