Beam bridge reinforcing structure and reinforcing method

A reinforcement structure, beam type technology, applied in bridge reinforcement, bridge, bridge maintenance and other directions, can solve problems such as difficulty in ensuring bearing capacity requirements and service life, unfavorable engineering widely popularization and application, complex construction process, etc., to reduce dead load. and live load bending moment force effect, reducing load burden and operational risk, and reducing burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the drawings and specific embodiments, but the protection scope of the present invention is not limited to this.

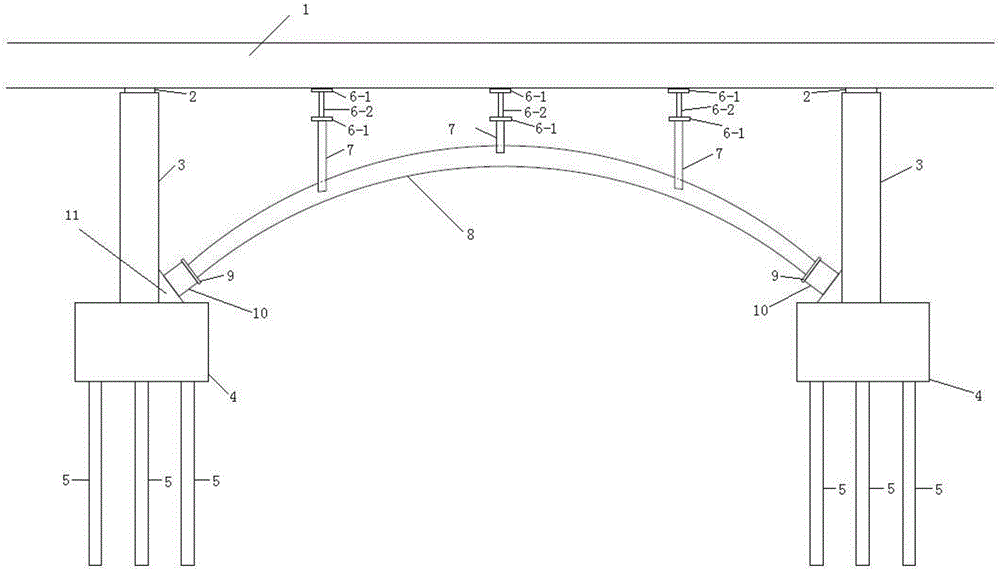

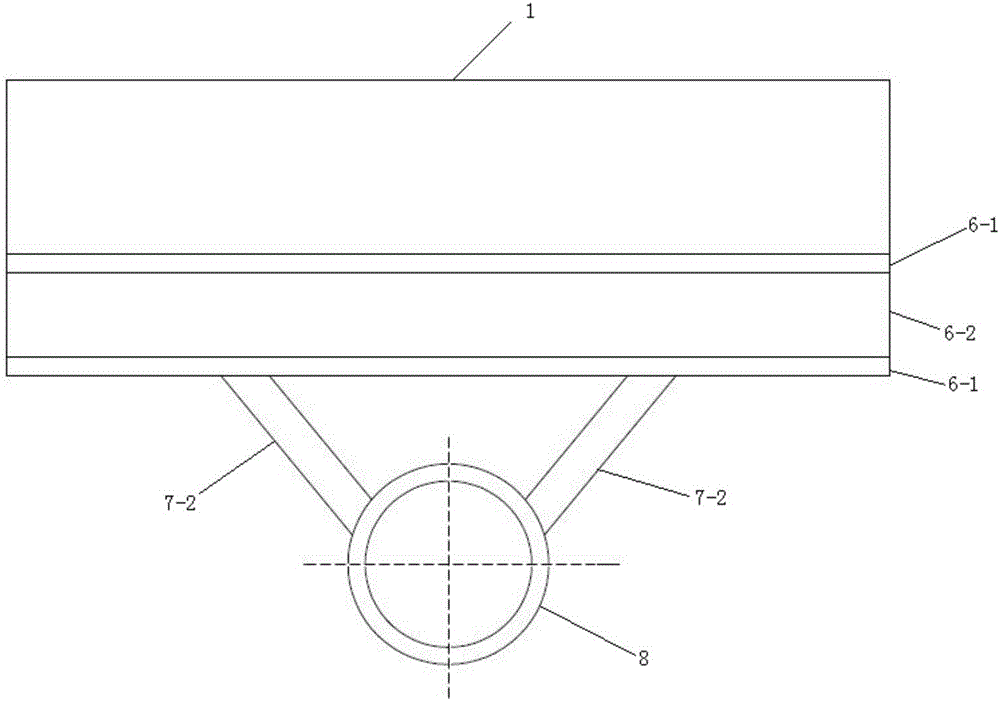

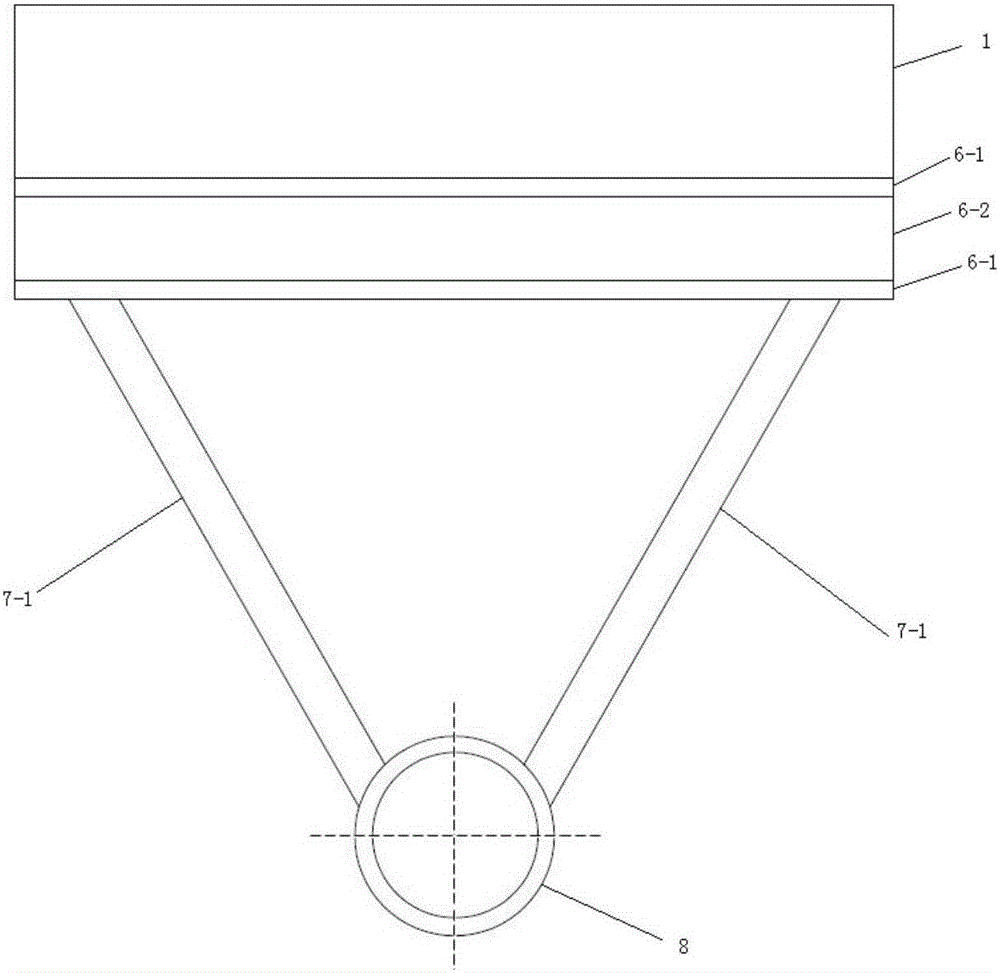

[0028] A beam-type bridge reinforcement structure, comprising an arched steel pipe member 8, I-beam 6-1, 6-2 and steel diagonal braces 7; both ends of the arched steel pipe member 8 are fixed to two adjacent piers 3 of the bridge body; The middle section of the arched steel pipe member 8 is fixedly connected to the steel diagonal brace 7, and the steel diagonal brace 7 is fixedly connected to the I-beam 6-1, 6-2; the I-beam 6-1, 6- 2 is fixedly installed on the upper beam body of the bridge body; the steel diagonal brace 7 includes a left diagonal brace 7-1 and a right diagonal brace 7-2, the left diagonal brace 7-1 and the right diagonal brace 7-2 One end is fixedly connected with the arched steel pipe member 8, and the other end is fixedly connected with I-beam 6-1, 6-2.

[0029] The tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com