Forklift through, top loading and unloading van

A technology for forklifts and automobiles, which is applied in the field of multi-purpose box-type vehicles, and can solve problems such as man-machine mixed operations, low efficiency, and environmental damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

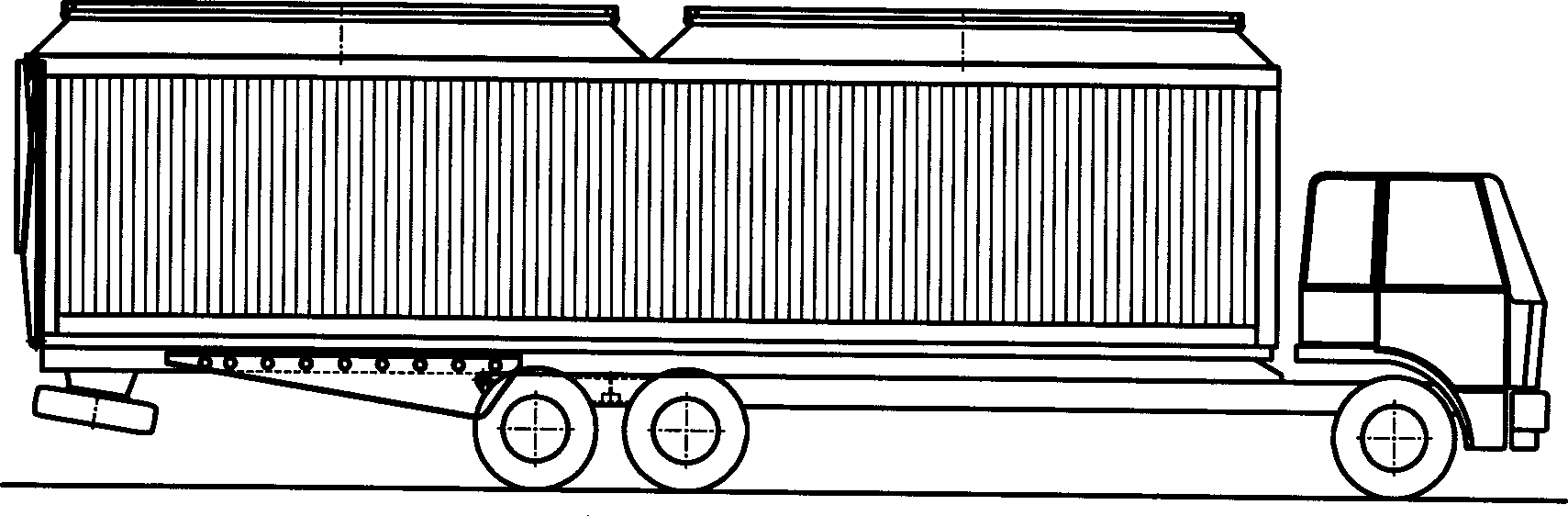

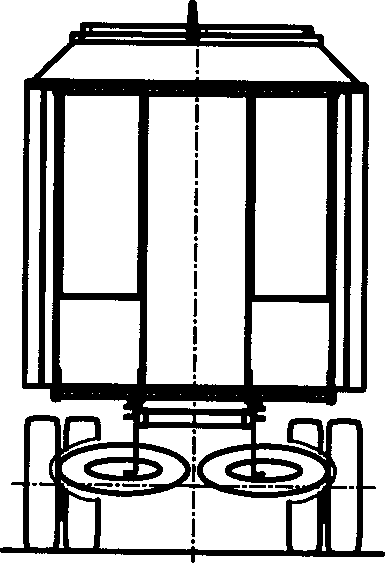

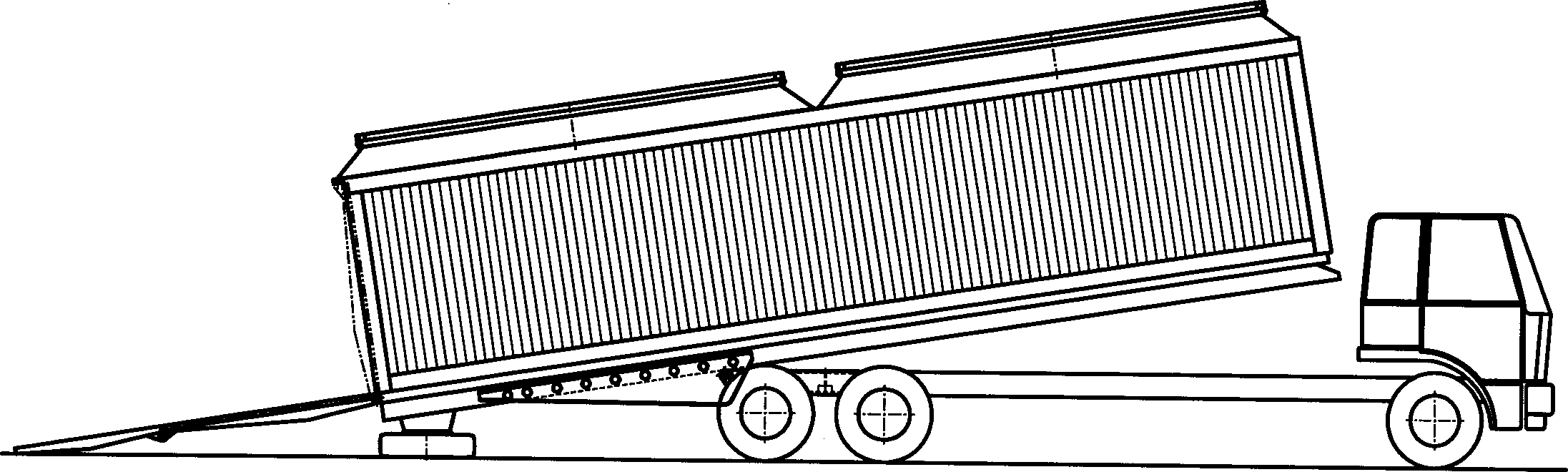

[0006] According to the embodiment of the present invention, it is described in detail with reference to the accompanying drawings: the product of the present invention needs to be specially manufactured in the automobile factory without a rear suspension as shown in Figure 9 and a second-class chassis with a hinge hole 7 at the tail end of the vehicle frame, and additionally install the chassis on the chassis. can lift the trunk, such as Figure 4 In middle 1, the pin shaft is used to connect with the carriage body, and the rear door of the carriage is designed to flip the door up and down, and the upper part of the door 2 is connected to a part of the transition bridge with a pin shaft, such as Figure 5 In this way, the rear door is turned down and together with 2 to form a transition bridge for the passage of forklifts; during operation, the spare tire is used as a load-bearing fulcrum as in 3, such as Image 6 The roof is designed to be in the shape of a bucket, and the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com