Cement concrete bridge floor composite pavement structure

A technology of cement concrete and asphalt concrete, applied in bridges, bridge parts, bridge construction, etc., can solve problems affecting the aesthetics of bridge decks, difficulties in maintenance work, and difficulties in bridge diversion, so as to improve the quality of paving and rolling and reduce heat , the effect of the effective level of shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

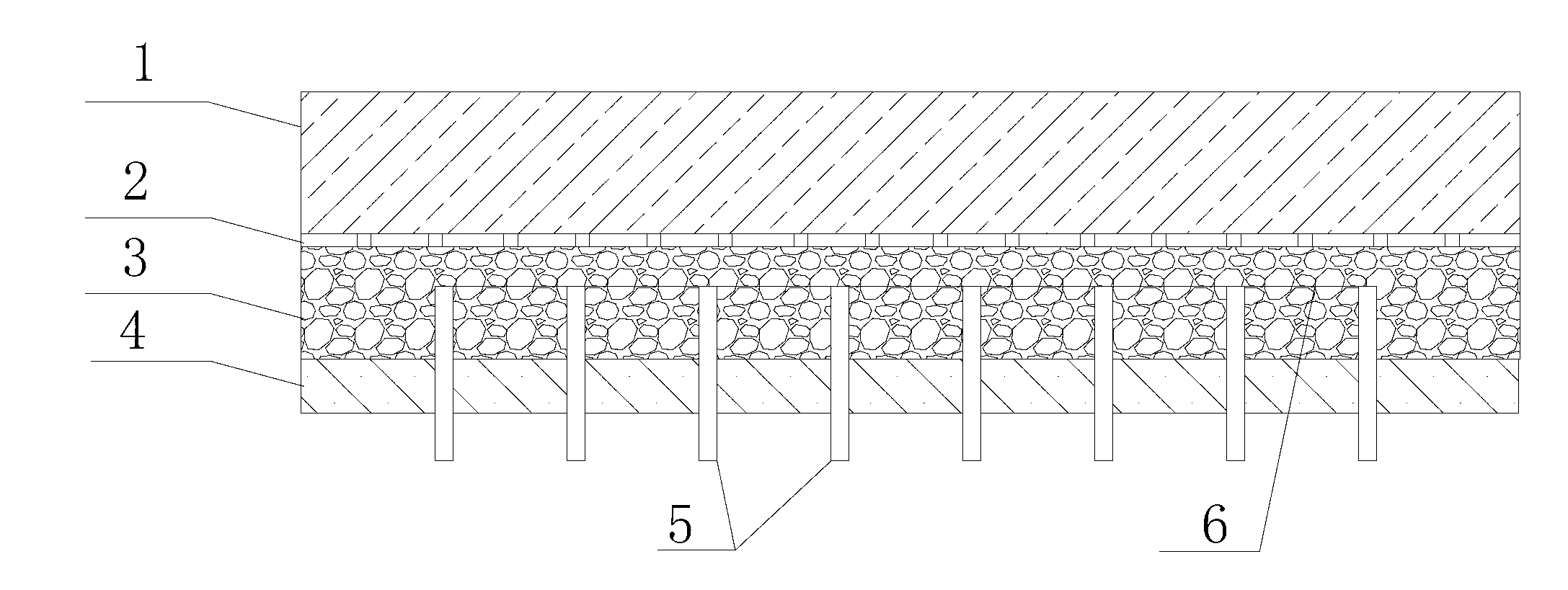

[0026] The present invention will be further described below in conjunction with accompanying drawing.

[0027] see figure 1 , on the bridge deck 4 there is an erecting steel bar 5, on which the erecting steel bar 5 is welded with a steel mesh 6, on the bridge deck 4 there is a layer of light polymer cement concrete transition layer 3 and the steel mesh 6 is in The middle part of the lightweight polymer cement concrete transition layer 3, the thickness of the lightweight polymer cement concrete transition layer 3 is 5cm to 8cm, and the upper surface of the lightweight polymer cement concrete transition layer 3 is provided with vertical and horizontal anti-skid grooves 2, lightweight A polymer modified asphalt concrete asphalt layer 1 is laid on the upper surface of the polymer cement concrete transition layer 3, and the thickness of the polymer modified asphalt concrete asphalt layer 1 is 3cm-5cm. . The vertical and horizontal anti-skid grooves 2 have a groove spacing of 18 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com