Thin-layer hood face structure for cement concrete bridge deck pavement modification and construction method thereof

A cement concrete and bridge deck paving technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of inability to solve reflection cracks, weak bonding between layers, insufficient surface slip resistance, etc. The effect of good elasticity and strong anti-reflection crack ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

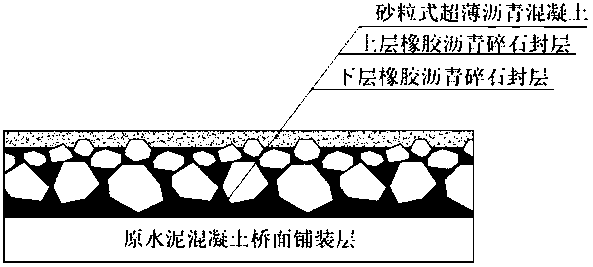

[0019] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

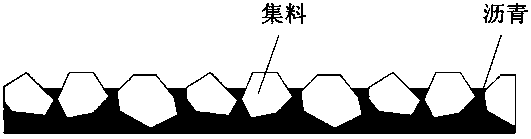

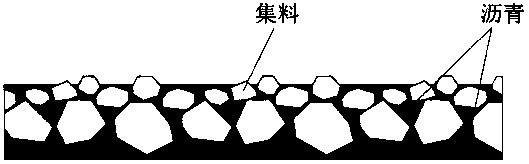

[0020] In order to solve the problem that the thickness of asphalt concrete is too thick and the dead load of the bridge is increased in the existing cement concrete bridge deck pavement reconstruction scheme, the present invention proposes a thin-layer overlay structure for cement concrete bridge deck pavement reconstruction for the first time. It is a combined structure composed of a double-layer rubber asphalt macadam seal layer on the lower layer and an ultra-thin asphalt concrete wear layer on the upper layer. The structures of each layer are embedded and bonded to each other.

[0021] Two layers of rubber asphalt macadam seals are embedded and squeezed; the nominal maximum particle size of the sand-type ultra-thin asphalt concrete is 6.7cm, and the thickness is not greater than 2.0cm. The invention also discloses the construction method of the abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com