Vertical electric spring fish scale removing machine

An electric spring and fish scale machine technology, applied in the direction of fish cleaning/descaling, can solve the problems of large damage to the fish body, time-consuming and laborious de-scaling steps, low de-scaling efficiency, etc., and achieves stable processing quality, high processing efficiency, and improved The effect of descaling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

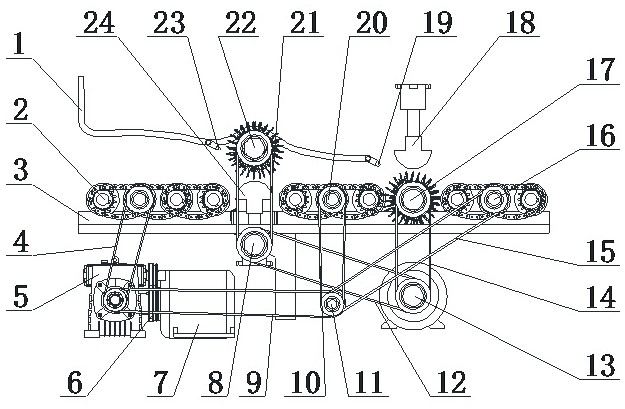

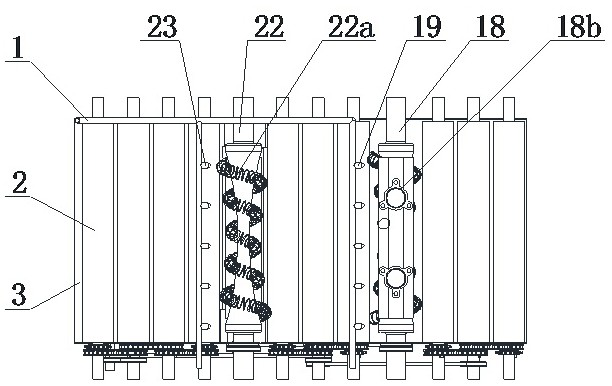

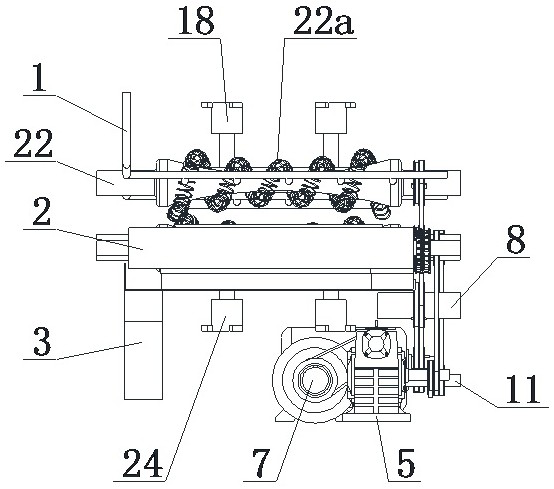

[0023] Such as Figure 1 to Figure 8 As shown, the vertical electric spring fish scale removal machine includes a conveying mechanism, a descaling mechanism, a flushing mechanism, a transmission mechanism, a control switch 28, a feed port 25 and a discharge port 26, and the conveying mechanism consists of a front conveying roller 2 and a middle conveying roller 20. , and the rear conveying roller 16. The descaling mechanism includes a descaling station 1 and a descaling station 2, wherein the descaling station 1 is composed of an upper descaling roller 22 and a lower pressing roller 24, and the descaling station 2 is composed of an upper pressing The roller 18 and the descaling roller 17 are composed, the flushing mechanism is composed of the flushing pipe 1 and the waste collection tank 3, and the transmission mechanism includes a conveying transmission part and a descaling transmission part, wherein the conveying transmission part is composed of a conveying motor 7, a couplin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com