Layered suspension structure of single-side double-main-cable steel truss stiffening girder suspension bridge

A suspension structure and steel truss technology, applied in suspension bridges, erecting/assembling bridges, bridges, etc., can solve the problems of increasing the dead load of stiffening beams, concentrating the force at the lifting point, occupying the bridge deck, etc., reducing the width of the bridge deck and reducing the constant load. load and reduce the effect of S-shaped deflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

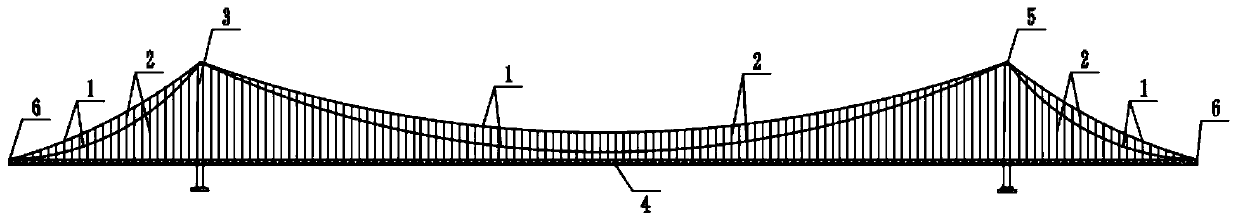

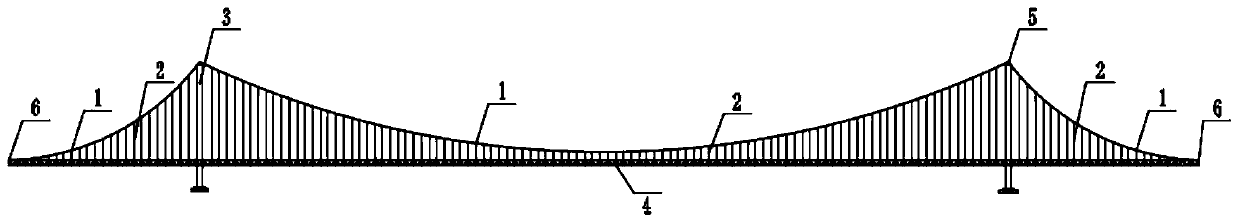

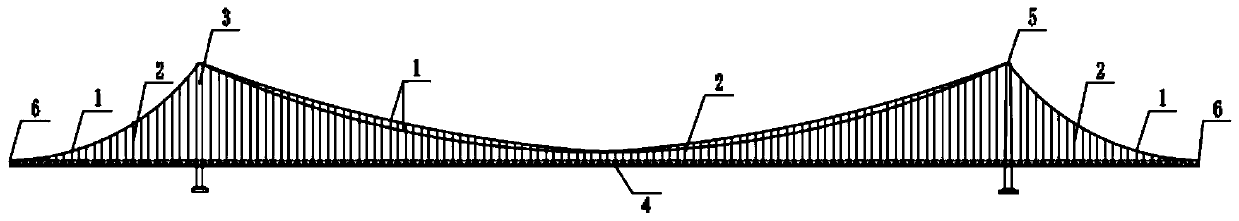

[0019] Such as Figure 1-5 As shown, a single-sided double main cable steel truss stiffened girder suspension bridge layered suspension structure system, single-sided double main cable 1 adopts the unequal height arrangement of "one main cable on the top and one main cable on the bottom" , or adopt the parallel layout of the inner and outer main cables, or adopt the double-chain arrangement of the inner and outer main cables. Among them, there are two main cables 1 on one side of the transverse bridge (four on both sides). The main cable 1 is connected with the corbel protruding from the lower chord of the steel truss stiffening beam 4 through the cable clamp and the sling 2.

[0020] Such as Figure 6 , as shown in 7, the current commonly used single-side single main cable suspension bridge structure system and the existing single-side double main cable suspension bridge structure system, the main cable 1 and the steel truss stiffening beam 4 are connected in the same way: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com