Construction joint for reinforcing welded ball space-frame pole and construction method of construction joint

A construction method and technology of grid poles, which are applied in the direction of manufacturing tools, welding equipment, building construction, etc., can solve the problems of consuming large resources and time, and the grid structure cannot meet the needs of use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

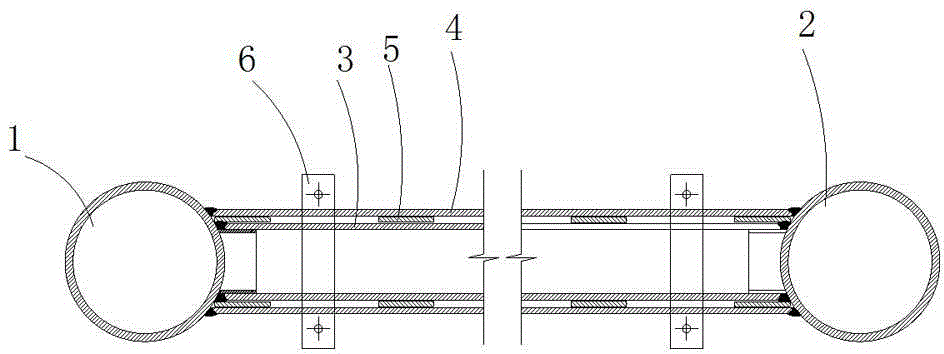

[0041] Embodiment 1: as figure 1 As shown, a construction node for welding ball grid rod reinforcement, including left welding ball 1, right welding ball 2 and grid rod 3, the left end of the grid rod 3 is provided with The left welding ball 1 fixed to the grid rod 3, the right side end of the grid rod 3 is provided with the right welding ball 2 fixed with the grid rod 3, and the grid rod 3 is covered There is an outsourcing steel pipe 4, the left end of the outsourcing steel pipe 4 is fixed to the left welding ball 1, the right side end of the outsourcing steel pipe 4 is fixed to the right welding ball 2, and the grid rod 3 is fixed to the right welding ball 2. Evenly distributed outsourcing liners 5 are arranged among the outsourcing steel pipes 4 .

[0042] The left end and the right end of the outsourcing steel pipe 4 are respectively provided with hoops 6, the left welding ball 1 is welded and fixed with the outsourcing steel pipe 4 and the grid rod 3 respectively, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com