Patents

Literature

37results about How to "Paste flat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

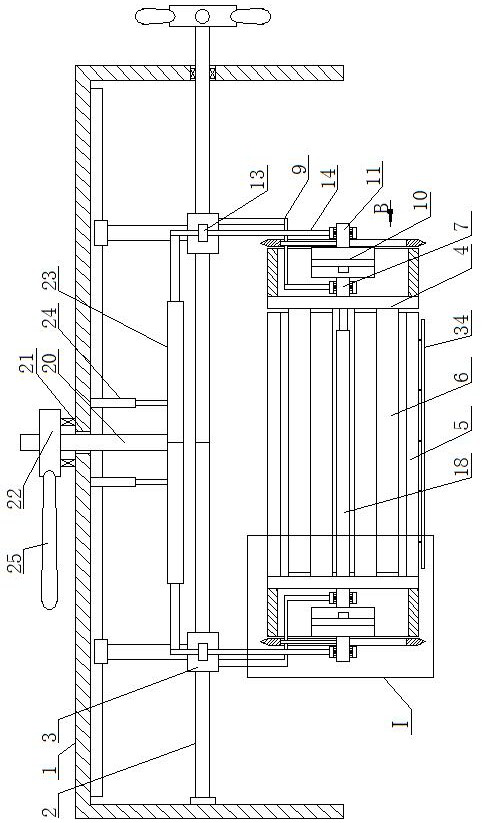

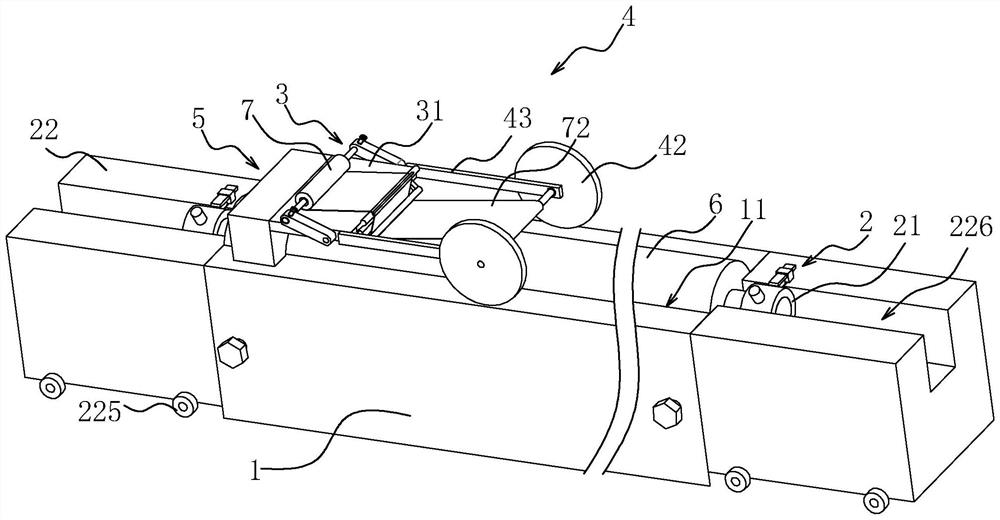

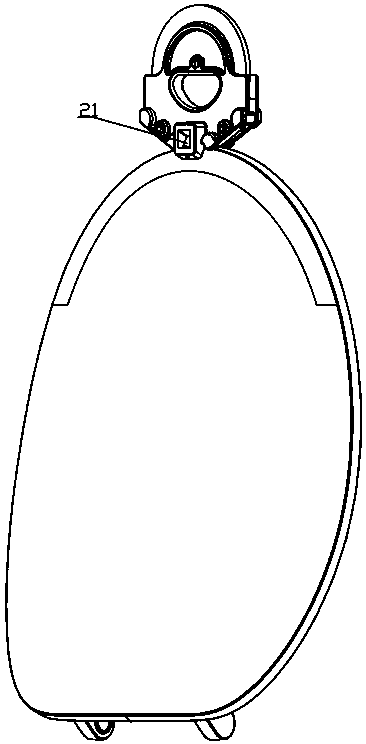

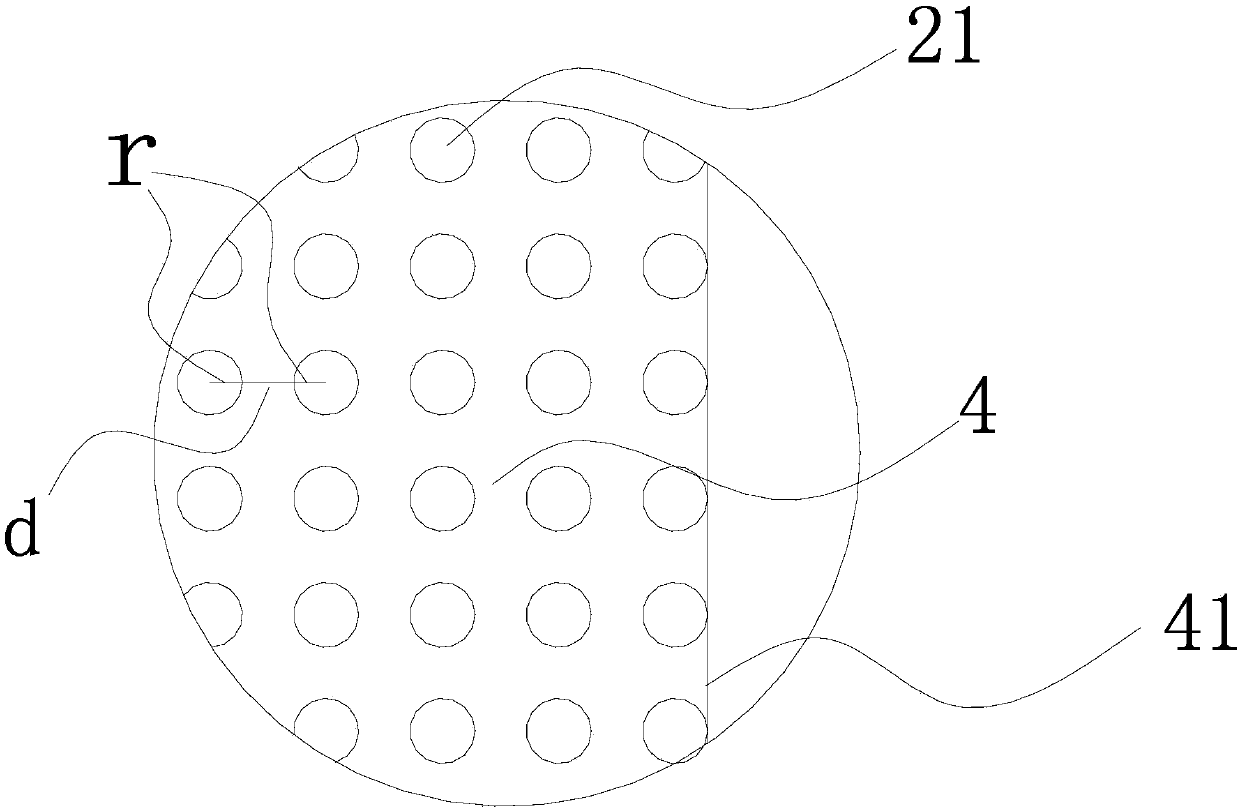

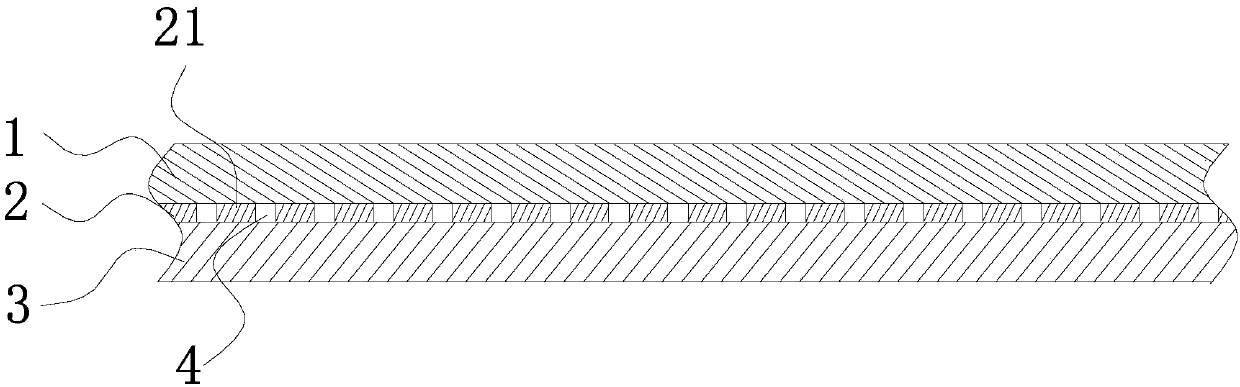

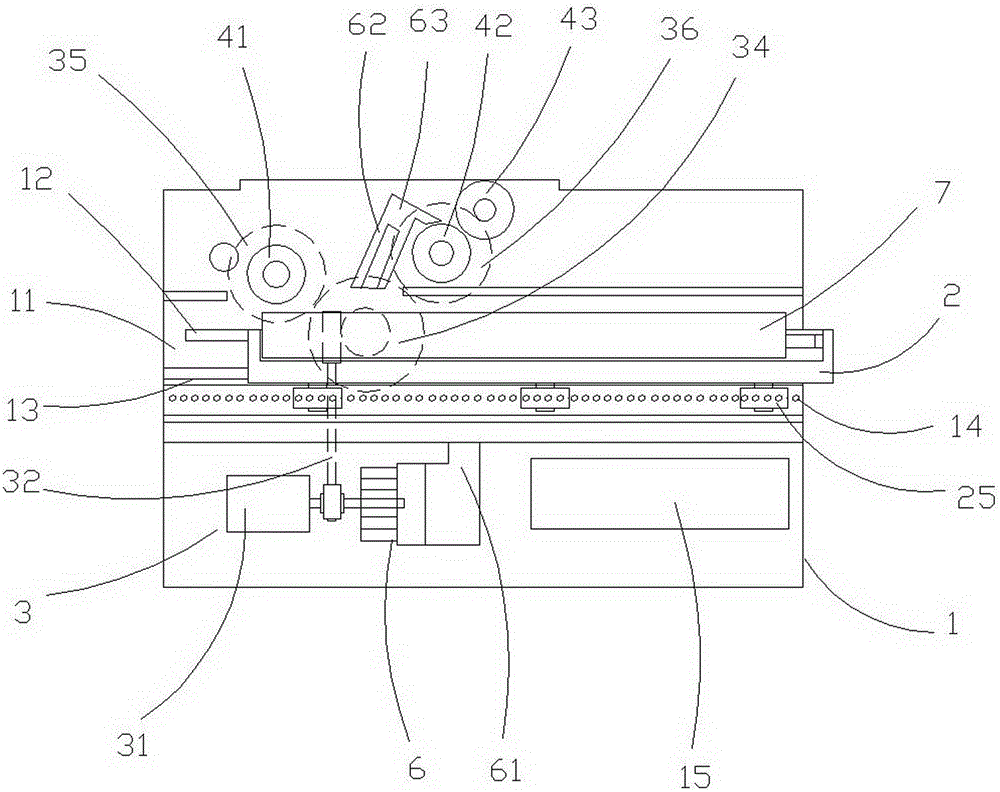

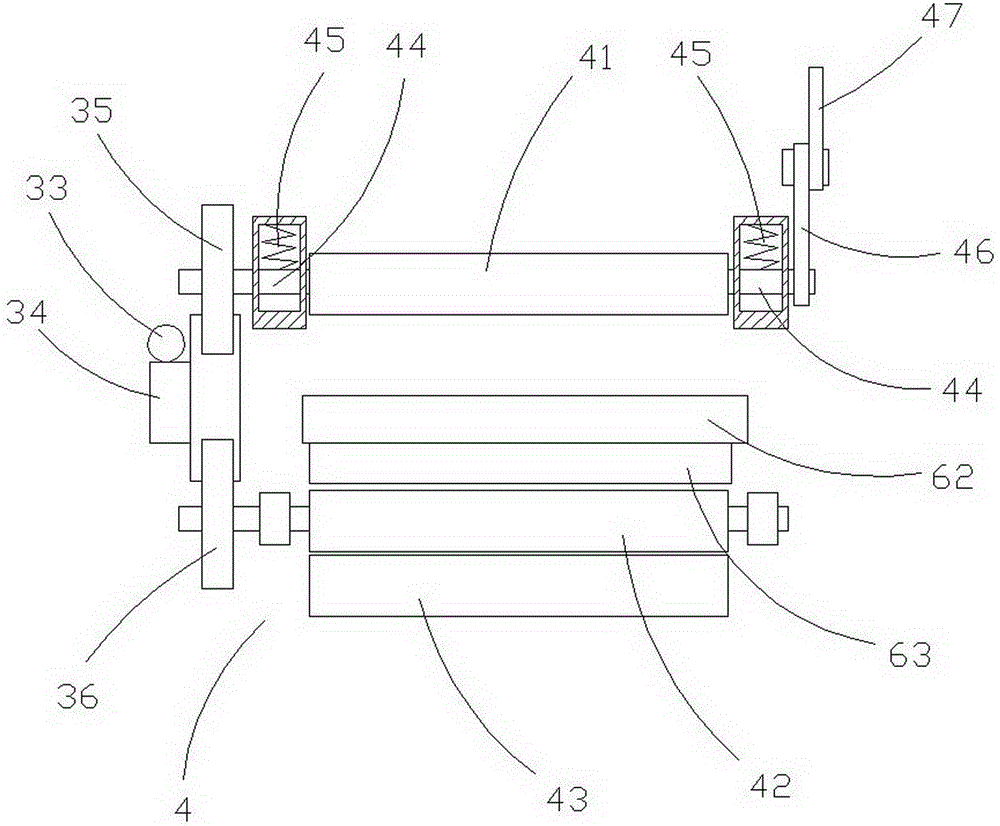

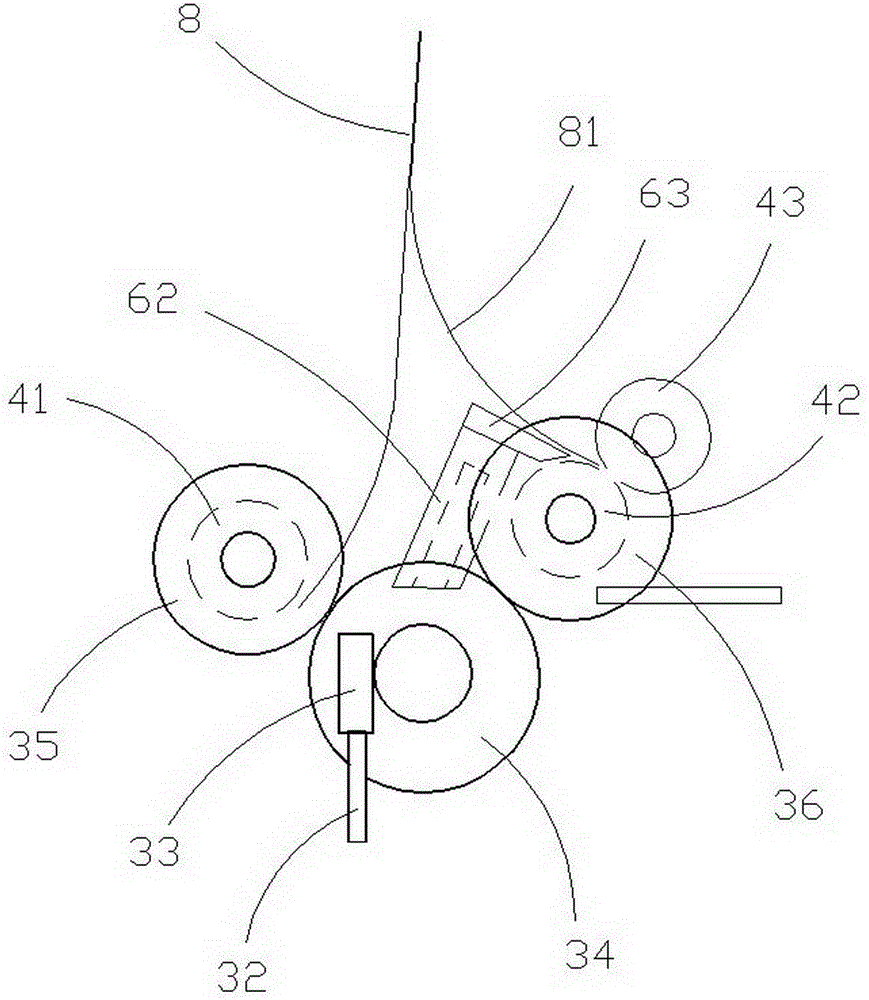

Automatic film pasting device

ActiveCN104118600APrecise positioningMake sure it is pasted flatPackagingEngineeringMechanical engineering

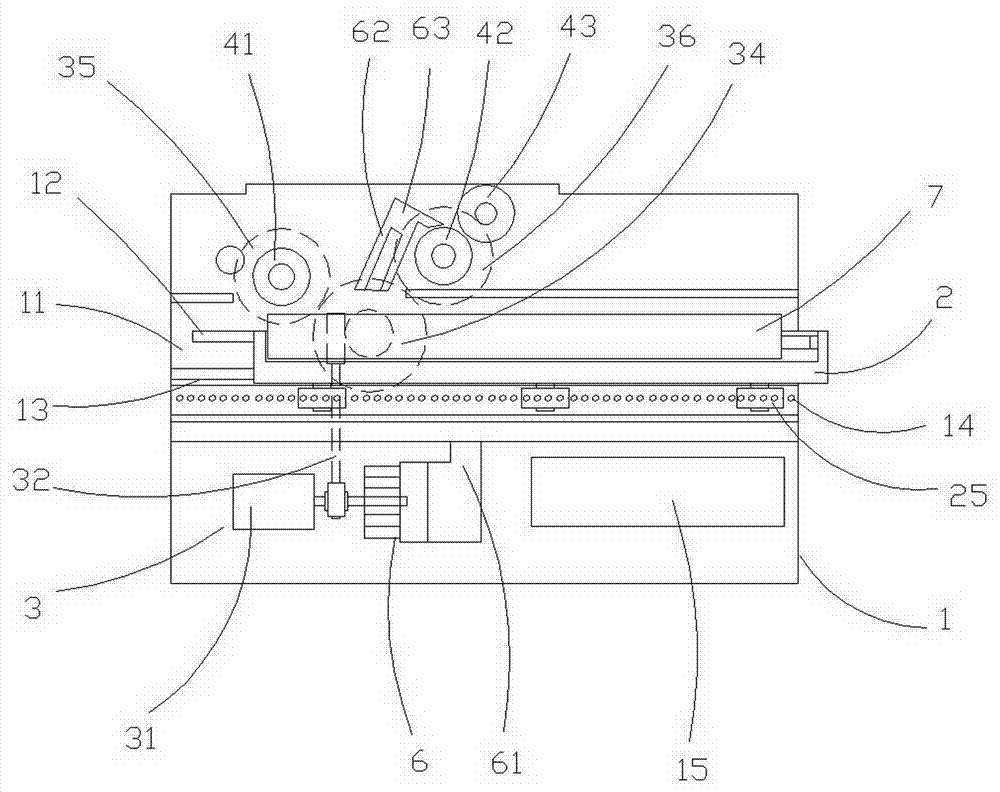

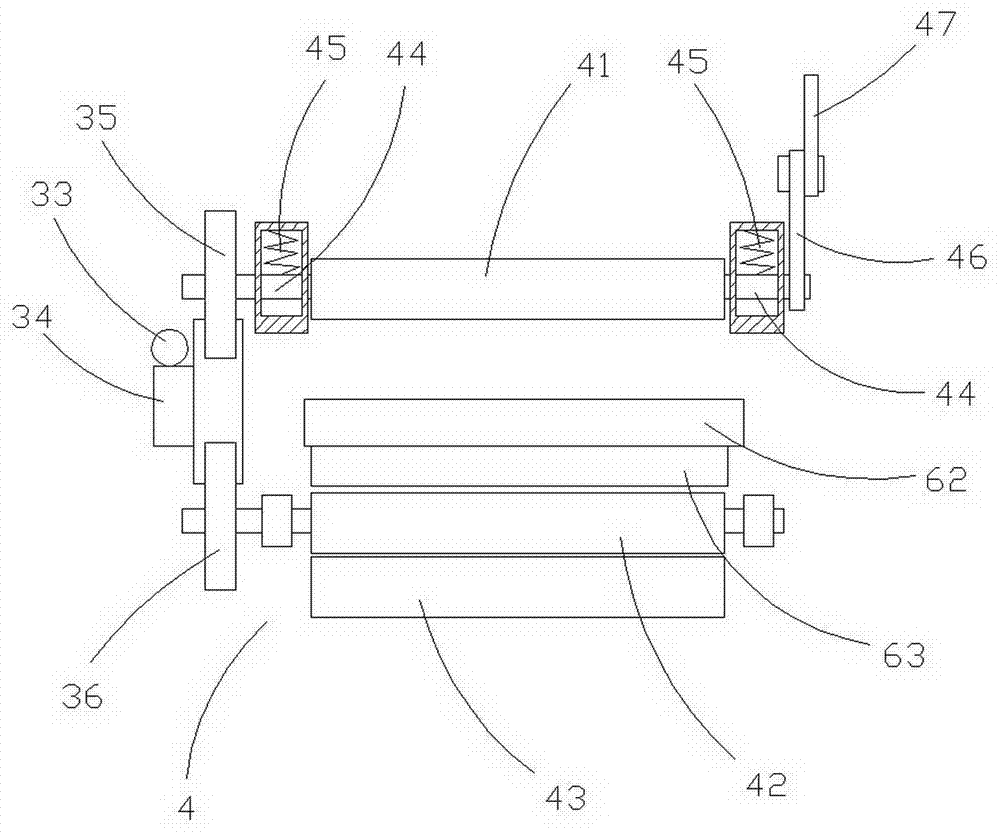

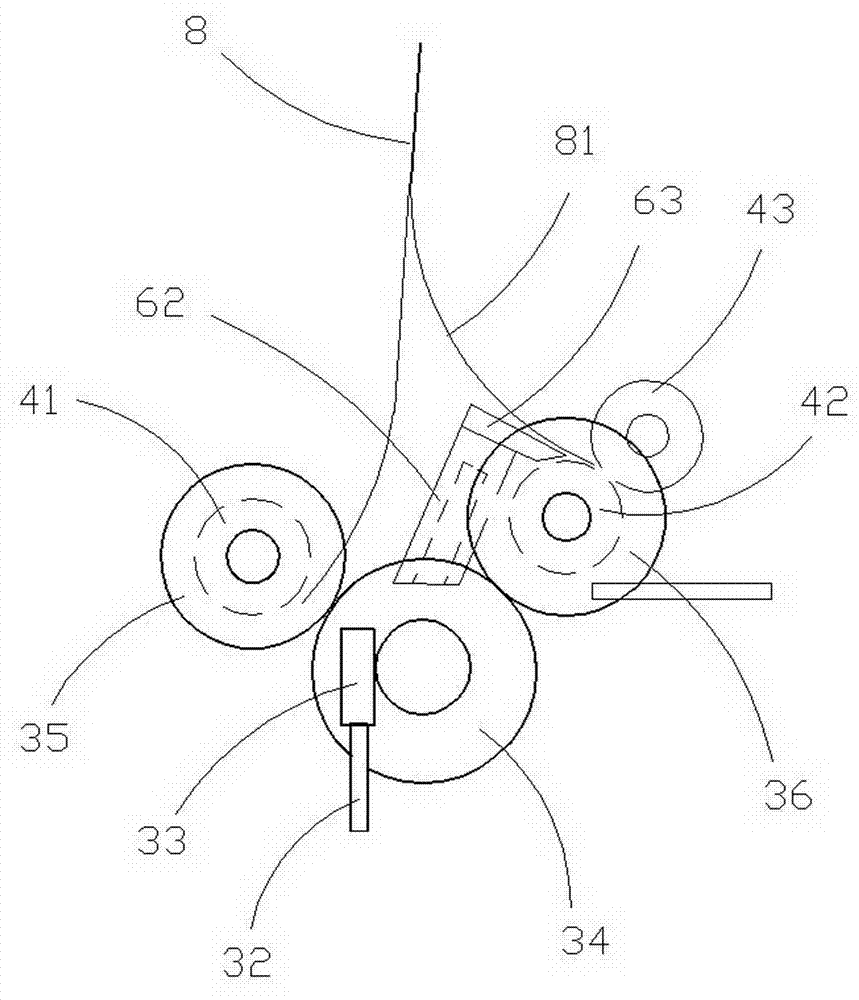

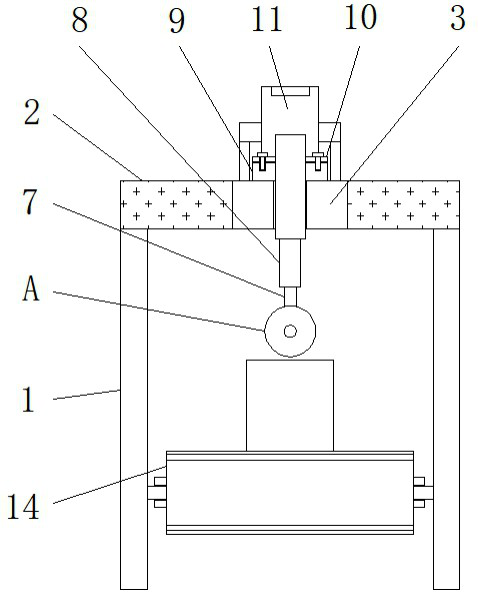

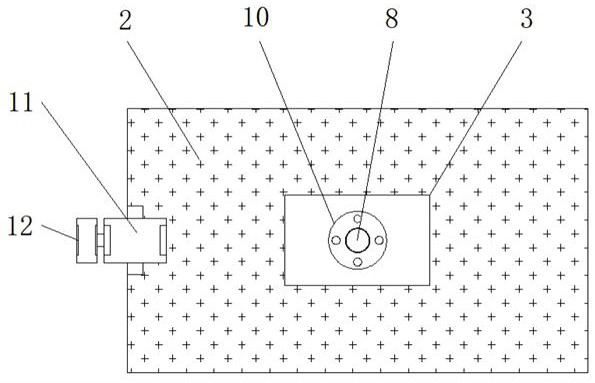

The invention discloses an automatic film pasting device. The automatic film pasting device is composed of an outer shell, a transmission device and a film pasting mechanism. A sliding accommodating disk for containing a mobile phone is arranged in a cavity of the outer shell. The transmission device drives a film pressing shaft and a film output shaft of the film pasting mechanism to rotate. A dust suction pipe of a dust collector is transversely arranged at an inlet portion between the film pressing shaft and the film output shaft to conduct micronic dust processing on the mobile phone. In the rotating process of the film pressing shaft and the film output shaft, the accommodating disk is forcibly driven to move forward, the film pressing shaft rolls a protective film onto the mobile phone, the film output shaft drives a roll shaft to rotate correspondingly to roll a clamped attachment film out of a cover body from a recovery port portion, and then pasting of the protective film and separation of the attachment film from the protective film are achieved synchronously.

Owner:广州美枫电子科技有限公司

Adhesive tape sealing device with cut-off function for carton packaging

InactiveCN112093152AEasy to cut automaticallyEasy to compressWrapper twisting/gatheringCartonAdhesive belt

The invention discloses an adhesive tape sealing device with a cut-off function for carton packaging. The adhesive tape sealing device comprises supporting rods, a top seat and side face pressing mechanisms, wherein the top seat is arranged at the upper ends of the supporting rods; a connecting disc is in threaded connection with the upper part of an installing block; an adhesive tape installing wheel arranged on the left side of the installing block is fixedly welded to the upper end of the top seat; a fixing base arranged on the inner side of each supporting rod is arranged on the lower endface of the top seat; the side face pressing mechanisms are connected to the lower end of an installing base; an installing frame fixed to the lower end of a pneumatic telescopic rod in a welded connection mode is arranged on the inner sides of the side face pressing mechanisms; a connecting shaft is arranged in each supporting rod; and a support frame is arranged between single bodies of the connecting shafts. The adhesive tape sealing device with the cut-off function for carton packaging is convenient to automatically cut off during use and convenient to press during pasting, so that pastingis smooth, and a problem that the cut-off adhesive tape is difficult to press in order to cause tilting of the adhesive tape at a fracture is solved.

Owner:郭菊花

Labelling machine

The invention relates to the field of product packing equipment, and particularly relates to a labelling machine for adhering labels to corrugated paper. The labelling machine comprises a corrugated paper conveying device for horizontally conveying the corrugated paper, a label conveying device which is erected at the upper part of the corrugated paper conveying device and is capable of synchronously conveying the labels in the same direction with the corrugated paper conveying device, and an adhering device which is erected at the upper part of the corrugated paper conveying device and is used for adhering the corrugated paper conveyed by the corrugated paper conveying device to the labels conveyed by the label conveying device. The labelling machine is capable of labelling the corrugatedpaper; the labelling process is simple; the automation degree is high; the labels can be uniformly coated with glue; the labels can be firmly and reliably adhered to the corrugated paper on the premise that the glue is saved, and the labels are smoothly adhered without any bubbles; in addition, the labelling process is basically not limited by the labelling range; the labelling machine is applicable to adhering of labels with various sizes, so that the industrial applicability is high.

Owner:ZHEJIANG GREAT SHENGDA PACKING CO LTD

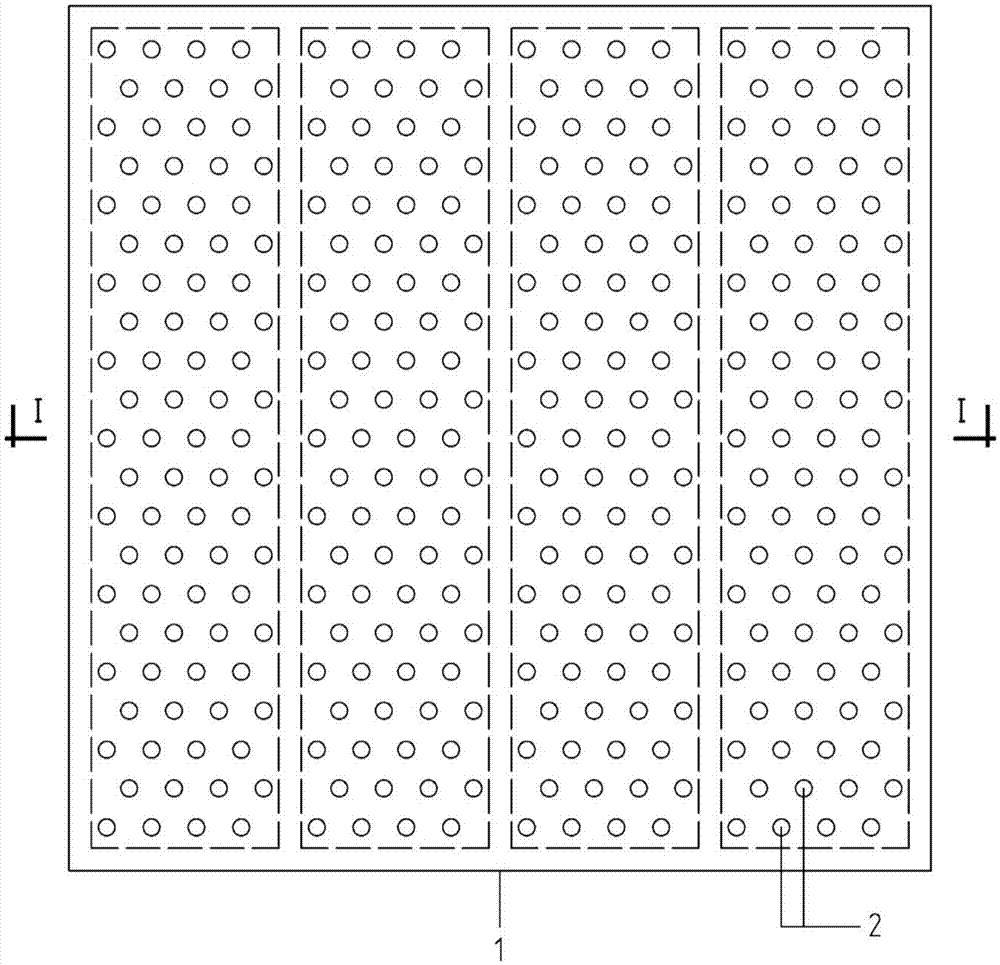

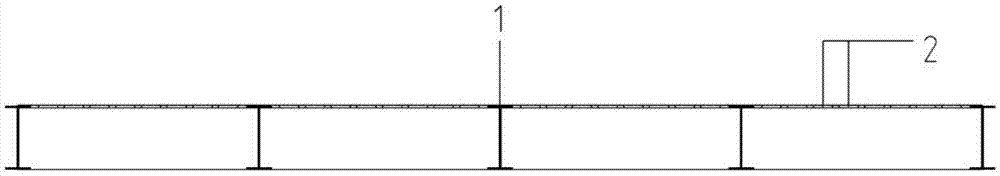

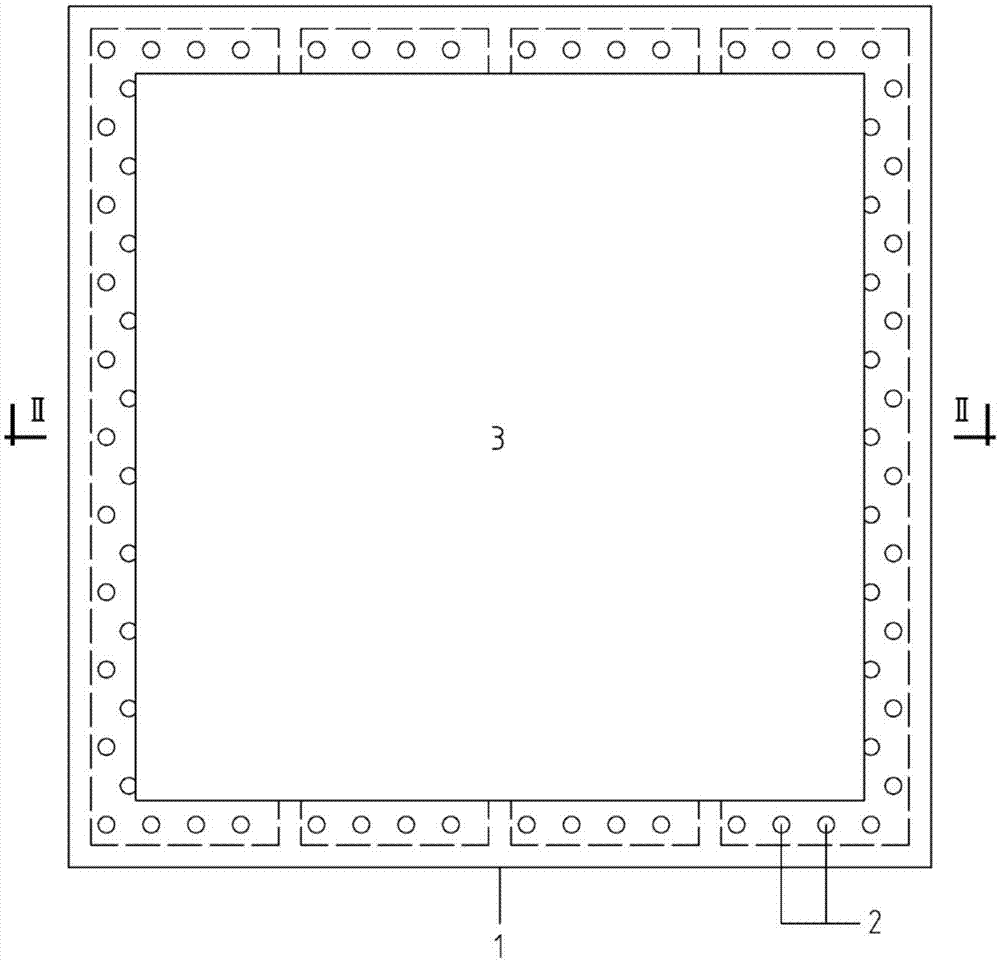

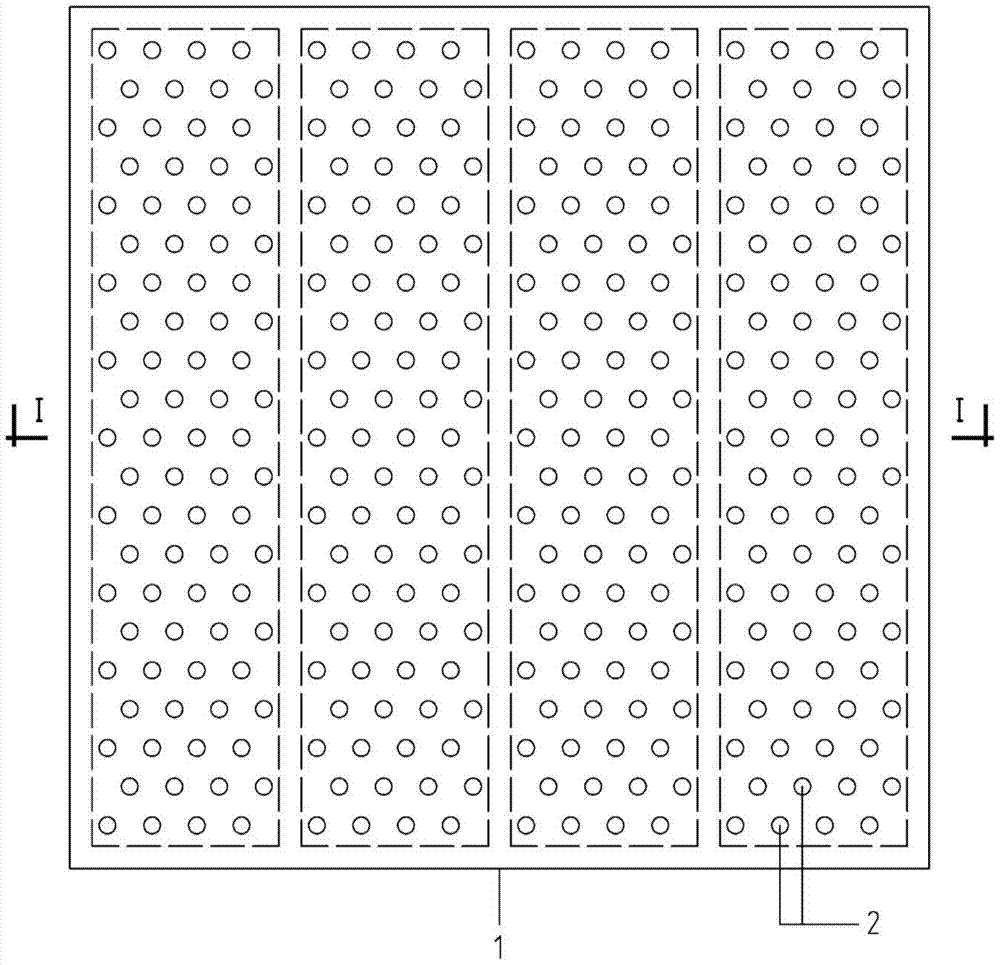

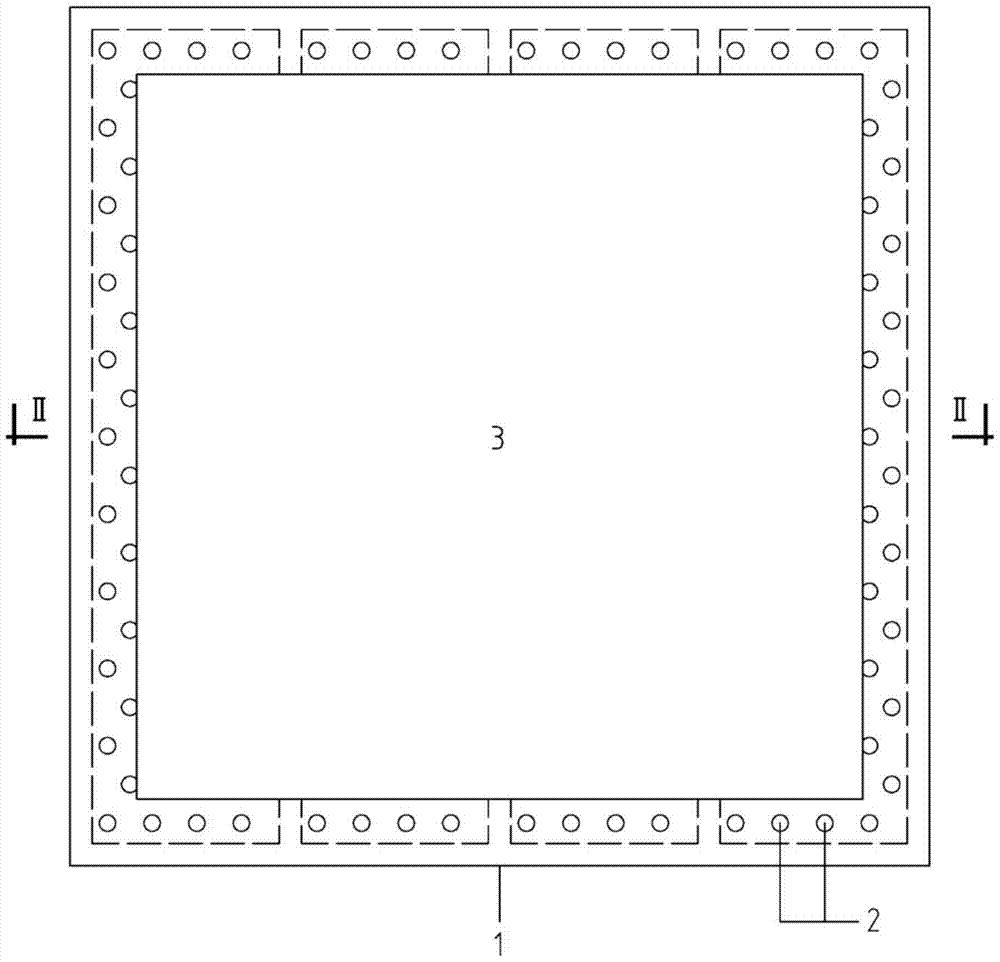

Method for pasting face bricks in prefabrication of concrete floor and concrete wallboard

The invention provides a method for pasting face bricks in prefabrication of a concrete floor and a concrete wallboard, and belongs to the technical field of construction engineering. The method includes the steps that a bottom mold for the prefabricated concrete floor or concrete wallboard is manufactured, a single-sided adhesive plastic film is laid on the bottom mold for the prefabricated concrete floor or concrete wallboard, a face brick positioning grid and the face bricks are placed on the bottom mold, laid with the single-sided adhesive plastic film, for the prefabricated concrete floor or concrete wallboard, and hot paraffin liquid is poured onto the bottom mold; and a side mold for the prefabricated concrete floor or concrete wallboard is mounted, steel bar materials of the prefabricated concrete floor or concrete wallboard are bound, concrete of the prefabricated concrete floor or concrete wallboard is poured, and after the needed strength is achieved through curing, construction is completed. By means of the method, the pasting quality of the face bricks for a wall surface or a building surface can be remarkably improved, pasting materials are saved, manpower is reduced, and the construction cost of construction engineering is lowered. According to the method, the production process and equipment are simple, operation is easy, the bonding strength is high, finished product protection is facilitated, and the face bricks are flat and clean in appearance; the method has positive significance to development of prefabricated and assembled type concrete buildings.

Owner:江苏亿科博建筑科技有限公司

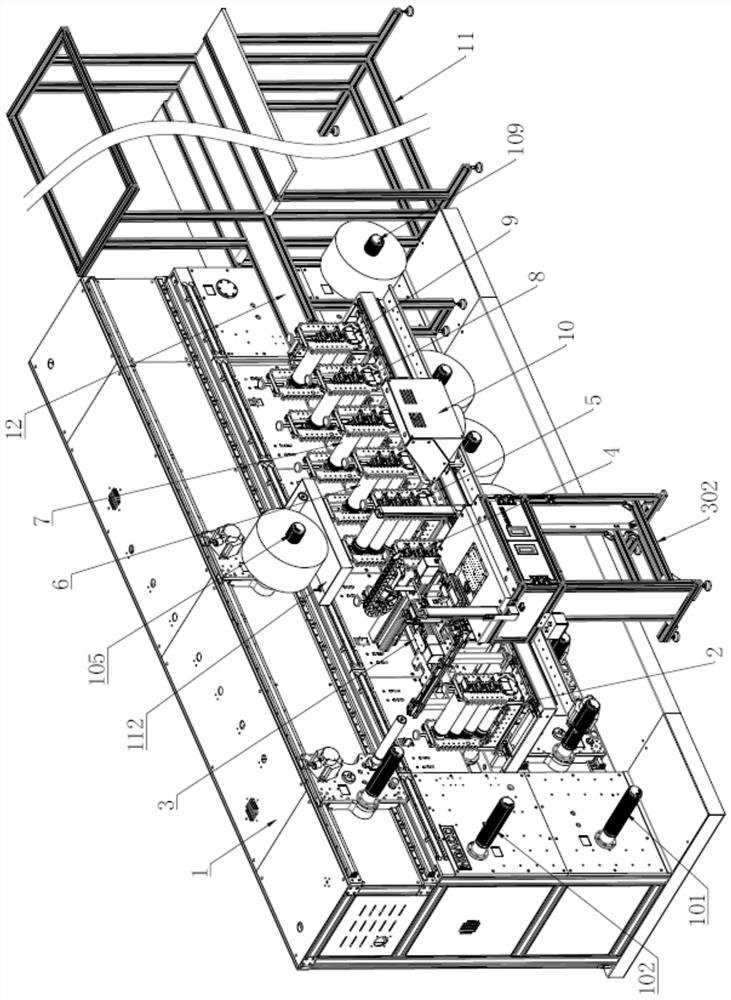

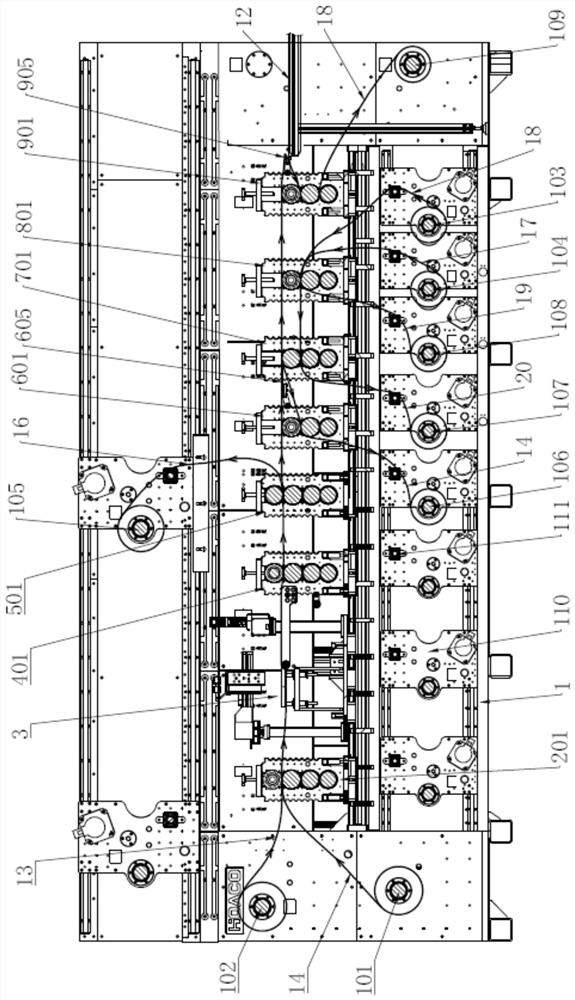

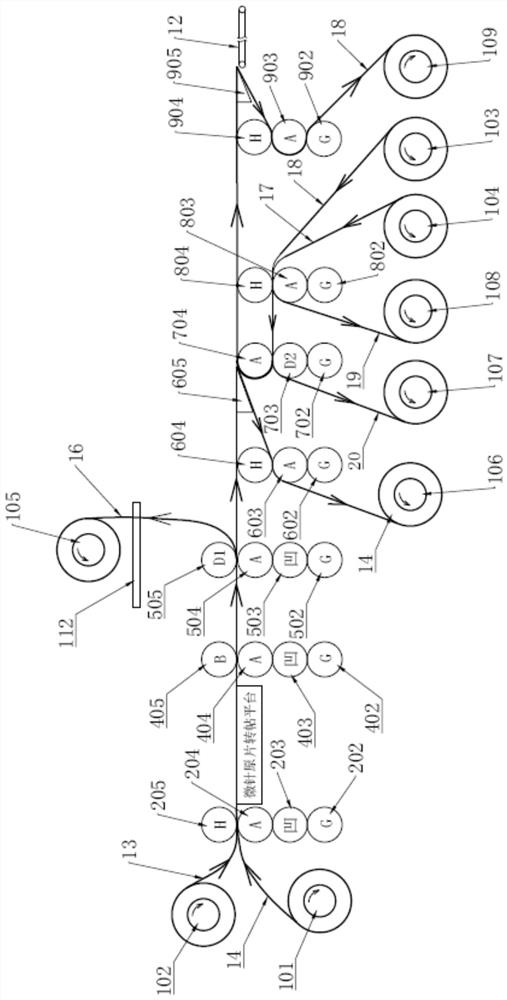

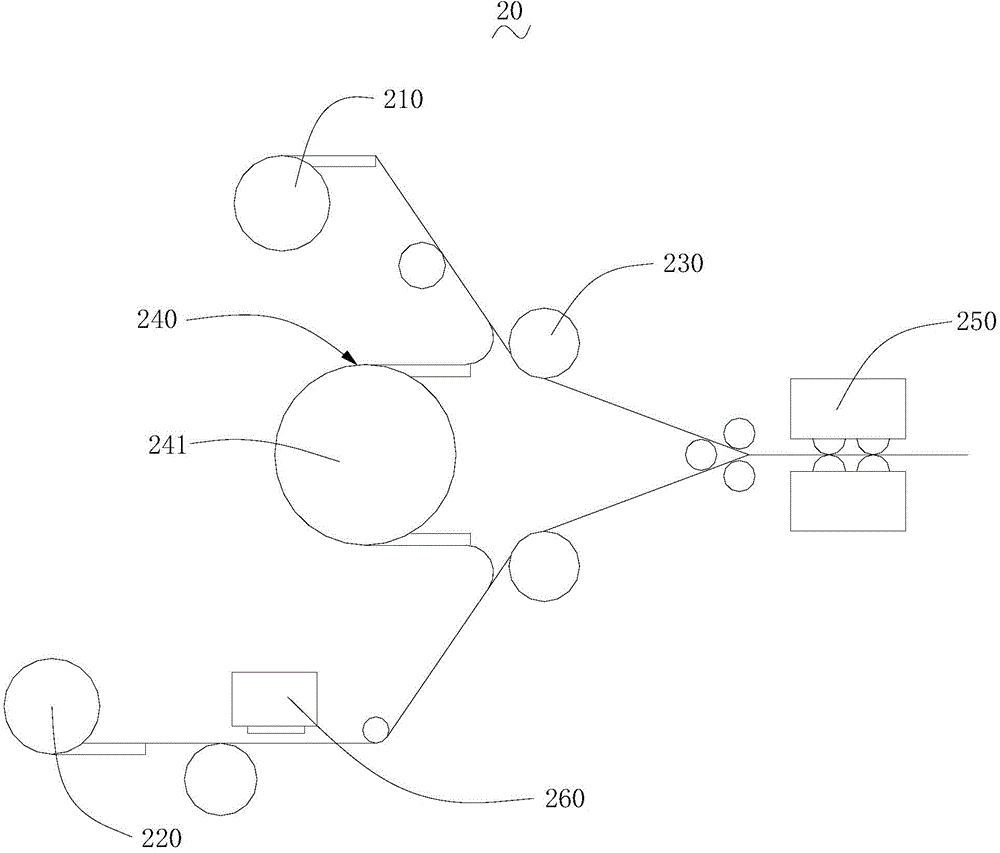

Micro-needle eye patch processing equipment and processing method thereof

ActiveCN113548511AImprove processing efficiencyImprove processing qualityMicroneedlesPharmaceutical delivery mechanismWaste materialDie cutting

The invention belongs to the technical field of micro-needle eye patch processing, and provides micro-needle eye patch processing equipment and a processing method thereof. The micro-needle eye patch processing equipment comprises an eye patch sheet making machine and an eye patch conveyor, and the eye patch sheet making machine comprises a sheet making machine rack provided with a plurality of material belt discharging shafts and waste material rolling shafts; a first traction composite device, a micro-needle original sheet repasting device, a traction conveying device, a micro-needle original sheet die cutting device, a first low-viscosity film waste collecting device, a medical rubber strip die cutting device, a second traction composite device and a second low-viscosity film waste collecting device are sequentially arranged from one end to the other end of the sheet making machine rack; the micro-needle original sheet repasting device comprises an original sheet feeding base platform installed on the sheet making machine rack, a bonding supporting plate and an original sheet moving mechanism are arranged on the original sheet feeding base platform, and an original sheet feeding mechanism is arranged on the upstream of the original sheet moving mechanism. According to the micro-needle eye patch processing equipment and the processing method thereof, the processing efficiency and the processing quality of micro-needle eye patches are greatly improved, and micro-needle eye patch products obtained through processing are convenient to use and good in attaching effect.

Owner:SHANDONG HOACO AUTOMATION TECH

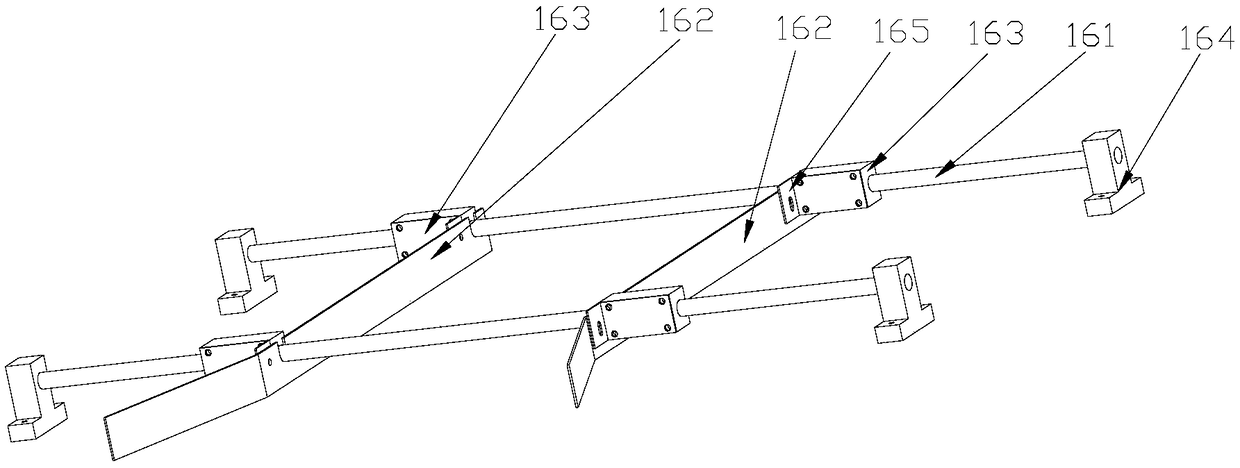

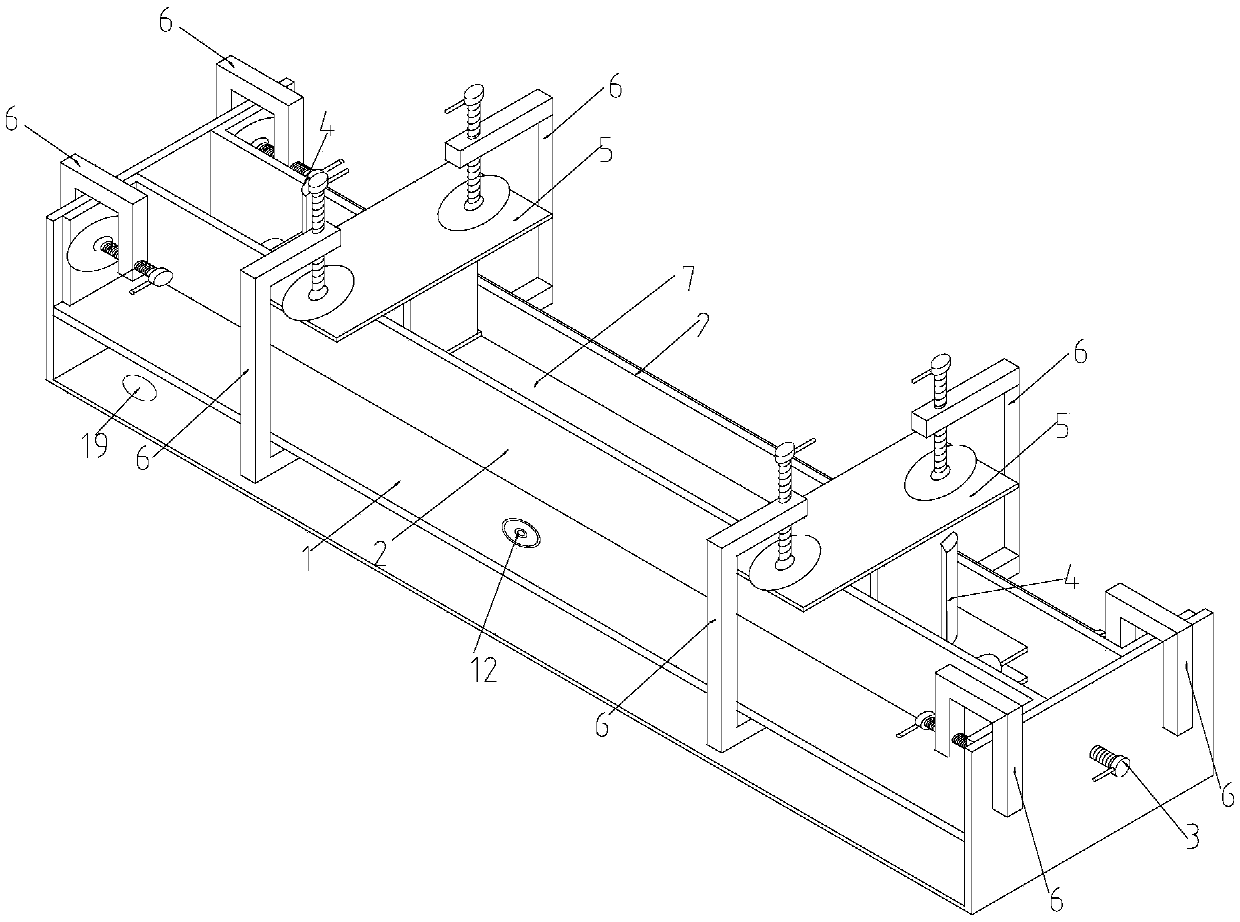

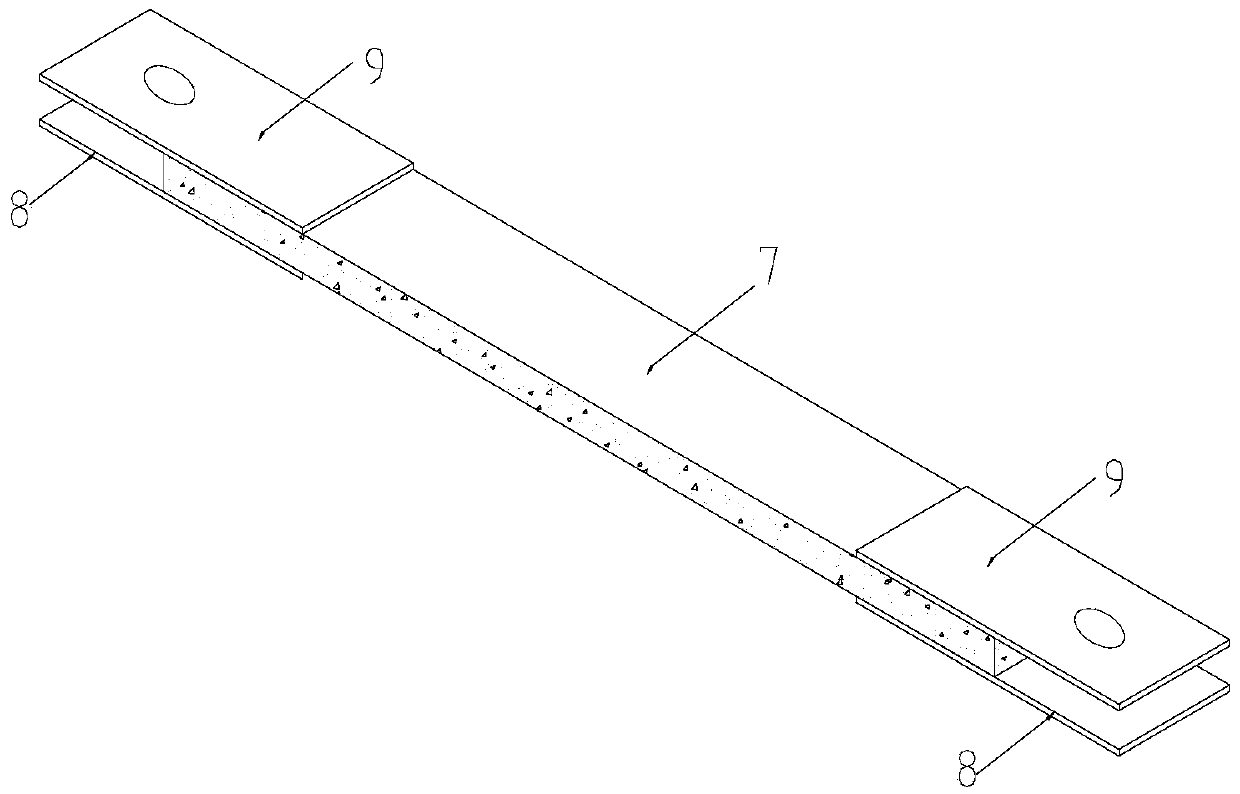

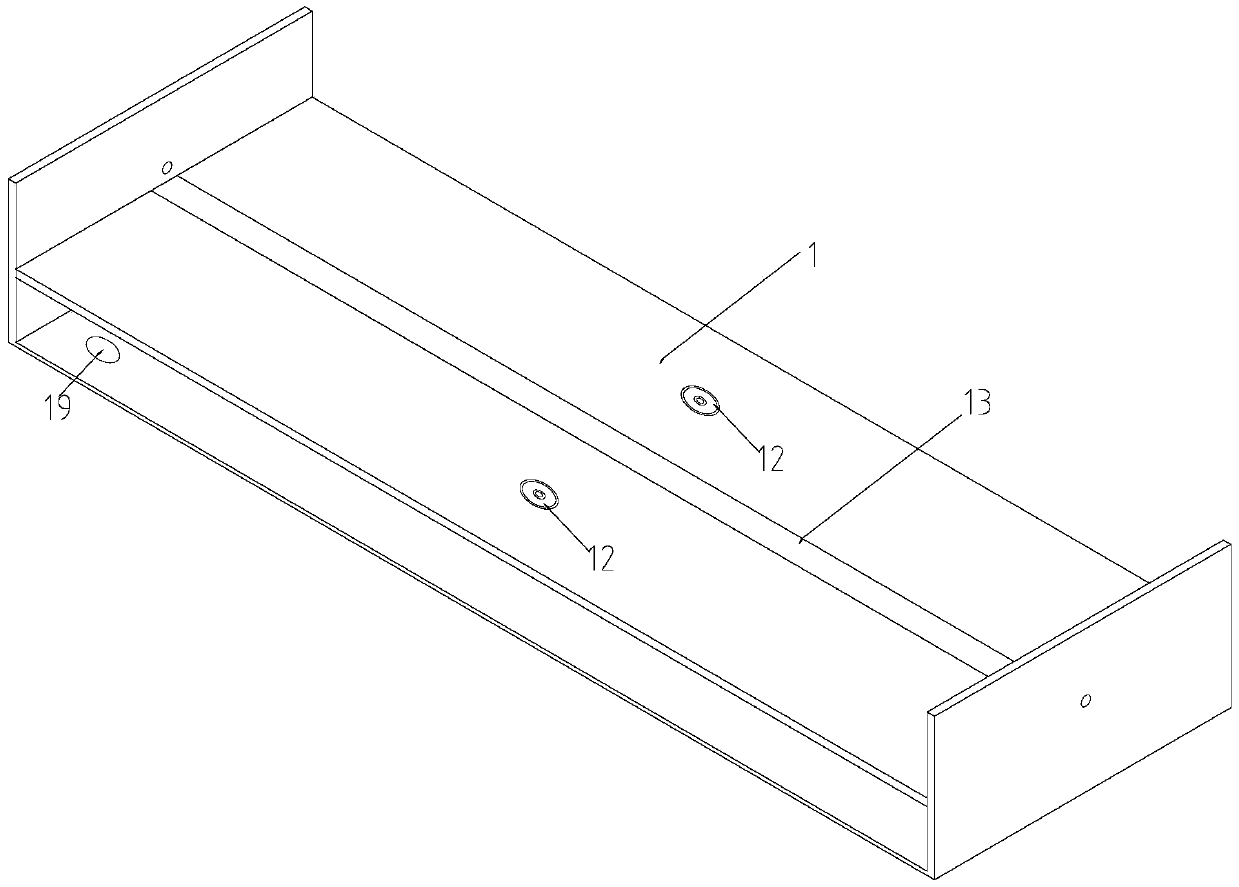

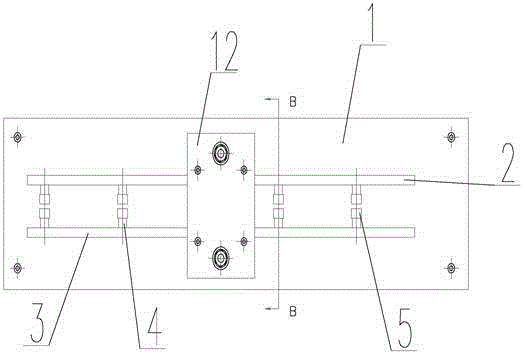

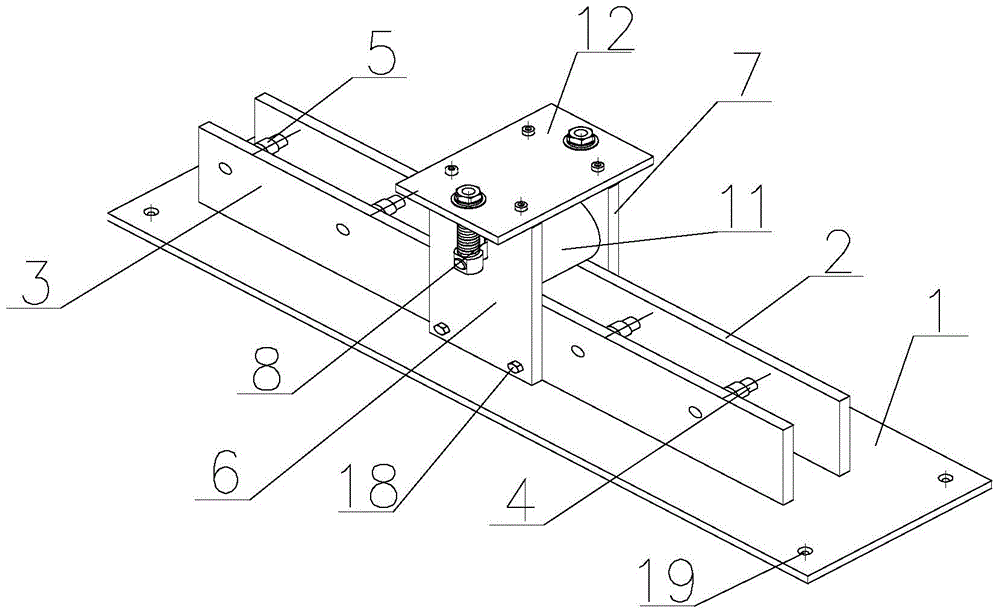

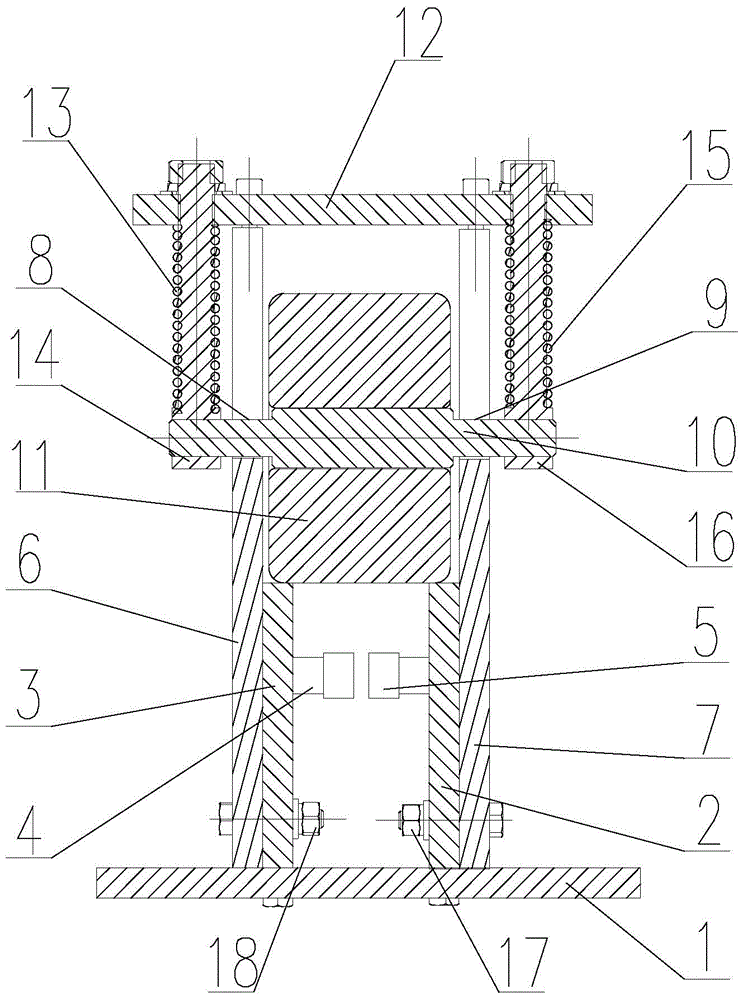

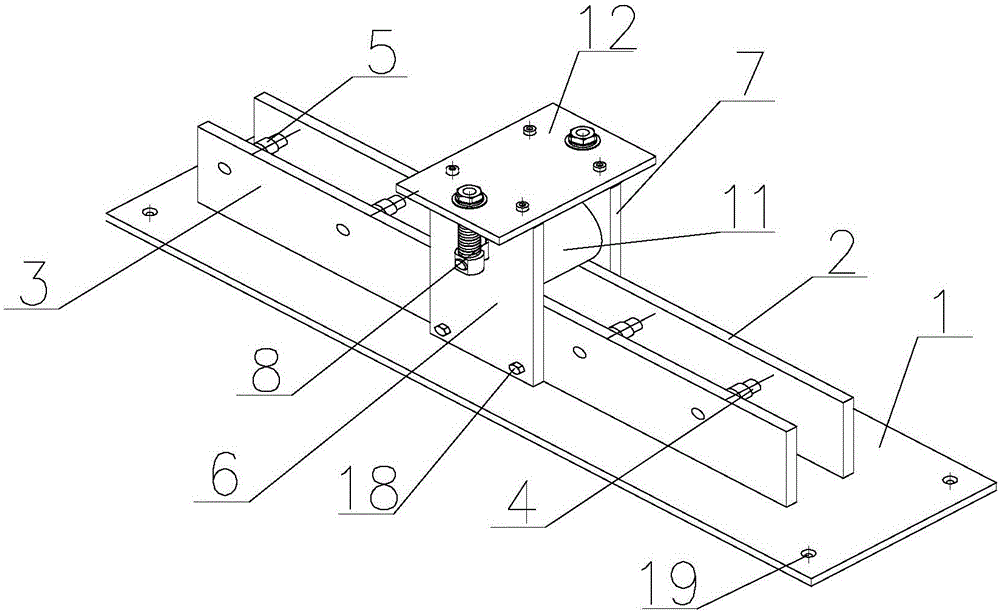

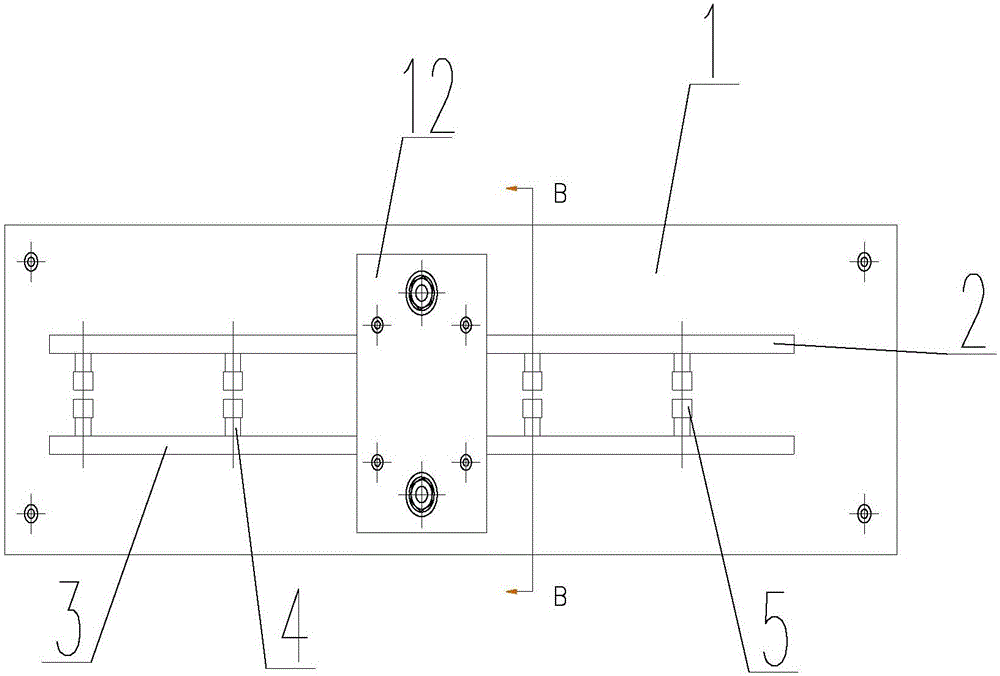

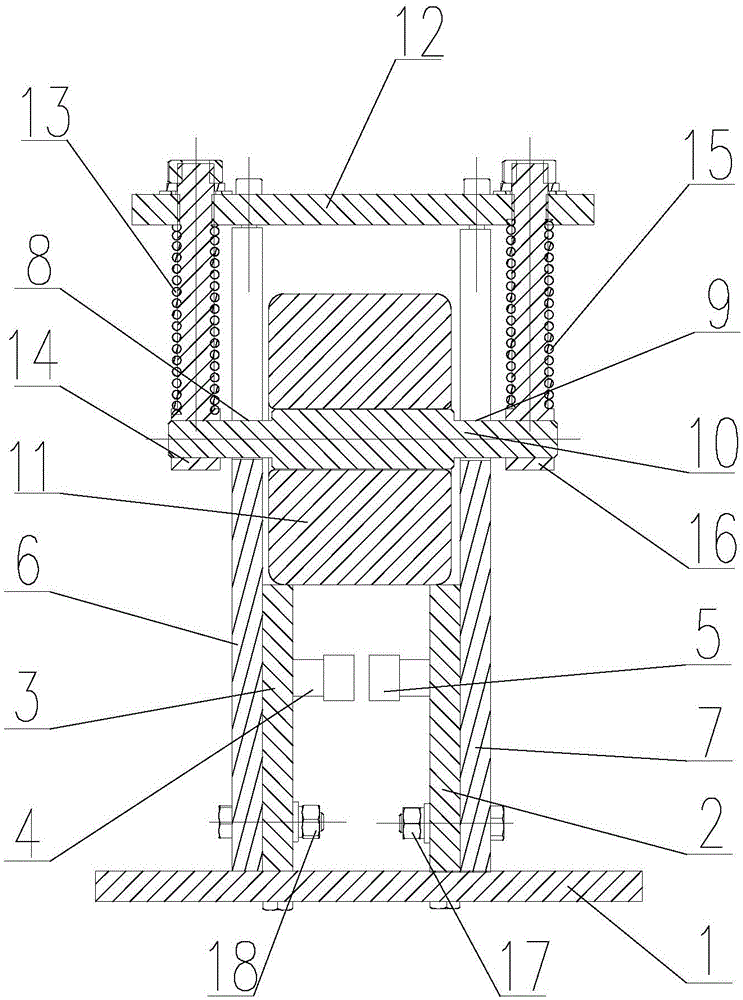

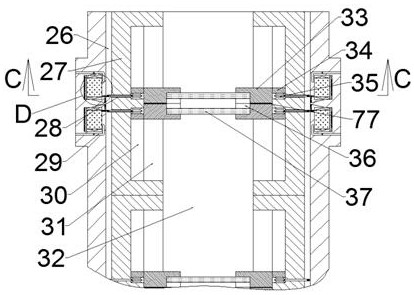

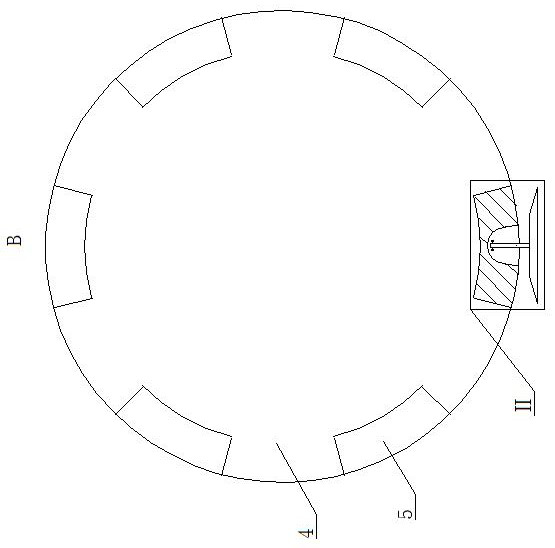

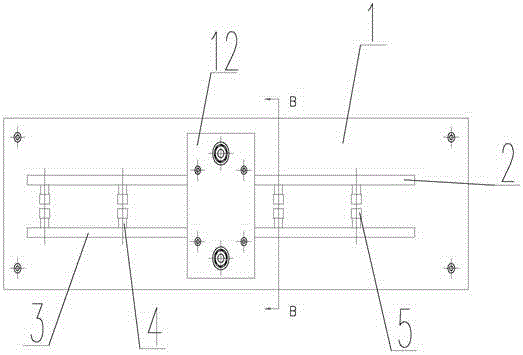

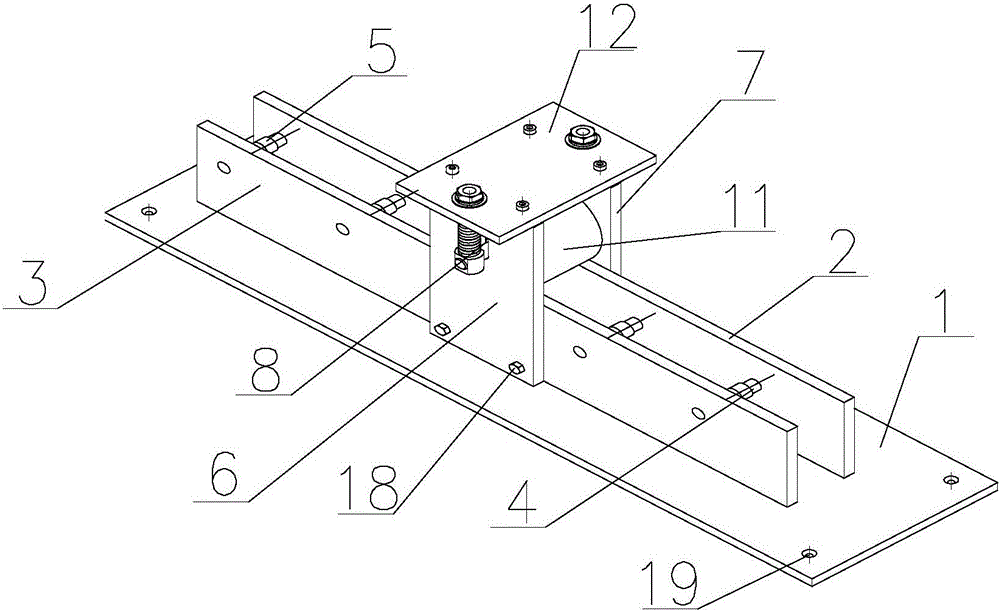

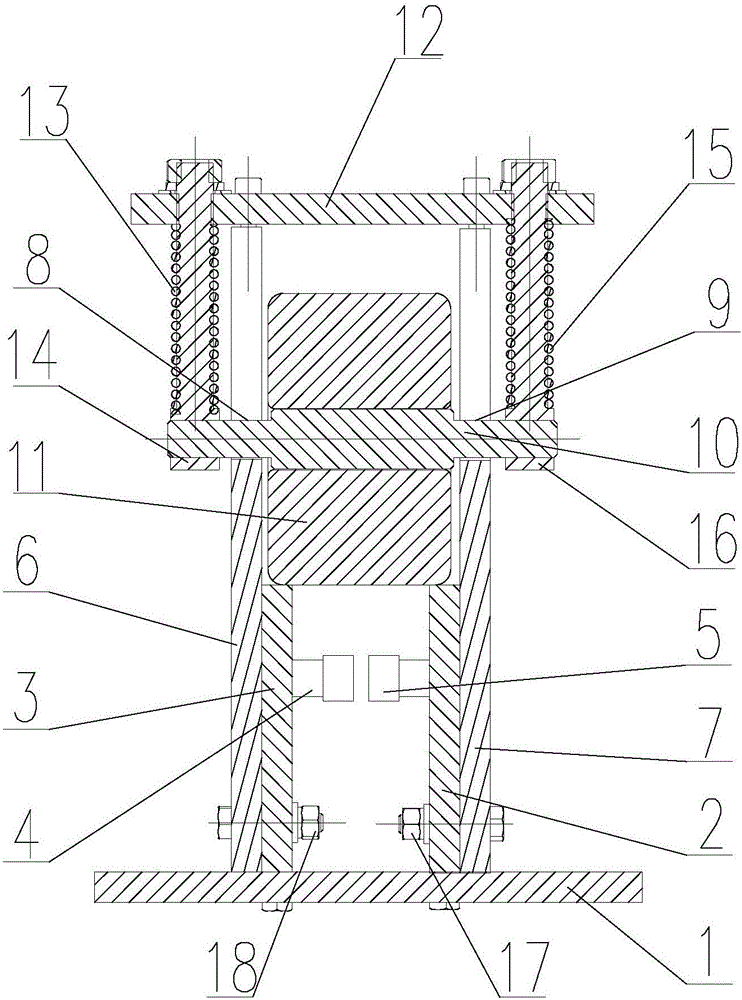

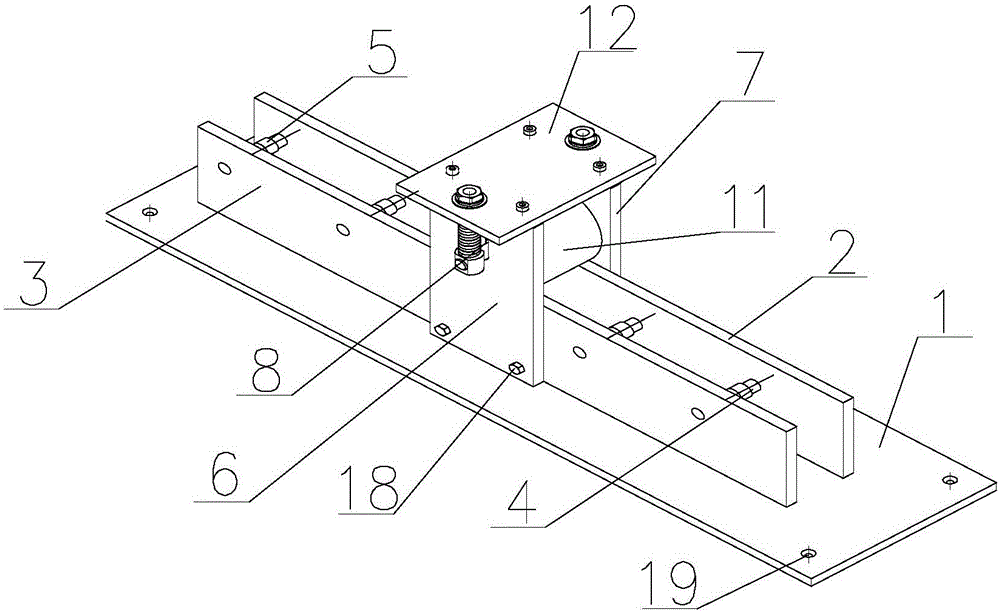

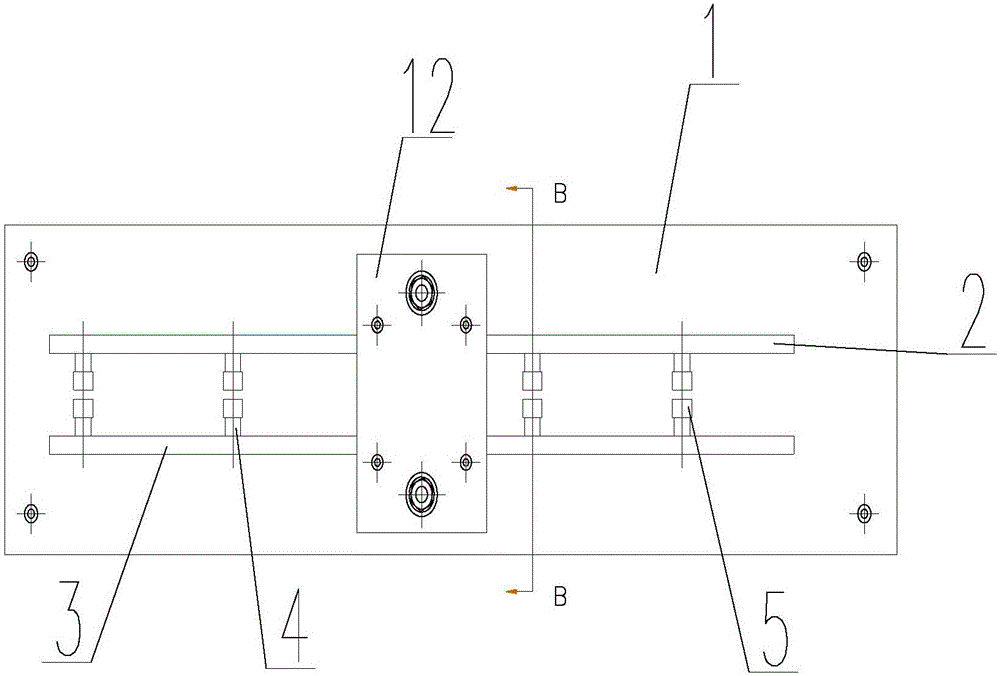

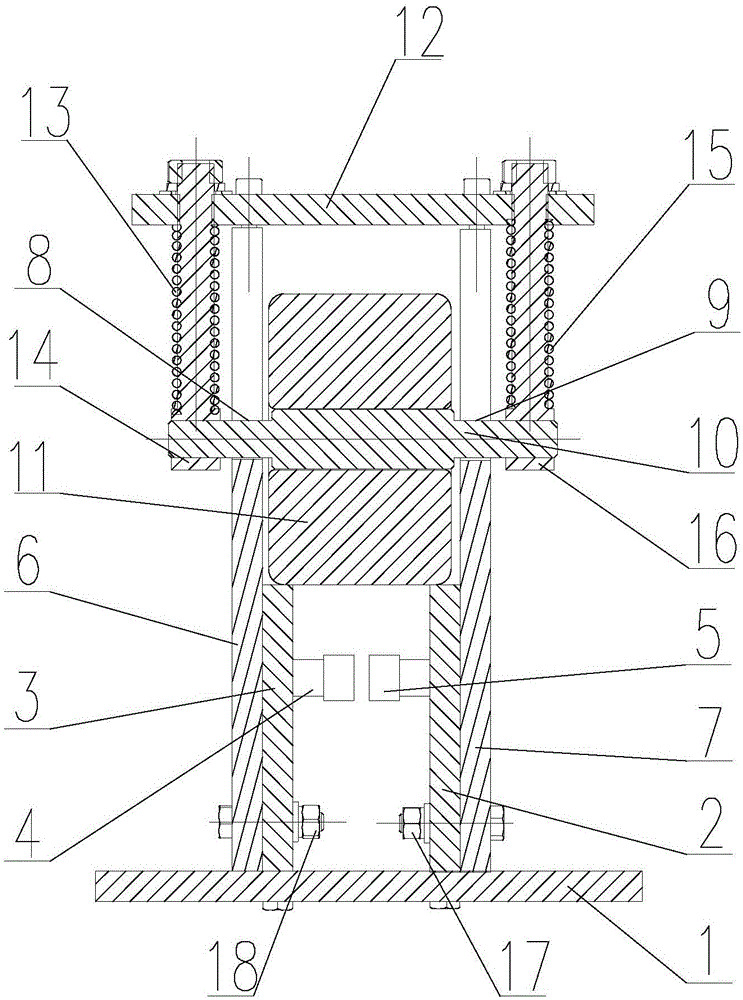

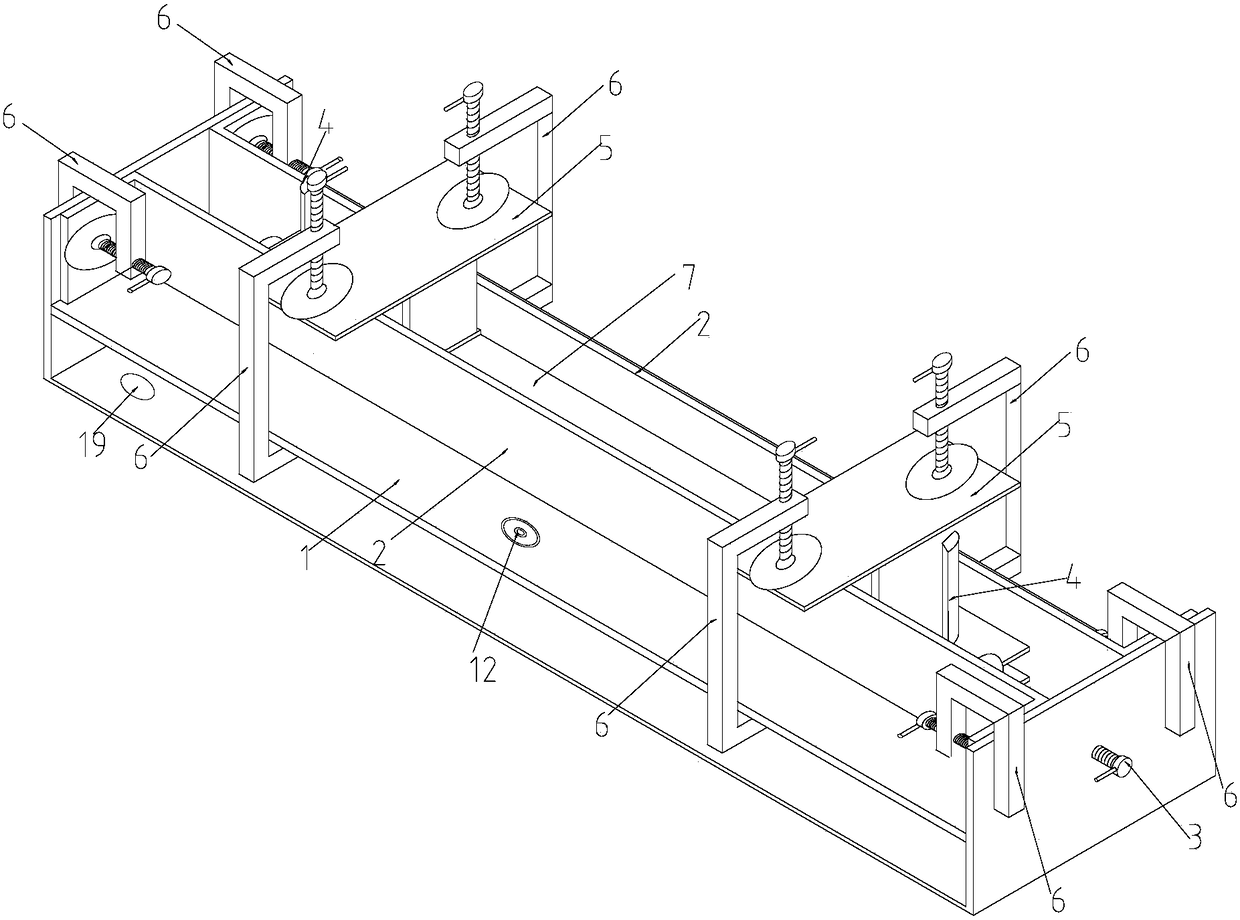

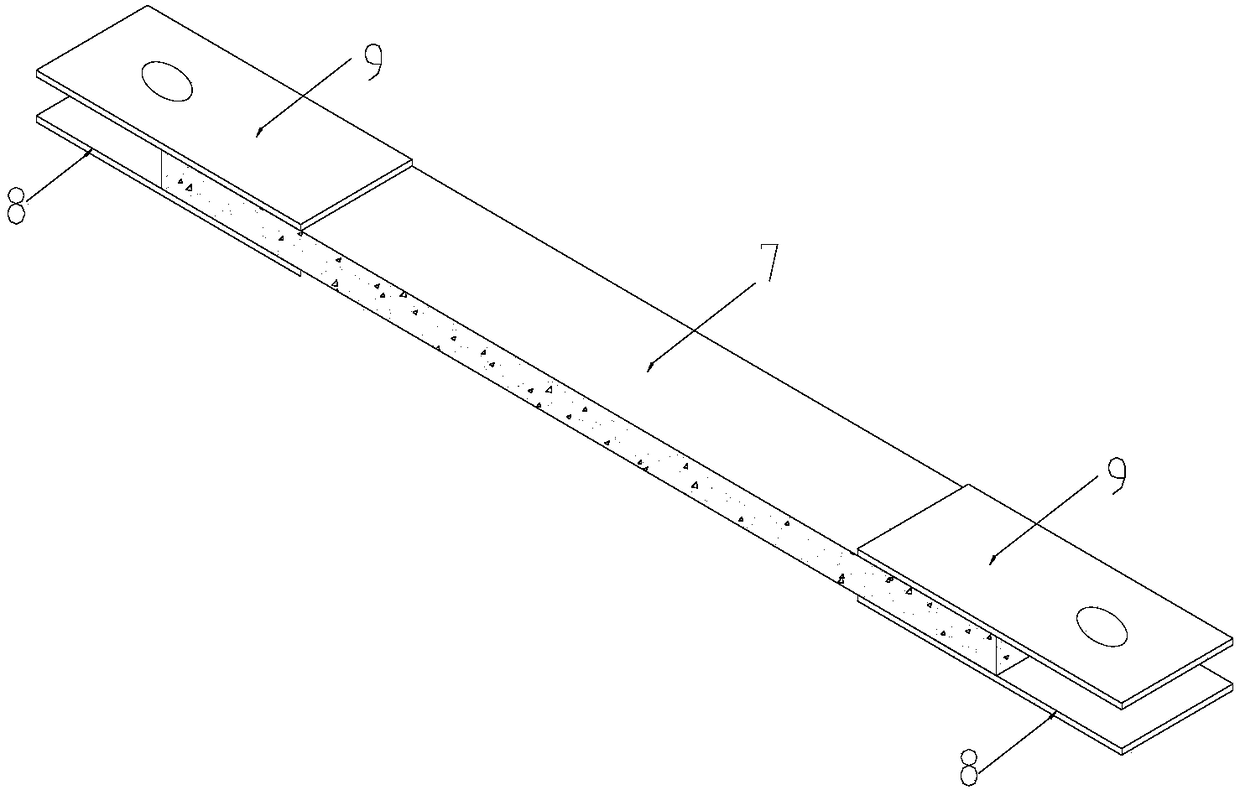

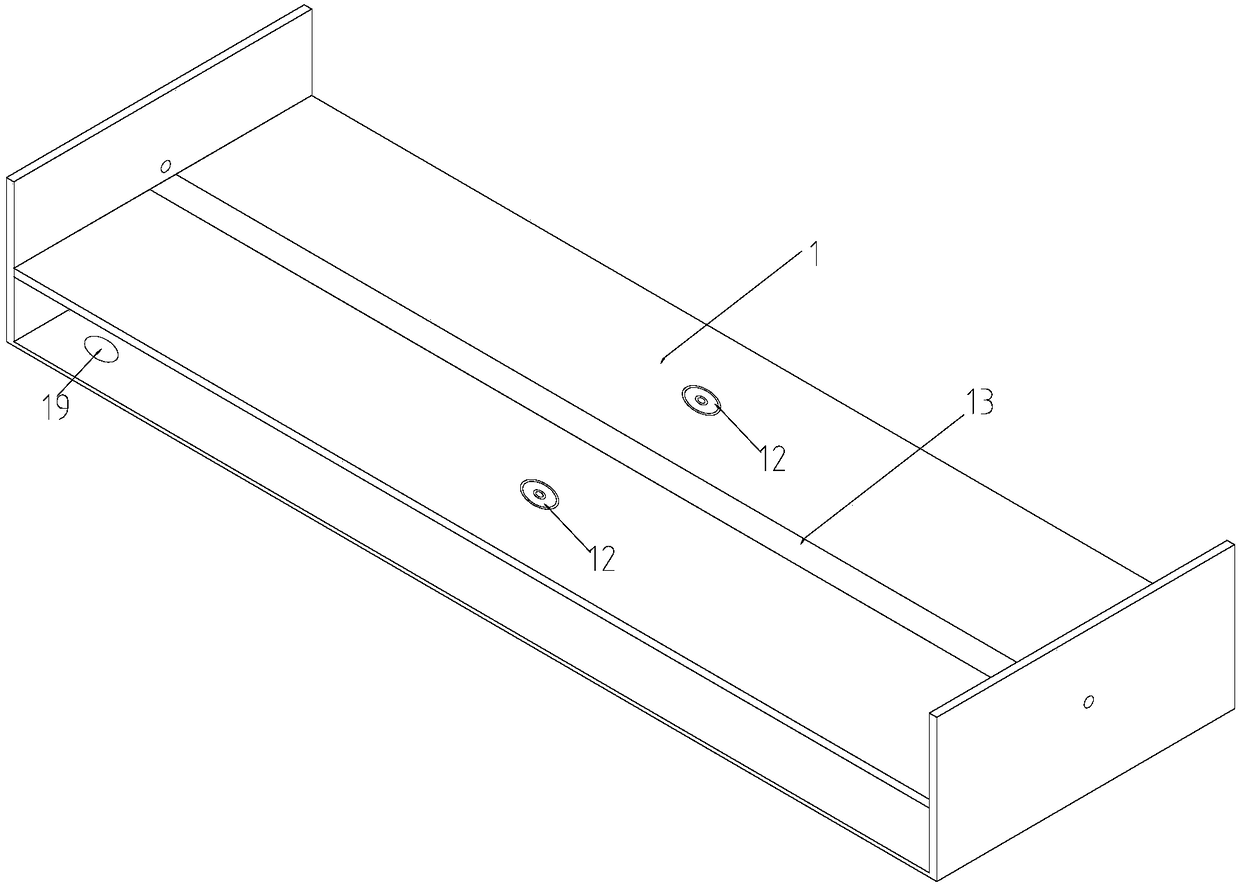

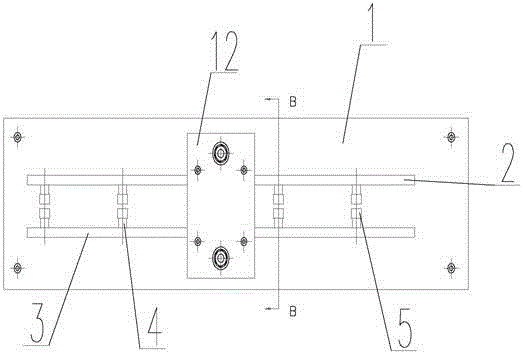

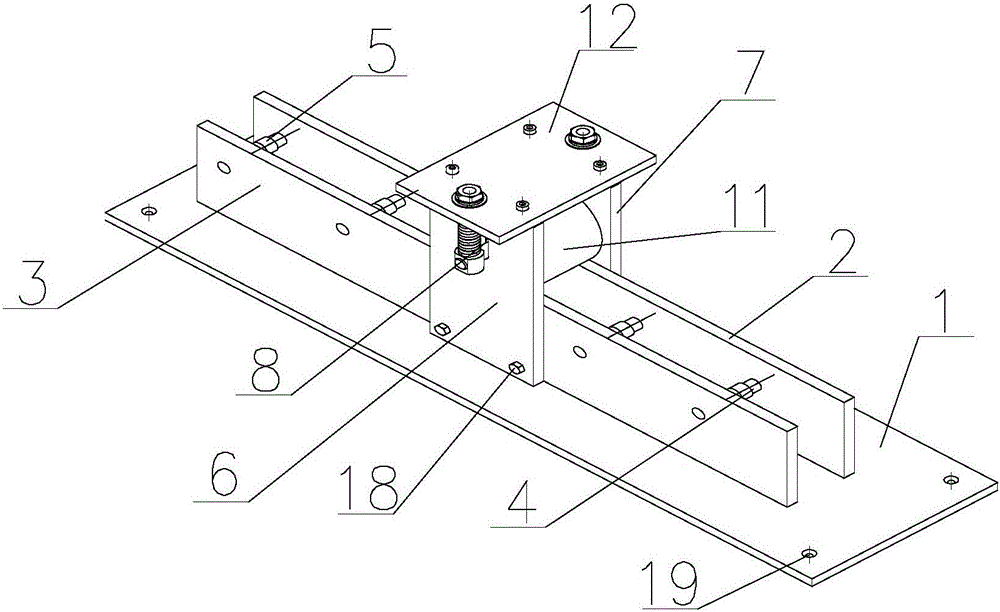

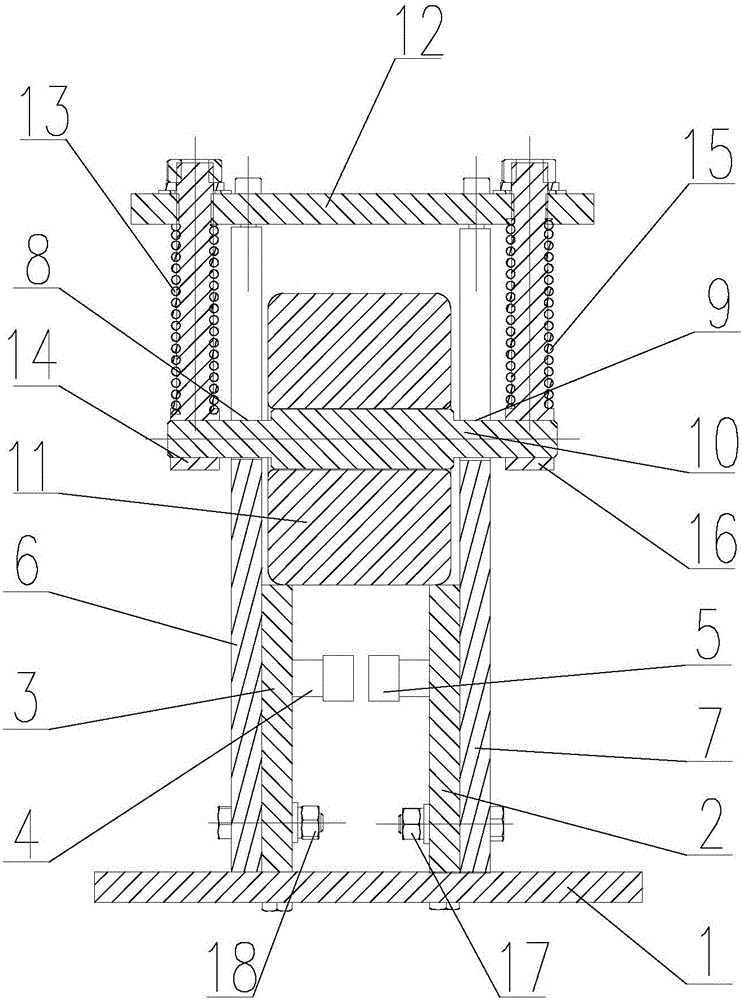

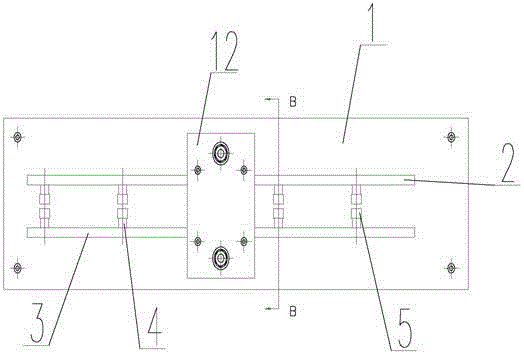

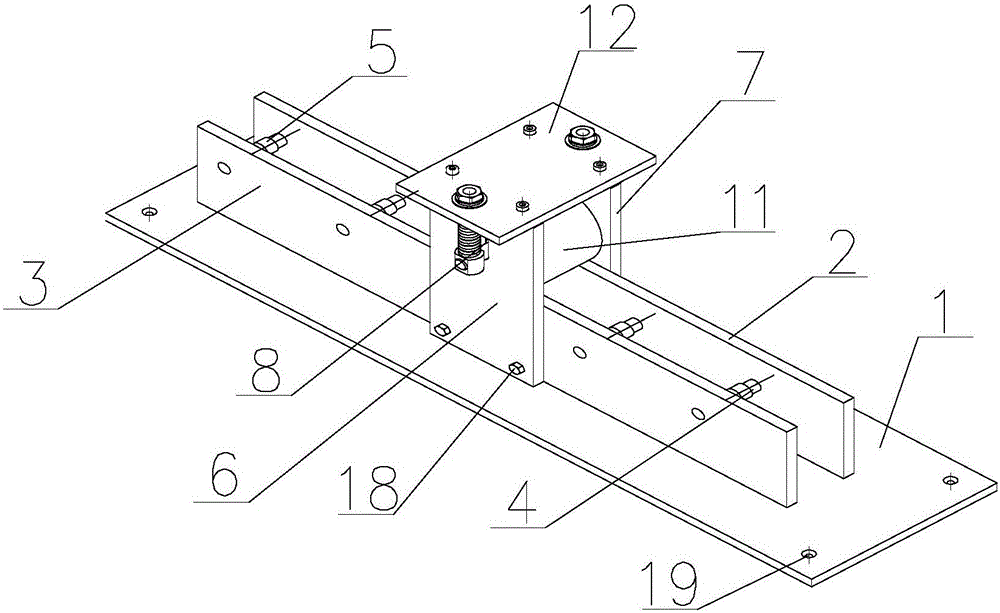

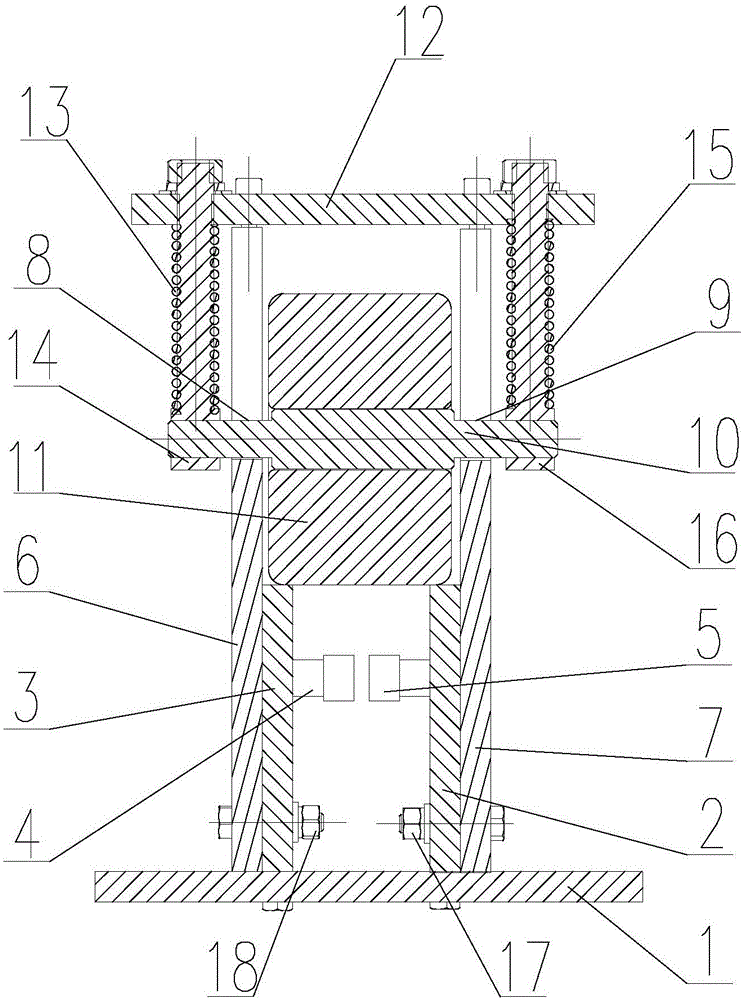

Assembly device capable of reducing axial eccentricity of tensile sample, and operation method

The invention discloses an assembly device capable of reducing the axial eccentricity of a tensile sample, and an operation method. The assembly device comprises a sample assembly steel platform (1), two clamping devices (2), two pulling-jacking devices (3), two location rods (4) and two pressing devices (5), wherein the clamping devices (2) next to the two sides of the sample, and are fixed with the sample assembly steel platform by U-shaped clamps; each pulling-jacking device (3) is composed of a pulling-jacking screw rod and a pulling-jacking disc surface; the location rods (4) are fixed onto the sample assembly steel platform by connection gaskets and locking nuts; and the pressing devices (5) are fixed with the sample assembly steel platform by U-shaped clamps. According to the invention, steel sheets with circular holes are symmetrically bonded on the end parts of the tensile sample with a rectangular section, of a cement base, and loads are applied through shafts inserted in the circular holes. According to the invention, the position centring of the circular holes is ensured through operating the pulling-jacking devices (3) and the pressing devices (5), and the bonding materials are controlled to be uniform, so that the steel sheets are closely and flatly bonded on the surface of the sample, and then the axial eccentricity of tensile sample is reduced.

Owner:HUNAN UNIV

Device for installing LED light box conveniently

InactiveCN105114416APrevent fallingSpeed up the installation processFastening meansSoftware engineeringLED lamp

The invention discloses a device for installing an LED light box conveniently. The device comprises a base plate, wherein a plurality of threaded through holes are formed in the base plate, a first pulley installation plate and a second pulley installation plate are arranged on the base plate in parallel, and a plurality of pulley installation bases are arranged between the first pulley installation plate and the second pulley installation plate and are fixed to the first pulley installation plate and the second pulley installation plate respectively in a one-to-one corresponding mode; pulleys are arranged on the pulley installation bases respectively, the first pulley installation plate and a second supporting plate are fixed with two first screws, and the second pulley installation plate and a first supporting plate are fixedly connected through two second screws. The device has the advantages that panel falling is prevented; installation progress is accelerated; an installed panel can be attached to the light box flat, safety is improved, and attractiveness is improved.

Owner:重庆卡斯特模具有限公司

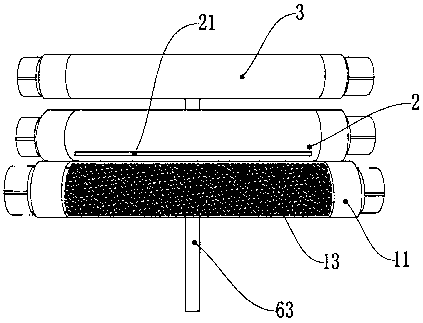

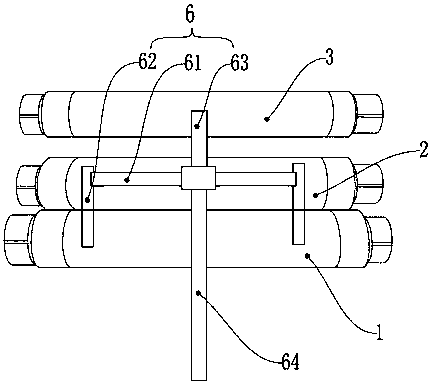

Convenient and fast antithetical couplet pasting device

The invention discloses a convenient and fast antithetical couplet pasting device. The device comprises, from bottom to top in sequence, a glue distributing roller, an antithetical couplet winding roller and a pressure roller which are arranged and connected transversely. The glue distributing roller comprises a glue distributing barrel, a baffle and a bristlebrush roller body; glue inlets are formed in the two ends of the glue distributing barrel correspondingly; the baffle is mounted in the glue distributing barrel and partitions the glue distributing barrel into a front glue outlet cavity and a rear glue inlet cavity; a glue applying port is formed in the front glue outlet cavity; the rear glue inlet cavity communicates with the corresponding glue inlet; the front glue outlet cavity communicates with the rear glue inlet cavity through through holes which are uniformly distributed and formed in the surface of the baffle; the bristlebrush roller body is mounted in the front glue outlet cavity and right faces the glue applying port; an antithetical couplet outlet is formed in the front end of the side surface of the antithetical couplet winding roller; and the glue distributing roller, the antithetical couplet winding roller and the pressure roller roll synchronously from top to bottom. The convenient and fast antithetical couplet pasting device has the advantages that glue applying is uniform and stable, and sticking is fast and flat.

Owner:佛山市禅城区下朗小学

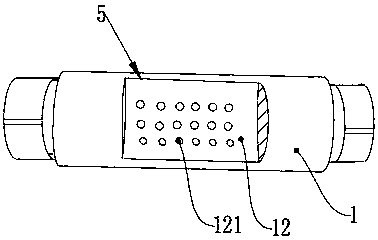

Extrusion device for LED lamp panels

InactiveCN105127948APrevent fallingSpeed up the installation processMaterial gluingMetal-working hand toolsPulp and paper industryLED lamp

The invention discloses an extrusion device for LED lamp panels. The extrusion device comprises a bottom plate, wherein a first roller mounting plate and a second roller mounting plate which are parallel with each other are arranged on the bottom plate; a plurality of roller mounting bases are arranged between the first roller mounting plate and the second roller mounting plate; the roller mounting bases are fixed on the first roller mounting plate and the second roller mounting plate in a one-to-one correspondence manner respectively; rollers are arranged on the roller mounting bases; a first supporting plate and a second supporting plate are arranged on the bottom plate; the first roller mounting plate and the second roller mounting plate are located between the first supporting plate and the second supporting plate; the first roller mounting plate and the second supporting plate are fixed through two first screws; the second roller mounting plate and the first supporting plate are fixedly connected through two second screws. The extrusion device has the benefits as follows: the panels are prevented from falling; the mounting progress is accelerated; the mounted panels can be flatly attached to lamp boxes, and the safety and the attractiveness are improved.

Owner:重庆卡斯特模具有限公司

Labeling machine production process

InactiveCN109533536AAvoid tearingAvoid foldingCleaning using toolsLabelling machinesConveyor beltIndustrial engineering

The invention discloses a labeling machine production process. The labeling machine production process comprises the following steps of S1, label fixing, specifically, a label roller is placed on a moving rack, a label is pulled out and winded on the surface of a scaleplate, and the moving speed of the label roller and the scaleplate on the moving rack is adjusted to keep consistent; and S2, article placing, specifically, an article is placed at the upper portion of a conveyor belt, and the upper portion of the conveyor belt is connected with a layer of duster cloth, the article moves under the duster cloth by means of the conveyor belt, and the moving speed of the conveyor belt is the same as that of the scaleplate. Compared with other workflows, the labeling machine production process islow in price, mature in process, smooth in pasting and convenient to operate, and by way of the article pasting effect, the label use quality is greatly improved.

Owner:天津比朗德机械制造有限公司

Automatic electronic tag pasting device capable of adjusting length

InactiveCN112009839AImprove cutting efficiencyHigh degree of automationLabelling machinesStructural engineeringMechanical engineering

The invention discloses an automatic electronic tag pasting device capable of adjusting the length. The automatic electronic tag pasting device comprises a box, and a carrier belt conveying groove communicating front and back is formed in the box; carrier guide grooves with openings facing the carrier belt conveying groove are symmetrically formed in the left end wall and the right end wall of thecarrier belt conveying groove; five length-divided conveying blocks are uniformly and slidably connected in the carrier guide grooves in front and back; two adjusting clamping block sliding grooves with openings facing the carrier belt conveying groove are symmetrically formed in the length-divided conveying blocks; protective cushion blocks are fixedly arranged on the second-generation end walls, away from the carrier belt conveying groove, of the downward adjusting clamping block sliding grooves; adjusting clamping blocks located on the front sides and the rear sides of the protective cushion blocks are slidably connected into the adjusting clamping block sliding grooves; and adjusting blocks are fixedly arranged on the end faces, away from the carrier belt conveying groove, of the adjusting clamping blocks, and the adjusting blocks are located in the adjusting block sliding grooves with the openings facing the carrier belt conveying groove and slidably connected with the adjustingblock sliding grooves. The length of an electronic tag pasting carrier needing to be cut can be freely adjusted for multiple times of cutting, and pasting is smoother through a pressing roller.

Owner:TIANJIN FENGWEI PACKAGING PROD SALES CO LTD

A method for pasting facing bricks in prefabricated concrete floor and wall panels

The invention provides a method for pasting face bricks in prefabrication of a concrete floor and a concrete wallboard, and belongs to the technical field of construction engineering. The method includes the steps that a bottom mold for the prefabricated concrete floor or concrete wallboard is manufactured, a single-sided adhesive plastic film is laid on the bottom mold for the prefabricated concrete floor or concrete wallboard, a face brick positioning grid and the face bricks are placed on the bottom mold, laid with the single-sided adhesive plastic film, for the prefabricated concrete floor or concrete wallboard, and hot paraffin liquid is poured onto the bottom mold; and a side mold for the prefabricated concrete floor or concrete wallboard is mounted, steel bar materials of the prefabricated concrete floor or concrete wallboard are bound, concrete of the prefabricated concrete floor or concrete wallboard is poured, and after the needed strength is achieved through curing, construction is completed. By means of the method, the pasting quality of the face bricks for a wall surface or a building surface can be remarkably improved, pasting materials are saved, manpower is reduced, and the construction cost of construction engineering is lowered. According to the method, the production process and equipment are simple, operation is easy, the bonding strength is high, finished product protection is facilitated, and the face bricks are flat and clean in appearance; the method has positive significance to development of prefabricated and assembled type concrete buildings.

Owner:江苏亿科博建筑科技有限公司

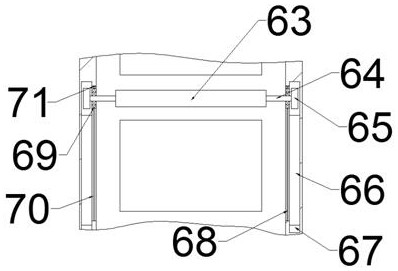

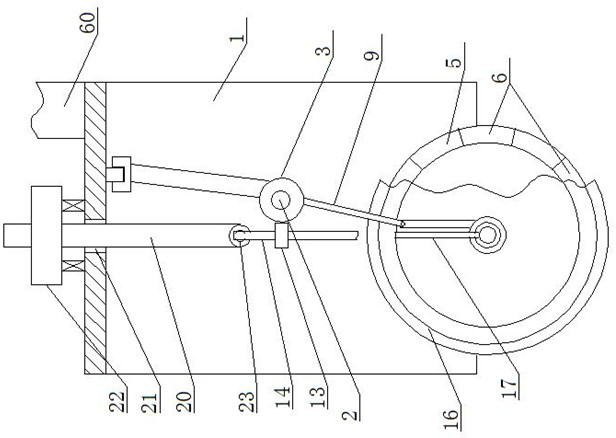

Efficient flat pasting device

ActiveCN113942056ASimple structureIngenious ideaMechanical working/deformationPaper recyclingEngineeringStructural engineering

The invention discloses an efficient flat pasting device. The efficient flat pasting device comprises a shell, a lead screw is rotationally installed in the shell, the screwing directions of threads at the two ends of the lead screw are opposite, nuts are installed on the two sides of the periphery of the lead screw in a threaded mode respectively, and the nuts can only move left and right; two coaxial rotating circular plates are arranged below the lead screw, first arc-shaped plates and second arc-shaped plates which are evenly and circumferentially distributed are arranged between the rotating circular plates, and the first arc-shaped plates and the second arc-shaped plates are distributed in a crossed mode to form a paper collecting roller structure; a first shaft seat is fixedly connected with the corresponding nut through a connecting rod, and the lower end of a vertical rod is fixedly connected with a corresponding second shaft seat; and a paper clamping device is fixedly installed below the first arc-shaped plate on the lowermost side, and an annular cutting knife is fixedly installed on the periphery of a second supporting shaft. According to the efficient flat pasting device, the structure is simple, paper strips with different widths can be cut and wound around the periphery of the paper collecting roller structure, subsequent manual gluing is facilitated, the glued paper strips are rolled on a notebook through the paper collecting roller structure, pasting is flatter, and market requirements can be met.

Owner:河北中鑫科技发展有限公司

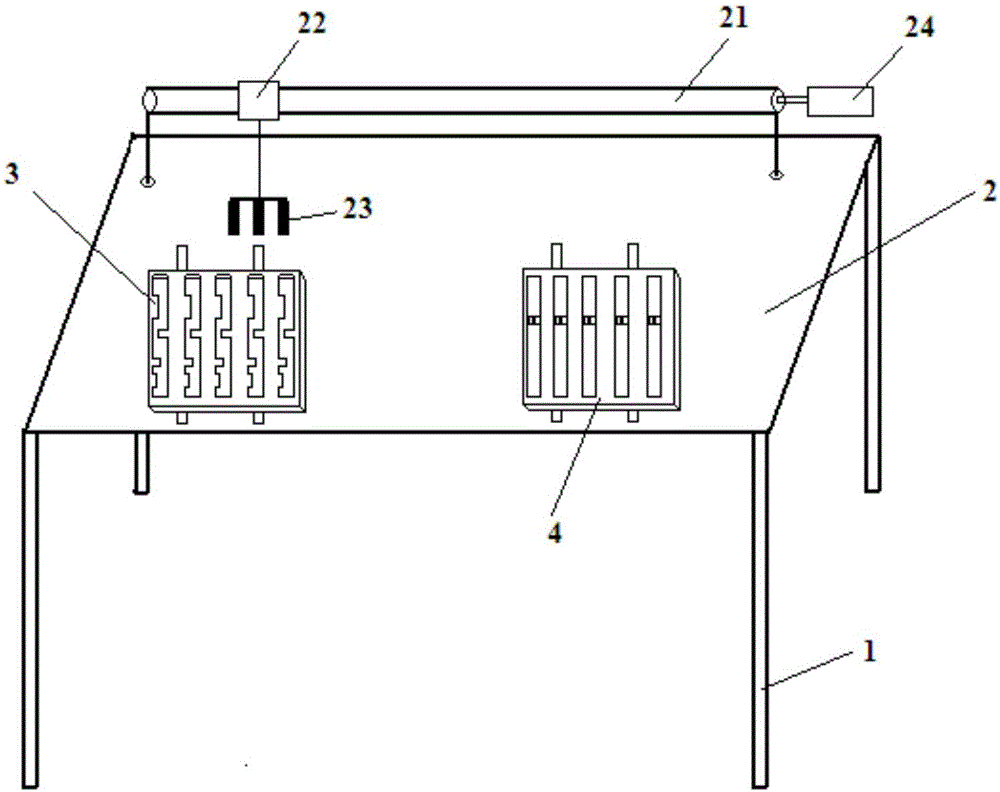

Material taking platform of conductive foam of antenna body

PendingCN106549219AImprove product qualitySimple structureRadiating elements structural formsEngineeringElectrical and Electronics engineering

Owner:HANGZHOU HAIZE ELECTRONICS TECH CO LTD

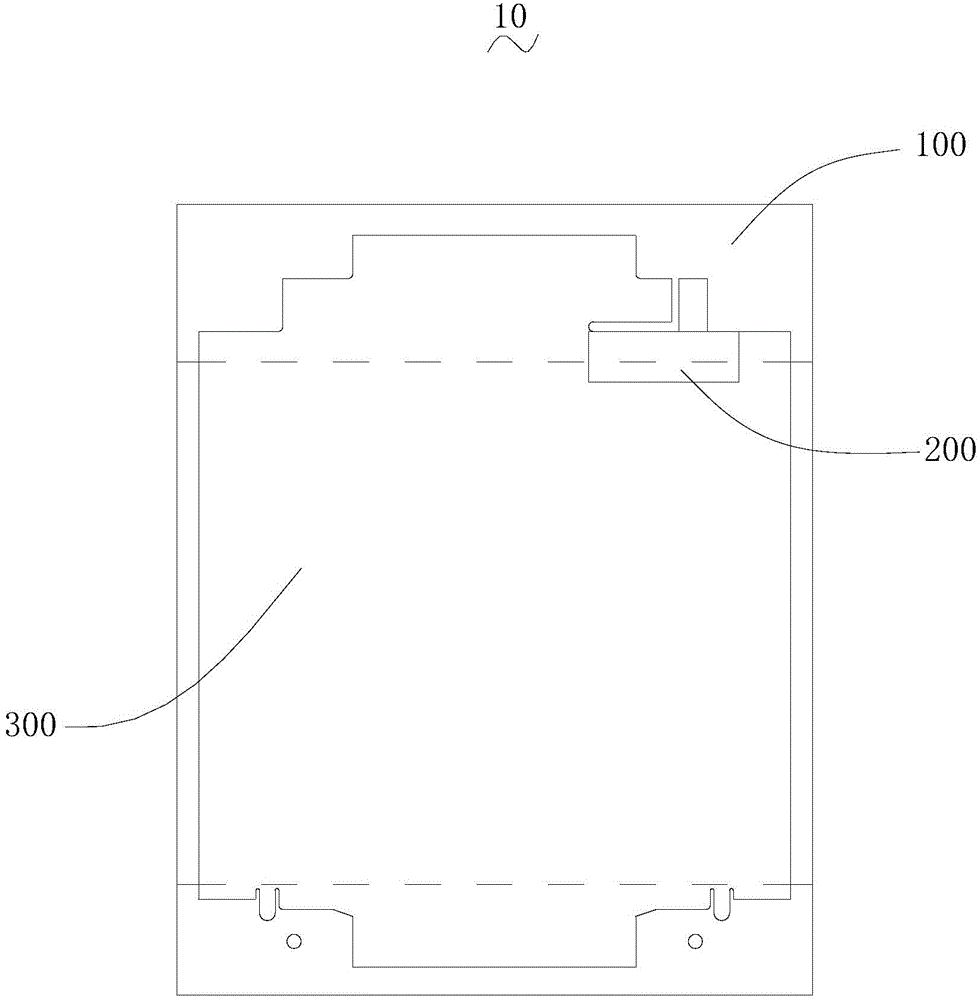

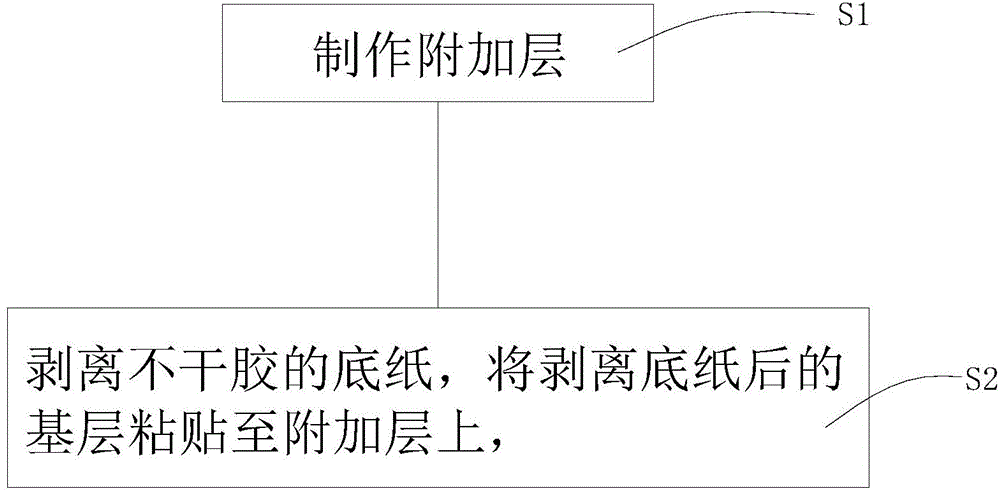

Label making method and label producing equipment

The invention relates to a label making method and label producing equipment. The method comprises the following steps of providing an adhesive sticker and an additional layer, wherein the adhesive sticker is provided with a base layer and a piece of backing paper which are arranged in an overlapping way, the additional layer is provided with an interlayer and a bottom layer which are arranged in an overlapping way, and the interlayer covers part of the bottom layer; stripping the backing paper of the adhesive sticker to expose the base layer covered by the backing paper in the adhesive sticker; sticking the base layer onto the additional layer so as to enable the interlayer of the additional layer to be located between the base layer and the bottom layer and to cover part of the base layer. According to the label making method, the hardness and the strength of the local part of a label obtained through the method are enhanced, and when an object to be stuck is not smooth, the interlayer fills the unsmooth area, then the label is stuck more smoothly, and the depression of the object to be stuck is not easy to collapse and puncture. Therefore, the sticking object of the label obtained by applying the method is stronger in reliability and smoother to stick.

Owner:赛维精密科技(广东)有限公司

Device used for squeezing LED lamp

InactiveCN105114419APrevent fallingSpeed up the installation processFastening meansEngineeringLED lamp

The invention discloses a device used for squeezing an LED lamp. The device comprises a bottom plate. A plurality of threaded through holes are formed in the bottom plate, a first pulley installation plate and a second pulley installation plate parallel with the first pulley installation plate are arranged on the bottom plate, and pulleys are arranged between the first pulley installation plate and the second pulley installation plate. The device has the advantages that a panel is prevented from falling; the installation progress is accelerated; the installed panel can be smoothly pasted on a lamp box, and safety and attractiveness are improved.

Owner:重庆卡斯特模具有限公司

Compression roller tipping device and method

The invention discloses a compression roller tipping device and method and relates to the technical field of textile compression roller tipping. The compression roller tipping device comprises a rack;a placing groove is formed in the rack; a compression roller is partially exposed to the external part of the placing groove; a fixing mechanism is arranged on the rack; the compression roller tipping device further comprises an unwinding mechanism, a winding mechanism and a downward pressing mechanism; the unwinding mechanism comprises a support plate and a loop bar; a hinge joint rod is detachably connected with the two ends of the loop bar; the end, far away from the loop bar, of the hinge joint rod is hinged to the support plate; the winding mechanism comprises a rotary shaft and idler wheels fixedly connected with the two ends of the rotary shaft; one end of a sealing strip is fixedly connected with the rotary shaft; the winding mechanism further comprises a connecting rod rotatablyconnected with the rotary shaft; one end of the connecting rod is fixedly connected with the support plate; the downward pressing mechanism comprises a downward pressing plate and balls rotatably mounted on the downward pressing plate; and the balls are in rolling connection with antiskid cloth adhered to the compression roller. The compression roller tipping device improves the problem that the antiskid cloth wrapping the compression roller is not flat.

Owner:福建豪丰纺织有限公司

Packaging tape installer

Owner:RUYUAN NANLING INTELLIGENT HOUSEHOLD MACHINERY CO LTD

Flatly pasted floor covering film

InactiveCN110330903AEasy to remove and replaceEasy to squeeze outFilm/foil adhesivesSurface layerAdhesive

The invention relates to a decorative material, in particular to a flatly pasted floor covering film. The flatly pasted floor covering film comprises a surface layer, an adhesive layer and a base layer. The adhesive layer is formed by an adhesive distributed between the surface layer and the base layer, and gaps are left among the adhesive. The flatly pasted floor covering film provided by the invention has the advantages of convenient pasting, flat pasting, no blistering, convenient tear and replacement, and no residual adhesive.

Owner:广东省大匠科技发展有限公司

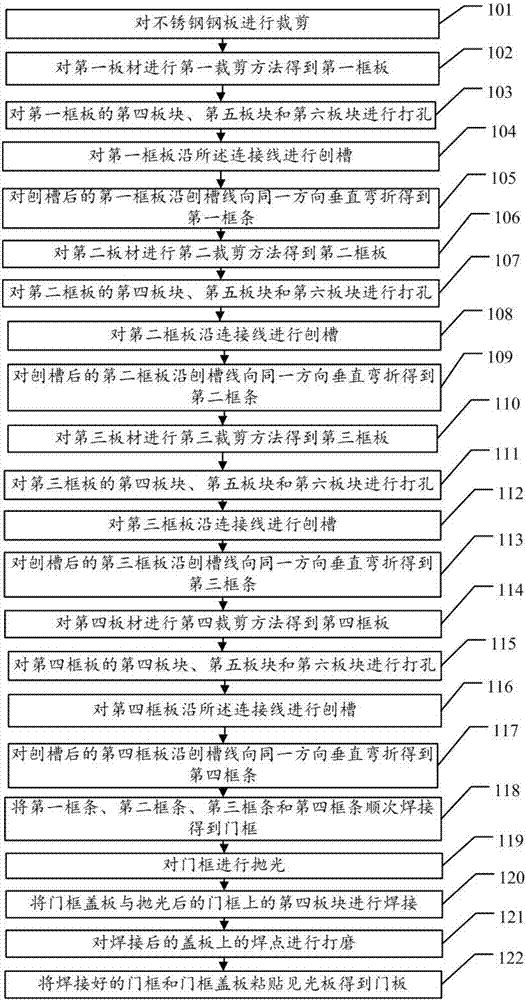

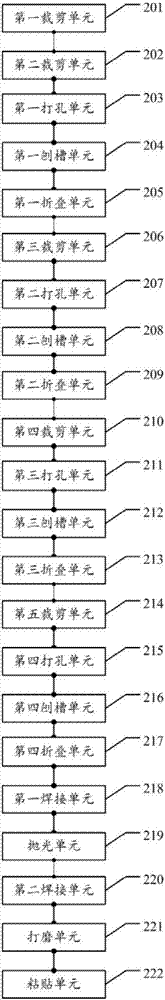

Method and system for processing glass door panels

The invention discloses a glass door plank machining method and system and provides a manufacturing technique of a frameless stainless steel glass door plank. The machining technique for manufacturing a frameless glass door plank through stainless steel and the 45-degree splicing manufacturing technique are achieved. The glass door plank machining method comprises the steps that S1, a stainless steel plate is cut, and a first plate, a second plate, a third plate and a fourth plate are obtained; S2, a first cutting method is conducted on the first plate, a first frame plate is obtained, and the first frame plate comprises a first board, a second board, a third board, a fourth board, a fifth board and a sixth board; S3, the fourth board, the fifth board and the sixth board of the first frame plate are punched; S4, dadoing is conducted on the first frame plate along connection lines; and S5, the first frame plate subjected to dadoing is bent perpendicularly along a dadoing line in the same direction, and a first frame strip is obtained.

Owner:沈奕荣

Extrusion device for LED lamps

InactiveCN105127671ASpeed up the installation processImprove securityMaterial gluingMetal working apparatusSurface platePulley

The invention discloses an extrusion device for LED lamps. The extrusion device comprises a bottom plate, wherein a first roller mounting plate and a second roller mounting plate which are parallel with each other are arranged on the bottom plate; a plurality of roller mounting bases are arranged between the first roller mounting plate and the second roller mounting plate; the roller mounting bases are fixed on the first roller mounting plate and the second roller mounting plate in a one-to-one correspondence manner respectively; rollers are arranged on the roller mounting bases; a first supporting plate and a second supporting plate are arranged on the bottom plate; the first roller mounting plate and the second roller mounting plate are located between the first supporting plate and the second supporting plate; the first roller mounting plate and the second supporting plate are fixed through two first screws; the second roller mounting plate and the first supporting plate are fixedly connected through two second screws. The extrusion device has the benefits as follows: panels are prevented from falling; the mounting progress is accelerated; the mounted panels can be flatly attached to lamp boxes, and the safety and the attractiveness are improved.

Owner:重庆卡斯特模具有限公司

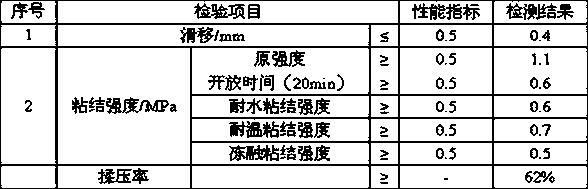

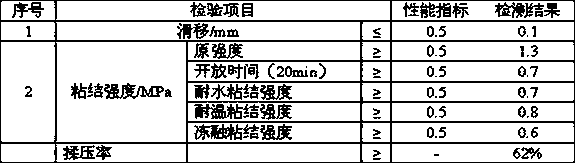

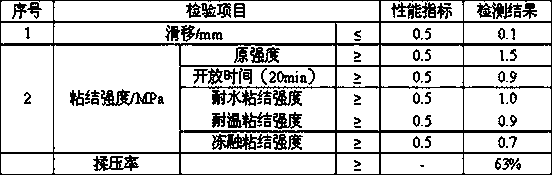

A kind of low elastic tile adhesive

The invention discloses a low-elasticity tile adhesive, belonging to the field of tile adhesives. The low-elasticity tile adhesive is prepared from the following components in parts by mass: 300-500 parts of Portland cement, 0-100 parts of calcium powder, 0-200 parts of 30-100-mesh quartz sand, 200-400 parts of 100-180-mesh quartz sand, 0-10 parts of an early strength agent, 1-3 parts of hydroxypropyl methyl cellulose, 1-5 parts of guar gum ether, 0-2 parts of starch ether, 4-10 parts of a magnesium aluminum silicate thixotropic thickener and 5-20 parts of redispersible latex powder. According to the low-elasticity tile adhesive, the mixing amount of hydroxypropyl methyl cellulose is reduced, and the guar gum ether, the starch ether and the magnesium aluminum silicate thixotropic thickener are added, so that the cohesion and elasticity of tile adhesive slurry are greatly reduced when the primary excellent water retention capacity of the tile adhesive is guaranteed, the contradiction between the low elasticity and high water retention capacity is solved, the construction and the rolling are easy, the adhesion is flat, the hollowing is unlikely to occur, and the adhesion quality of tiles is improved.

Owner:西卡(上海)管理有限公司

Reflecting material paste

InactiveCN103317782AIngenious ideaSimple structurePaper/cardboard layered productsComposite material

The invention discloses a reflecting material paste which comprises flexible reflecting materials. The reflecting material paste is characterized in that an adhesive sticker layer is coated at the reverse side of the flexible reflecting material, and the surface of the adhesive sticker layer is correspondingly provided with protecting body paper. The reflecting material paste is ingenious in concept, simple in structure and convenient to use; the reflecting material paste can be used for pasting smoothly and firmly by tearing off the protecting body paper; and besides, the paste can be used at any place, and convenience and safety are brought for people at night.

Owner:李琴

Assembly device and operation method for reducing axial eccentricity of tensile test piece

InactiveCN105508357BPaste tightlyPaste flatMaterial gluingElectrical and Electronics engineeringCement

The invention discloses an assembly device capable of reducing the axial eccentricity of a tensile sample, and an operation method. The assembly device comprises a sample assembly steel platform (1), two clamping devices (2), two pulling-jacking devices (3), two location rods (4) and two pressing devices (5), wherein the clamping devices (2) next to the two sides of the sample, and are fixed with the sample assembly steel platform by U-shaped clamps; each pulling-jacking device (3) is composed of a pulling-jacking screw rod and a pulling-jacking disc surface; the location rods (4) are fixed onto the sample assembly steel platform by connection gaskets and locking nuts; and the pressing devices (5) are fixed with the sample assembly steel platform by U-shaped clamps. According to the invention, steel sheets with circular holes are symmetrically bonded on the end parts of the tensile sample with a rectangular section, of a cement base, and loads are applied through shafts inserted in the circular holes. According to the invention, the position centring of the circular holes is ensured through operating the pulling-jacking devices (3) and the pressing devices (5), and the bonding materials are controlled to be uniform, so that the steel sheets are closely and flatly bonded on the surface of the sample, and then the axial eccentricity of tensile sample is reduced.

Owner:HUNAN UNIV

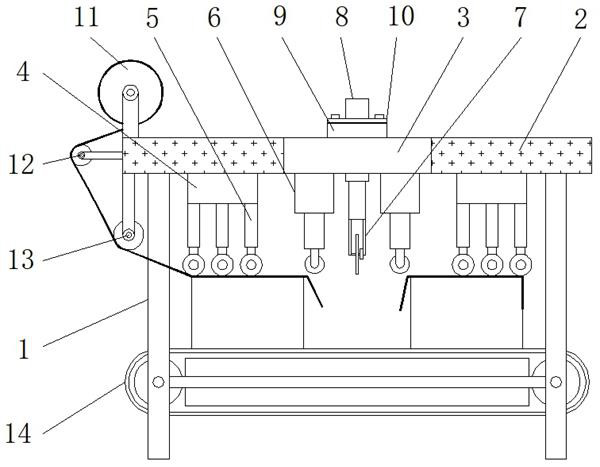

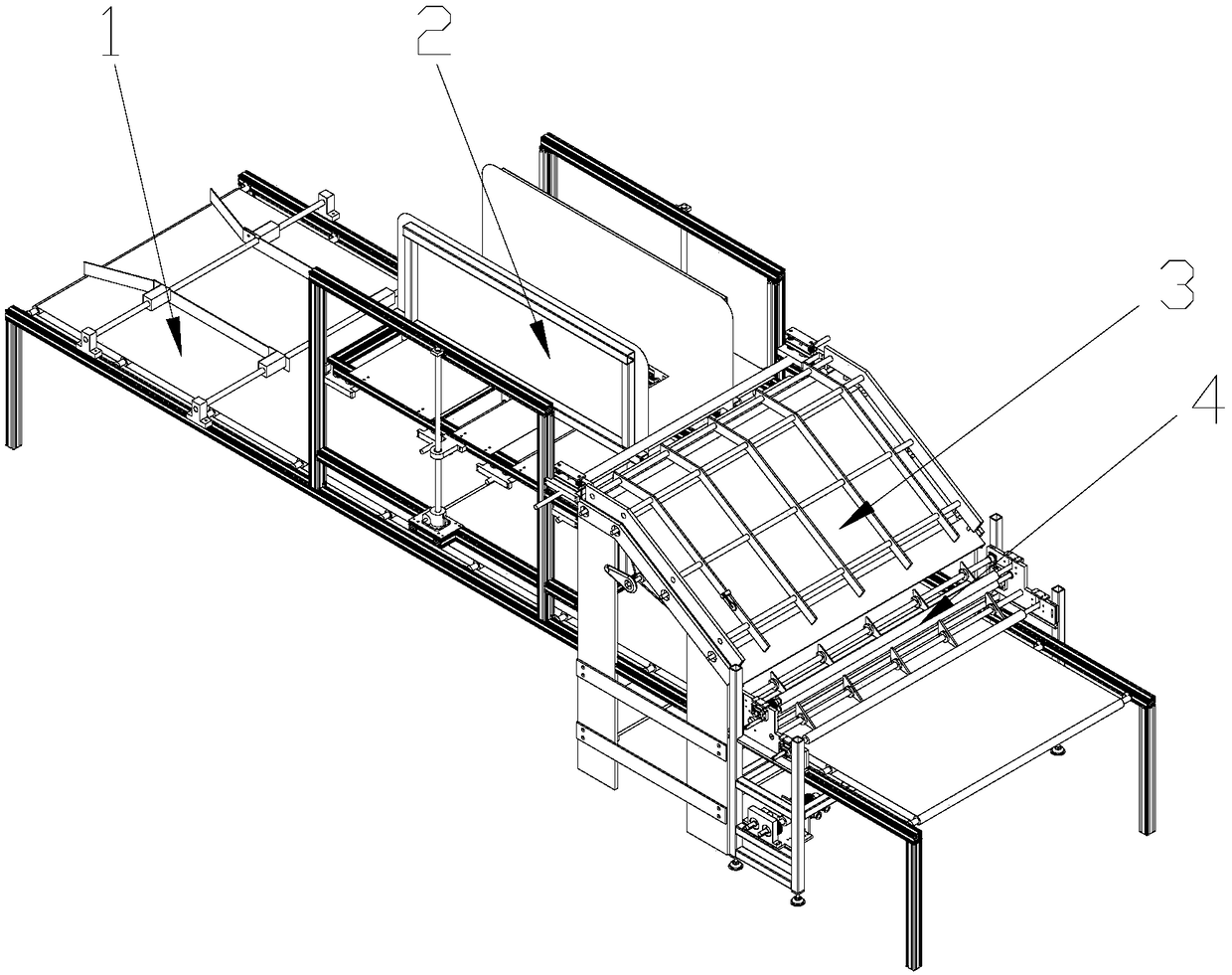

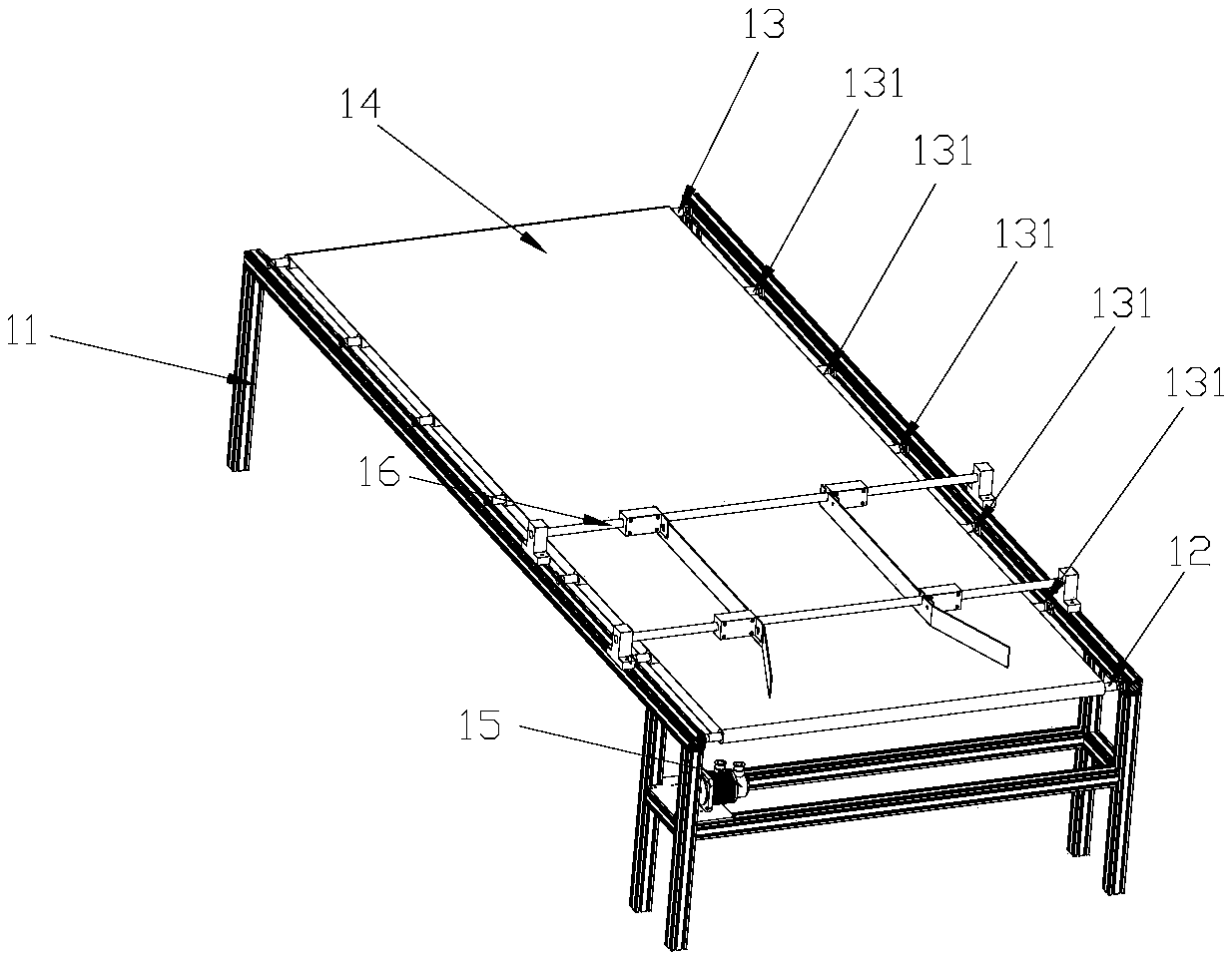

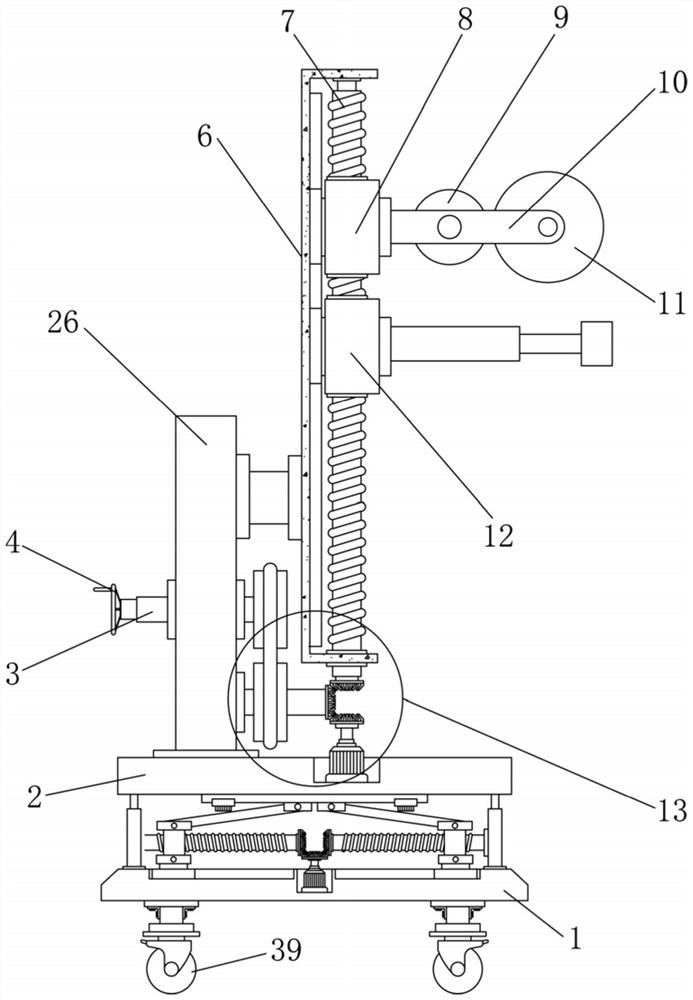

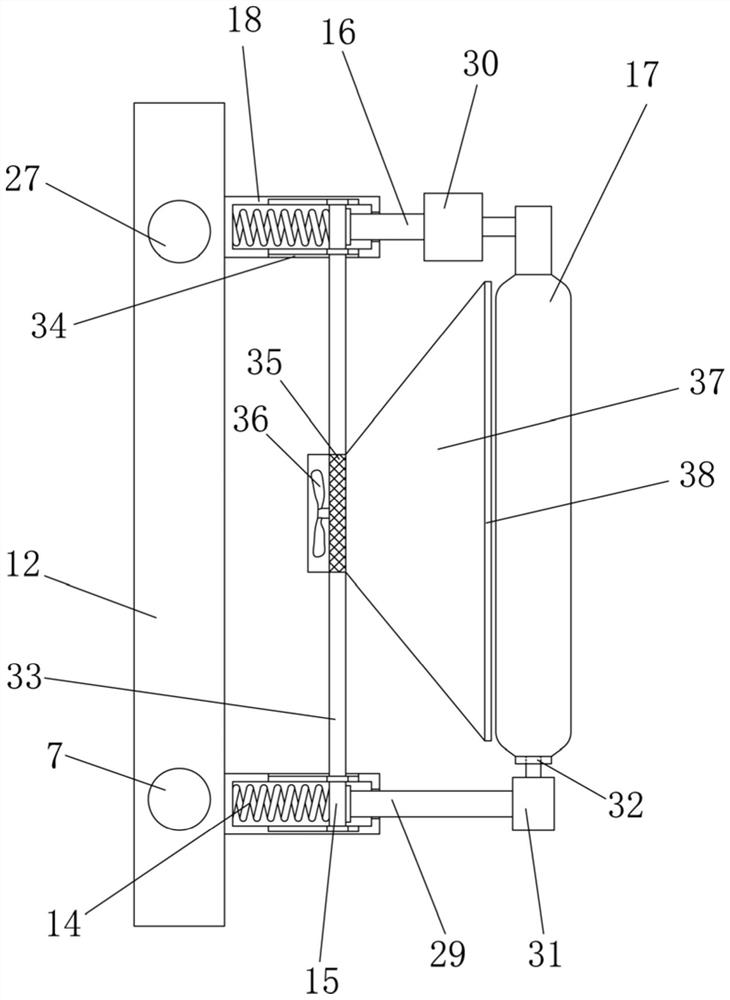

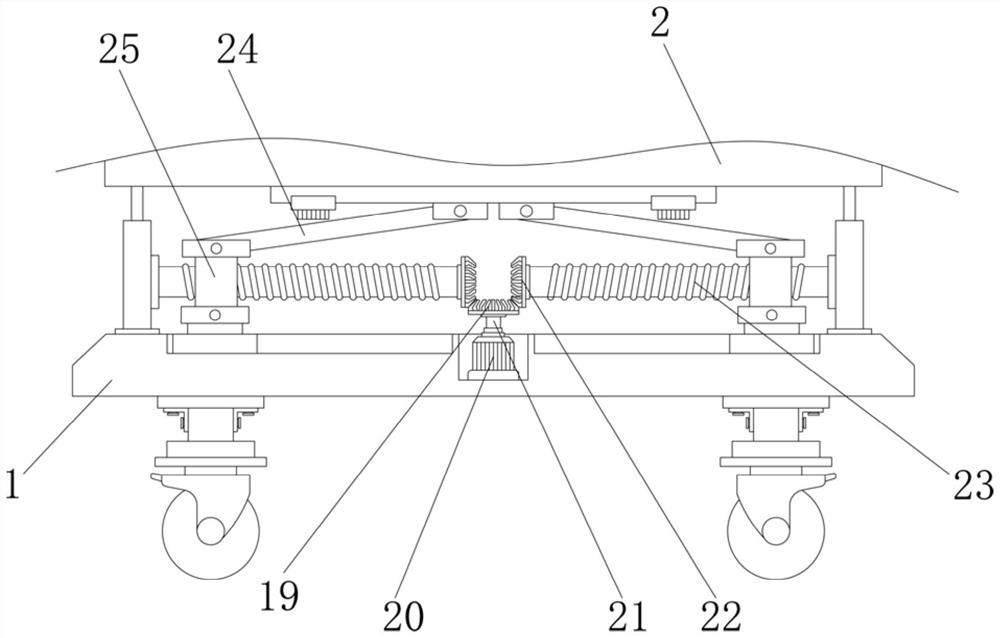

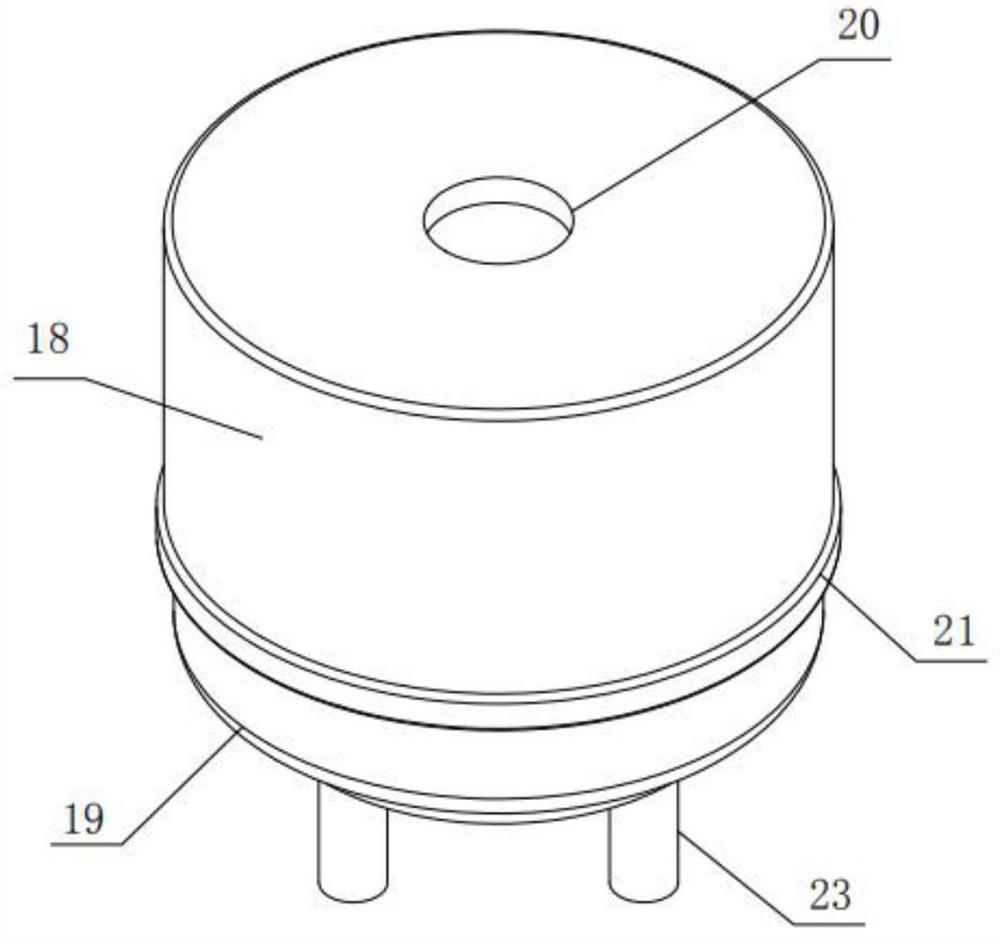

Wallpaper pasting device for building decoration

PendingCN112477500AImprove pasting effectIncrease the scope of applicationCarpet cleanersFloor cleanersBuilding renovationScrew thread

The invention discloses a wallpaper pasting device for building decoration. The wallpaper pasting device comprises a base (1) and a mounting table (2), wherein the mounting table (2) is connected to the upper part of the base (1) through a lifting mechanism; a mounting column (26) is fixed on the mounting table (2); a supporting frame (6) is fixed on one side of the mounting column (26); a threaded shaft (7) is rotationally connected to the top of the supporting frame (6); a first movable plate (8) and a second movable plate (12) are in threaded connection with the threaded shaft (7); guide columns (27) are arranged on the first movable plate (8) and the second movable plate (12) in a sliding and sleeving manner; the threaded shaft (7) and the guide columns (27) are arranged in parallel; and a mounting frame (10) is erected on the outer wall of one side of the first movable plate (8). According to the wallpaper pasting device, the pasting effect of the device is improved, the application range of the device to different wall heights is expanded, and the labor intensity of workers is reduced.

Owner:万永超

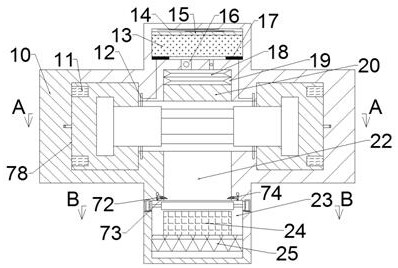

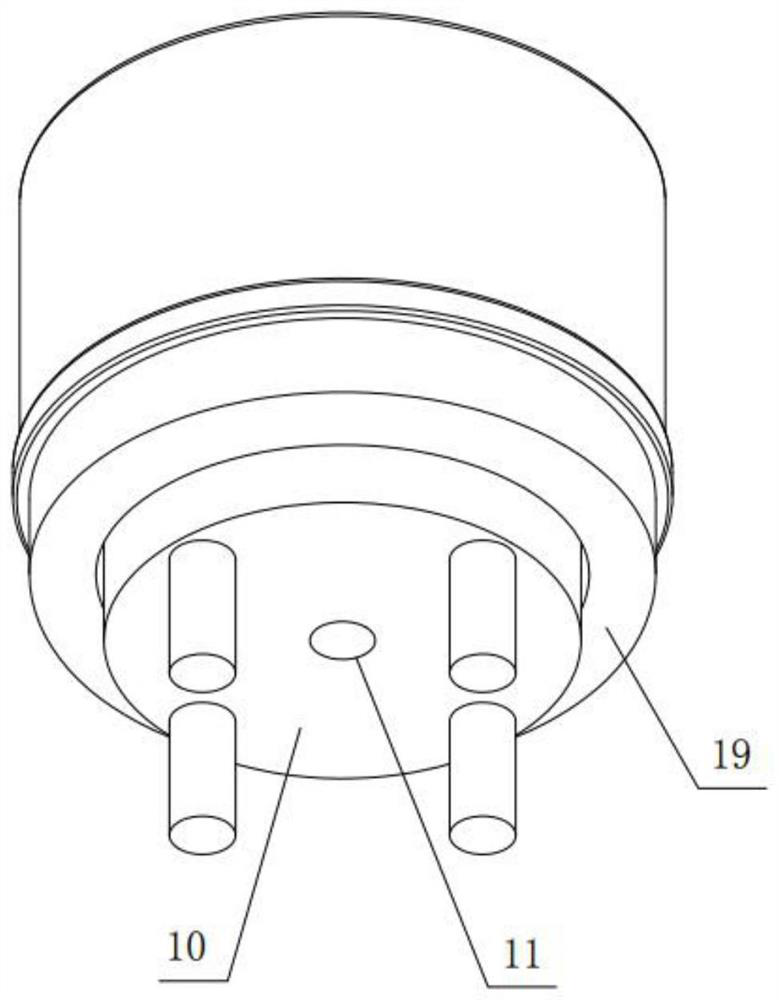

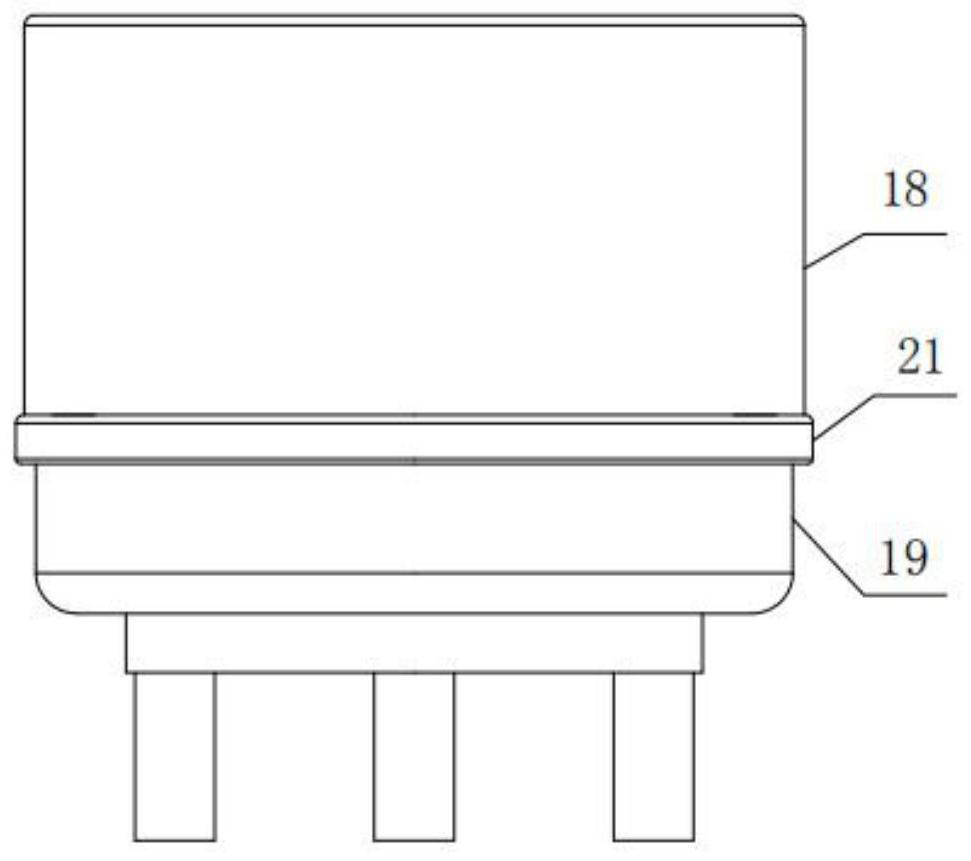

An air flotation device for optical device coupling and using method

ActiveCN113059267BGuaranteed performancePaste flatWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention discloses an air flotation device for optical device coupling, which comprises a support table, a ball seat, a floating ball, a compressed air joint and a vacuum joint. The support table is a cylindrical support table, and the inside of the support table has an installation cavity. The ball seat is a cylindrical structure, and the inner side wall of the ball seat is provided with an annular groove, and the side wall of the ball seat is symmetrically provided with a first air path and a second air path, both of which are Connected with the annular groove, the floating ball is movably embedded inside the upper end of the ball seat, and the top of the floating ball extends to the outside of the upper end of the ball seat, the top of the floating ball is provided with a horizontal plane, and the top of the floating ball is provided with a working position slot . The invention can conveniently make the bottom of the optical fiber socket and the two surfaces of the upper part of the semi-finished product of the optical device completely flat, avoid the existence of angles, the relative position of the optical port and the optical device will not change after welding, and effectively ensure the performance of the optical device.

Owner:深圳市亚微科技有限公司

Device for extruding LED lamp

InactiveCN105114417APrevent fallingSpeed up the installation processFastening meansEngineeringLED lamp

The invention discloses a device for extruding an LED lamp. The device comprises a bottom plate, a first pulley installing plate and a second pulley installing plate which are in parallel with each other are arranged on the bottom plate, and pulleys are arranged between the first pulley installing plate and the second pulley installing plate; a first support plate and a second support plate are vertical to the bottom plate; a shaft is arranged between the first support plate and the second support plate; the two ends of the shaft penetrate through the first support plate and the second support plate respectively; the shaft is sleeved with a rolling-compaction wheel. The device has the advantages that a panel is prevented from falling; the installation progress is accelerated; the installed panel can be attached to a lamp box flatly, the safety is improved, and the aesthetic effect is enhanced.

Owner:重庆卡斯特模具有限公司

Device for extruding LED lamp box

InactiveCN105114420ASpeed up the installation processPanel pasteFastening meansEngineeringLED lamp

The invention discloses a device for extruding an LED lamp box. The device comprises a bottom plate, a first pulley installing plate and a second pulley installing plate which are in parallel with each other are arranged on the bottom plate, and pulleys are arranged between the first pulley installing plate and the second pulley installing plate; a first support plate and a second support plate are arranged on the bottom plate, and the first pulley installing plate and the second pulley installing plate are located between the first support plate and the second support plate; the two ends of a shaft are in clearance fit with a first shaft hole and a second shaft hole and extend out of the first shaft hole and the second shaft hole; the shaft is sleeved with a rolling-compaction wheel, the minimum distance between the outer circumferential face of the rolling-compaction wheel and the corresponding pulley ranges from 10 cm to 40 cm, and the rolling-compaction wheel is located over the first pulley installing plate and the second pulley installing plate. The device has the advantages that a panel is prevented from falling; the installation progress is accelerated; the installed panel can be attached to a lamp box flatly, the safety is improved, and the aesthetic effect is enhanced.

Owner:重庆卡斯特模具有限公司

Manufacturing method of chip type alloy foil resistor

ActiveCN113571275AHigh accuracy of resistance valueSmall temperature coefficient of resistanceResistor manufacture by lithographyResistors adapted for applying terminalsAviationEtching

The invention discloses a manufacturing method of a chip type alloy foil resistor, and belongs to the technical field of alloy foil resistors. According to the present invention, by adopting a uniform hexamethyldisilazane process, the adhesive force of photoresist is improved, and the side etching of a foil is effectively reduced; the reliability is improved by adopting an aging process; the manufactured chip type alloy foil resistor is high in precision and small in resistance temperature coefficient; within a wider temperature coefficient range, the temperature coefficient is automatically compensated, a tracking temperature coefficient is extremely small, the noise is small, the stability is high, the high-frequency characteristic is good, the response is fast, and the distribution parameter is small; the method can be applied to precision measurement, digital-to-analog conversion, aviation and navigation inertial navigation systems, computer interface circuits and some systems with special requirements, and is suitable for large-scale popularization.

Owner:BDS ELECTRONICS

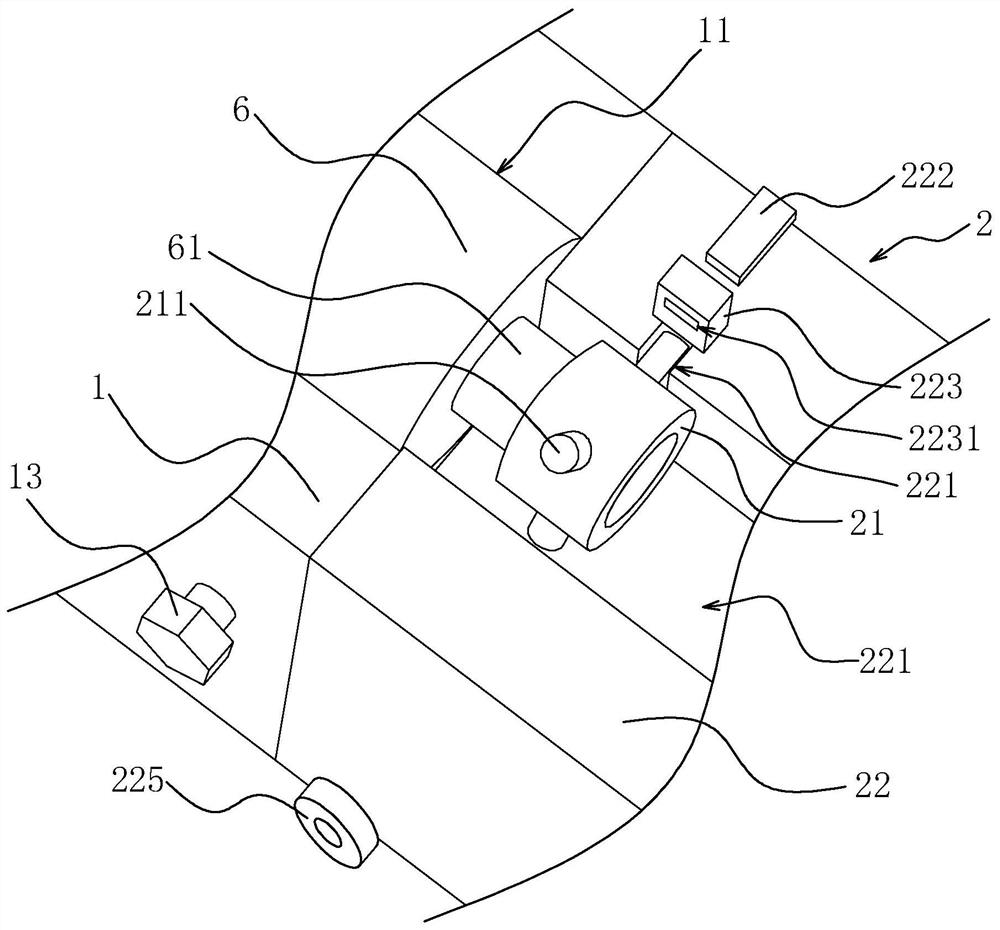

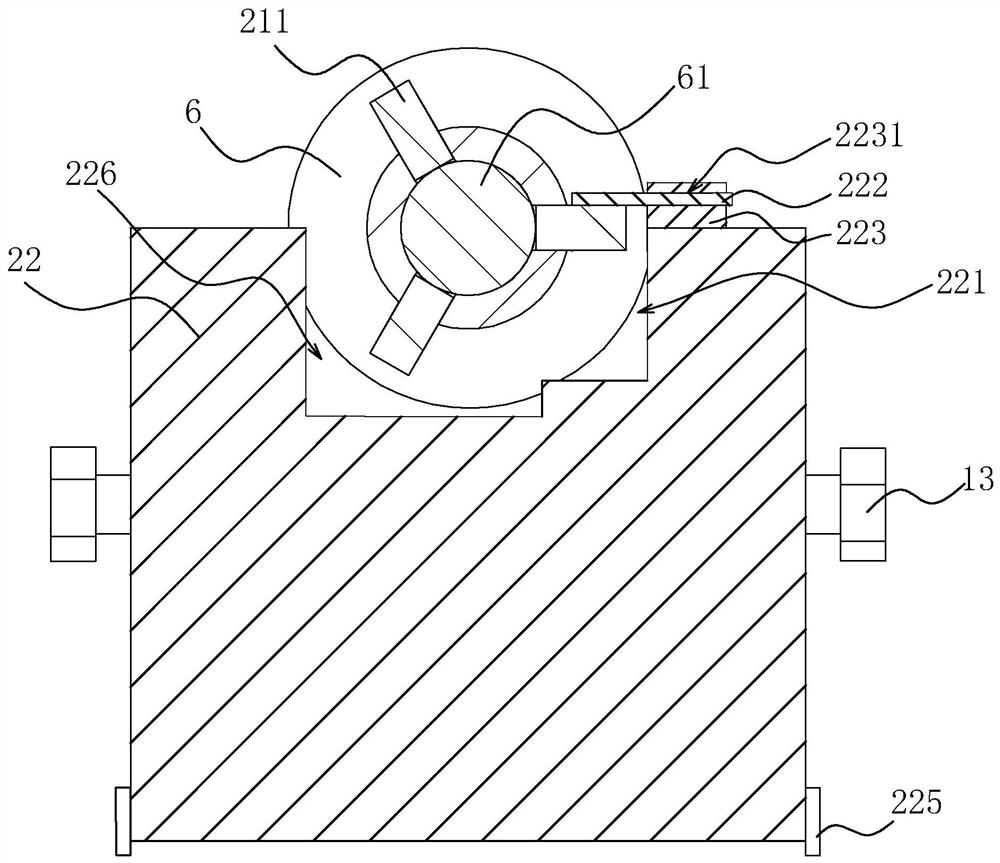

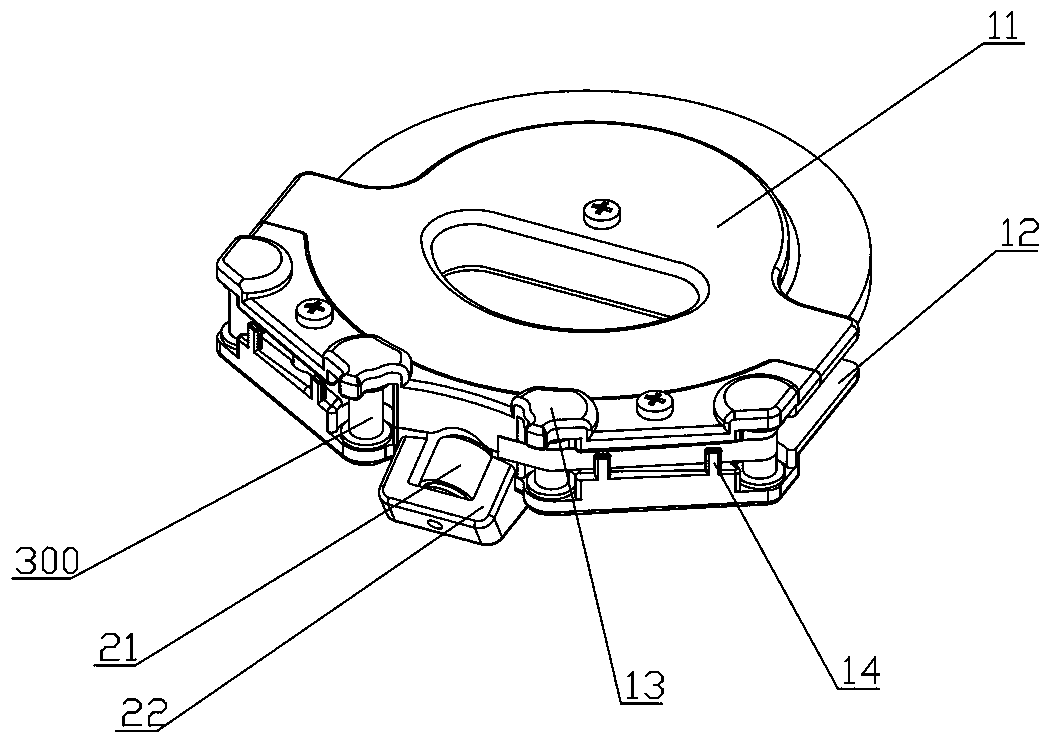

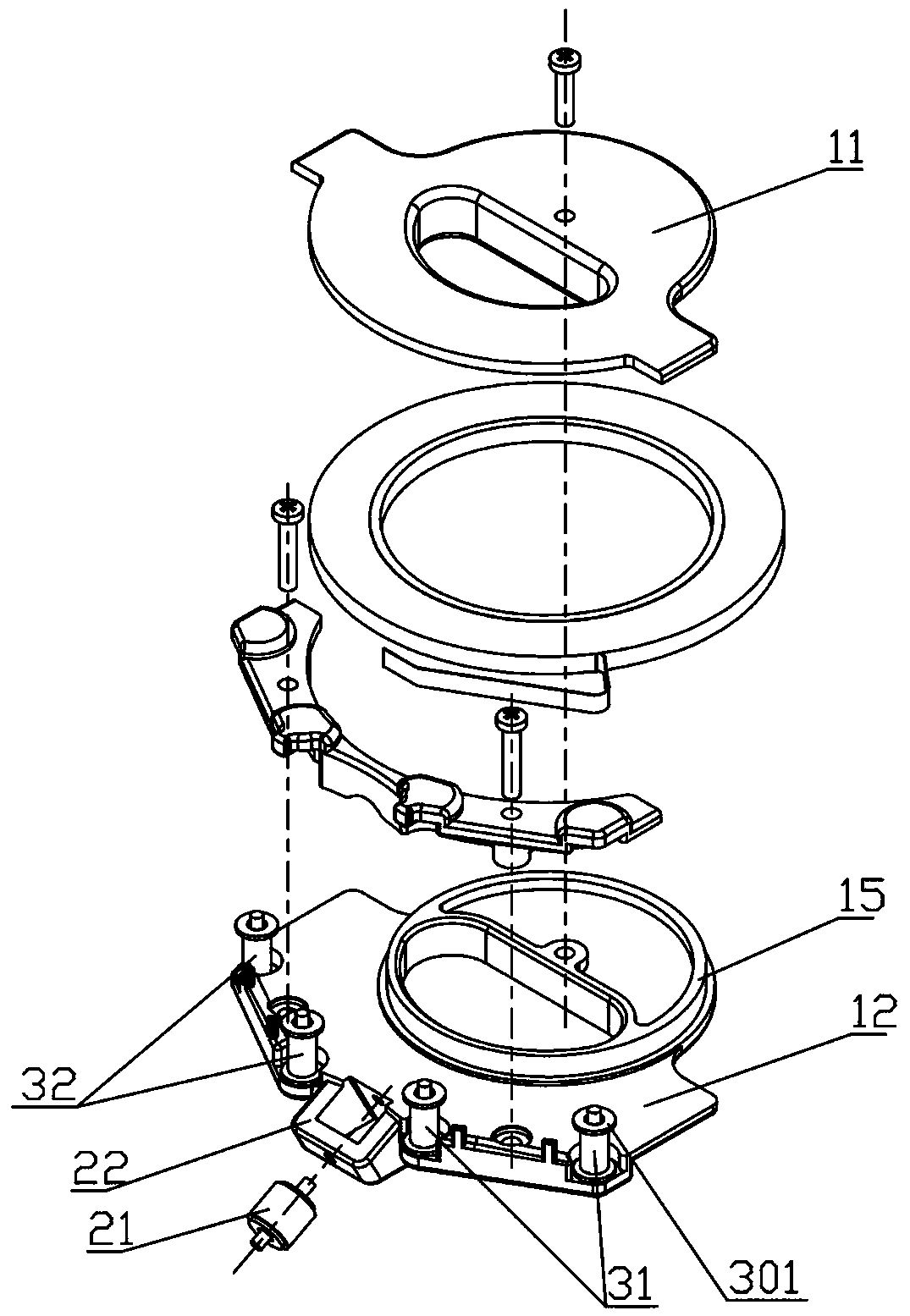

Automatic film applicator

ActiveCN104118600BPrecise positioningMake sure it is pasted flatPackagingEngineeringMechanical engineering

The invention discloses an automatic film pasting device. The automatic film pasting device is composed of an outer shell, a transmission device and a film pasting mechanism. A sliding accommodating disk for containing a mobile phone is arranged in a cavity of the outer shell. The transmission device drives a film pressing shaft and a film output shaft of the film pasting mechanism to rotate. A dust suction pipe of a dust collector is transversely arranged at an inlet portion between the film pressing shaft and the film output shaft to conduct micronic dust processing on the mobile phone. In the rotating process of the film pressing shaft and the film output shaft, the accommodating disk is forcibly driven to move forward, the film pressing shaft rolls a protective film onto the mobile phone, the film output shaft drives a roll shaft to rotate correspondingly to roll a clamped attachment film out of a cover body from a recovery port portion, and then pasting of the protective film and separation of the attachment film from the protective film are achieved synchronously.

Owner:广州美枫电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com