Patents

Literature

57 results about "Resistance Process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A Resistance Process consists of activities of biologic molecules or complexes involved in processes that maintain immunity to, or counteract, defeat, or withstand the effects of, an antagonistic agent.

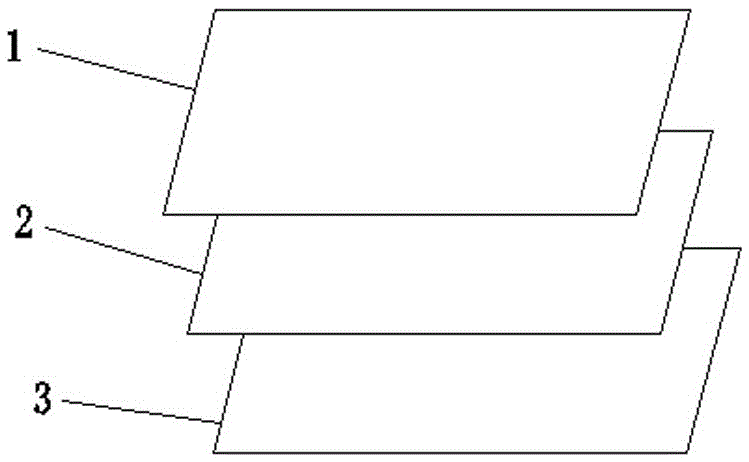

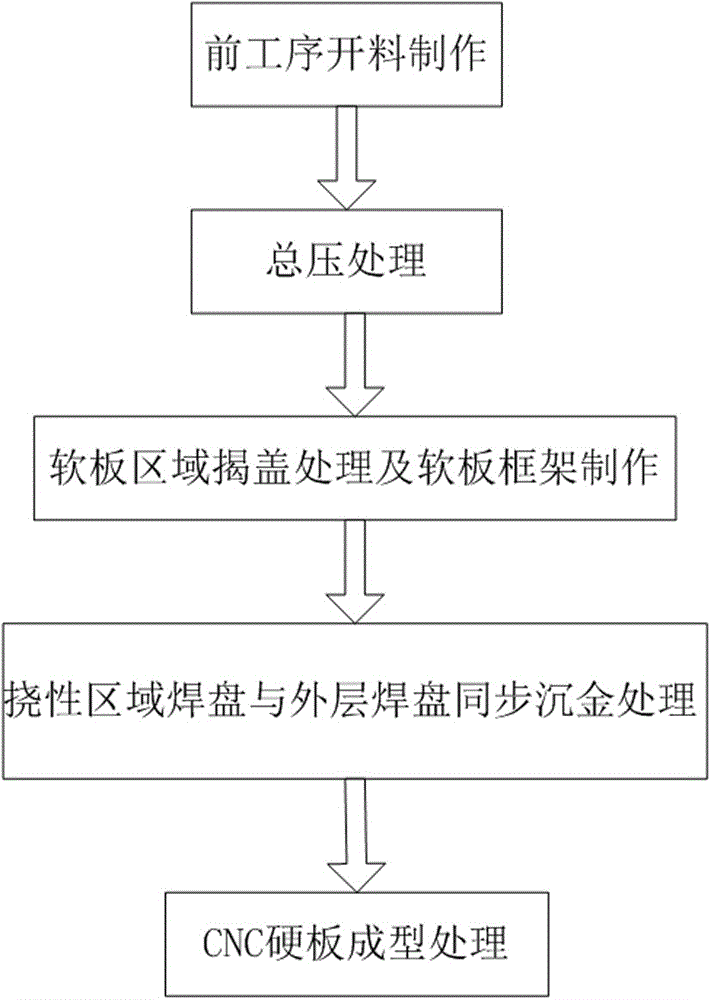

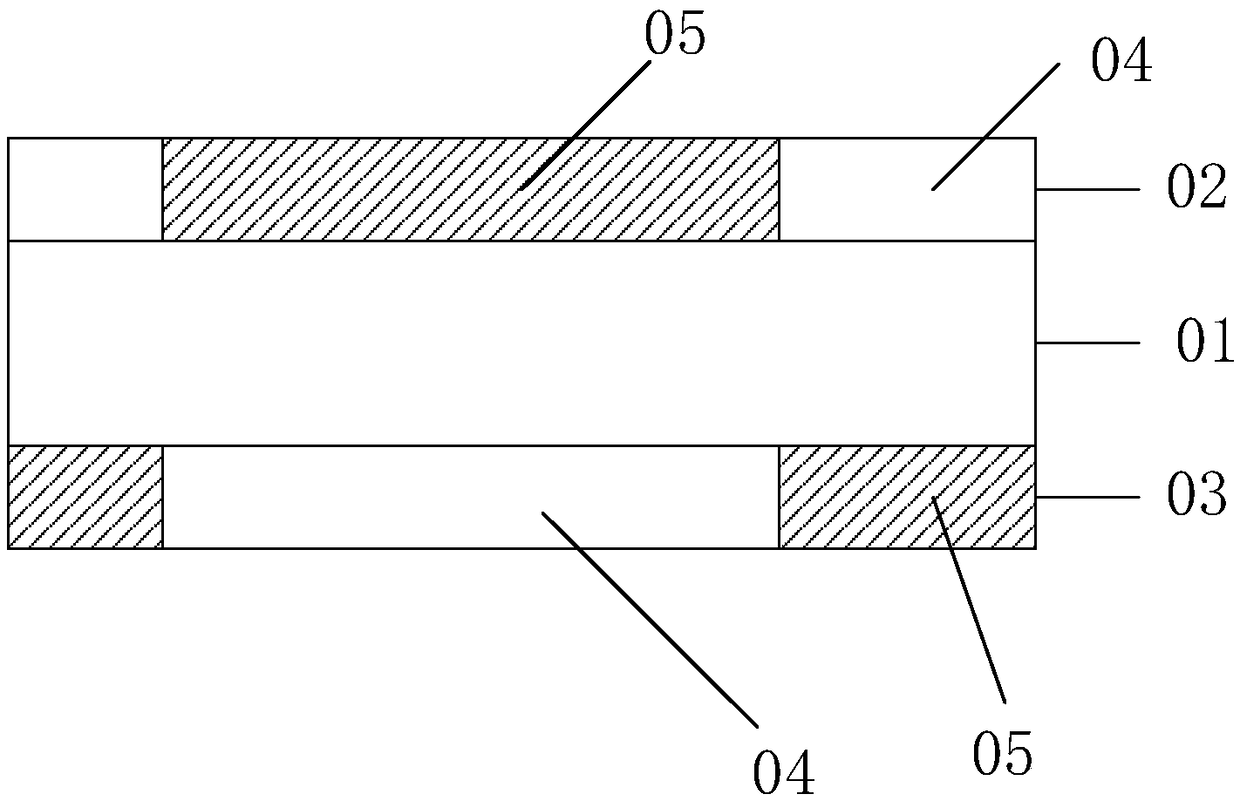

Rigid-flex PCB with flexible region equipped with solder pad and manufacturing method thereof

ActiveCN105430899AReduce the number of immersion goldIncrease productivityPrinted circuit assemblingPrinted circuits structural associationsAbrasive blastingEngineering

The invention discloses a rigid-flex PCB with a flexible region equipped with a solder pad and a manufacturing method thereof. The manufacturing method includes the steps that raw materials of a pre-process flexible board, a PP prepreg and a rigid board are manufactured, manufacturing of internal wiring of the flexible board is completed to a quick pressing cover film, laser winding processing and quick pressing adhesive resistance processing of the cover film are performed on the cover film, and the flexible board with a copper solder pad and the prepreg and the rigid board are laminated together from the top to the bottom in turn and then transferred to a board lamination pressing process to perform total pressing processing; after total pressing processing is completed, the process goes to an external layer solder resistance process according to the conventional process; then flexible board region de-cap processing and manufacturing a flexible board framework are performed, the copper surface is cleaned by an abrasive blasting mode, and then internal and external solder pad synchronous gold immersion processing is performed on the flexible region solder pad and an external solder pad; and finally CNC rigid board formation processing is performed on a rigid board framework so that a finished board meeting the profile dimension required by a client can be obtained. The rigid-flex PCB with the flexible region equipped with the solder pad and the manufacturing method thereof have advantages of being concise in flow, low in cost and environment-friendly and pollution-free without skip plating in gold immersion.

Owner:HUIZHOU KING BROTHER CIRCUIT TECH +2

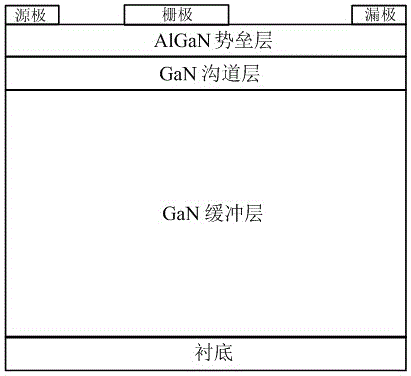

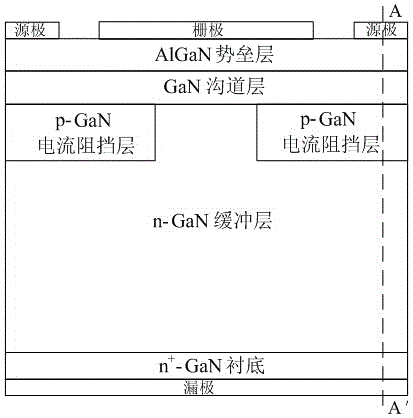

GaN vertical heterojunction field-effect transistor with charge compensation voltage-resistant structure

The invention discloses a GaN vertical heterojunction field-effect transistor with a charge compensation voltage-resistant structure. The device is characterized in that the GaN vertical heterojunction field-effect transistor with the charge-compensation voltage-resistant structure further comprises a barrier layer, a channel layer, a current barrier layer and a charge compensation insulating layer outside an n-GaN buffer layer, and the fixed charges high in density exist at boundaries between the charge compensation insulating layer and the barrier layer, the channel layer, the current barrier layer and the n-GaN buffer layer, wherein the charge compensation insulating layer is formed by an insulating dielectric medium. The fixed charges high in density exist at boundary between the charge compensation insulating layer and the n-GaN buffer layer, so that in a voltage resistance process, negative charges at the boundary enable inversion of the closer n-GaN buffer layer, a formed p+ column consumes electrons in the n-GaN buffer layer, the buffer layer is enabled to form a p+n super junction structure which is completely exhausted, an electric field in the buffer layer is kept to 3MV / cm in the perpendicular direction after full optimization, and the a device breakdown voltage reaches a voltage-resistant limit of the GaN material.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Casting technology for ductile iron box body

ActiveCN106222534AImprove heat transfer coefficientInhibited porosityFoundry mouldsFoundry coresThermal insulationHeat transmission

The invention discloses a casting technology for a ductile iron box body. The casting technology comprises the following steps: coated sand preparation, outer mold and mud core manufacturing, mold closing, smelting, pouring and sand cleaning, wherein mold closing is to close an outer mold and a mud core to form a sand mold, lock the sand mold in a sand box by a locking device and fill a cavity between the sand box and the sand mold with steel shots until the steel shots completely cover the sand mold. According to the casting technology, the steel shots filled between the sand box and the sand mold apply pressure to the sand mold by utilizing the self weight, thus the phenomena of deformation and thermal expansion generated in the pouring resistance process of the sand mold are effectively prevented; the heat transmission coefficient of the steel shots is large, and molten iron in a cast can be rapidly cooled, thus the tendencies of the cast of shrinkage porosity and shrinkage cavity are reduced; meanwhile, the steel shots also have the thermal insulation action in an interval between the sand box and the sand mold, and the cast cannot have the chill structure phenomenon due to too fast cooling speed, thus the qualified rate of the cast is greatly increased; and as the steel shots can be repeatedly used, the production cost can be greatly lowered.

Owner:衢州顺丰汽车部件有限公司

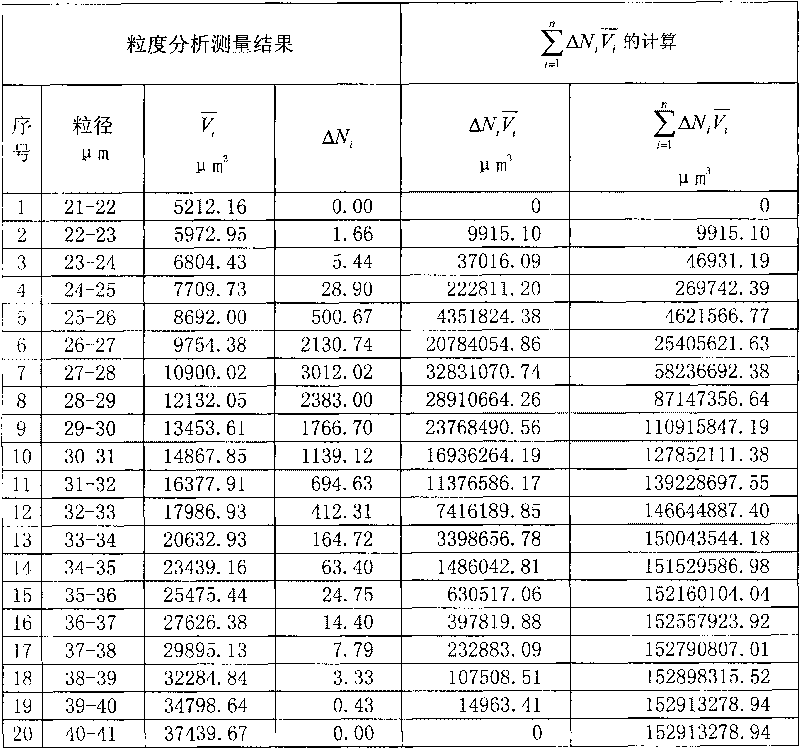

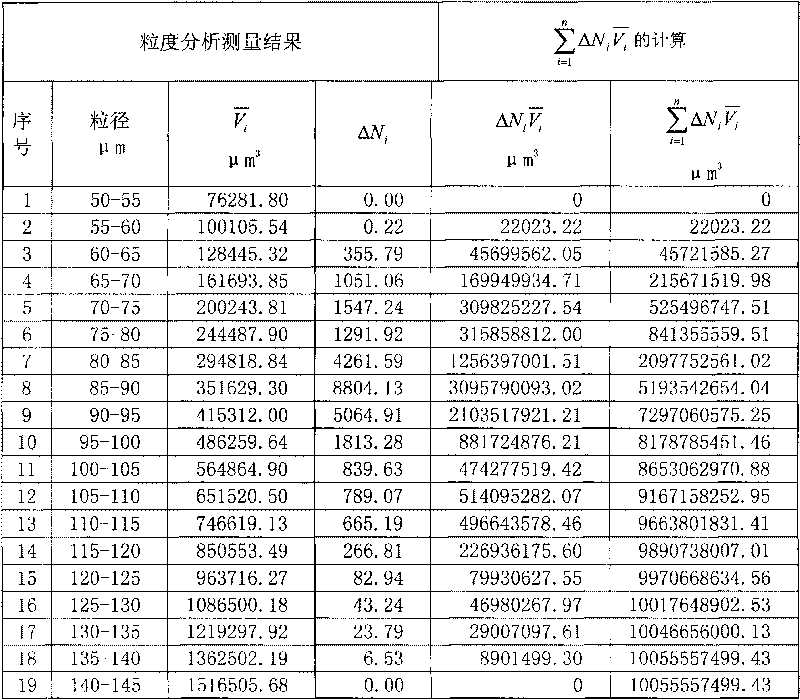

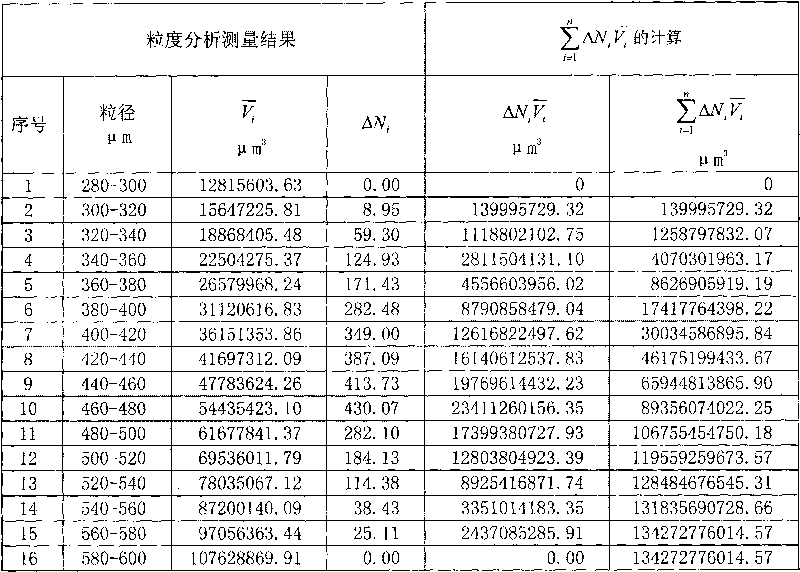

Method for measuring solid grain size calibration factor Kd of resistance process granulometer

InactiveCN101762443AImprove accuracyUniversal applicabilityParticle size analysisPorosityGranularity

The invention relates to a method for measuring the solid grain size calibration factor Kd of a resistance process granulometer, belonging to the technical field of measurement and testing. The invention is characterized in that the method comprises the following steps: a. measuring infiltration density phi; b. calibrating initial solid grain size calibration factor Kda; c. preparing sample; d. analyzing granularity; and e. calculating the solid grain size calibration factor Kd of the resistance process granulometer according to the following formula. By adopting the technical scheme, the invention has the advantages that: 1. the impact of factors such as grain shape, porosity, electrical conductivity and the like on the measurement results is not considered; 2. the method is an absolute measurement method; and 3. the common practicability and the traceability in the measurement are high, and the accuracy of the magnitude measurement is improved.

Owner:SHANGHAI INST OF MEASUREMENT & TESTING TECH

New QPQ nitrocarburizing corrosion resistance process for iron casting surface

InactiveCN105506542AIncreasing the thicknessImprove corrosion resistanceSolid state diffusion coatingWater basedElectrolysis

The invention provides a new QPQ nitrocarburizing corrosion resistance process for an iron casting surface. The process comprises the following steps: 1) under the effect of a water base cleaning agent, the electrolytic cleaning is performed by 0.05-0.1 s with a current density of 100-150 A / dm2; 2) a workpiece is heated by 30-60 min in an air furnace at a temperature of 350-390 DEG C; 3) nitrocarburizing: the preheated workpiece is put in salt bath of 420-460 DEG C for treating by 150-180 min; 4) the workpiece is cooled below 150 DEG C in air; residual salt is cleaned by hot water; clear water is used for rinsing; and the polishing is performed; 5) the workpiece is heated by 30-60 min in the air furnace at a temperature of 350-390 DEG C; 6) the preheated workpiece is put in the salt bath of 420-460 DEG C for treating by 90 min; 7) the oxidized workpiece is rinsed by the clear water is used for rinsing, and is polished; and salt nitride comprises the following components in percentage by mass: 30-50% of urea, 4-8% of Na2CO3, 6-10% of K2CO3, 5-10% of Li2CO3, 12-25% of KCNO, 8-15% of NaCNO, 5-8% of NaCl, 4-8% of Na2S, 6-10% of K2S, and 2-5% of LiOH.

Owner:SICHUAN QUANFENG NEW MATERIALS & TECH CO LTD

Zincizing infiltrated layer corrosion resistance process for metal

InactiveCN105839047AStrong adhesionUniform and dense thicknessSolid state diffusion coatingPotassiumRare earth

The invention relates to a zincizing infiltrated layer corrosion resistance process for metal. The zincizing infiltrated layer corrosion resistance process for metal includes the steps that a zinc and nickel infiltrated layer and a metal base body are arranged in a closed metal container to be heated at the heating speed of 50-60 DEG C / min, and subjected to heat preservation heating for 120-180 min when heated to 480-500 DEG C; the adding amount of the zinc and nickel infiltrated layer accounts for 1.5%-4.5% of the weight of the metal base body, and the zinc and nickel infiltrated layer is prepared from zinc powder, nickel powder, aluminum powder and energizer particles with the weight ratio of 1:(0.03-0.05):(0.02-0.04):(0.09-0.15), the particle diameter of the raw materials is controlled to be 0.1-1 mm, the energizer particles are composed of 40-90wt% of rare earth chloride and 10-60wt% of auxiliaries, and the auxiliaries are composed of 50-70wt% of potassium chloride, 20-40% of sodium chloride and 2-10wt% of boric acid. The zincizing infiltrated layer corrosion resistance process for metal is short in period, the strength and abrasion resistance of the infiltrated layer are good, and the mechanical performance and the corrosion resistance of finished products are excellent.

Owner:福建大统铁路精密装备股份有限公司

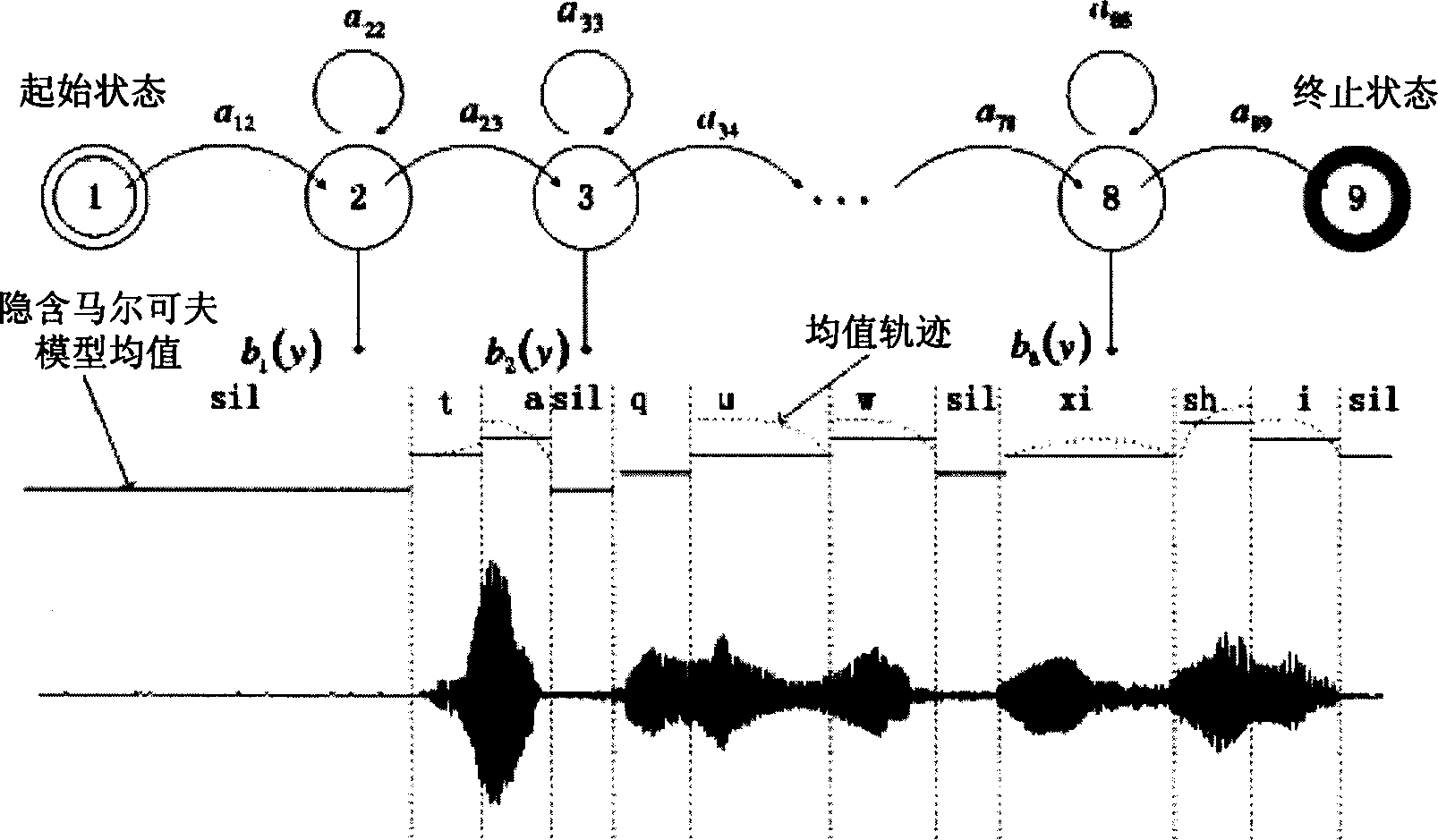

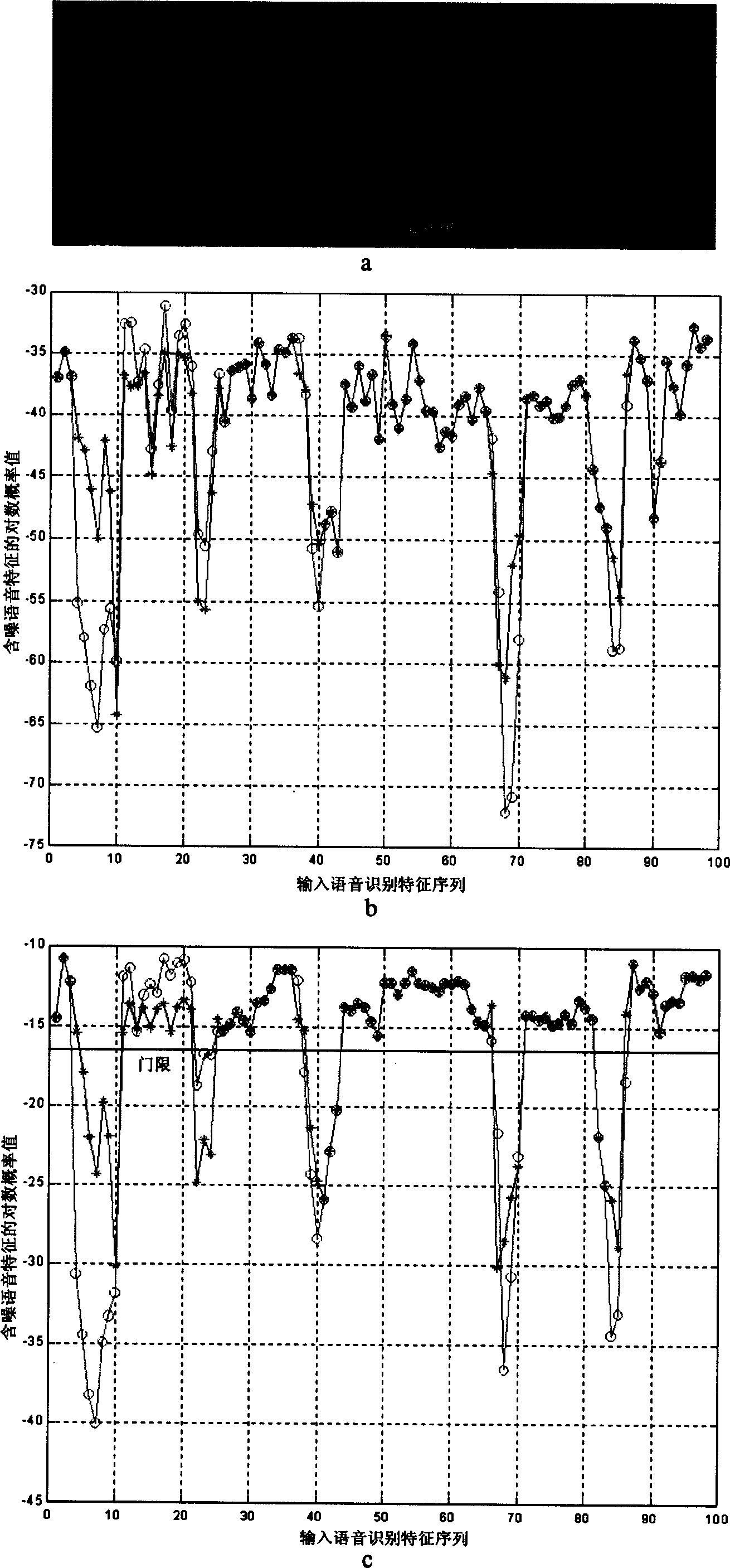

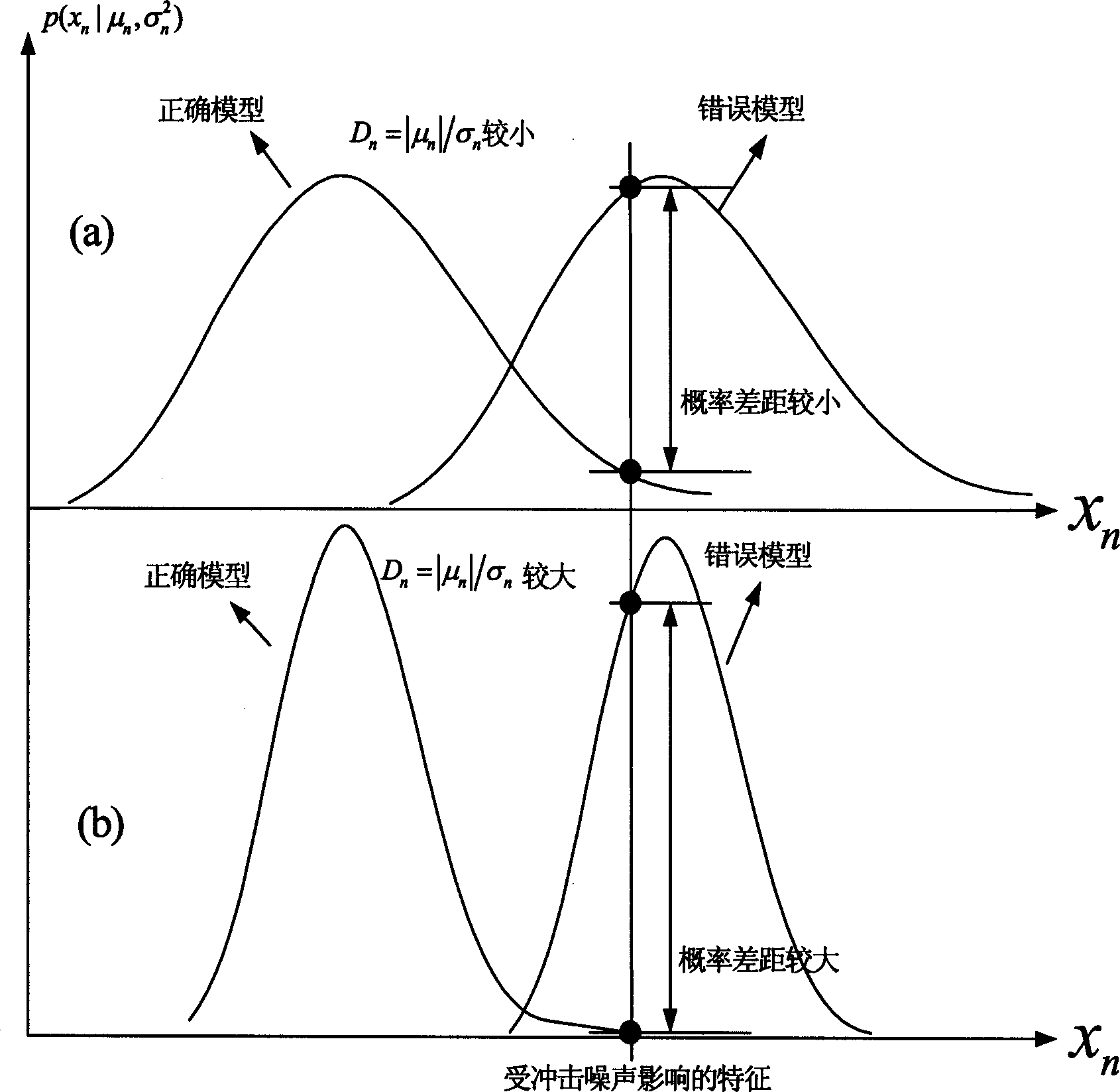

An impact and noise resistance process of limiting observation probability minimum value in a speech recognition system

An impact and noise resistance process of limiting observation probability minimum value in a speech recognition system characterized by that, in the optimum state sequence searching stage of the implicit Malkov model probability statistics recognition method, first using the scattering index to classify the noise sensibility degree of each dimension of the voice characteristics, then using threshold to perform minimum value limitation to the observation probability of the sensible characteristics, so as to diminish effectively the influence caused by noise abatement, and at the same time keep more information useful for recognition, which can substantially improve the function of the speech recognition system in impact and noise.

Owner:TSINGHUA UNIV

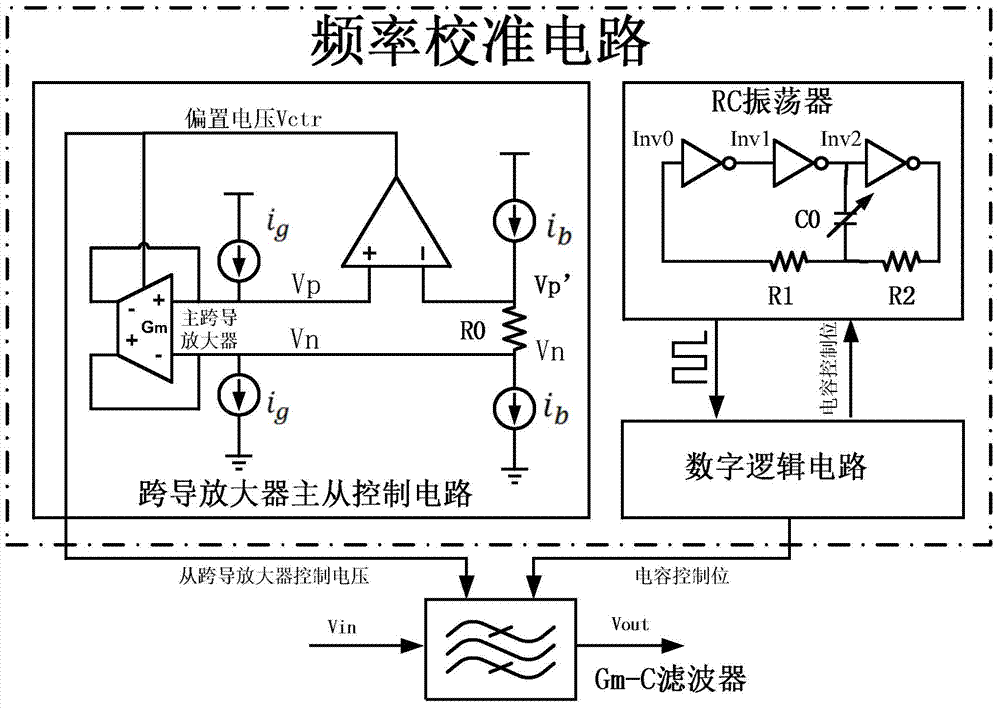

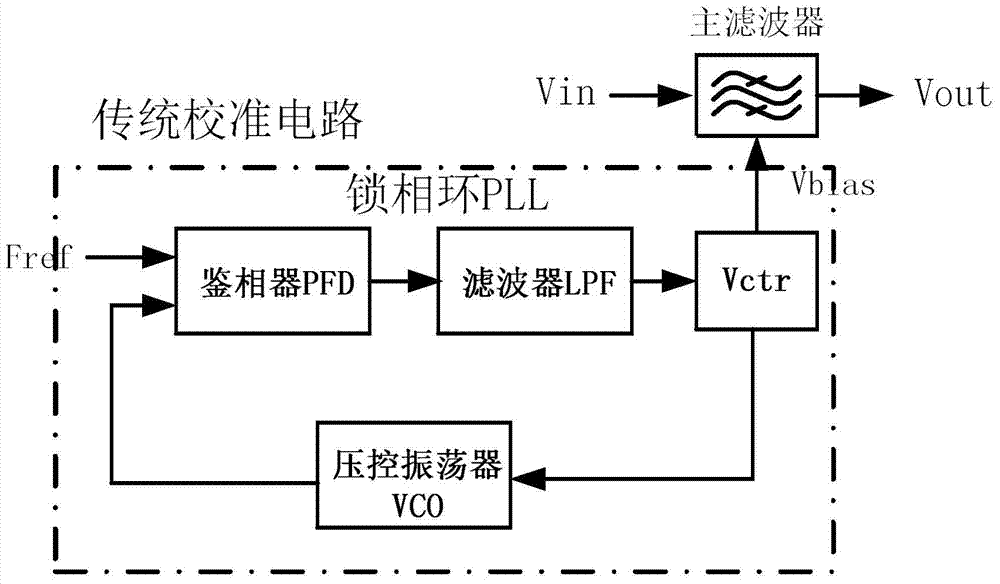

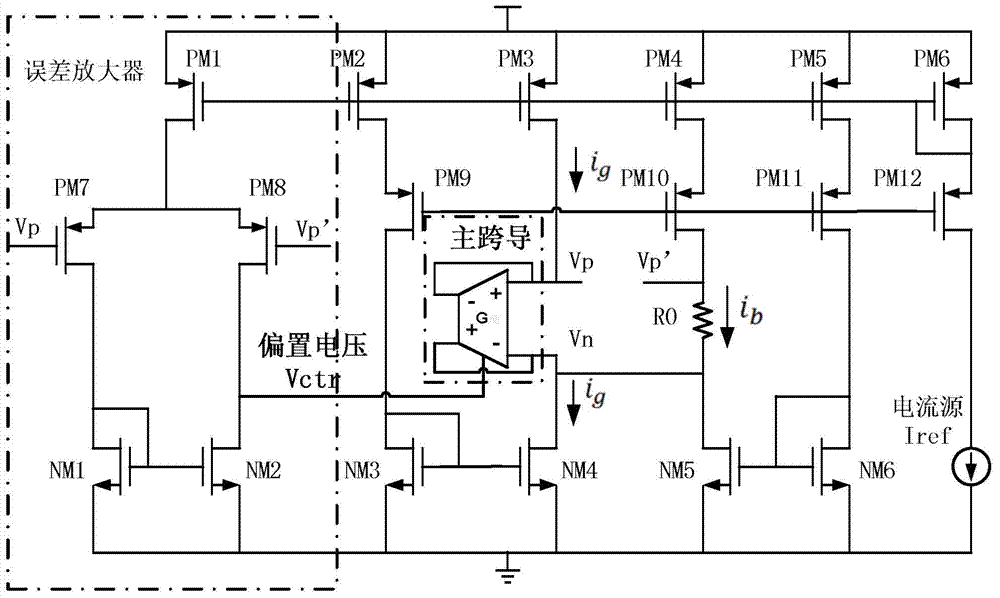

Principal and subordinate structure frequency calibration circuit used for Gm-C filter

InactiveCN103905037ASimple structureImprove stabilityPulse automatic controlDifferential amplifiersElectrical resistance and conductanceAudio power amplifier

The invention discloses a principal and subordinate structure frequency calibration circuit used for a Gm-C filter. The principal and subordinate structure frequency calibration circuit used for the Gm-C filter comprises a transconductance amplifier principal and subordinate structure control circuit, an RC oscillating circuit and a digital logic circuit, wherein a principal transconductance amplifier in the principal and subordinate structure control circuit and a subordinate transconductance amplifier inside the Gm-C filter are matched and are controlled through the same bias voltage, so that the transconductance value Gm and the resistance R in the principal and subordinate structure control circuit are in accurate inverse relation; influence on the frequency by errors of the transconductance amplifier process is converted to be influence on the frequency by the errors of the resistance process. Compared with a traditional frequency calibration circuit for the Gm-C filter, the principal and subordinate structure frequency calibration circuit used for the Gm-C filter has the advantages of being simple in structure and good in robustness.

Owner:SOUTHEAST UNIV

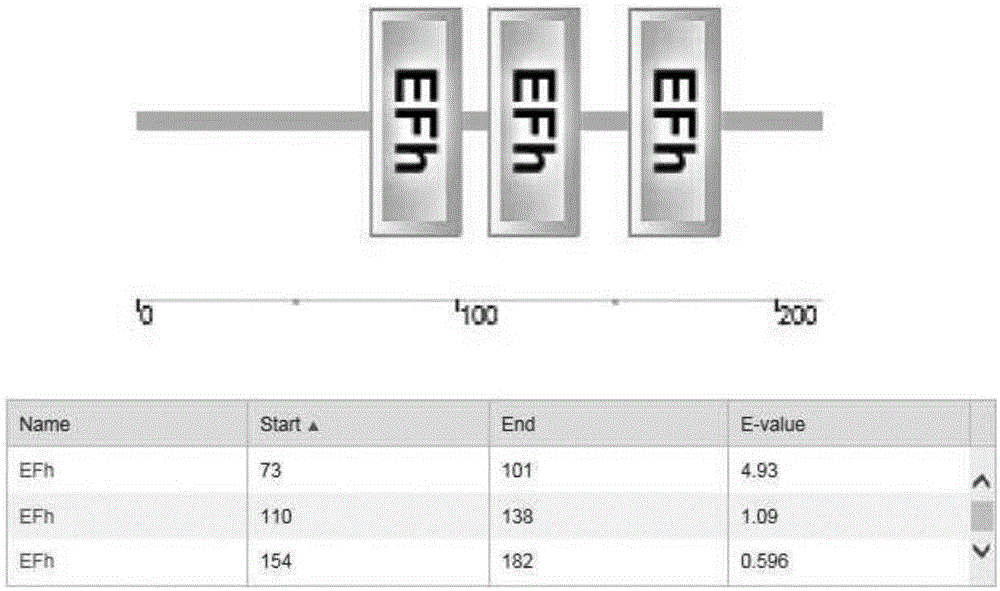

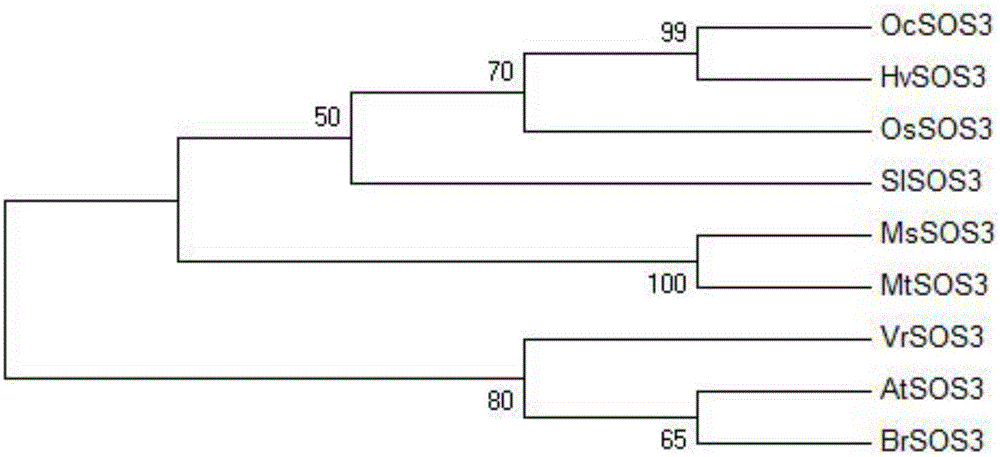

Medicago sativa MsSOS3 gene and encoding protein and application thereof

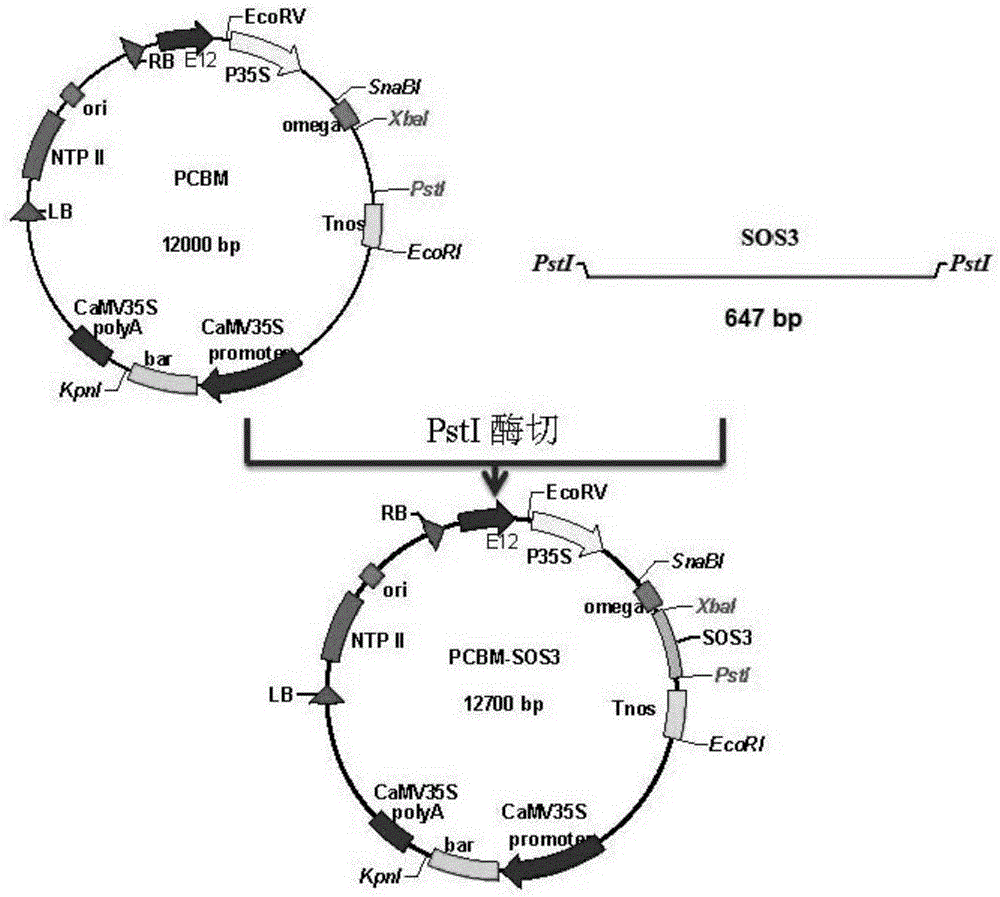

InactiveCN105039354AIncrease resistanceStrong salt and alkali resistancePlant peptidesFermentationOpen reading frameNicotiana tabacum

The invention discloses a medicago sativa saline-alkali stress responsive gene MsSOS3 and the encoding protein and application thereof, and belongs to the technical field of gene engineering. The overall length of a gene open reading frame is 647 bp, and 215 pieces of amino acid are encoded. A nucleotide sequence shown as SEQ. ID. NO. 1 is achieved, the sequence information is used for cloning the gene, a cloning vector and a plant expression vector of the MsSOS3 gene are established, the gene is shifted into a model plant tobacco through an agrobacterium-mediated method, and the transgenic tobacco is cultivated on an MS culture medium containing saline-alkali components. Results show that a transgenic plant has high saline-alkali resistance by contrast, it means that the overexpression of the MsSOS3 gene improves the resistance of the plant to saline and alkali, and it further means that the gene can participate in the adverse resistance process of plants. The MsSOS3 gene provides a theoretical basis for studying adverse resistance molecular mechanisms and breeding of medicago sativa.

Owner:HARBIN NORMAL UNIVERSITY

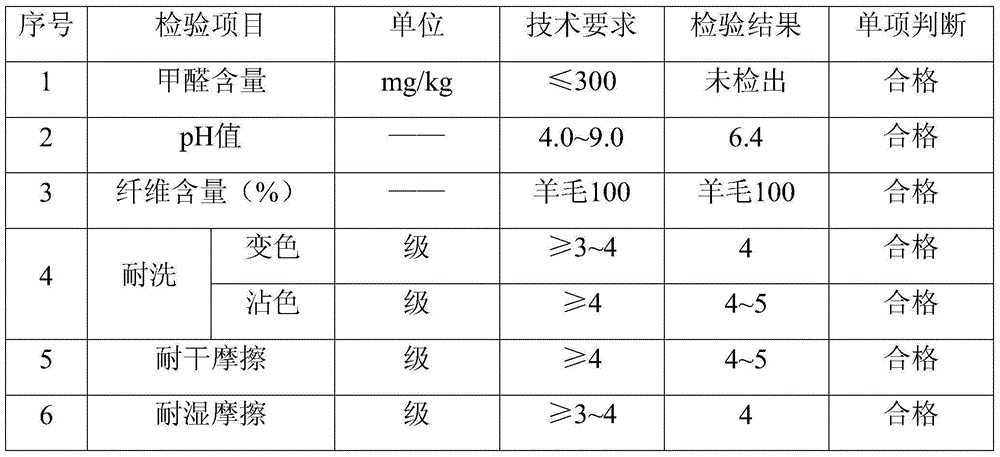

Preparation method for stereoscopic concave-convex auomerino full-woolen fancy yarn

The invention discloses a preparation method for a stereoscopic concave-convex auomerino full-woolen fancy yarn. The preparation method comprises steps of selecting wool shrink-resistance processed and natural un-processed auomerino common Australasian wool as raw material, dividing various raw material traction areas of a twisting machine into a traction area (A) and a traction area (B), applying mechanical external force to fancy wool yarns under a hot and humid condition to achieve local felting and bulge; and at last, stereoscopic concave-convex auomerino full-woolen fancy yarns are achieved. With the double-traction inlets of the twisting machine, wool rough yarns of different colors and different properties are tracted and fluff is achieved via a roller fluffing machine; a loop part becomes wool yarns and the flat yarns are remained; and interval segmental fluffing wool yarn is realized; deficiencies of type singularity of a traditional twisting fibers and fancy yarns are enriched; and the stereoscopic concave-convex auomerino full-woolen fancy yarn requires no post-color dying, thereby being a green environment-friendly product.

Owner:江苏鹿港科技有限公司

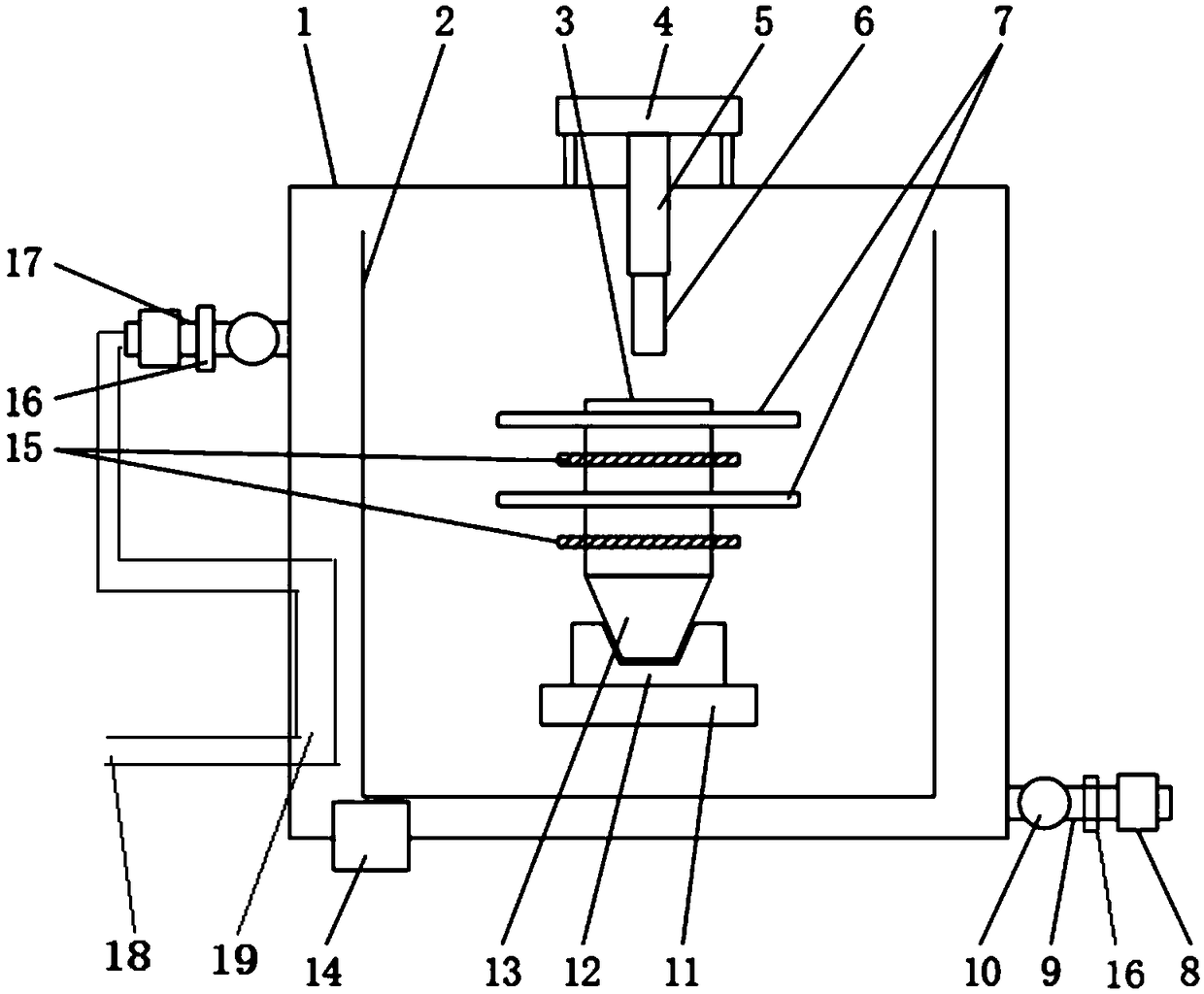

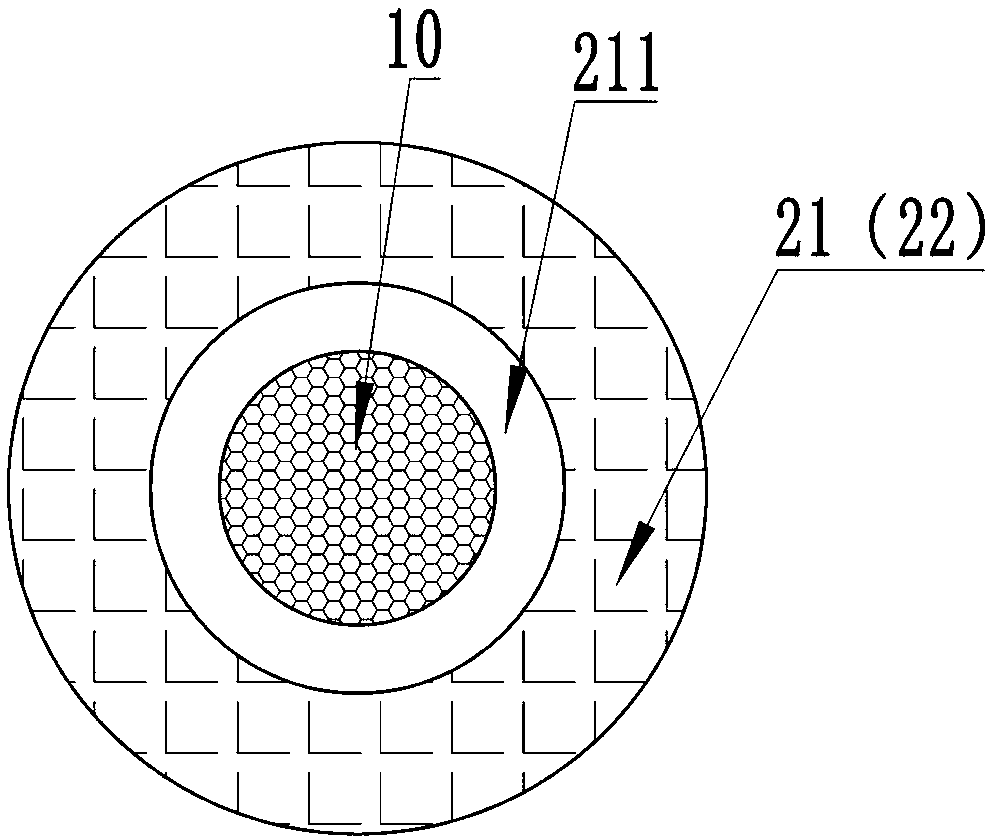

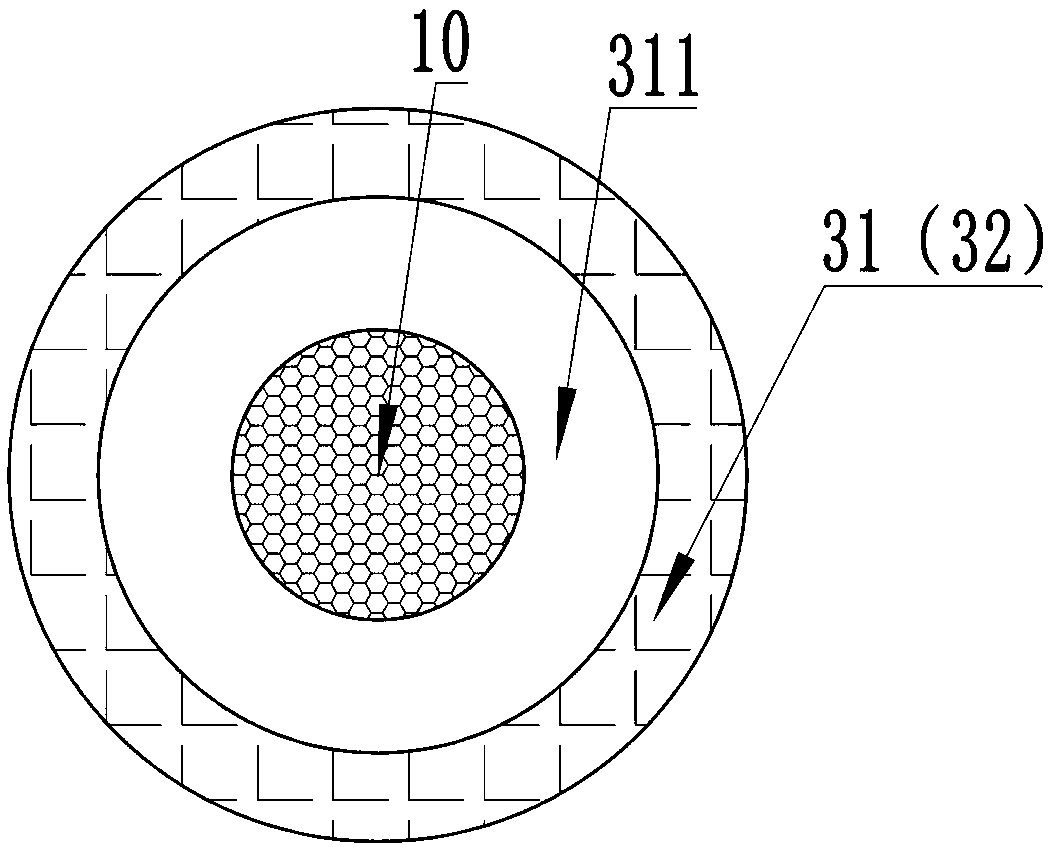

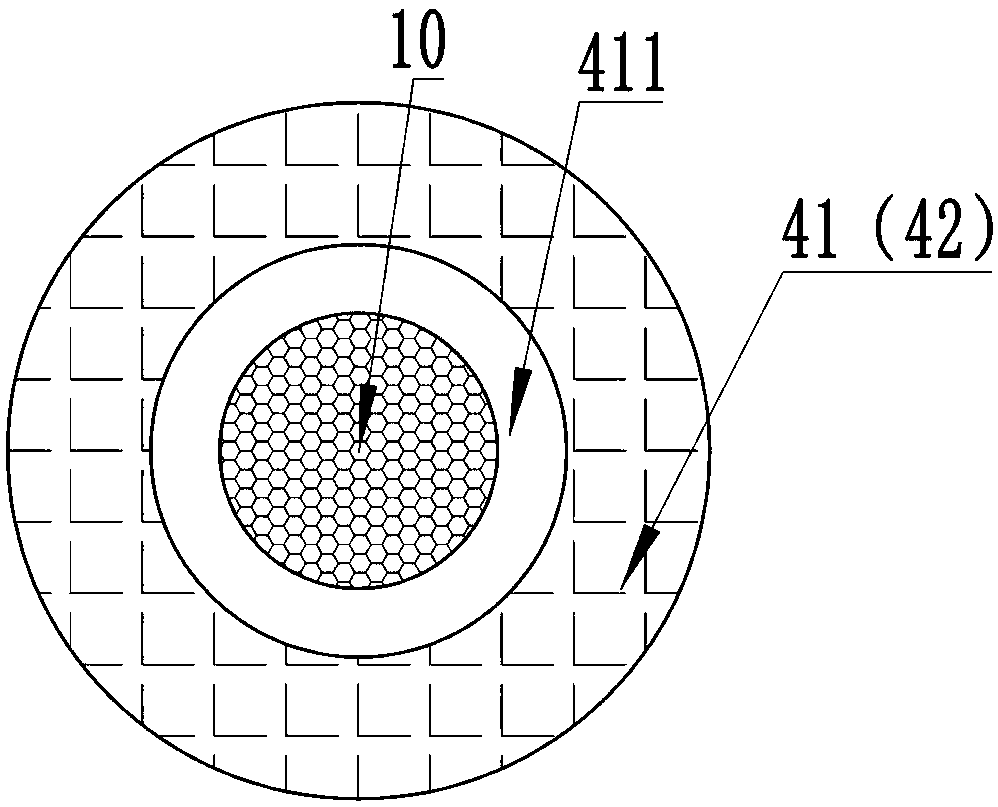

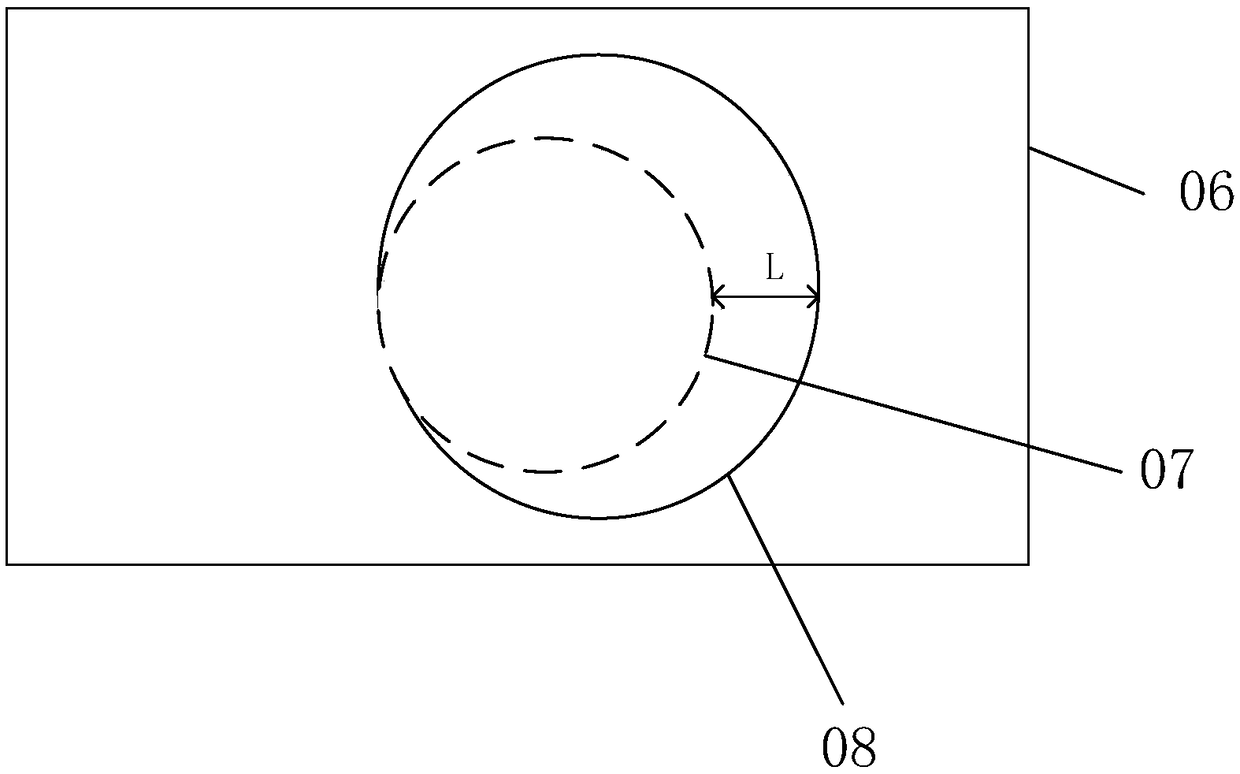

Device and method for growing silicon carbide crystals by aid of electric resistance processes

InactiveCN109371461AReduce heating areaSave devicesPolycrystalline material growthUsing seed in meltElectrical resistance and conductanceCrucible

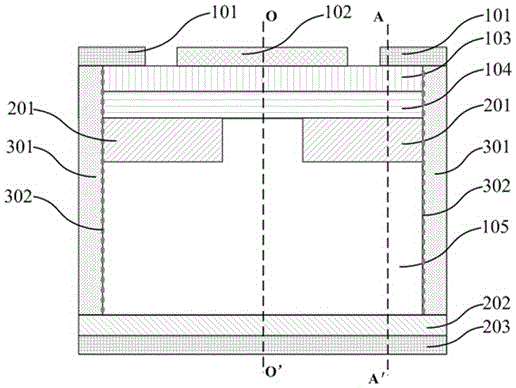

The invention discloses a device for growing silicon carbide crystals by the aid of electric resistance processes. The device comprises a furnace body of a growing furnace. A base is arranged on the lower side of the inside of the furnace body, a crucible support is connected with the upper side of the base, a seed crystal rod is arranged above a crucible, a seed crystal groove is formed in the bottom of the crucible, temperature measuring thermocouples are arranged on the periphery of the crucible, a heat-insulation cover is arranged between the furnace body and the crucible, the furnace bodyis provided with a gas inlet pipe and a gas outlet pipe, and a flow control device, a temperature gauge and a gas pressure gauge are mounted on the gas outlet pipe. A method for growing the silicon carbide crystals by the aid of the electric resistance processes includes a heating and trial run step, a cooling simulation phase, an adjustment and correction step and a crystal actual growth preparation step.

Owner:国宏中宇科技发展有限公司

Production process for improving fire resistance duration of foamed ceramic partition wall board

InactiveCN108395273AReduce internal stressImprove thermal shock resistanceCeramic materials productionCeramicwareFiberTunnel kiln

The invention discloses a production process for improving fire resistance duration of a foamed ceramic partition wall board, and belongs to the field of a fire resistance process of a foamed ceramicpartition wall board. The production process comprises the particular production process steps of: after adding water into formula raw materials of the foamed ceramic partition wall board to carry outball milling for 8 hours, carrying out spraying drying to form powder with a specification of 20 to 60 meshes; paving the powder with the specification of 20 to 60 meshes in a fire resistance die cushioned with ceramic fiber paper by a thickness of 60 to 70mm; firing by using a roller kiln or a tunnel kiln to form a foamed ceramic blank board with a thickness of 120 to 140mm; then by gas-cuttingprocessing, enabling the thickness within a range of 100 to 120mm so as to form a building internal partition wall for use. In the formula, zirconium oxide is added, crystal transfer occurs at a temperature of about 1,000 DEG C, and accompanied with the characteristic of volume shrinkage, microscopic cracks are generated in a liquid phase, so that an internal stress of heated foamed ceramic is reduced, and heat impact resistance of a foamed ceramic material is improved. Fire resistance duration is prolonged.

Owner:辽宁罕王环保科技有限公司

Corrosion resistance process of carbon steel frying pan

ActiveCN105506536AIncreasing the thicknessHigh hardnessSolid state diffusion coatingSodium sulfateResistance Process

The invention discloses a corrosion resistance process of a carbon steel frying pan, and belongs to the technical field of corrosion and protection of metal materials. Firstly, the inner surface of a carbon steel frying pan blank molded through punching is sanded; then, the inner surface of the frying pan blank is uniform and smooth through sand blasting; the frying pan is dipped by 0.5-2 hours in sodium sulfate water solution of 50-80 DEG C with a concentration of 2-20 wt.% after nitriding treatment and oxide treatment; and the frying pan is taken out for water washing and drying to obtain a finished frying pan. The carbon steel frying pan, treated by the process, prominently improves the strength and the corrosion resistance; and through 5 wt.% saline water or iron chloride solution dipping corrosion experiment, saline water or iron chloride solution is clear within 200 hours and free of rust.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

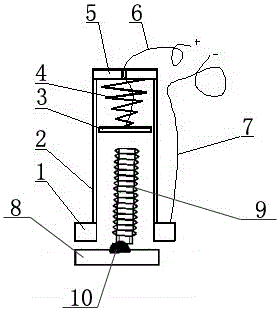

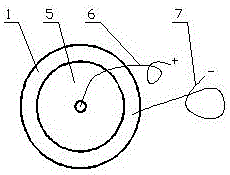

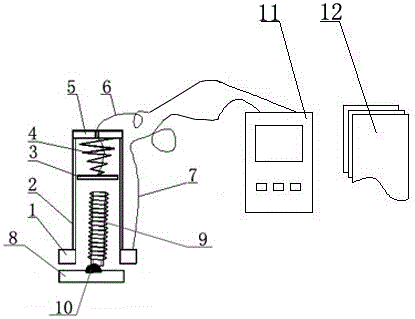

A nondestructive method for detecting a fusion degree of a stud weld seam and a special-purpose probe therefor

PendingCN106501320AWon't hurtIncrease contact areaMaterial resistanceNuclear energy generationElectrical resistance and conductanceProduction line

The invention relates to a nondestructive method for detecting a fusion degree of a stud weld seam and a special-purpose probe therefor, and belongs to the technical field of detection equipment. According to a technical scheme, when the stud weld seam has a poor-fusion defect which directly causes a change of the size of the weld seam bonding area, and the change is further reflected in a change of a measurement value on a screen of a direct-current resistance tester (11); and the direct-current resistance tester displays a difference between a practical measurement value and a standard value, thus completing nondestructive detection of the fusion degree of the stud weld seam. A positive and negative pole contact integrated structure is adopted by the special-purpose probe, and therefore a contact area is large during detection, stress is even, a structure is simple, operation is flexible, a detection efficiency is high and an error is little. The fusion degree of the stud weld seam is measured through a direct current resistance process, damages to a stud and weld seam strength are avoided, operation is convenient, a detection efficiency is high, and the method and the probe are suitable for large-scale rapid detection on a production line and on site.

Owner:BAODING TIANWEI BAOBIAN ELECTRICAL

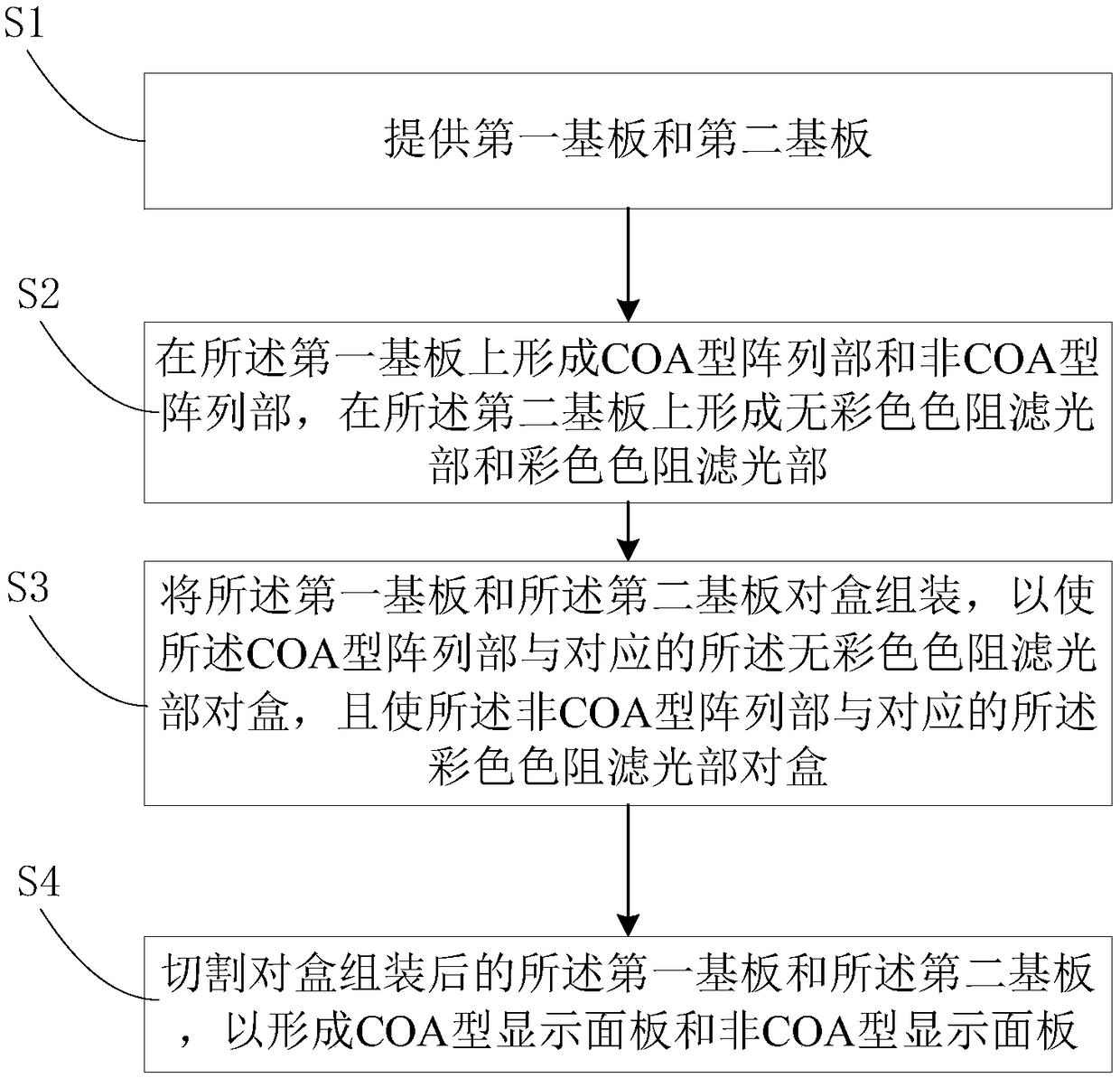

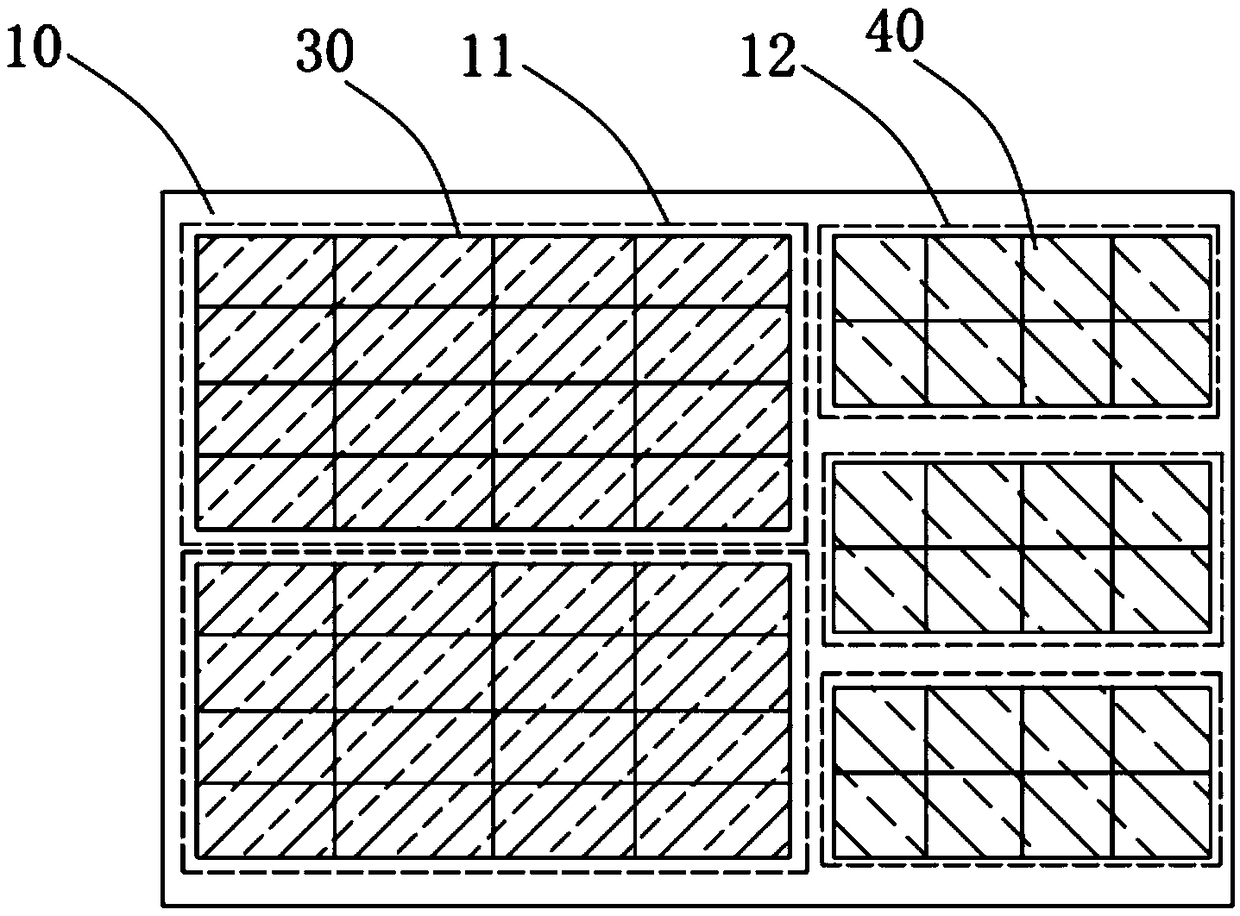

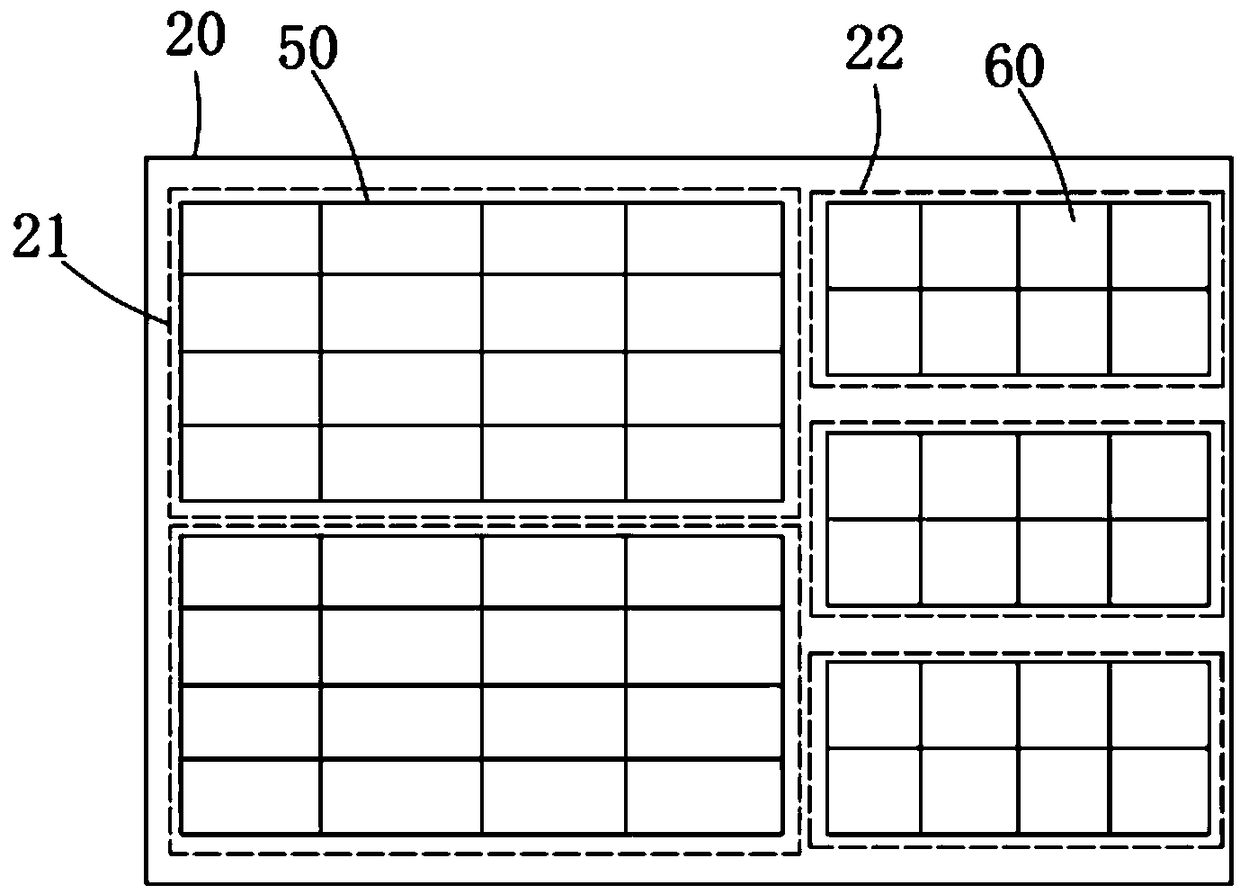

Method for manufacturing display panel in mixing and cutting mode, and display panel

The invention discloses a method for manufacturing a display panel in a mixing and cutting mode and the display panel. The method comprises the steps of providing a first substrate and a second substrate; forming a COA-type array part and a non-COA-type array part on the first substrate, and forming a neutral color color-resistance light-filtering part and a colorful color-resistance light-filtering part on the second substrate; assembling the first substrate and the second substrate in a box pairing mode, so that the COA-type array part and the corresponding neutral color color-resistance light-filtering part are arranged in a box pairing mode, and the non-COA type array part and the corresponding colorful color-resistance light-filtering part are arranged in a box pairing mode; and cutting the first substrate and the second substrate which are assembled in a box pairing mode, so as to form a COA type display panel and a non-COA type display panel. The method for manufacturing the display panel in the mixing and cutting mode can be compatible with the difference of the color resistance process technology in the mixing and cutting scheme, and the flexibility of the mixing and cutting technology is improved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

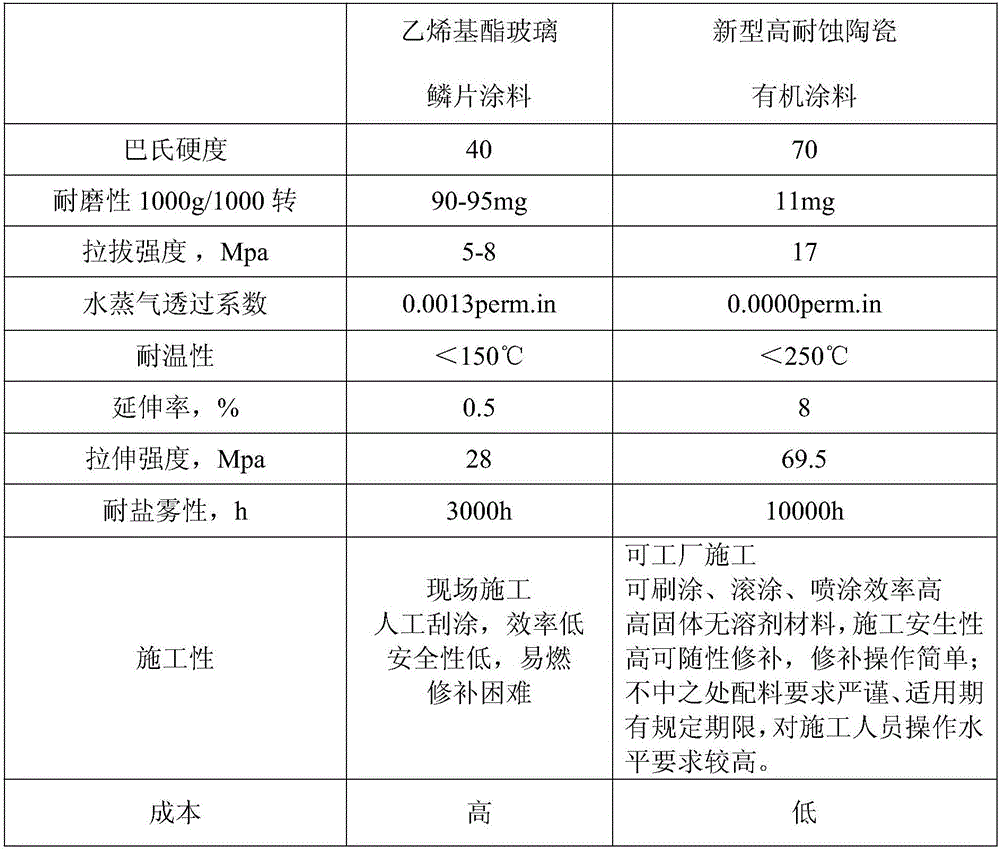

Construction process of anticorrosion ceramic organic coating used for inner wall of desulfurizing tower and inner wall of flue

InactiveCN106622897AImprove securityHigh degree of innovationPretreated surfacesCoatingsEnergy conservationMaterials science

The invention provides a construction process of an anticorrosion ceramic organic coating used for an inner wall of a desulfurizing tower and an inner wall of a flue. The process comprises the following steps of examining the state of a primary surface, treating a welded joint, derusting by sandblasting, examining cleaning and protecting, detecting and confirming by a technical staff, spraying an undercoat, spraying a finishing coat, examining the appearance of a coating and the membrane thickness, conducting electric spark testing, repairing a leaking point, and maintaining. The spraying process improves the construction safety and shortens the construction period, and the comprehensive cost performance ratio of a vinyl glass flake is lower than that of the organic coating. The project changes the corrosion resistance process of the existing desulfurizing tower, the manual blade coating is improved to mechanical spraying, the construction process is high in solid content and environmentally friendly and realizes energy conservation and emission reduction, the construction safety is improved, the construction period is shortened, the degree of innovation of the project is high, the innovations of the performances of corrosion resistance and abrasion resistance of the product and the process route are prominent, the effect of promoting the technical progress of the industry is obvious, the overall technology reaches the domestic advanced level, and the situation that only the vinyl glass flake can be used as the anticorrosion layer in the former application of the industry is changed.

Owner:SHANDONG GUOSHUN CONSTR GRP

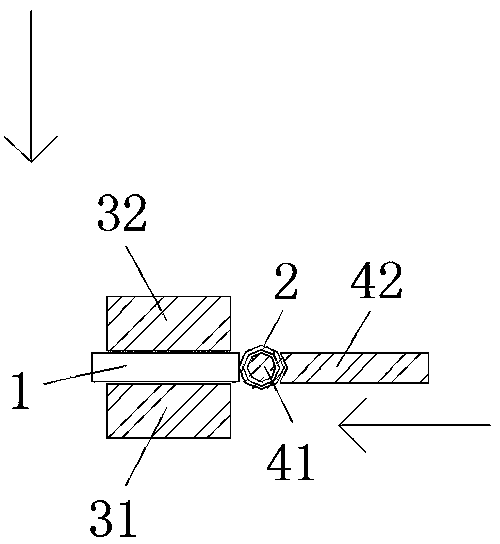

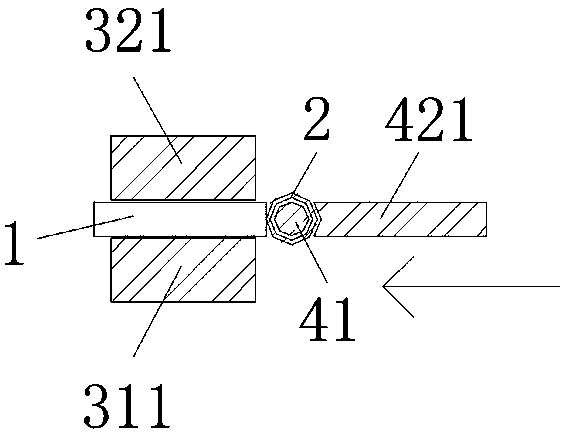

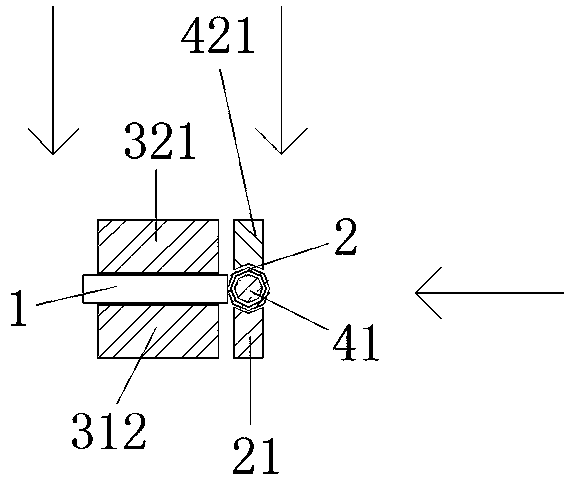

Hinge electric resistance welding process

ActiveCN108161195AInnovative production processEasy to produceResistance welding apparatusElectrical resistance and conductanceEngineering

The invention provides a hinge electric resistance welding process. A hinge comprises a hinge piece and a shaft sleeve which is assembled with the hinge piece, the shaft sleeve is formed by cutting asteel pipe, and the hinge piece is formed by cutting a steel strip or a steel plate. The hinge is manufactured by accurately positioning the hinge piece and the shaft sleeve and then welding the hingepiece and the shaft sleeve through a resistance welding process, and the electric resistance welding process is controlled by an electric resistance welding system. The electric resistance welding system comprises a shaft sleeve positioning tool system and a hinge piece positioning tool system, the hinge piece positioning tool system comprises a reference electrode and a hinge piece limiting andfixing electrode, and the shaft sleeve positioning tool system comprises a shaft sleeve positioning shaft and a shaft sleeve limiting and fixing electrode. According to the hinge electric resistance process, the traditional production process of the hinge is innovated, the production process of the hinge is simplified, the production efficiency of the hinge is high, the production time is short, the use of arc welding is avoided, and the phenomenon that the environment is polluted or the environment is damaged is avoided; and the process is environment-friendly, convenient, rapid and simple touse, low in cost, and uniform and full in welding spots of welding joints.

Owner:HERON INTELLIGENT EQUIP CO LTD

Method for smell removal, disinfection and stain resistance process on fabric

InactiveCN103061108AEfficient decompositionNo brittle deteriorationFibre treatmentResistance ProcessHydroxyapatites

The invention discloses a method for a smell removal, disinfection and stain resistance process on a fabric. The method comprises coating a smell-removal, disinfection and stain-resistant complex agent on the surface of a fabric, and carrying out drying, wherein the smell-removal, disinfection and stain resistant complex agent comprises a TiO2-hydroxyapatite photocatalytic composite nanomaterial. The method can effectively and economically perform photocatalyst effects.

Owner:湖州诺普医疗科技有限公司

A secondary welding resistance method of thick copper plate and a thick copper plate structure

InactiveCN109219268AReduce solder resist pad phenomenonFulfill design requirementsNon-metallic protective coating applicationResistSoldering

The invention discloses a secondary soldering resistance method and a thick copper plate structure of a thick copper plate. The method comprises the following steps: providing a thick copper plate with a soldering resistance layer to be printed; A first resist welding is carried out on the thick copper plate, and a first film is used for alignment exposure in the first resist welding process; Thefirst film chip is provided with a first opening window, and the area of the first opening window is a first opening area S1; Performing a second resistance welding on the thick copper plate which completes the first resistance welding, and performing alignment exposure by using a second film sheet in the second resistance welding process; The second film chip is provided with a second opening window, and the area of the second opening window is a second opening area S2; The first window area S1 is larger than the second window area S2. The invention enlarges the window area of the first filmused in the first soldering resistance process of the thick copper plate, and reduces the phenomenon of soldering resistance upper pad when the thick copper plate is soldered.

Owner:SHENZHEN WUZHU TECH

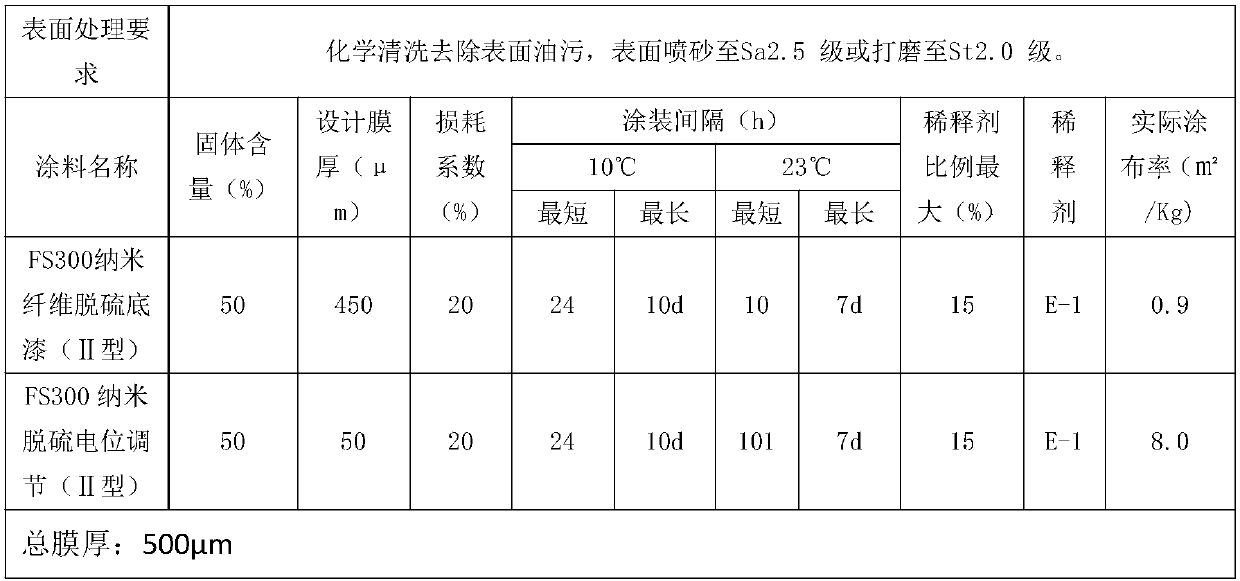

Flue baffle door nano heavy corrosion resistance process

The invention discloses a flue baffle door nano heavy corrosion resistance process. The nano heavy corrosion resistance process comprises coating and steps, wherein the coating comprises two layers ofpriming paint and finishing paint, the priming paint adopts FS300 nano fiber desulfurization double-component priming paint (type II), and the finishing paint adopts FD300 nano fiber desulfurizationelectric potential adjusting paint (type II); the steps comprises surface pretreatment and coating process, wherein the first priming coating of the coating process is carried out within 4 hours afterthe surface treatment is finished; all-component paint vehicle is fully and uniformly stirred before preparation by adopting extrusion coating, spraying coating or roller coating; and after coating construction is completed, the coating is maintained. According to the flue baffle door nano heavy corrosion resistance process, the operation is easy and convenient during product production, the repair is easy during local damage, the service life is prolonged, and the cost is low.

Owner:无锡市华通环保设备有限公司

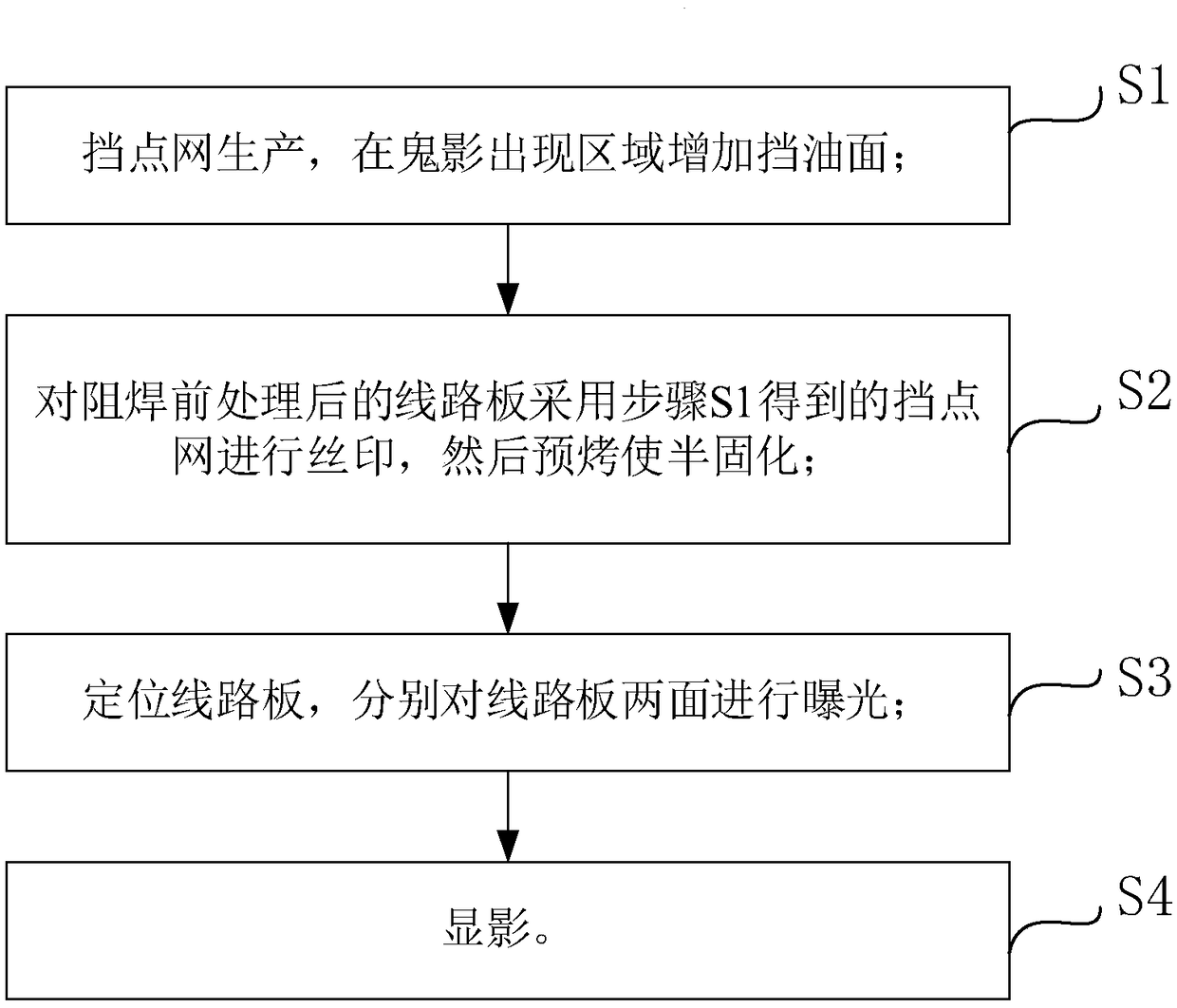

Solder resist process method for improving solder resist ghost

ActiveCN109275278AAvoid quality problemsImprove qualityNon-metallic protective coating applicationResistPre treatment

The invention discloses a welding resistance process method for improving the welding resistance ghost, which comprises the following steps: step S1, producing a stopping point net, adding an oil stopping surface in the region where the ghost appears; step S2, adding a oil stopping surface in the region where the ghost appears; step S1, adding an oil stopping surface in the region where the ghostappears. Step S2: The circuit board after the pre-treatment of solder resistance is screen-printed with the stop screen obtained in step S1, and then pre-roasted to make semi-solidified; 3, position that circuit board and exposing both side of the circuit board respectively; Step S4: Development. The invention has the advantages of reducing the production cycle and shortening the production process, which not only improves the quality problems such as ghost, oil dropping and bridge dropping, but also saves the production cost.

Owner:DALIAN CHONGDA CIRCUIT

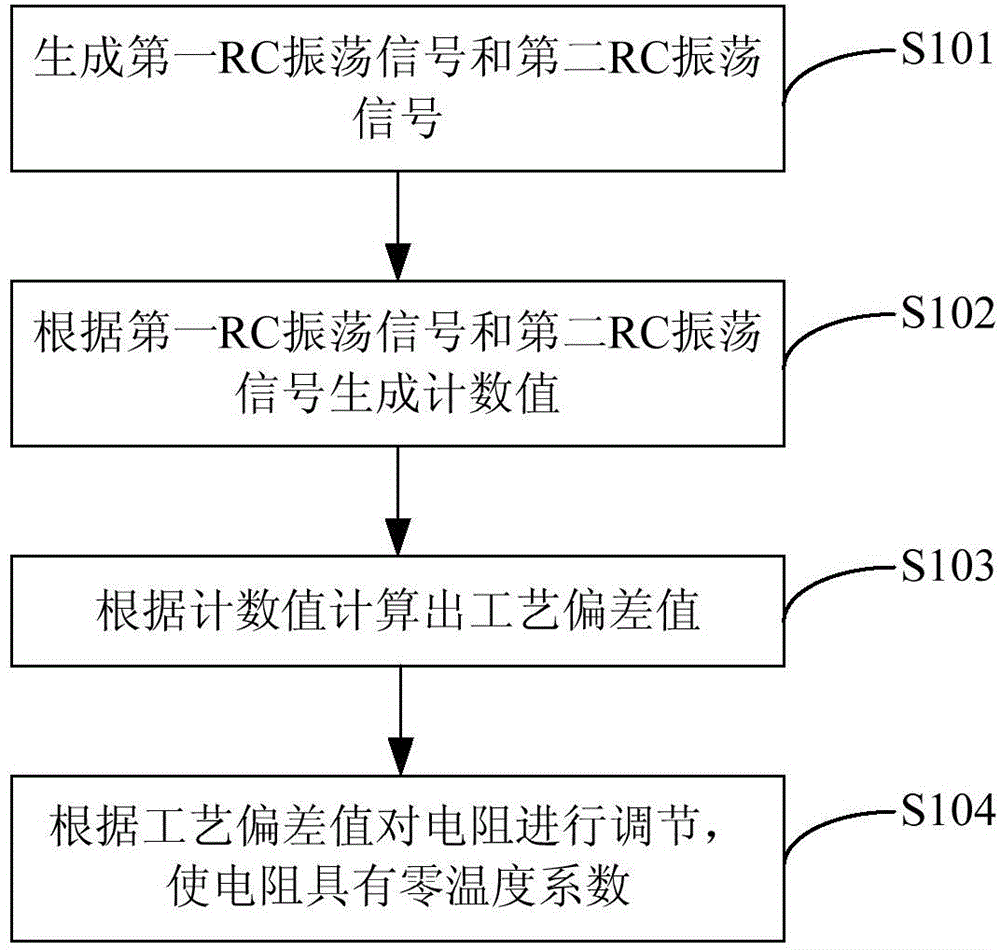

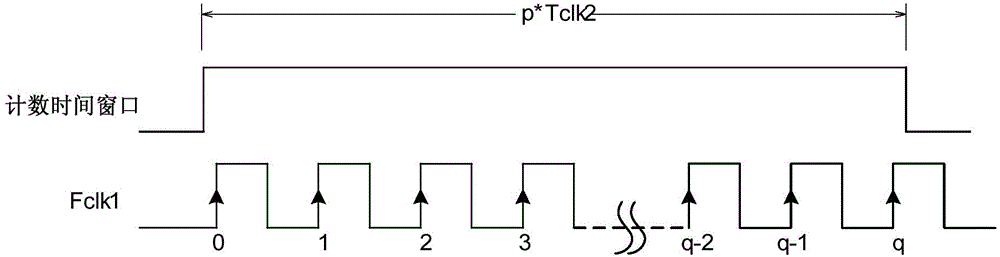

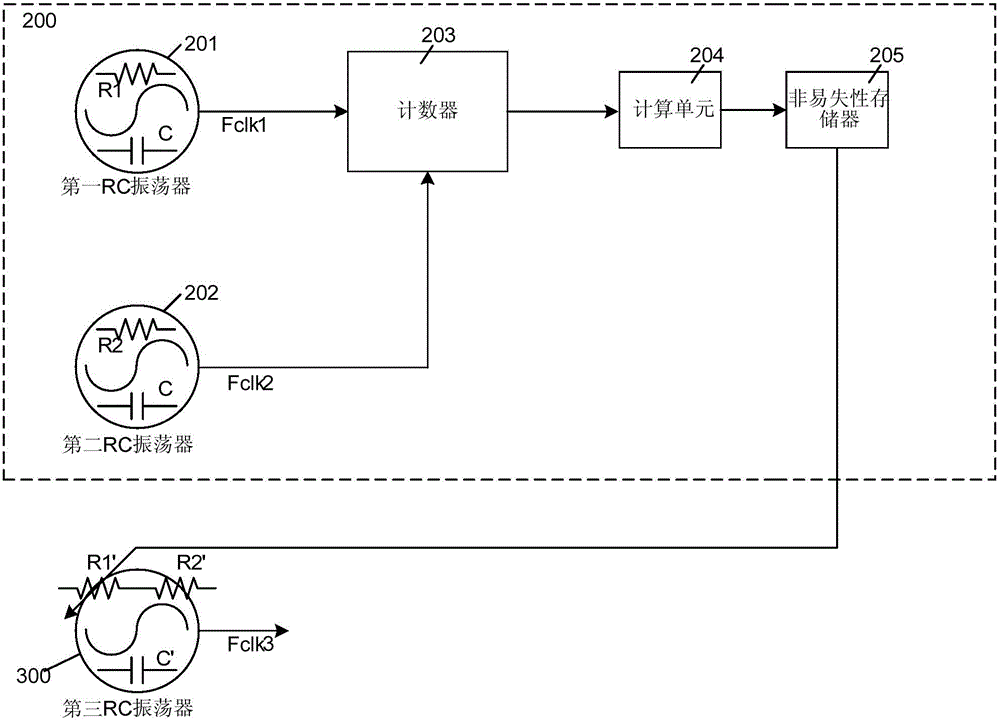

Method and device for compensating for resistance process deviation, resistors and RC oscillators

The invention is suitable for the field of integrated circuits, and provides a method and a device for compensating for a resistance process deviation, zero-temperature-coefficient resistors and RC oscillators. The method comprises the following steps: generating a first RC oscillation signal and a second RC oscillation signal; generating a count value according to the first RC oscillation signal and the second RC oscillation signal, wherein the count value comprises resistance process deviation information; computing a resistance process deviation value according to the count value; and compensating for the resistors according to the resistance process deviation value in order that the resistors have zero temperature coefficients. A clock of one RC oscillator is used for counting a clock of another RC oscillator, the resistance process deviation value is computed through a computing unit by using the count value reflecting relative process deviation information between the resistors having reverse temperature coefficients, and a resistor of a third RC oscillator is compensated by using the resistance process deviation value, so that the resistor of the third RC oscillator is changed into the zero-temperature-coefficient resistor reliably and effectively, and the temperature compensating aim is fulfilled.

Owner:SHENZHEN RENERGY TECH

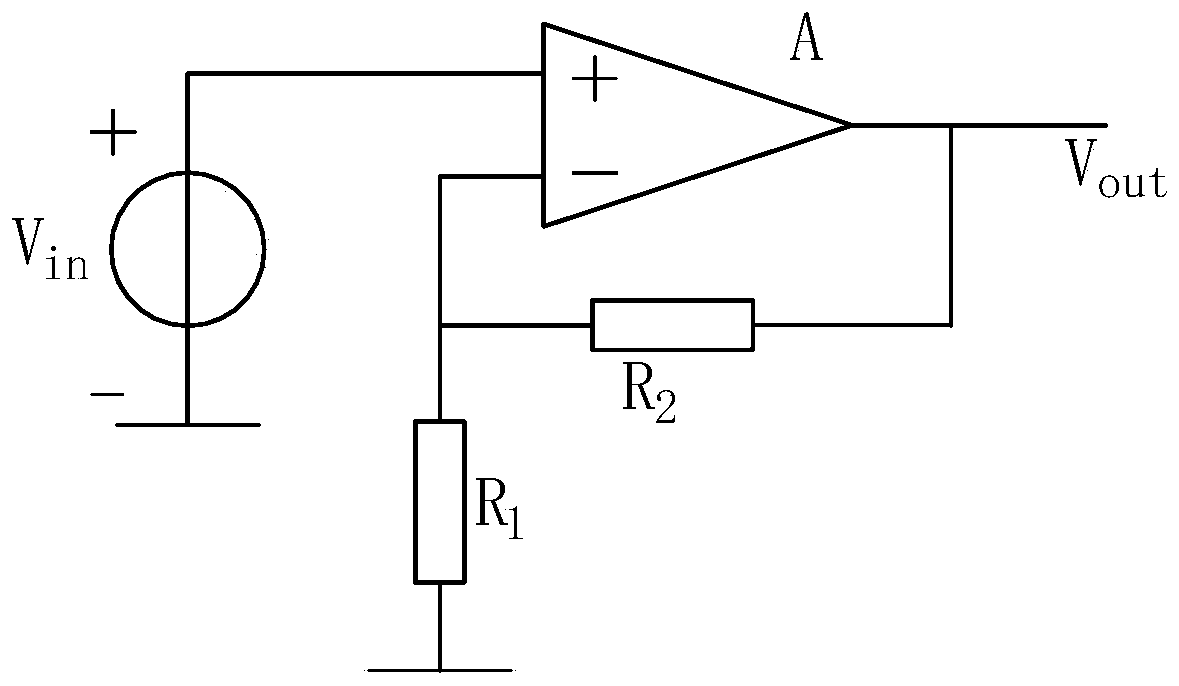

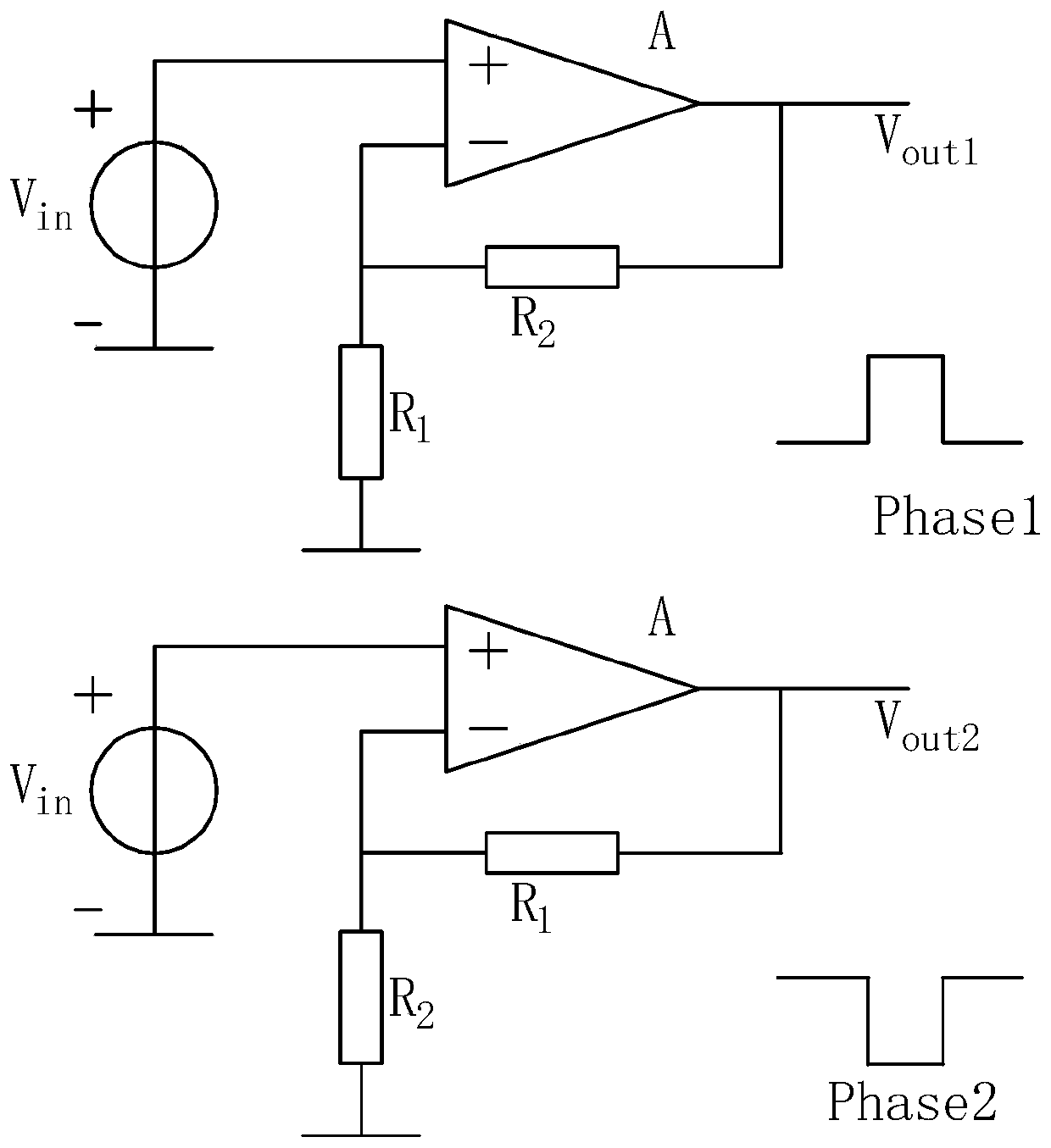

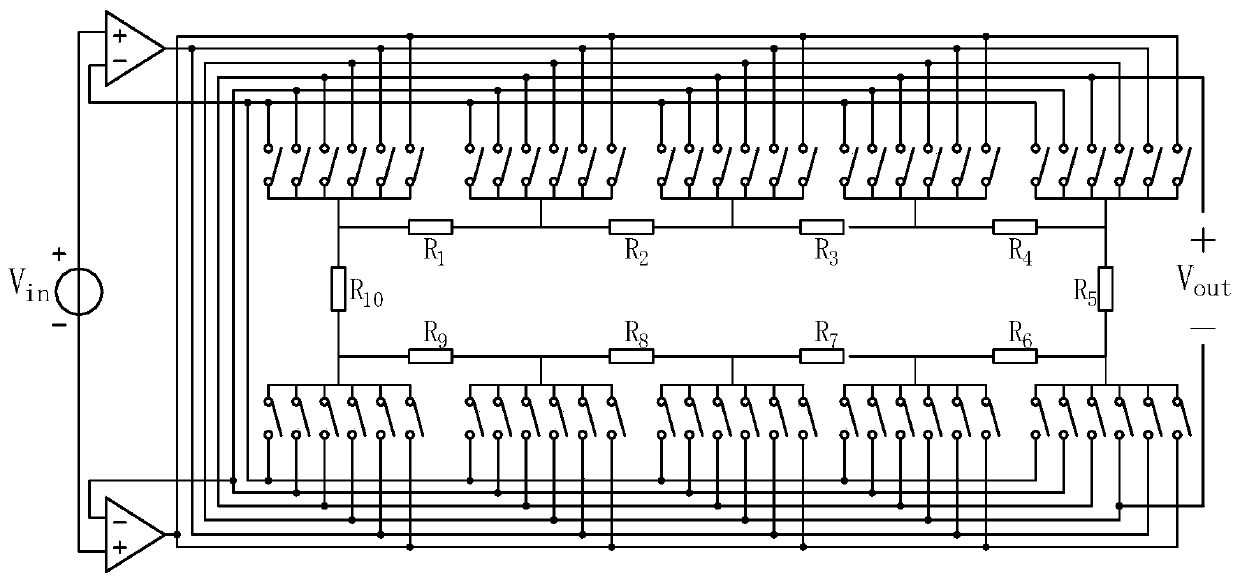

A dynamically matched voltage amplifier for eliminating resistance process errors

PendingCN109714007AReduce Gain AccuracyGain Accuracy GuaranteedNegative-feedback-circuit arrangementsGain controlAudio power amplifierProcess error

The invention discloses a dynamic matching voltage amplifier for eliminating a resistor process error. The dynamic matching voltage amplifier comprises a first amplifier, a second amplifier and a resistor rotating chain, wherein the positive input end of the first amplifier and the positive input end of the second amplifier are connected with a signal input end; The resistor rotating chain comprises a plurality of resistors which are connected end to end to form a closed loop; every two adjacent resistors are connected with the switch group; Each switch group comprises six switches which are connected in parallel; and the inner sides of the six switches are communicated with the two adjacent resistors, and the outer sides of the six switches are respectively connected with the negative input end of the first amplifier, the negative input end of the second amplifier, the positive voltage output end, the negative voltage output end, the output end of the first amplifier and the output end of the second amplifier. The dynamic matching voltage amplifier has wide applicability, can avoid using a trimming technology required by a resistor matching error, saves time and process cost required by trimming, and can achieve long-time stability.

Owner:深圳市万微半导体有限公司

A kind of anticorrosion technology of anticorrosion tank

ActiveCN106966079BImprove qualityStrong adhesionFireproof paintsLarge containersDispersityCooking & baking

The invention discloses a corrosion resistance process for an anti-corrosion tank. Superfine FEP powder with excellent anti-corrosion performance is selected as a raw material, and FEP is formed by copolymerizing tetrafluoroethylene and hexafluoropropylene and is resistant to inflaming and fire, resistant to chemicals and corrosion, high in electricity, excellent in liquidity, low in friction and excellent in heat resistance, cold resistance and weather resistance; a small amount of talcum powder is added, through high-temperature baking, the stability, tension strength, shear strength and bending strength of an anti-corrosion layer are enhanced, deformation is lowered, grains are uniform and high in dispersity, and the anti-corrosion effect is good; before machining, the inner wall of the anti-corrosion tank is subjected to abrasive blasting, the molten anti-corrosion layer and the inner wall of the anti-corrosion tank will be attached tightly, a tank body is internally provided with at least one set of cross-shaped grooves, the anti-corrosion layer is embedded into the grooves, the anti-corrosion layer and the inner wall of the anti-corrosion tank are attached more tightly and will not disengage or separate within 5 years, and the quality of the anti-corrosion tank is improved. According to the corrosion resistance process, the preparation method is scientific and practical, the cost is low, the floor space is small, and the anti-corrosion layer is high in adhesive force, long in service life and worthy of popularization.

Owner:徐州势甲信息科技有限公司

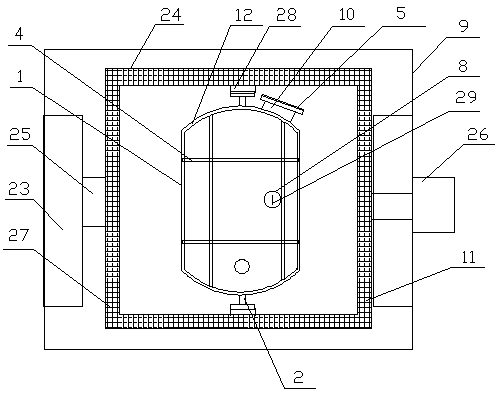

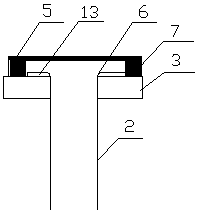

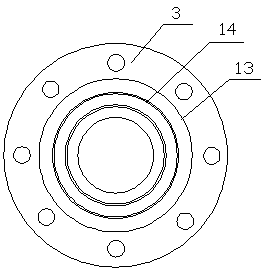

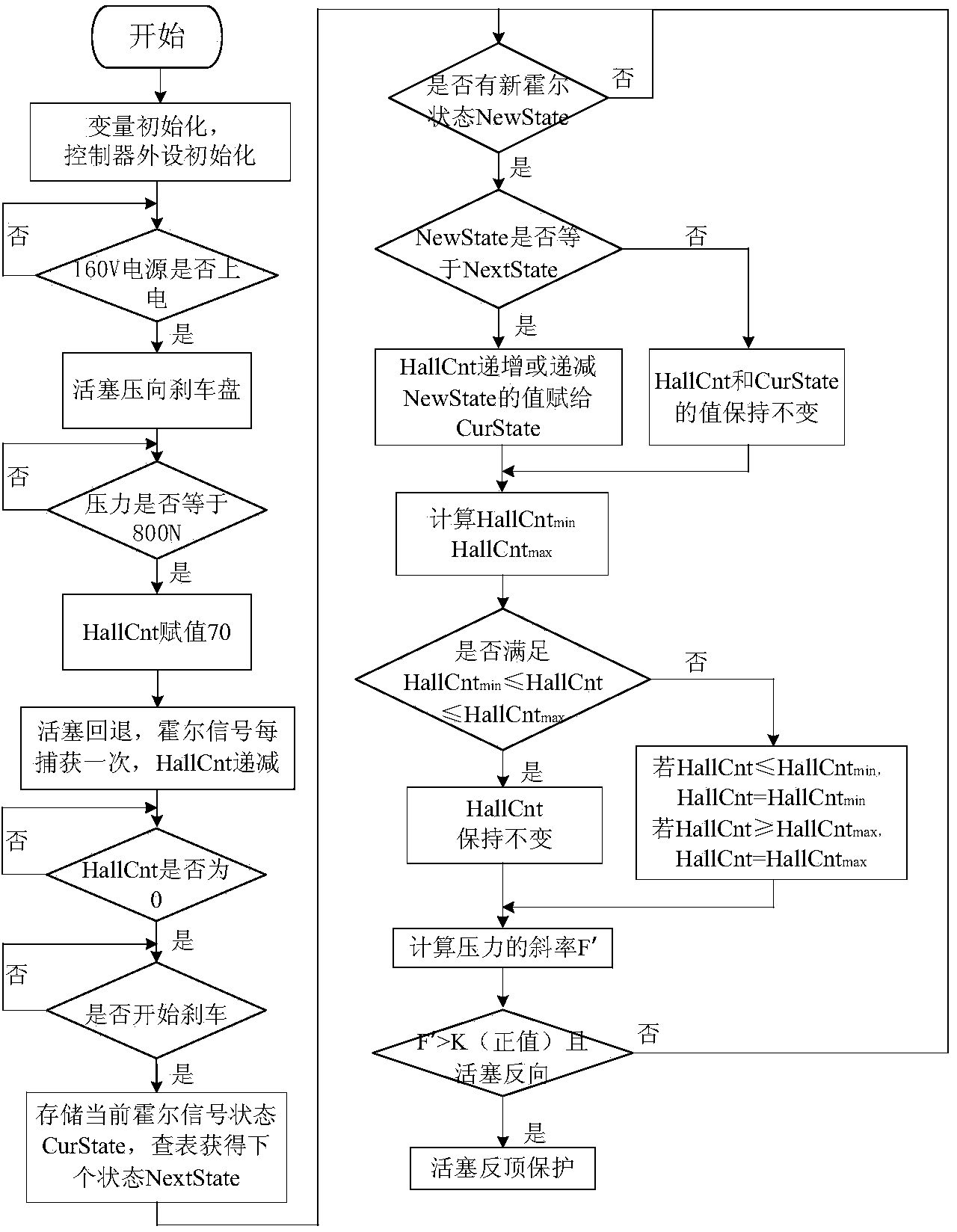

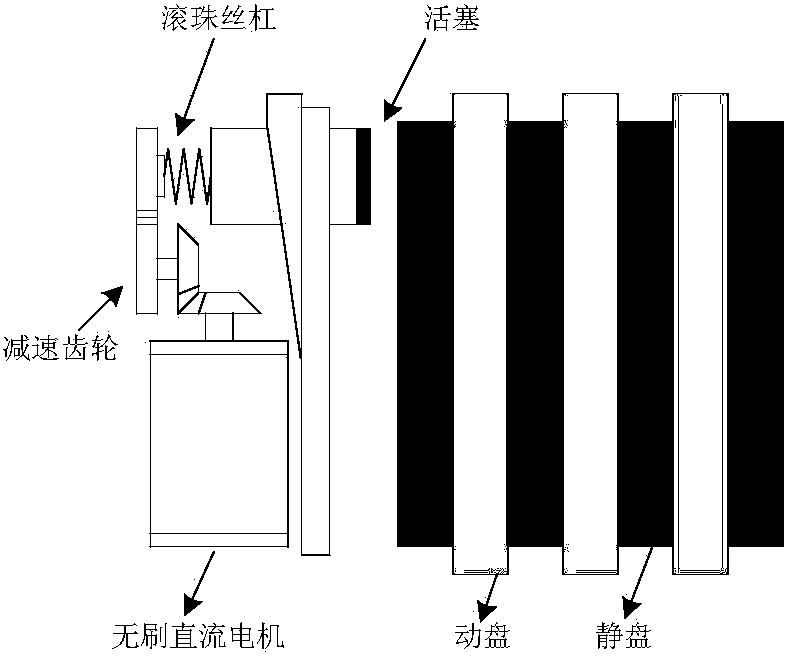

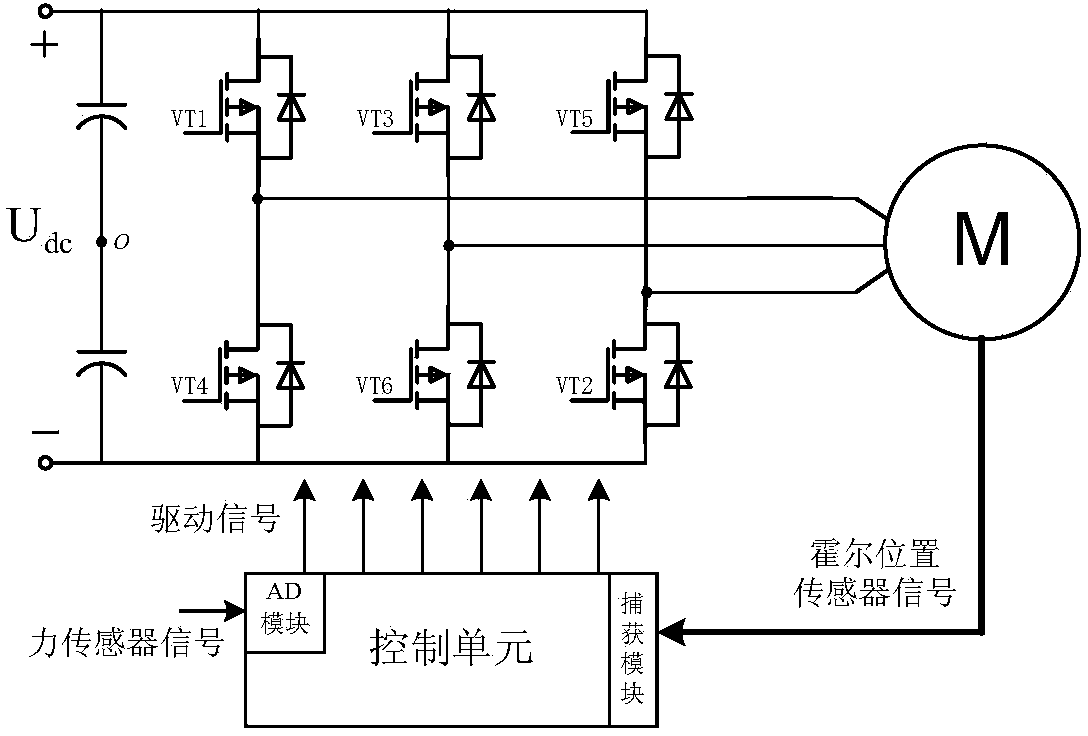

Method for obtaining and protecting piston position of aircraft electric brake actuator

InactiveCN103707870AAvoid easy reverse outputAvoid stickingBraking action transmissionBrake safety systemsElectricityActuator

The invention relates to a method for obtaining and protecting the piston position of an aircraft electric brake actuator. According to the method, position information of a piston can be obtained in real time in the working process of an aircraft brake system, and therefore the problems that the piston easily exerts force in the reverse direction to be stuck when the actuator is in the zero alignment process and the deep skid resistance process can be effectively solved, and the strong support is provided for stable and reliable running of the aircraft electric brake system.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Corrosion resistance process of magnesium alloy in mechanical processing process and corrosion resistance tool thereof

The invention relates to a corrosion resistance process of magnesium alloy in mechanical processing process, which comprises a surface pretreatment step and an electric insulating layer preparation step. The process cuts off a reaction pathway of a primary cell causing filiform corrosion on the surface of the magnesium alloy by preparing a membrane layer of the electric insulating layer on the surface of a jig where mechanical processing needs to be carried out on the magnesium alloy, and fundamentally prevents filiform corrosion from being generated on the surface of the magnesium alloy.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

Trunk coating preparation for control of fruit tree rot disease and preparation method thereof

InactiveCN110627565APromote repairEase of self-healingBiocidePlant growth regulatorsDiseasePhosphate

Belonging to the technical field of trunk coating preparations for control of fruit tree rot disease, the invention relates to a trunk coating preparation for control of fruit tree rot disease and a preparation method thereof. The trunk coating preparation is mainly composed of a seaweed extract liquid, humic acid, potassium hydroxide, potassium dihydrogen phosphate, potassium sulfate, potassium nitrate and urea. The humic acid and seaweed liquid in the trunk coating preparation cooperate with each other to generate an obvious inhibiting effect on pathogenic bacteria, thus facilitating prevention and treatment of fruit tree rot disease. Also the trunk coating preparation has no need for scraping disease spots during use, and can be directly coated, avoids secondary damage to fruit tree wounds, and is beneficial to rapid repair of fruit trees. Meanwhile, the trunk coating preparation can provide nutritional ingredients to crops and automatically adjust the vegetative growth and reproductive growth of crops, thus increasing the yield of crops. The seaweed extract liquid, nitrogen, phosphorus, potassium and the like in the trunk coating preparation can provide nutritional factors beneficial to the growth and development of fruit trees to crops, and the nutritional factors can be directly absorbed and utilized by fruit trees through epidermis of fruit trees, thus being easier for the self-rehabilitation of fruit trees in the disease prevention and disease resistance process.

Owner:嘉特(烟台)生态农业科技研发有限公司

Method for increasing effect activity of chemical agent on brown planthopper by using insecticidal bacteria

InactiveCN106577765AImprove the effect of prevention and controlHigh activityBiocideDead animal preservationThiamethoxamSynergy

The invention discloses a method for increasing effect activity of chemical agent on brown planthopper by using insecticidal bacteria. The insecticidal microbe and a chemical pesticide are combined for usage to generate synergistic, neutral or antagonistic effects. By aiming at large insects on production, the effective insecticidal microbe is screened for synergistic combination with a chemical agent, and the safe and efficient control level of the insects can be obviously increased. and the control of large brown planthopper in paddy rice is mainly dependent on the chemical agent. The method uses sub-lethal dosage for killing bacterial serratia marcescens, can obviously increase the effect activity of the chemical agent thiamethoxam and on brown planthopper, and reduces the usage amount of the chemical agent. Reasonable utilization of the combined synergy effect of the insecticidal bacteria and the chemical agent can effectively increased the control effect on the insects, reduces the usage amount of the chemical pesticide, alleviates insect resistance process, and increases the protection effect on environment.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

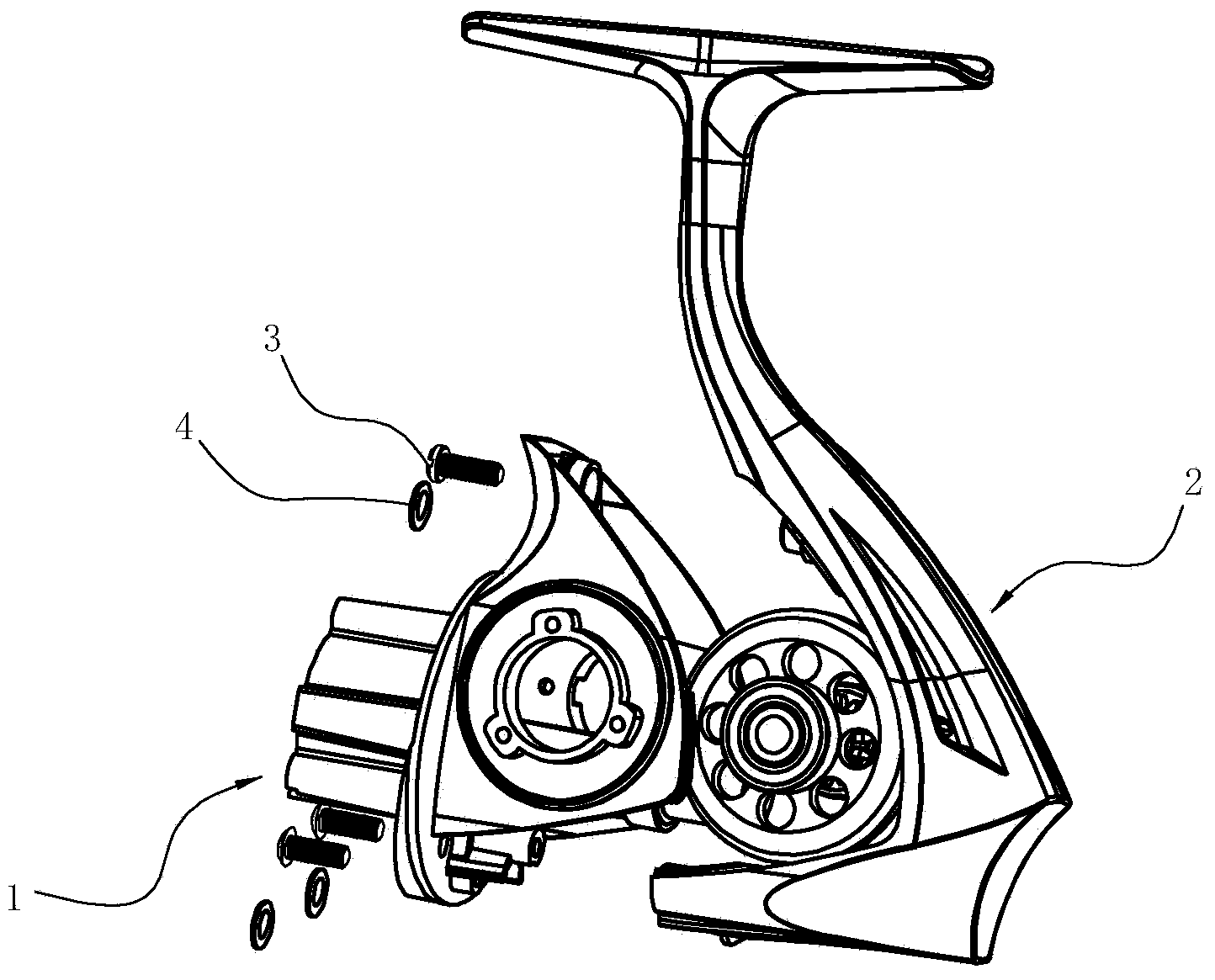

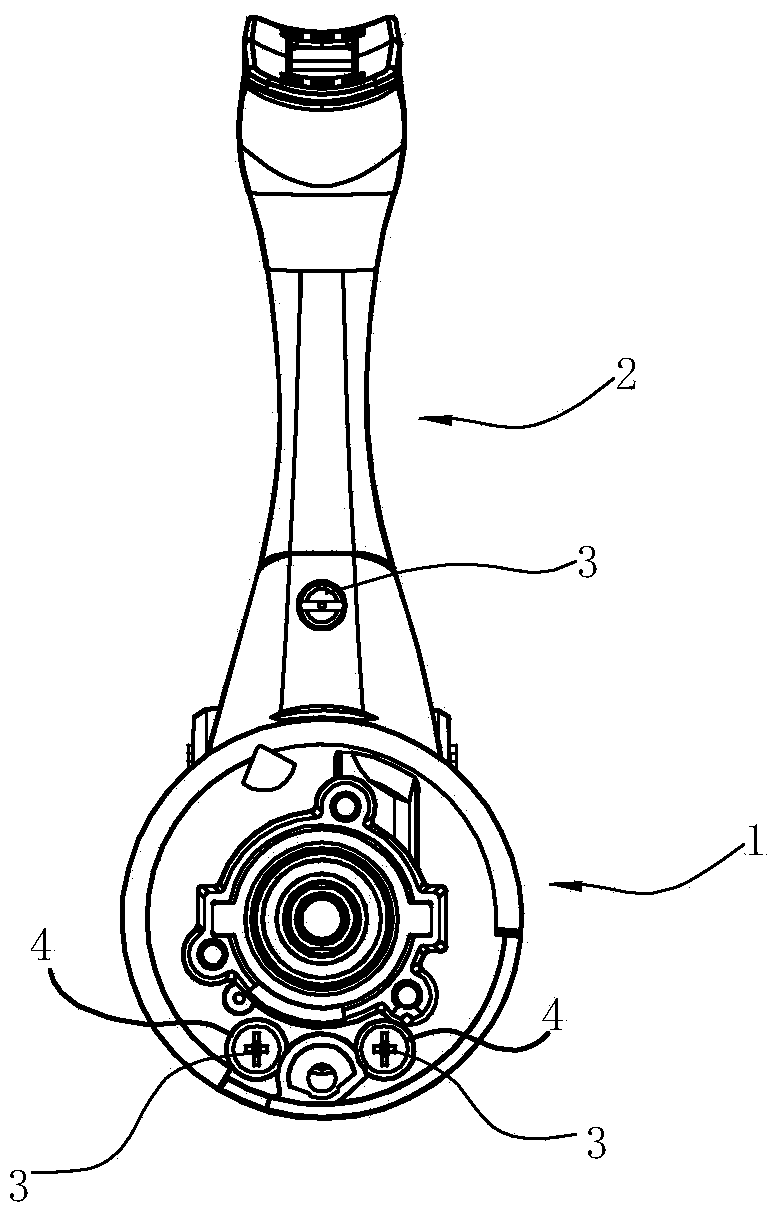

Fishing reel surface corrosion resistance process

ActiveCN103710716AImprove corrosion resistanceReduce pollutionElectrophoretic coatingsElectrophoresisEngineering

The invention relates to a fishing reel surface corrosion resistance process. A fishing reel comprises a main body and a main cover, wherein the main body is connected with the main cover via screws to form a main structure of the fishing reel. The process is characterized by comprising the following steps: (1) carrying out surface treatment by shot blasting, (2) carrying out immersion cleaning, (3) spraying, (4) washing, (5) activating; (6) cleaning up acid on the surface of the main structure of the fishing reel with purified water, (7) phosphating, (8) washing, (9) carrying out electrophoresis, (10) washing and (11) drying. Compared with the prior art, the fishing reel surface corrosion resistance process has the beneficial effects that after the fishing reel undergoes 168-hour neutral and acid salt spray tests, the surface of the fishing reel does not have obvious changes and does not fall off in scribing tests after the tests, thus greatly improving the corrosion resistance of the fishing reel; the fishing reel has beautiful appearance, high production efficiency and low labor intensity and is slight in environmental pollution in the treating process.

Owner:NINGBO HAIBO GRP CO LTD

White shirt interlining thermal yellowing resistance process

InactiveCN106320017AEliminate yellow lightAchieve whitening effectHeating/cooling textile fabricsDyeing processEngineeringComplementary colors

The invention discloses a white shirt interlining thermal yellowing resistance process comprising the steps of adding the mixing liquor of Ciba Erionyl blue A-R and Ciba Polar red 10B in the 0.5-1L finishing liquor of ordinary white shirt fabric and completing the thermal yellowing resistance process by padding and setting. The time of each padding is 5-8 seconds, the pressure of padder is 0. 10- 0. 28MPa, the speed of the setting machine is 20- 30m / min and the setting temperature is 180- 190oC. Through the complementary color principle of light, the invention adds Ciba Erionyl blue A-R and Ciba Polar red 10B dye in the finishing liquor, which are absorbed into the fabric by padding, thus eliminate the yellow light of fabric and realize whitening of the fabric. The technology of the invention is easy to operate, with no need to add any procedures and with significant whitening effect.

Owner:QINGDAO WINCHANCE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com