Bulk-cargo grab bucket with high grabbing ratio

A technology of grab ratio and bucket body, applied in the directions of load hanging components, transportation and packaging, can solve the problems of high structural strength, and achieve the effects of high structural strength, improved ship unloading efficiency, and light dead weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

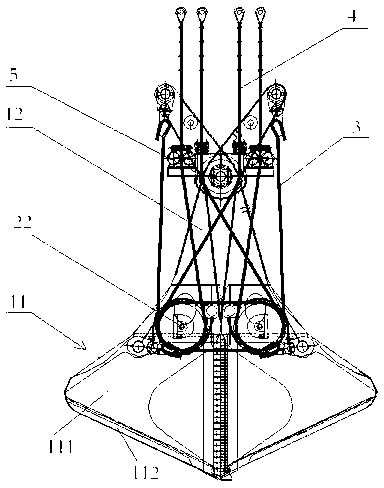

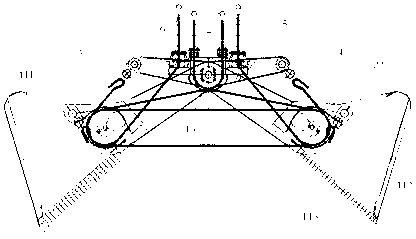

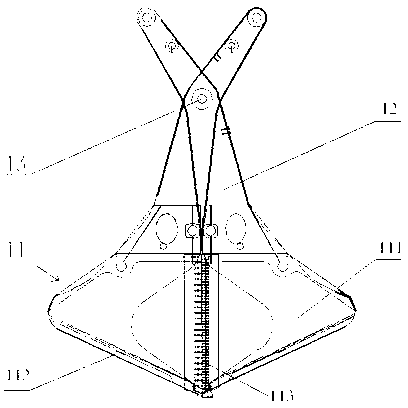

[0031] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

[0032] Such as Figure 1~7 As shown, a bulk cargo grab with a high grabbing ratio includes two symmetrically arranged bucket bodies 11. The bucket body 11 includes two bucket body side plates 111, a bucket body bottom plate 112 and support rods arranged therein. The bucket body The material of 11 is alloy steel; respectively corresponding to the two main ribs 12 supporting the two-petal bucket body 11, the two main ribs 12 intersect at the hinge point 13 and are fixedly connected, the grab moves in an arc around the hinge point 13, and also includes: Rope guide frame 5, a pair of movable pulleys 22, a pair of open bucket ropes 3, and a pair of closed bucket ropes 4. Among them, the rope guide frame 5 is fixedly connected with the two main ribs 12 at the hinge point 13; the movable pulley 22 is arranged in the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com