Vertical landing lifting system of vertical landing plane

A vertical take-off and landing, lift technology, applied to the power plant, aircraft parts, machine/engine, etc. on the aircraft, can solve the problems of large invalid load, enlarged aircraft cross-section, ground erosion and erosion, etc., to simplify the structure and reduce invalid The effect of loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

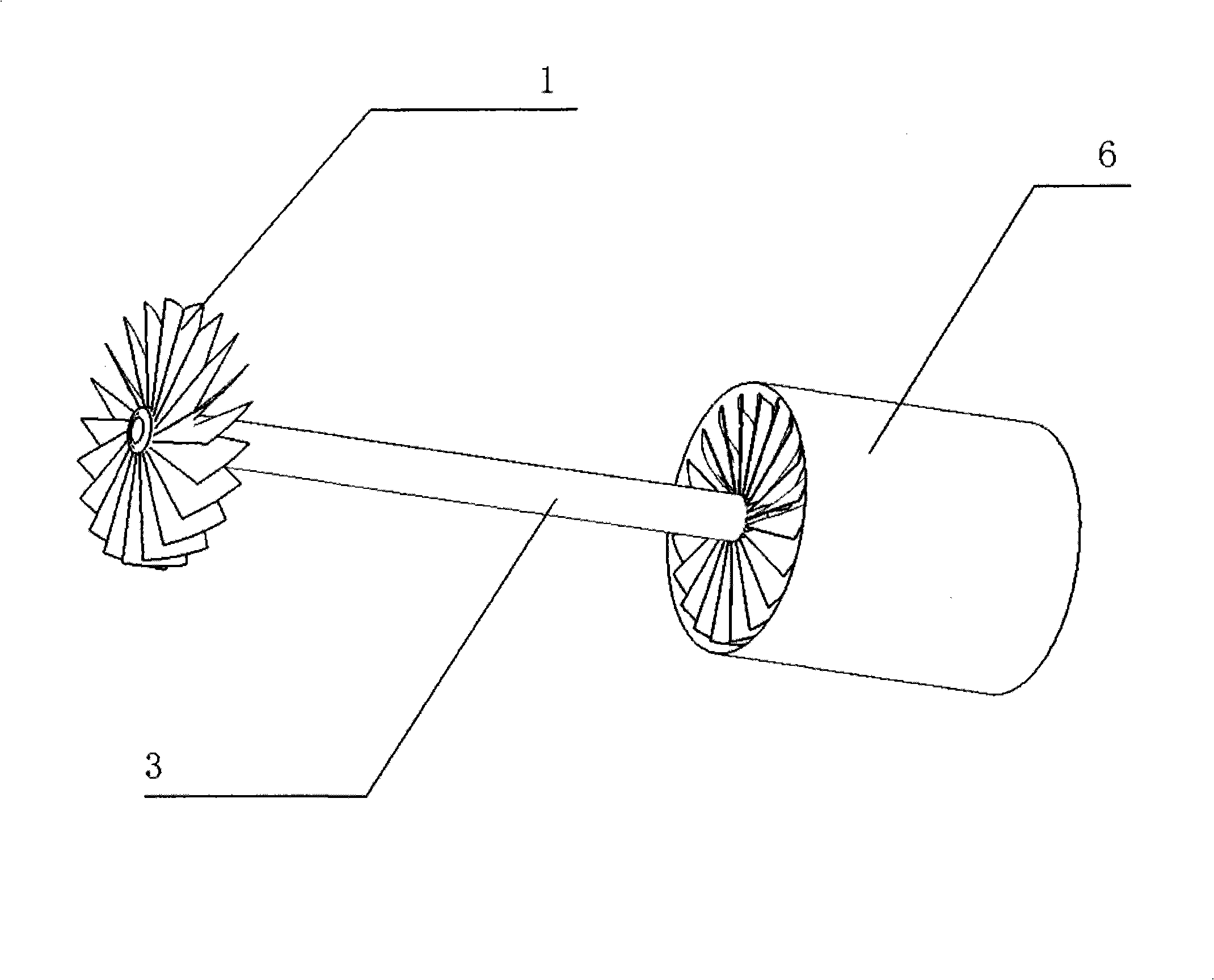

[0033] exist Figure 1 to Figure 16 Middle, 1. Front low-pressure fan, 2. Vector control guide plate, 3. PTO shaft, 4. Front air duct, 5. Down damper, 6. Turbo fan or turbojet engine, 7. Gas down damper, 8. Gas vector Control guide plate, 9. gas channel, 10. tail nozzle.

[0034] exist figure 1 Among them, the turbofan or turbojet engine (6) drives the power take-off shaft (3) to rotate, and the power take-off shaft (3) drives the front low-pressure fan (1) to rotate, and generates low-pressure propulsion airflow; the power take-off shaft (3) makes the front A certain distance is created between the low pressure fan (1) and the turbofan or turbojet (6).

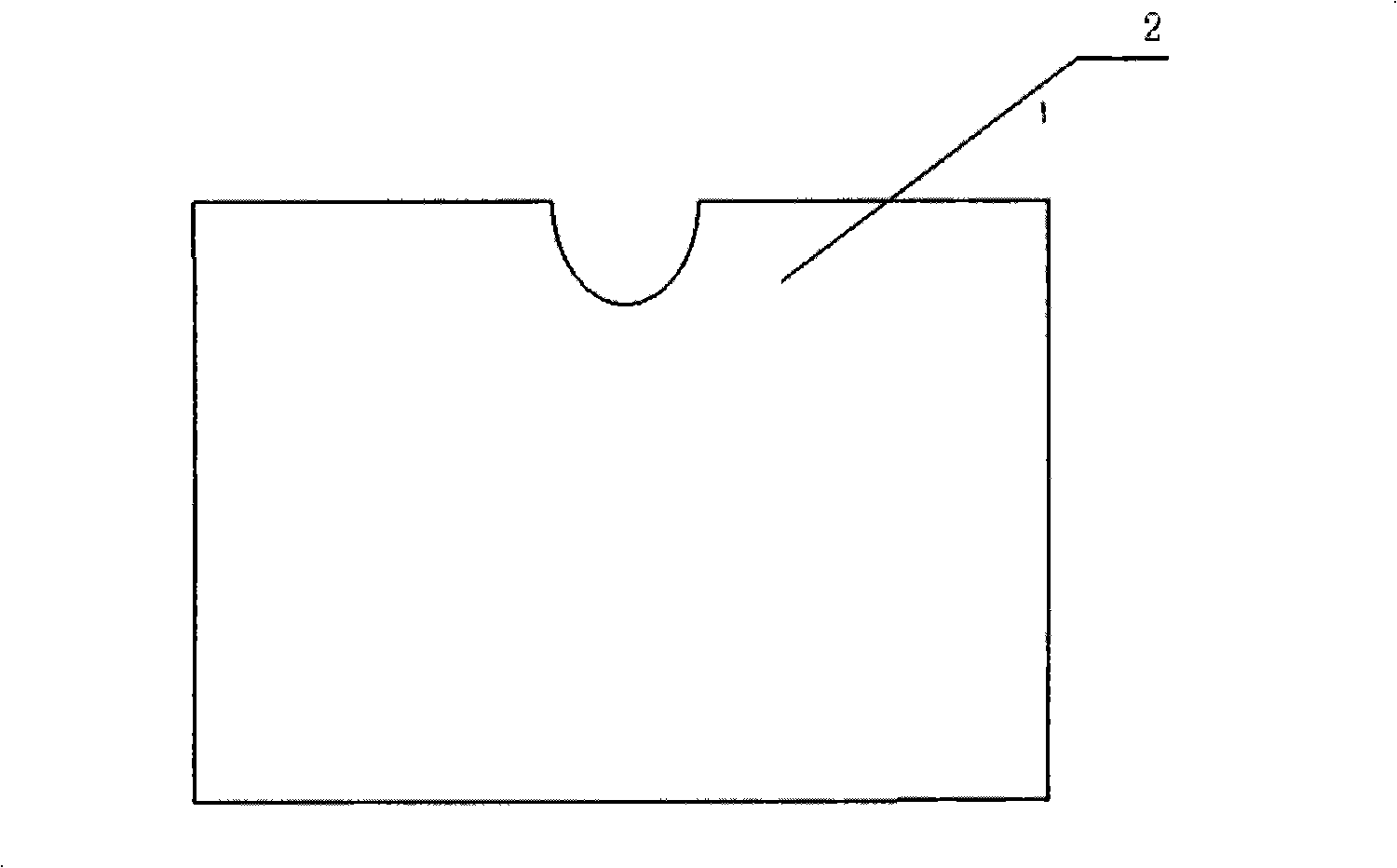

[0035] exist figure 2 , the vector control guide plate (2) has a gap, so that the power take-off shaft (3) passes through without contact under the state of being at an angle of 45 degrees with the vector control guide plate (2).

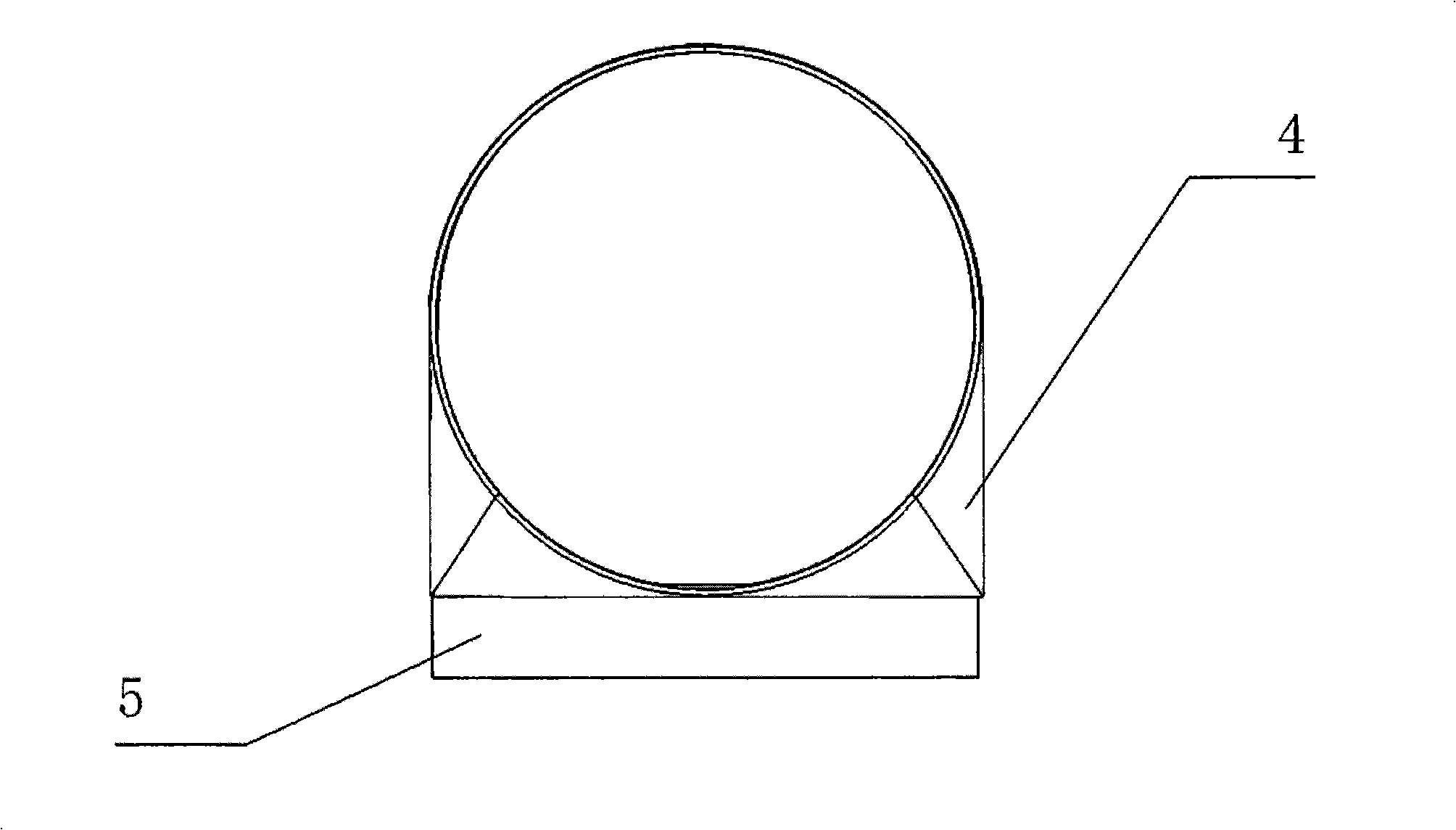

[0036] exist image 3 Among them, the front view of the front air duct (4), the front air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com