Patents

Literature

62results about How to "Fulfill design requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

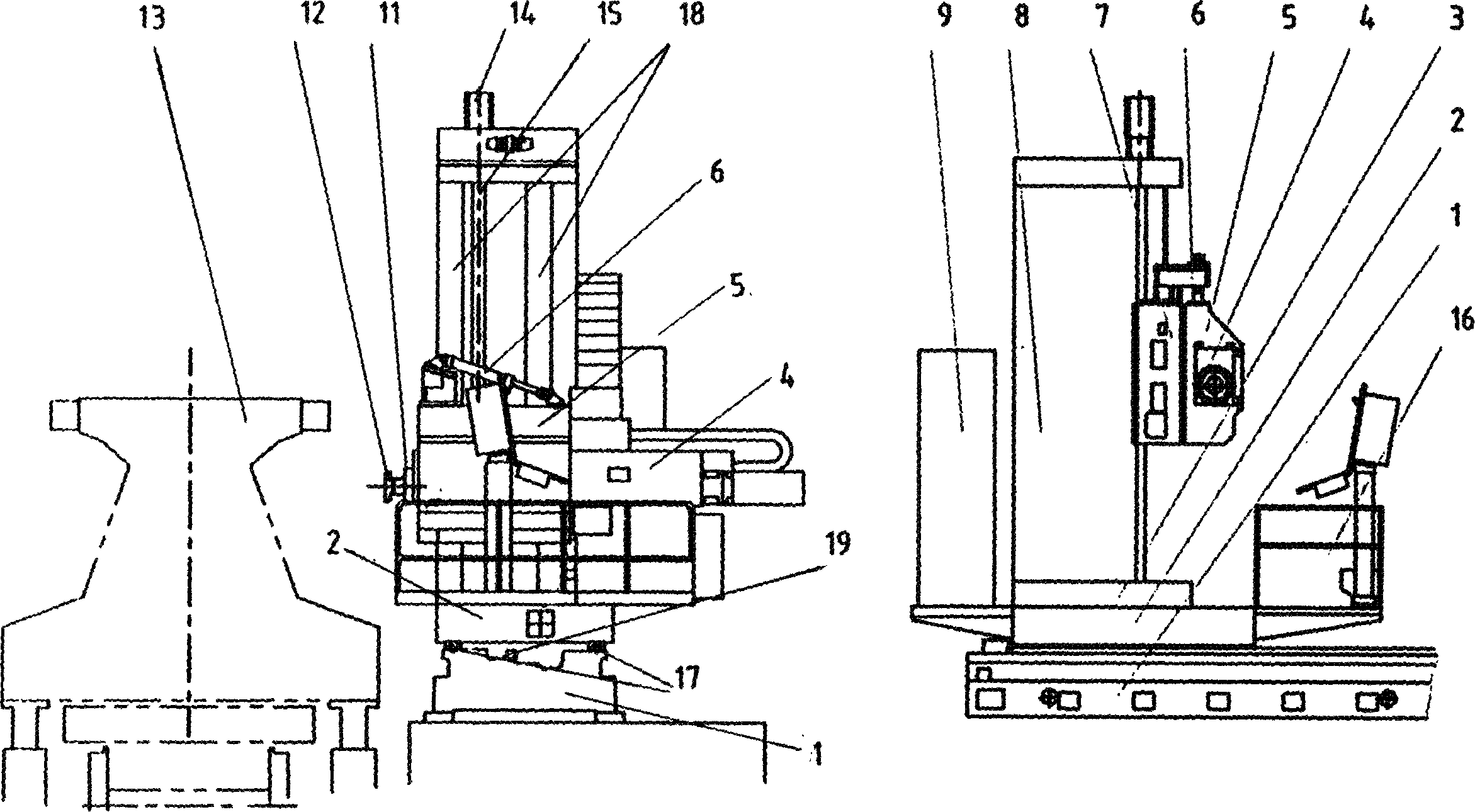

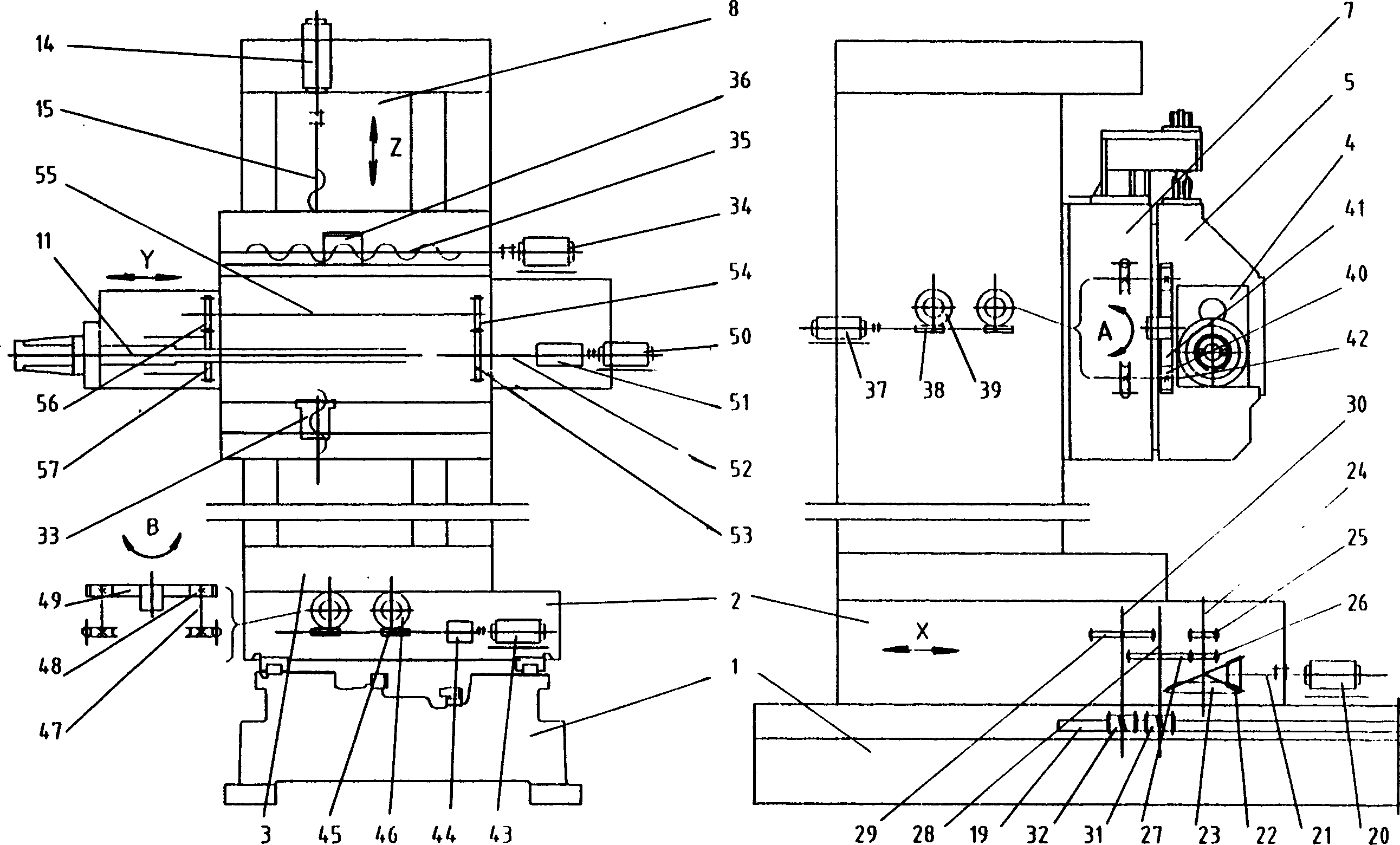

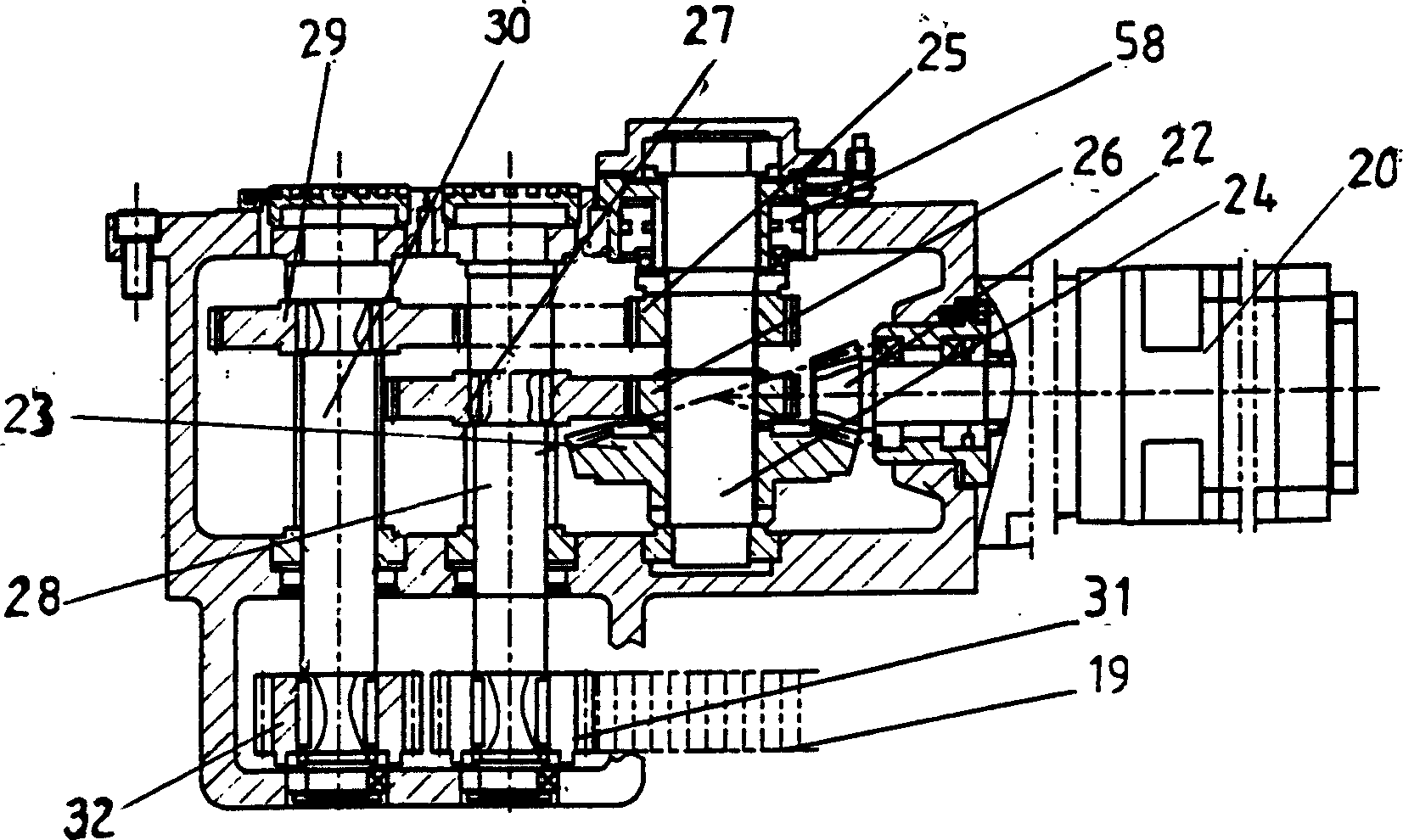

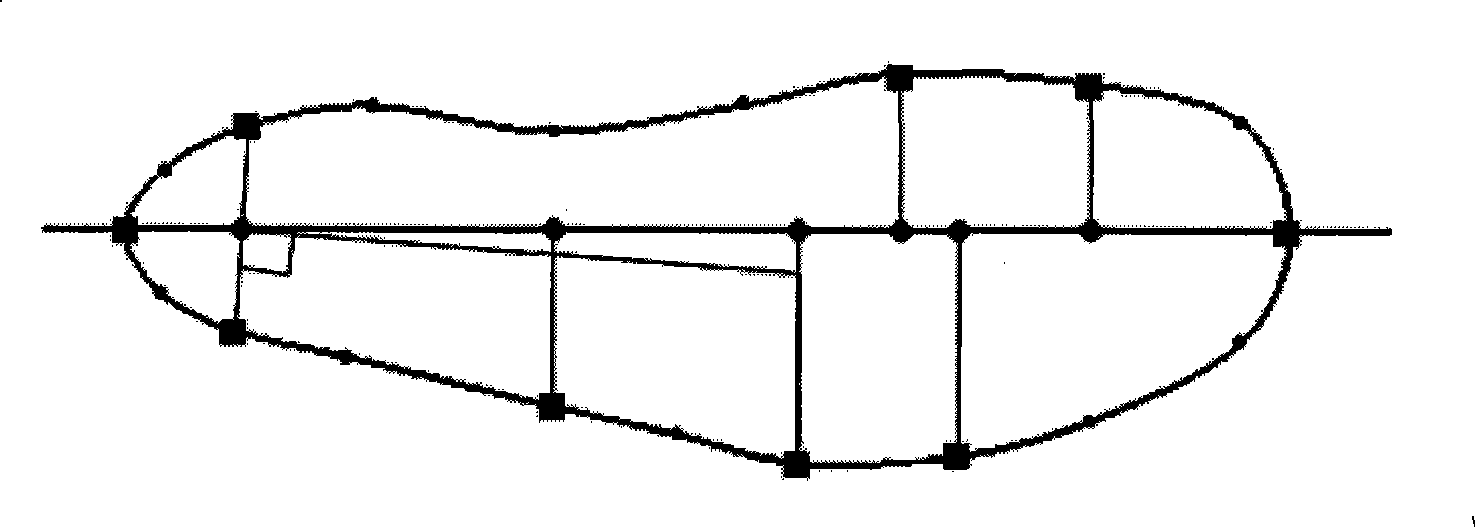

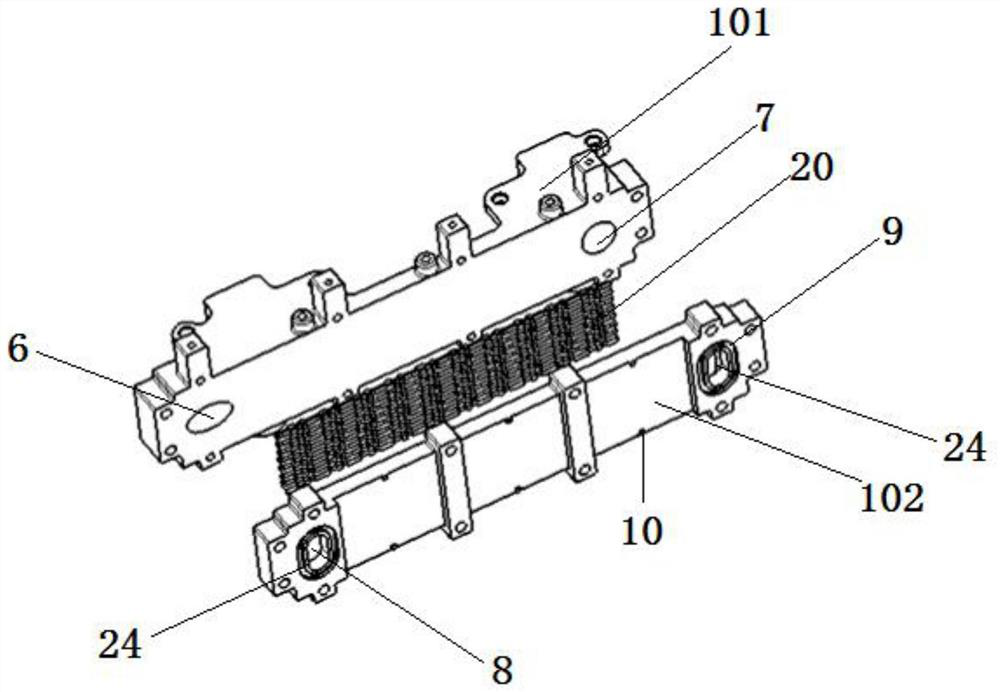

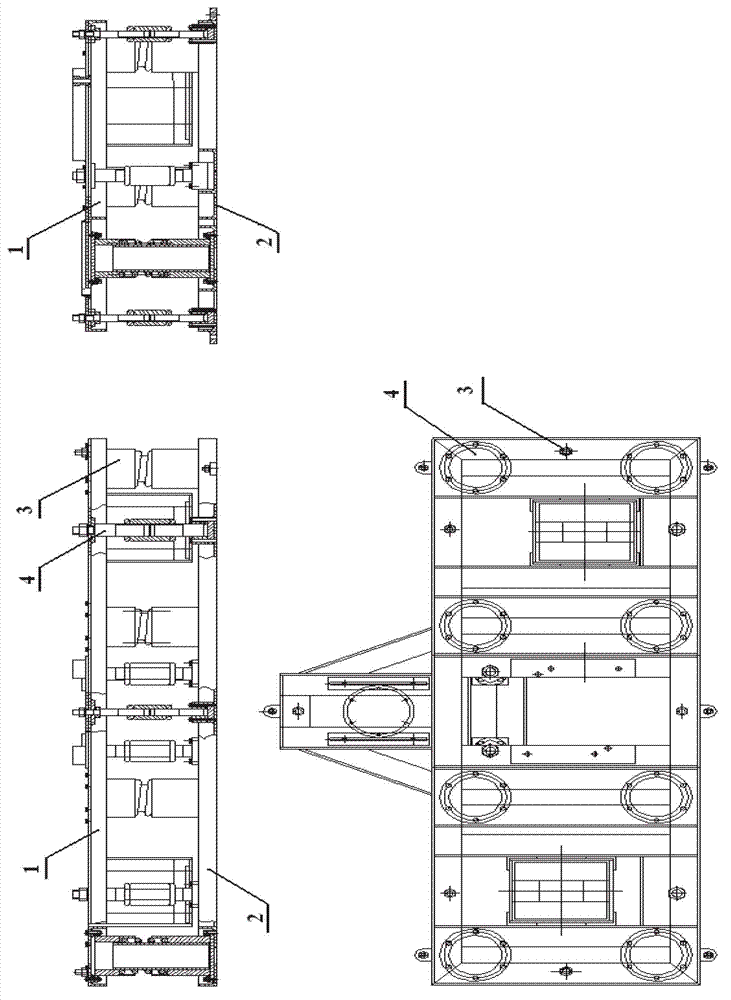

Digital control machine with magnetic suspension track girder

InactiveCN1462660AAchieve smooth controlAchieve positioningAutomatic/semiautomatic turning machinesSliding/levitation railway systemsNumerical controlVertical plane

A numerally controlled machine-tool for machining the magnetically levitating rail is composed of main body with 36 m in length, vertical column, mainshaft box, control system and manipulating station. It features its other units including three drive mechanisms for X, A and B axises, a slide seat of vertical column, a rotary seat of vertical volumn and a slide saddle moving along vertical column. The said mainshaft box is arranged to slide saddle. The said control system and manipulating station are connected to slide seat. Its advantage is high precision in whole length range of workpiece.

Owner:TONGJI UNIV

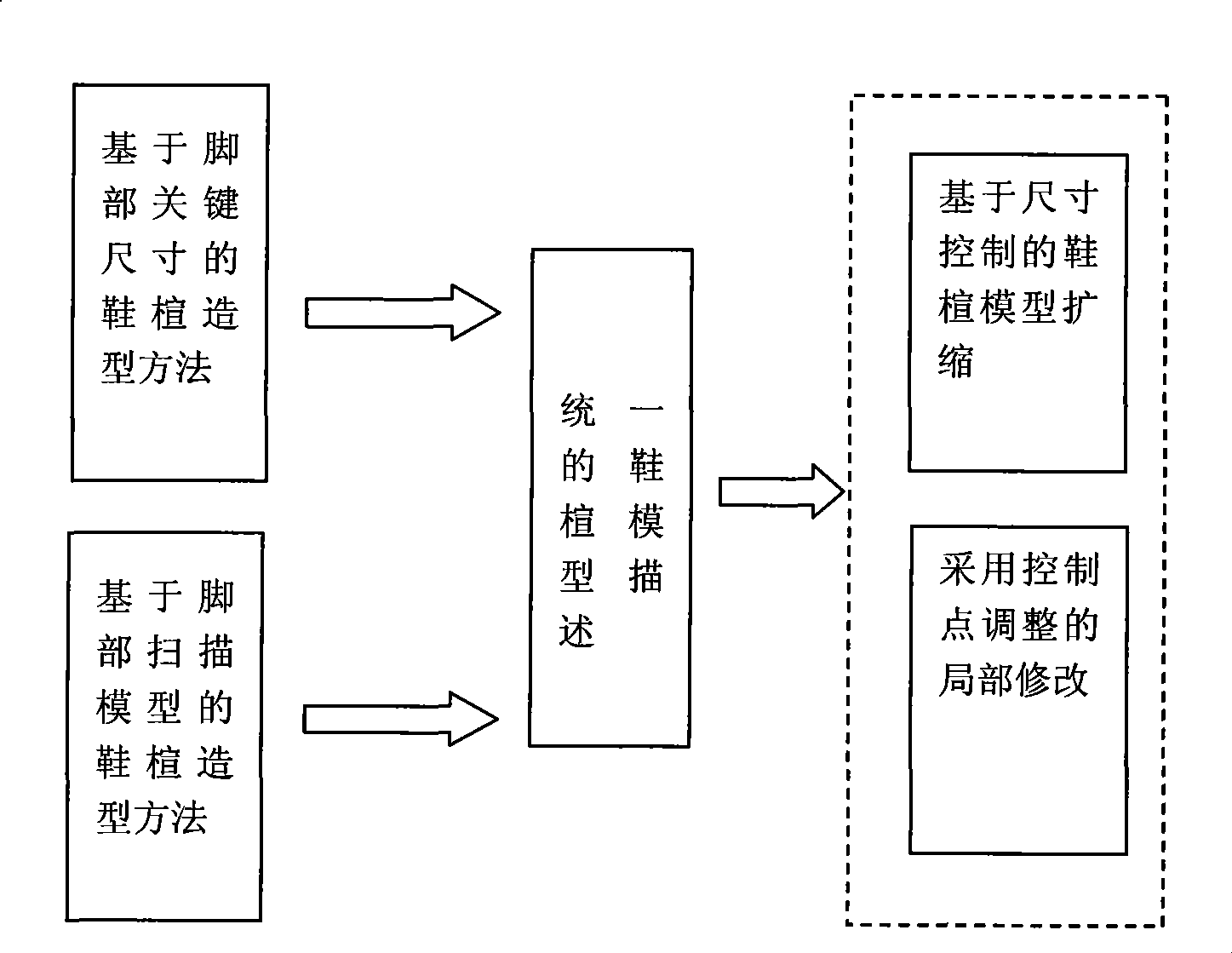

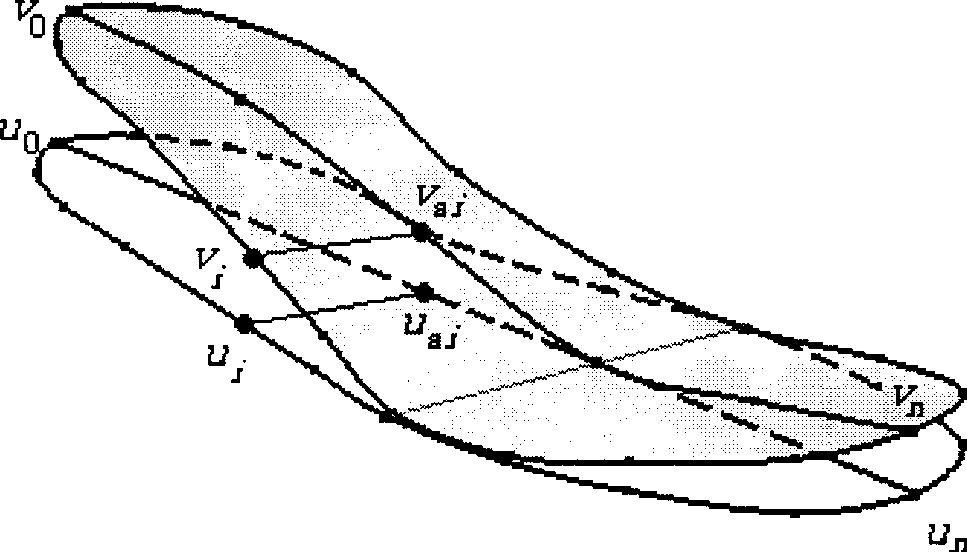

Interactive shoehorn modeling method based on human foot characteristic size

InactiveCN101369145AFulfill design requirementsRealize the shapeProgramme controlComputer controlKey sizeModel description

The invention discloses an interactive shoe last modeling method based on foot feature size, and the shoe last modeling method based on foot key size is to build a key contour curve through inputting the foot key size of a user and combine the contour curve into a shoe last curve frame for building shoe last sub-curves in blocks, and the shoe last sub-curves are spliced and faired for obtaining a whole shoe last curve; the shoe last modeling method based on a foot scanning model of the user introduces a user foot model, builds a foot feature model and a corresponding shoe last feature template, and combines the shoe last feature template and the contour curve to subdivide the initial grid surface of the shoe last feature template for obtaining a shoe last surface prototype; builds a unified shoe last model description; and adopts two modes of adjustment to the shoe last surface based thereon: scaling of the shoe last model based on size control or partial surface modification by adopting control points for adjustment. The invention realizes the shoe last modeling method without solid last.

Owner:ZHEJIANG UNIV

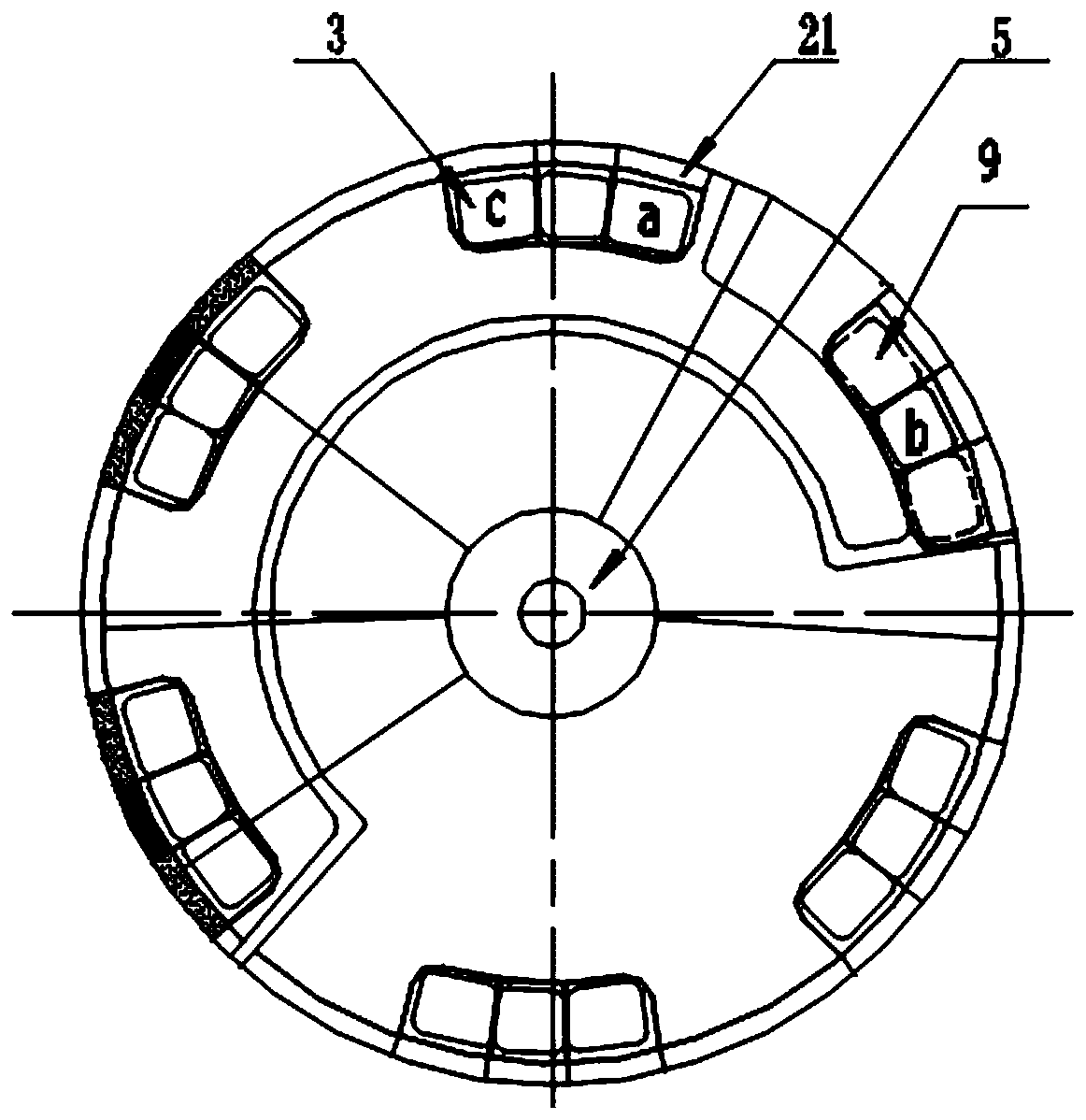

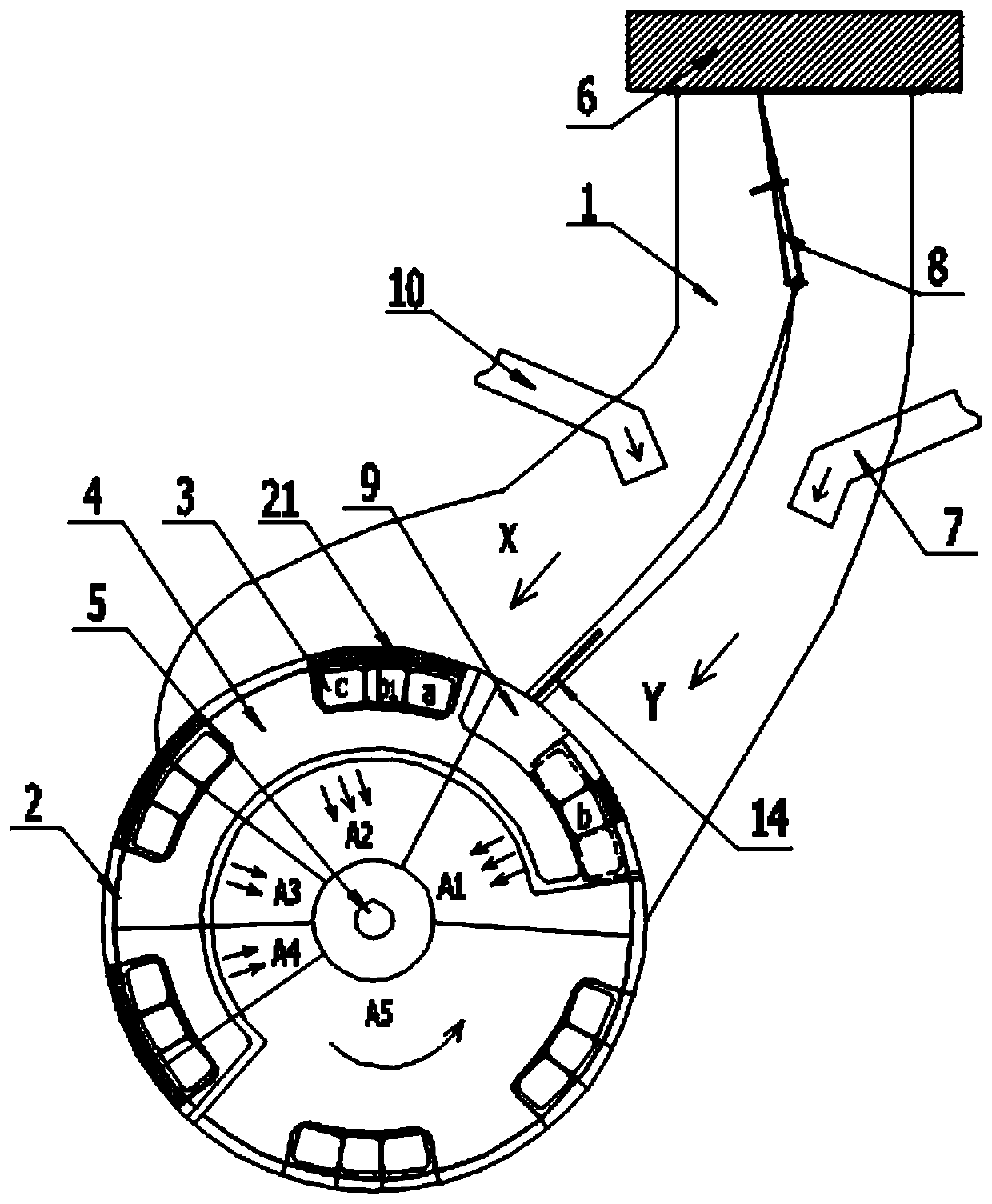

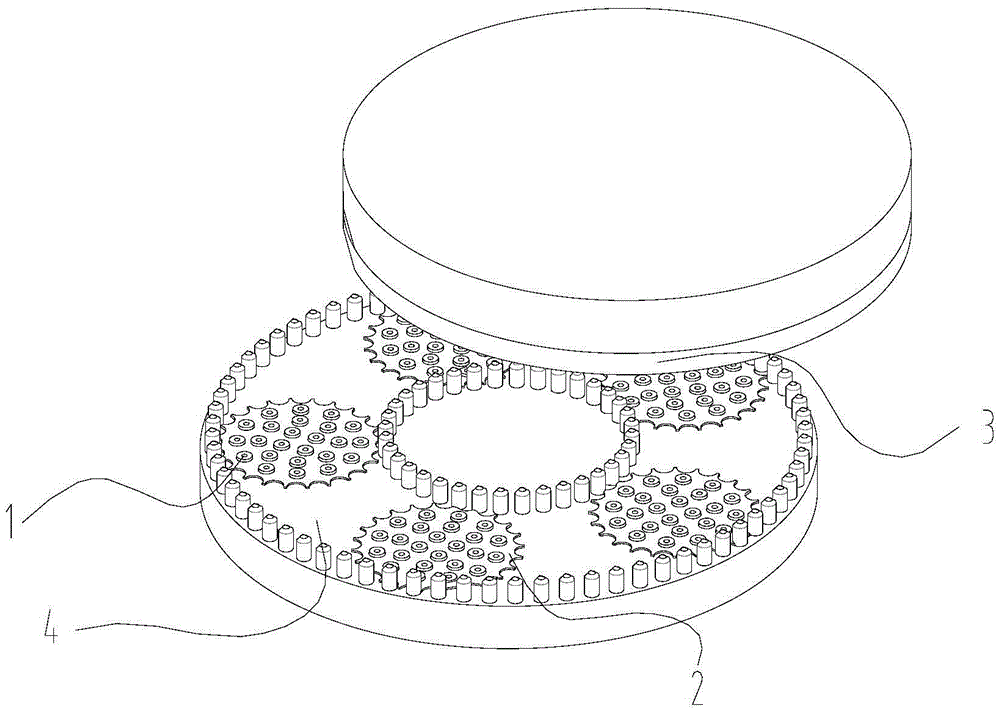

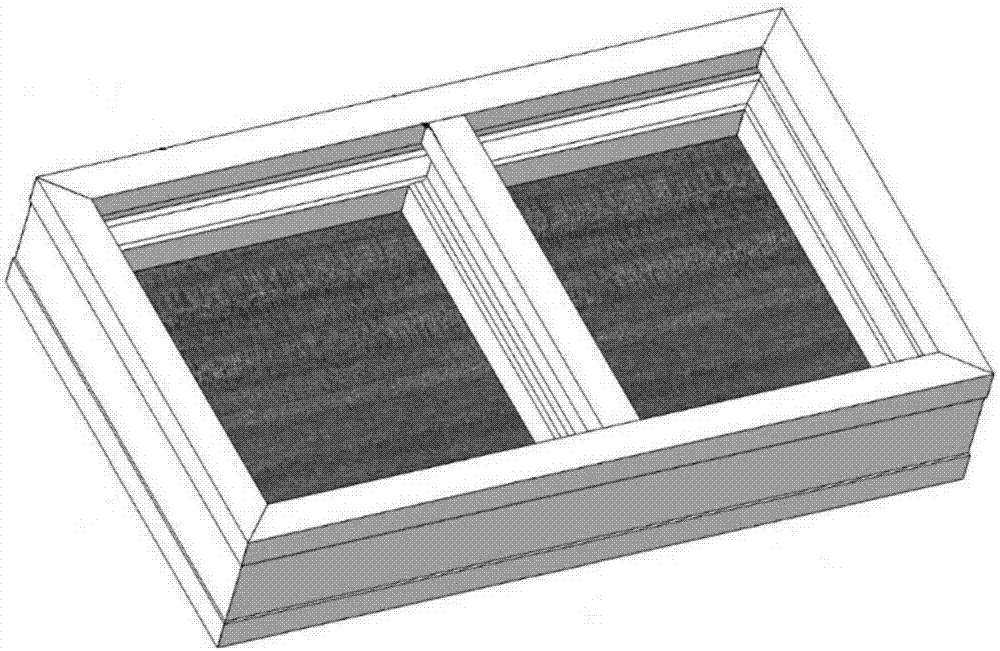

Hygienic product raw material fixed-point application and absorber forming device and technology

PendingCN109793611AAccurately realize the position of adsorptionFulfill design requirementsAbsorbent padsBaby linensEngineeringVALVE PORT

The invention relates to the technical field of disposable hygienic products, in particular to a hygienic product raw material fixed-point application and absorber forming device and technology. The device comprises a forming hub, the center of the forming hub is provided with a rotating device, a mould is fixed onto the forming hub and divided into a plurality of forming areas, inner partition bins corresponding to the forming areas are arranged on the forming hub, openings are formed in the tops of the inner partition bins, and the sizes of the openings correspond to the corresponding forming areas, the forming hub is connected with a negative-pressure assembly for forming negative pressure in one or a plurality of inner partition bins, a distributing valve and a distributing disk for connecting or disconnecting the inner partition bins with the negative-pressure assembly are arranged on the forming hub, the forming device further comprises at least one wool collecting bin, outlets of the wool collecting bins are communicated with the outer surface of a mould component, the wool collecting bins are connected with a raw material application device for supplying materials, the rawmaterial application device at least comprises a first raw material application device and a second raw material application device. According to the device, design requirements of different absorbersare met by adjusting adsorption positions and total adsorption amount.

Owner:ANQING HENG CHANG MACHINERY

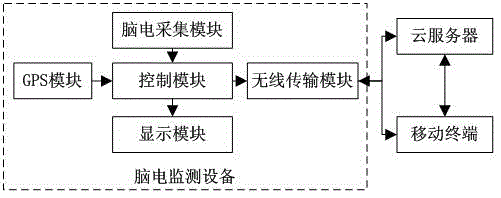

Electroencephalogram real-time monitoring control system and method based on positioning

InactiveCN105534521AReasonable planningEmergency rescue in timeTransmission systemsSensorsEmergency rescueControl system

The invention discloses an electroencephalogram real-time monitoring control system and method based on positioning. The system comprises an electroencephalogram monitoring device, a cloud server and a mobile terminal, wherein the electroencephalogram monitoring device comprises an electroencephalogram collecting module, a GPS module, a control module, a wireless transmitting module and a display module. The method includes the steps that electroencephalogram signals of a carrier are collected, and positioning data is obtained through real-time positioning; a regional map containing location data of medical service points is prestored; an abnormal threshold value judging model is built to judge abnormity of the collected electroencephalogram signals, and when the electroencephalogram signals are judged to be abnormal, the current obtained positioning data is mapped to the regional map to determine the location data of the nearest medical service points; paths are planned to form emergency routes, and the emergency routes serve as feedback data to be transmitted. By means of the electroencephalogram real-time monitoring control system and method, real-time transmission and dynamic monitoring of the electroencephalogram signals can be achieved, abnormal judgment and path planning can be achieved, and emergency rescue is carried out according to the planned emergency routes, and the in-time and accurate monitoring effect is achieved.

Owner:NANJING UNIV OF POSTS & TELECOMM

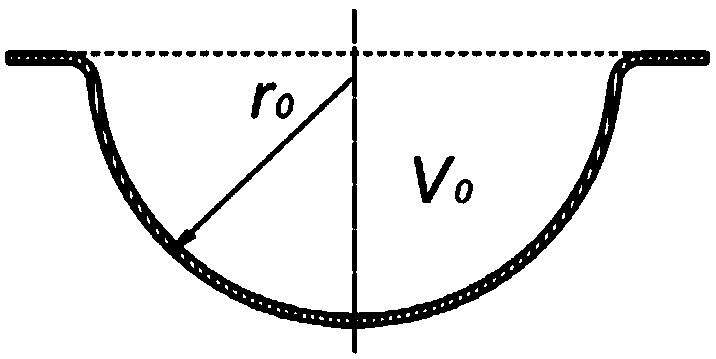

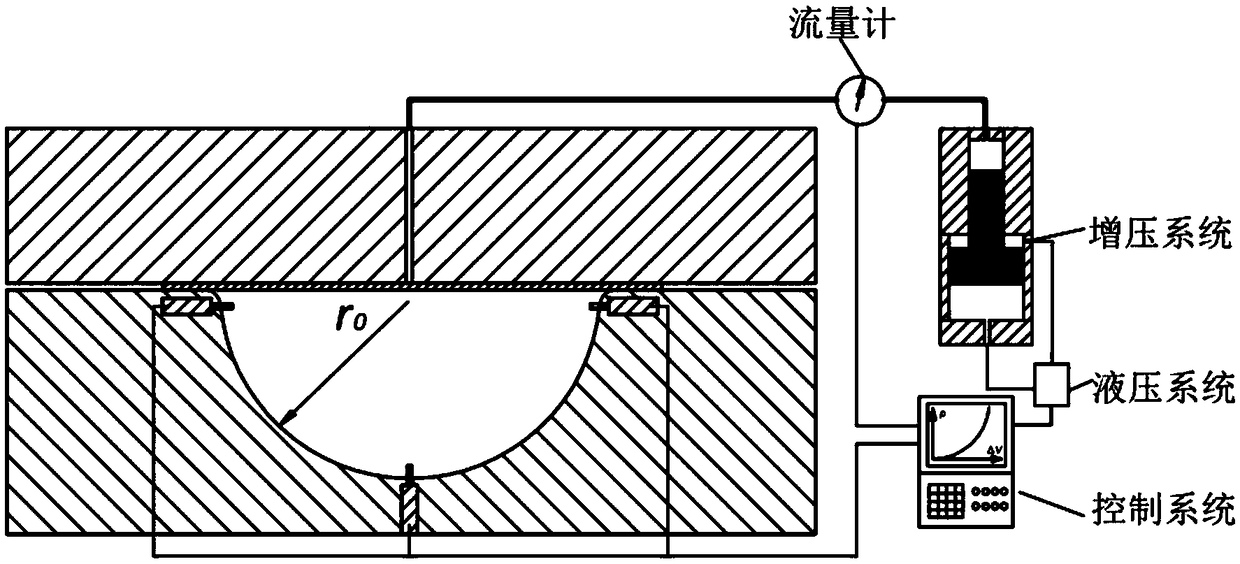

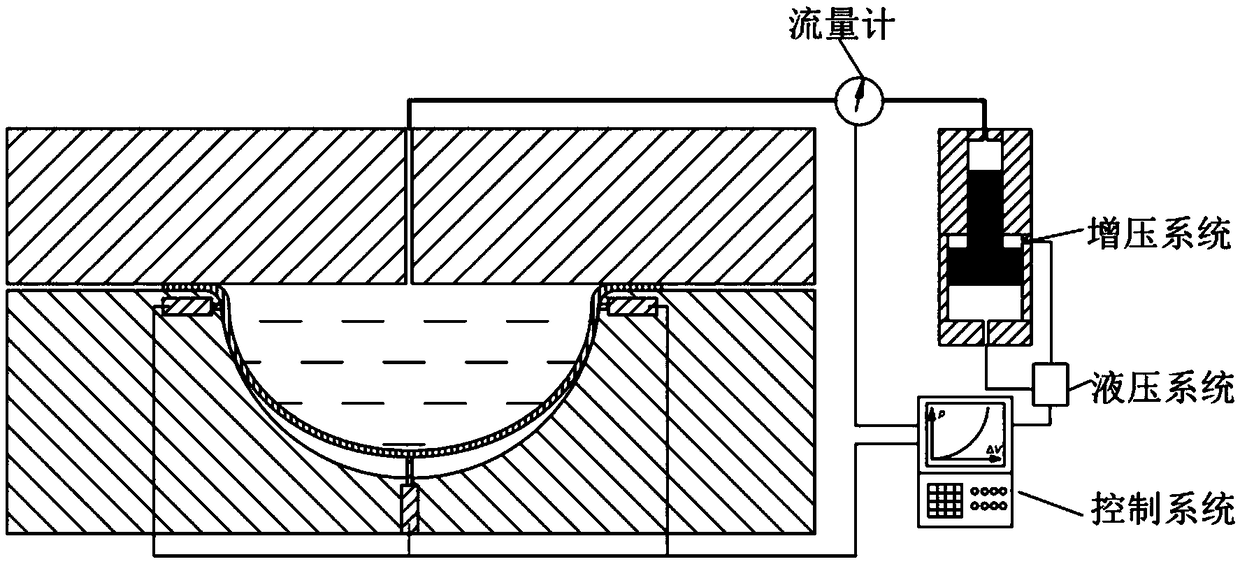

Component hydroforming springback accurate compensation method based on liquid volume control

ActiveCN108994141AShorten the debugging cycleAccurate springback compensationVolume variationEngineering

The invention discloses a component hydroforming springback accurate compensation method based on liquid volume control, and relates to a metal curved plate forming manufacturing method. According tothe component hydroforming springback accurate compensation method, a plate liquid male die deep drawing forming method is utilized, the difference between the theoretical volume of a target part andthe volume of an actual part after springback is calculated, a die is elastically deformed by adjusting and controlling the volume of injected liquid, the elastic deformation and the springback amountof the die are controlled to be equal, the springback of a curved plate is accurately compensated, and the size of a component meets the design requirement. According to the component hydroforming springback accurate compensation method, a die does not need to be repaired, and springback caused by plate batch changes and die machining errors can be accurately compensated on line in place. According to the component hydroforming springback accurate compensation method, the springback amount compensation is realized by adopting measurable and numerically-controlled liquid volume variation, theadvantages of high compensation precision, simple process, high efficiency, short period and low production cost are achieved, and the requirements of precise springback compensation and high profileprecision control of curved plates in different batches can be met.

Owner:HARBIN INST OF TECH

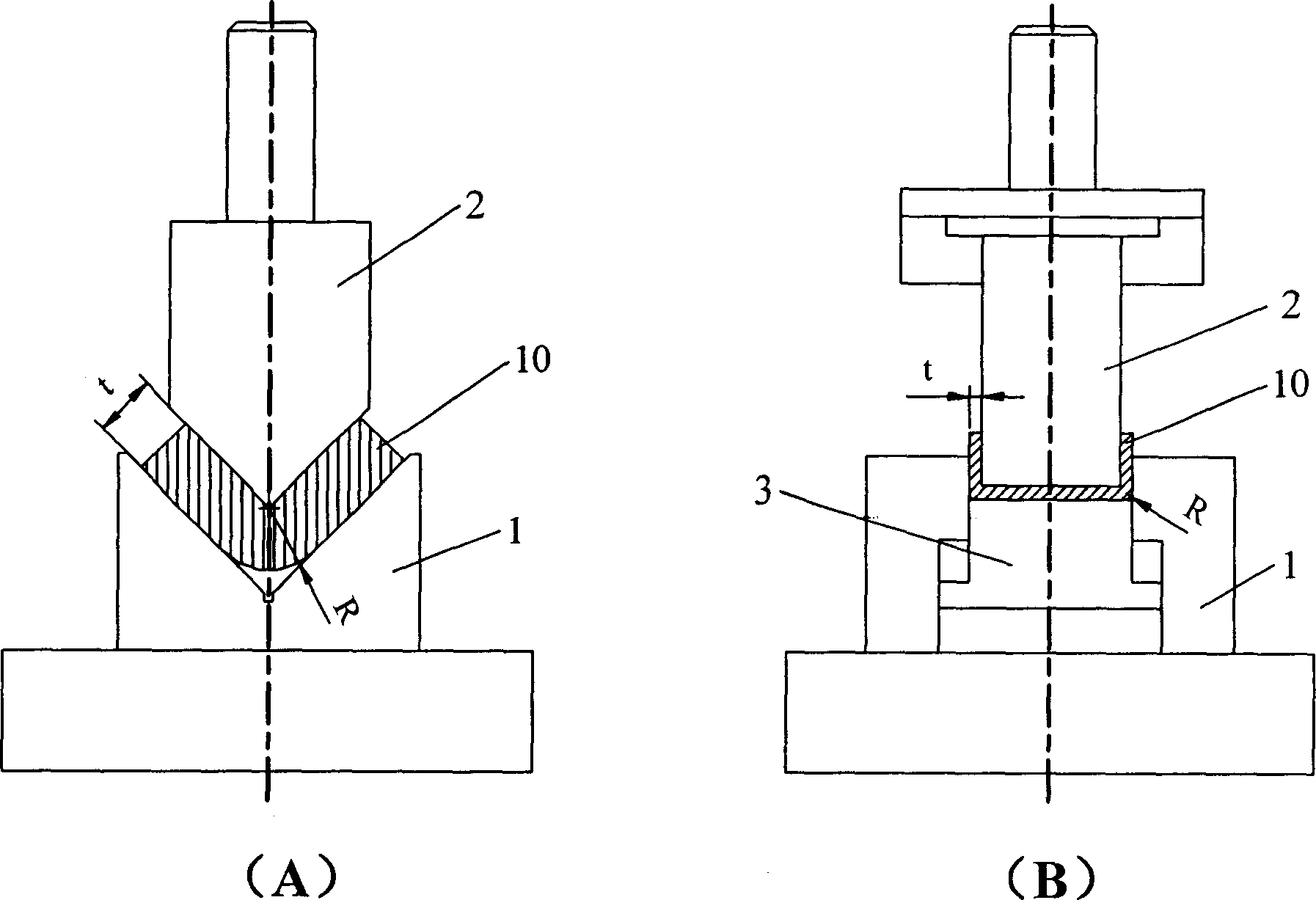

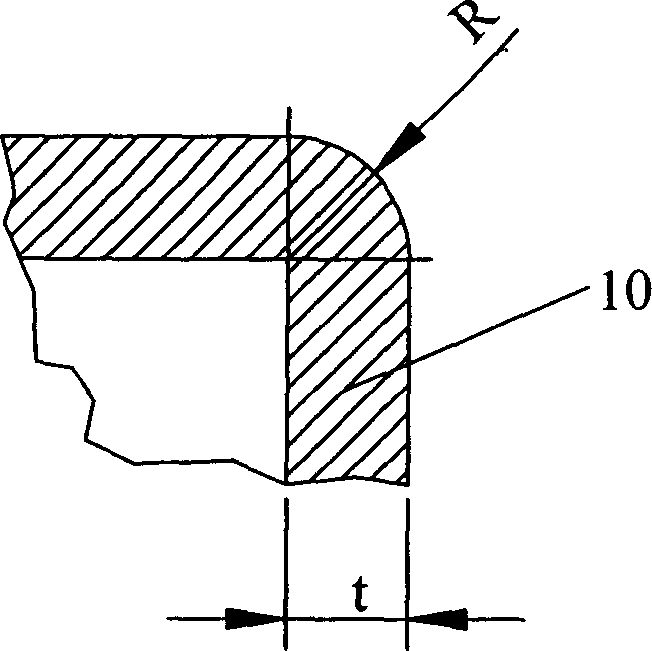

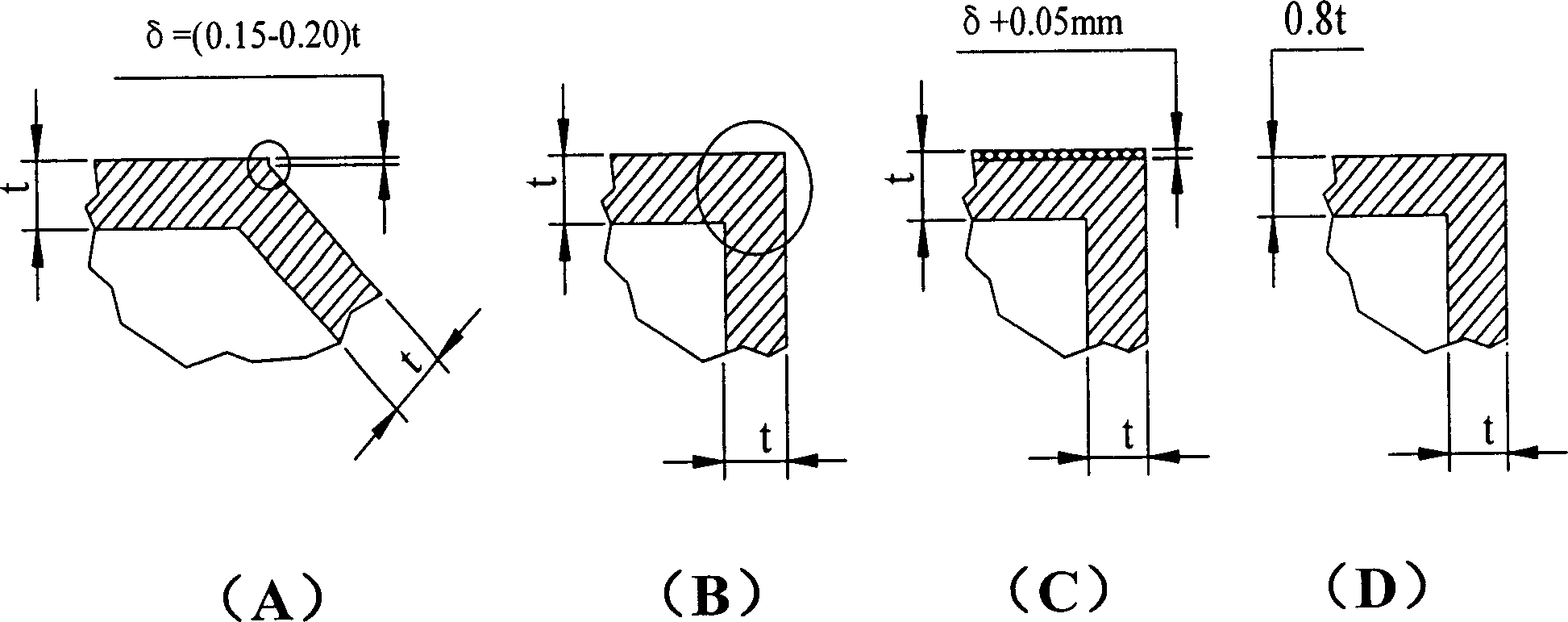

Bent machining method for metal plate

The invention discloses a metal plate bend preparing method, which comprises the following steps: adopting twice cold extrusion and metal cutting handling synthesis craft; realizing extrusion component appearance without circular arc angle (the bend external surface of component is right angle), wherein the thickness of metal plate is low steel with the thickness smaller or equal to 3mm, copper, copper alloy, aluminum and aluminum alloy and other low hardness non-ferro metals. The invention reduces the cost, which makes the production more delicate and beautiful.

Owner:LENOVO (BEIJING) CO LTD

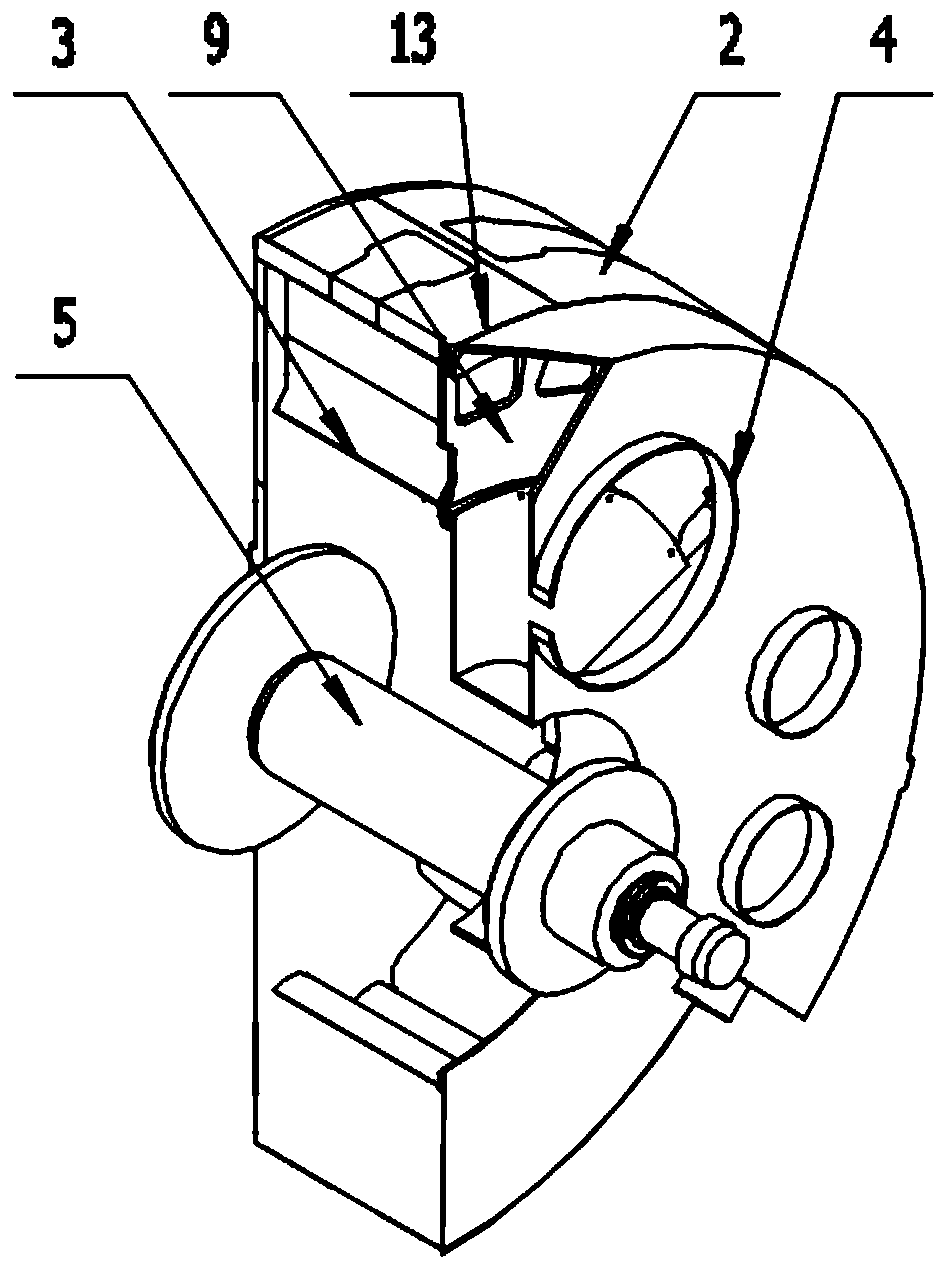

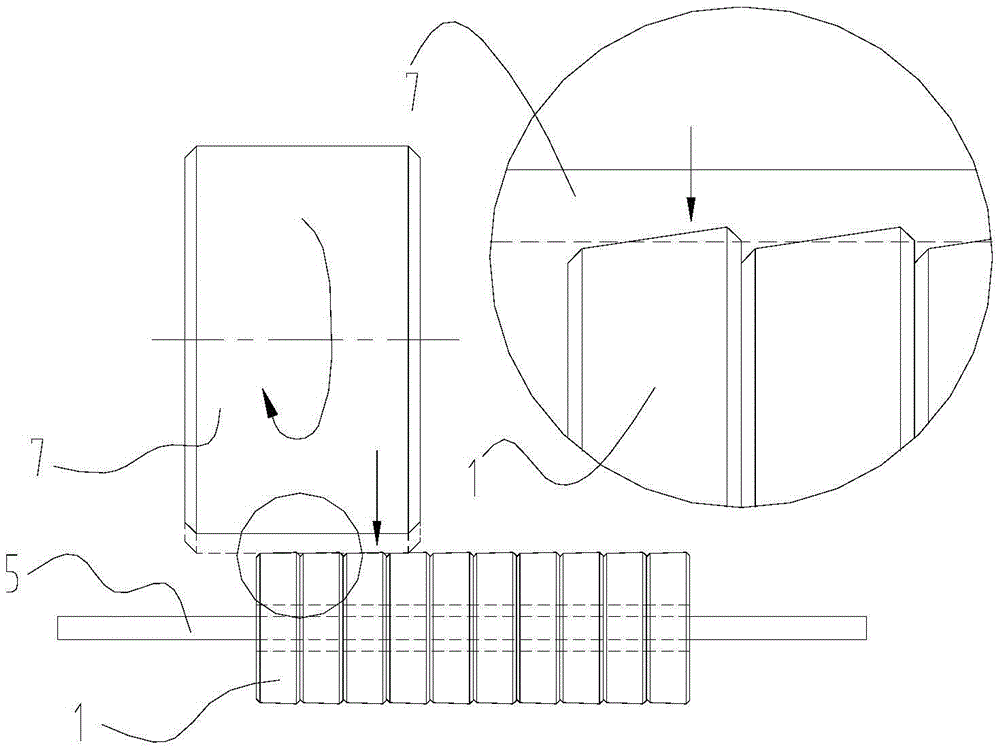

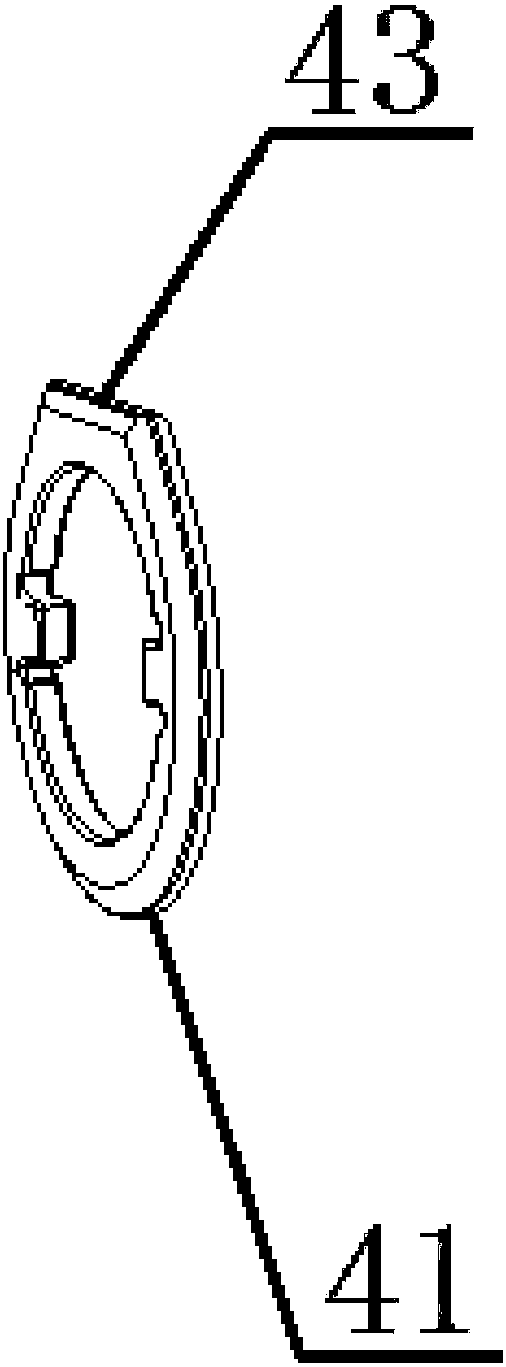

Machining method for small NdFeB magnetic ring with high verticality requirement

ActiveCN105538108AMeet mass productionAchieve mass productionRevolution surface grinding machinesGrinding drivesSurface finishEngineering

The invention discloses a machining method for a small NdFeB magnetic ring with a high verticality requirement. A semi-finished small NdFeB magnetic ring product is obtained through the steps of grinding a small magnetic pillar in a centerless grinding mode, drilling an inner hole and cutting the thickness. Surface finishing is carried out on the upper surface and the lower surface of the semi-finished small NdFeB magnetic ring product through a high-precision two-surface grinding machine. Finishing is carried out on the outer diameter of the small NdFeB magnetic ring subjected to surface finishing through a high-precision centerless grinding machine. Finally, finishing is carried out on the inner diameter of the small NdFeB magnetic ring subjected to outer diameter finishing through an automatic bearing inner circle grinding machine. A machining allowance is reserved on the semi-finished small NdFeB magnetic ring product and then is eliminated through machining, and finally, the location degree of an inner hole of the small NdFeB magnetic ring relative to the outer diameter is smaller than 0.015 mm, and the verticality, measured with the inner hole as the benchmark, of the plane of the small magnetic ring is 0.01 mm-0.03 mm. The machining method for the small NdFeB magnetic ring with the high verticality requirement has the advantages that machining is achieved through mature automatic equipment, the machining method is simple, volume production of the small NdFeB magnetic ring can be realized, and the small NdFeB magnetic ring machined through the method can meet the verticality design requirement.

Owner:NINGBO YUNSHENG MAGNET DEVICES TECH +1

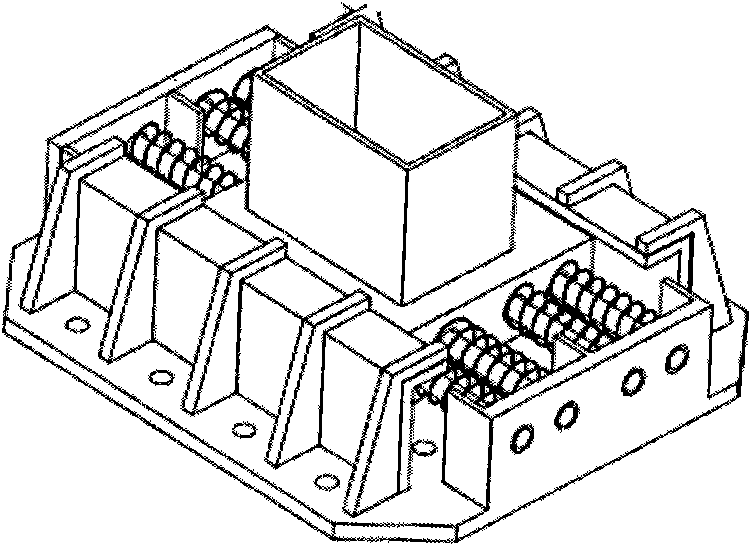

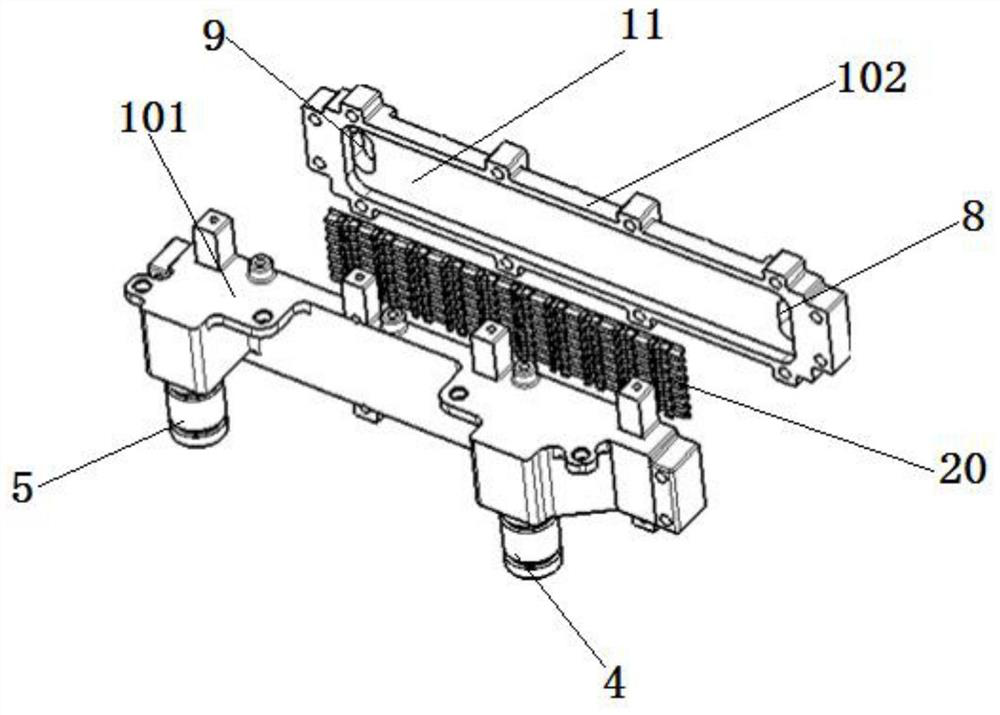

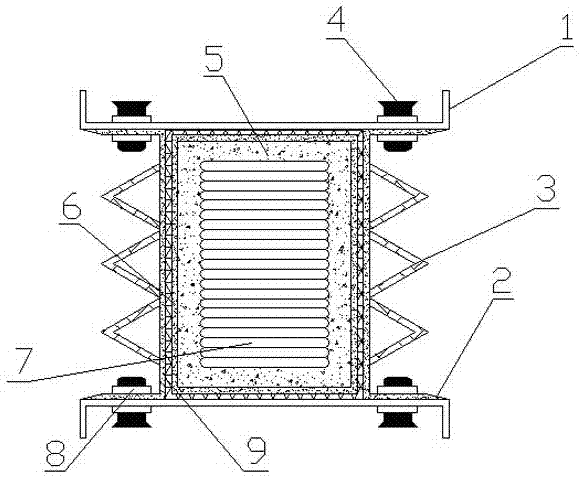

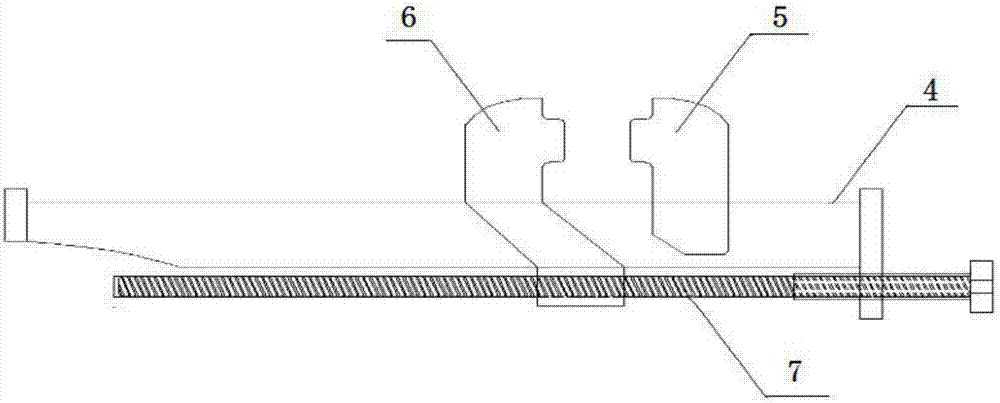

Thrust spring support for limiting rolling and slipping of rolling shaft

ActiveCN102345325ARealize the design conceptSatisfy the force transmission design requirementsBuilding constructionsFriction force

The invention provides a thrust spring support for limiting rolling and slipping of a rolling shaft, which comprises a support bottom plate, a support clamping seat, a short-column lower box body and a support short column, wherein the support clamping seat clamps the short-column lower box body on the support bottom plate; the support short column is arranged on the short-column lower box body; the front side and the rear side of the short-column lower box body are respectively provided with springs corresponding to spring baffles arranged at the two sides of the support bottom plate; the left side, the right side and the bottom part of the short-column lower box body are respectively provided with side-surface rolling shafts and bottom-surface rolling shafts; the side-surface rolling shafts are arranged among the left side and the right side of the short-column lower box body and the support clamping seat; and the bottom-surface rolling shafts are arranged between the bottom part of the short-column lower box body and the support bottom plate. According to the thrust spring support provided by the invention, the friction force is less, stable and reliable elastic stiffness is realized by a reliable mechanism, and reliable limiting and return devices are provided.

Owner:SHANGHAI ARCHITECTURAL DESIGN & RES INST +1

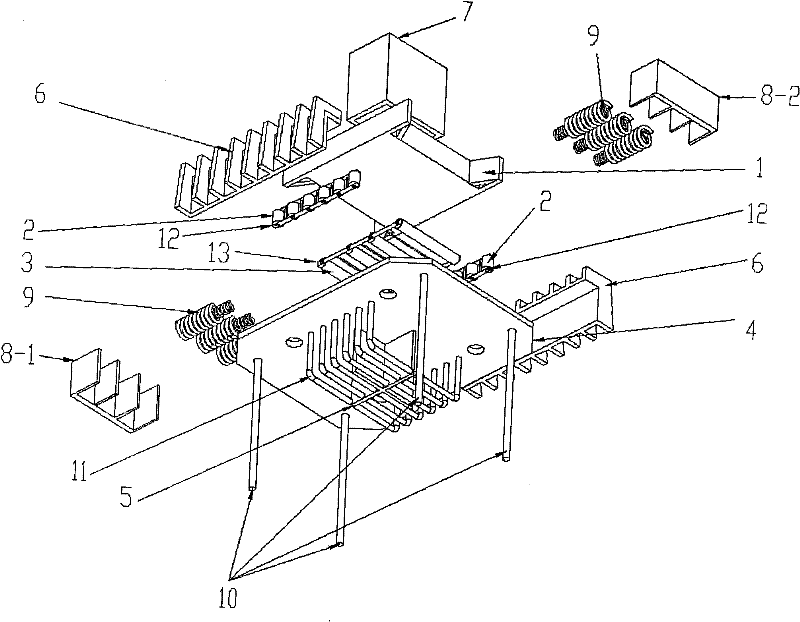

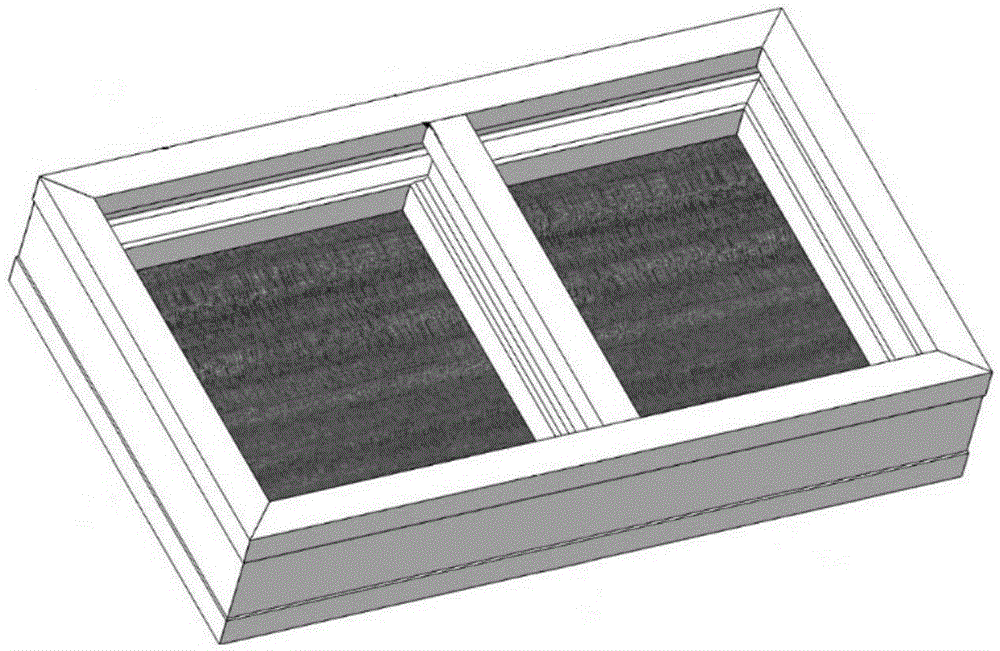

Double-sided water-cooled IGBT radiator and radiating mounting structure thereof

ActiveCN111799238AIncrease cooling areaEnhanced turbulence effectSemiconductor/solid-state device detailsSolid-state devicesNew energyElectric machine

The invention discloses a double-sided water-cooled IGBT radiator which comprises a first heat dissipation plate set provided with a water inlet pipe and a water outlet pipe, and a second heat dissipation plate set which can guide cooling water from one side of the water inlet pipe of the first heat dissipation plate set to one side of the water outlet pipe of the first heat dissipation plate set,and the first heat dissipation plate set is provided with a positioning structure used for installing an IGBT. Through the water inlet and the water outlet provided with the sealing rings designed oneach radiator set, the expansion and communication can be easily achieved by increasing the number of the middle transition plate sets, the expansion of an IGBT parallel connection number is achieved, and the power density is improved. The whole power module is compact in structure and reasonable in layout, the design requirement of a high-power-density motor controller is well met, the power system requirement of the new energy electric vehicle is met, the structure is compact, the power density is high, and the cost is low.

Owner:DONGFENG MOTOR CORP HUBEI

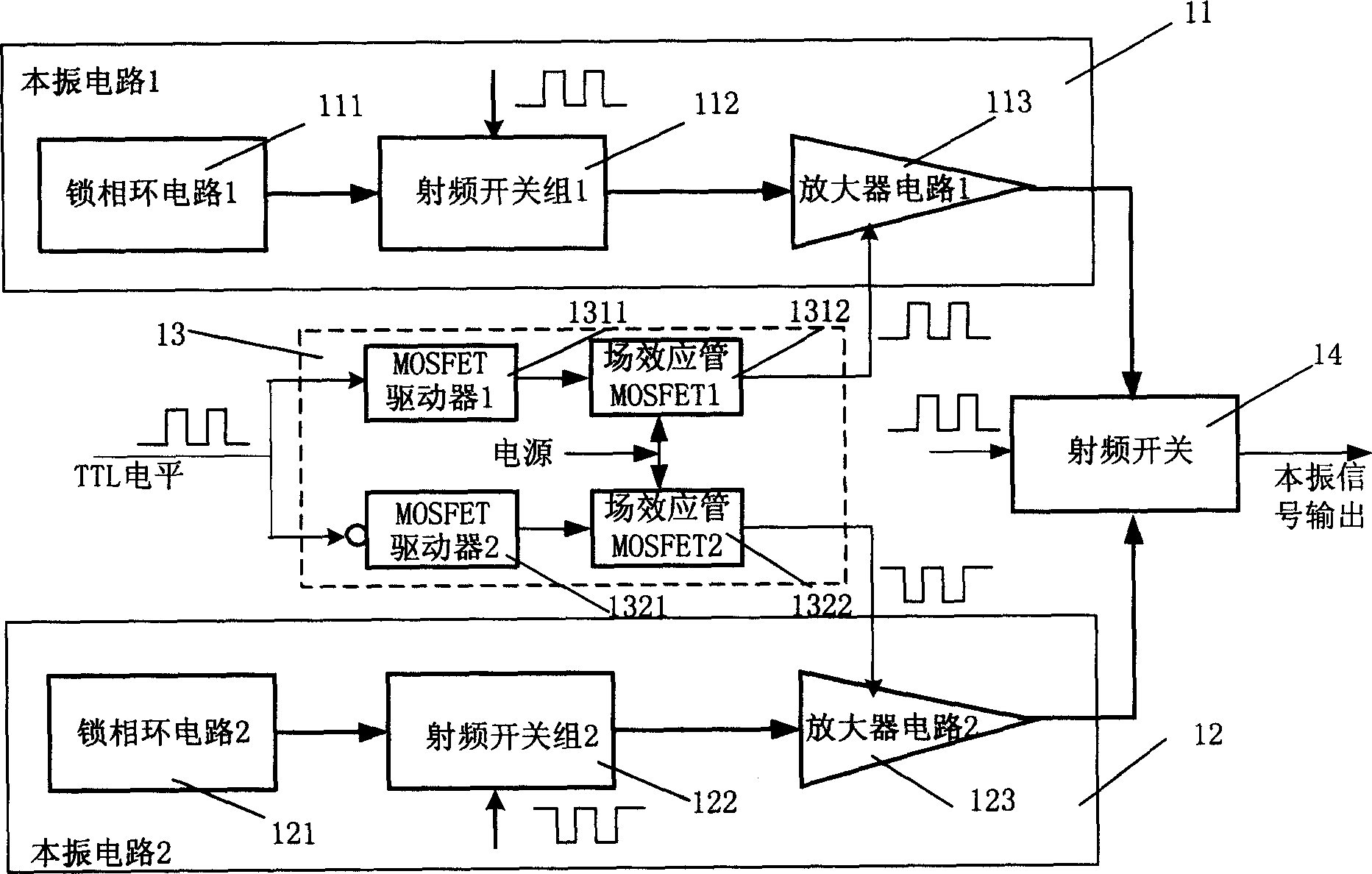

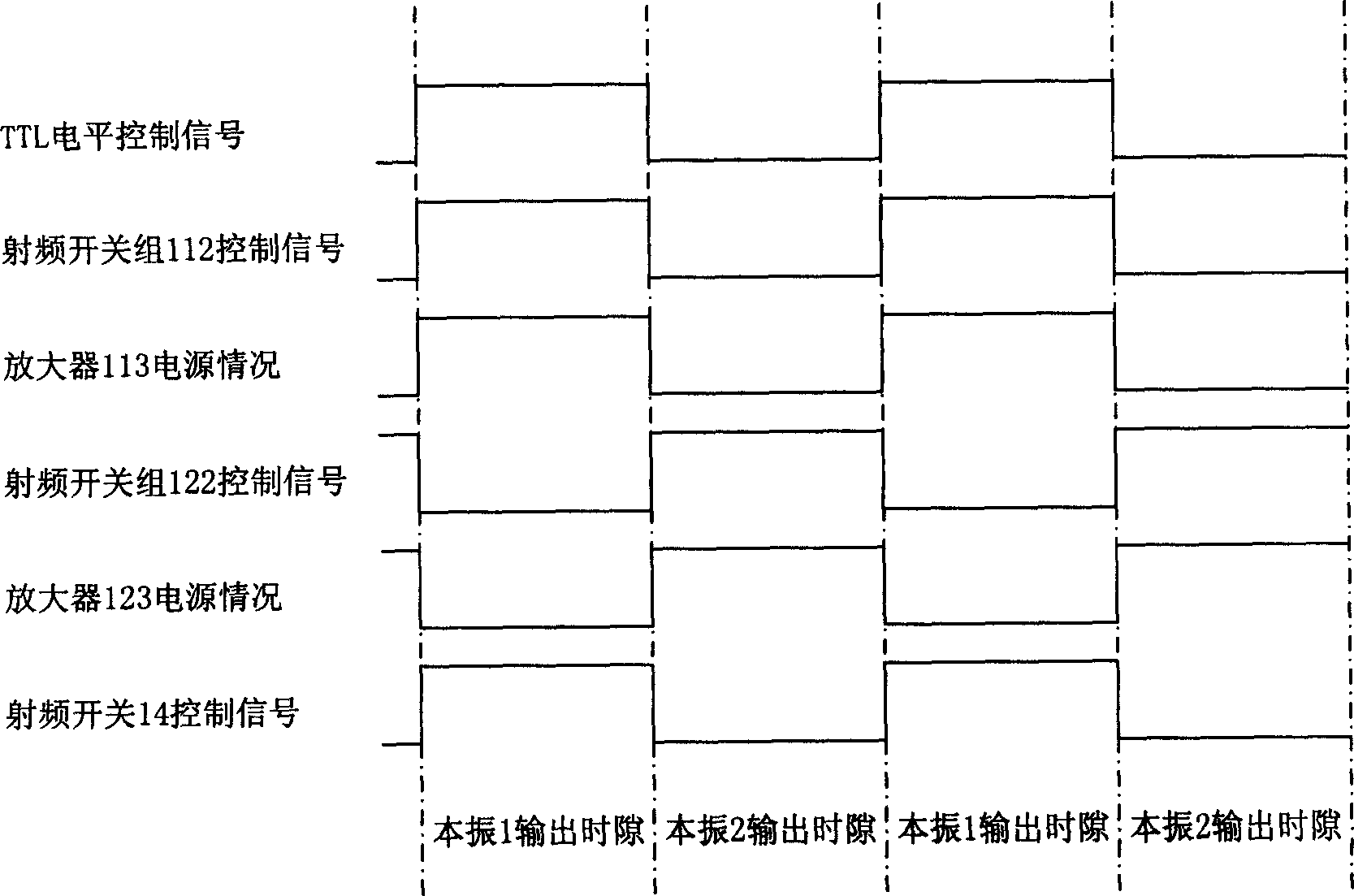

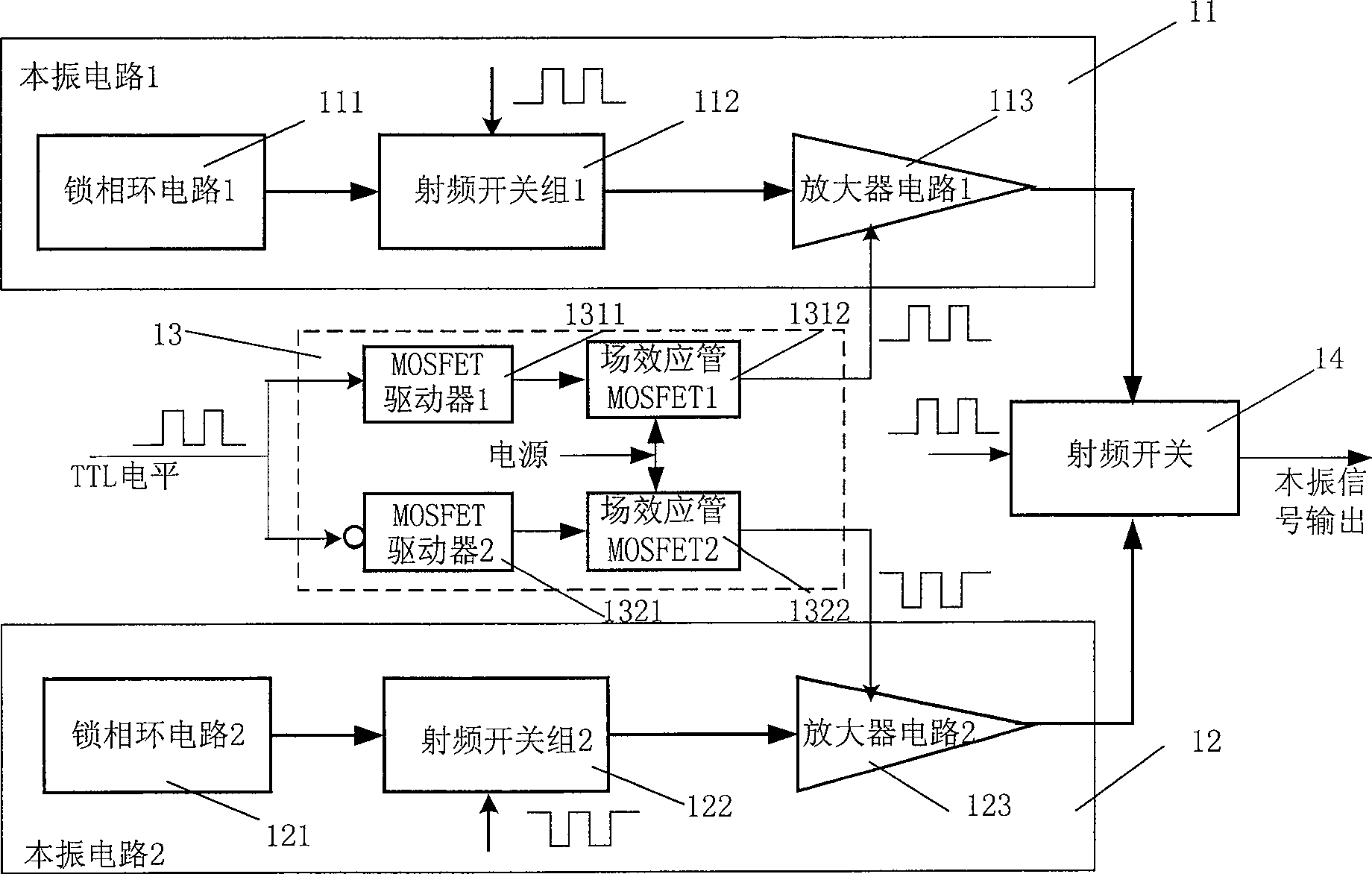

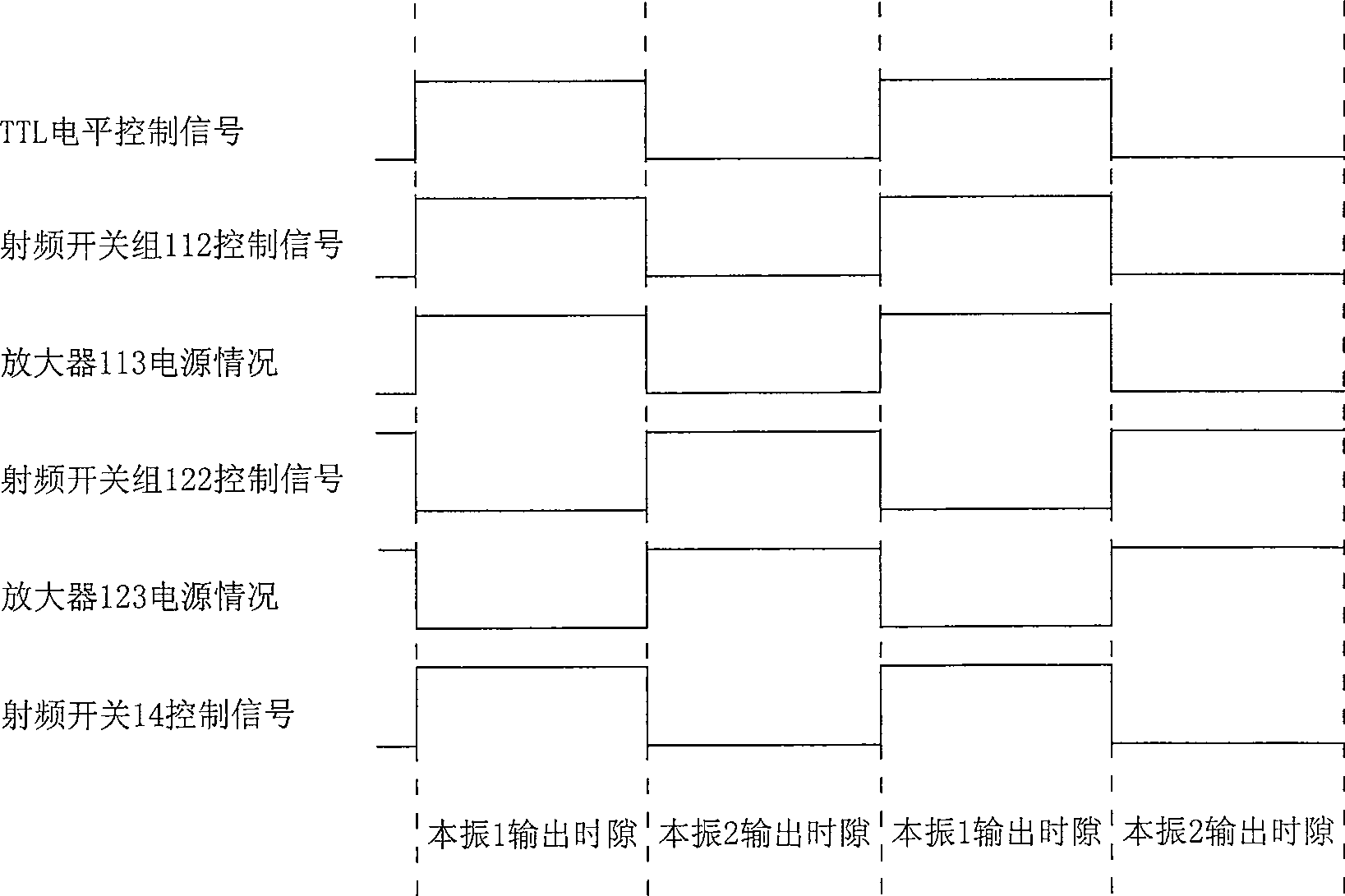

Bipath parent oscillation source device

InactiveCN1538647ALow costHigh purityTime-division multiplexTransmissionLocal oscillator signalAudio power amplifier

The device includes two identical and independent local oscillating circuits 1 and 2, a single-pole double-throw radio frequency switch, and a power supply control circuit. Local oscillator signals from local oscillator circuits 1 and 2 are insulated, gated and output. The power supply control circuit turns power supply of local oscillator circuit 1 to on and power supply of local oscillator circuit 2 to off; as well as turns power supply of local oscillator circuit 1 to off and power supply of local oscillator circuit 2 to on. The invention manages power supply of amplifier and keeps synchronization with switch so as to reduce signal leaking and radiation effectively, raise isolation and purity of two Local oscillator signals etc.

Owner:ZTE CORP

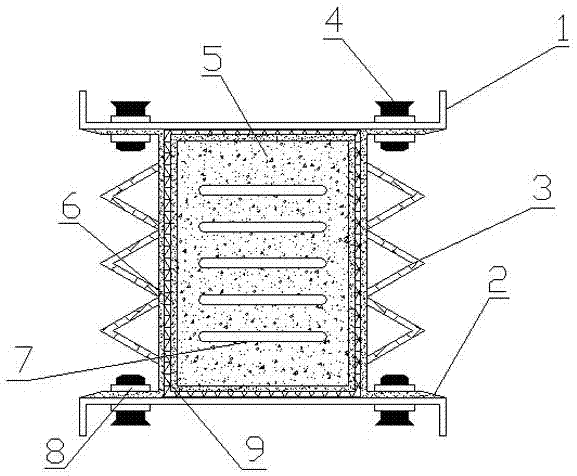

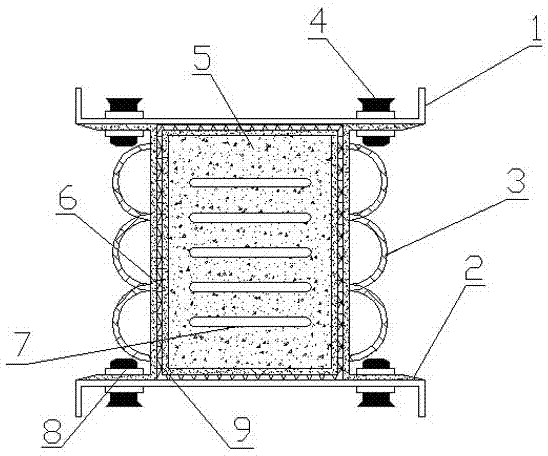

Fireproof type bus duct with heat dissipation rings

InactiveCN107968371AIncrease in sizeSimplified volumeCooling bus-bar installationsTotally enclosed bus-bar installationsEngineeringElectromagnetic shielding

The invention relates to a fireproof type bus duct, particularly a fireproof type bus duct with heat dissipation rings. According to the fireproof type bus duct with the heat dissipation rings, coverplates are fixedly arranged at the upper and lower ends of the bus duct; side plates are fixedly arranged on the two sides of the bus duct; heat dissipation rings are fixedly arranged on the side plates; fixed screws are fixedly arranged on the cover plates; fixed gaskets are fixedly arranged on the corresponding fixed screws; a plurality of conductive plates are uniformly arranged in the bus duct; a fireproof filling layer with a rectangular section is fixedly arranged outside the conductive plates; an insulating layer is fixedly arranged outside the fireproof filling layer; and an electromagnetic shielding layer with a rectangular section is fixedly arranged outside the insulating layer. The fireproof type bus duct with the heat dissipation rings is low in cost, creative in design, and high in innovativeness, and the design requirement of the fireproof type bus duct with the heat dissipation rings can be better satisfied.

Owner:FUXIN POWER SUPPLY COMPANY STATE GRID LIAONING ELECTRIC POWER +1

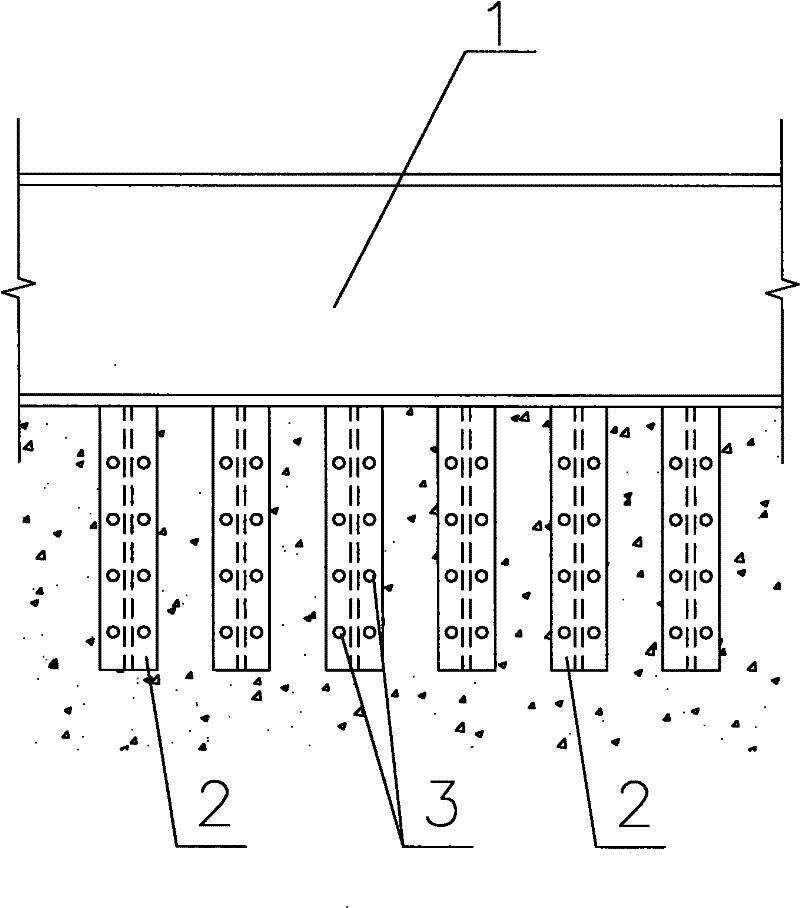

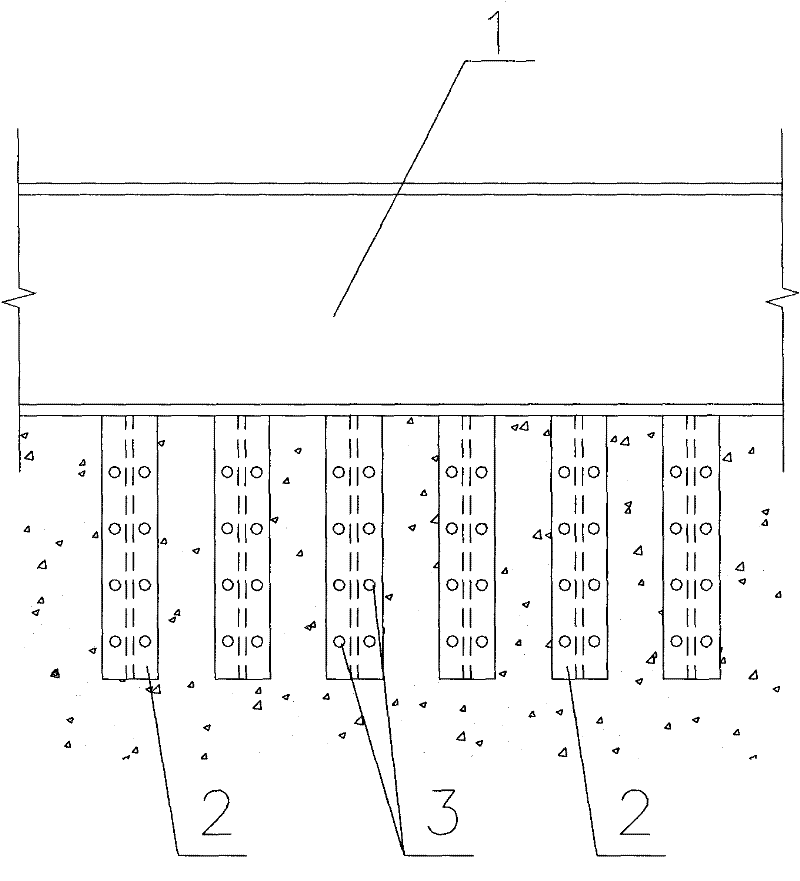

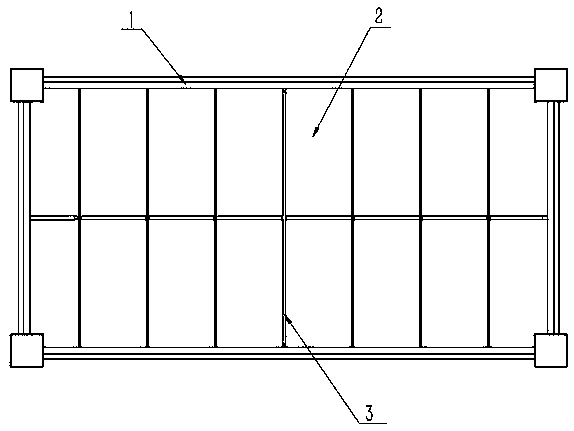

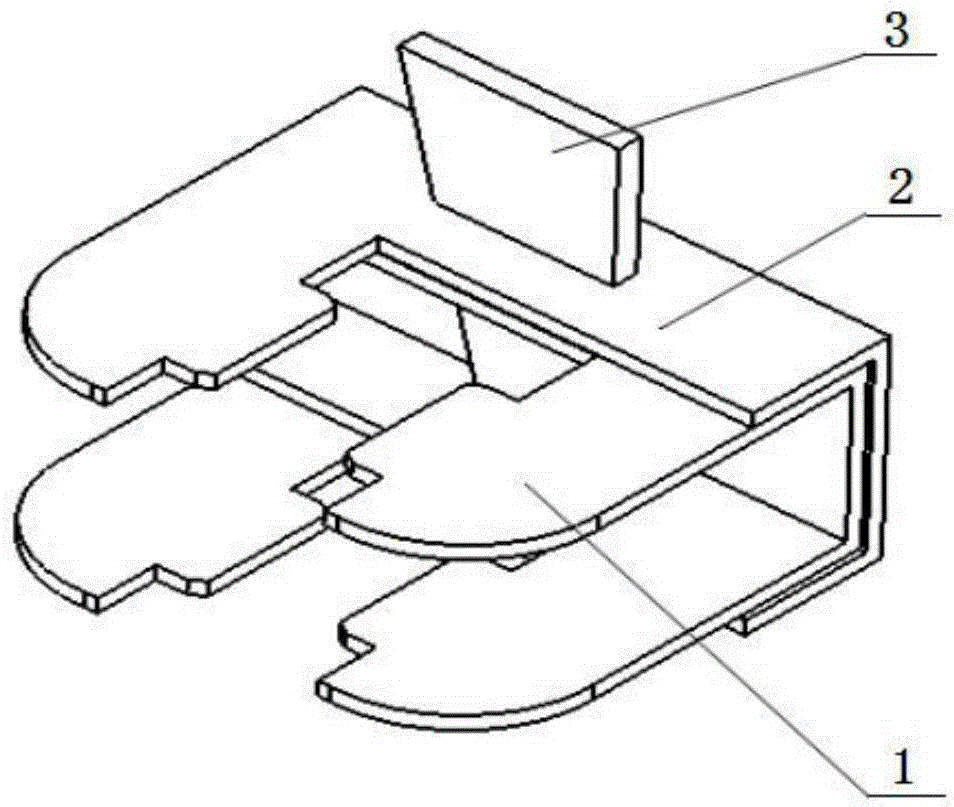

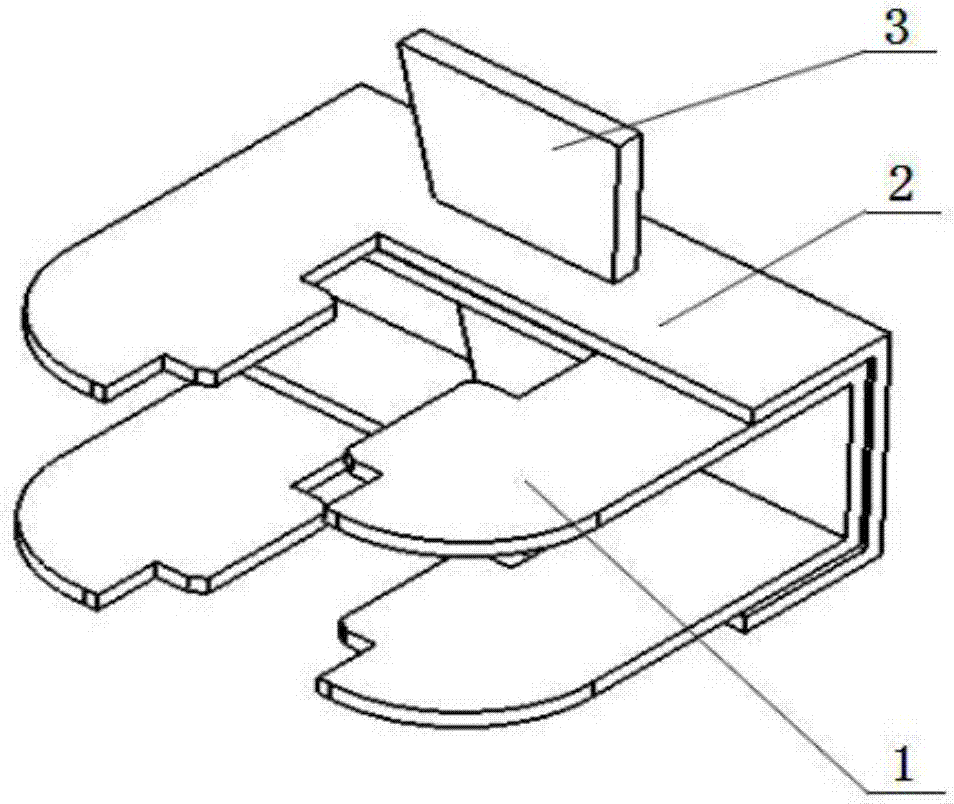

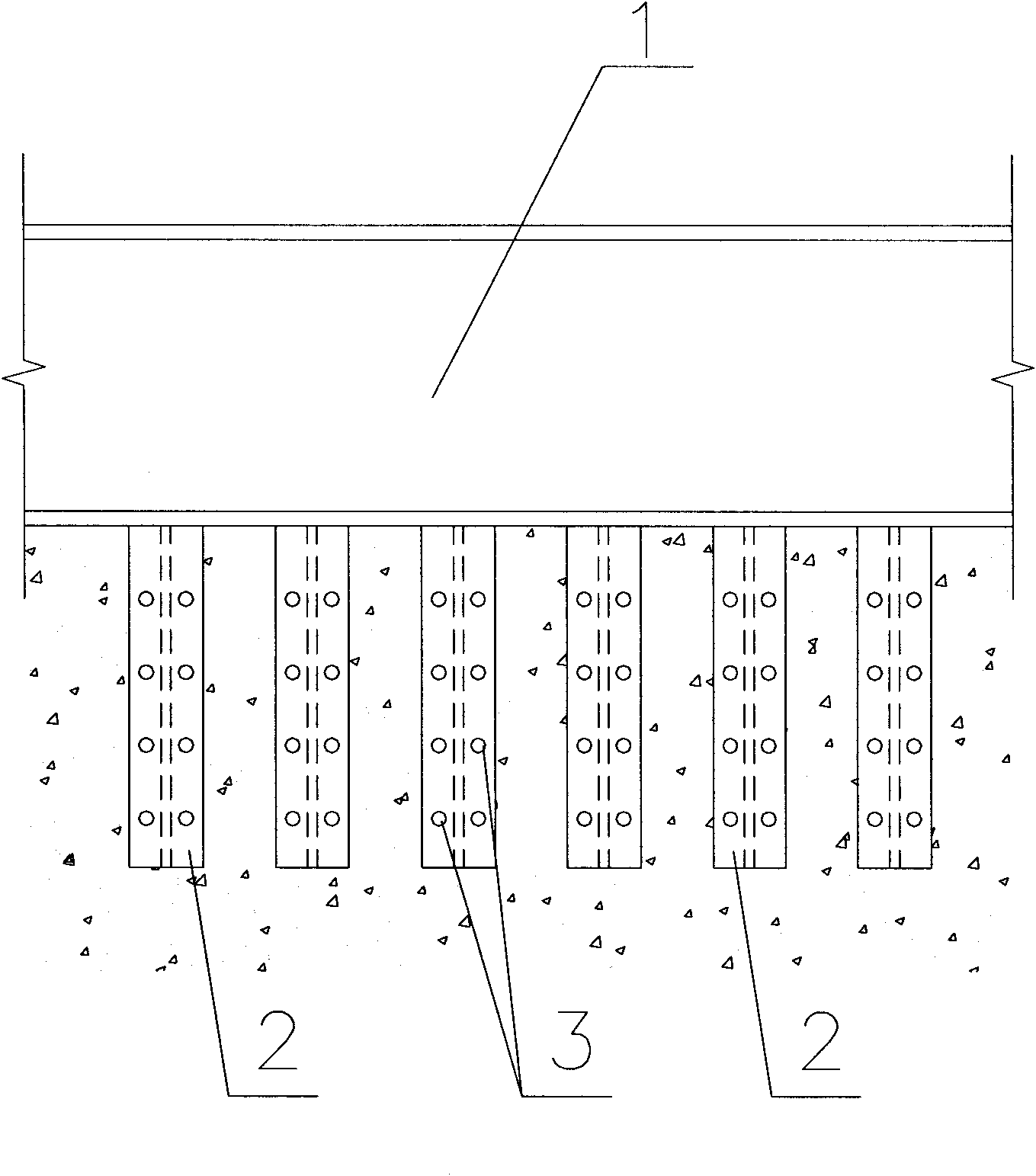

Connected node of horizontal member and foundation of thin steel-plate shear wall

InactiveCN102235033ALarge sectionIncrease girthBuilding constructionsSteel plate shear wallTension field

The invention discloses a connected node of a horizontal member and a foundation of a thin steel-plate shear wall, which belongs to the field of architectural construction engineering, and comprises a horizontal member (1) and a foundation of a thin steel-plate shear wall. The connected node disclosed by the invention is characterized in that anchoring members (2) which are uniformly arranged and welded at a certain interval along the lower length centerline of the horizontal member (1) at the bottom layer are vertically buried into the foundation, a shear key (3) is respectively welded on the front and rear side surfaces (parallel to the horizontal member (1)) of the anchoring members (2), and the shear keys (3) are uniformly arranged at a certain interval. The technical problem solved by the invention is to provide a new connected node, and the node greatly enhances the anchoring capacity (namely, pullout resistant capacity) of the anchoring members (2), thereby effectively balancing a tension field generated by a bottom thin steel-plate shear wall.

Owner:EAST CHINA ARCHITECTURAL DESIGN & RES INST +1

Profiled steel assembled composite floor slab and construction method thereof

The invention discloses a profiled steel assembled composite floor slab and a construction method thereof. The profiled steel assembled composite floor slab comprises steel cross beams and forms, wherein the forms are arranged between the two adjacent steel cross beams, the forms are laid on the steel cross beams, a supporting component is arranged between every two adjacent forms, the two ends ofthe supporting components are located on the upper sides of the two steel cross beams and are fixedly connected with the two steel cross beams, the two sides of the supporting components are abuttedagainst the forms, and the height of the supporting components is larger than the thickness of the forms; and a reinforcing mesh is further laid above the forms, and concrete is poured above the formsand the supporting components, so that the concrete covers the steel cross beams, the forms, the supporting components and the reinforcing mesh, and therefore the composite floor slab is formed. According to the profiled steel assembled composite floor slab, the supporting components in the profiled steel assembled composite floor slab play a role in pipeline containing grooves while playing a role in supporting, so that the floor slab is simple in structure and convenient in construction on site, the forms are not prone to deform after the concrete is poured, the floor slab forming effect isgood, the forms are divided into small units to enable the forms to be modularized, the transportation and the installation are convenient, the construction efficiency is improved, and the profiled steel assembled composite floor slab is suitable for industrial mass production.

Owner:渝建实业集团股份有限公司

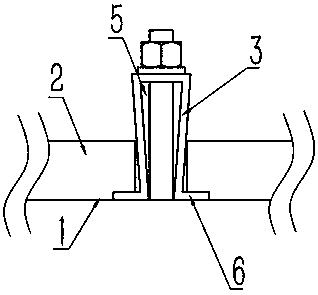

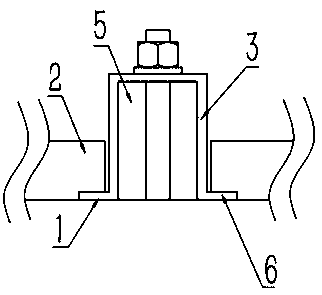

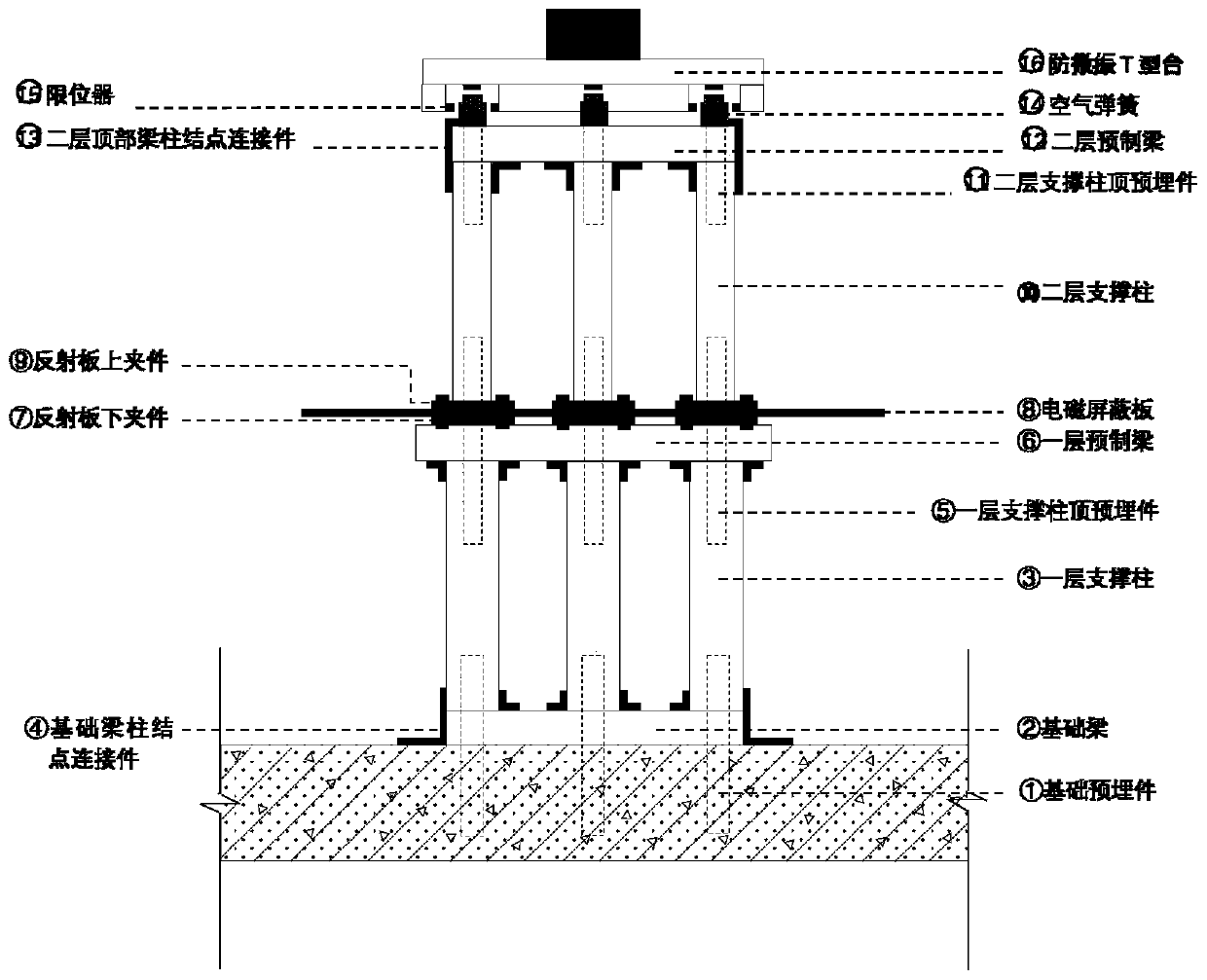

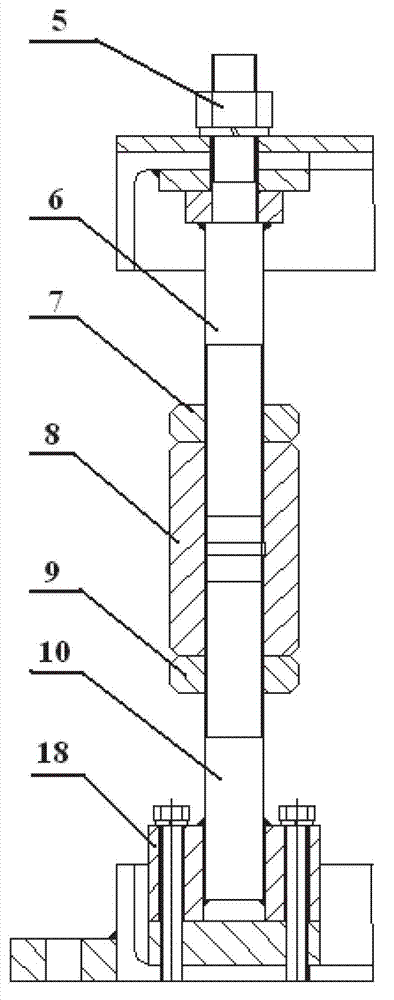

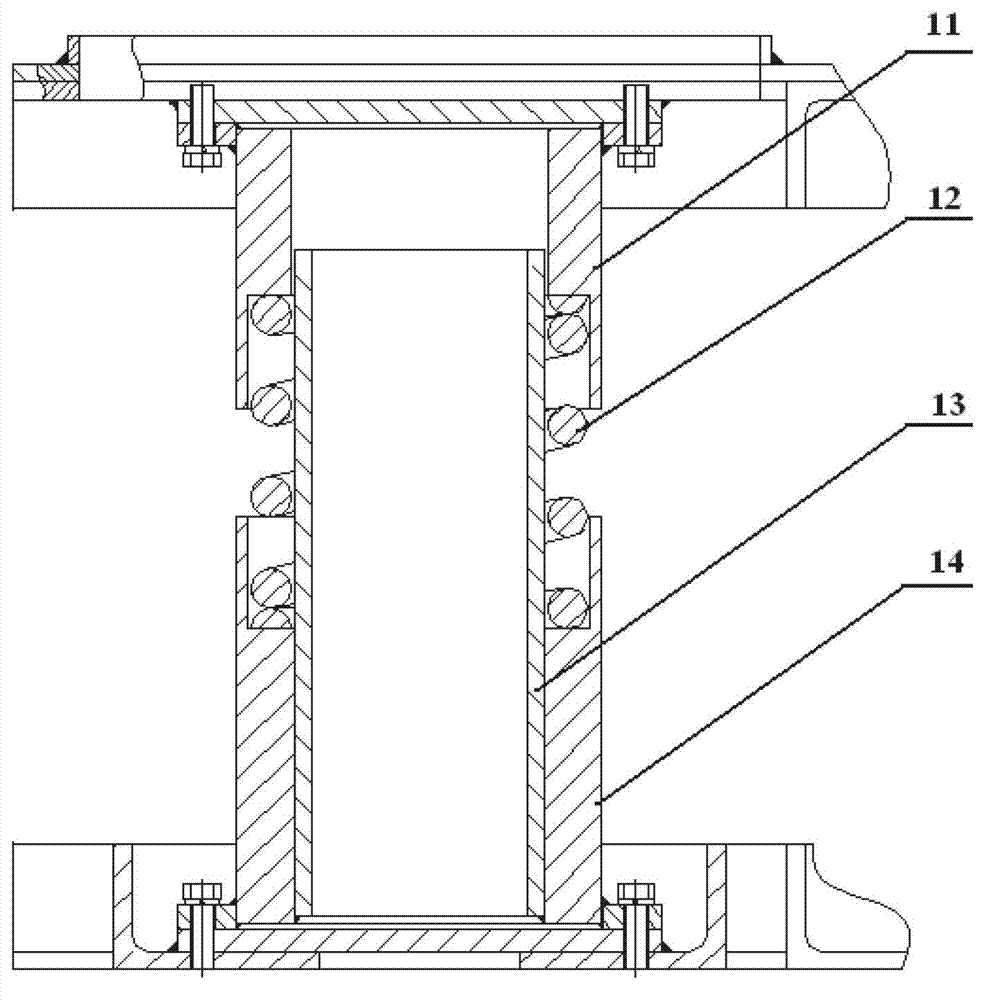

High-rise type suspension type micro-vibration equipment construction structure and construction structure

ActiveCN109827033AFulfill design requirementsEasy to disassembleFoundation engineeringSpecial foundation layoutControl systemAir spring

The invention provides a high-rise type suspension type micro-vibration equipment construction structure. The structure comprises a rigid supporting structure, an air floatation control system and ananti-micro-vibration T-shaped table (16); the rigid supporting structure comprises a foundation beam structure, a first-layer supporting structure and a second-layer supporting structure, wherein a foundation beam is connected with the first-layer supporting structure through first-layer supporting columns (3), the first-layer supporting structure and the second-layer supporting structure are connected through second-layer supporting columns (10), the first-layer supporting columns (3) are connected with the foundation beam, and the six circular-section concrete stand columns are arranged in total; the air floatation control system comprises an air floatation system (14) and a limiter (15); the air floatation system (14) is an independent air spring structure and is composed of a mechanical height valve, a main air chamber, an additional air chamber, an air inlet and an air outlet; the limiter (15) is arranged between the anti-micro-vibration T-shaped table (16) and the air floatationsystem (14); and the anti-micro-vibration T-shaped table (16) provides a supporting platform structure with a certain balance weight and a rigid body characteristic for the air floatation system (14),and radar detection equipment is placed on the anti-micro-vibration T-shaped table (16). The invention further provides a corresponding equipment construction method.

Owner:SINOMACH

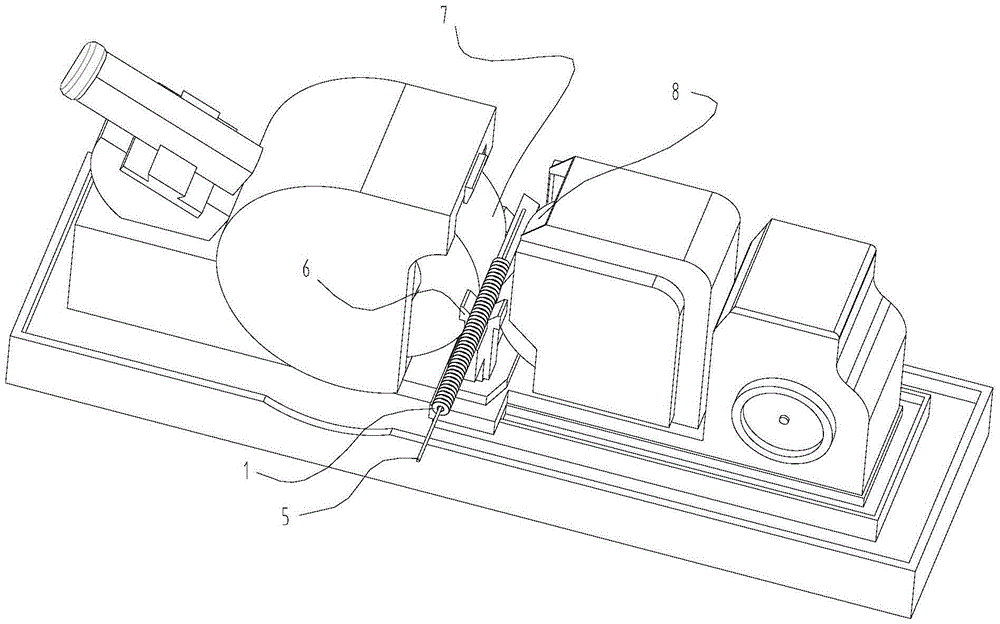

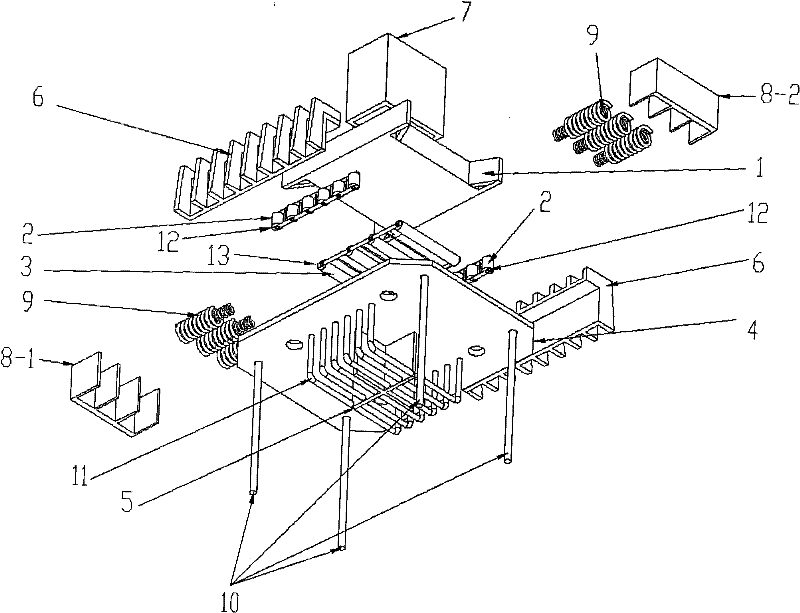

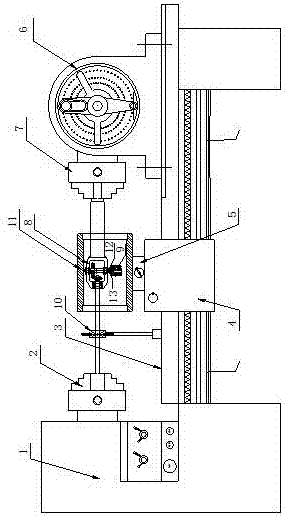

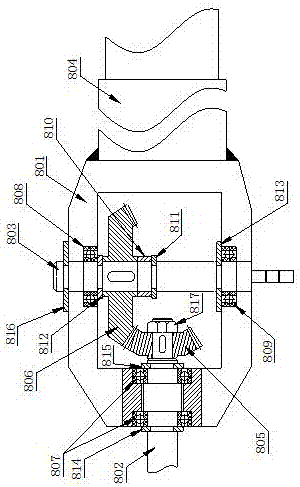

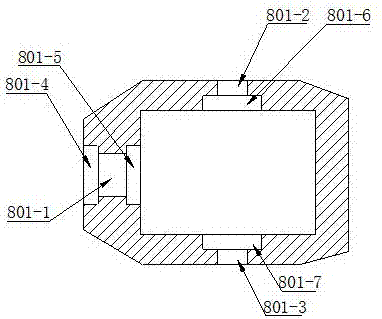

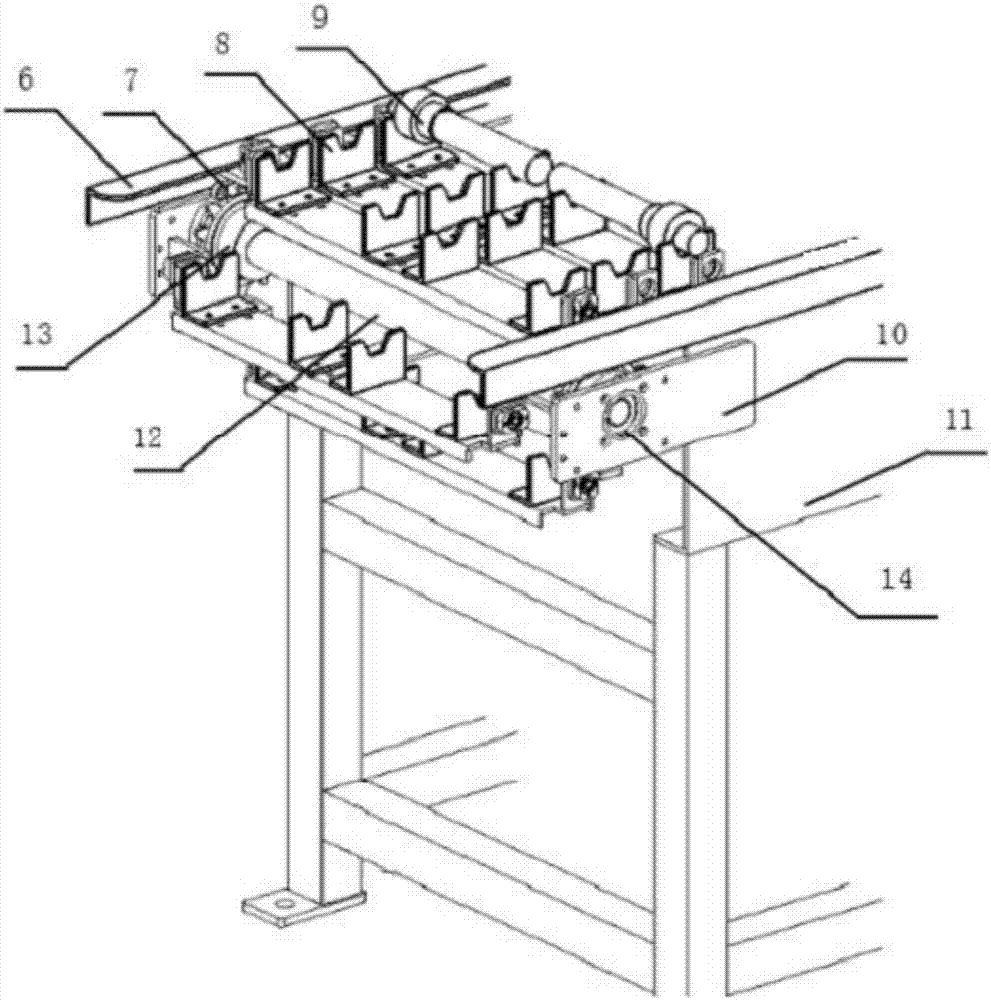

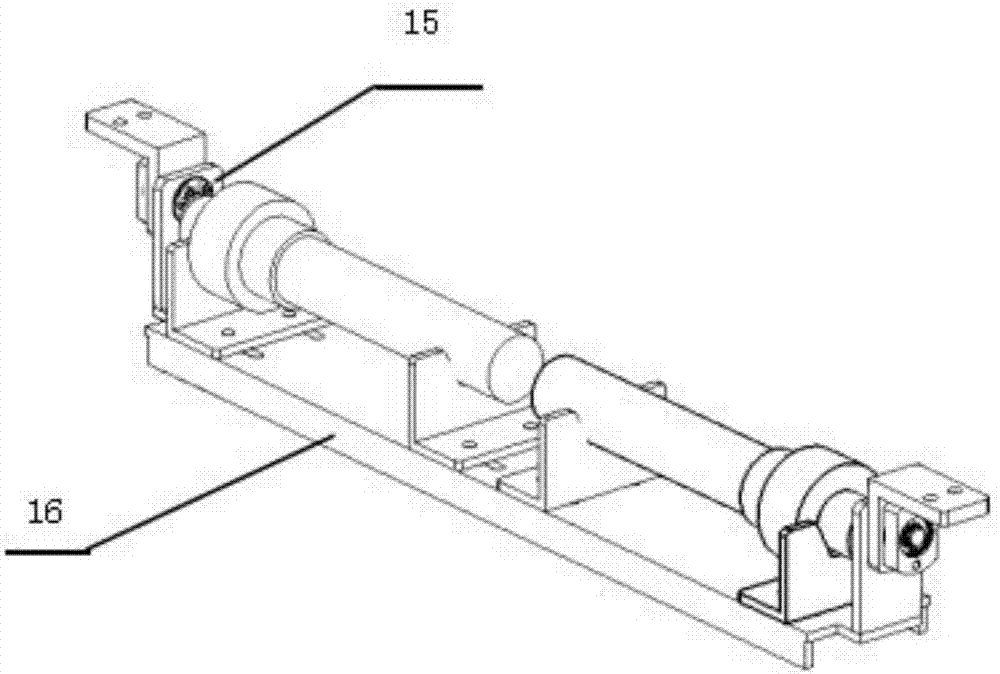

Floating type reciprocating compressor fault simulation test bench

ActiveCN102926984AImprove flexibilityFulfill design requirementsPump testingPositive-displacement liquid enginesSimulationSteel frame

The invention relates to a floating type reciprocating compressor fault simulation test bench, wherein a main body structure of the floating type reciprocating compressor fault simulation test bench comprises an upper layer frame, a lower layer frame, a flexible support and a rigid support, the upper layer frame is used to fix a reciprocating compressor and a driver, the lower frame is directly fixed on the ground, or is fixed on an offshore production platform steel frame, a test bench support structure is formed by adopting a mode that the flexible support and a rigid stand column support are combined, the flexible support selects a spring or a hydraulic system, the rigid support uses a stand column support, stand columns use positive and negative screw thread structures, the height of the stand columns can be adjusted, and the stress state of the flexible support can be changed to achieve change of test bench support stiffness. The stand column support uses a self-lock structure, and the flexible support is provided with a guide column. The floating type reciprocating compressor fault simulation test bench can be used for the reciprocating compressor, further can be used for design, processing and installation of other large key mobile equipment on an offshore platform, and is used to solve the different problems of fault diagnosis and the design of supporting structures of offshore platform large mobile equipment.

Owner:BEIJING UNIV OF CHEM TECH

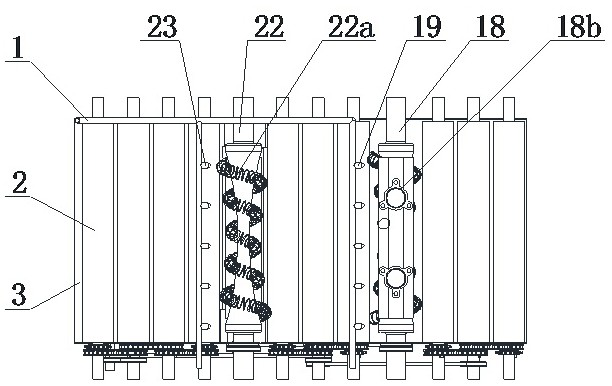

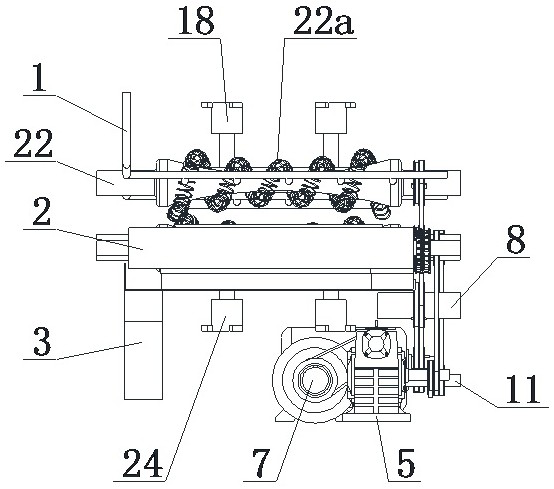

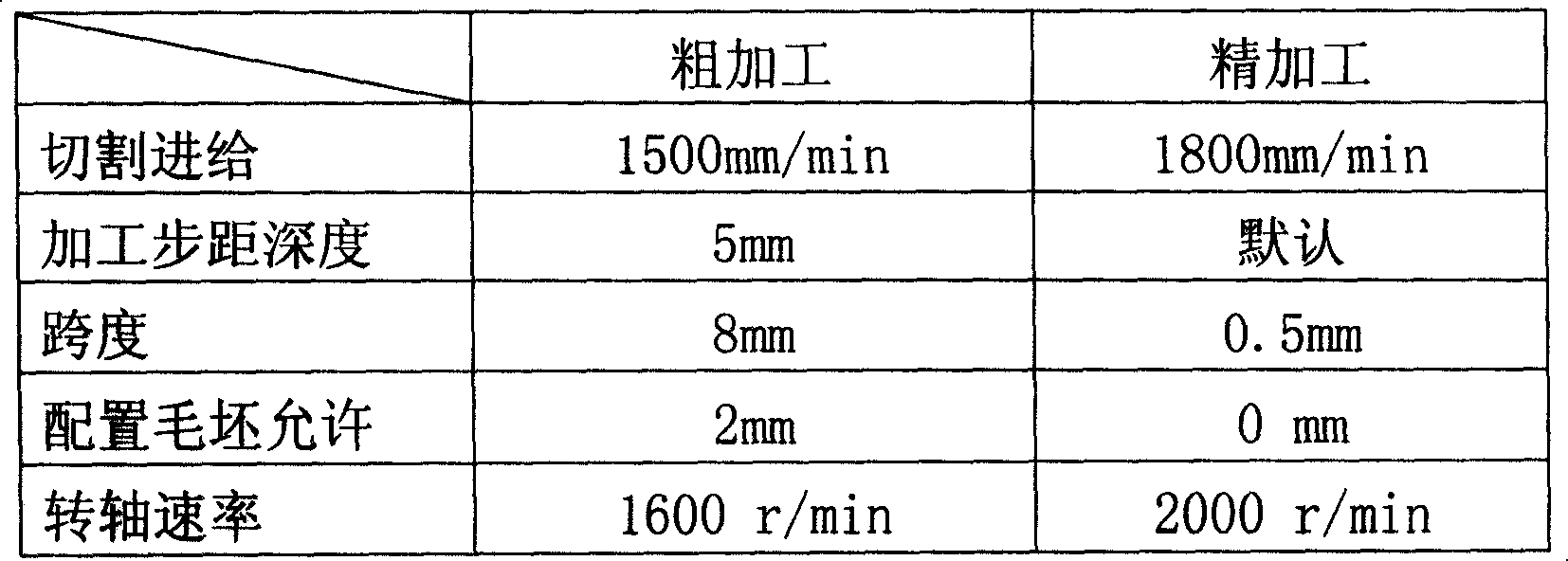

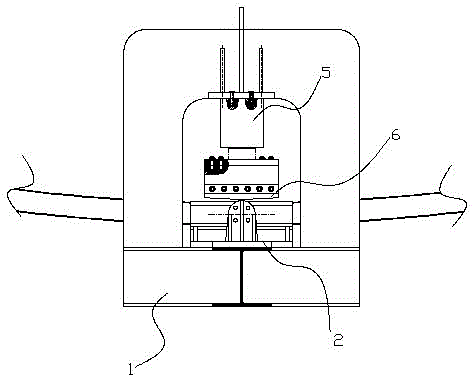

Processing device for drilling and milling internal cavity by refitting ordinary horizontal lathe

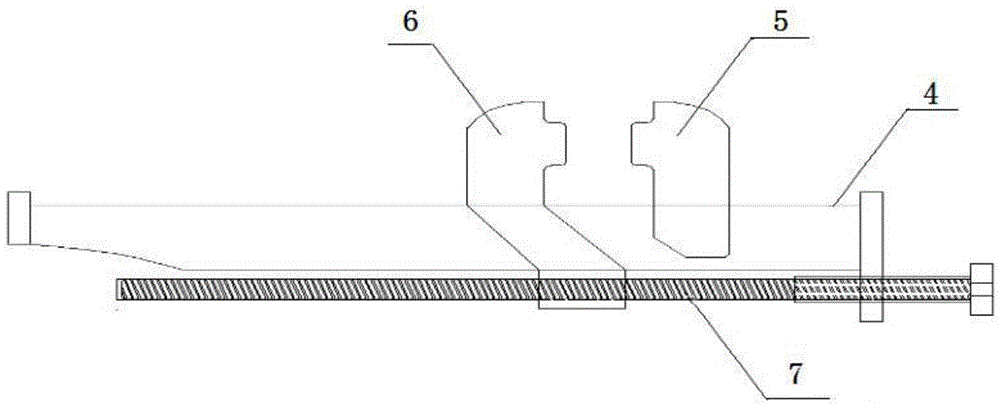

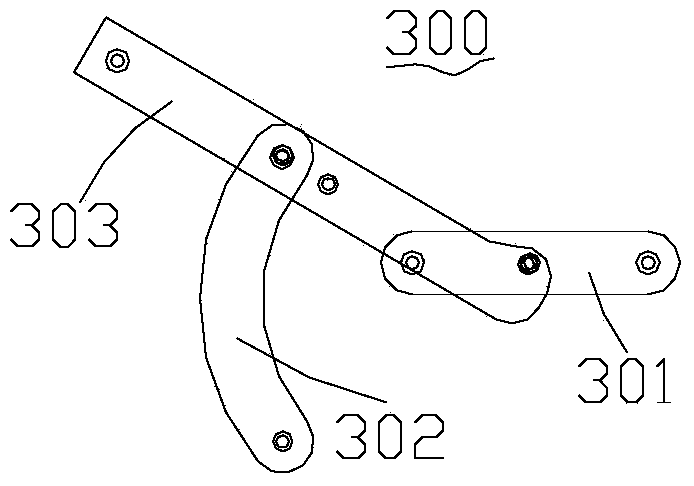

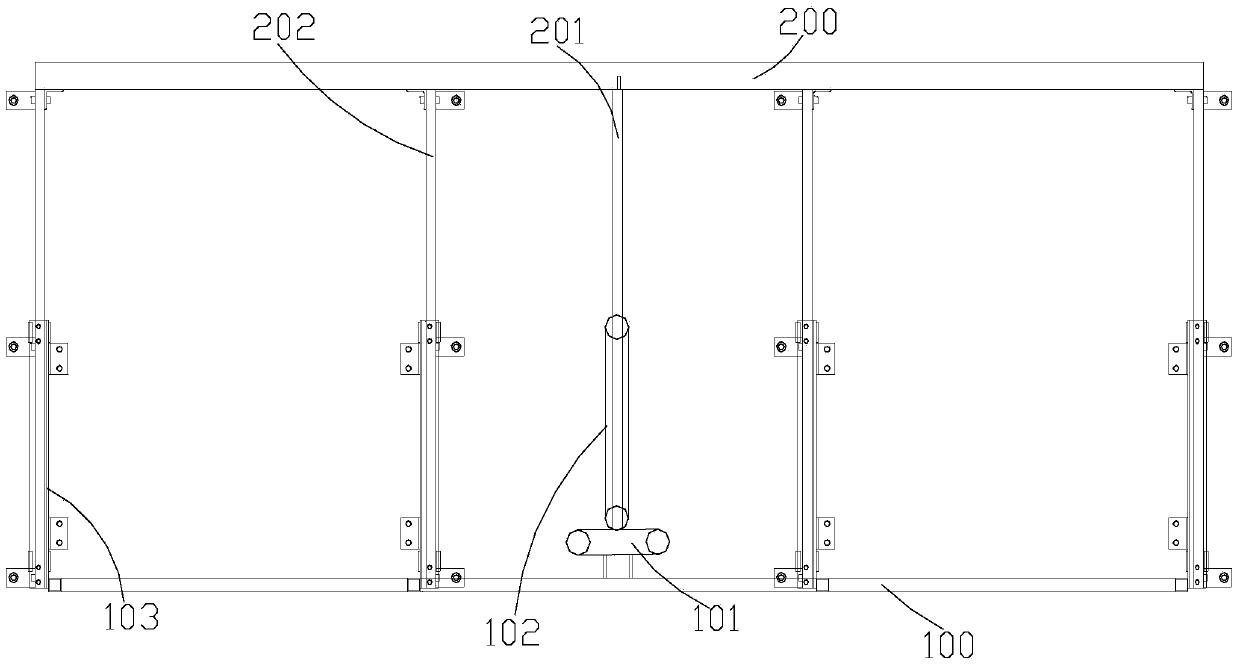

PendingCN107253054AFixed firmlyFulfill product design requirementsOther manufacturing equipments/toolsDriving apparatusInternal cavityEngineering

The invention discloses a processing device for drilling and milling an internal cavity by refitting an ordinary horizontal lathe, and relates to the technical field of mechanical processing. The device includes an ordinary horizontal lathe, a first three-jaw chuck, a lathe guide rail, a large pallet, a middle plate, a 360-degree rotatable indexing disc, a second three-jaw chuck, a gear box and a drilling and milling cutter chuck, wherein the ordinary horizontal lathe is provided with the first three-jaw chuck and the lathe guide rail, the first three-jaw chuck is connected with the gear box through a first shaft, and the lathe guide rail is provided with the large pallet capable of doing linear motions along the guide rail, and the large pallet is provided with the middle pallet capable of fixedly processing workpieces; the 360-degree rotatable indexing disc is provided with the second three-jaw chuck which is fixed with the gear box through a connecting rod, and the bottom of the gear box is provided with the drilling and milling cutter chuck through a first bolt and a first nut. The processing device for drilling and milling the internal cavity by refitting the ordinary horizontal lathe has the advantages of firm fixation, effective achievement of internal cavity processing of parts, achievement of product design requirements, strong practicability, and easy popularization and application.

Owner:SHANGHAI FINEPOWER TECH

Aluminum wood composite formwork system for buildings

ActiveCN105625708AImprove versatilityRealize the needs of aluminum wood compositeForming/stuttering elementsSupporting systemWall plate

The invention provides an aluminum wood composite formwork system for buildings. The aluminum wood composite formwork system is composed of a formwork system, a supporting system and a reinforcing system. The formwork system is composed of a wall formwork, a beam formwork, a top formwork and a core tube formwork. The supporting system comprises a wallboard support, a beam plate support and a top plate support. The reinforcing system comprises main and auxiliary wood former structures for reinforcing wallboards and aluminum frame wood former structures for reinforcing the wallboards. The aluminum wood composite formwork system for the buildings has the advantages of being simple and applicable in structure, convenient to operate, easy to process, economical and the like, and can be applied to building projects more reasonably and economically.

Owner:云南建投建材科技有限责任公司 +2

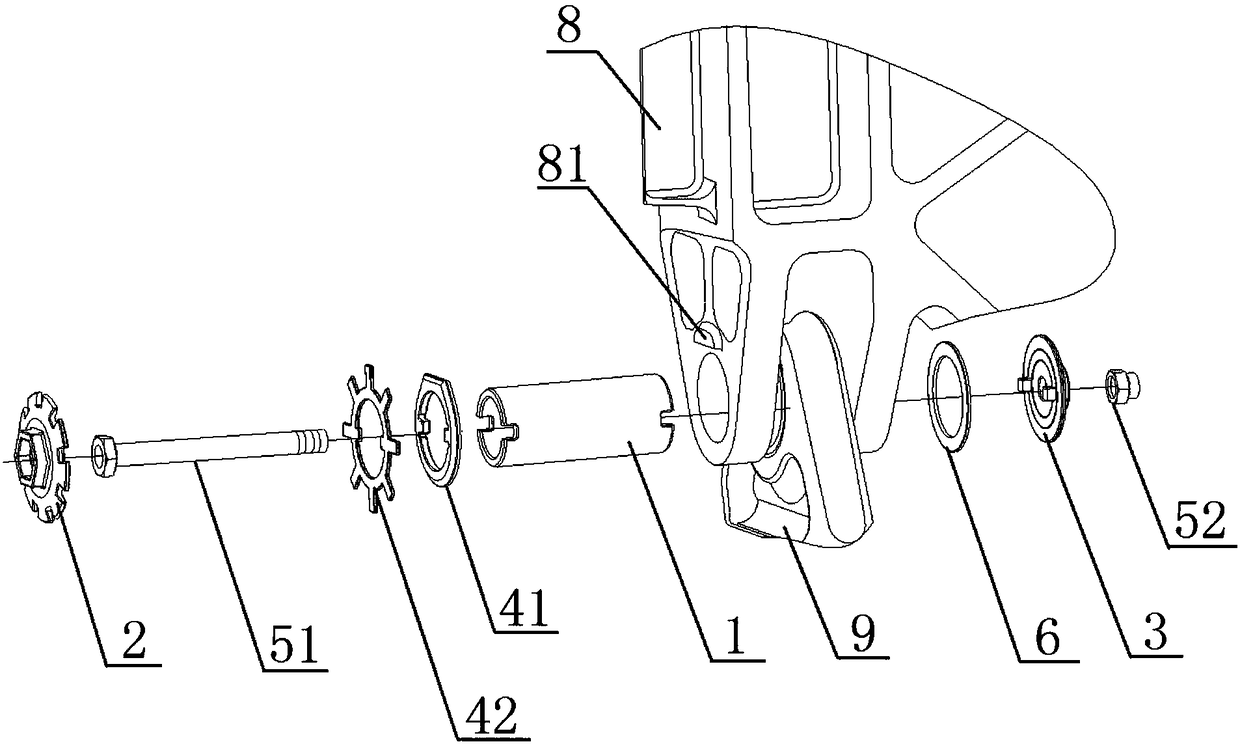

Intelligent electric sofa bed

InactiveCN103689944AMeet the requirements of integrationMeet the design requirementsSofasCouchesEngineeringSupport point

The invention provides an intelligent electric sofa bed, which is characterized in that a screw type motor arranged in a functional iron rack drives a slide slot frame composed of a pushing tube and a pushing embedded tube of a movement piece to move forwards and backwards, so that a seat bed body connected on the functional iron rack can be driven to move forwards and backwards, and three movable supporting points arranged on metal transmission pieces at the two sides of the bed body are driven to spread and contract, and therefore, a backrest bed body is pulled to ascend and descend, so as to realize erecting and falling of the backrest bed body, namely conversion between a sofa and a bed is realized. The intelligent electric sofa bed disclosed by the invention realizes a technology of spreading and flatly laying the sofa with single seat or more into the sofa bed, and achieves the purpose of converting the sofa with length of three seats and double seats into the bed; integration requirements of the sofa and the bed are achieved by the motor and the connected iron rack, especially a design idea that the sofa bed serves as a sofa in daytime and serves as a bed in night on appearance is achieved; the design requirements of various designers on sofa appearance can be realized; besides, on comfort level, a design process of a mattress is used for reference on the basis of the original sofa process, so that human feeling for sitting and sleeping achieves considering user requirements of balancing; and meanwhile, sleep quality is also ensured.

Owner:SHANGHAI YOUSHANG HOUSEHOLD

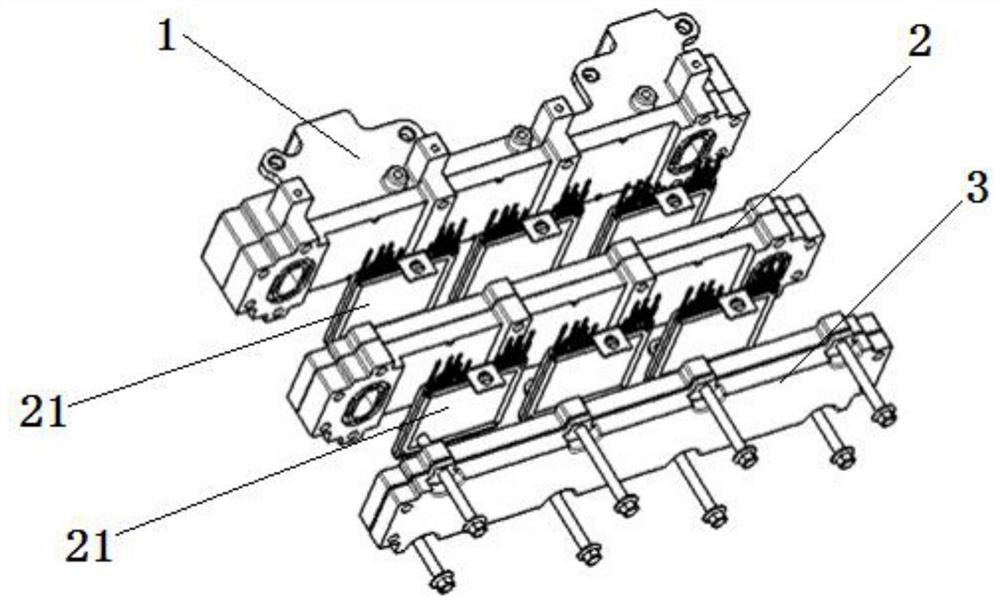

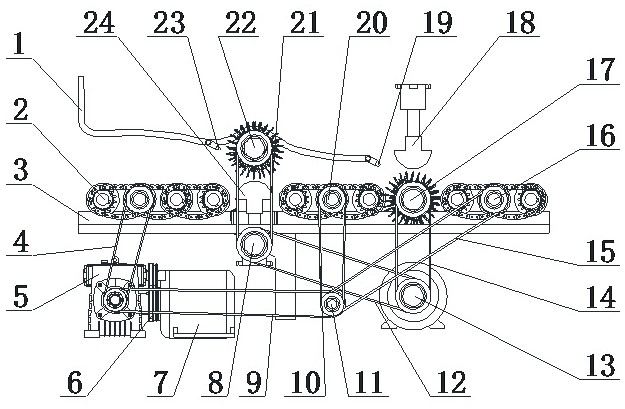

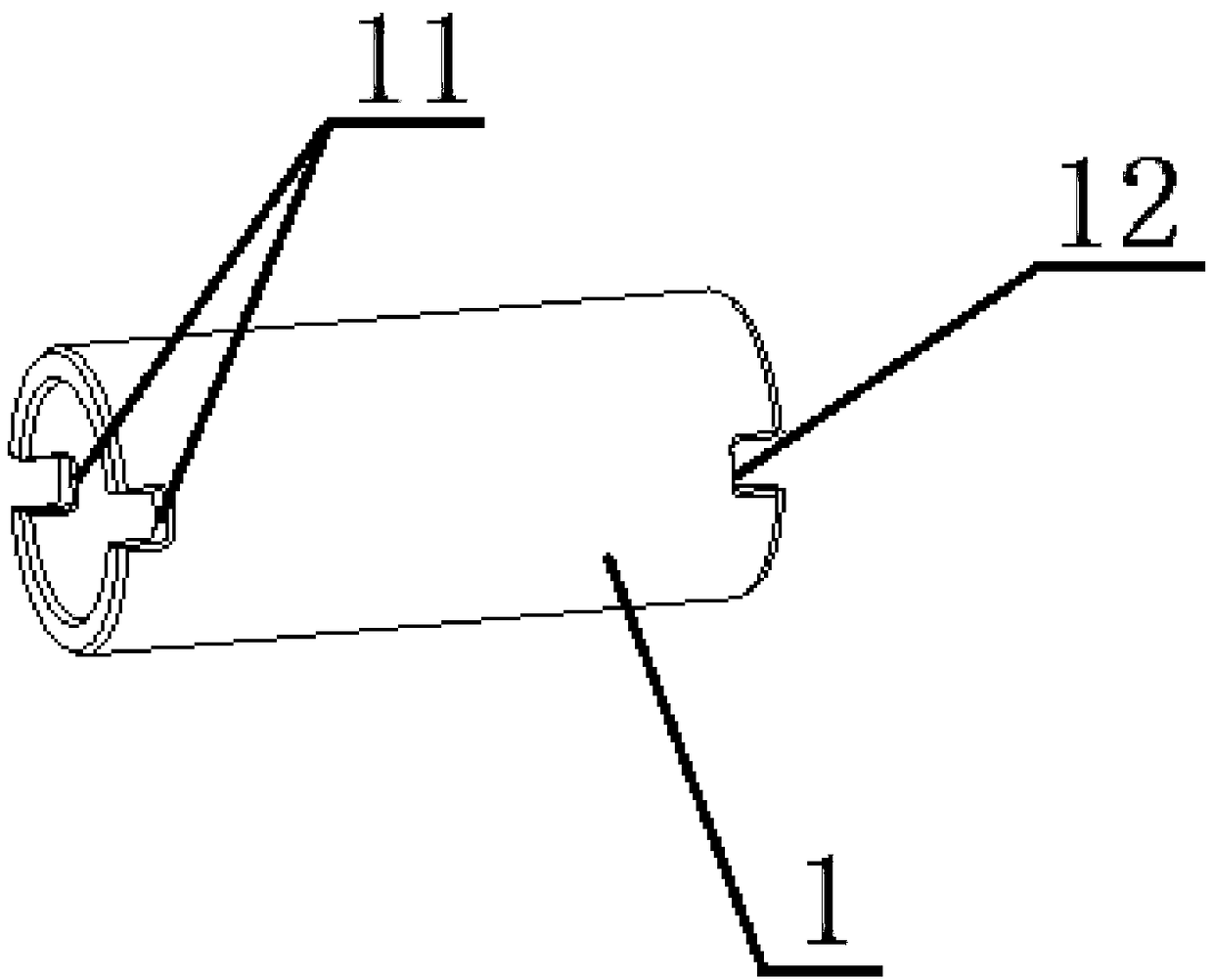

Vertical electric spring fish scale removing machine

PendingCN113133481AImprove descaling rateImprove processing efficiencyFish washing/descalingElectric machinerySprat

The invention discloses a vertical electric spring fish scale removing machine which comprises a conveying mechanism, a fish scale removing mechanism, a flushing mechanism, a transmission mechanism and the like, the conveying mechanism adopts a conveying roller form and comprises a front-section conveying roller, a middle-section conveying roller and a rear-section conveying roller, and the fish scale removing mechanism is composed of two groups of fish scale removing rollers and pressing rollers which are staggered and reversely arranged; and each fish scale removing roller is composed of a girdled roller body and a scaling cutter spring wound and welded on the roller body, and each pressing roller is composed of a pressing roller body, a pressure adjusting spring and a pressing roller seat. The whole vertical electric spring fish scale removing machine adopts a vertical structure layout, the shape is regular and stable, the vertical electric spring fish scale removing machine is conveniently applied to a fish processing production line, a spring type fish scale removing cutter can effectively remove fish scales and protect fish meat from being damaged, and a pressure adjustable compression roller ensures full and appropriate contact between a fish body and the cutter; and the conveying mechanism and the fish scale removing mechanism are driven by different motors, the performance is stable, and the reliability is high.

Owner:DALIAN POLYTECHNIC UNIVERSITY

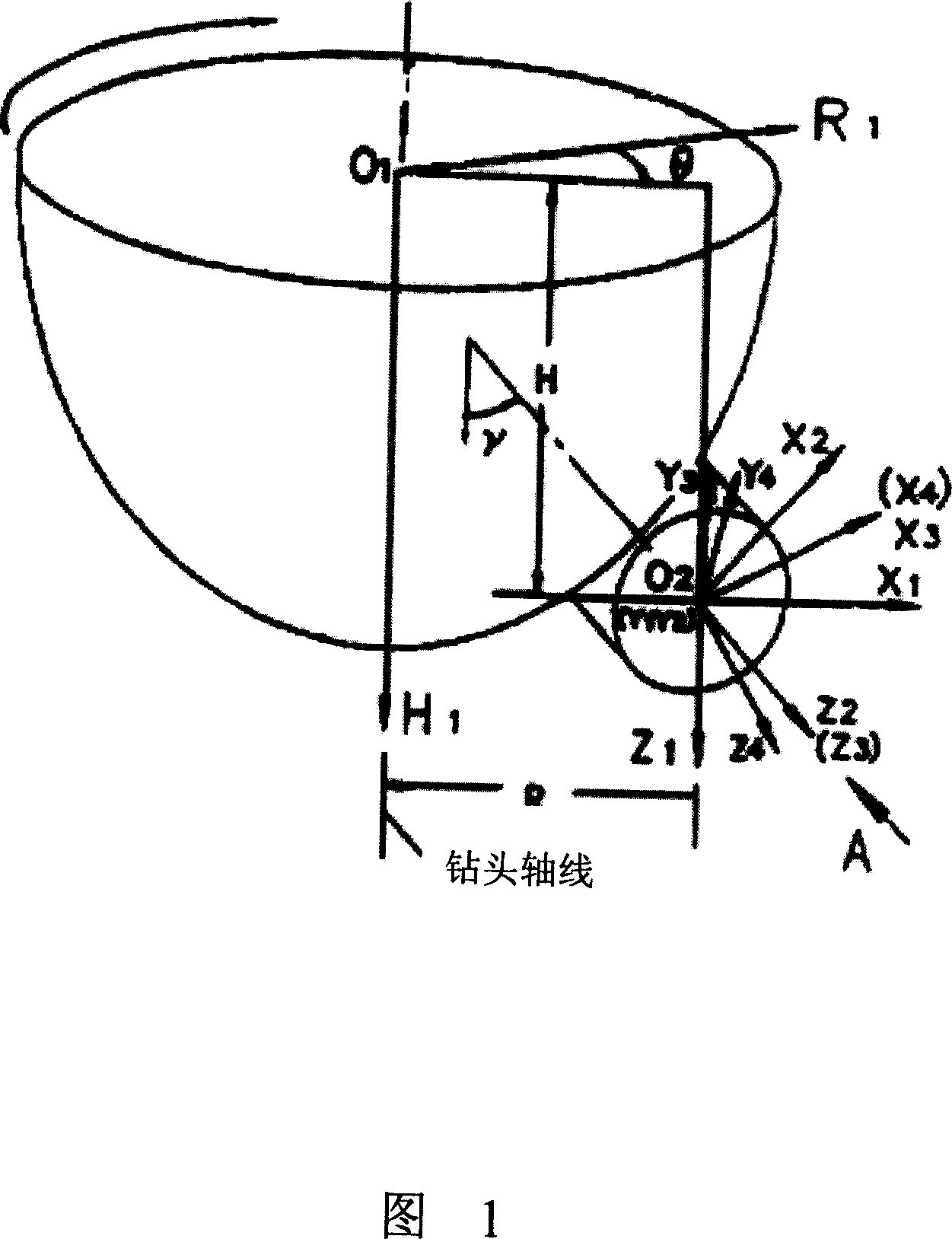

Manufacturing method for bottom die of drill bit with composite synneutic diamond plate

A method for manufacturing the bottom die of drill bit with composite synneutic diamond plate includes such steps as analyzing the characteristic elements of said bottom die to obtain the relation between them, gradually creating its graphite blank characteristics, its coronary characteristics, cutting tooth's space location characteristics, and substitute tooth characteristics, combining the characteristics of cutting tooth location and substitute tooth, removing the substitute teeth installed according to the position of cutting teeth, performing the location of cutting teeth, generating the shape of milling pit, forming the hydraulic structure according to size of discharged filings etc. Its advantages are high precision and low cost.

Owner:DAQING PETROLEUM ADMINISTRATION

Bipath parent oscillation source device

InactiveCN100502264CLow costHigh purityTime-division multiplexTransmissionLocal oscillator signalAudio power amplifier

Owner:ZTE CORP

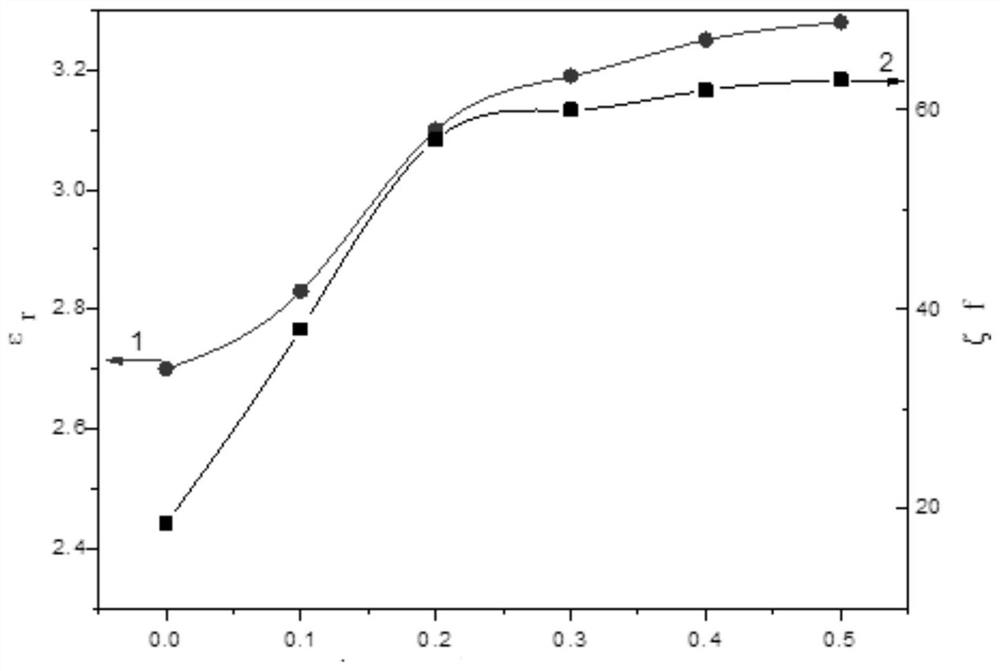

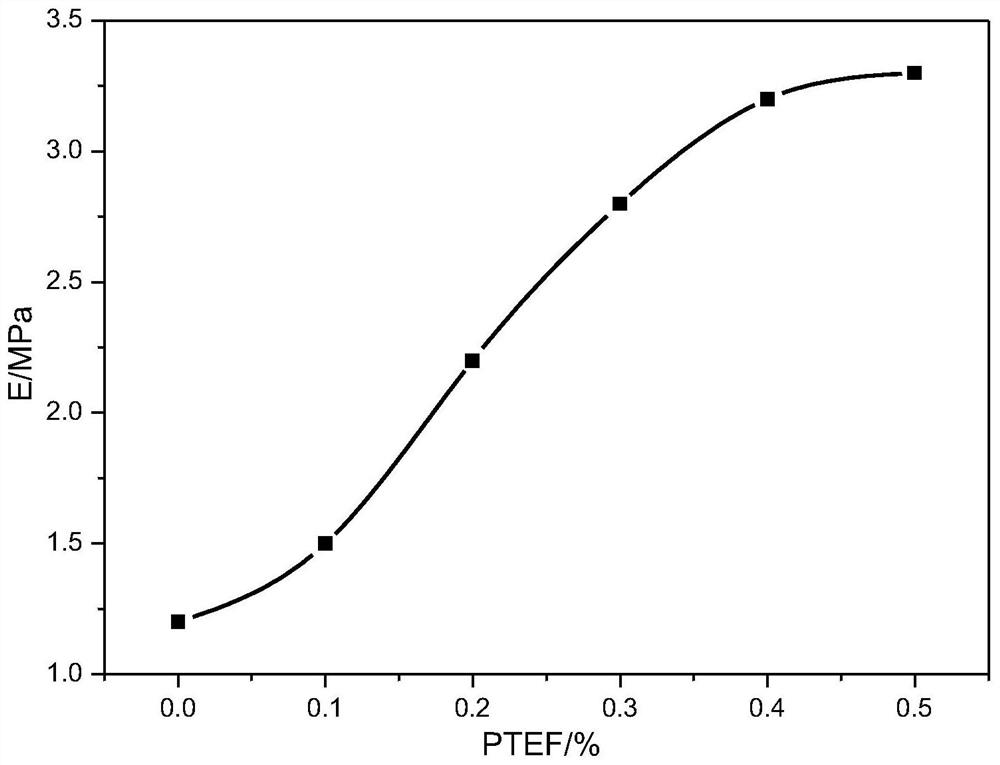

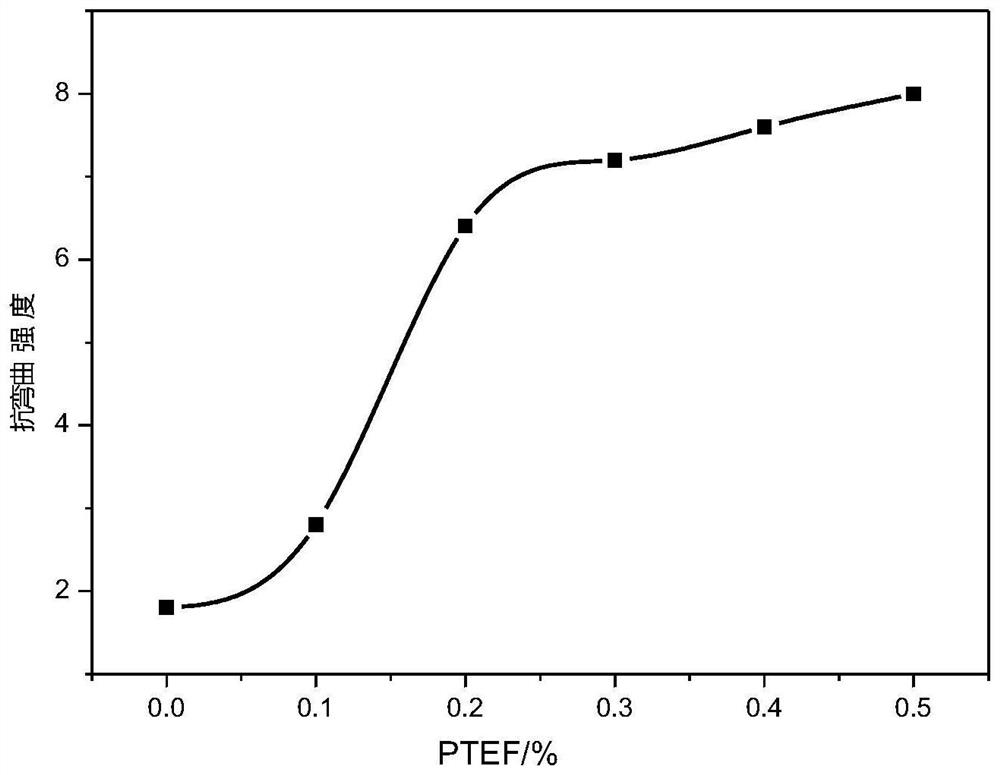

A kind of preparation method of composite material for flexible circuit board

ActiveCN110655378BFulfill design requirementsFulfill process requirementsCircuit susbtrate materialsFlexible circuitsSilica gel

The invention provides a kind of preparation method of composite material for flexible circuit board, comprising: A) whisker shape Ba 2 Ti 9 o 20 The powder, silica gel and solvent are mixed, dried to obtain the mixture; B) the mixture is pressed and crushed to obtain composite particles; the composite particles are ball-milled and dried to obtain powder particles; C) the powder is The pellets are pressed into shape and sintered to obtain a composite material for a flexible circuit board. In the present invention, the whisker-like Ba 2 Ti 9 o 20 Powder and silica gel are compounded to prepare flexible substrate materials, which combines the easy processability of polymers with the excellent dielectric and thermal properties of ceramics, and can better meet the design and processing requirements of circuit components. At the same time, the use of whiskers instead of other ceramic powders can better provide dielectric properties such as flexible substrate materials, bending strength and elastic modulus, and is more conducive to the processing and application of flexible components.

Owner:KUNSHAN BRANCH INST OF MICROELECTRONICS OF CHINESE ACADEMY OF SCI

A two-way rolling process for section steel

ActiveCN103341533BSolve the problem of side-bending rollingFulfill design requirementsMetallurgyJoist

The invention discloses a section steel bidirectional winding technology and equipment used in the section steel bidirectional winding technology. The section steel bidirectional winding technology mainly comprises a section steel sidewise winding technology and a section steel radial cone shape winding technology. Through the section steel bidirectional winding technology, sidewise bending winding of various types of section steel which includes section steel, H section steel, joist steel, angle steel and the like can be well completed without purchasing new equipment, and the difficulty of sidewise bending winding of the section steel is solved. Moreover, winding of the products which have special shapes can be completed efficiently, and not only are sidewise winding and radial big end and small end winding of the section steel are solved, but also manufacturing precision is high and drawing design requirements can be realized conveniently.

Owner:NINGBO HUAYE STEEL STRUCTURE

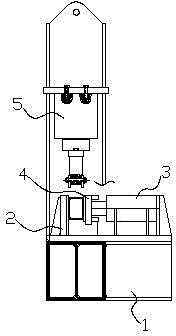

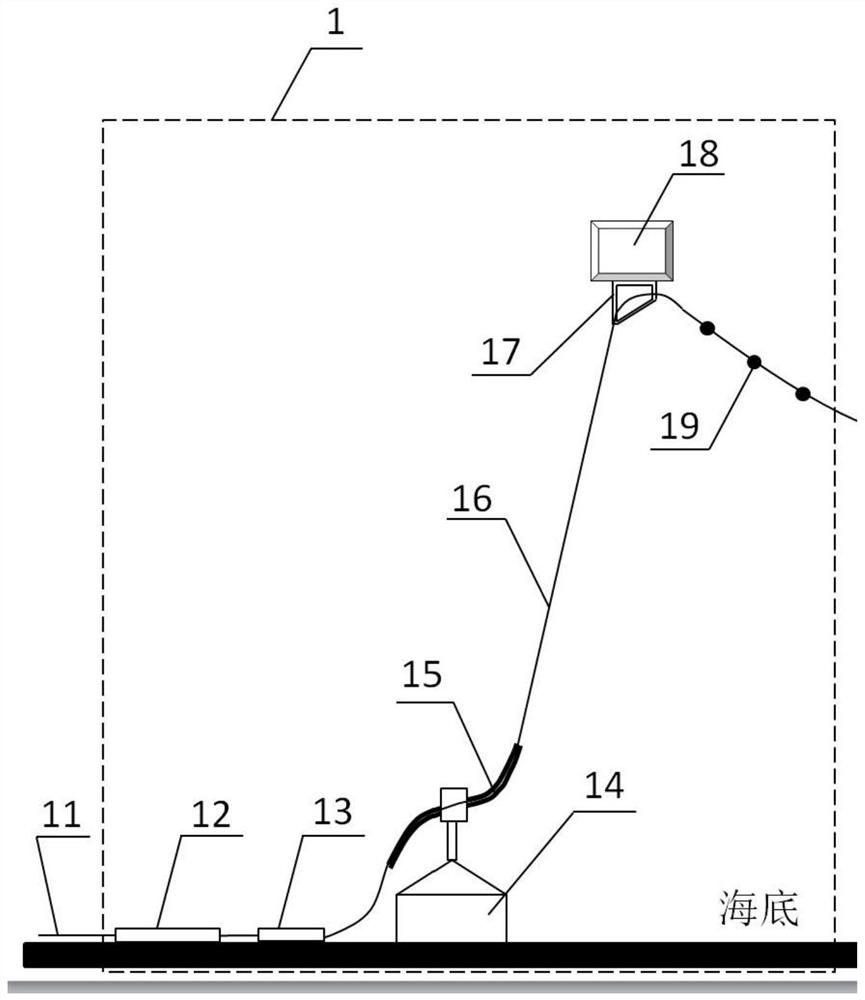

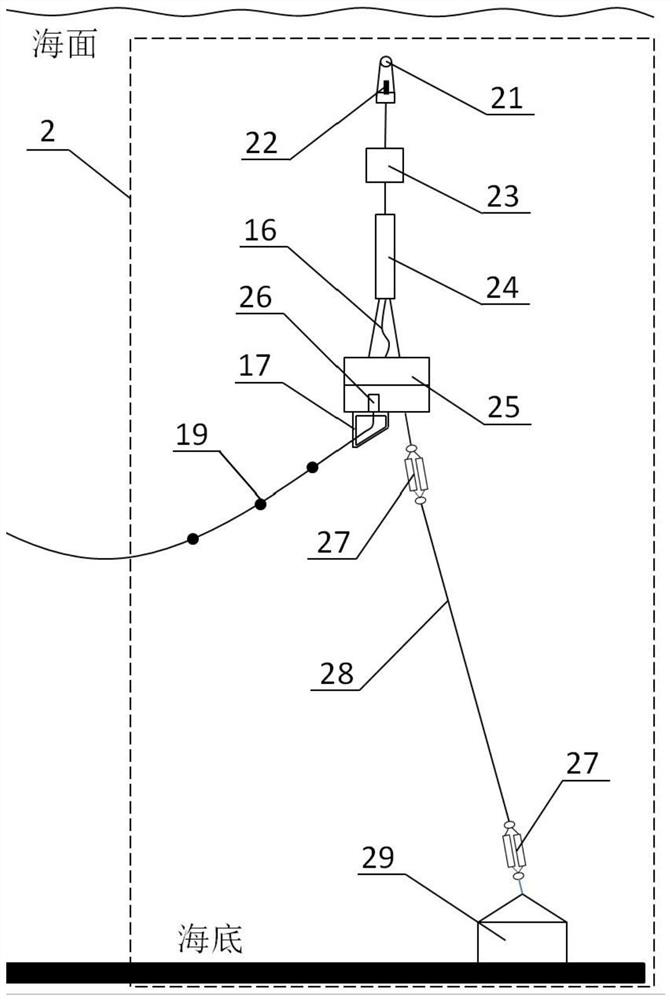

Large-water-depth anti-flow type anchoring system based on photoelectric composite umbilical cable

PendingCN114537586APrecise positioningFulfill design requirementsWaterborne vesselsBuoyMechanical engineering

The invention relates to an ocean anchoring system, in particular to a large-water-depth anti-flow type anchoring system based on a photoelectric composite umbilical cable. Wherein the photoelectric composite umbilical cable (16) between the umbilical buoy (18) and the underwater electronic equipment is arranged to be a catenary, and provides lateral tension and torque for a main cabin body (25) of the main mooring anchor system (2) and the umbilical buoy (18), so that the photoelectric composite umbilical cable (16) between the main mooring anchor system (2) and the umbilical buoy (18) and the umbilical mooring anchor block (14) is in a line type required by design; the main cabin body (25) is subjected to vertical tension provided by the main mooring anchor system (2) and lateral tension provided by the photoelectric composite umbilical cable (16), so that the posture is kept stable.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

A kind of aluminum-wood composite formwork system for building

ActiveCN105625708BImprove versatilityRealize the needs of aluminum wood compositeForming/stuttering elementsSupporting systemWall plate

Owner:云南建投建材科技有限责任公司 +2

Connected node of horizontal member and foundation of thin steel-plate shear wall

InactiveCN102235033BImproved gripping abilityLarge sectionBuilding constructionsSheet steelProblem solve

The invention discloses a connected node of a horizontal member and a foundation of a thin steel-plate shear wall, which belongs to the field of architectural construction engineering, and comprises a horizontal member (1) and a foundation of a thin steel-plate shear wall. The connected node disclosed by the invention is characterized in that anchoring members (2) which are uniformly arranged and welded at a certain interval along the lower length centerline of the horizontal member (1) at the bottom layer are vertically buried into the foundation, a shear key (3) is respectively welded on the front and rear side surfaces (parallel to the horizontal member (1)) of the anchoring members (2), and the shear keys (3) are uniformly arranged at a certain interval. The technical problem solved by the invention is to provide a new connected node, and the node greatly enhances the anchoring capacity (namely, pullout resistant capacity) of the anchoring members (2), thereby effectively balancing a tension field generated by a bottom thin steel-plate shear wall.

Owner:EAST CHINA ARCHITECTURAL DESIGN & RES INST +1

Bearing stop pin shaft

InactiveCN109307003AReduce structural weightDesign requirements for realizing structural double insurancePivotal connectionsEngineeringMechanical engineering

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

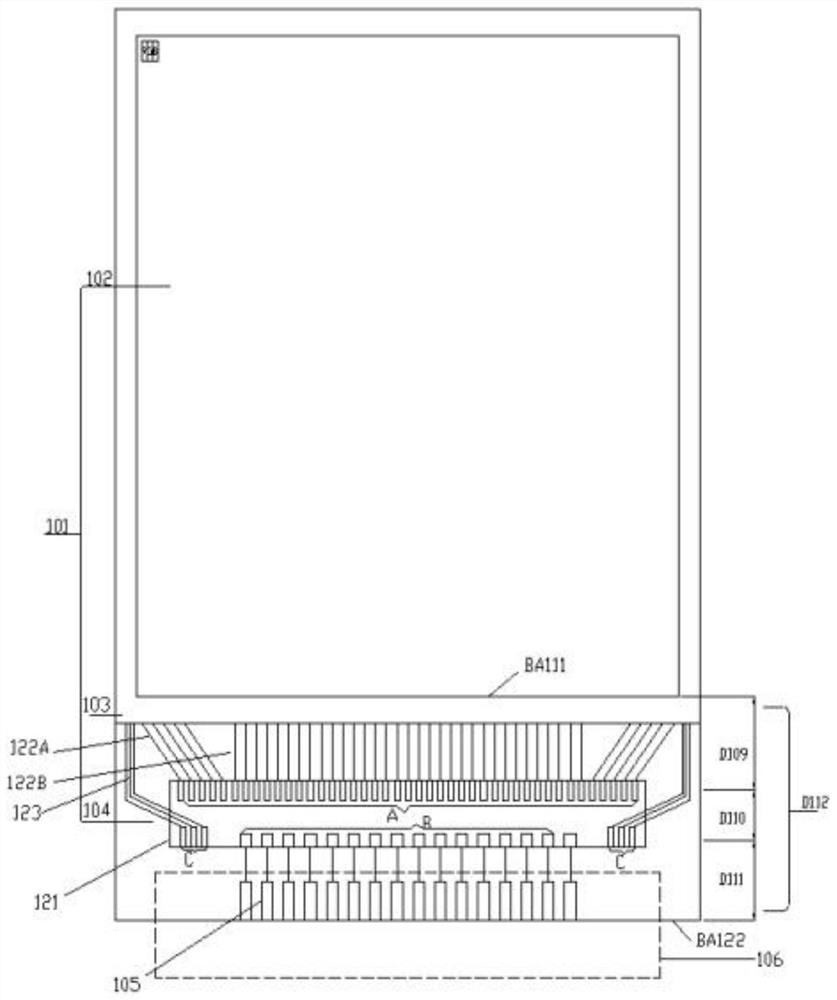

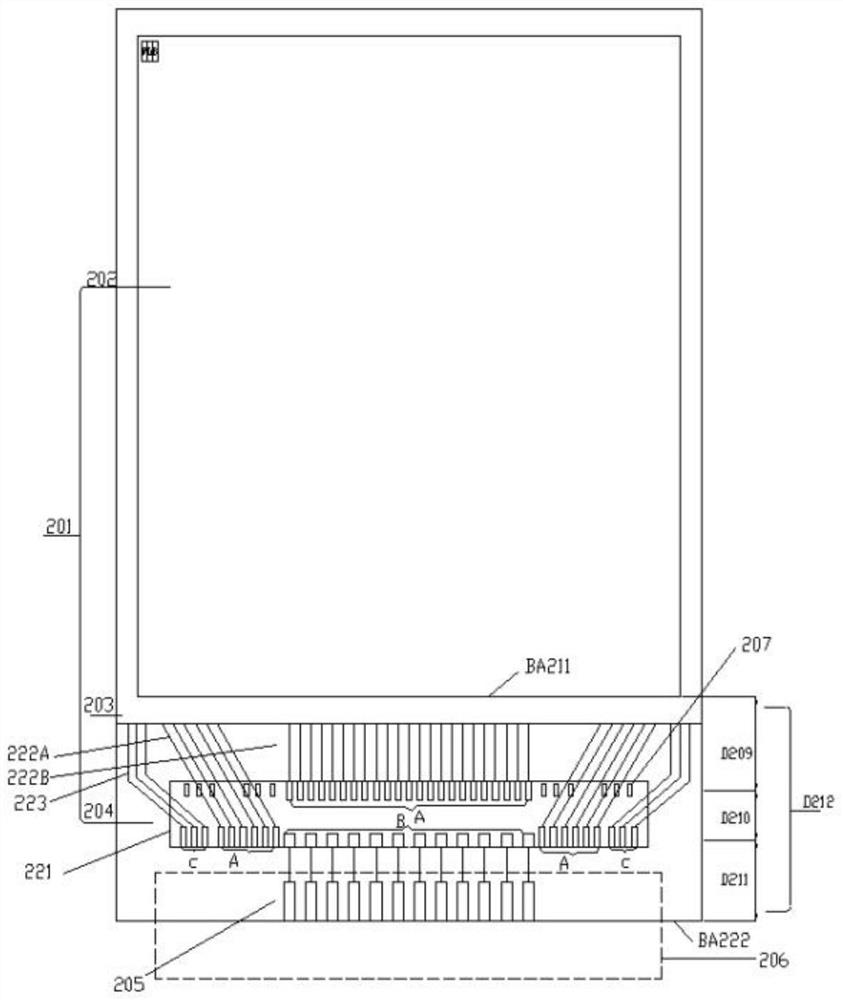

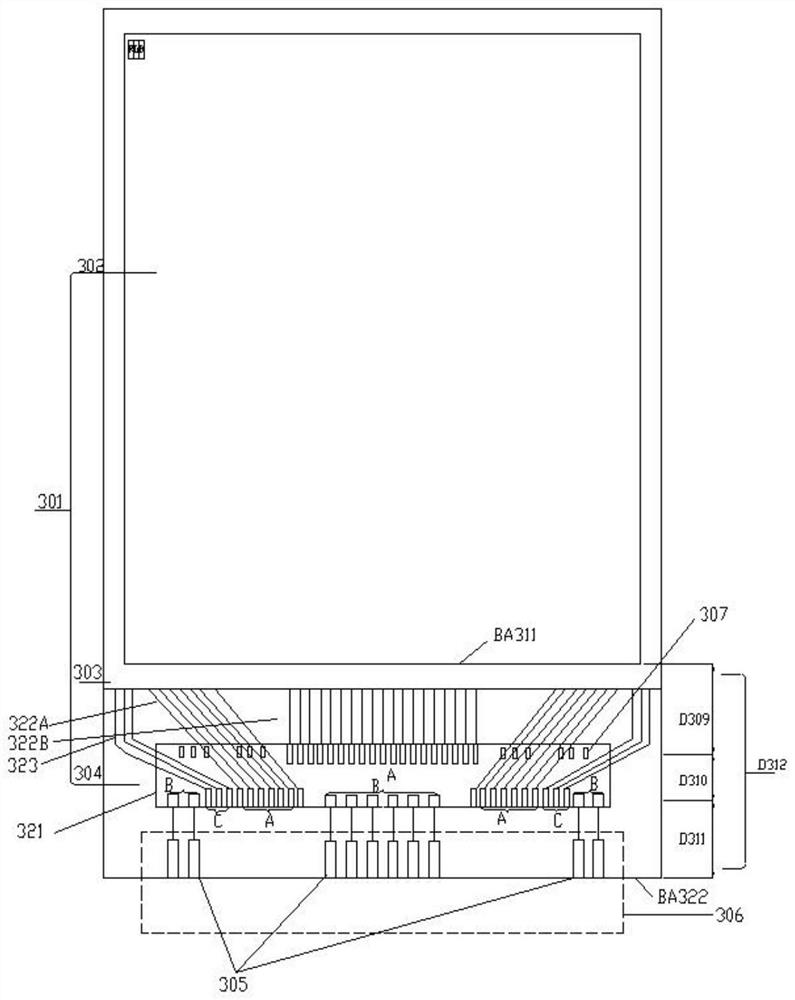

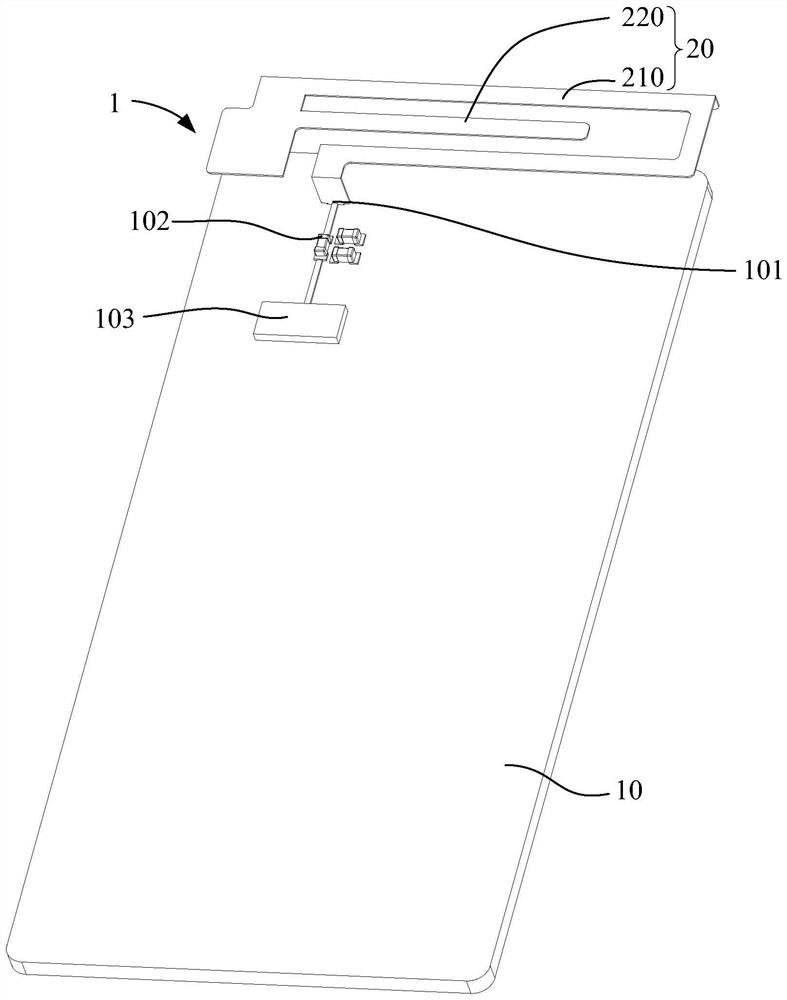

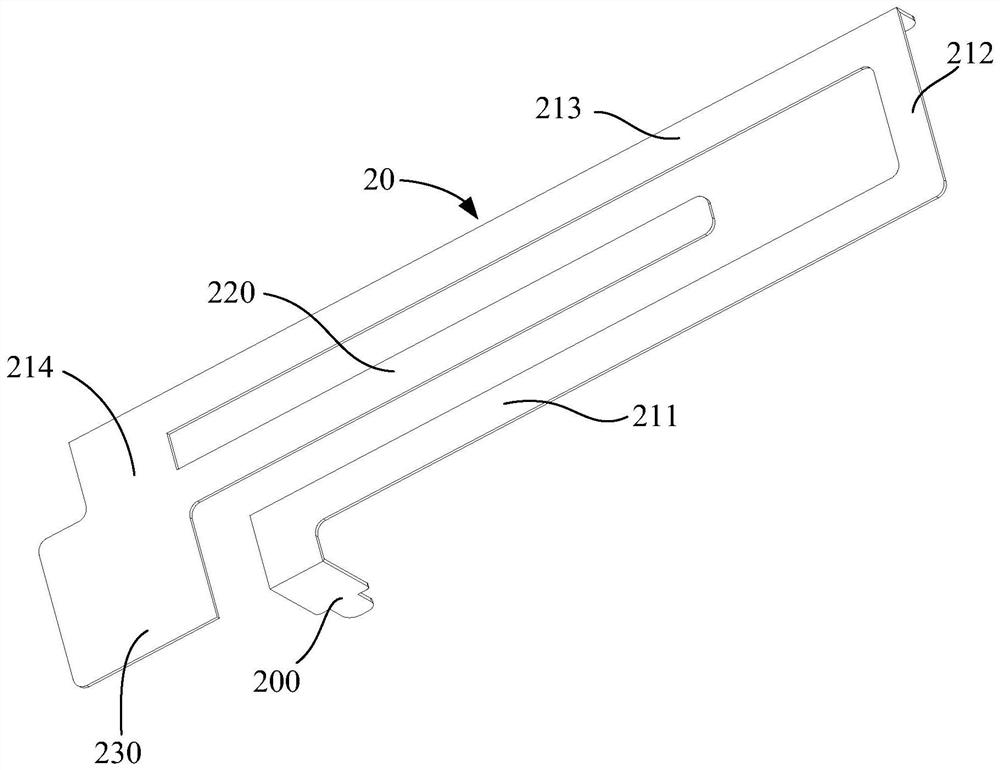

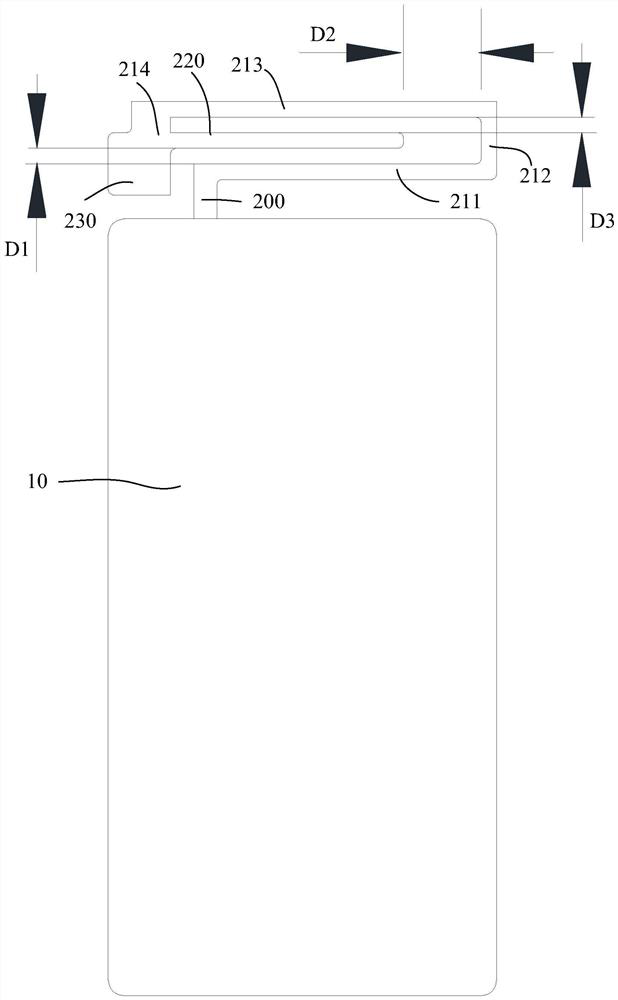

Portable display

PendingCN114220345AReduce the overall heightFulfill design requirementsIdentification meansComputer hardwareFlexible circuits

The invention belongs to the technical field of displays, and particularly relates to a portable display. The display comprises a display panel, a driving chip and a flexible circuit board, the display panel comprises a display area, a display panel frame and a driving chip binding area, the driving chip is arranged in the driving chip binding area, and a part of driving chip Source signal output connecting lines in the driving chip or a part of driving chip Source output arrays in the driving chip are arranged on one side, close to the frame of the display panel, of the lower portion of the driving chip in a mixed mode and located between the driving chip gate output array and the driving chip input pin array. The display panel is suitable for display panels made of various materials, the size of a non-display area can be reduced, meanwhile, the narrow frame requirement of the portable display is greatly improved, the attractive and portable effects are achieved, and cost is saved.

Owner:NEW VISION MICROELECTRONICS INC

Multi-frequency built-in antenna and wireless terminal

ActiveCN108417970BSave bandwidthGuaranteed efficiencySimultaneous aerial operationsAntenna supports/mountingsMulti bandFrequency Unit

The invention discloses a multi-frequency built-in antenna and an antenna terminal. The multi-frequency built-in antenna comprises a multi-frequency built-in antenna and an antenna radiation arm, wherein the multi-frequency built-in antenna comprises a circuit board, an antenna feeding point is arranged on the circuit board, one end of the antenna radiation arm is electrically connected with the antenna feeding point, the antenna radiation arm is folded and wired to form a low-frequency unit, and the other end of the antenna radiation arm and an adjacent part are automatically coupled to forma first high-frequency resonant unit. With the multi-frequency built-in antenna disclosed by the technical scheme, the low-frequency and high-frequency design of the antenna is achieved on the premisethat relatively small space volume is met, and the multi-frequency built-in antenna has the beneficial effects of multiple frequency bands and high efficiency.

Owner:深圳创维无线技术有限公司

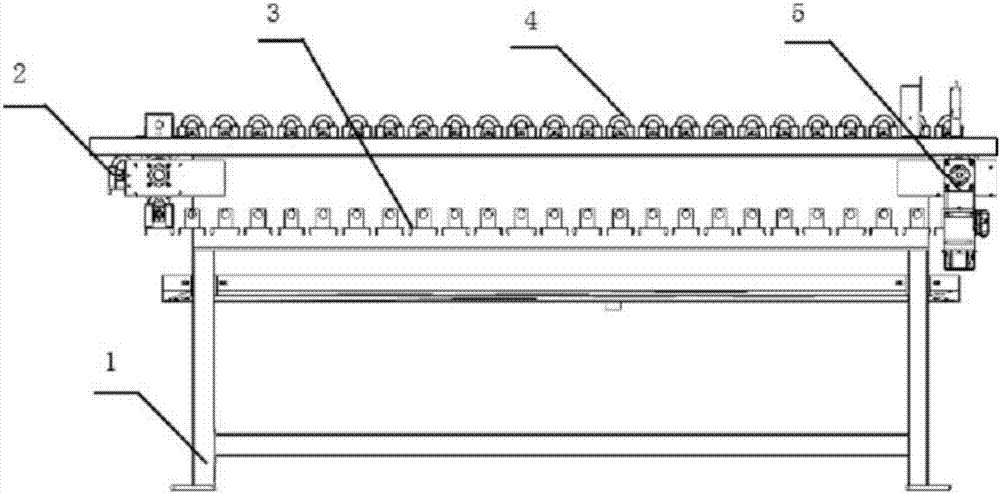

Cradle type storage conveyor

The invention provides a cradle type storage conveyor. The cradle type storage conveyor includes a rack, a chain wheel position region, a lower position region, an upper position region, a motor, a main metal plate, and a transmission shaft; chain plates are arranged on an inner side of a guide metal plate; L-shaped supporting metal plates are arranged on the chain plates; axial long-bar-shaped holes are formed in the chain plates; chain plate connectors are arranged on two sides of the chain plates; the chain plate connectors are used for fixedly connecting the chain plates and attaching plate connectors; a round hole is formed in each of folded edges at two ends of the chain plates; outer cylindrical surfaces of key-free bushings and the round holes are connected through a clearance fit;the chain plates, the L-shaped supporting metal plates, rotation shafts, the chain plate connectors, the key-free bushings, second bearings with seats and shaft clamping springs form an accompanyingtooling. The beneficial effects of the invention are that on the basis of the action of gravity of a work piece, the design demand of the accompanying tooling in the chain wheel position area can be met by designing and calculating a geometrical relation between the center of gravity and the rotation axis of the accompanying tooling; and a simple structure of the accompanying tooling can be achieved through the key-free bushings.

Owner:NINGXIA KOCEL MACHINE TOOL ACCESSORIES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com