Combined foundation structure suitable for lagoon face island-reef environment and construction method thereof

A technology that combines foundation and environment, applied in foundation structure engineering, sheet pile wall, caisson, etc., can solve the problems of airport bearing capacity, deformation and quality requirements that are difficult to meet the conditions of coral lagoon, lack of reinforcement of foundation effect, etc., to avoid structural problems. The effect of damage and damage, reducing construction risk and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

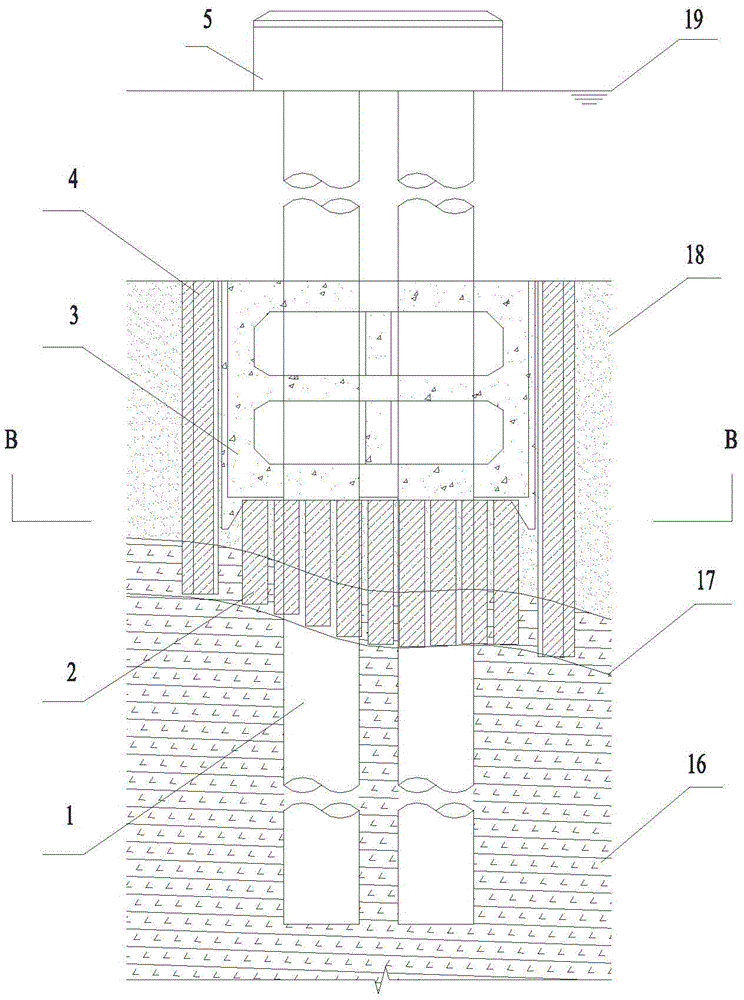

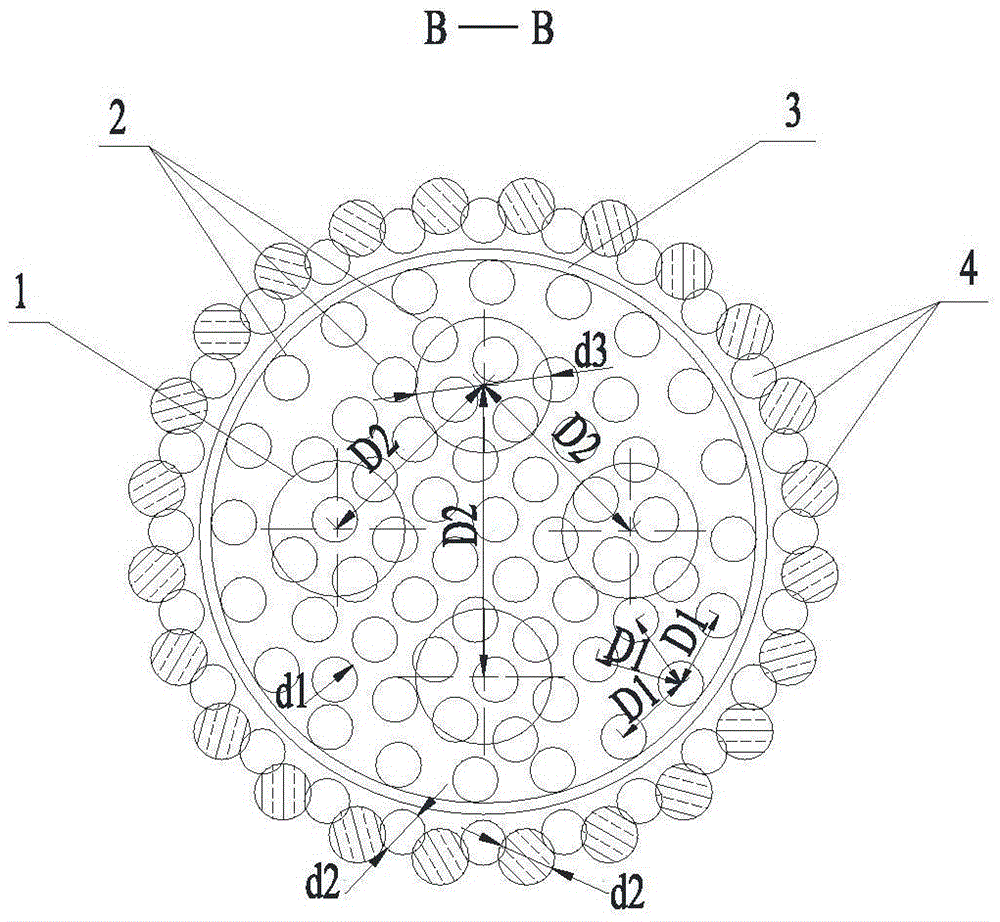

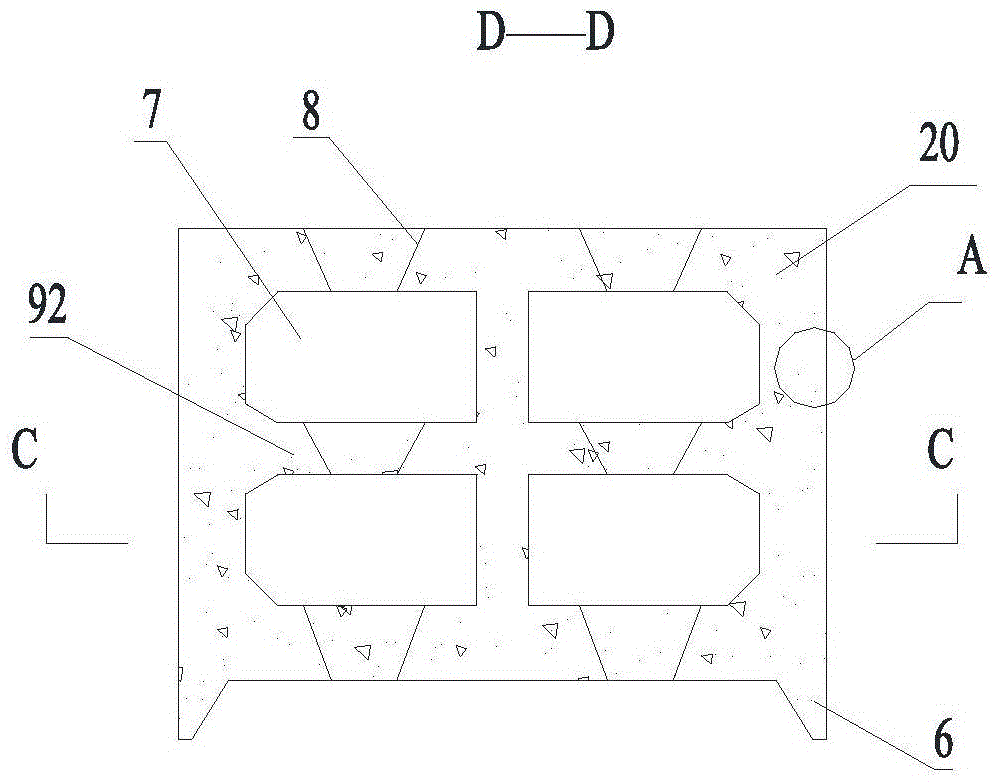

[0049] see figure 1 and figure 2 As shown, the embodiment of the present invention provides a combined foundation structure suitable for the environment of lagoon-like islands and reefs, which is suitable for the geological conditions of coral lagoons, including high-pressure jet-grouting stabilized piles 2, prefabricated caissons 3, side-limited high-pressure jet-grouting piles 4, Prefabricated bored pile 1, prefabricated cap 5. A plurality of side-constrained high-pressure jet grouting piles 4 form a curtain structure, and the prefabricated caisson 3 is located on the high-pressure jet-grouting stable pile 2, and within the curtain structure of the side-limited high-pressure jet grouting piles 4, the prefabricated caisson 3 includes a large A well hole 8 is reserved in the prefabricated caisson of the small inverted cylindrical platform. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com