Forming method of large shallow foundation pit with soft soil foundation

A forming method and soft soil foundation technology, which is applied in excavation, foundation structure engineering, sheet pile walls, etc., can solve the problems of not being able to meet the requirements of large-area soft soil foundation shallow foundation pit construction, and no formation, so as to avoid collapse and subsidence , reduce moisture content, improve the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

[0023] A method for forming a large-area shallow foundation pit on a soft soil foundation, especially for shallow foundation pits with a depth of 3.5 to 6 m, the method includes the following steps:

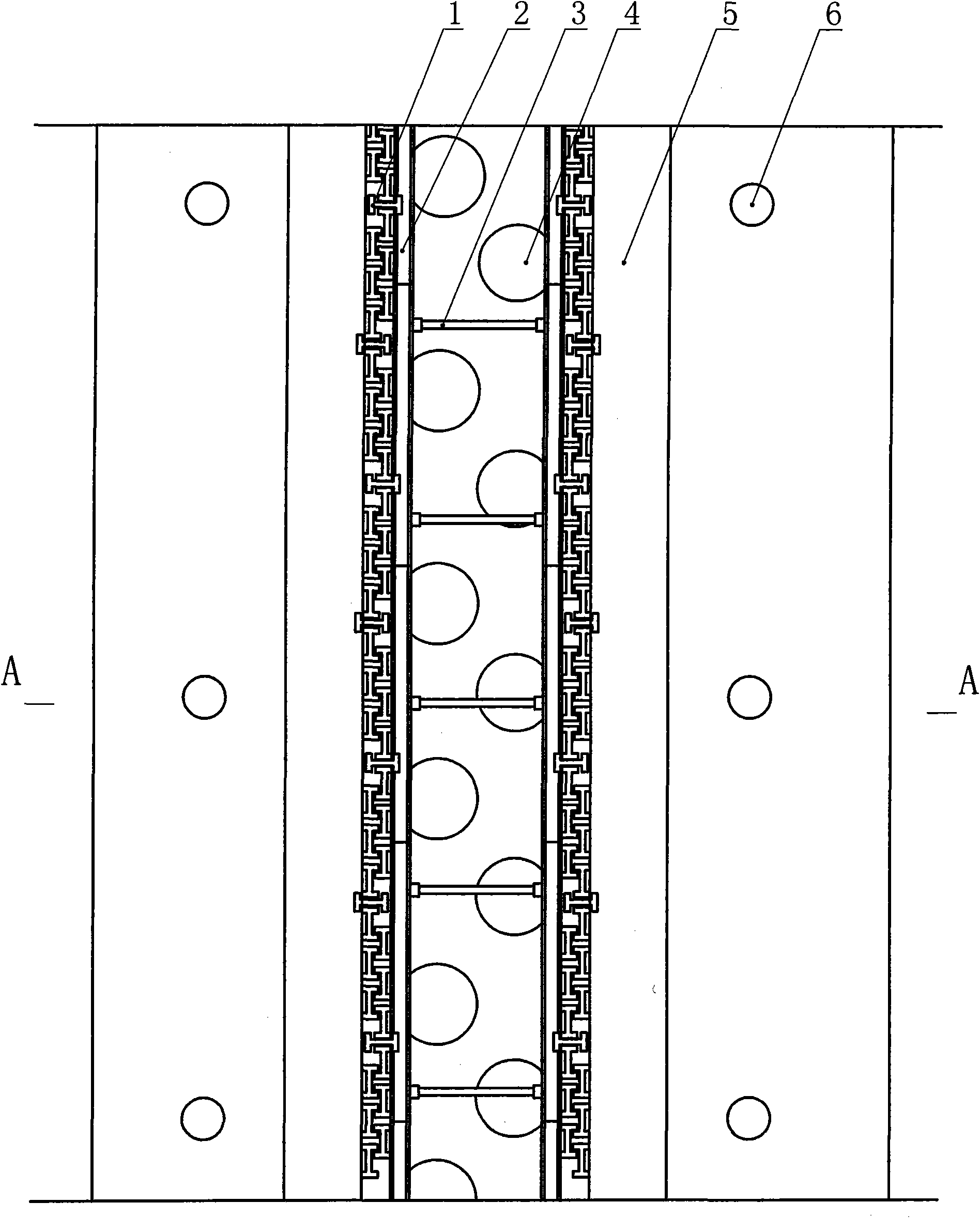

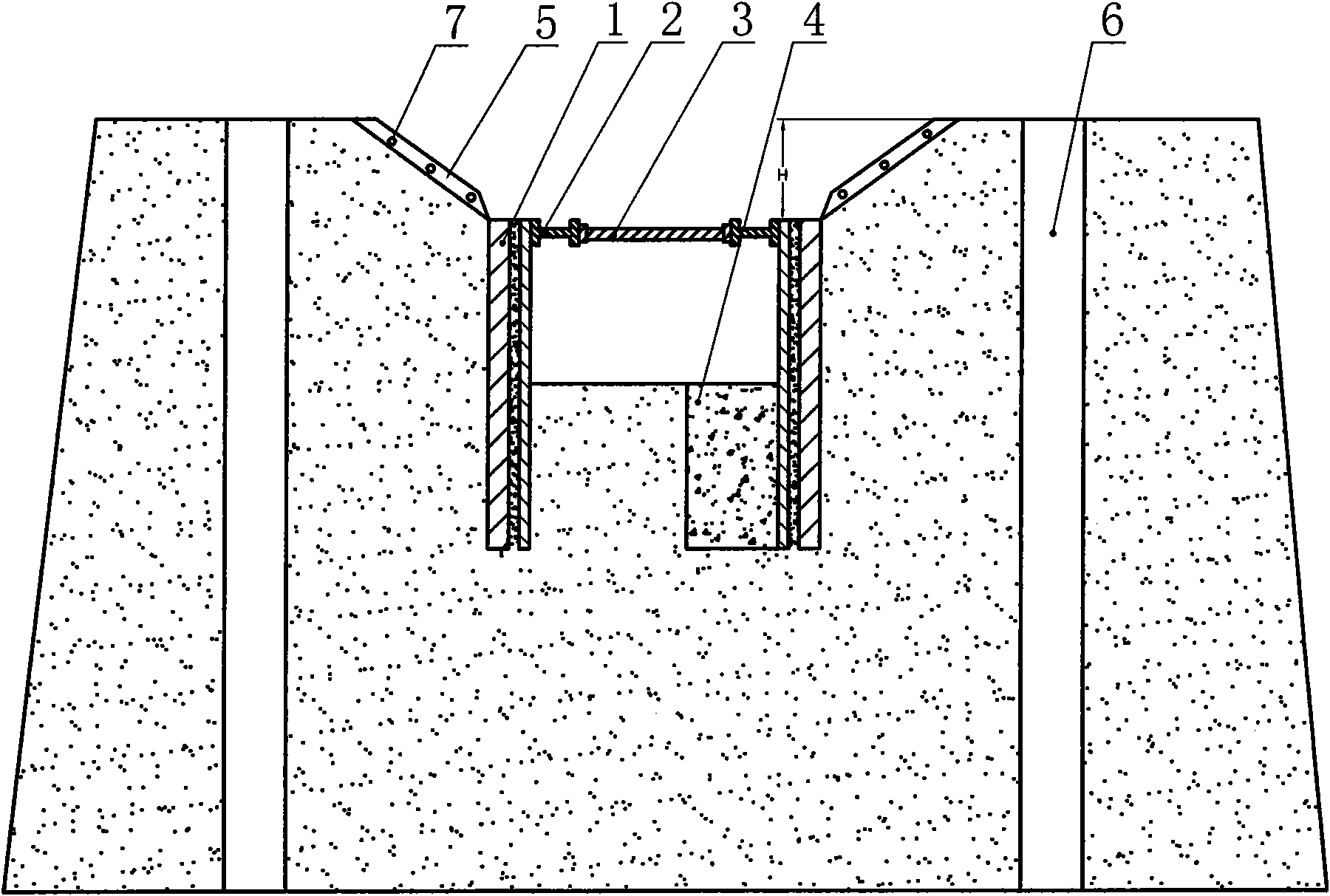

[0024] (1). Grading: Grading the soil within the range of elevation H=2.0m below the surface of the foundation pit. The slope of the slope is 1:1. Longitudinally add short steel bars 7 (steel meshes can also be added) in the mortar.

[0025] (2). Support: The support structure piles in this embodiment are steel sheet piles, and its material is I40B. For support calculations, the steel sheet piles 1 are fixed on the side of the foundation pit wall after grading, and the crown beam 2 is fixed. Installed on the upper end of the side of the steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com