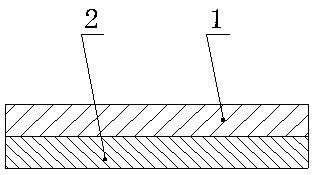

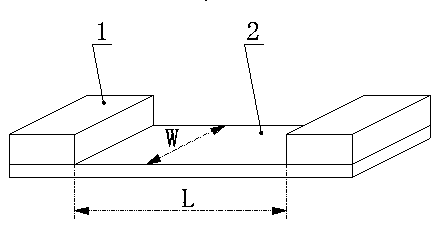

Chemical fine resistance adjusting method and etchant for resistor embedded in nickel-phosphorus layer

A technology for burying resistors and nickel-phosphorus layers, applied in resistors, resistor manufacturing, coating resistor materials, etc., can solve the problems of thickness variation, small target value, and influence of buried resistor layers, achieve uniform corrosion, and improve control accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the specific embodiments in the accompanying drawings.

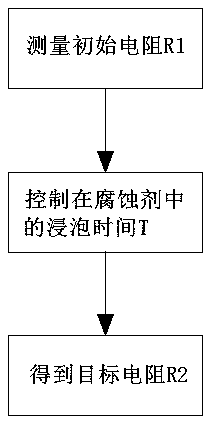

[0034] refer to image 3 , a method for chemically fine-tuning the resistance of a nickel-phosphorus layer embedded resistance. First, measure the initial resistance value R1 of the resistance before the resistance adjustment, and obtain the target resistance of the resistance by controlling the immersion time T of the resistance in the etchant used to corrode the nickel-phosphorus alloy layer. Value R2. The working temperature of the etchant is 50-90°C, preferably, the working temperature of the etchant is 65°C, the activity of the etchant is high, and the corrosion is fast and stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com