Fishing reel surface corrosion resistance process

A fishing reel and process technology, which is applied in the direction of electrolytic coating, electrophoretic plating, coating, etc., can solve problems that affect product performance and life, cannot reach service life, and corrosion of aluminum alloy main body, so as to improve corrosion resistance and avoid Potential corrosion and less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

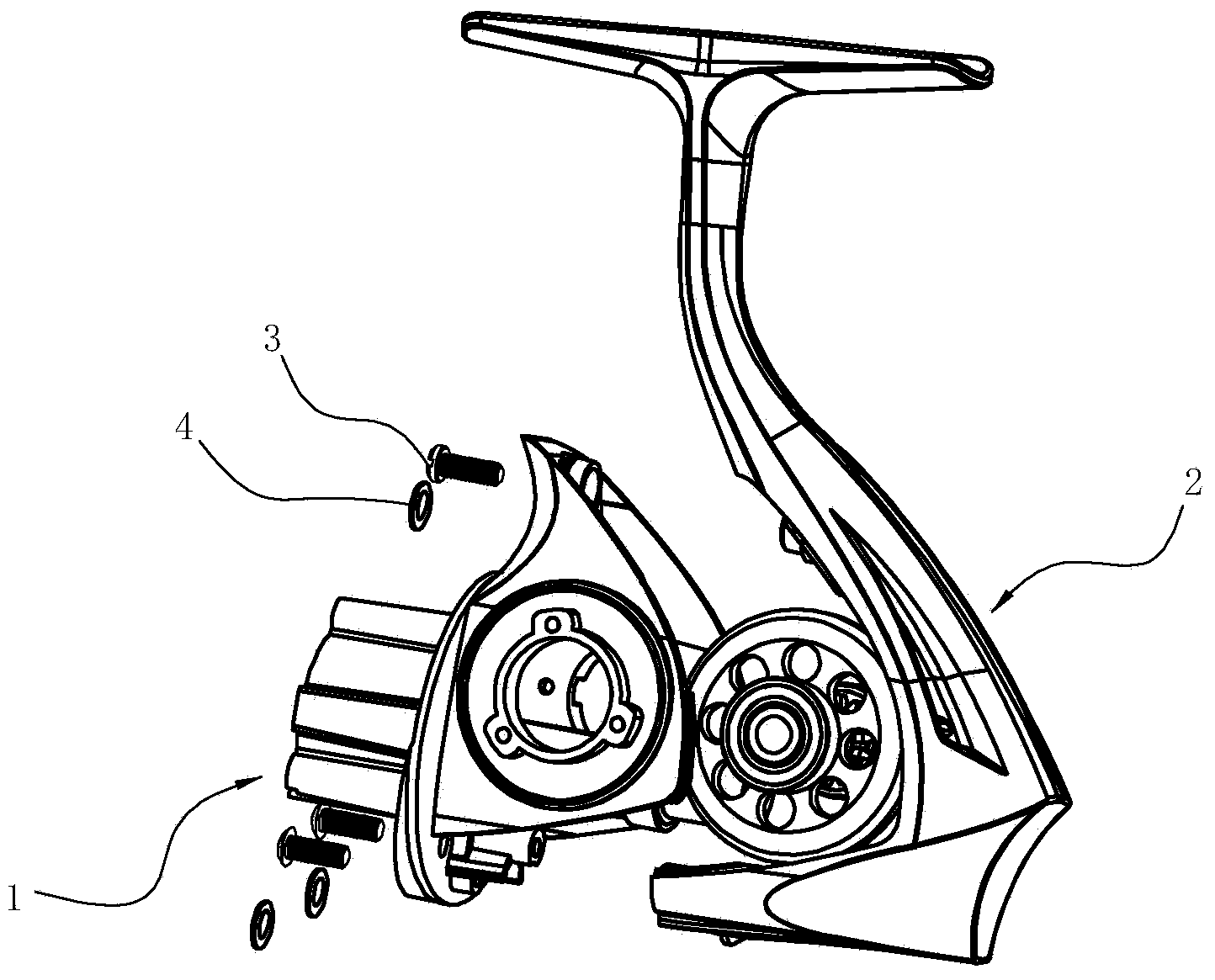

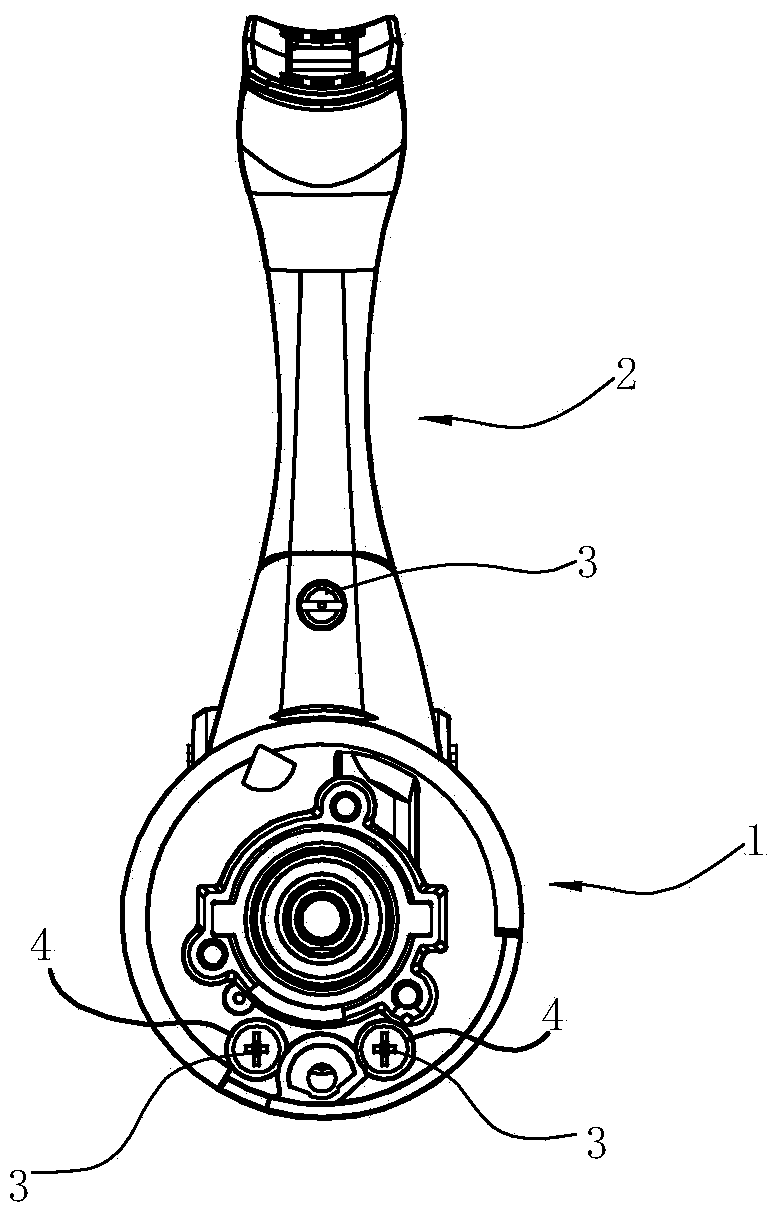

[0040] like figure 1 and figure 2 As shown, the fishing reel includes a main body 1 and a main cover 2, the main body 1 and the main cover 2 are joined front and rear, and are connected with each other by screws 3 to form the main structure of the fishing reel. In the anti-corrosion process, anti-corrosion treatment is first performed on the surface of the main structure 1 of the fishing reel.

[0041] Firstly, shot peening is performed on the blank of the fishing reel main structure 1 .

[0042] Shot peening is to make the dead corner of the inner cavity of the product be shot blasted, so as to achieve the required smoothness, cleanliness, roughness, surface density and strengthen the surface of the part, making the surface of the part stronger. For example, the surface hardness of the main structure of the PA2000 fishing reel is HRB67, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com