Patents

Literature

77results about "Resistor manufacture by lithography" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

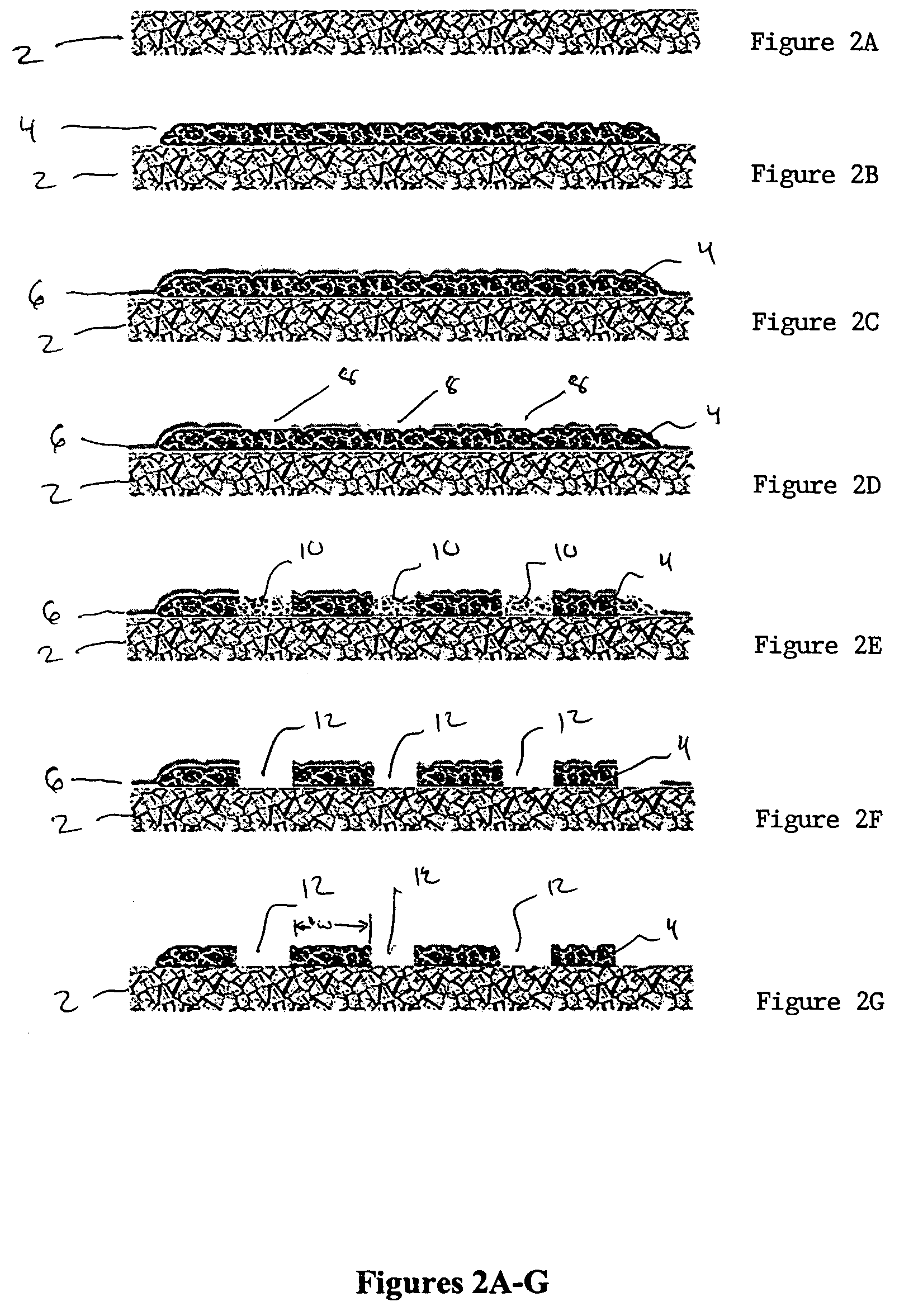

Heating elements deposited on a substrate and related method

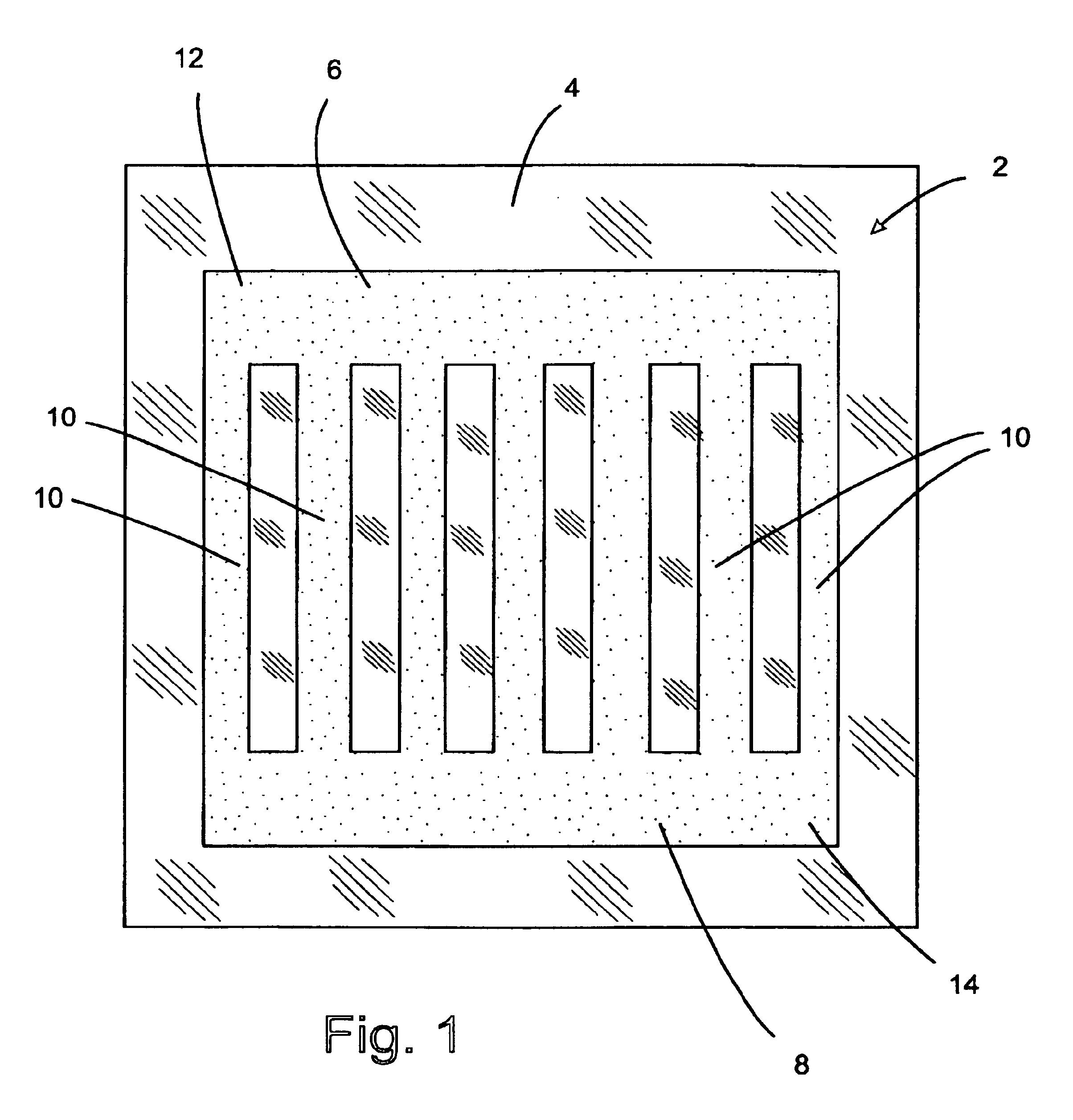

InactiveUS20050051536A1Overcome problemsFully curedResistor manufacture by lithographyHeating element shapesVolatile organic compoundElectrically conductive

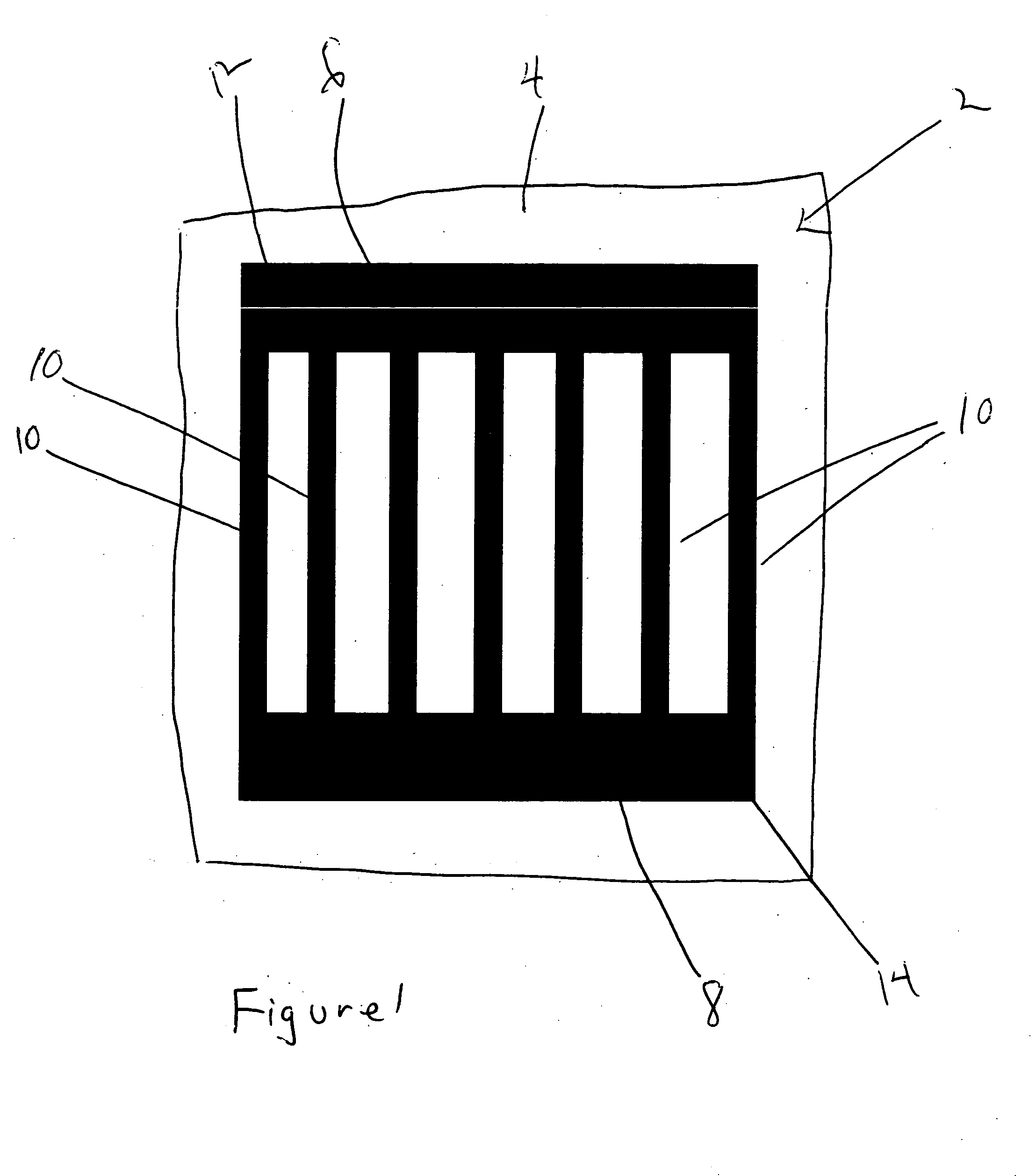

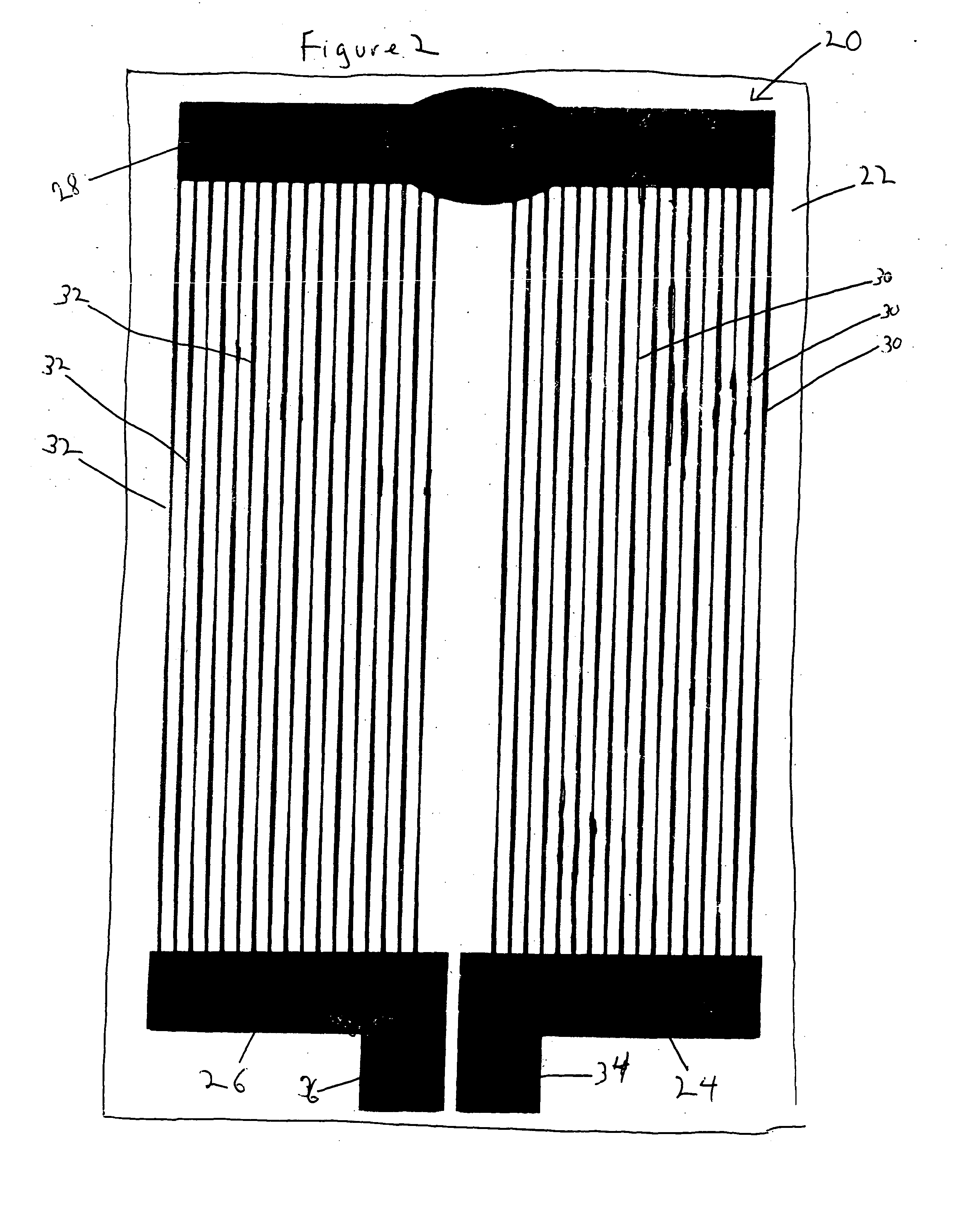

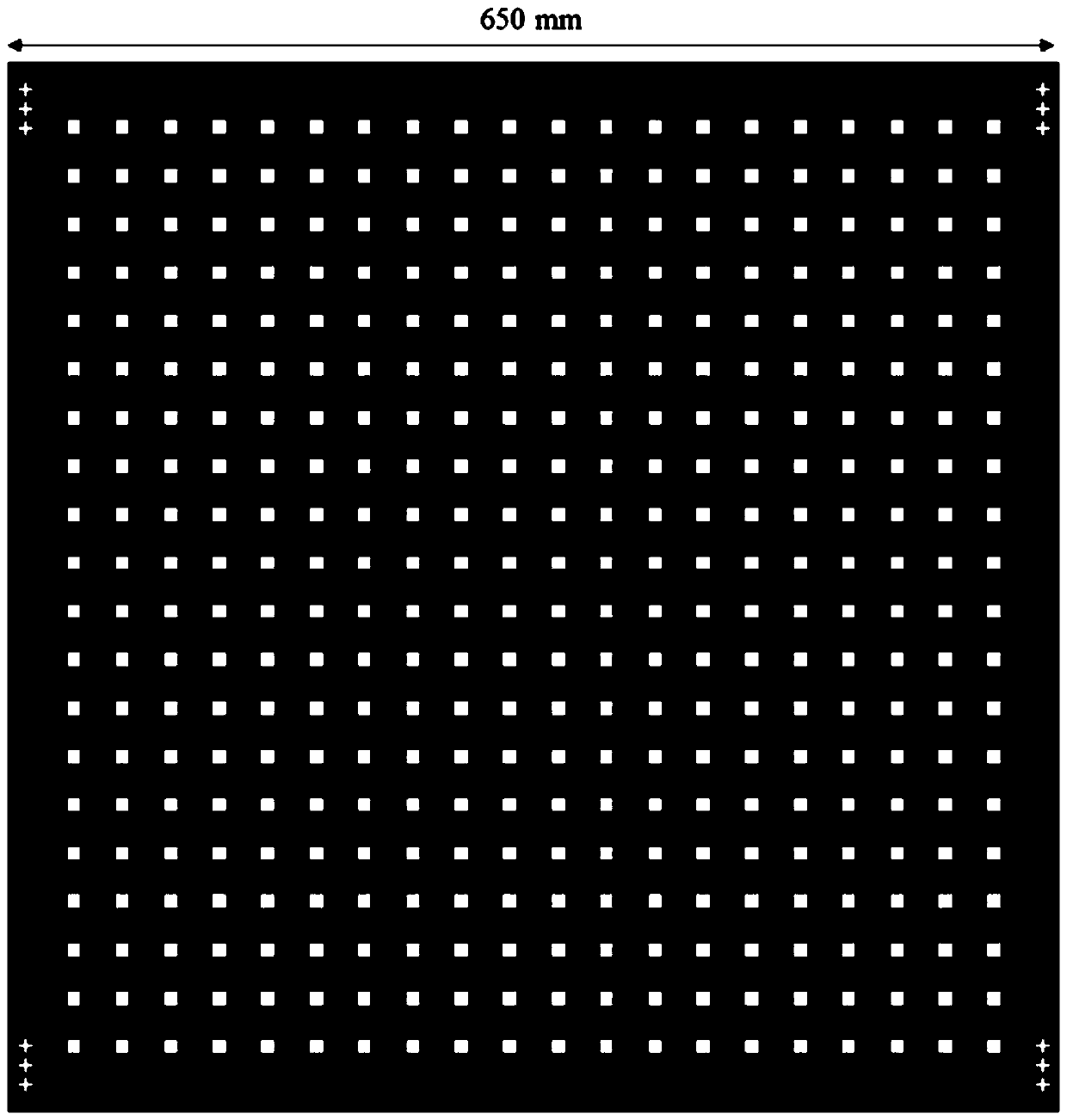

The present invention provides a method for making a heating element adhered to a substrate by applying a photocurable composition to a flexible substrate in a pattern having one or more grid lines. The photocurable composition is curable into an electrically conductive layer and volatile organic compounds are present in an amount of less than about 10% of the total weight of the photocurable composition. After the pattern is deposited on the substrate it is cured by illuminating the photocurable composition with light for a sufficient period of time to cure the photocurable composition. In another embodiment of the invention heating elements made by the method of the invention are provided.

Owner:KLAI ENTERPRISES

Heating elements deposited on a substrate and related method

InactiveUS6946628B2Resistor manufacture by lithographyHeating element shapesVolatile organic compoundElectrically conductive

A method for making a heating element adhered to a substrate by applying a photocurable composition to a flexible substrate in a pattern having one or more grid lines is provided. The photocurable composition is curable into an electrically conductive layer and volatile organic compounds are present in an amount of less than about 10% total weight of the photocurable composition. After the pattern is deposited on the substrate is cured by illuminating the photocurable composition with light for a sufficient period of time to cure the photocurable composition. Heating elements made by the method are also provided.

Owner:KLAI ENTERPRISES

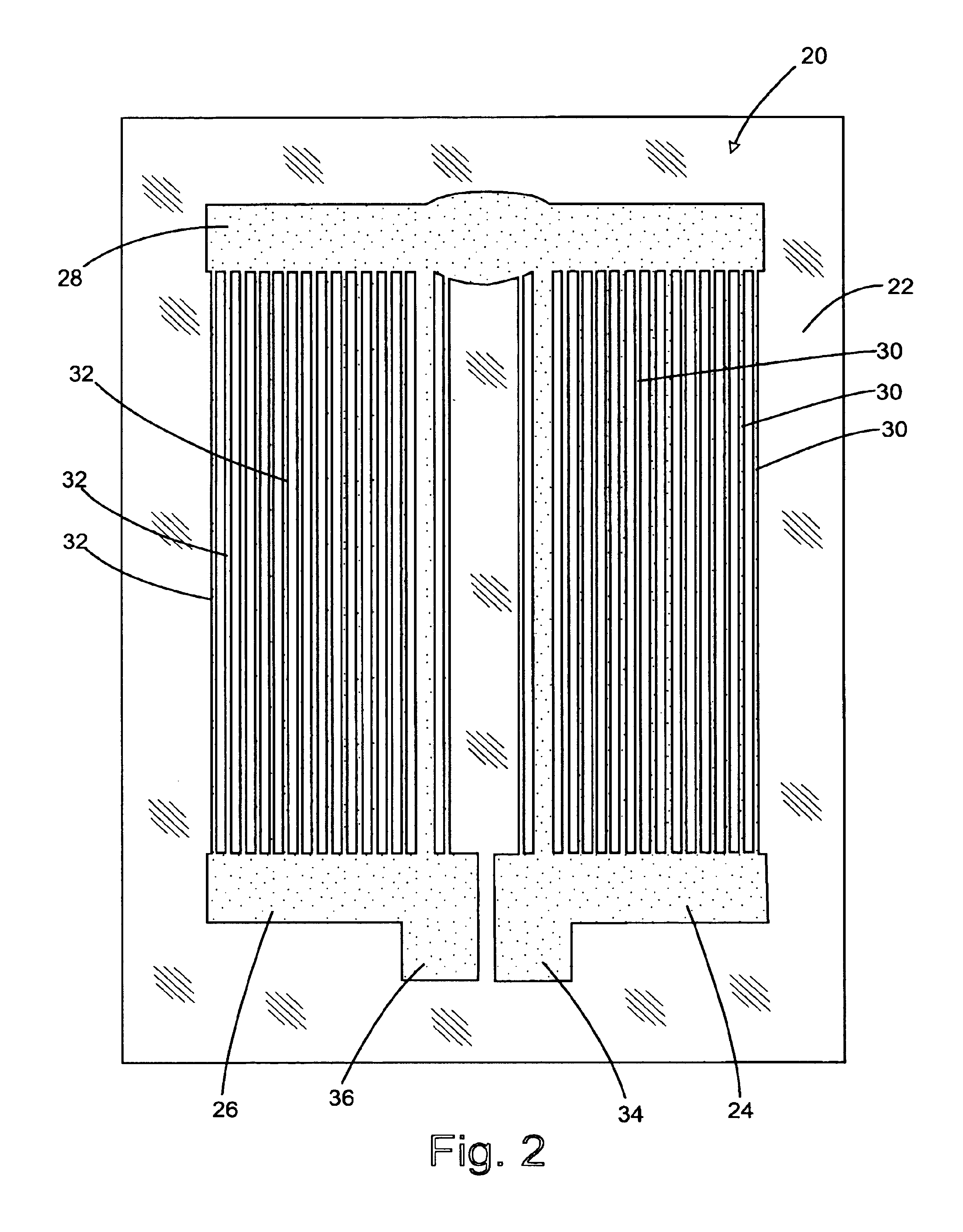

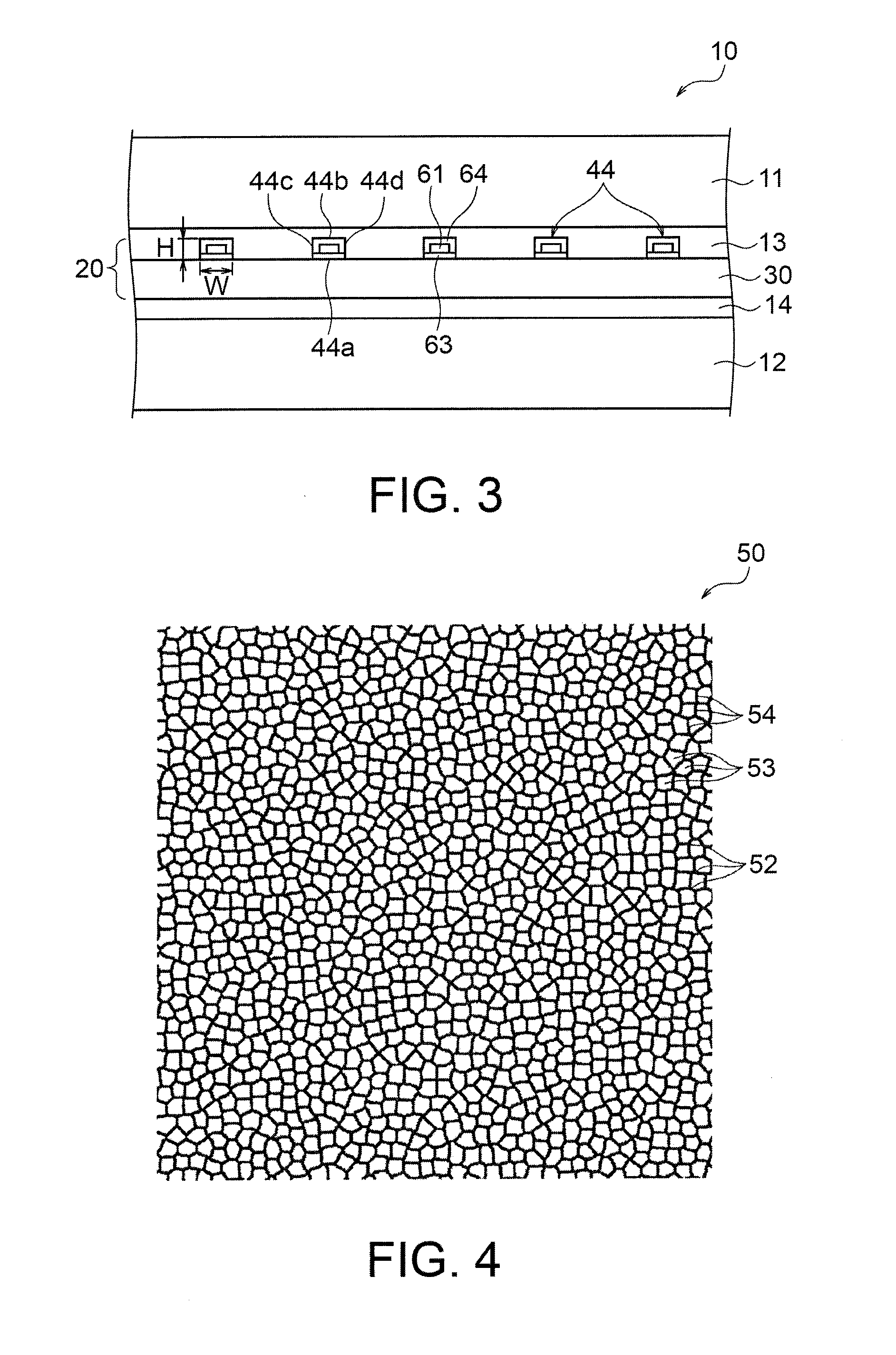

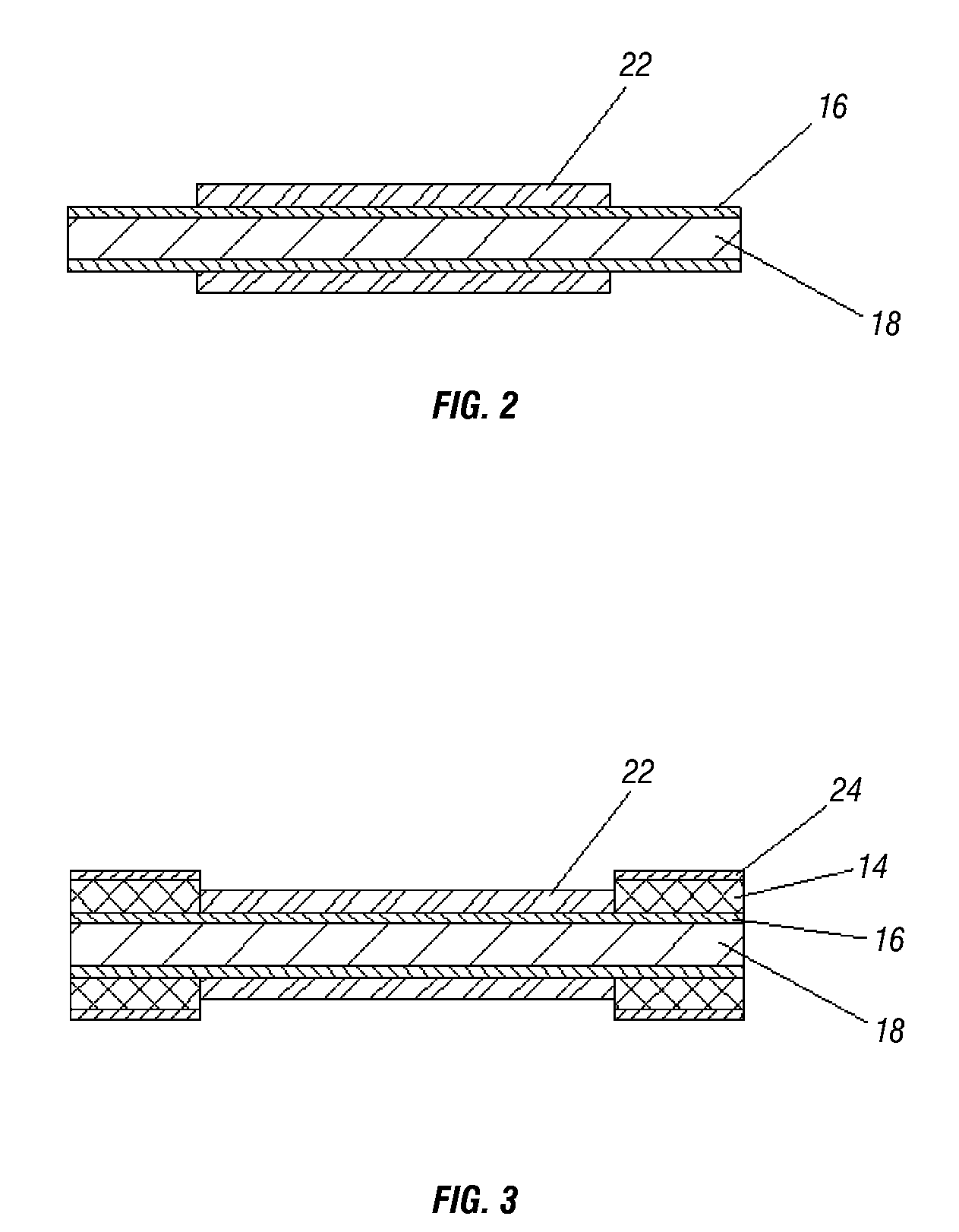

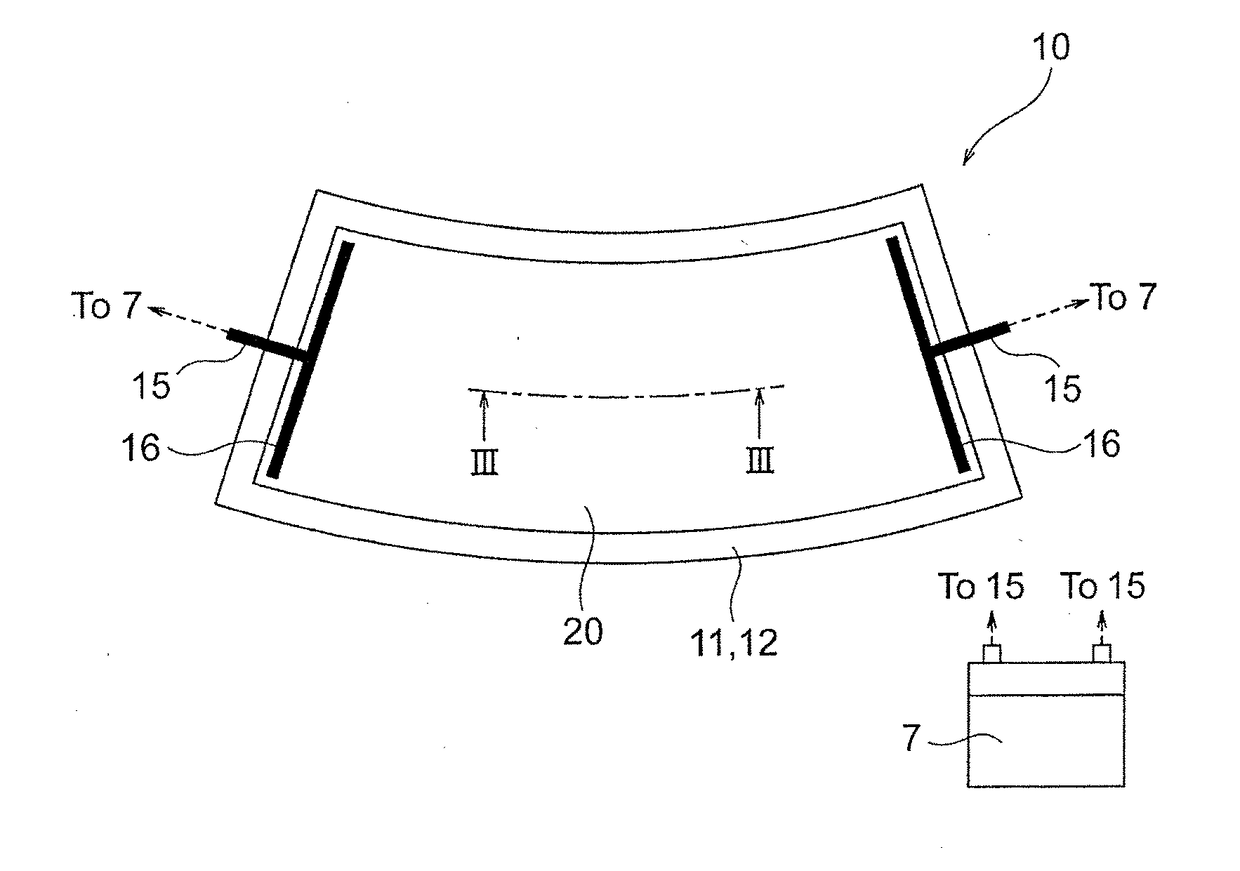

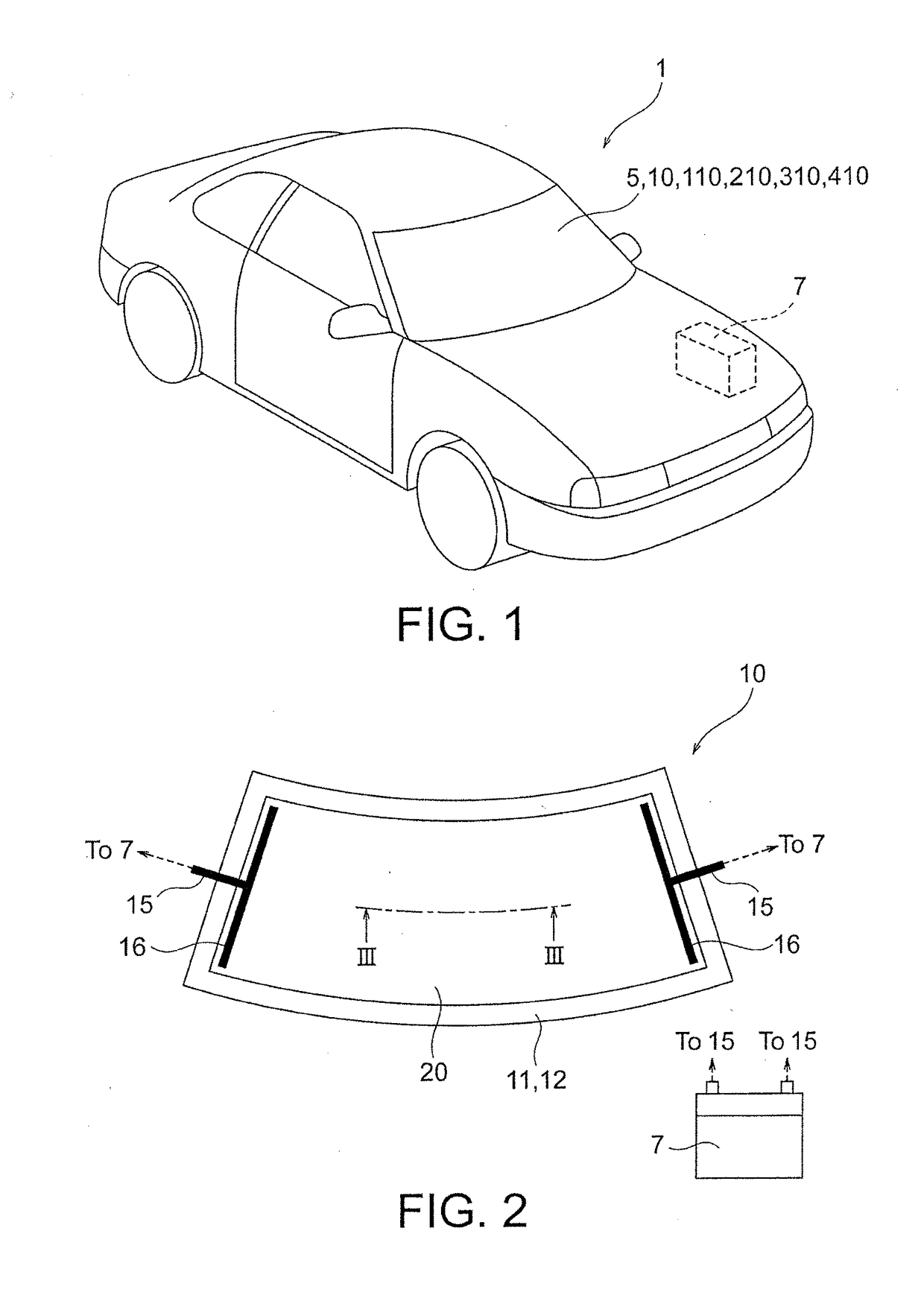

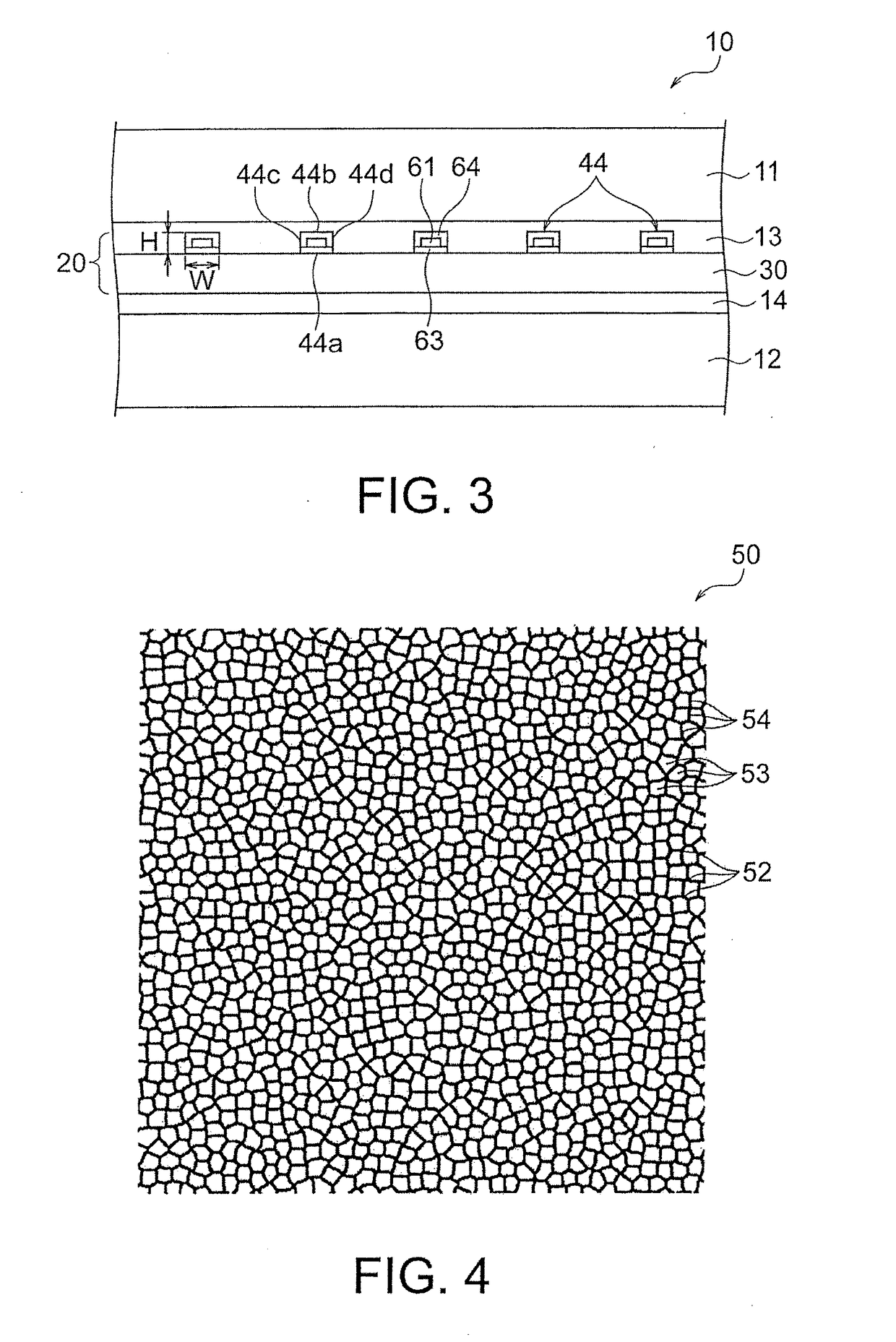

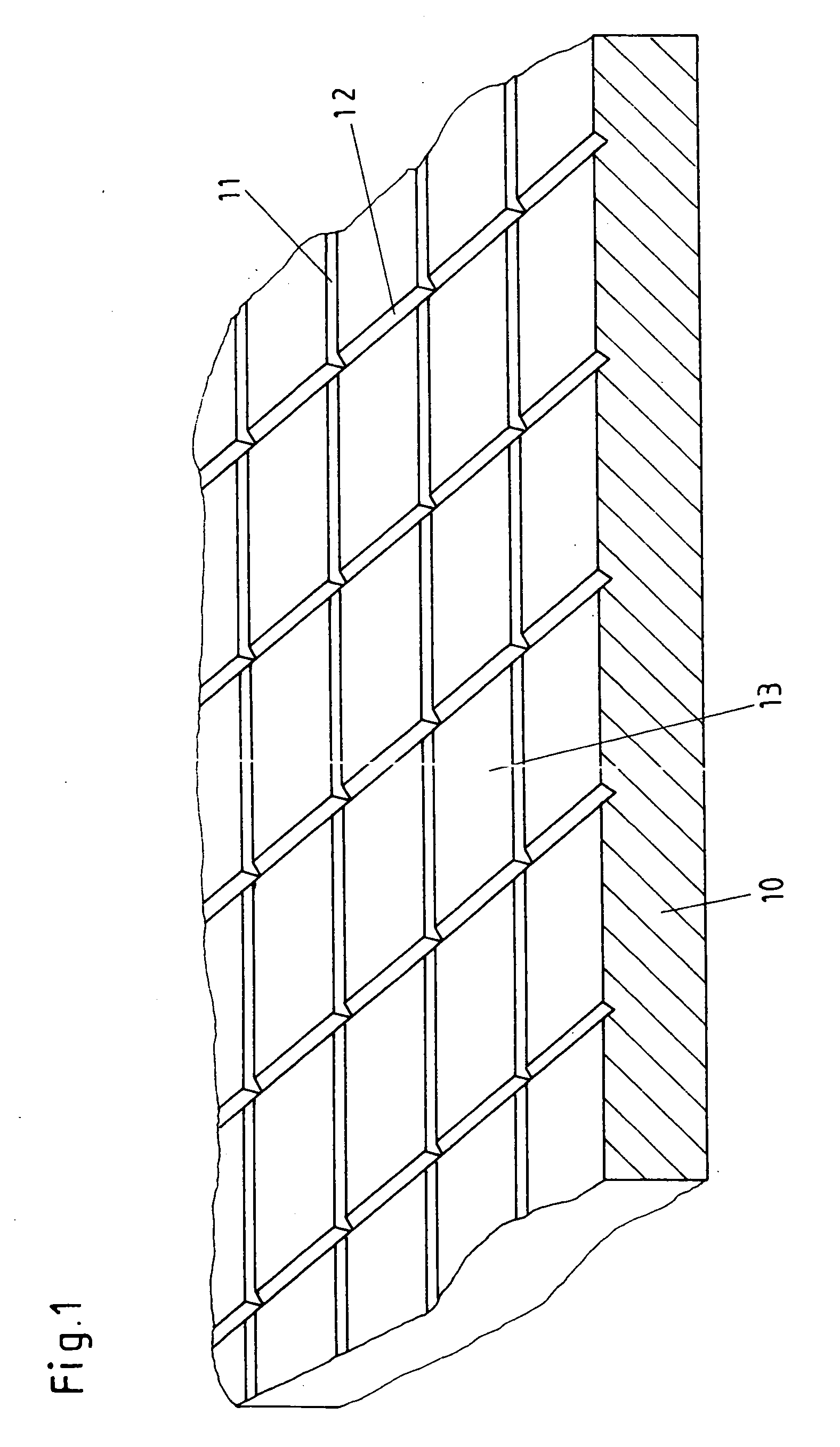

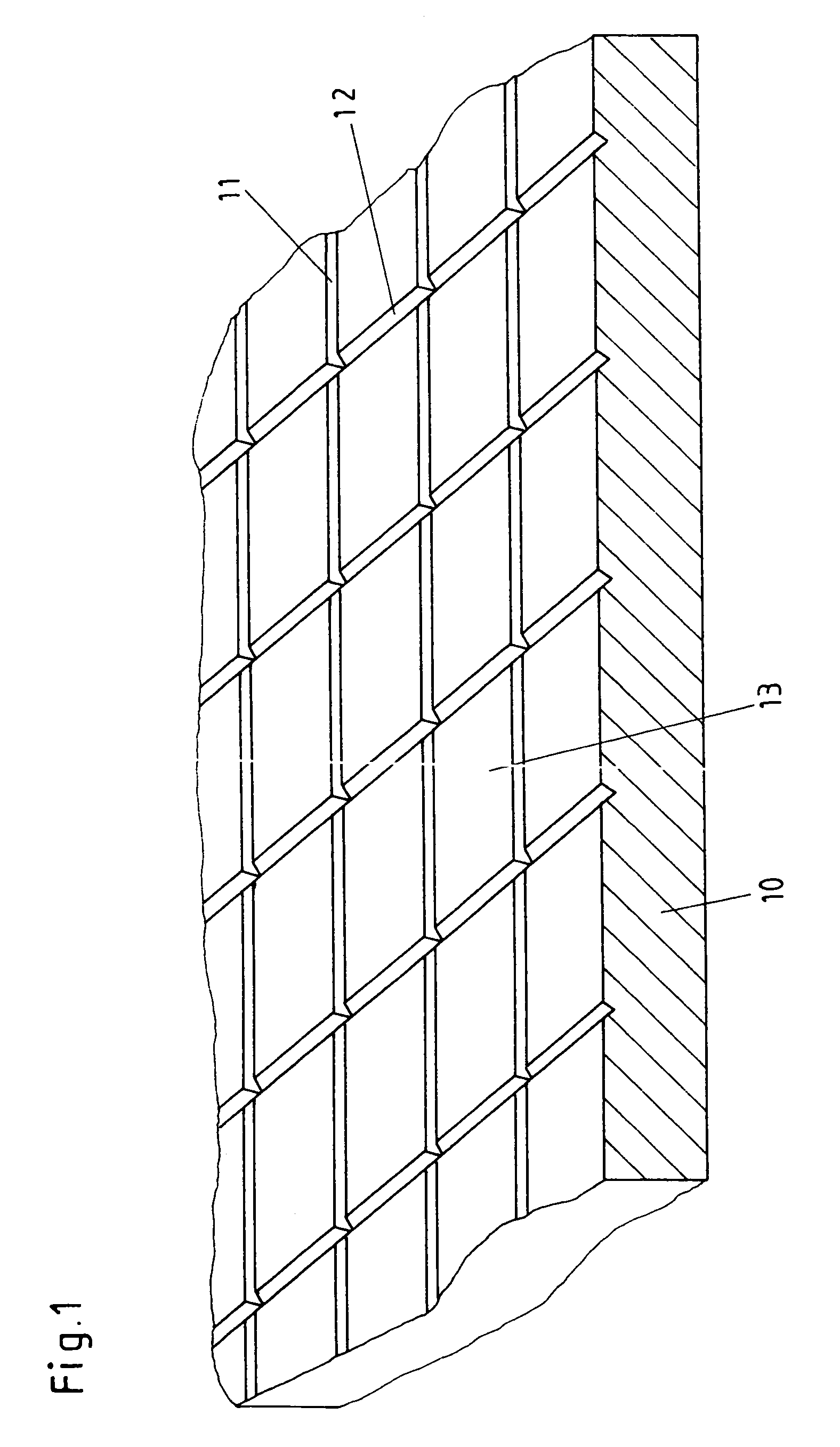

Heating plate, conductive pattern sheet, vehicle, and method of manufacturing heating plate

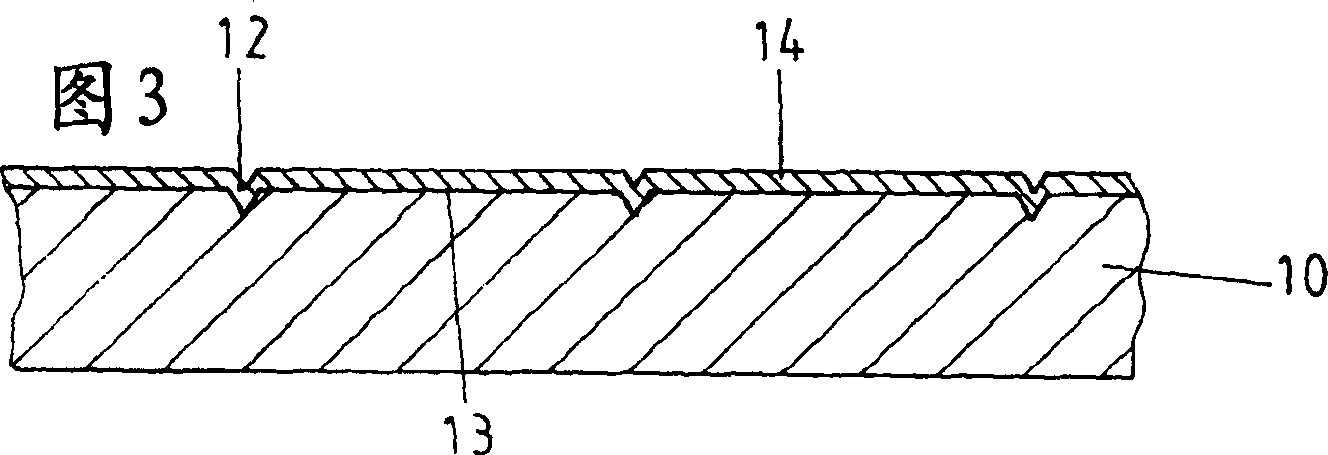

ActiveUS20160311402A1Avoid bubblingImprove stealth performanceResistor manufacture by lithographyTransparent/reflecting heating arrangementsGlass sheetLine segment

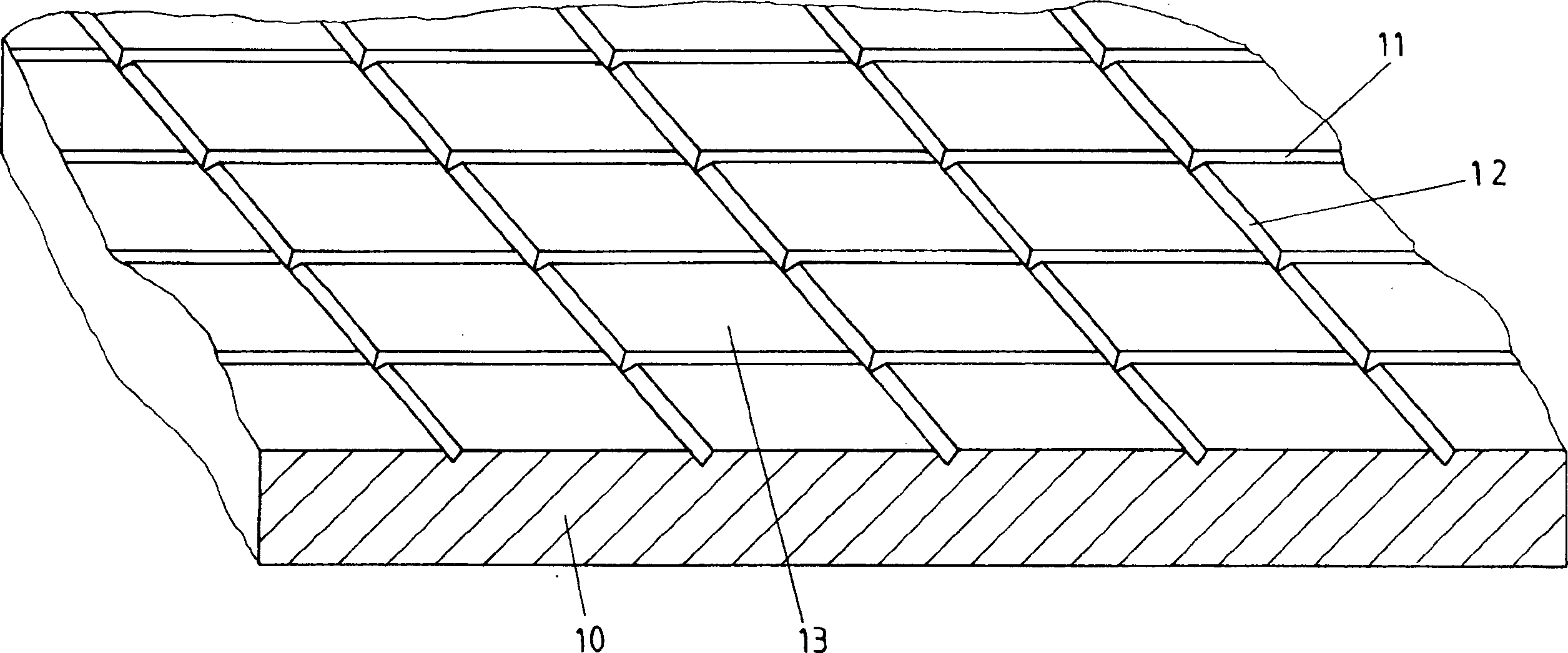

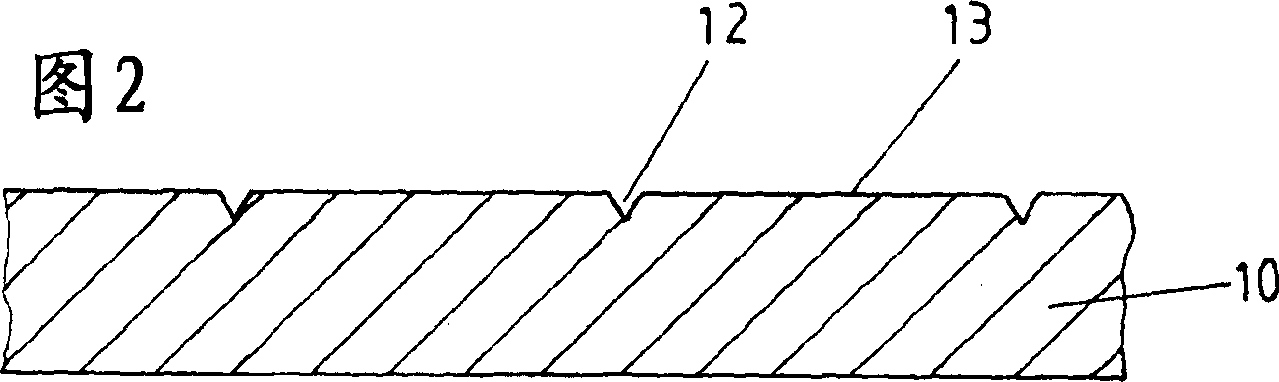

A heating plate 10 includes: a pair of glass plates 11, 12; a conductive pattern 40, 70 disposed between the pair of glass plates 11, 12 and defining a plurality of opening areas 43, 73; and a joint layer 13, 14 disposed between the conductive pattern 40, 70 and at least one of the pair of glass plates 11, 12; wherein the conductive pattern 40, 70 includes a plurality of connection elements 44, 74 that extend between two branch points 42, 72 to define the opening areas 43, 73; and a rate of the connection elements 44, 74, which are straight line segments connecting the two branch points 42, 72, relative to the plurality of connection elements 44, 74, is less than 20%.

Owner:DAI NIPPON PRINTING CO LTD

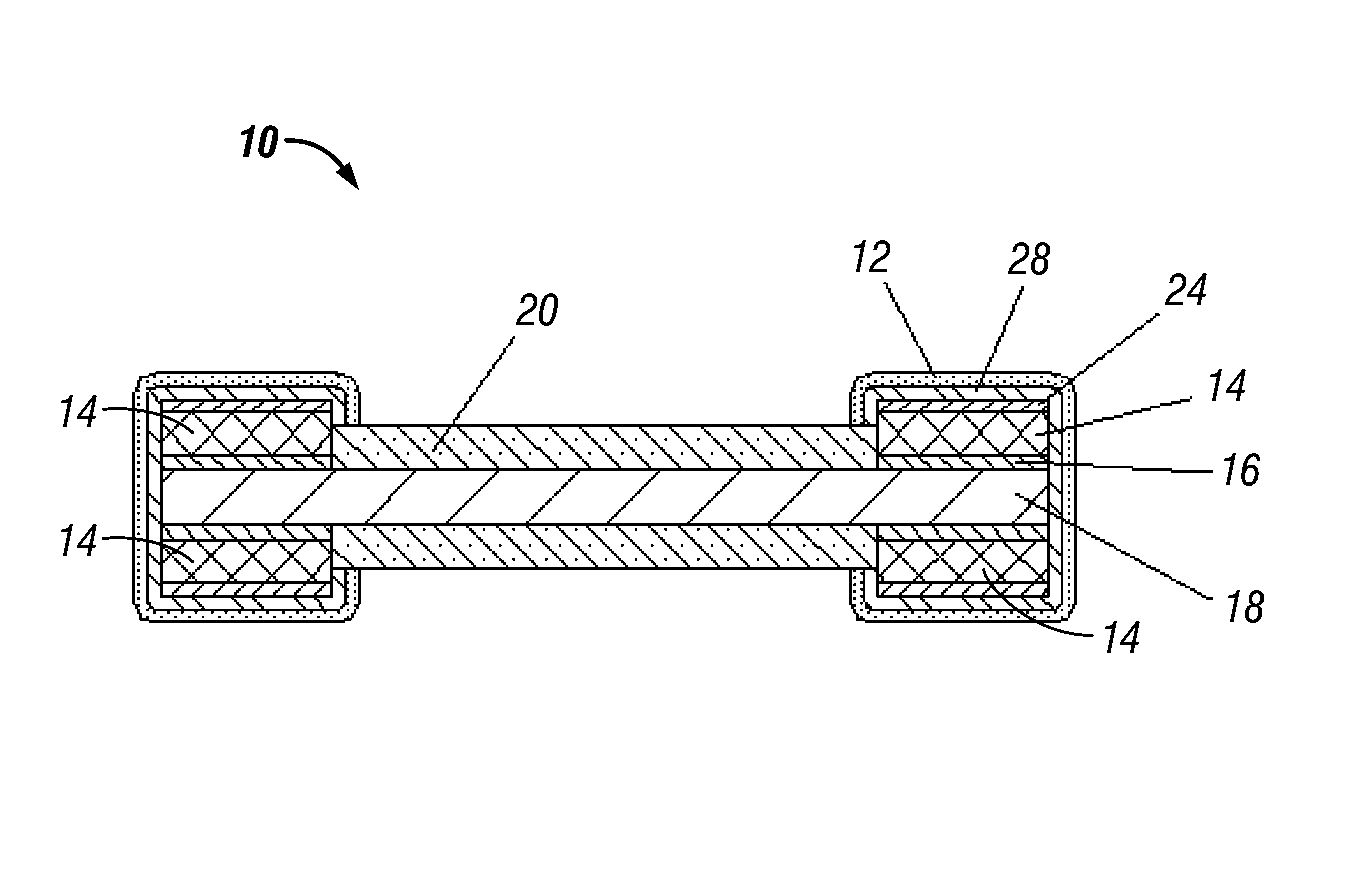

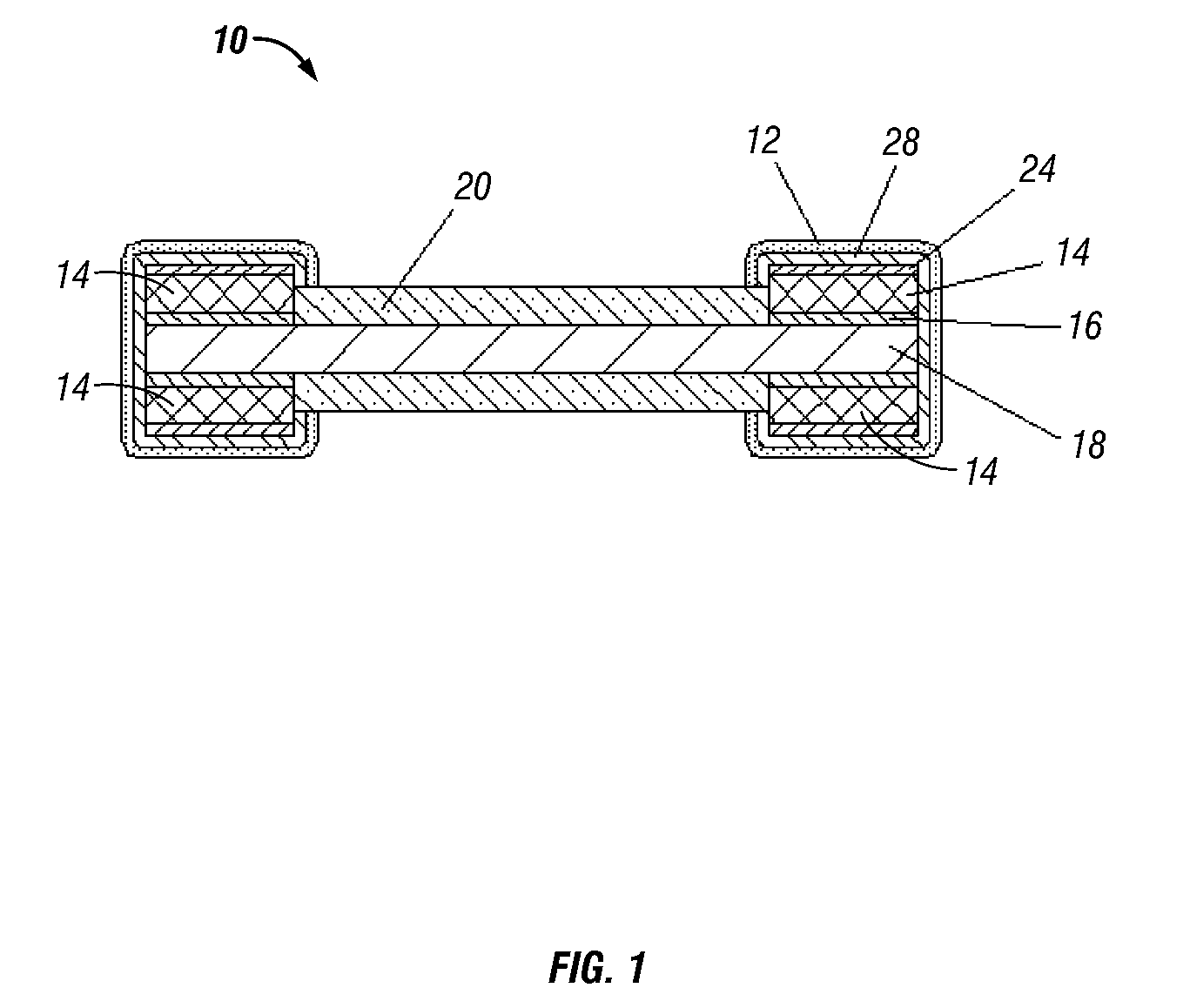

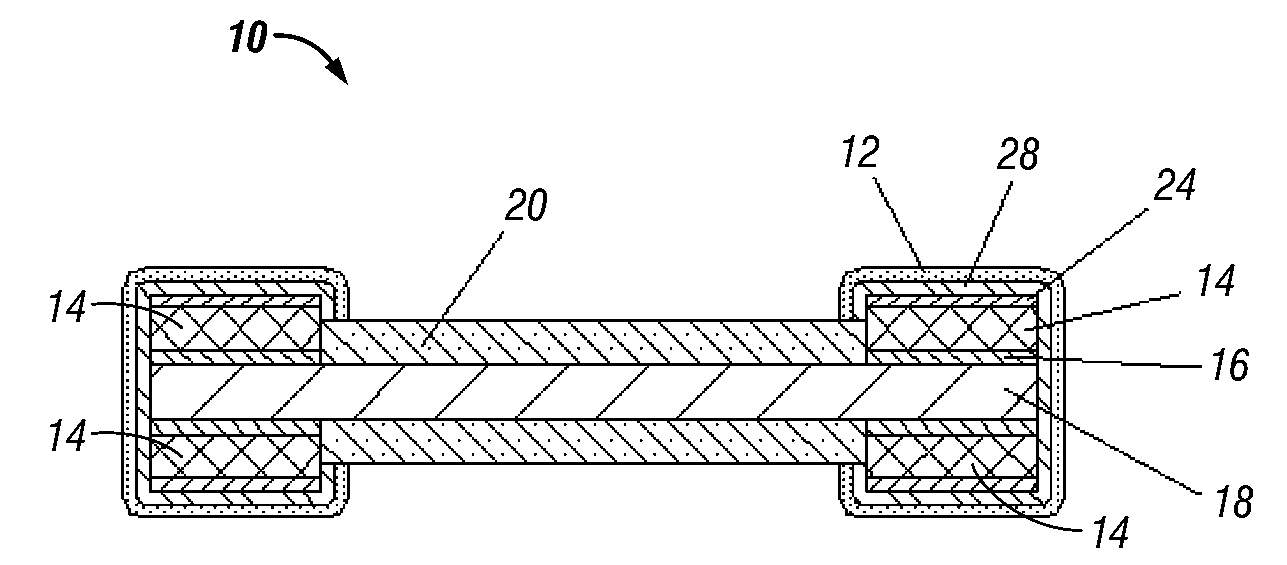

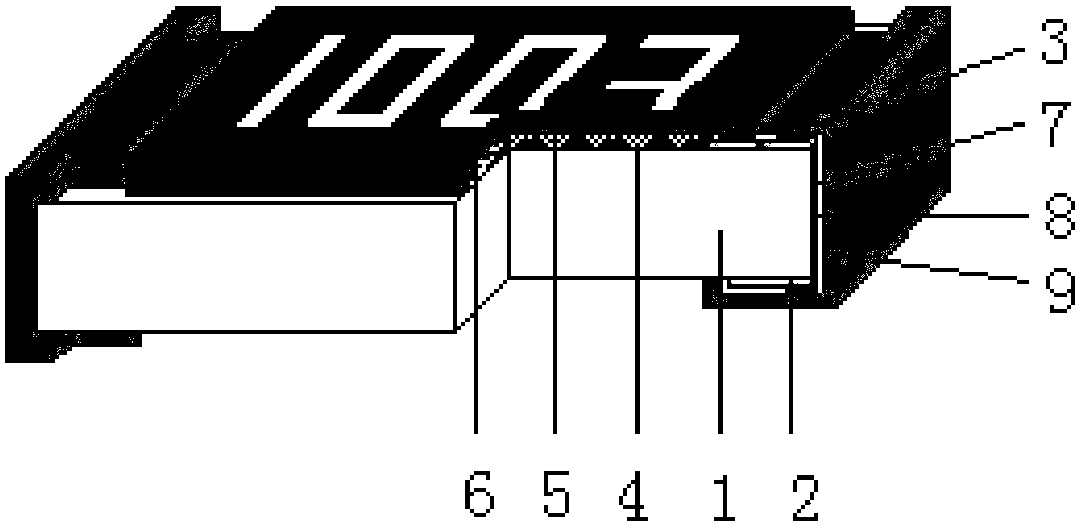

Resistor and method for making same

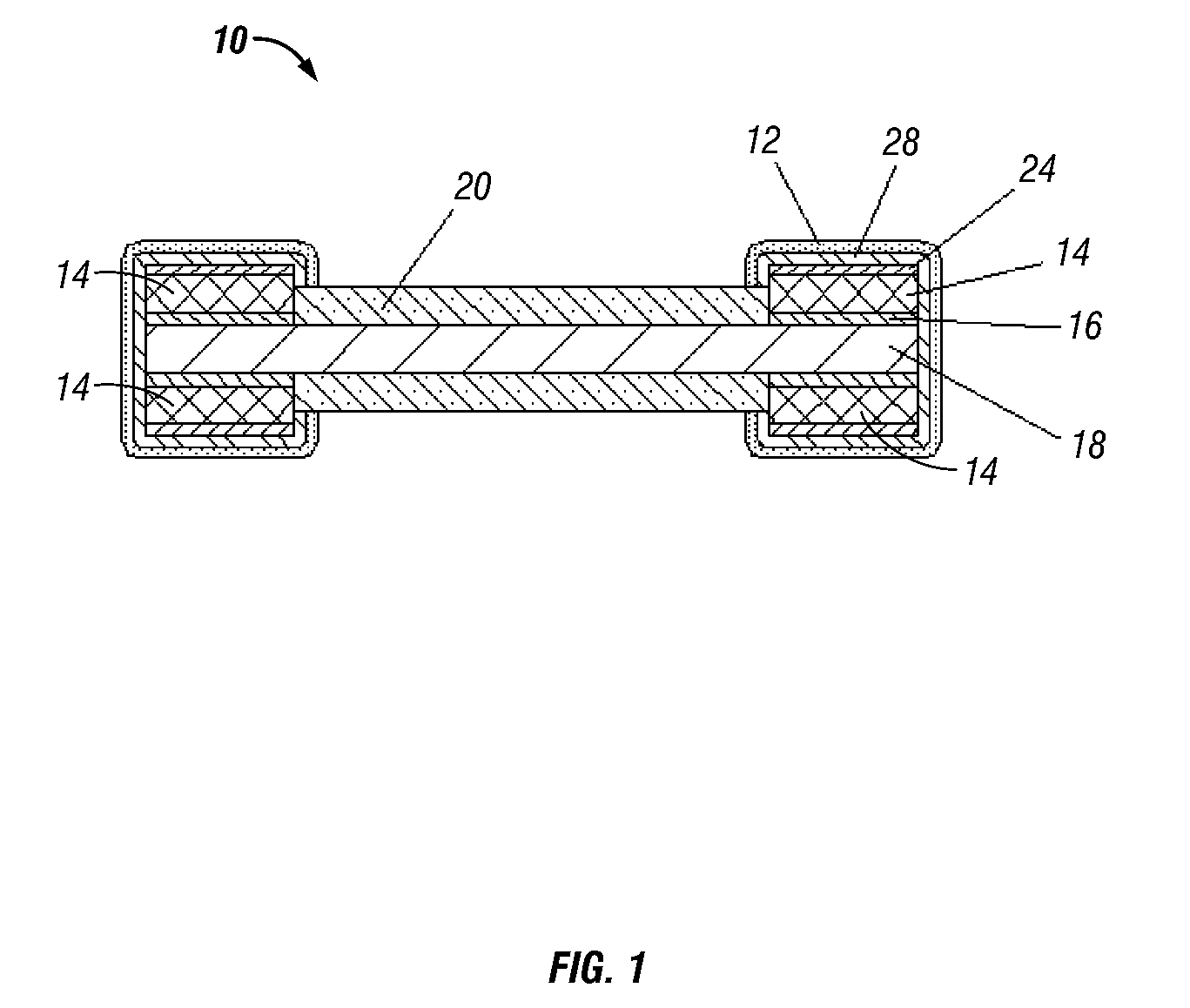

ActiveUS8242878B2Increase heightLower resistanceResistor manufacture by lithographyResistor mounting/supportingMetal stripsElectroplating

A metal strip resistor is provided. The metal strip resistor includes a metal strip forming a resistive element and providing support for the metal strip resistor without use of a separate substrate. There are first and second opposite terminations overlaying the metal strip. There is plating on each of the first and second opposite terminations. There is also an insulating material overlaying the metal strip between the first and second opposite terminations. A method for forming a metal strip resistor wherein a metal strip provides support for the metal strip resistor without use of a separate substrate is provided. The method includes coating an insulative material to the metal strip, applying a lithographic process to form a conductive pattern overlaying the resistive material wherein the conductive pattern includes first and second opposite terminations, electroplating the conductive pattern, and adjusting resistance of the metal strip.

Owner:VISHAY DALE ELECTRONICS INC

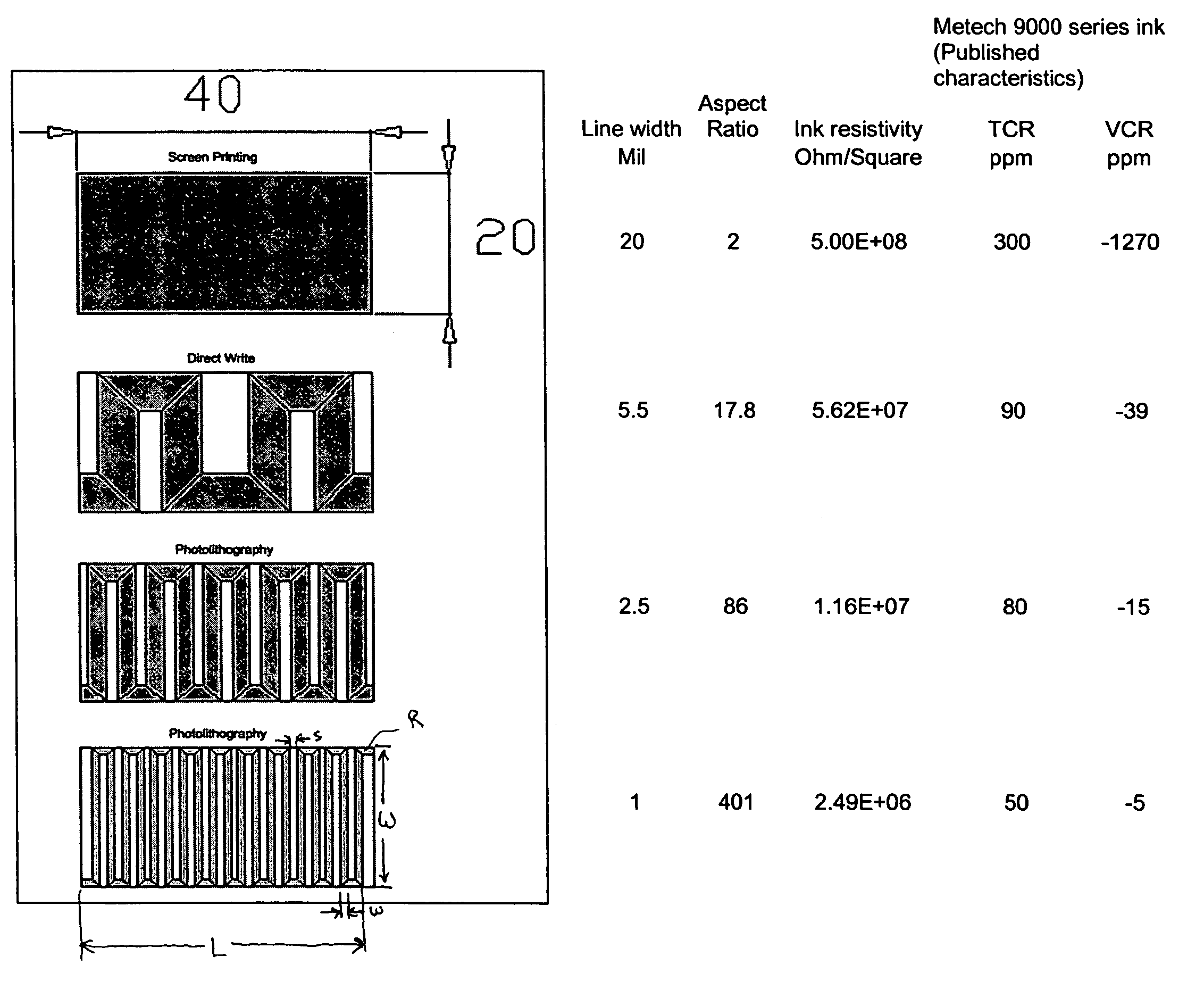

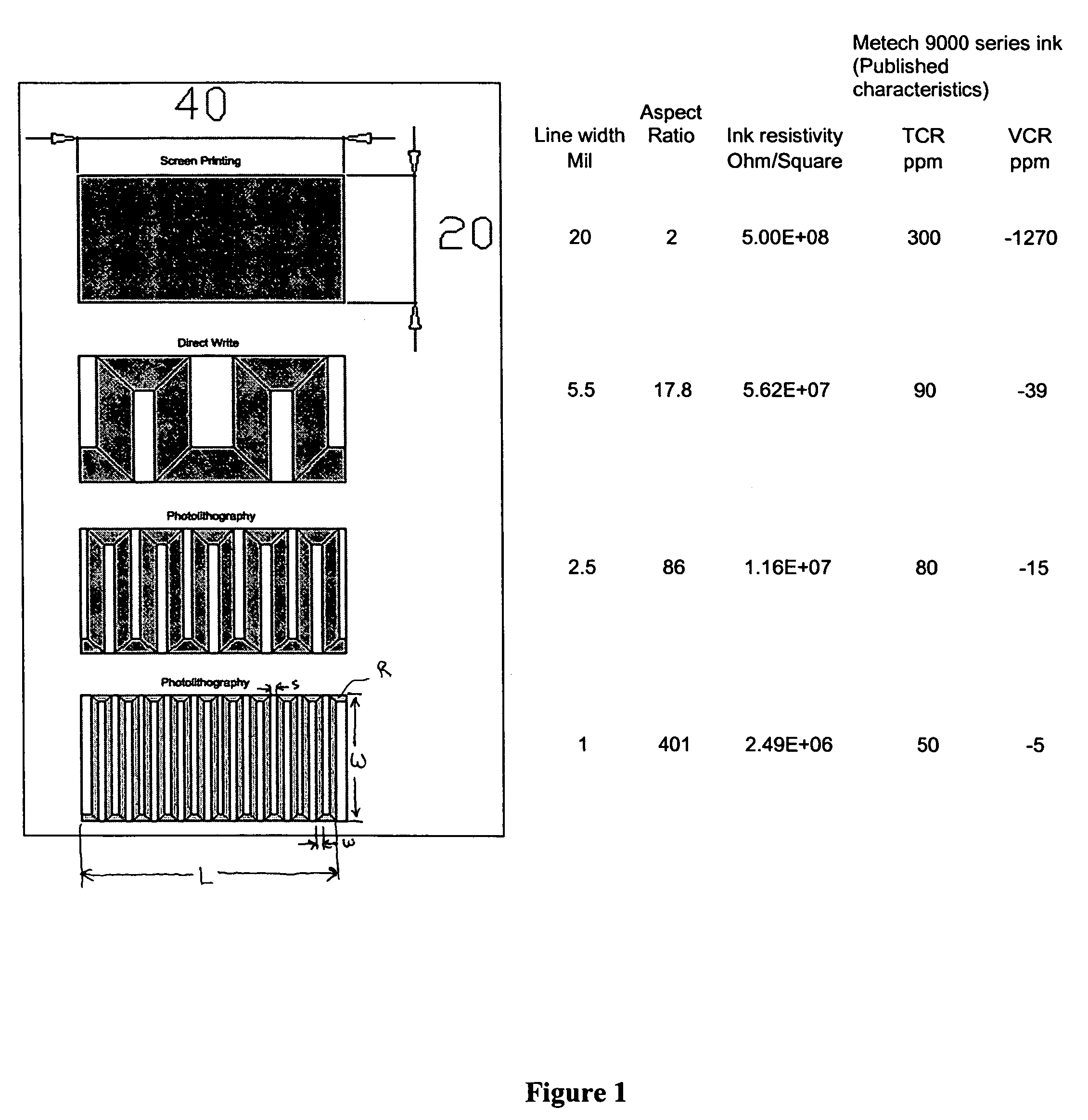

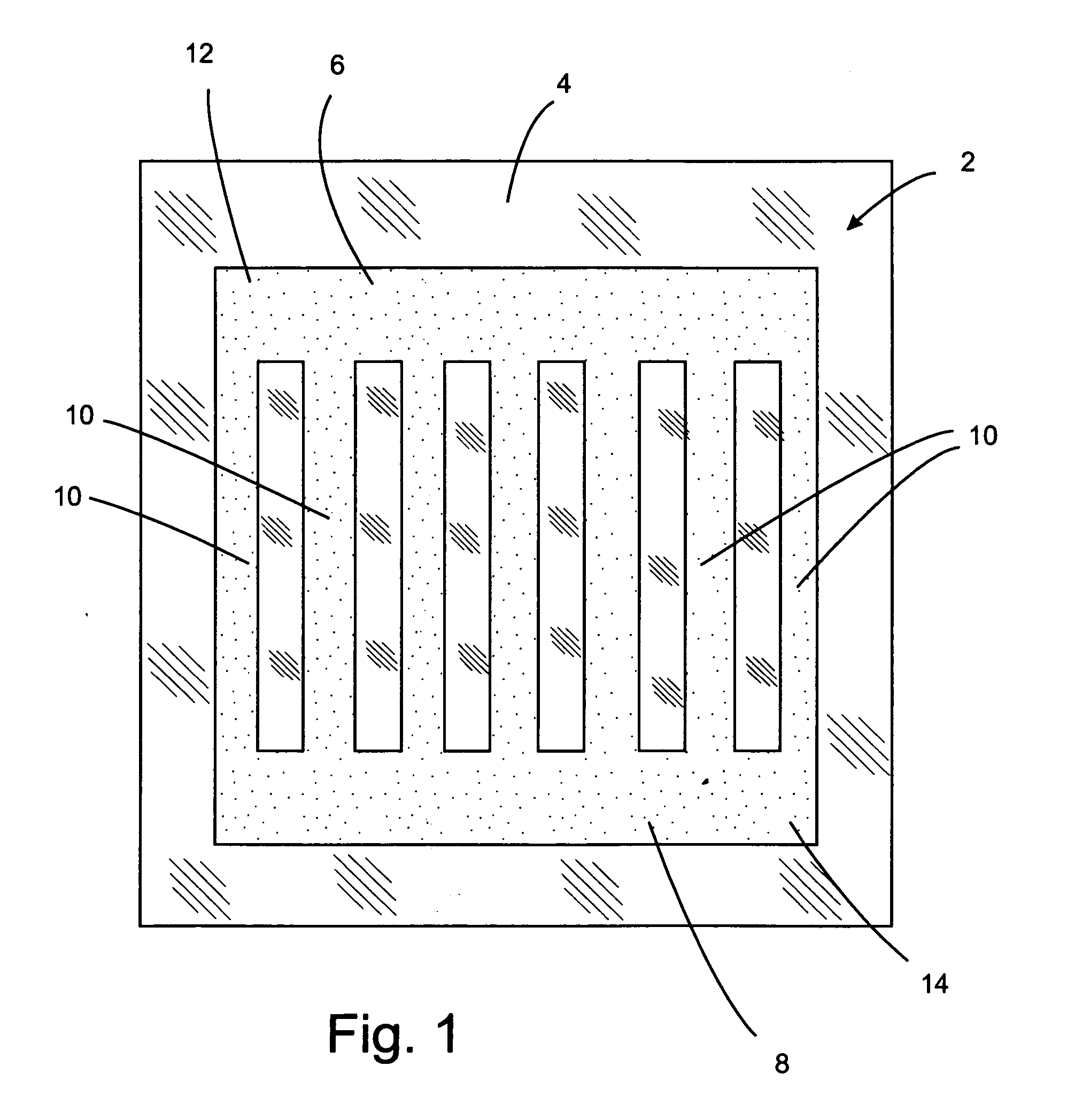

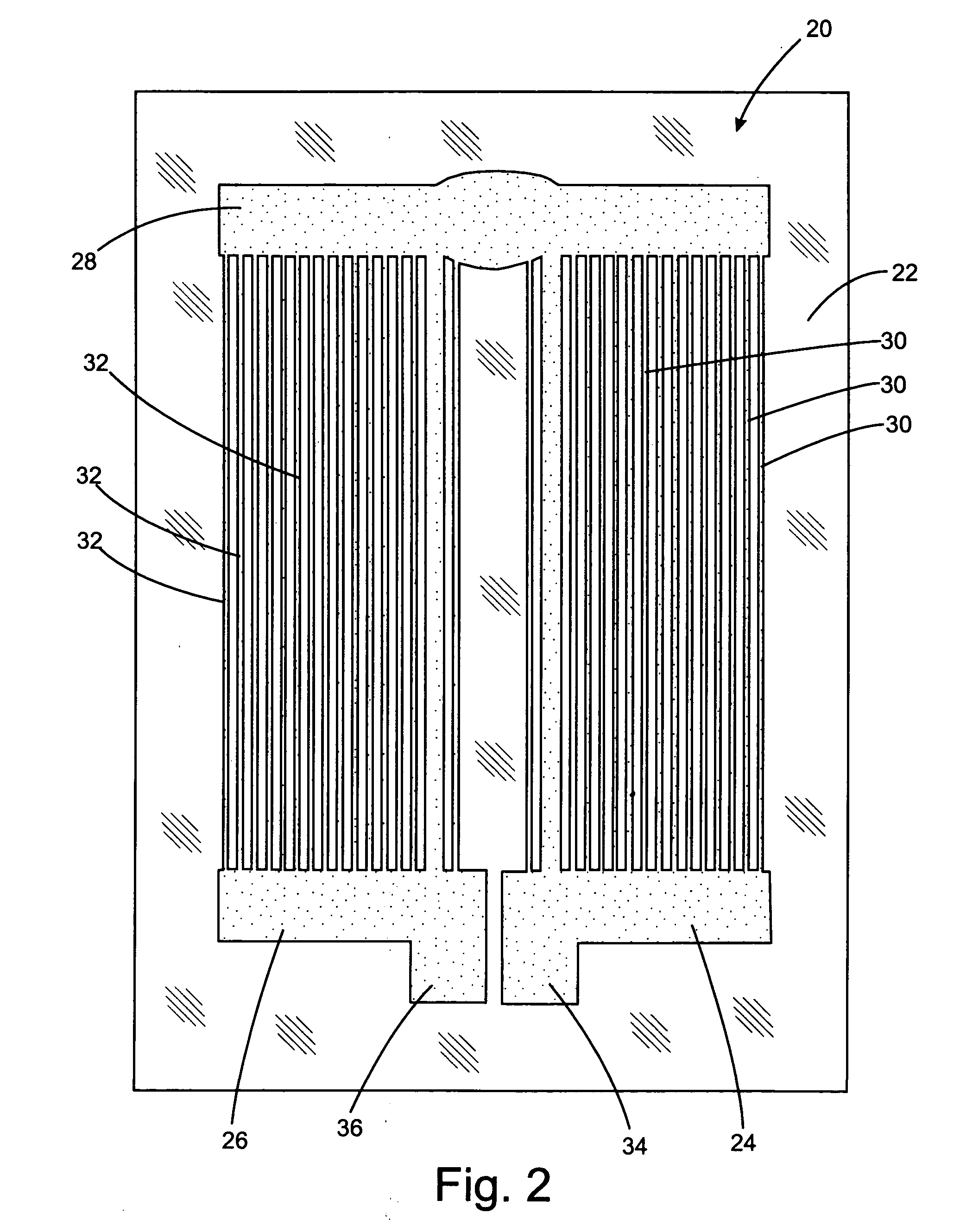

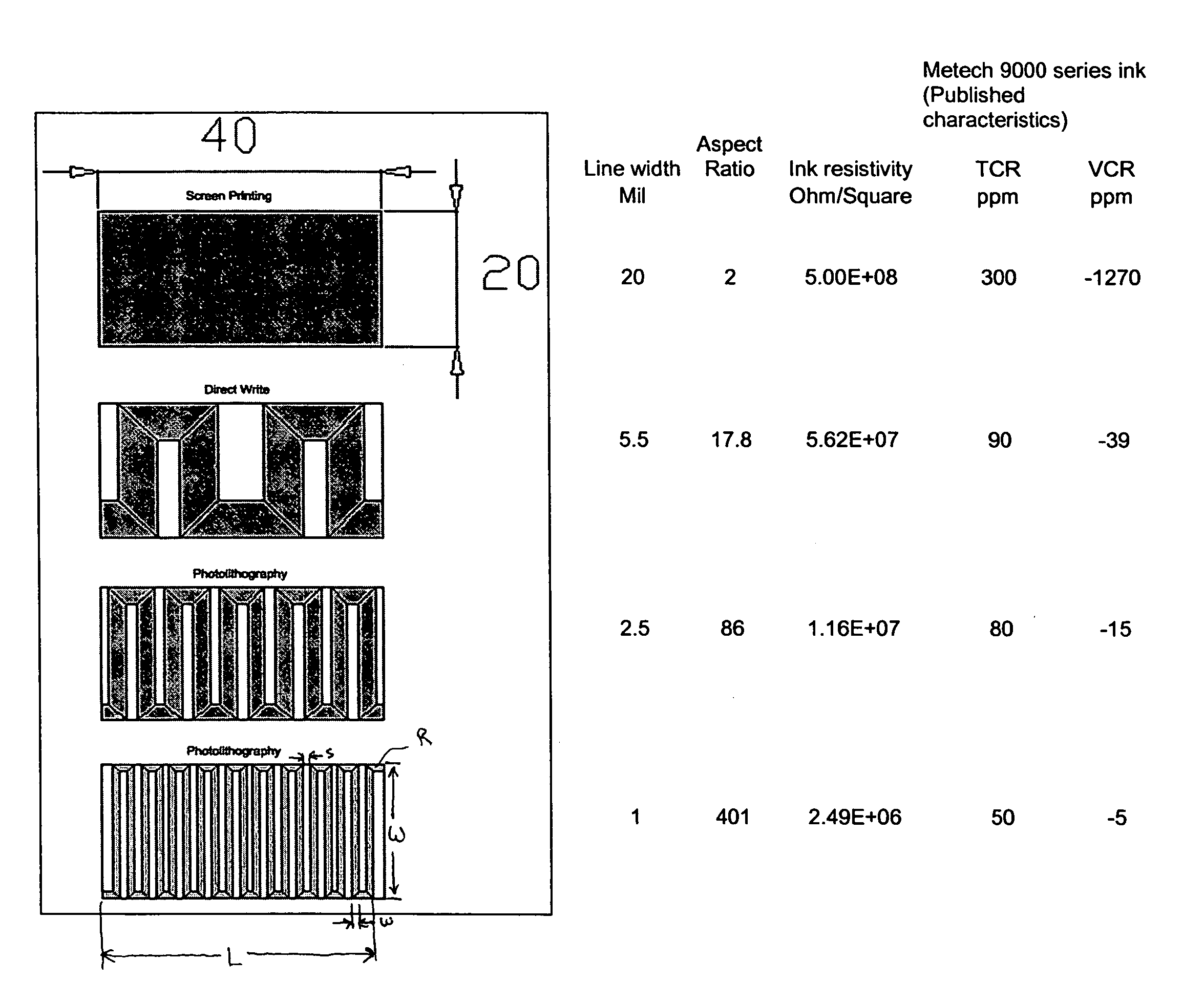

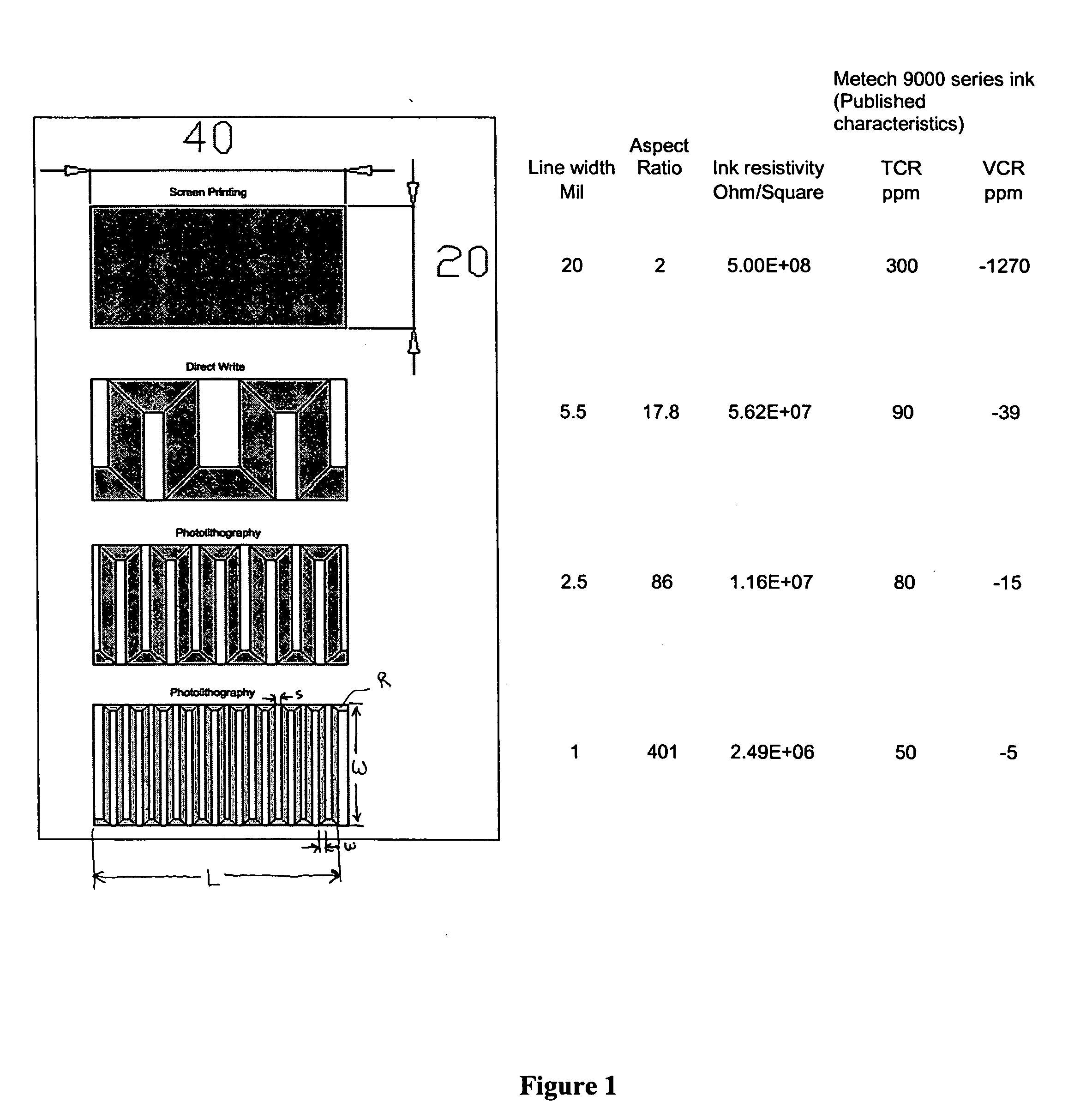

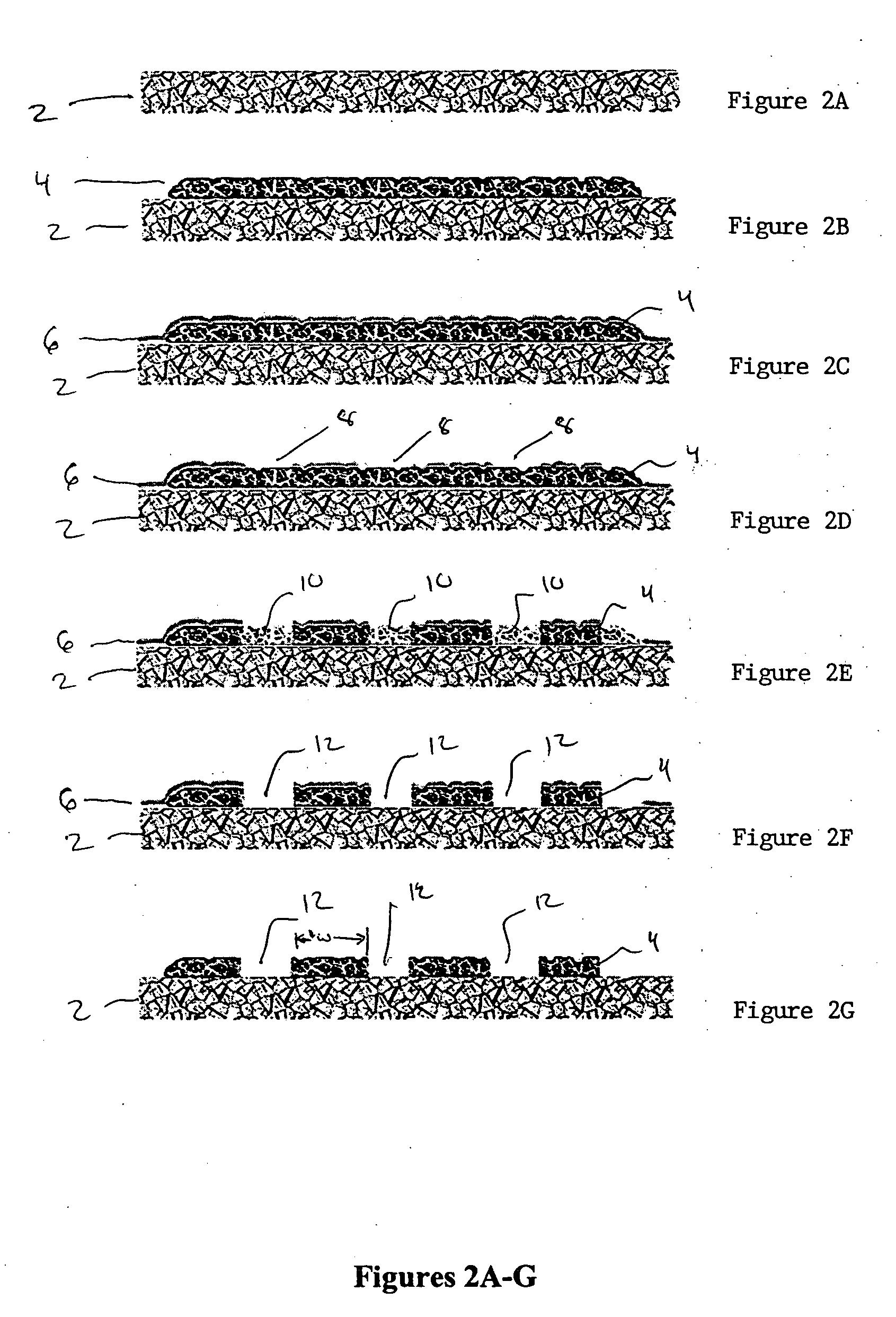

Fine line thick film resistors by photolithography

InactiveUS7224258B2Low resistivityStable working characteristicsResistor manufacture by lithographyPrinted resistor incorporationFine lineEngineering

The present invention is directed to a thick film patterned resistor on a substrate and to a method of forming it. The method involves providing a substrate with opposed surfaces, where one surface is coated with a layer of a resistor composition. A photoresist is applied over the layer of the resistor composition, and a desired pattern in the photoresist is formed, where the pattern leaves certain regions of the resistor composition layer uncovered by the photoresist. The resistor composition layer which is uncovered by the photoresist is etched under conditions effective to leave a mass of loosely bound resistor particles at regions of the resistor composition which are not covered by photoresist. The mass of resistor particles is then removed from the substrate to produce a thick film patterned resistor on the substrate.

Owner:OHMCRAFT

Heating elements deposited on a substrate and related method

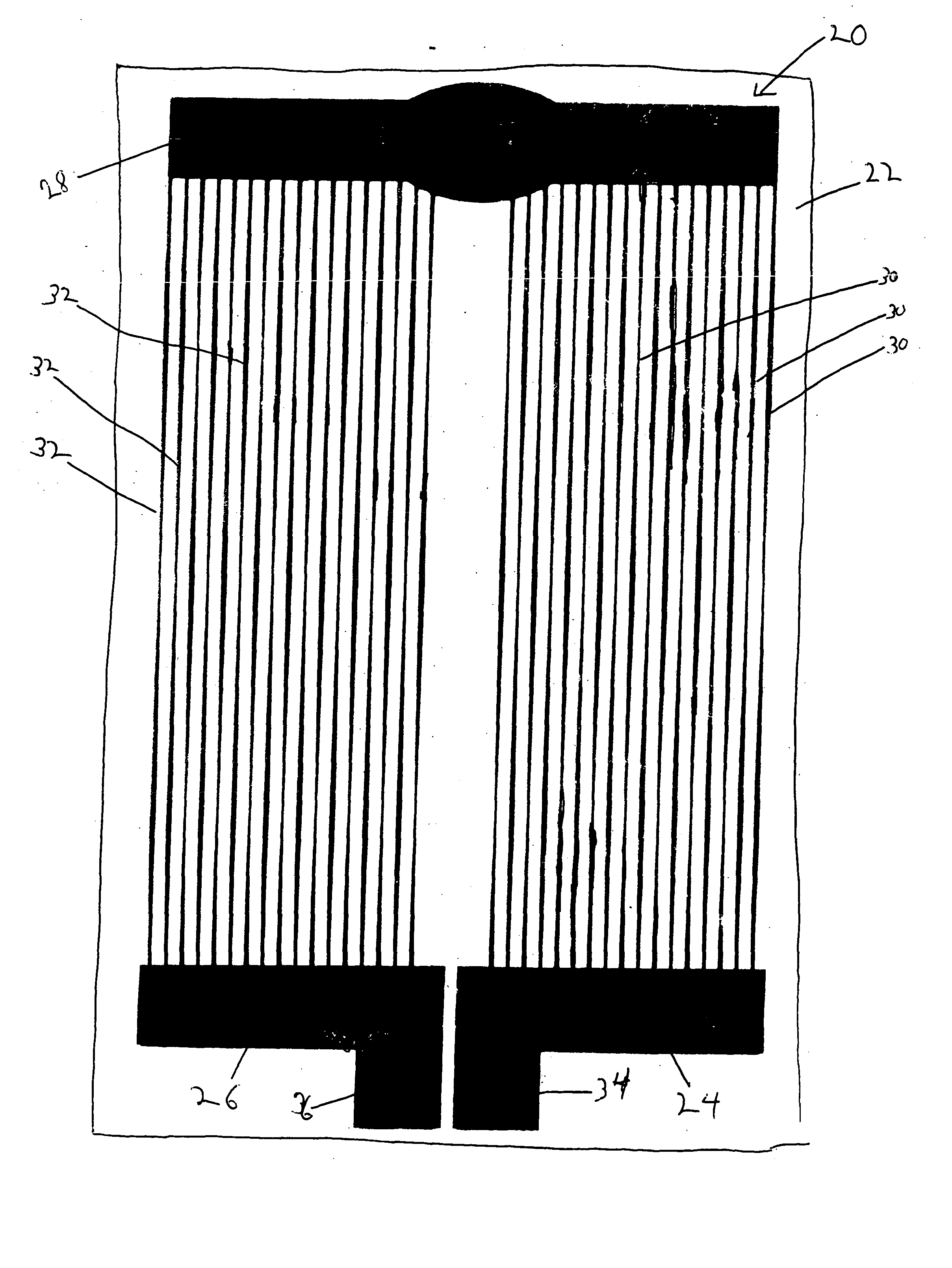

InactiveUS20050244587A1Overcome problemsFully curedResistor manufacture by lithographyOhmic-resistance heatingVolatile organic compoundElectrically conductive

The present invention provides a method for making a heating element adhered to a substrate by applying a photocurable composition to a flexible substrate in a pattern having one or more grid lines. The photocurable composition is curable into an electrically conductive layer and volatile organic compounds are present in an amount of less than about 10% of the total weight of the photocurable composition. After the pattern is deposited on the substrate it is cured by illuminating the photocurable composition with light for a sufficient period of time to cure the photocurable composition. In another embodiment of the invention heating elements made by the method of the invention are provided.

Owner:KLAI ENTERPRISES

Fine line thick film resistors by photolithography

InactiveUS20060087399A1Low costImprove reliabilityResistor manufacture by lithographyPrinted resistor incorporationFine lineEngineering

The present invention is directed to a thick film patterned resistor on a substrate and to a method of forming it. The method involves providing a substrate with opposed surfaces, where one surface is coated with a layer of a resistor composition. A photoresist is applied over the layer of the resistor composition, and a desired pattern in the photoresist is formed, where the pattern leaves certain regions of the resistor composition layer uncovered by the photoresist. The resistor composition layer which is uncovered by the photoresist is etched under conditions effective to leave a mass of loosely bound resistor particles at regions of the resistor composition which are not covered by photoresist. The mass of resistor particles is then removed from the substrate to produce a thick film patterned resistor on the substrate.

Owner:OHMCRAFT

Method for manufacturing metal thin film resistor

InactiveUS6993828B2Minimized in sizeImprove responsivenessSemiconductor/solid-state device detailsResistor manufacture by lithographyHigh resistanceForming processes

A metal resistor and a method for manufacturing the resistor are provided. A first insulation film is formed on a substrate, a photosensitive film is applied on the insulation film, and an insulation film pattern is formed by patterning the insulation film. After a metal thin film is formed among the insulation film pattern and on the photosensitive film, with removing the photo-sensitive film is a metal thin film pattern formed among the insulation film pattern. On the metal thin film pattern and the insulation film pattern is a second insulation film formed and at the pad region of the metal thin film pattern is a lead wire connected, after that, a metal thin film resistor is manufactured with forming a preservation film on and around the lead wire. Using a pattern-forming process by etching of the insulation film for forming the metal thin film pattern, the deterioration of the device or the lowering of the durability can be overcome, the resistance of the metal thin film resistor can be easily controlled, and the resolving power can be improved by producing the high-resistance metal thin film temperature having reduced line with of the metal thin film pattern.

Owner:INOSTEK

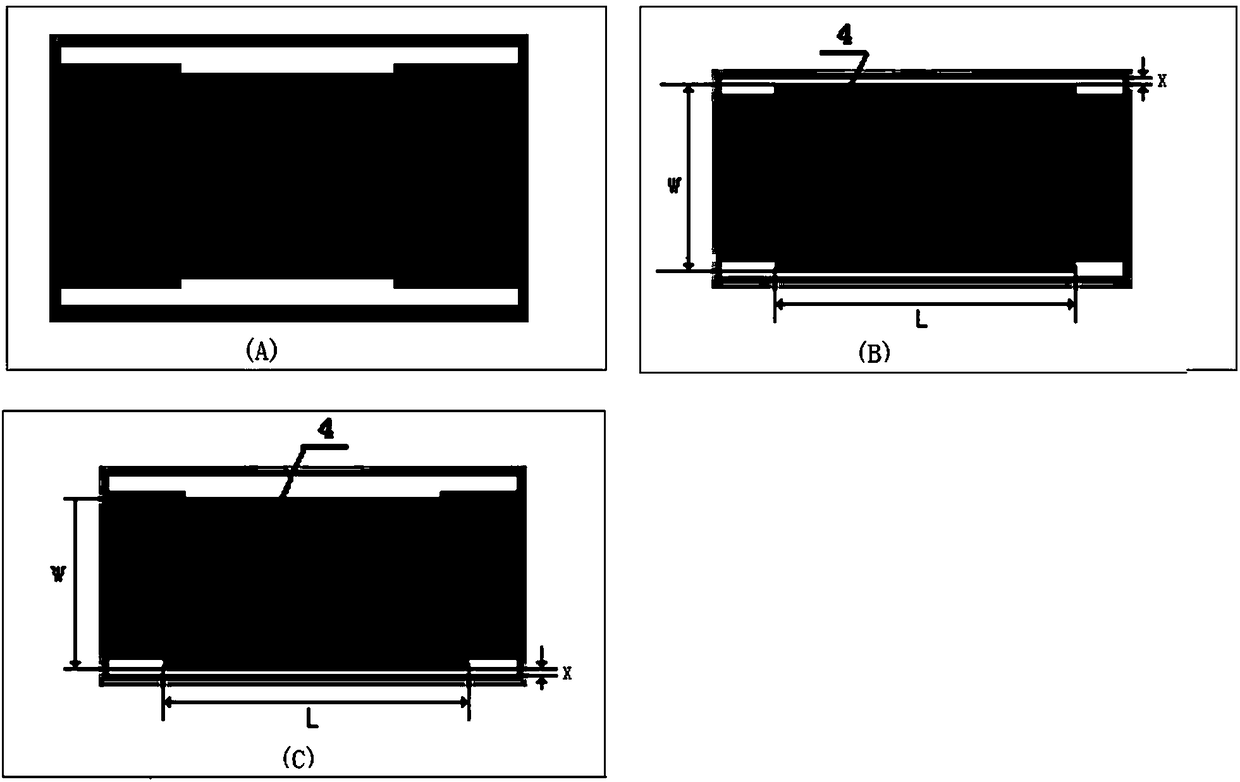

Low-impedance electrical resistor and process for the manufacture of such resistor

InactiveUS20050046543A1High precisionGood reproducibilityResistor chip manufactureResistor manufacture by lithographyElectrical resistance and conductanceMetal forming

In the manufacture of low-impedance electrical resistors made of a metal sheet or a film consisting of a metallic resistance alloy, a metal forming the connection contacts of the resistors is electroplated onto a multitude of photolithographically defined parallel strips, which extend, at regular mutual intervals, over the entire metal sheet or film surface. To separate the resistors, the electroplated metal piece is sawed longitudinally into cutting planes, which extend perpendicularly with respect to each other, and with respect to the metal sheet, where, in each case, the cutting planes of one group divide one of the connection contact strips in its longitudinal direction.

Owner:ISABELLENHUTTE HEUSLER

Resistor and method for making same

ActiveUS20100060409A1Avoid depositionIncrease heightResistor manufacture by lithographyResistor mounting/supportingMetal stripsMaterials science

A metal strip resistor is provided. The metal strip resistor includes a metal strip forming a resistive element and providing support for the metal strip resistor without use of a separate substrate. There are first and second opposite terminations overlaying the metal strip. There is plating on each of the first and second opposite terminations. There is also an insulating material overlaying the metal strip between the first and second opposite terminations. A method for forming a metal strip resistor wherein a metal strip provides support for the metal strip resistor without use of a separate substrate is provided. The method includes coating an insulative material to the metal strip, applying a lithographic process to form a conductive pattern overlaying the resistive material wherein the conductive pattern includes first and second opposite terminations, electroplating the conductive pattern, and adjusting resistance of the metal strip.

Owner:VISHAY DALE ELECTRONICS INC

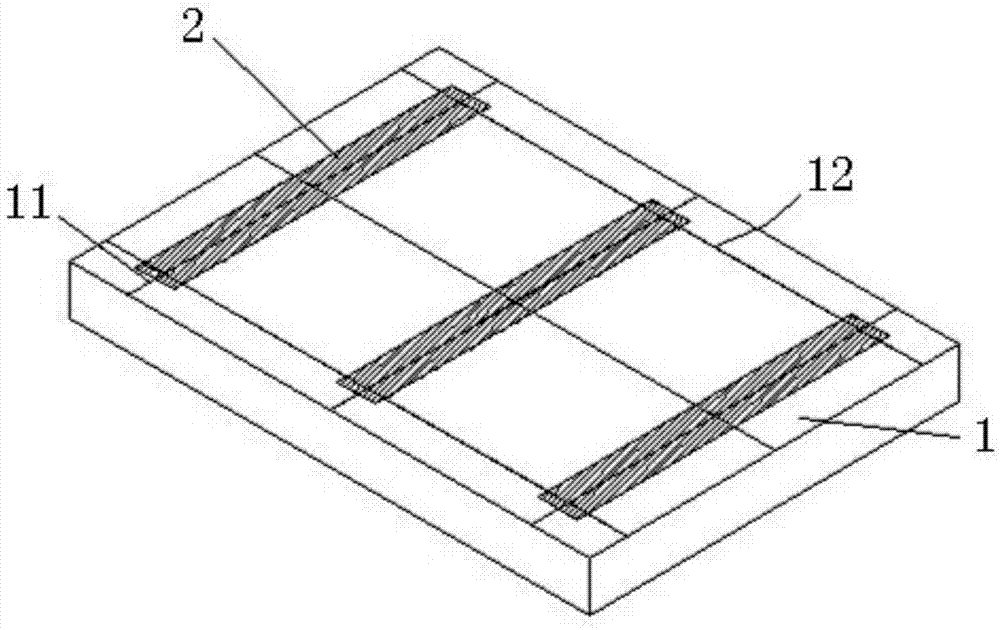

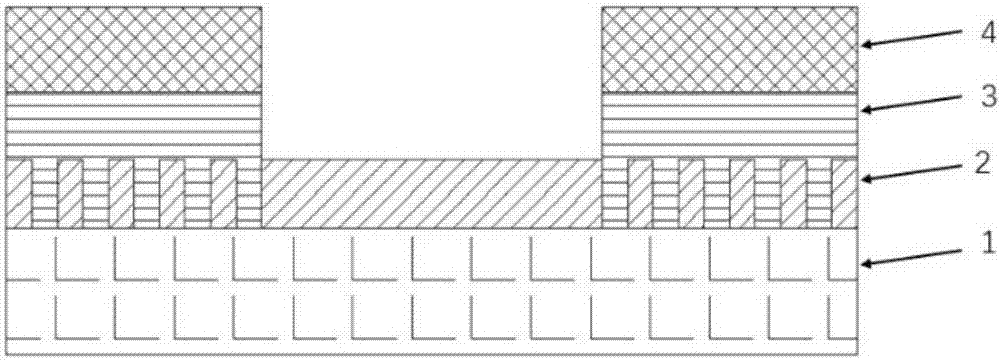

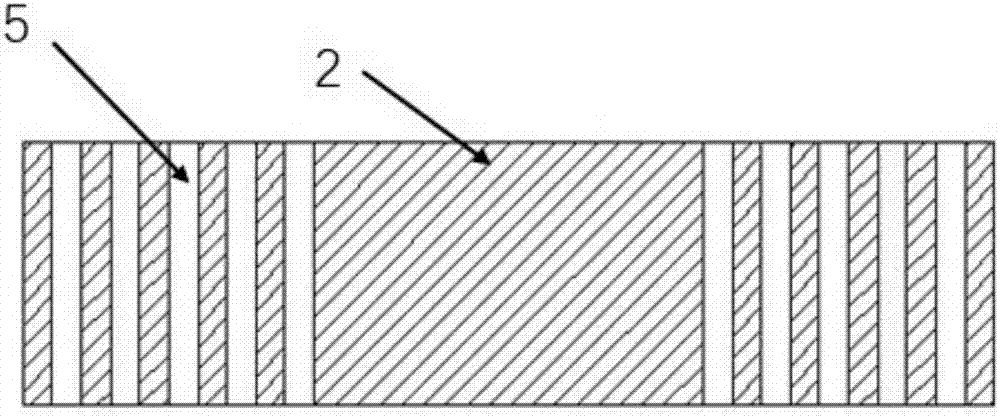

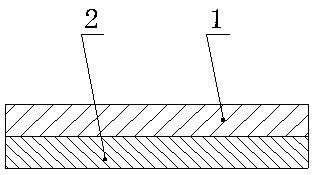

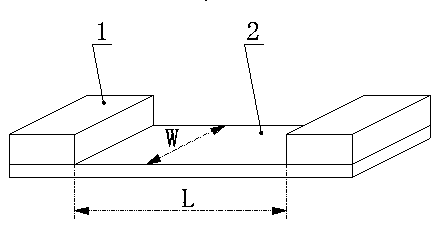

Metal foil piece type current detection resistor and manufacturing process thereof

ActiveCN107230537AIncrease powerExcellent temperature coefficient (TCR) indexResistor manufacture by lithographyResistors adapted for applying terminalsElectrical resistance and conductanceMetal foil

The invention discloses a metal foil chip type current detection resistor and a manufacturing process thereof. Front electrodes are symmetrically printed on two sides, extending along the x-axis direction, of the front surface of the insulating substrate, and back electrodes are symmetrically printed on two sides, extending along the x-axis direction, of the back surface of the insulating substrate, the back electrodes and the front electrodes are in one-to-one correspondence and are symmetrically arranged, so that the electrodes at the two ends of the insulating substrate are full, the resistance integrity is guaranteed, and the power of the chip fixed resistor is improved. The R part of the resistor is made of the alloy foil, so that the resistance value can be ensured, and the stability of the resistance value can be ensured, and an excellent resistor temperature coefficient index can be achieved; in addition, the R part of the resistor is arranged on the back surface of the insulating substrate, the heat dissipation path and the heat dissipation condition can be greatly improved, and the resistor can quickly dissipate the heat of the resistor to the PCB. It is guaranteed that the power of the chip fixed resistor is further improved. The metal foil type current detection resistor can be widely applied to manufacturing of a power supply.

Owner:UNIROYAL ELECTRONICS IND

Heating plate, conductive pattern sheet, vehicle, and method of manufacturing heating plate

ActiveUS20170223779A1Avoid bubblingReduce flickerResistor manufacture by lithographyTransparent/reflecting heating arrangementsEngineeringGlass sheet

Owner:DAI NIPPON PRINTING CO LTD

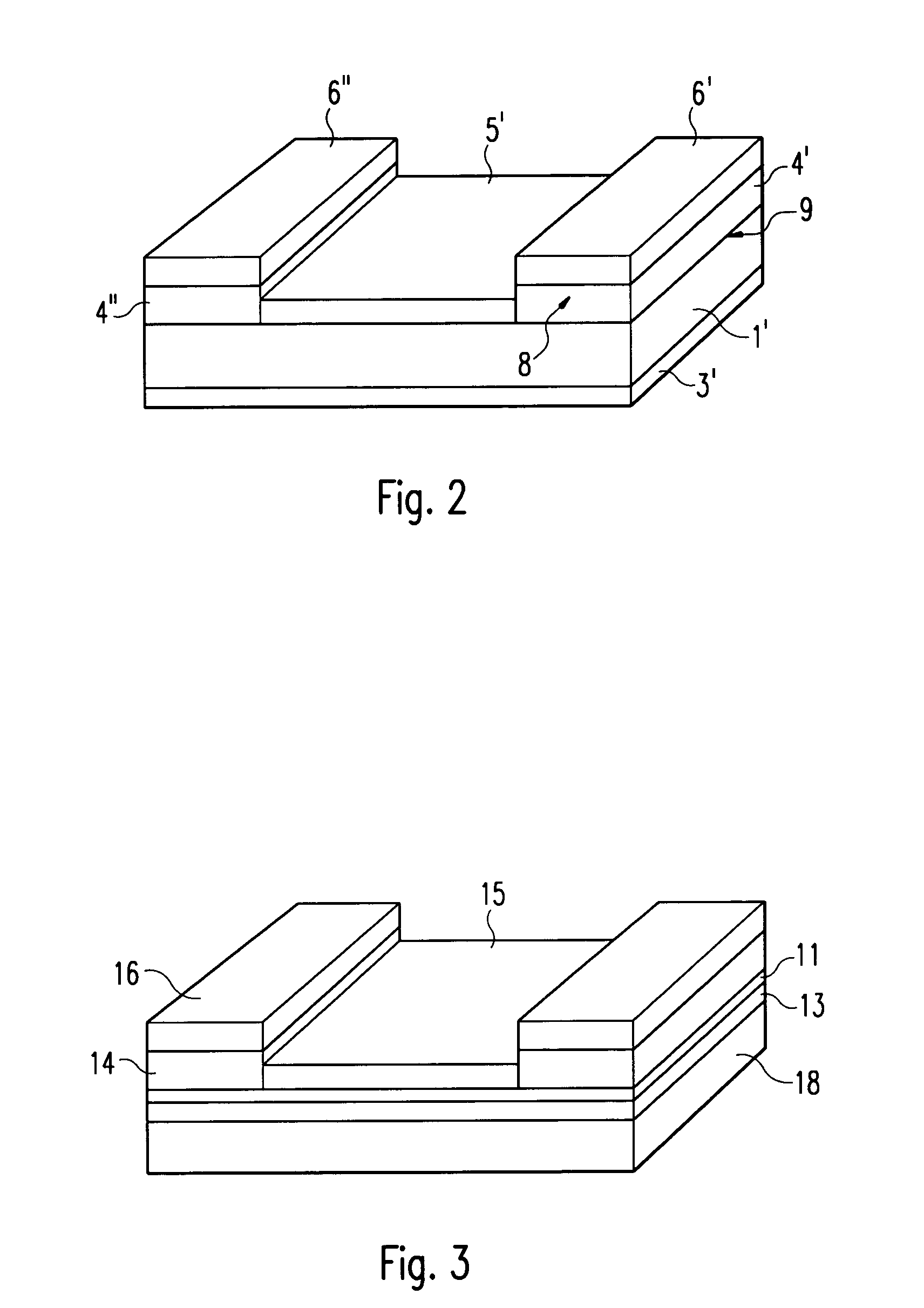

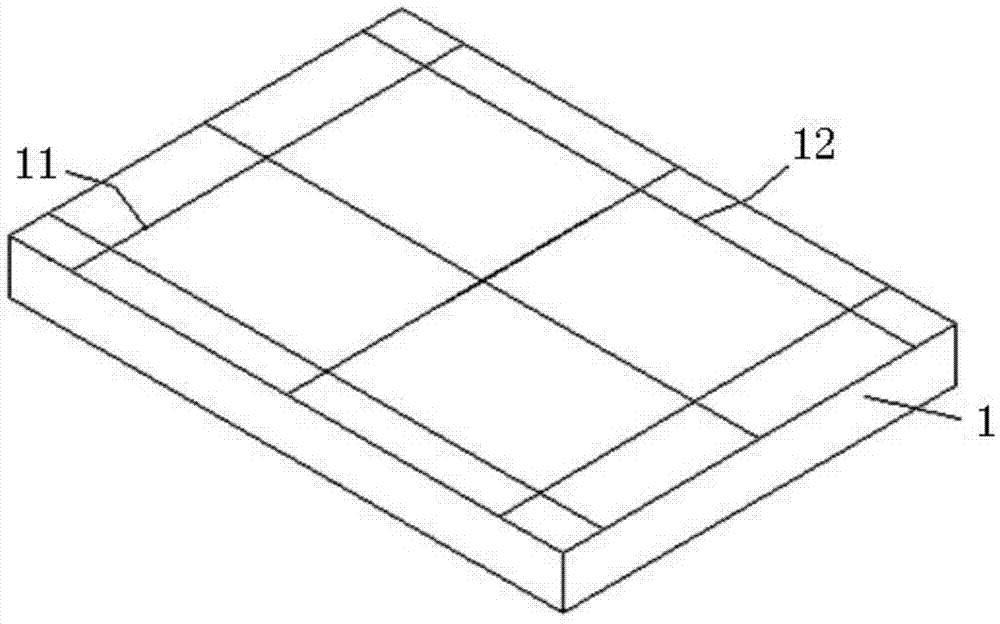

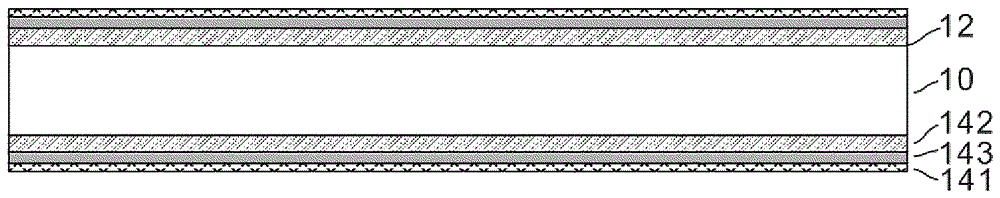

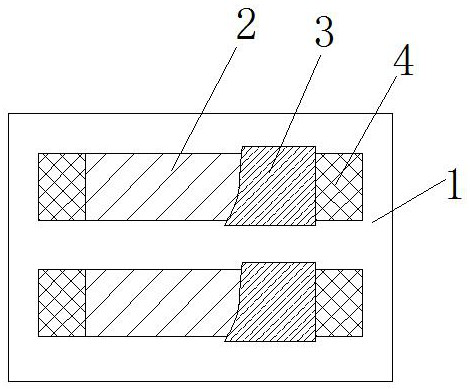

Thin film resistor and fabrication method thereof

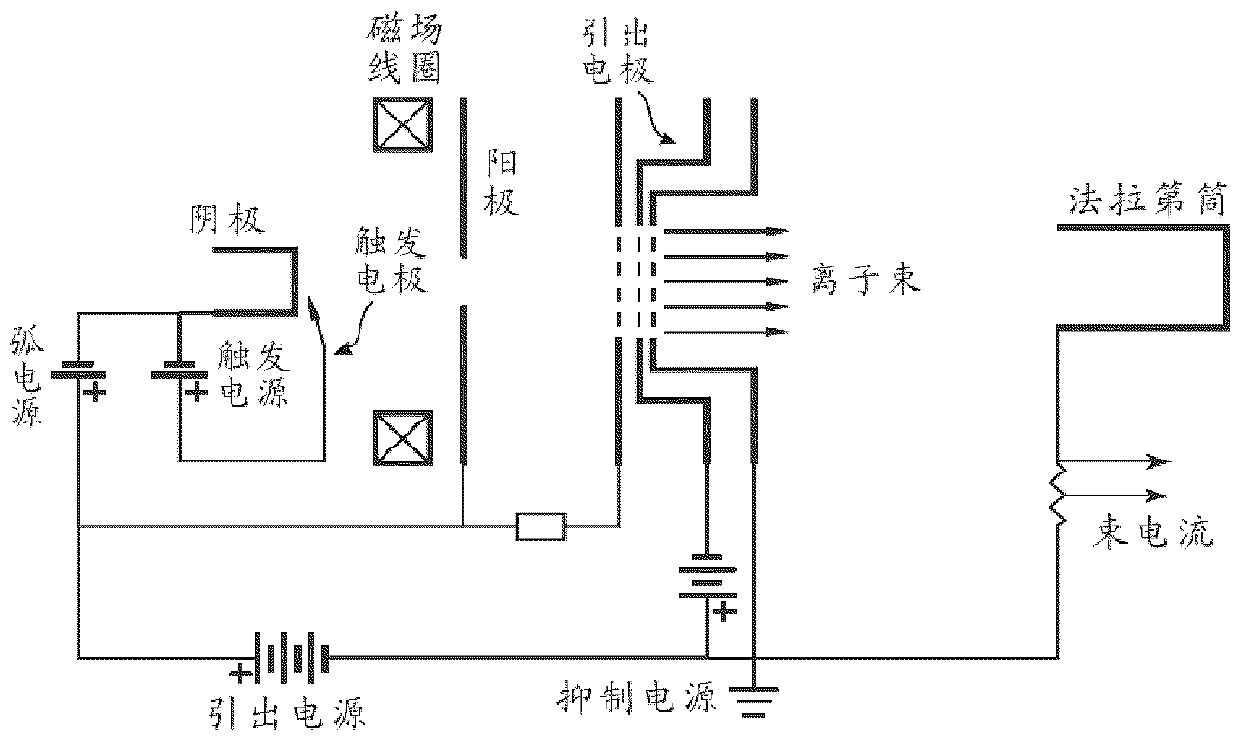

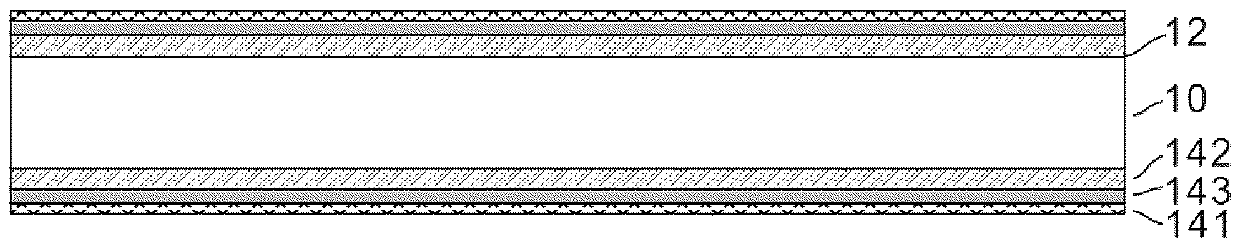

ActiveCN106298118AImprove film qualityImprove bindingResistor manufacture by lithographyThin film resistorsPlasma depositionIon implantation

The invention relates to a thin film resistor and a fabrication method thereof. The method for fabricating the thin film resistor (100) comprises the following steps of S1, pre-processing a substrate (10); S2, performing ion injection and / or plasma deposition processing on a surface (12) of the substrate by using a target material so as to form a resistance layer (14) on the surface of the substrate; and S3, forming electrodes (18) at two sides of the resistance layer.

Owner:SUMITOMO ELECTRIC INTERCONNECT PROD SHENZHEN LTD

TaN thin-film resistor for high-temperature environment and preparation method of TaN thin-film resistor

ActiveCN107331487AImprove thermal stabilityGood thermal reliabilityResistor manufacture by lithographyResistive material coatingThermal expansionEngineering

The invention discloses a TaN thin-film resistor for the high-temperature environment and a preparation method of the TaN thin-film resistor. The TaN thin-film resistor comprises a substrate, a resistive film, two transition metal layers and two electrodes from bottom to top sequentially, wherein the two transition metal layers are arranged on two sides of the resistive film respectively; the two electrodes are attached to the upper surfaces of the two transition metal layers respectively; the resistive film is attached to the upper surface of the substrate, is a TaN resistive film and is 100-200 nm thick; channels or holes are formed in the position, where the resistive film is connected with the transition metal layers, of the resistive film. The metal layers and the resistive layer are in embedded three-dimensional contact, the metal layers and the resistive layer in the embedded position extrude each other to be tightly contacted because of thermal expansion of the resistive layer and the metal layers when used at the high temperature, and failure caused by stripping of the metal layers is avoided, so that the resistor has better thermal stability and reliability.

Owner:SOUTH CHINA UNIV OF TECH

Manufacturing method of resistor, manufacturing method of chip resistor and chip resistor

ActiveCN108074692AThe internal structure is not damagedIncrease powerResistor manufacture by lithographyResistive material coatingElectrical resistance and conductanceEngineering

The invention discloses a manufacturing method of a resistor. The manufacturing method comprises the following steps: obtaining a first printing design size of a target resistor, and increasing the cross section area of the first printing design size according to a preset ratio, so as to obtain a second printing design size, wherein the first printing design size is designed according to the target resistance of the target resistor; according to the second printing design size, printing the resistor, so as to obtain a printed resistor; reducing the cross section area of the printed resistor bya resistance modifying technology, so as to enable the printed resistor to reach the target resistance, thereby obtaining the final resistor. The manufacturing method provided by the invention has the advantage that the power and pulse surge properties of the resistor are greatly improved.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

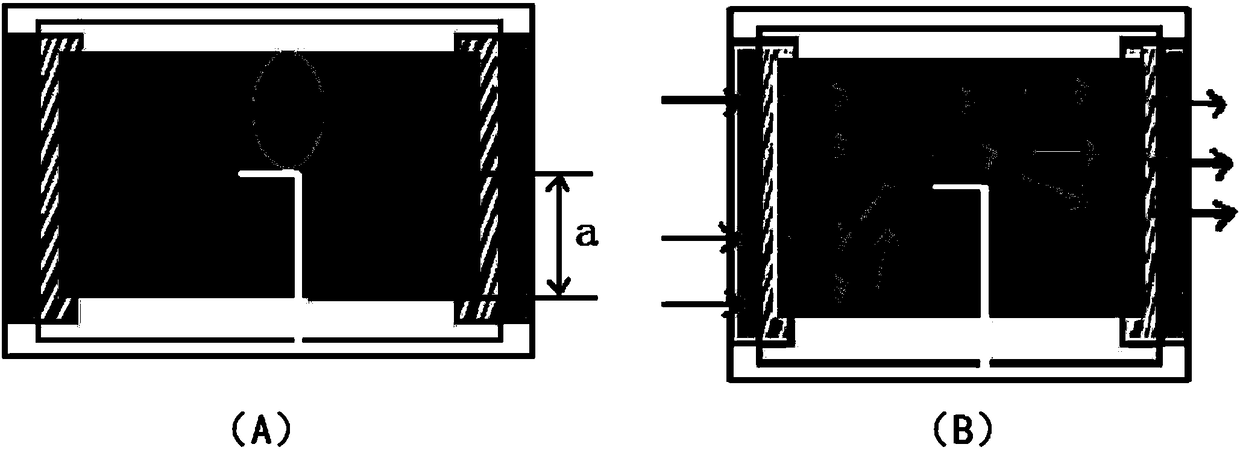

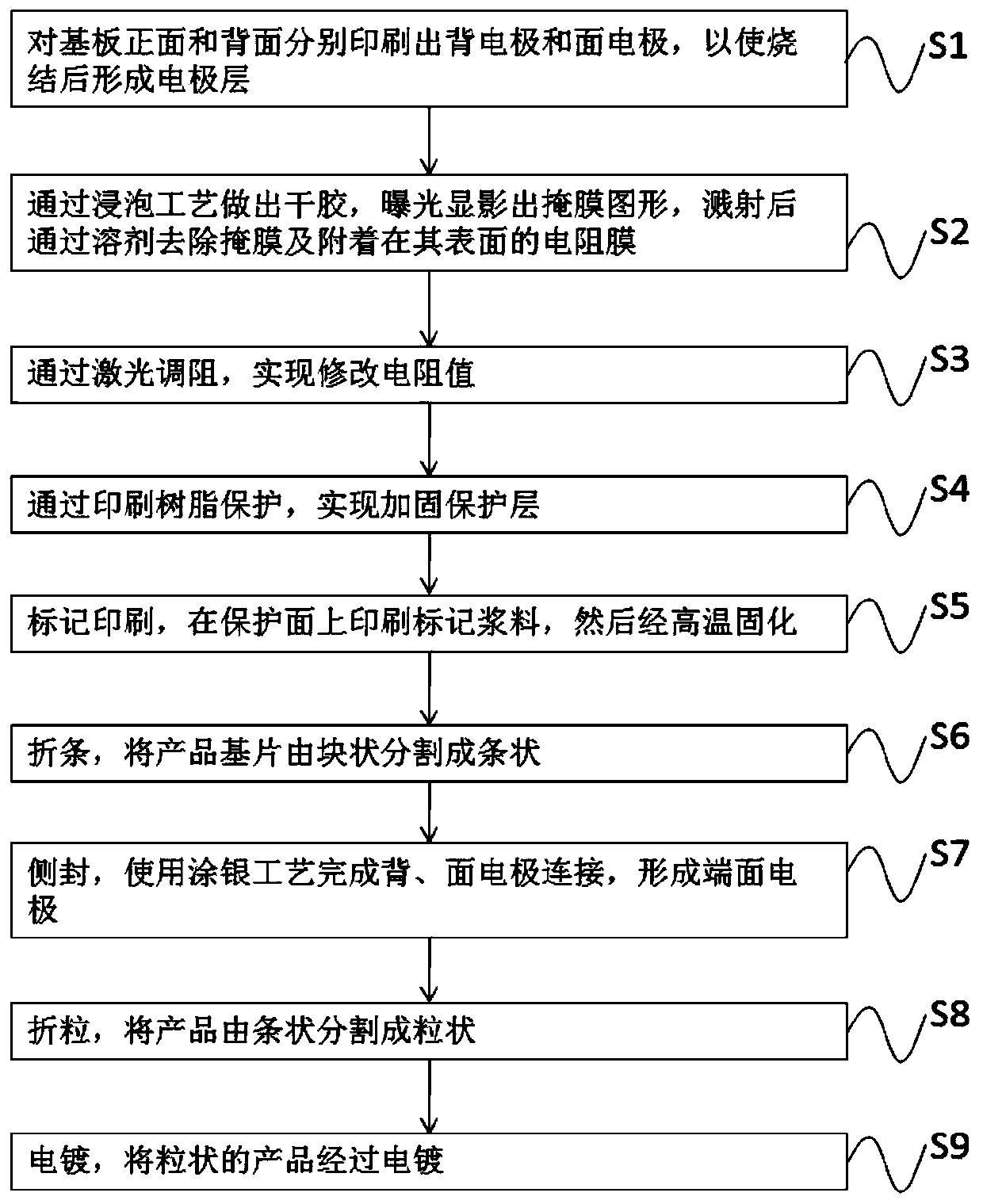

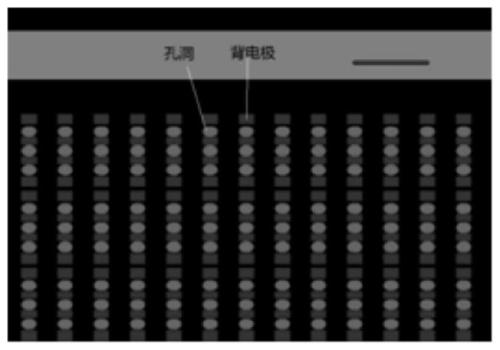

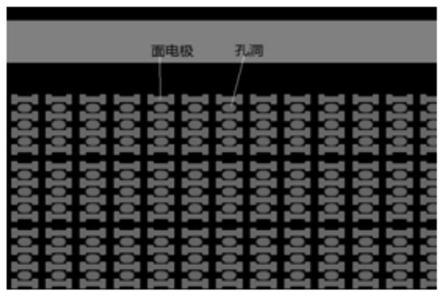

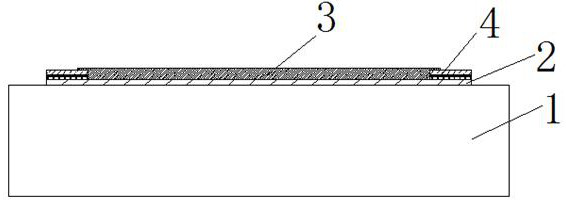

Chip precision film resistor array and manufacturing method thereof

ActiveCN111223620AImprove resistor qualityResistor manufacture by lithographyResistors adapted for applying terminalsSputteringThin membrane

The invention discloses a manufacturing method of a chip precision film resistor array. The method comprises the following steps: S1, respectively printing a back electrode and a surface electrode onthe front surface and the back surface of a substrate so as to form an electrode layer after sintering; s2, preparing dry glue through a soaking process, exposing and developing a mask pattern, and removing a mask after sputtering to obtain a resistor body, and the dry glue completely covering the whole resistor array substrate; s3, modifying the resistance value through laser resistance trimming;s4, reinforcing a protection layer through printing resin protection; s5, carrying out mark printing, specifically, printing mark slurry on the protection face, and then carrying out high-temperaturecuring; s6, strip folding: cutting the product substrate into strips from blocks; s7, carrying out side sealing, and a back electrode to a surface electrode through a silver coating process to form an end surface electrode; s8, carrying out grain folding to divide the product into grains from a strip shape; and s9, electroplating the granular product. According to the invention, the film sputtering mask shielding layer is formed through the soaking process, so that the chip resistor array is thinned to film, and the resistor quality is improved.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

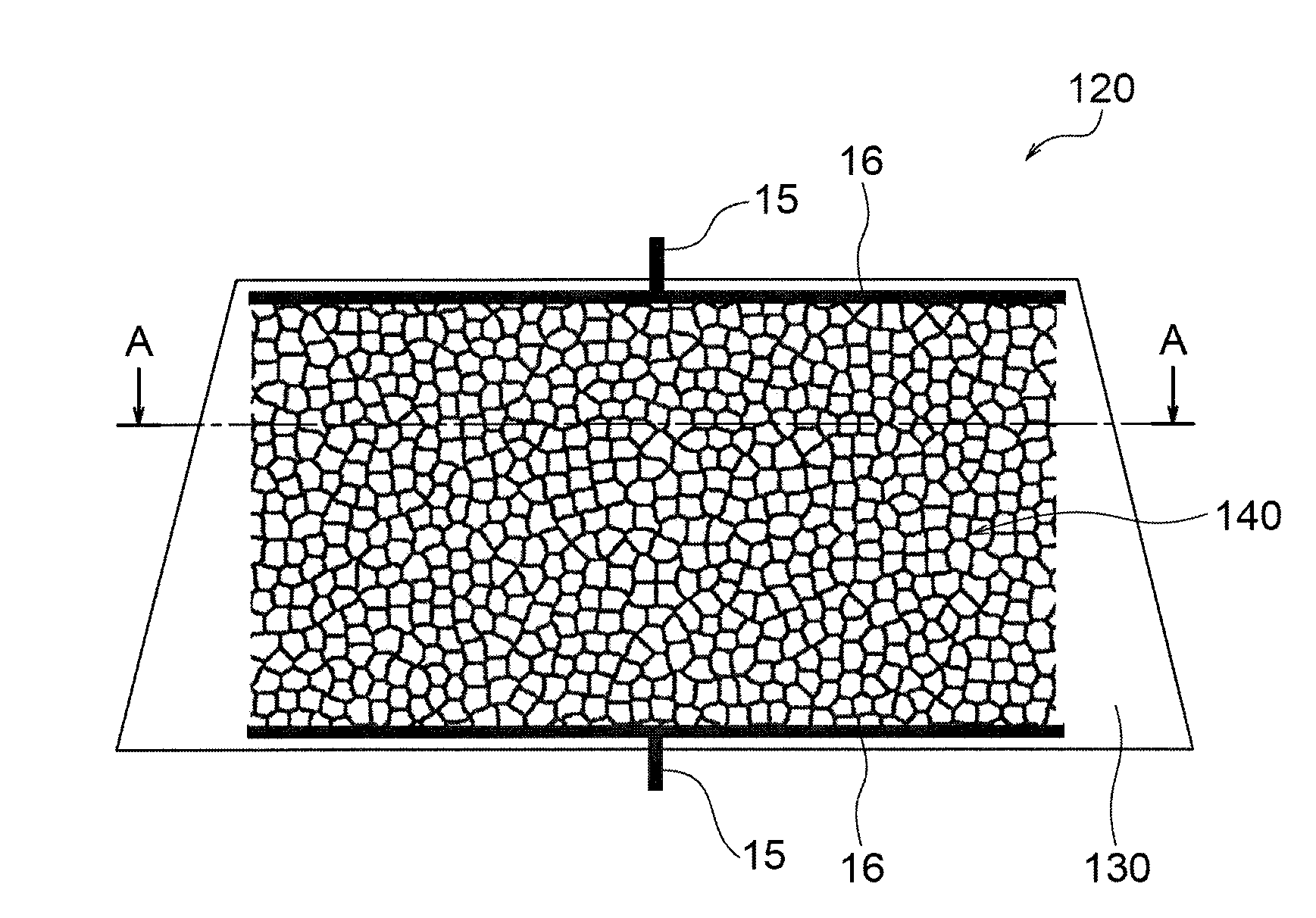

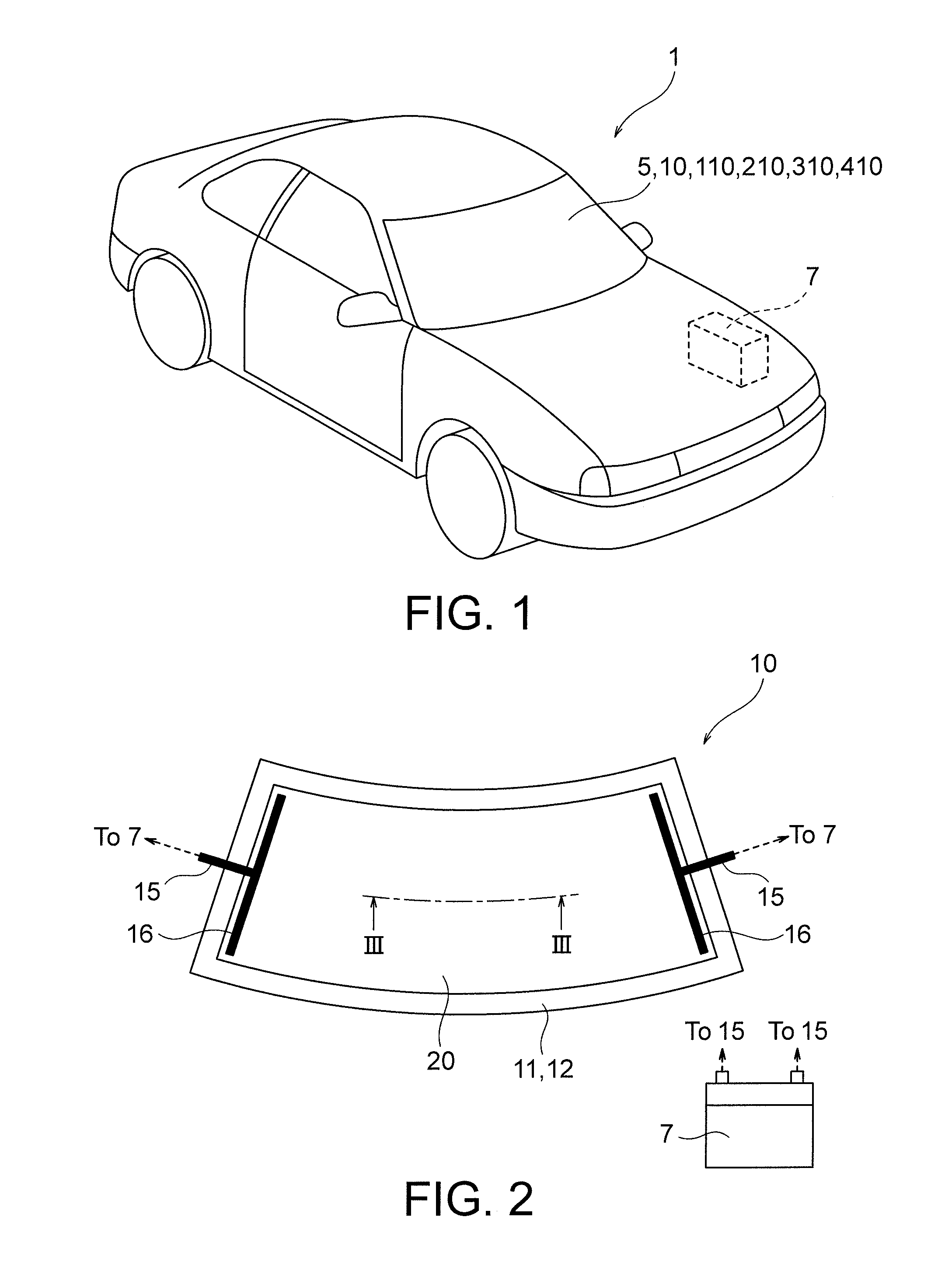

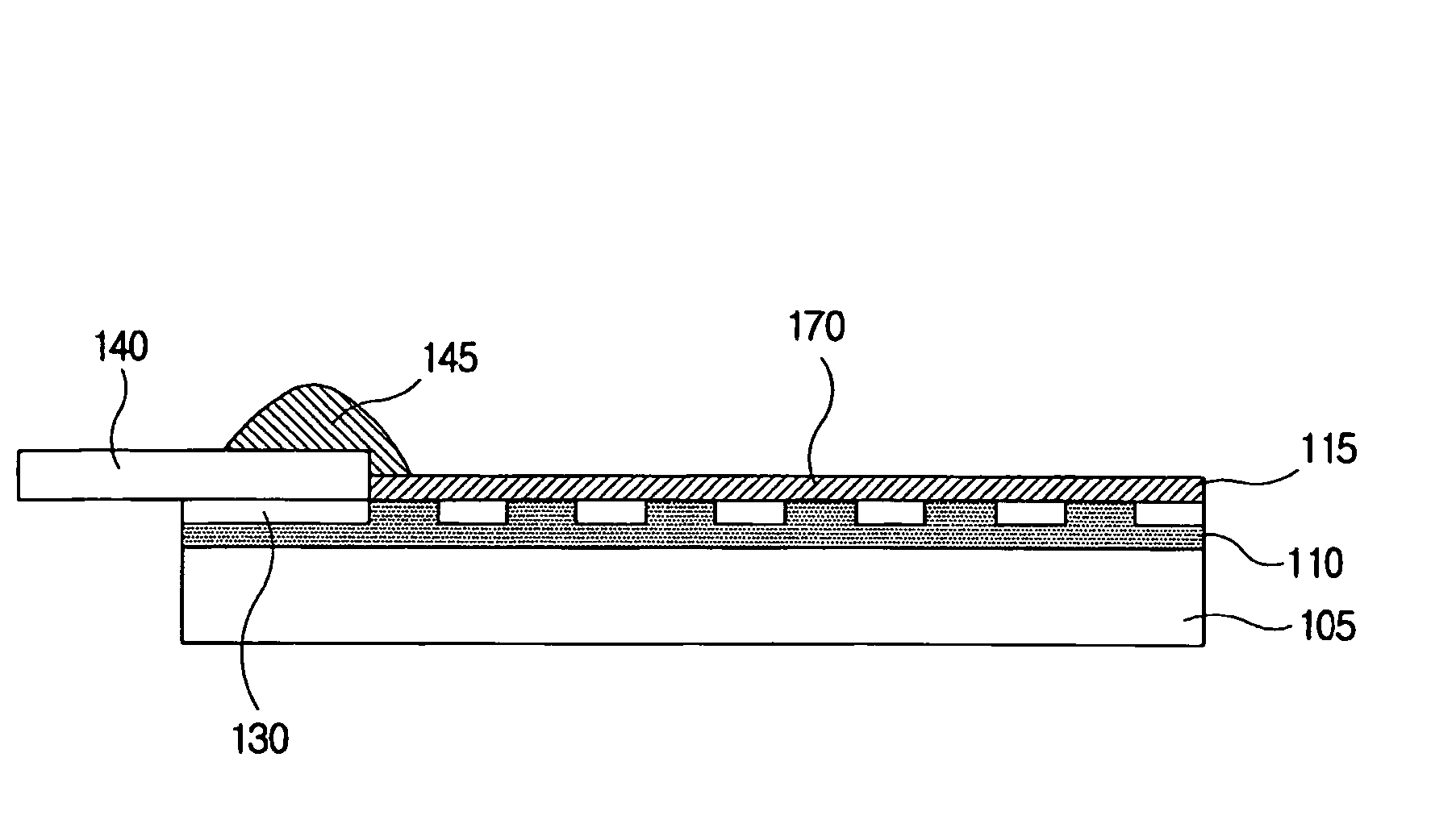

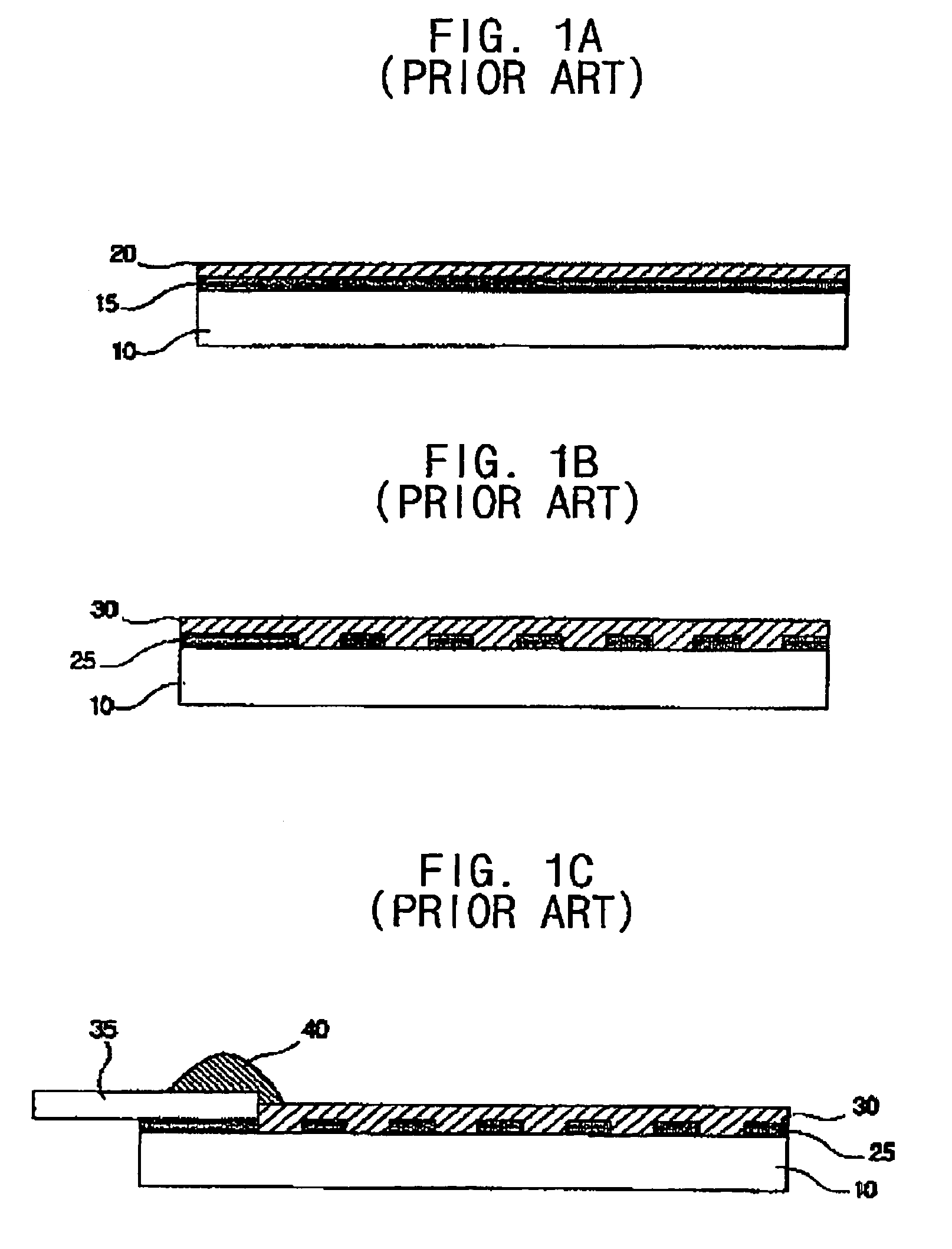

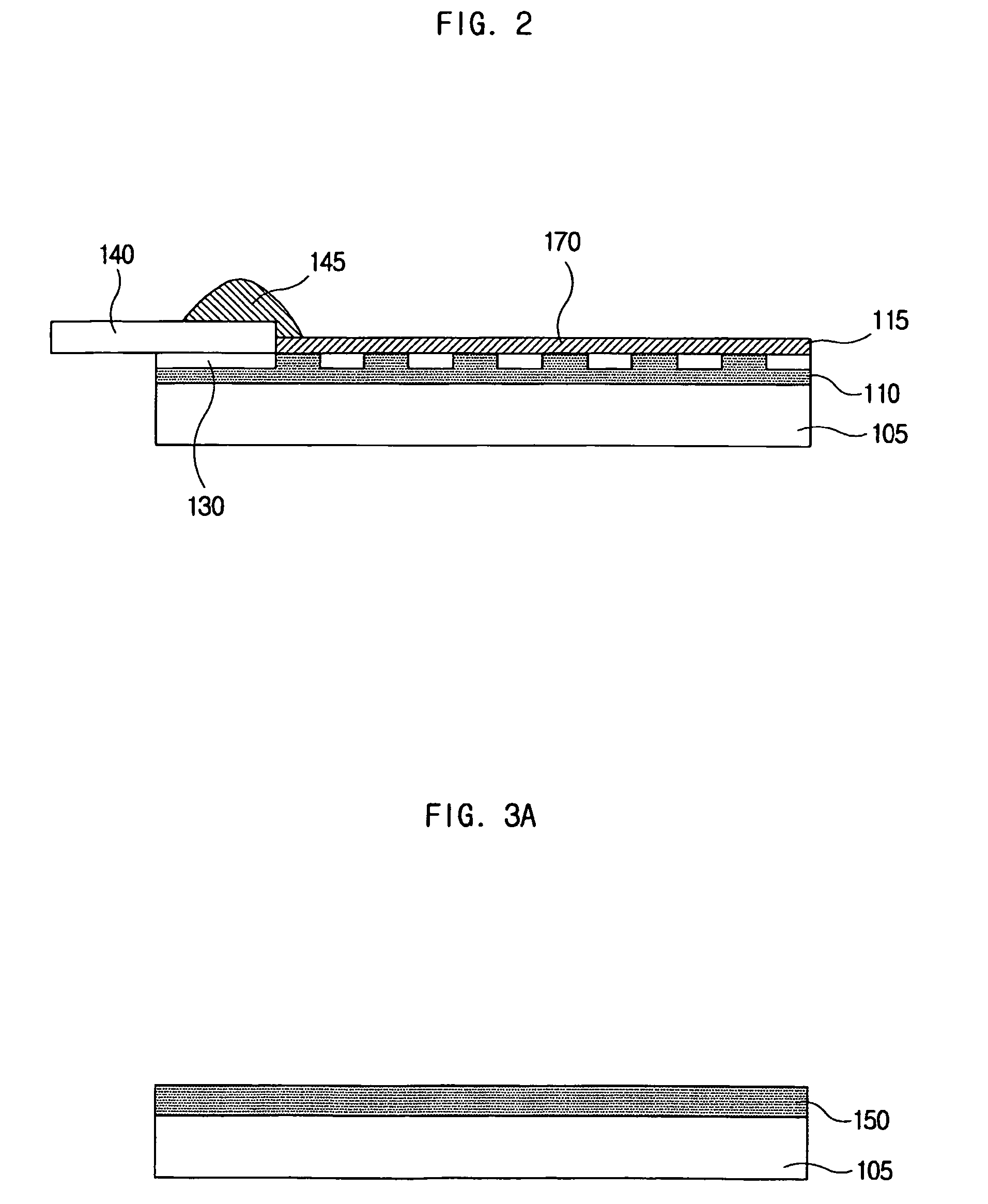

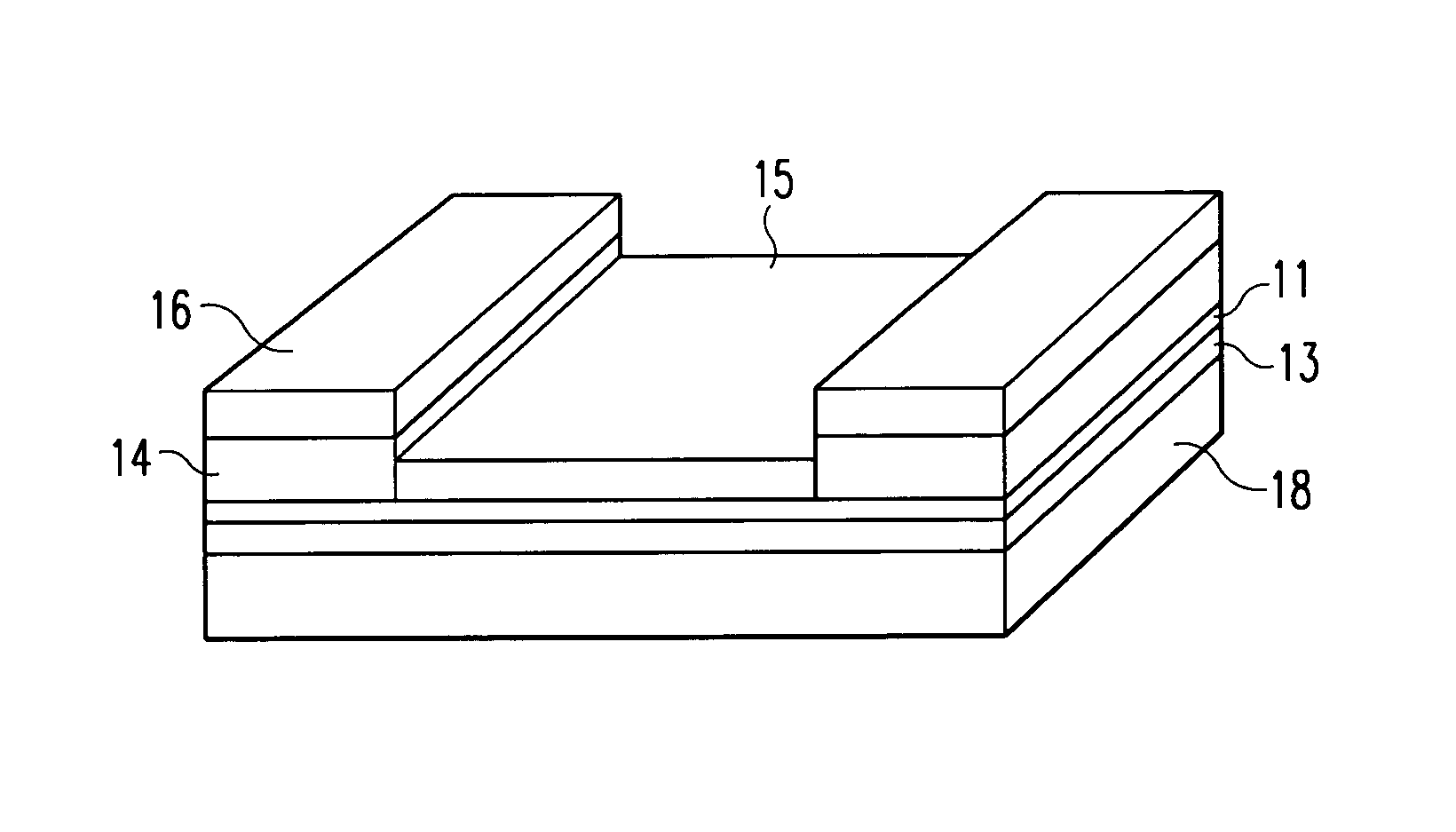

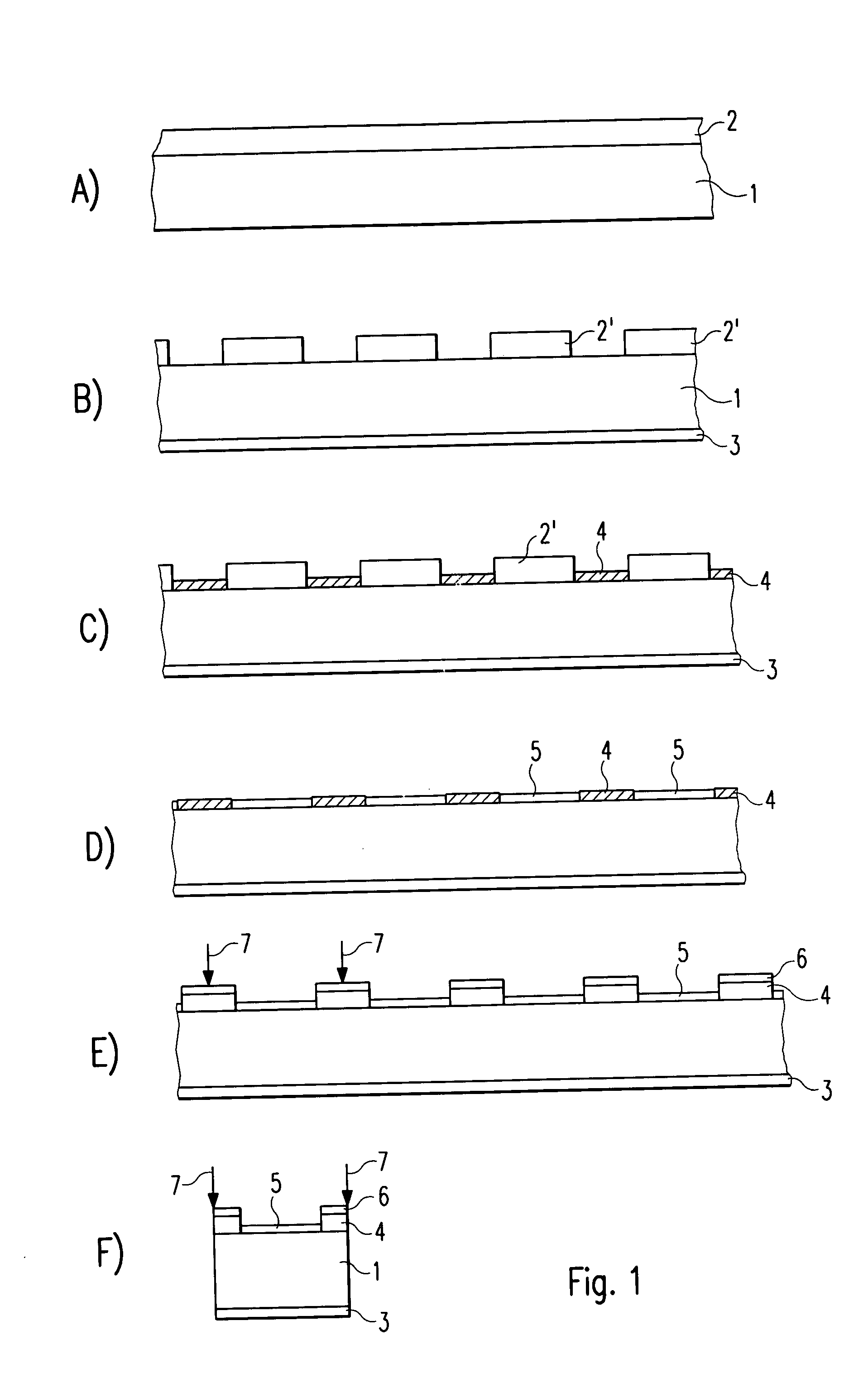

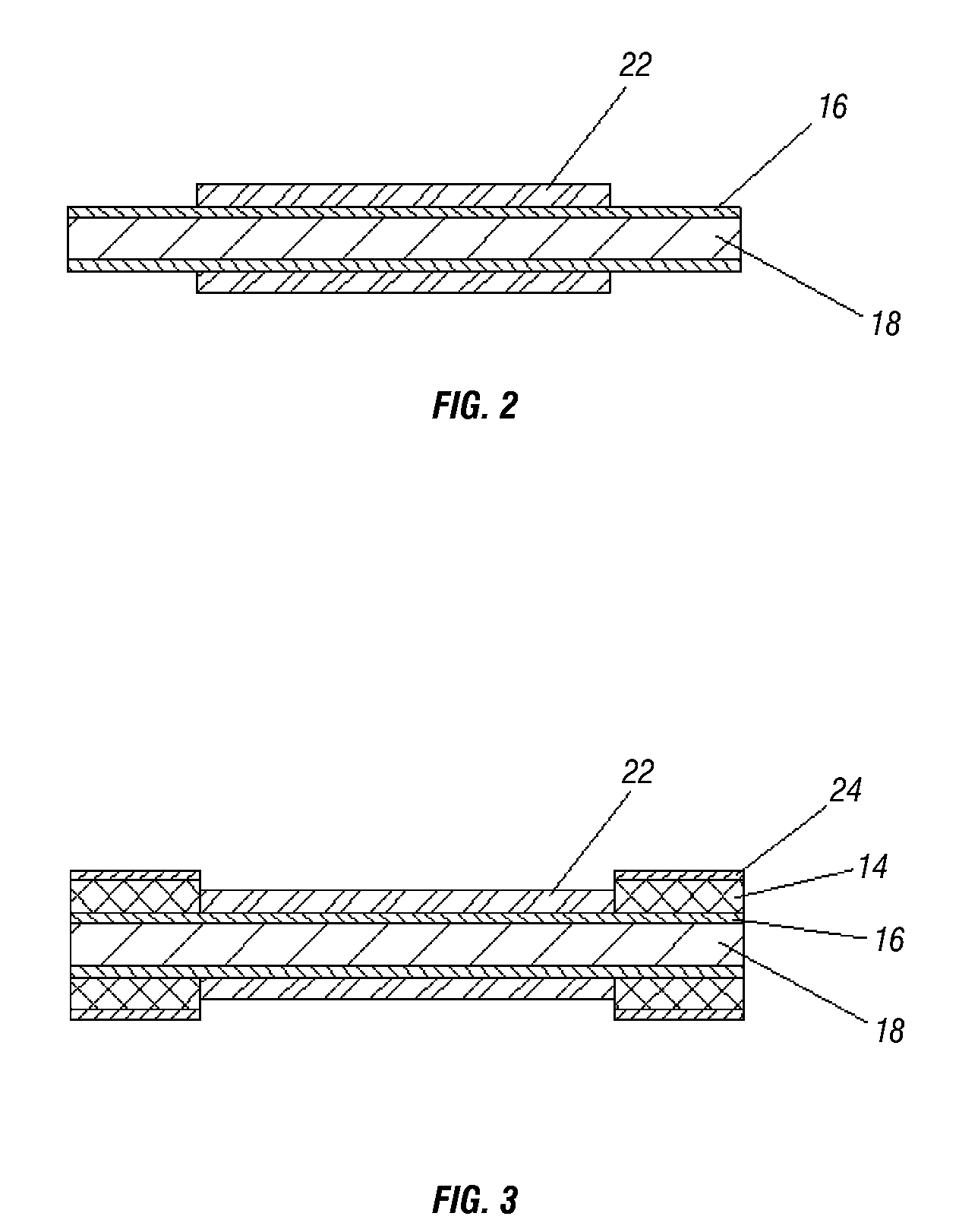

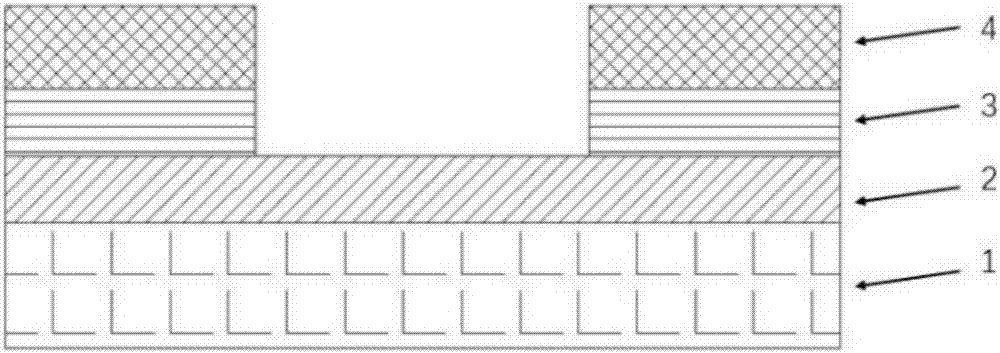

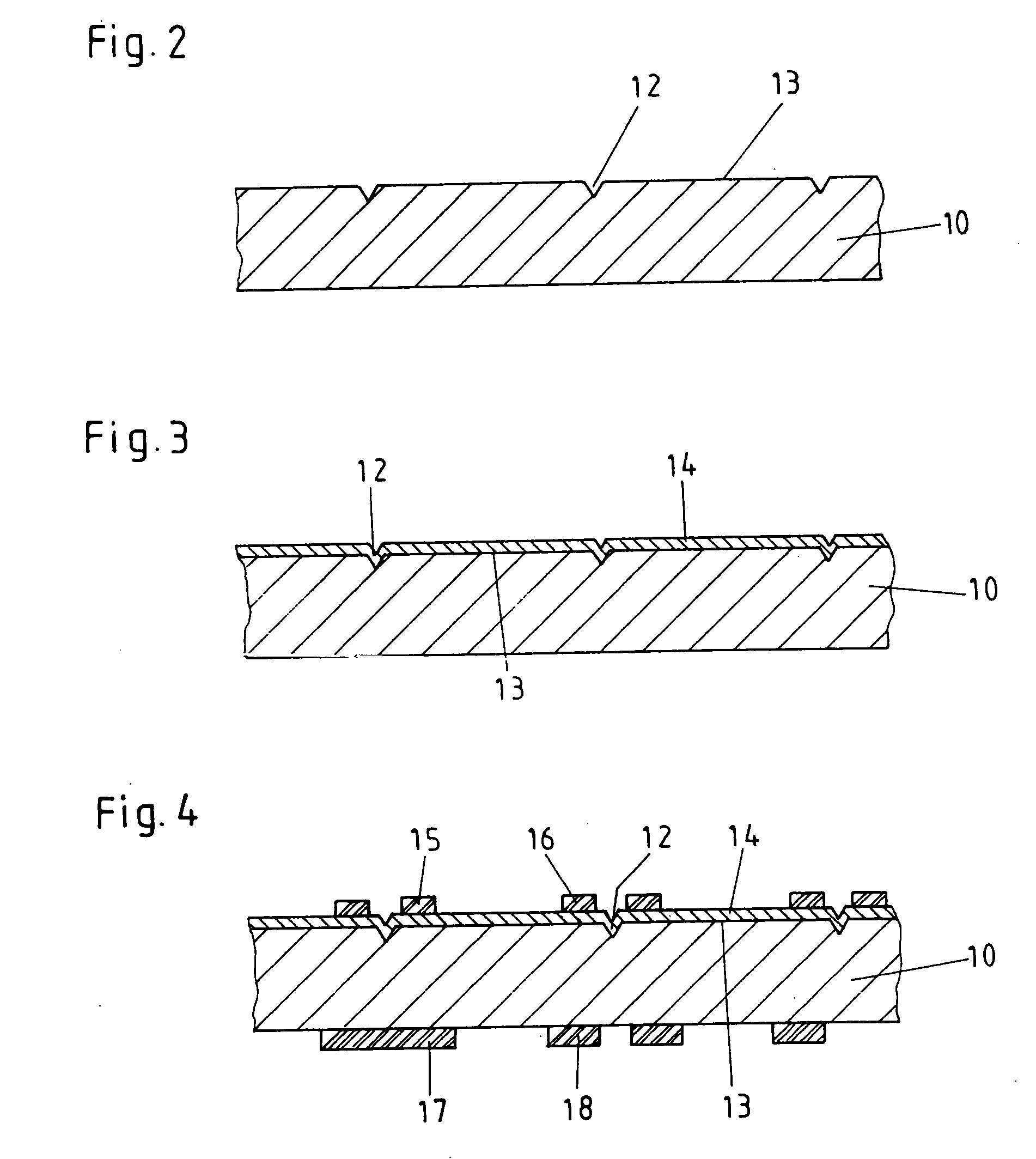

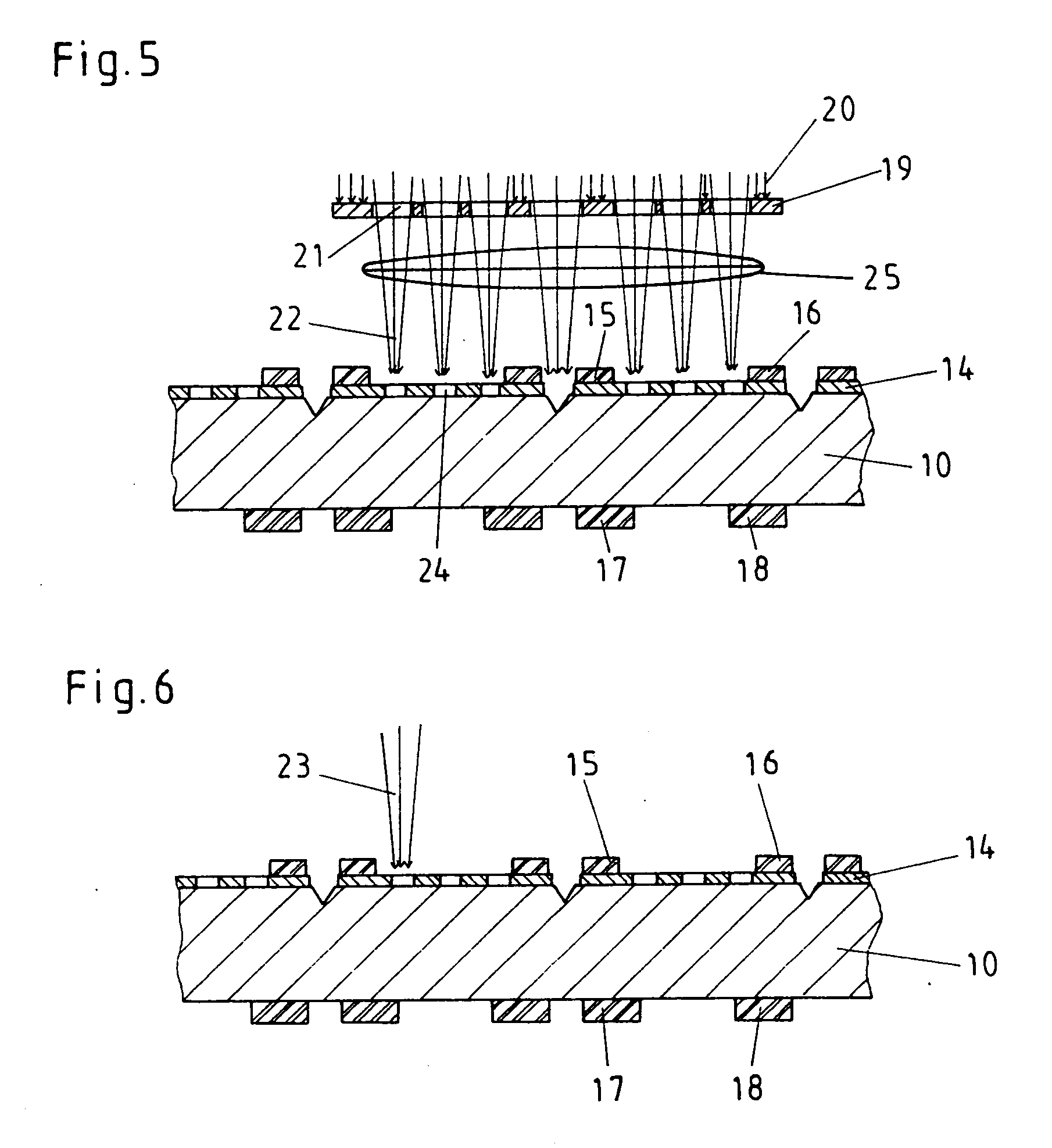

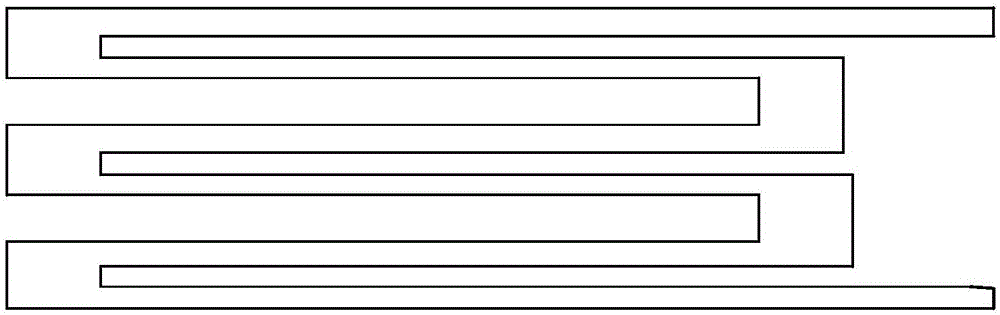

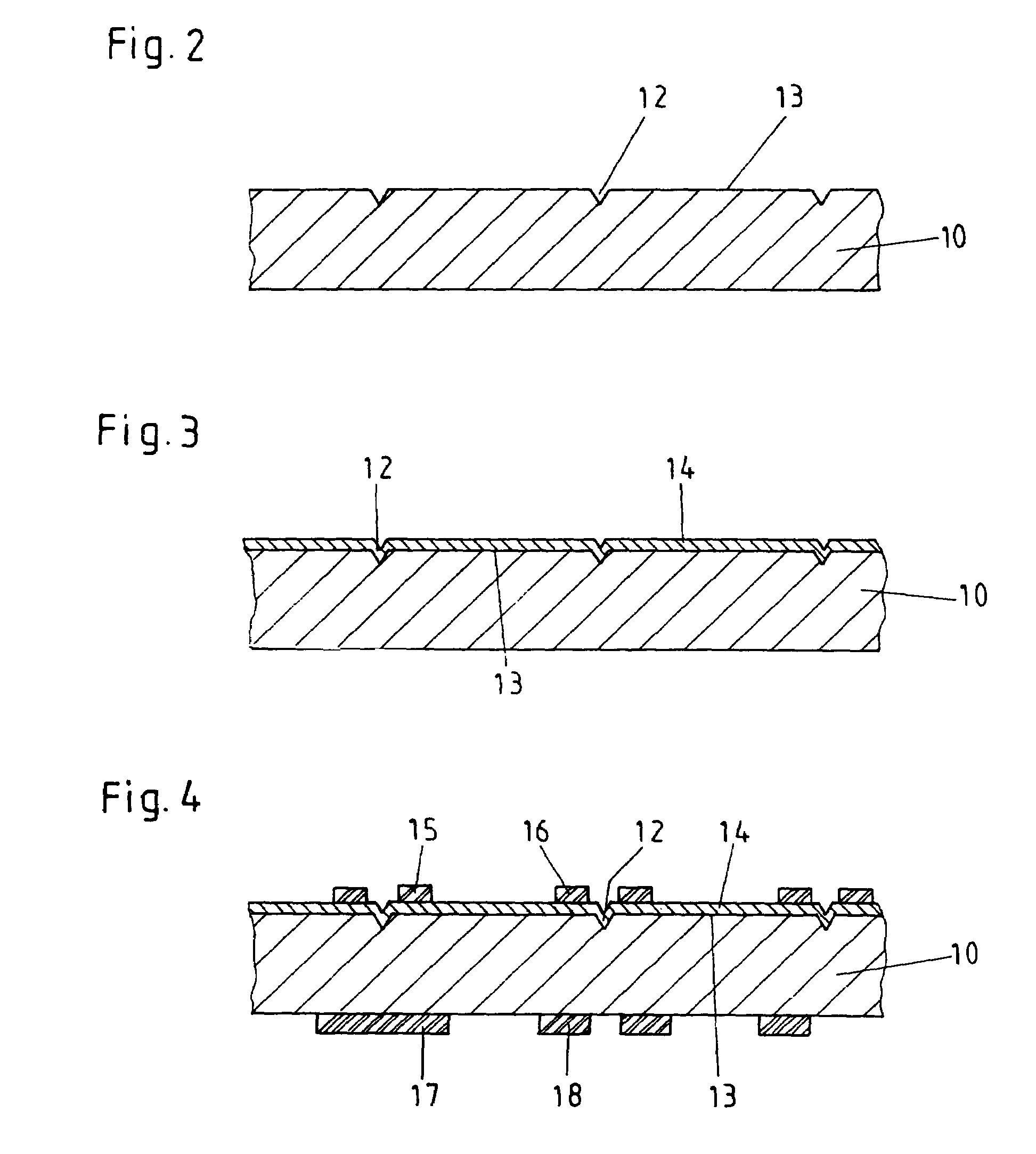

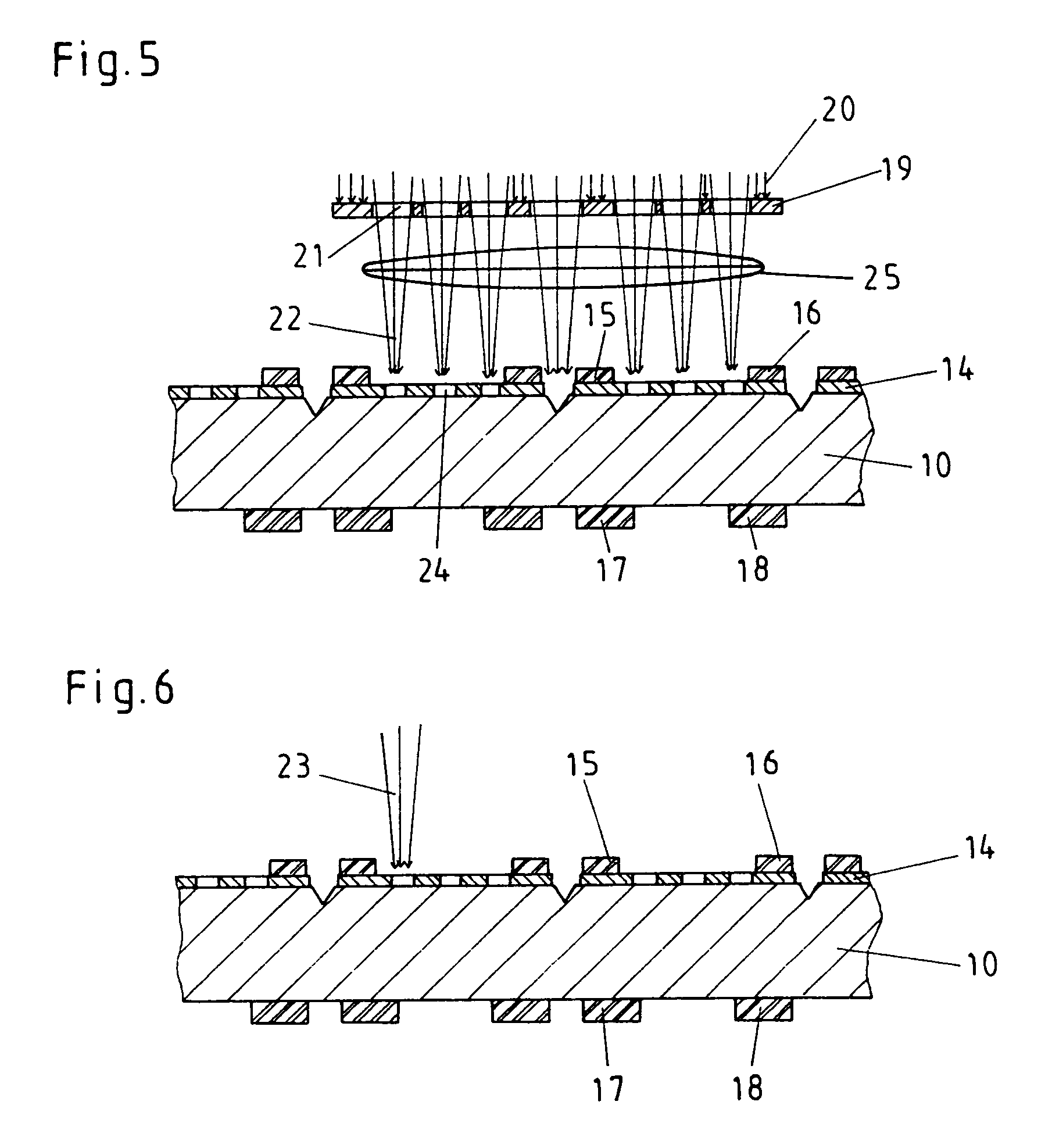

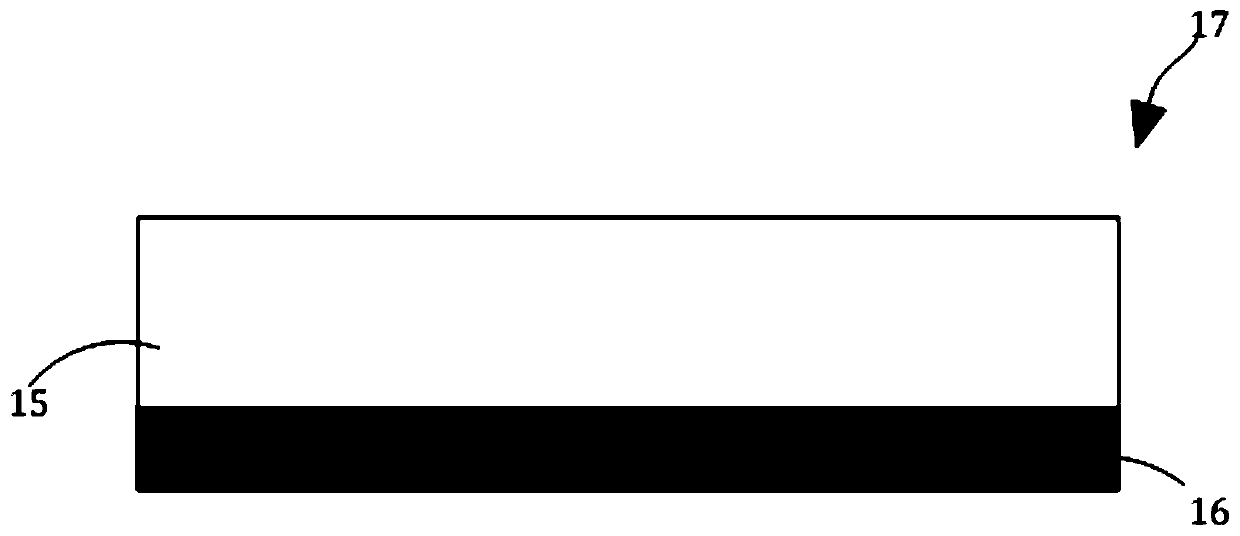

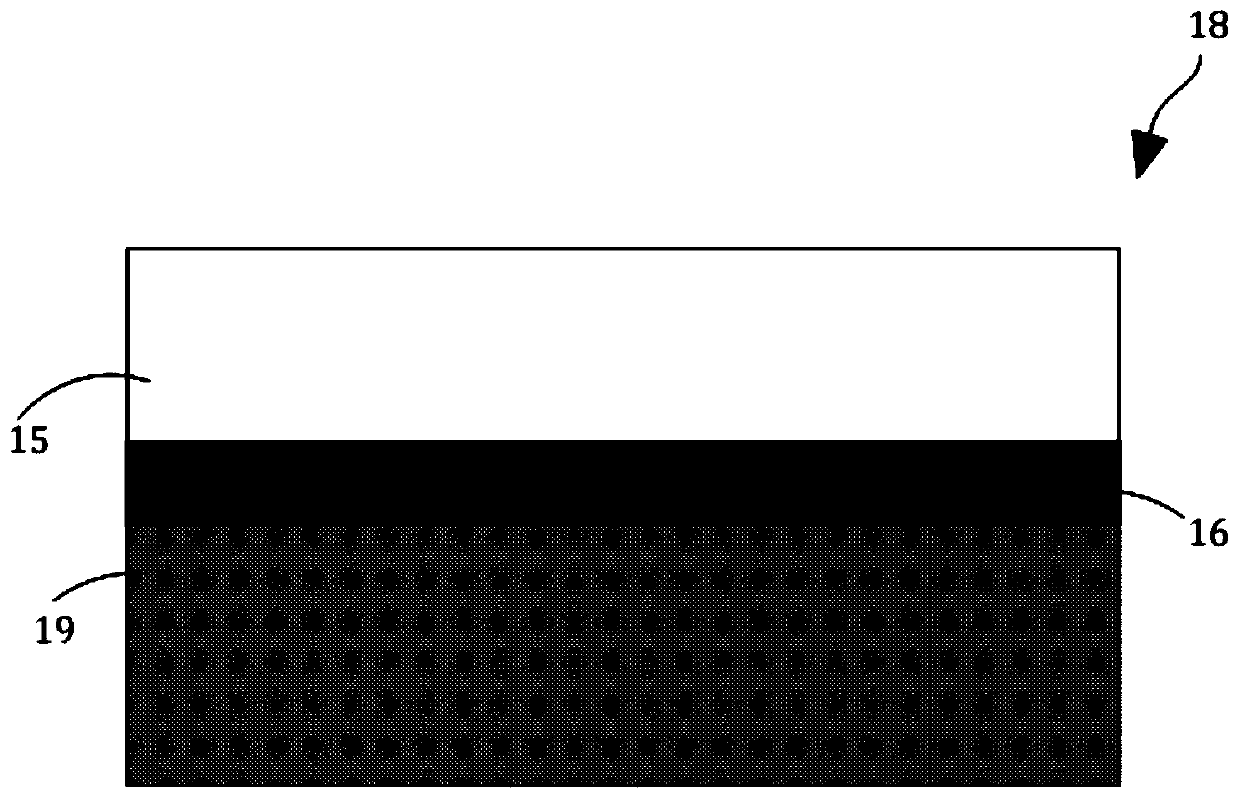

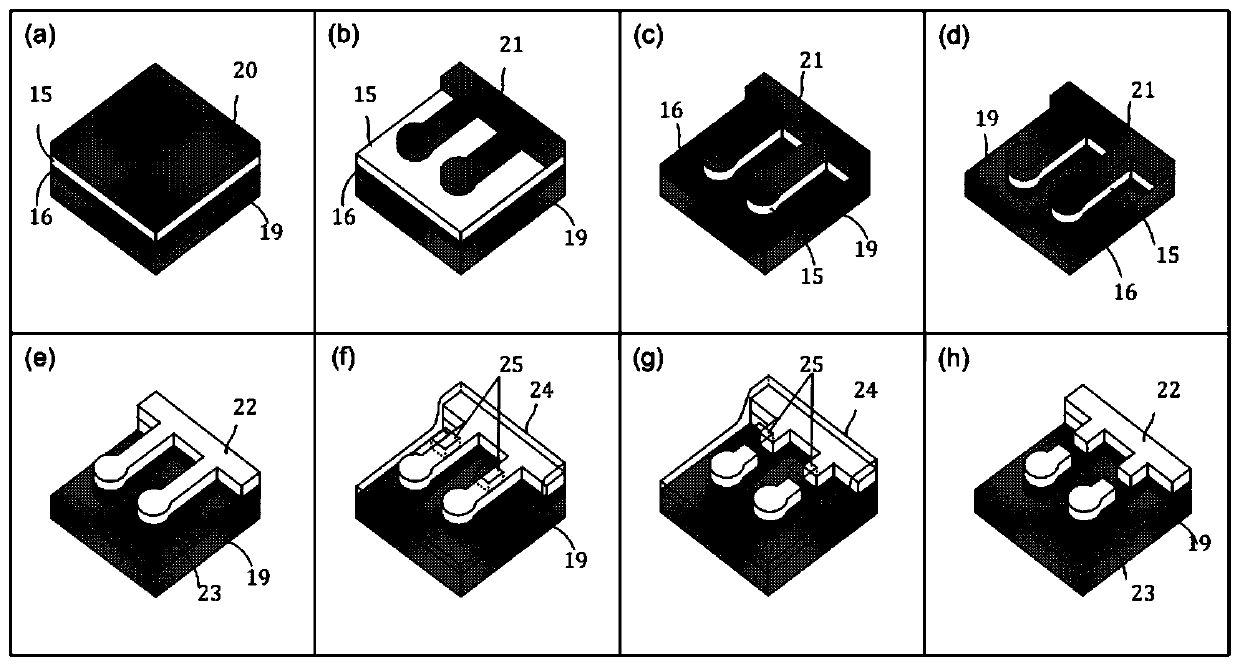

Method for the production of thin layer chip resistors

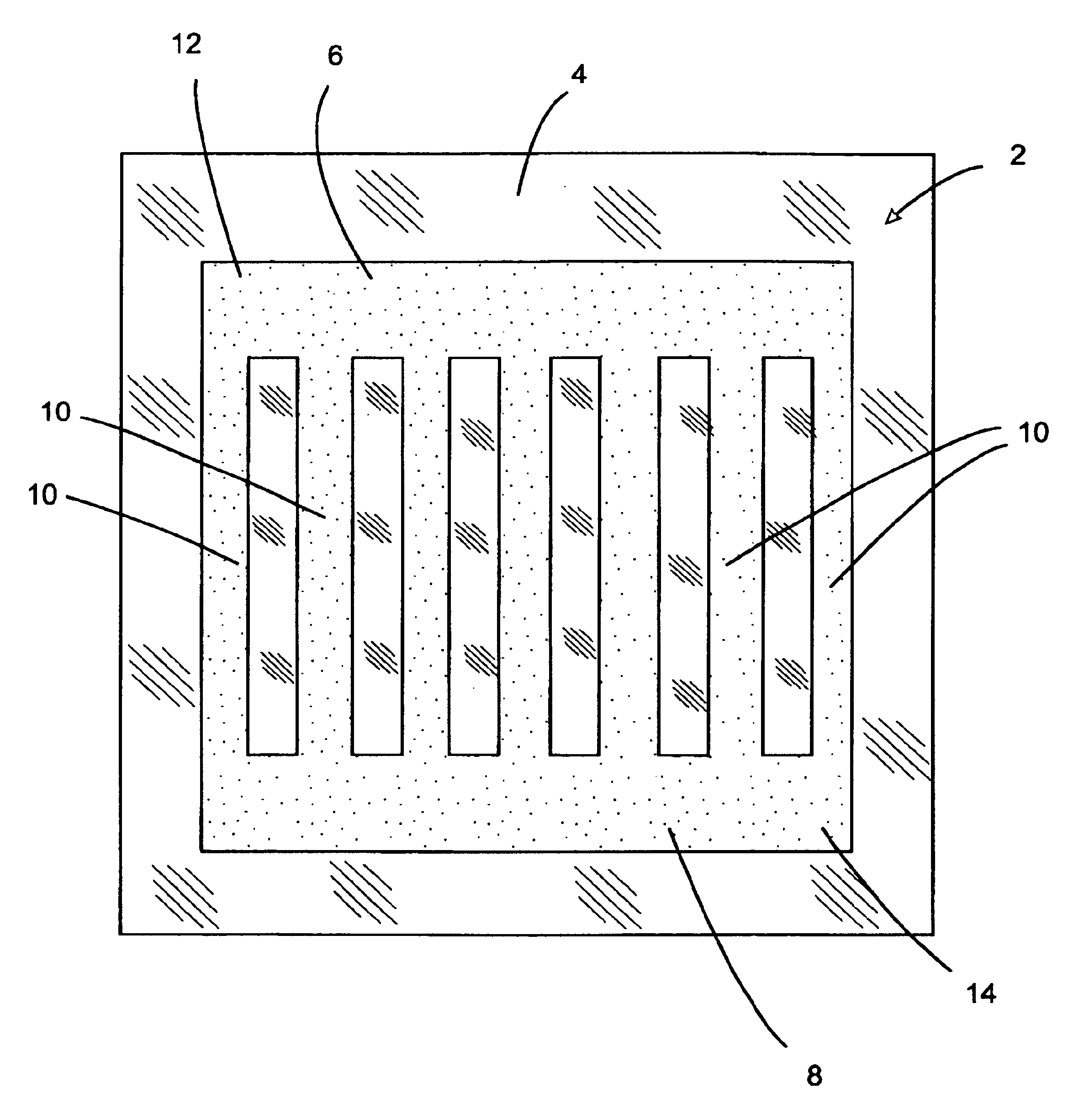

InactiveUS20040126704A1Faster and hence cheap manufacturingReduce manufacturing costResistor chip manufactureRadiation applicationsThin layerLaser light

A method for manufacturing thin-film chip resistors, in which method a resistor layer (14) and a contact layer (15, 16) are applied onto the upper surface of a substrate (10) and structured using laser light so as to form on said substrate (10) a plurality of adjacent, separate resistor lands (24) having a predetermined approximate resistance value, allows the simplified and cheap manufacturing by performing the electrical insulation of the resistor elements (24) and the structuring of the individual resistor lands (24) for the entire resistor land simultaneously by means of a laser-lithographic direct exposure method.

Owner:BCCOMPONENTS HLDG

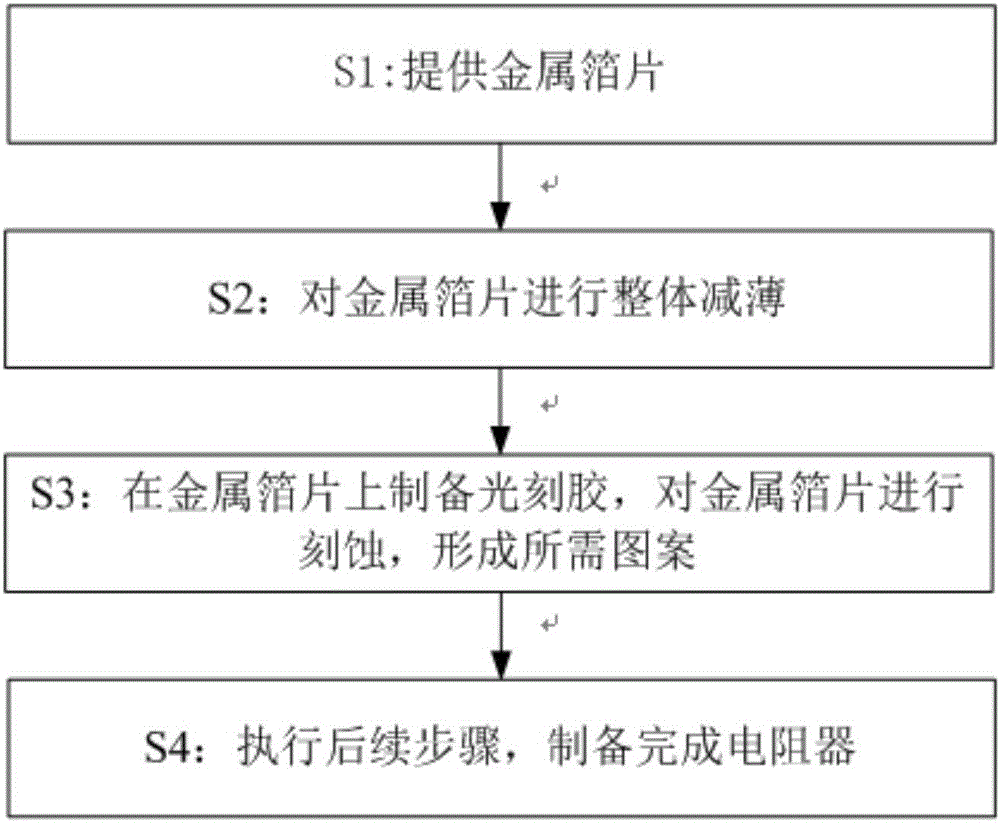

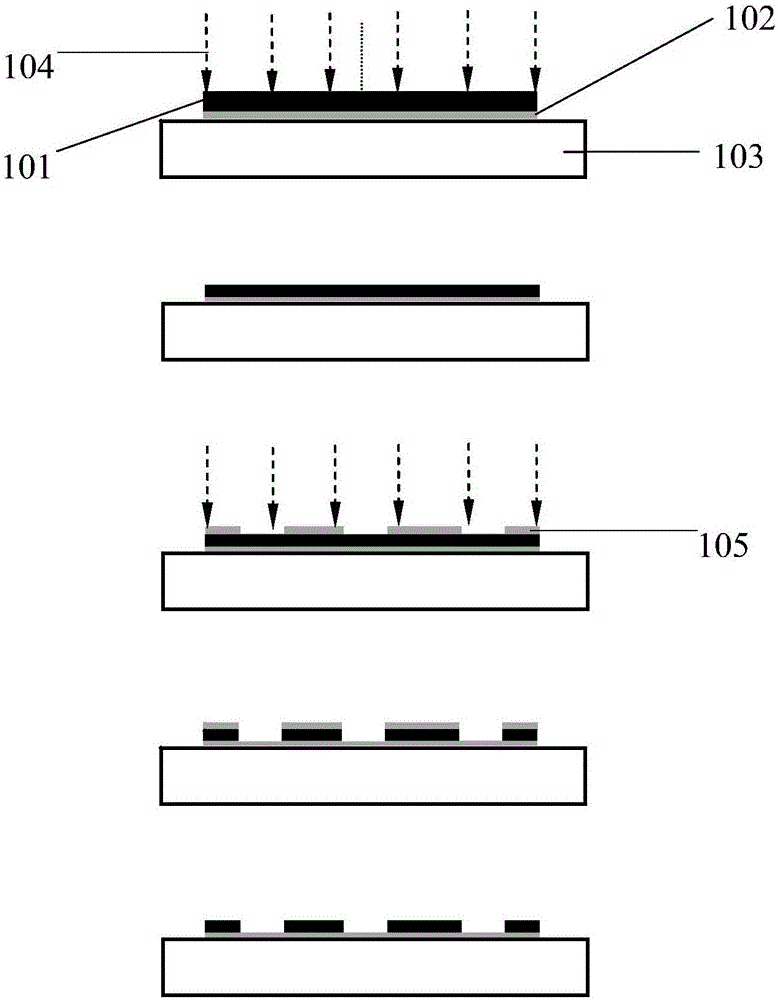

Resistor manufacturing method

InactiveCN106356169AIncrease resistanceIncrease temperatureResistor manufacture by lithographySemiconductor/solid-state device manufacturingMetal foilMetallurgy

The invention discloses a resistor manufacturing method, comprising: providing a metal foil; thinning the metal foil; producing photoresist on the metal foil, etching the metal foil, and forming a preset pattern on the metal foil; cleaning the residual photoresist to obtain a resistor. The method enables improved resistance for the resistor and increased temperature coefficient and high-temperature and low-temperature bidirectional stability, adhesion with an insulating base is improved, separation from the insulating base due to excessive internal stress is avoided, and the applicable range of resistance strain gauges is widened.

Owner:北京埃德万斯离子束技术研究所股份有限公司

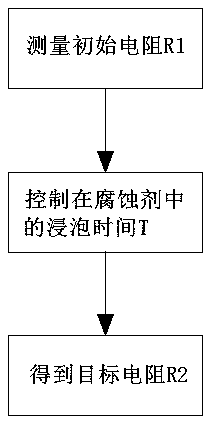

Chemical fine resistance adjusting method and etchant for resistor embedded in nickel-phosphorus layer

ActiveCN110473681AHigh control precisionUniform corrosionResistor manufacture by lithographyResistive material coatingElectrical resistance and conductanceAlloy

The invention discloses a chemical fine resistance adjusting method for a resistor embedded in a nickel-phosphorus layer, and belongs to the technical field of circuit boards. The method mainly solvesthe technical problem that a conventional resistance adjusting method cannot finely and uniformly adjust a resistance value. The method comprises firstly measuring the initial resistance value R1 ofa resistor before resistance adjustment; and obtaining the target resistance value R2 of the resistor by controlling the immersion time T of the resistor in an etchant for etching a nickel-phosphorusalloy layer. The invention discloses a chemical fine resistance adjusting etchant for a resistor embedded in a nickel-phosphorus layer. The method etches the nickel-phosphorus alloy layer uniformly, and can finely control the change of the resistance by controlling the time so as to obtain the target resistance value and improve the resistance control precision.

Owner:BOMIN ELECTRONICS CO LTD

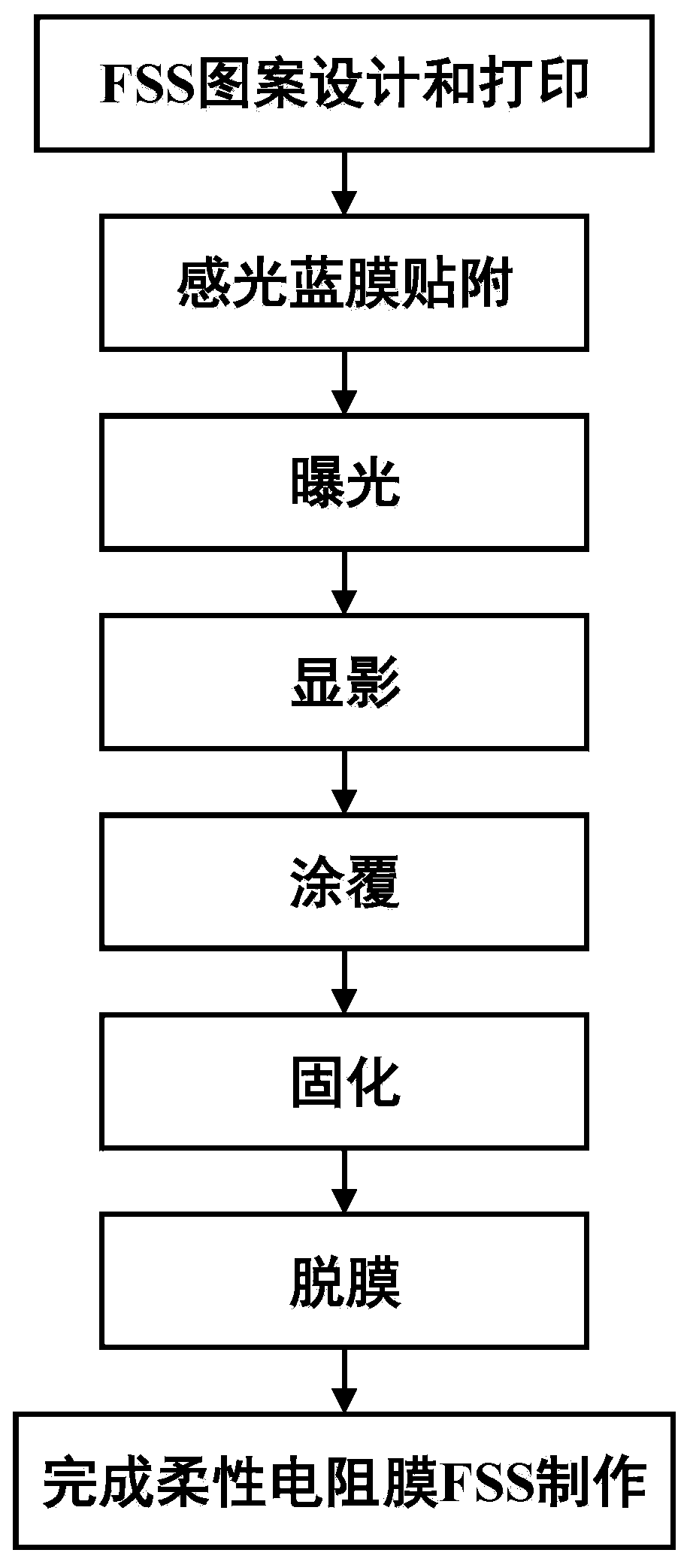

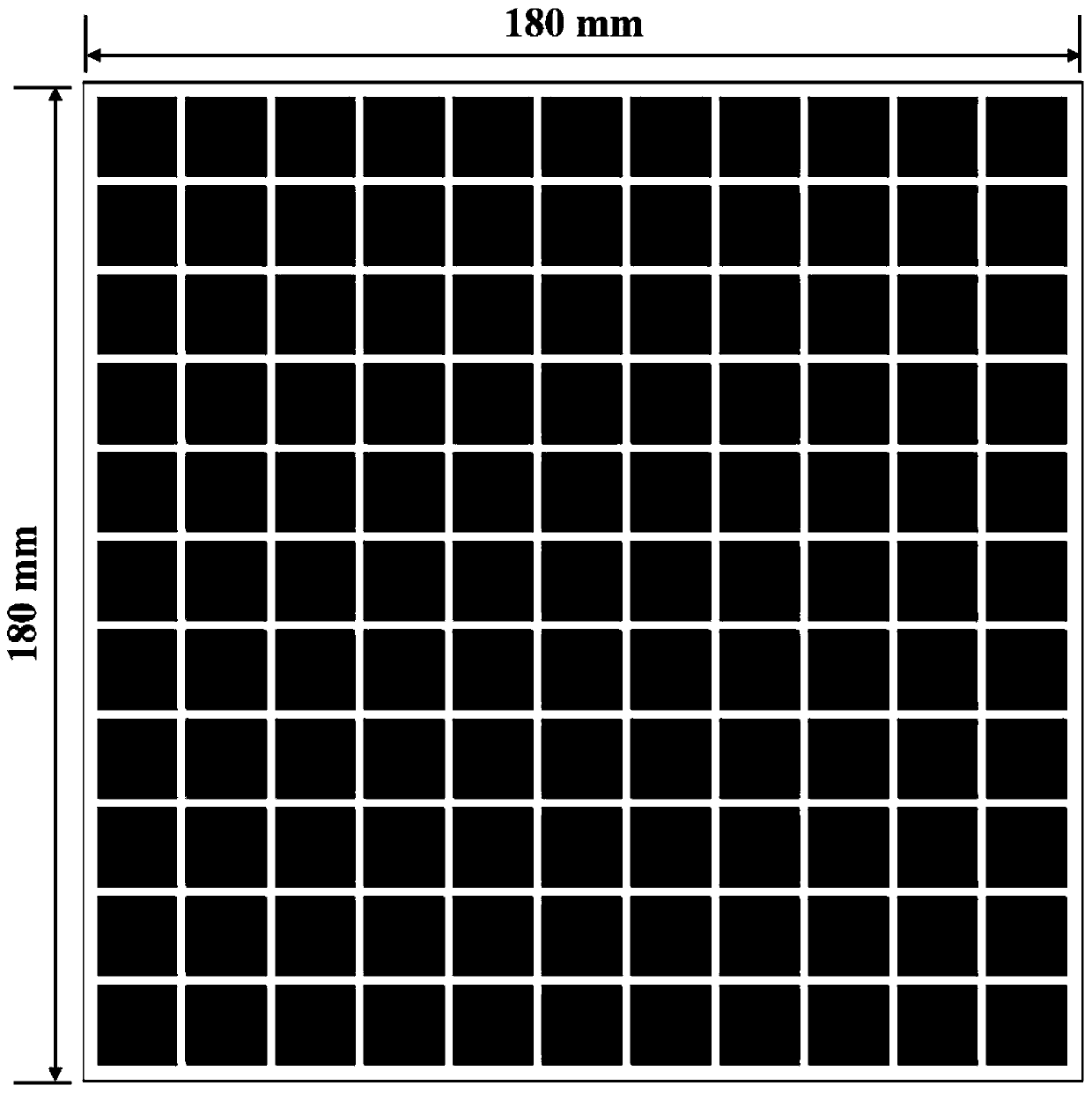

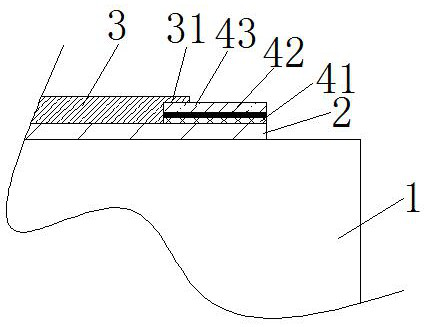

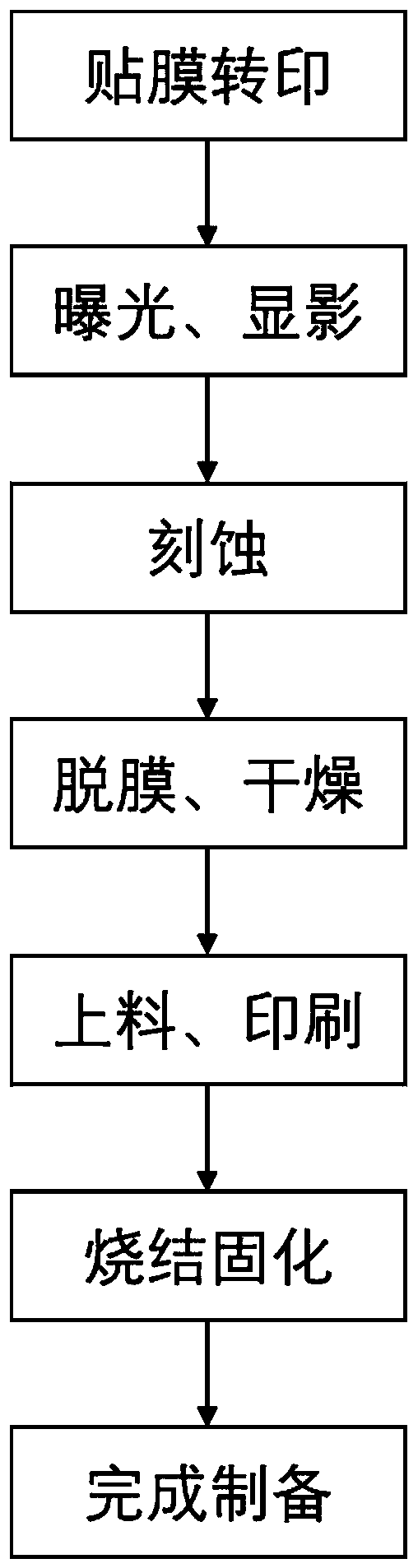

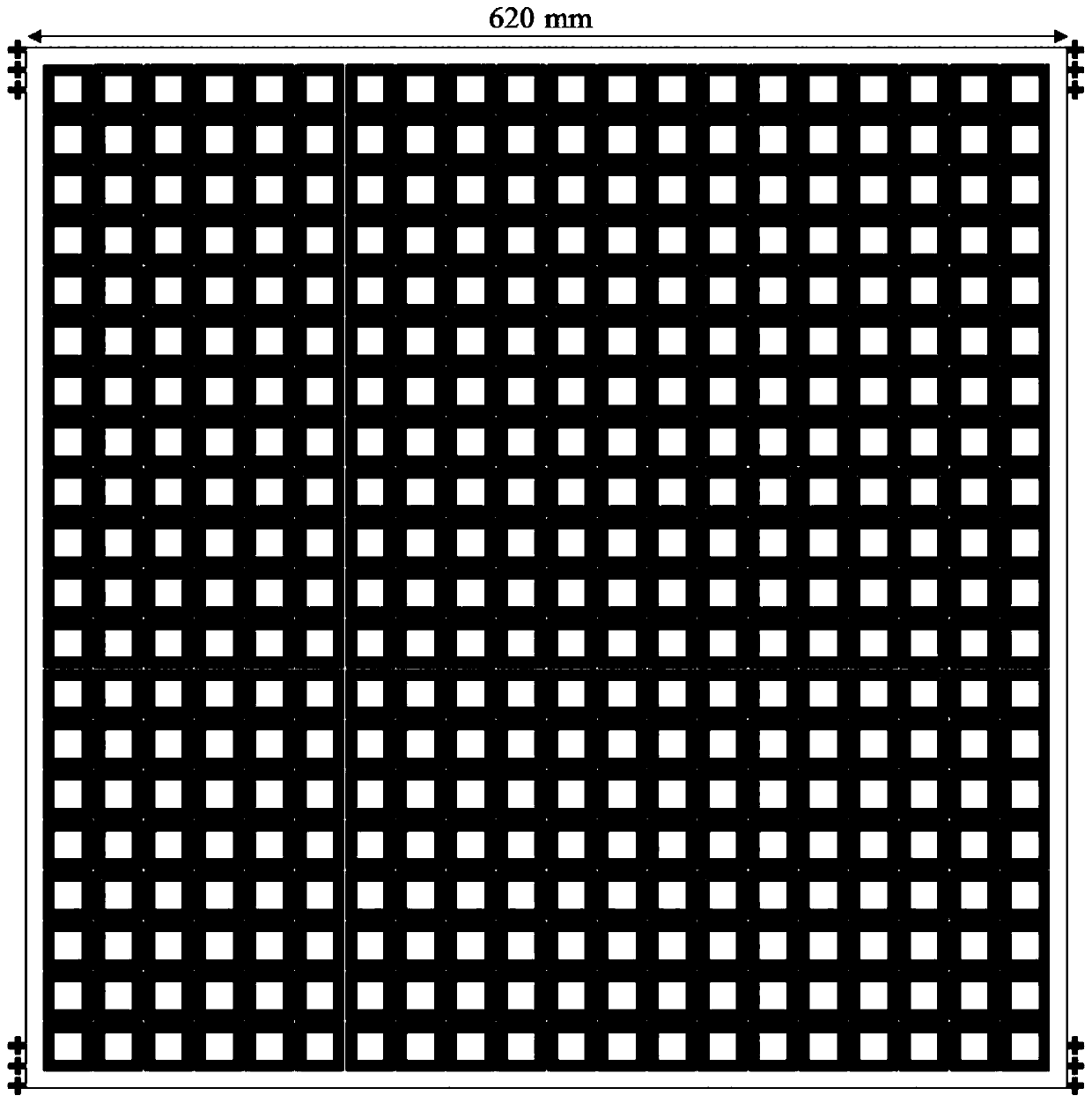

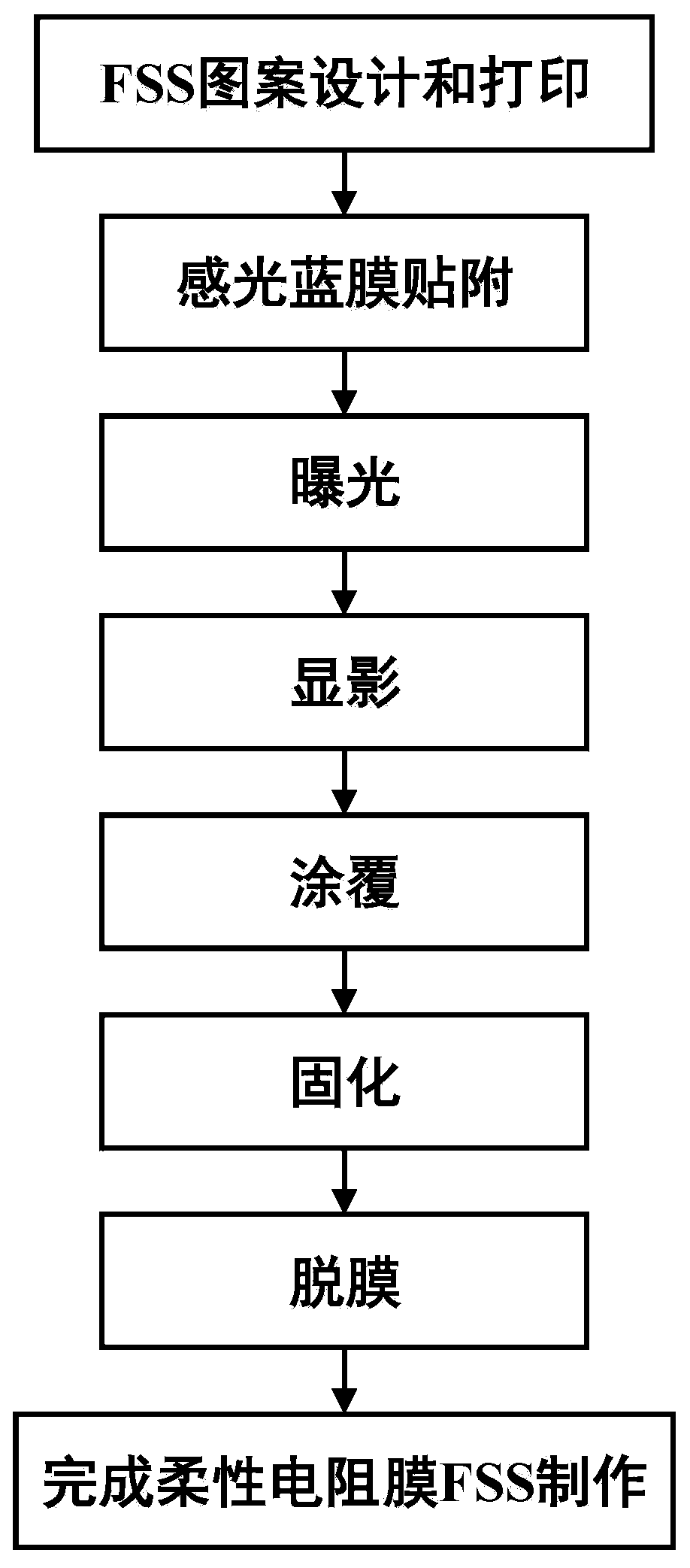

Flexible resistive film frequency selective surface, preparation method and application thereof

ActiveCN110247192AMature technologyEasy to operateMagnetic/electric field screeningResistor manufacture by lithographyRadarDielectric substrate

The invention belongs to the field of flexible FSS radar wave-absorbing structures, and more particularly to a flexible resistive film frequency selective surface, a preparation method and application thereof. The method comprises the steps of: printing a set frequency selective surface pattern on a photosensitive film, and attaching the photosensitive film to the surface of a flexible dielectric substrate; successively exposing and developing the photosensitive film on which the frequency selective surface pattern is printed in order to expose the frequency selective surface pattern on the surface of the flexible dielectric substrate; coating the surface of the developed flexible dielectric substrate with resistive conductive carbon paste, and sintering and curing the flexible dielectric substrate coated with the conductive carbon paste, wherein the cured conductive carbon paste is a resistive film; demolding the cured flexible dielectric substrate, removing the photosensitive film and the resistive film on the surface of the flexible dielectric substrate to obtain the flexible resistive film frequency selective surface. The FSS surface preparation method of the invention is simple, and can produce a large-area flexible passive resistive film frequency selective surface applied to a curved surface.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for the production of thin layer chip resistors

InactiveUS6998220B2Improve accuracyIncrease productionResistor chip manufactureRadiation applicationsThin layerEngineering

Owner:BCCOMPONENTS HLDG

Chip thin-film resistor network

PendingCN112038026AProtection stabilityEliminate vulcanizationOther resistor networksResistor terminals/electrodesFilm resistanceThin membrane

The invention belongs to the technical field of chip thin-film resistors, and particularly relates to a chip thin-film resistor network which comprises a ceramic substrate. A resistive film layer is sputtered on the front surface of the ceramic substrate and is cut into a plurality of resistor units by laser scribing, and two front electrodes are arranged on the surface of each resistor unit. Eachfront electrode comprises a barrier layer, an electrode bottom layer and an electrode surface layer from bottom to top, and a passivation layer is arranged between the front electrodes on the surfaceof each resistor. Compared with the prior art, the chip thin-film resistor network has the advantages that the tungsten-titanium film layer is sputtered to serve as the barrier layer, the stability of the front electrodes can be protected, and a vulcanization phenomenon is eradicated; the processing conditions are controllable, the absolute precision of the resistors of the obtained chip thin-film resistor network reaches + / - 0.05%, a temperature coefficient reaches + / - 5 *10 <6> / K, a relative temperature coefficient reaches + / - 2 *10 <6> / K, and the relative precision reaches + / - 0.02%.

Owner:BDS ELECTRONICS

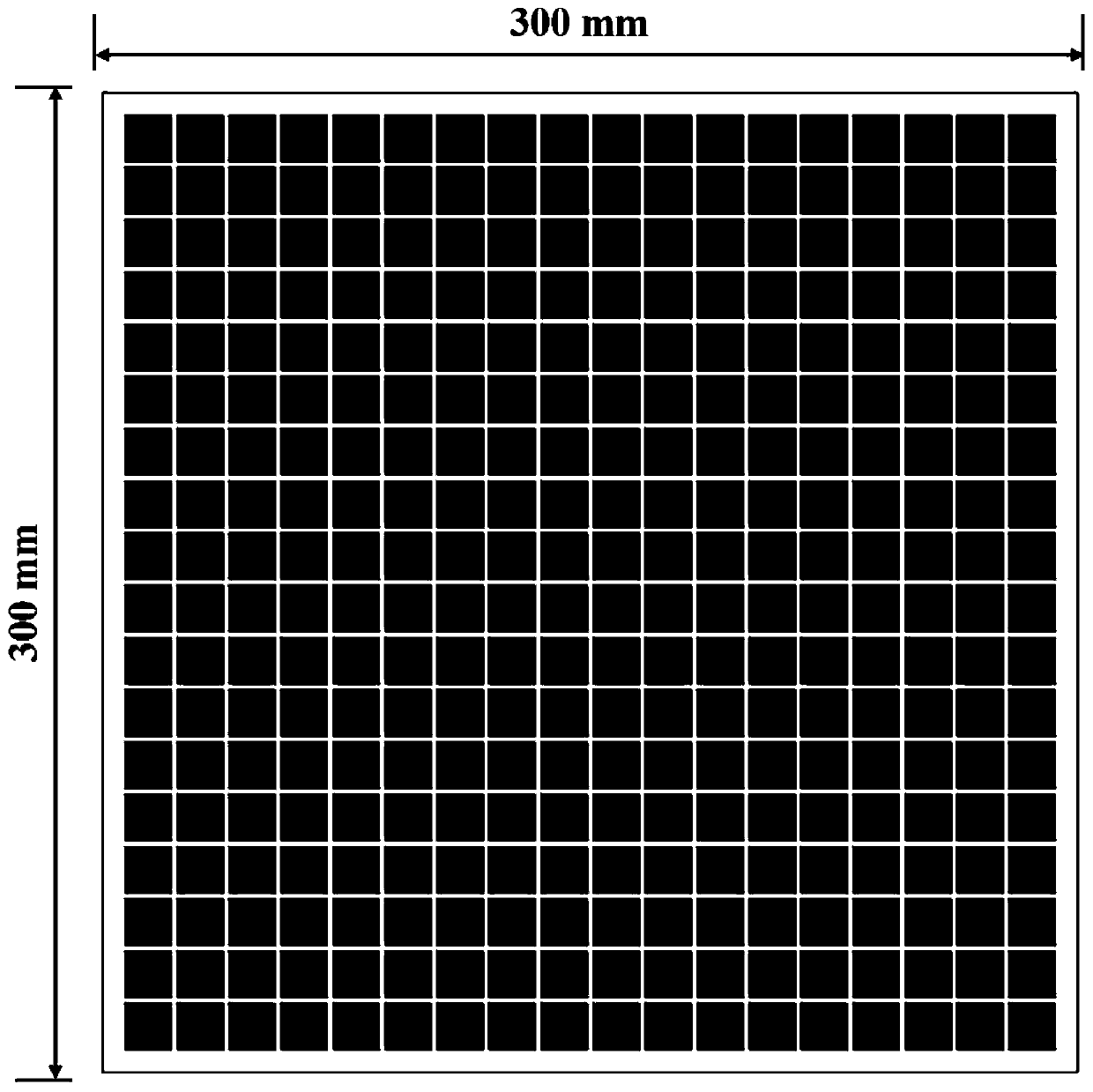

Flexible resistive film-metal composite frequency selective surface and preparation and application thereof

ActiveCN110556632AEasy to operateSimple preparation processMagnetic/electric field screeningResistor manufacture by lithographyScreen printingEngineering

The invention belongs to the field of flexible FSS wave-absorbing structures, and particularly relates to a flexible resistive film-metal composite frequency selective surface and a preparation and application thereof. A photosensitive film printed with a frequency selective surface pattern on the surface is attached to a flexible copper-clad plate, and exposing and developing are carried out in sequence to obtain a developed flexible copper-clad plate; the developed flexible copper-clad plate is etched to obtain an etched flexible copper-clad plate; the etched flexible copper-clad plate is de-molded and dried; a frequency selective surface pattern with a copper surface is obtained after de-molding; conductive carbon paste is extruded from the meshes of a silk-screen printing plate to thesurface or back of the de-molded flexible copper-clad plate by adopting a silk-screen printing technology, and a resistive film is obtained after sintering and curing; and a flexible resistive film-metal composite frequency selective surface is obtained. The preparation method provided by the invention is simple to operate, and can be used to prepare a large-area flexible resistive film-metal composite FSS applied to a curved surface.

Owner:HUAZHONG UNIV OF SCI & TECH

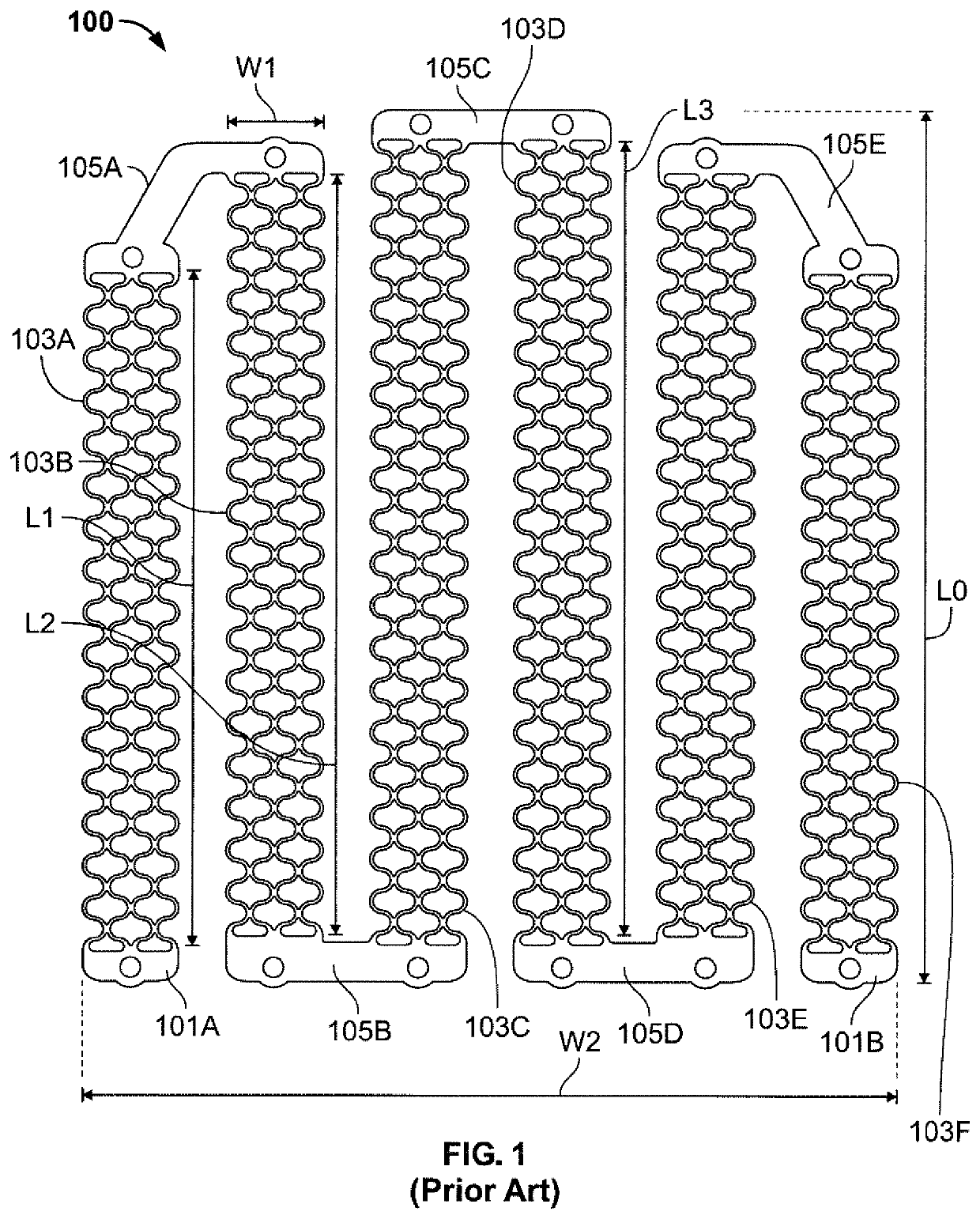

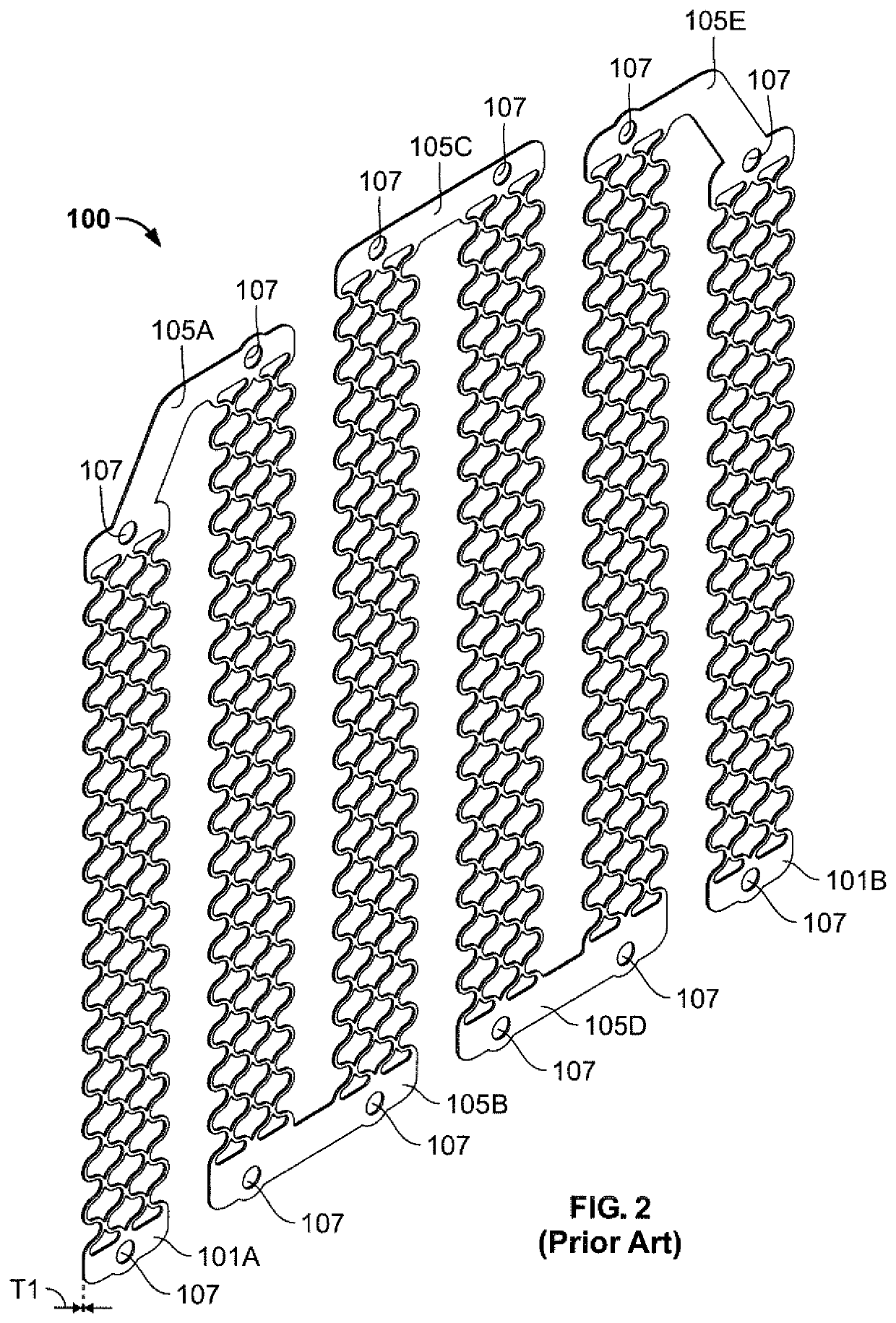

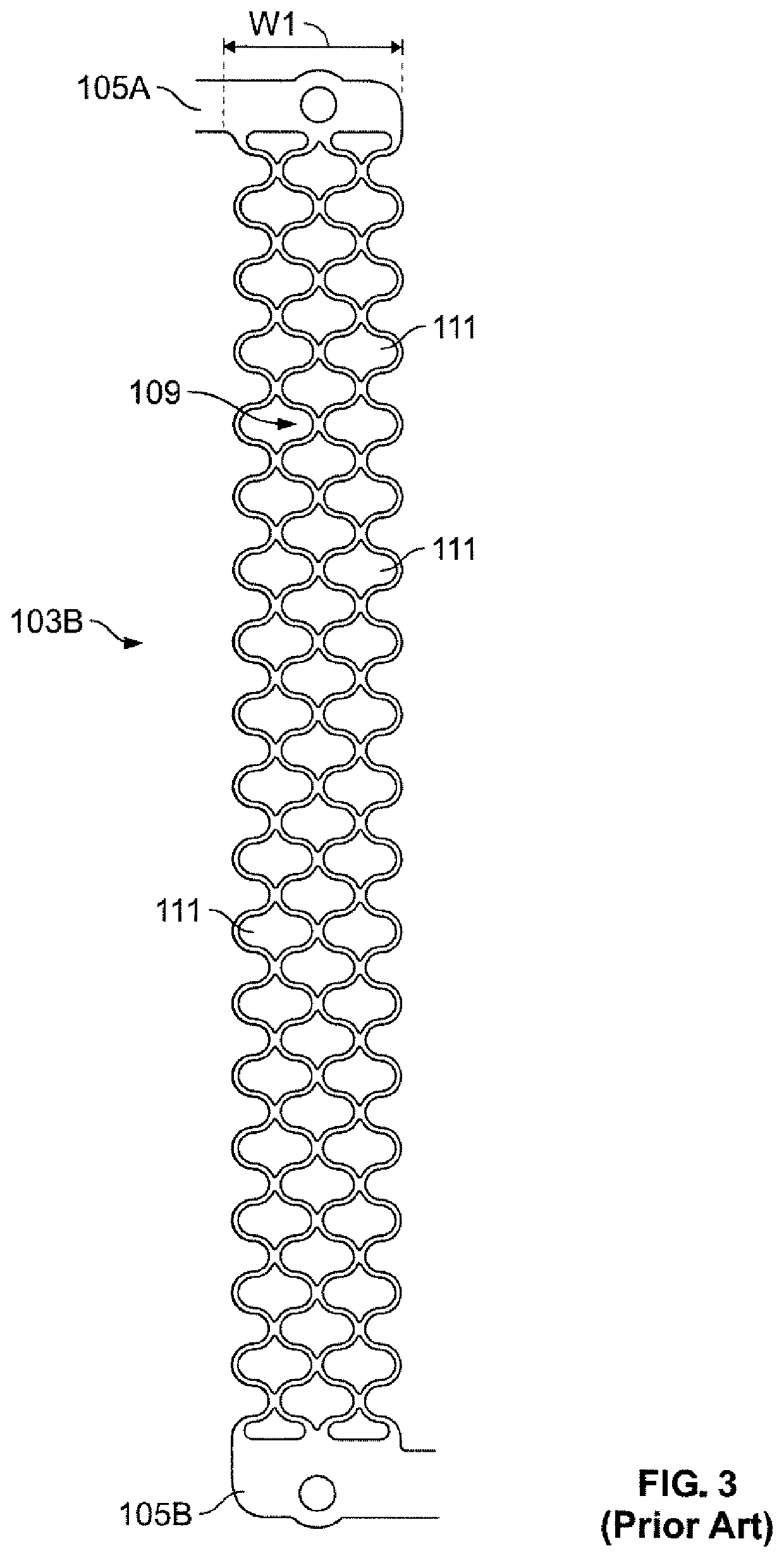

Heating element and method of use

PendingUS20210329745A1Simple designDomestic stoves or rangesLighting and heating apparatusEngineeringMechanical engineering

A heating element includes first and second terminals and one or more heating element segments extending between the first and second terminals. The one or more heating element segments have a circuit trace that includes at least first and second portions, the at least first and second portions configured so that a surface temperature difference exists between the at least first and second portions when a voltage is applied between the at least first and second terminals. The heating element can also be made with a three dimensional shape, including one that is generated by fastening of the heating element to one or more support plates. The heating element can also have a cylindrical shape and be disposed in an insulating medium in a tubular member to provide varied heating capability along the tubular member length.

Owner:TUTCO

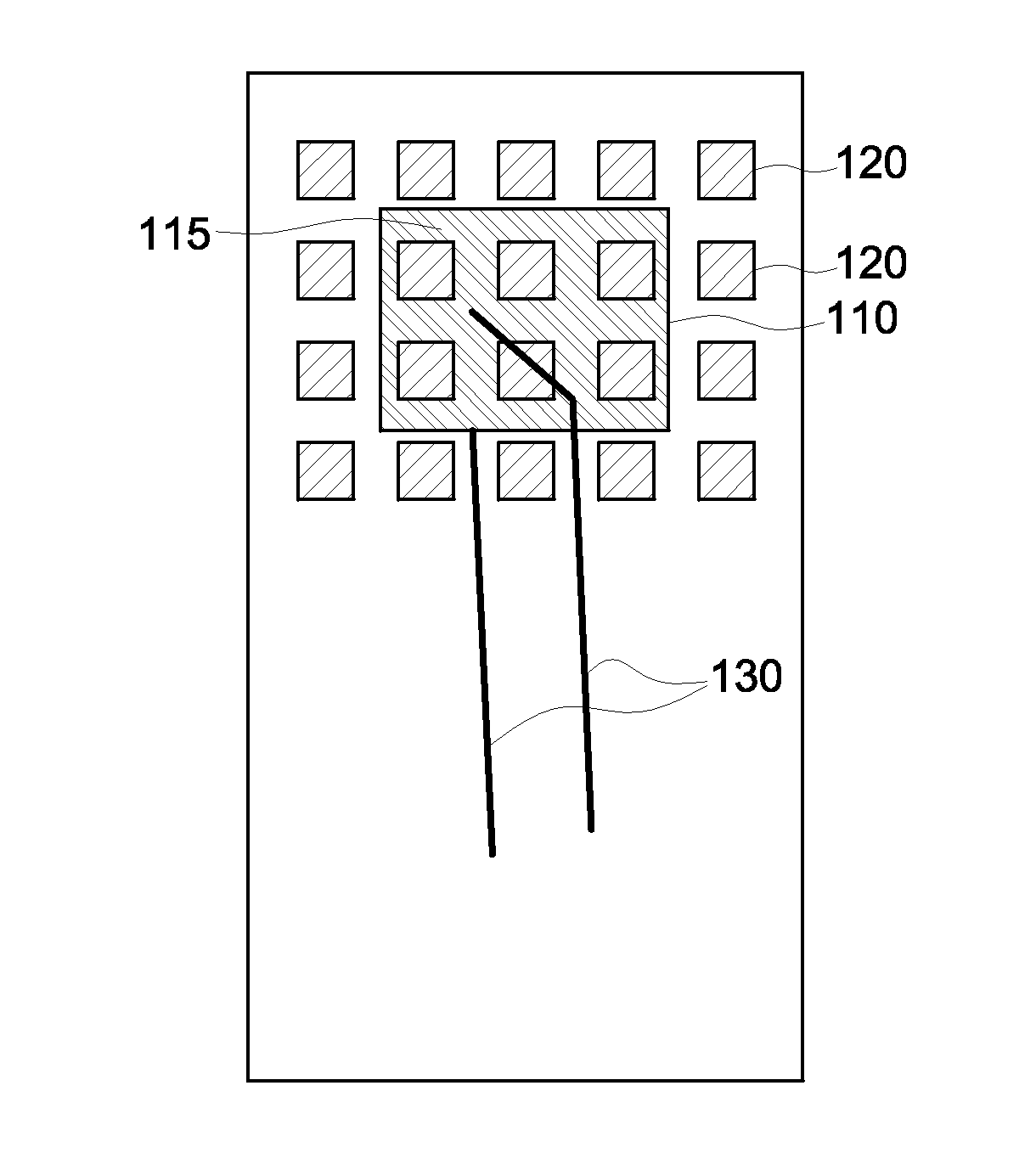

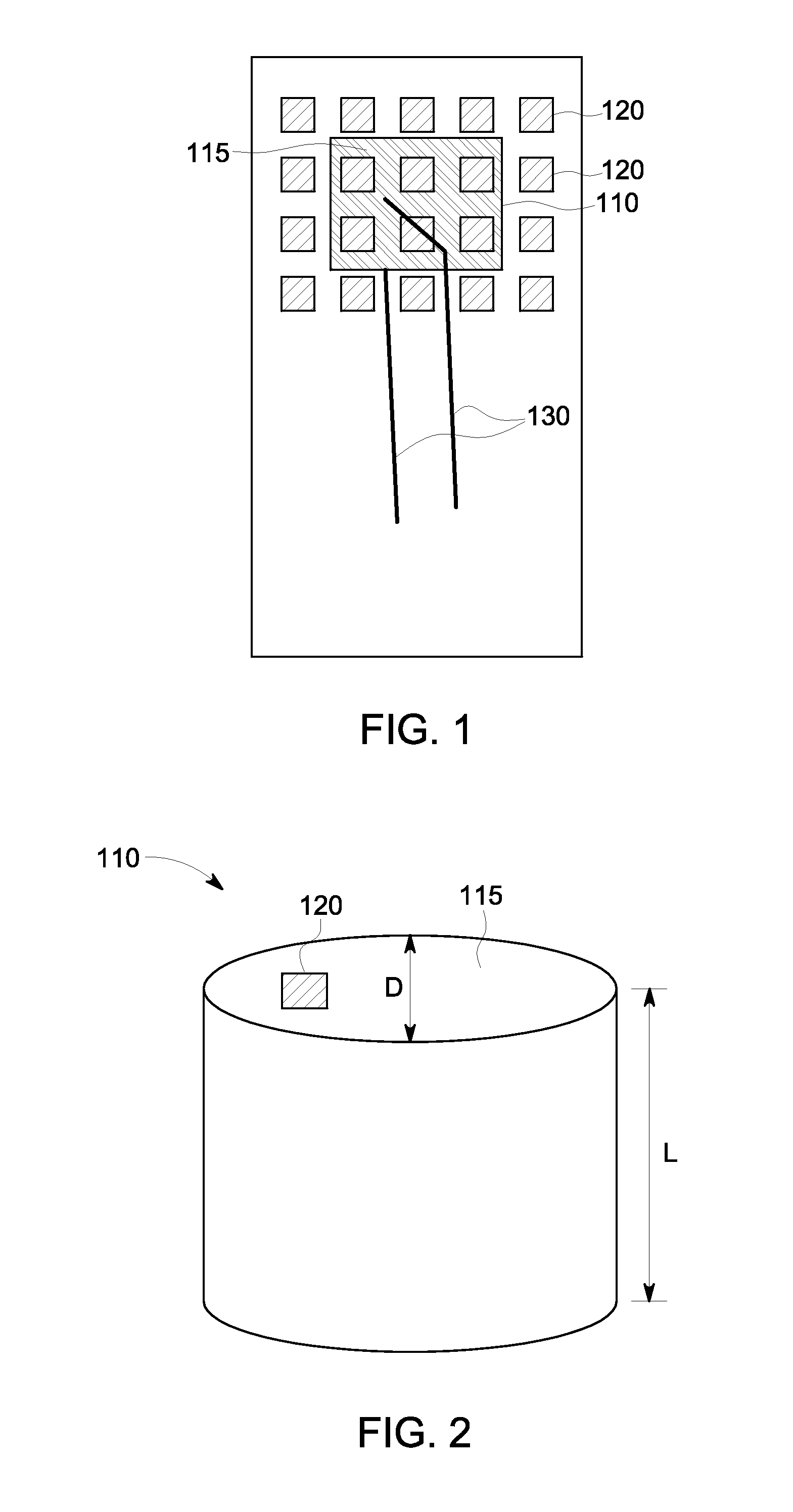

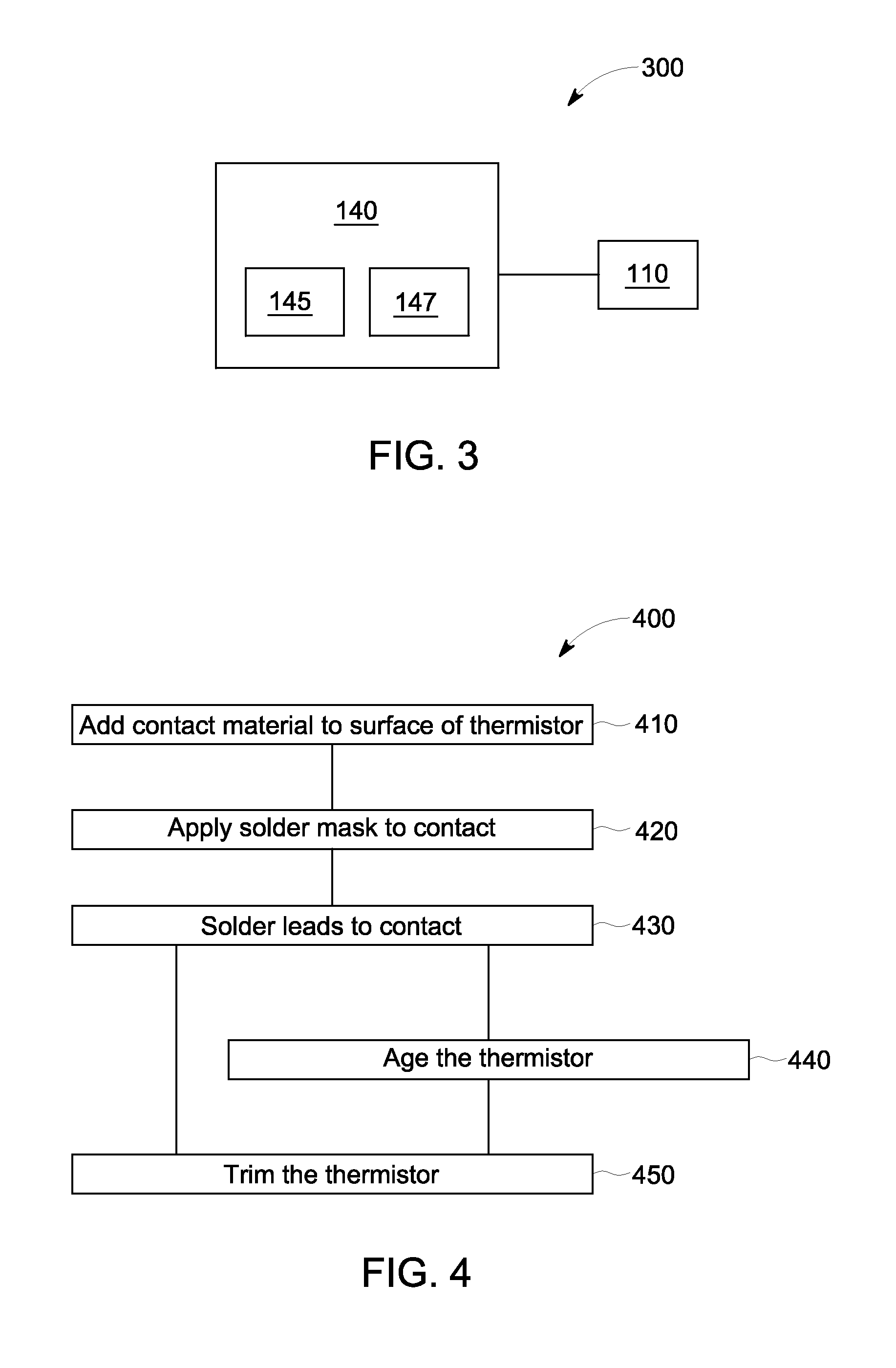

Thermistor and method of constructing a thermistor

InactiveUS20140145818A1Adjustable resistanceExhaust apparatusRadiation applicationsSolder maskMetallurgy

A method of constructing a thermistor includes forming a semiconductor ceramic substrate. The method also includes coating a surface of the substrate with contact material and applying a solder mask on the contact material. The applying includes applying the solder mask to one or more portions of the contact material to leave an exposed area without the solder mask and a masked area with the solder mask. The method includes trimming the contact material at the masked area to adjust a resistance of the thermistor.

Owner:AMPHENOL THERMOMETRICS

Preparation method and application of a flexible resistive film frequency selective surface

ActiveCN110247192BMature technologyEasy to operateMagnetic/electric field screeningResistor manufacture by lithographyRadarDielectric substrate

The invention belongs to the field of flexible FSS radar wave-absorbing structures, and more particularly to a flexible resistive film frequency selective surface, a preparation method and application thereof. The method comprises the steps of: printing a set frequency selective surface pattern on a photosensitive film, and attaching the photosensitive film to the surface of a flexible dielectric substrate; successively exposing and developing the photosensitive film on which the frequency selective surface pattern is printed in order to expose the frequency selective surface pattern on the surface of the flexible dielectric substrate; coating the surface of the developed flexible dielectric substrate with resistive conductive carbon paste, and sintering and curing the flexible dielectric substrate coated with the conductive carbon paste, wherein the cured conductive carbon paste is a resistive film; demolding the cured flexible dielectric substrate, removing the photosensitive film and the resistive film on the surface of the flexible dielectric substrate to obtain the flexible resistive film frequency selective surface. The FSS surface preparation method of the invention is simple, and can produce a large-area flexible passive resistive film frequency selective surface applied to a curved surface.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for the production of thin layer chip resistors

InactiveCN1552080AHigh precisionSimplify and speed up the production processResistor chip manufactureRadiation applicationsElectrical resistance and conductanceThin membrane

A method for manufacturing thin-film chip resistors, in which method a resistor layer ( 14 ) and a contact layer ( 15, 16 ) are applied onto the upper surface of a substrate ( 10 ) and structured using laser light so as to form on said substrate ( 10 ) a plurality of adjacent, separate resistor lands ( 24 ) having a predetermined approximate resistance value, allows the simplified and cheap manufacturing by performing the electrical insulation of the resistor elements ( 24 ) and the structuring of the individual resistor lands ( 24 ) for the entire resistor land simultaneously by means of a laser-lithographic direct exposure method.

Owner:BC COMPONENTS HLDG

Thin film resistor and manufacturing method thereof

ActiveCN106298118BImprove film qualityImprove bindingResistor manufacture by lithographyThin film resistorsFilm resistancePlasma deposition

The invention relates to a thin film resistor and a fabrication method thereof. The method for fabricating the thin film resistor (100) comprises the following steps of S1, pre-processing a substrate (10); S2, performing ion injection and / or plasma deposition processing on a surface (12) of the substrate by using a target material so as to form a resistance layer (14) on the surface of the substrate; and S3, forming electrodes (18) at two sides of the resistance layer.

Owner:SUMITOMO ELECTRIC INTERCONNECT PROD SHENZHEN LTD

Copper foil resistor and circuit board structure having the same

InactiveCN110246639AReduce generationResistor manufacture by lithographyPrinted circuit aspectsAlloyCopper foil

The present invention discloses a copper foil resistor and a circuit board structure having the same. The copper foil resistor mainly adopts nickel, chromium, tungsten, a nickel metal compound, a chromium metal compound, a tungsten metal compound, a nickel based alloy, a chromium based alloy or a tungsten based alloy as a resistive layer, the resistive layer and a copper foil co-constitute the copper foil resistor, and the copper foil resistor is adapted to be combined with a substrate to form the circuit board structure. It is worth noting that a sputtered alloy, metal or metal compound resistive layer has better plating density and continuity, so that the minimum surface resistance can be less than or equal to 5 ohms / port. At the same time, alloy, metal or metal compound resistive films made by sputtering technology can also effectively reduce the production of industrial wastewater. More importantly, in order to fabricate a resistor assembly required for an electronic circuit on the circuit board structure including the copper foil resistor, it is only necessary to perform two times of etching on the circuit board structure.

Owner:FLEX TEK

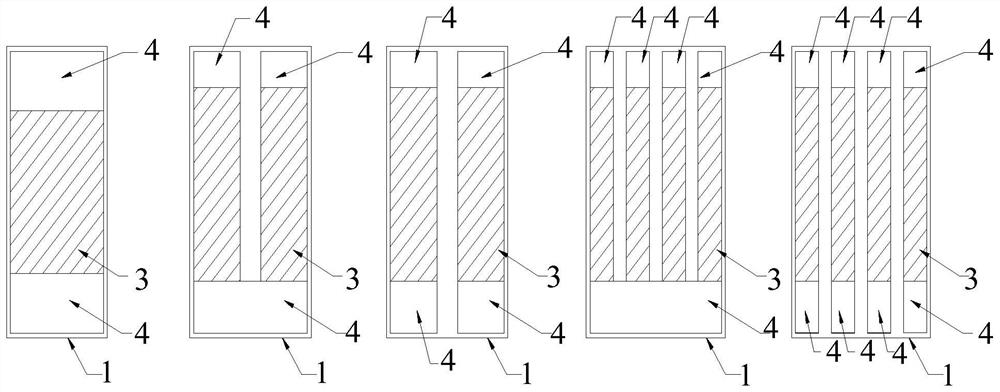

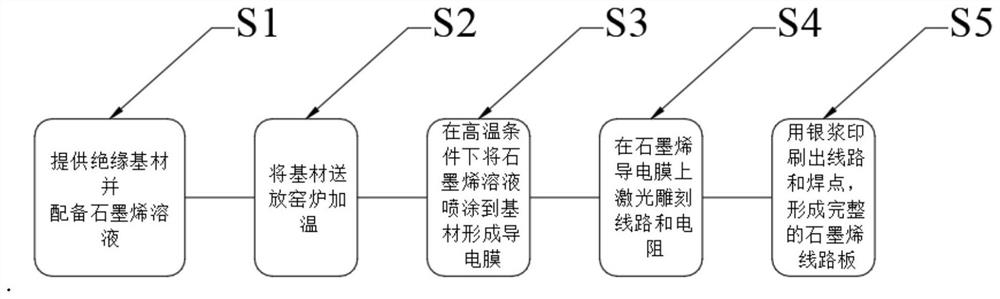

Graphene resistor

PendingCN114786334AEasy to adjust conductivityEasy to processResistor manufacture by lithographyPrinted circuit aspectsLaser engravingGraphite

The invention discloses a graphene resistor. The graphene resistor comprises a base material, the conductive layer is formed on the surface of the base material, and the conductive layer is made of a graphene material; and the resistor is engraved on the conductive layer through laser so as to form an independent resistor or a row resistor. According to the technical scheme, the surface of the base material is coated with the conductive layer, the conductive layer contains the graphene material, the conductivity of the conductive layer is convenient to adjust, then, some components such as resistors which can be formed through the laser engraving process are directly arranged on the conductive layer on the base material through laser engraving, one or more resistors can be arranged, and the cost is reduced. Therefore, an independent resistor or a row resistor is formed. According to the invention, through laser engraving, the plurality of resistors are arranged on the conductive layer, and compared with a traditional technology, the processing flow can be simplified.

Owner:潮州市烯陶新材料有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com