A two-way rolling process for section steel

A profiled steel and process technology, applied in the field of profiled steel bidirectional rolling, to achieve the effect of high production accuracy and the realization of drawing design requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

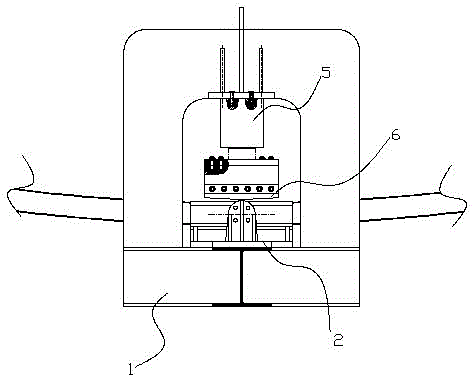

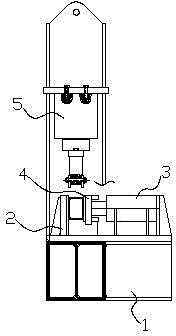

[0013] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment (the sample board described in the embodiment is the sample board that tries to do in advance, and the sample board has the radian identical with actual required radian, is convenient to detect): see Figure 1 to Figure 2 , a kind of equipment used in the two-way rolling process of shaped steel, including a base 1, on which a fixed platform 2 for placing shaped steel is arranged, and a first driving mechanism 3 is arranged on one side of the fixed platform 2, said The first drive mechanism 3 is connected to the profiled steel support 4. When the profiled steel is placed, the profiled steel is first put into the fixed platform 2, and then the first drive mechanism 3 promotes the profiled steel bracket 4 so that the profiled steel is firmly fixed on the fixed platform 2.

[0014] A second drive mechanism 5 is arranged above the fixed table 2, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com