Patents

Literature

380results about How to "Flexible processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

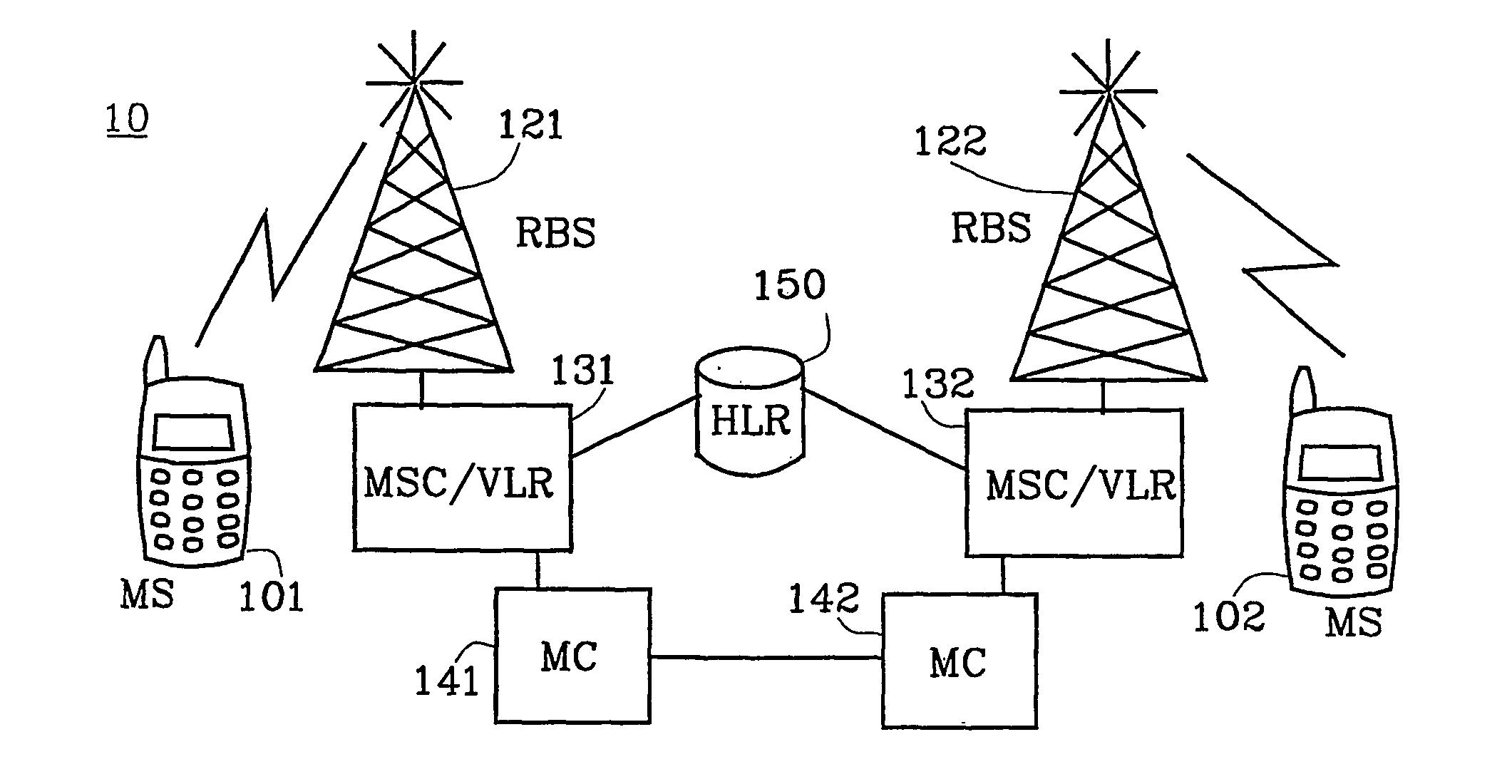

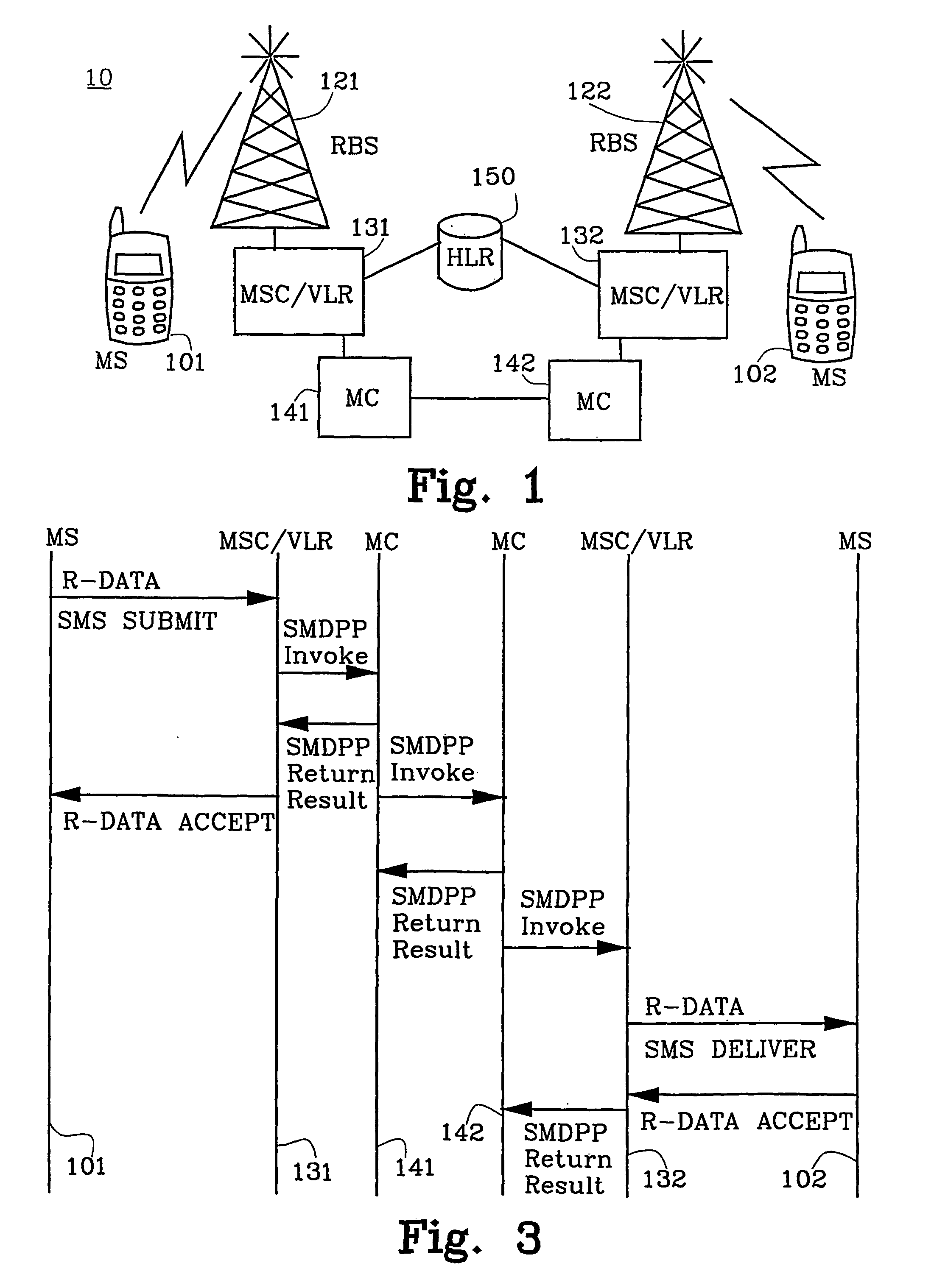

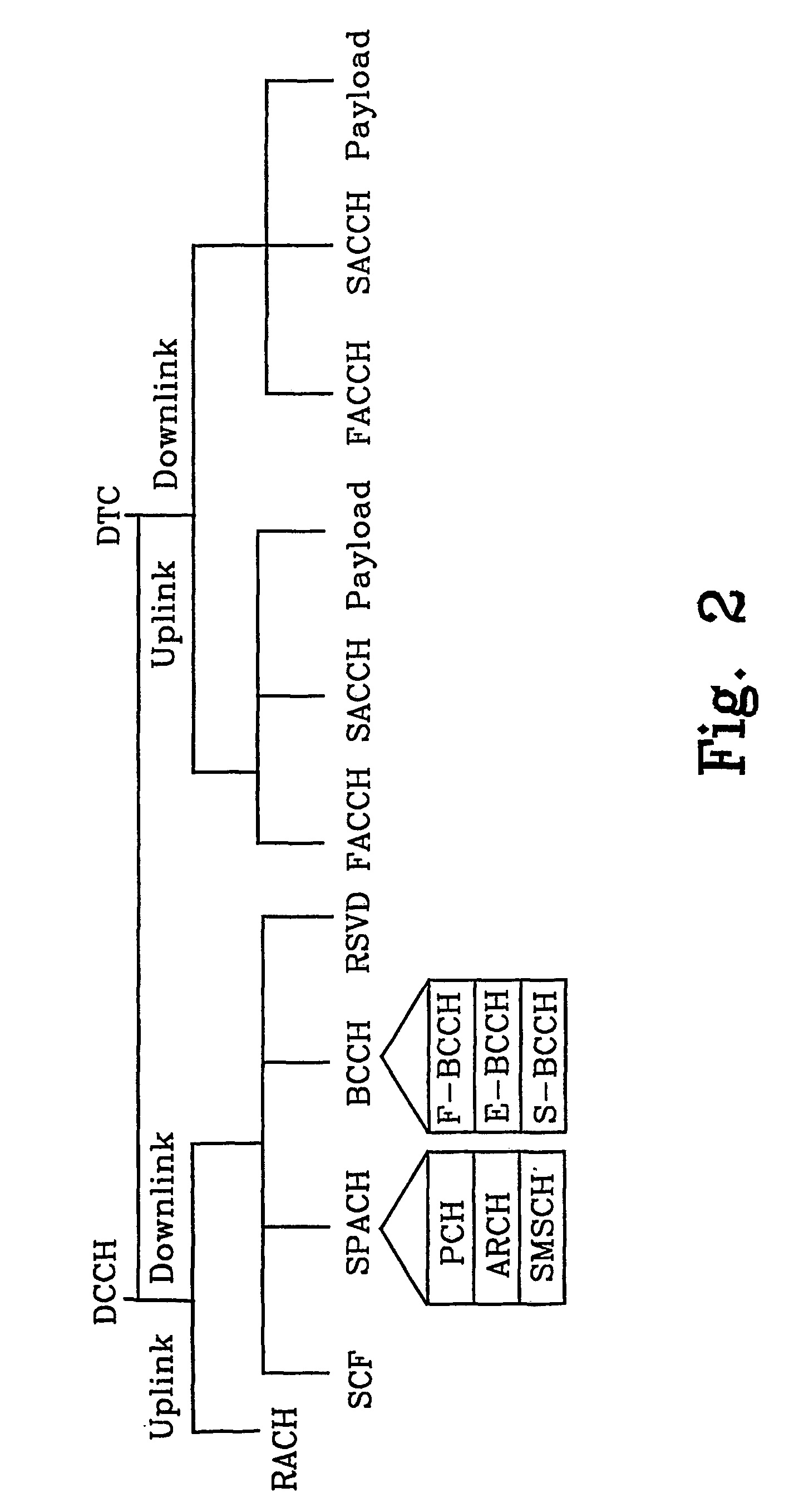

Method and apparatus for enhanced short message service

InactiveUS20040048627A1Flexible processingEasy to controlUser identity/authority verificationSpecial service for subscribersCommunications systemShort Message Service

The present invention relates generally to mobile communication systems, methods and apparatus for transmitting messages from an originating party to a receiving mobile station, and transmitting short message service (SMS) messages from an originating party to a receiving mobile station in a mobile communication system. Briefly, the present invention solves a problem by transmitting both a message and a validity period (401) associated with the message from the message center to the receiving mobile station. By transmitting both a message and a validity period (401), associated with the message, where the validity period (401) specified by the sender of the message, the receiving mobile station can use the validity period (610) information when making decisions on how to process the received message.

Owner:TELEFON AB LM ERICSSON (PUBL)

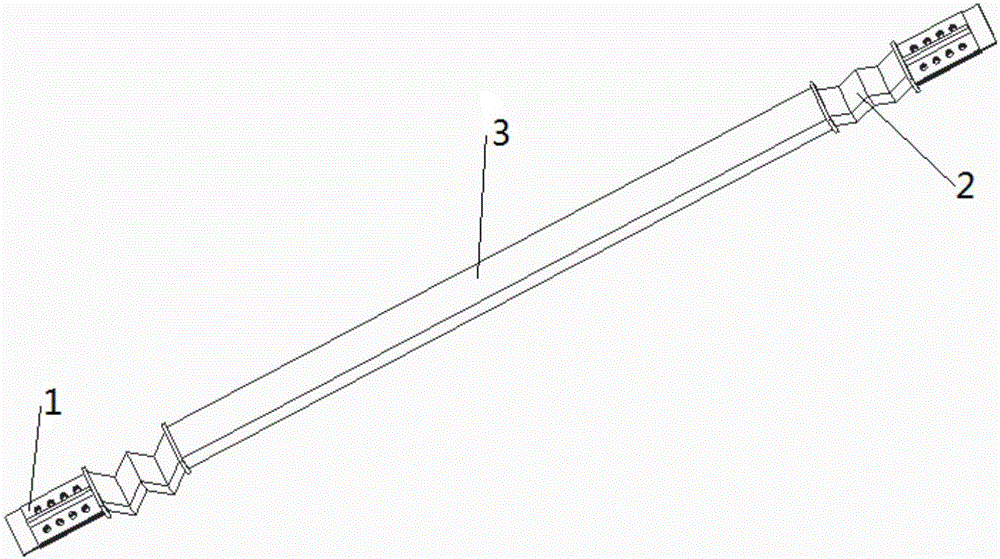

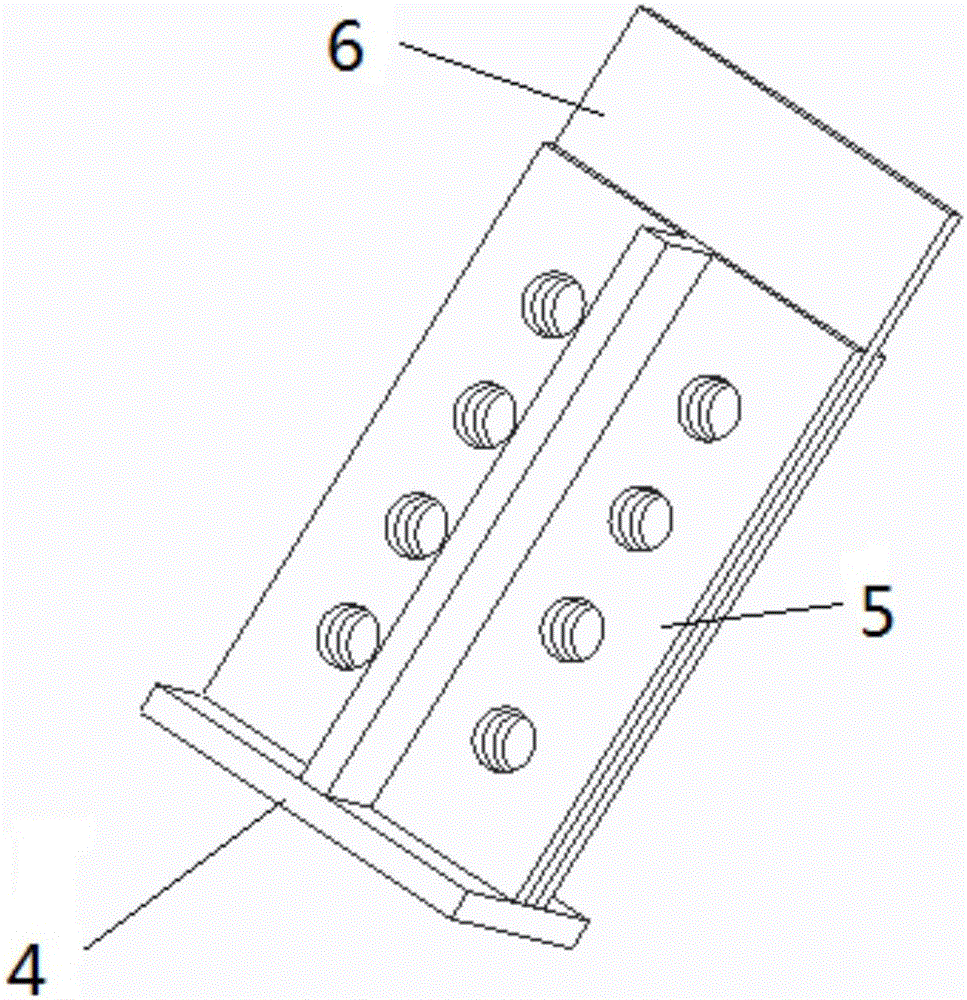

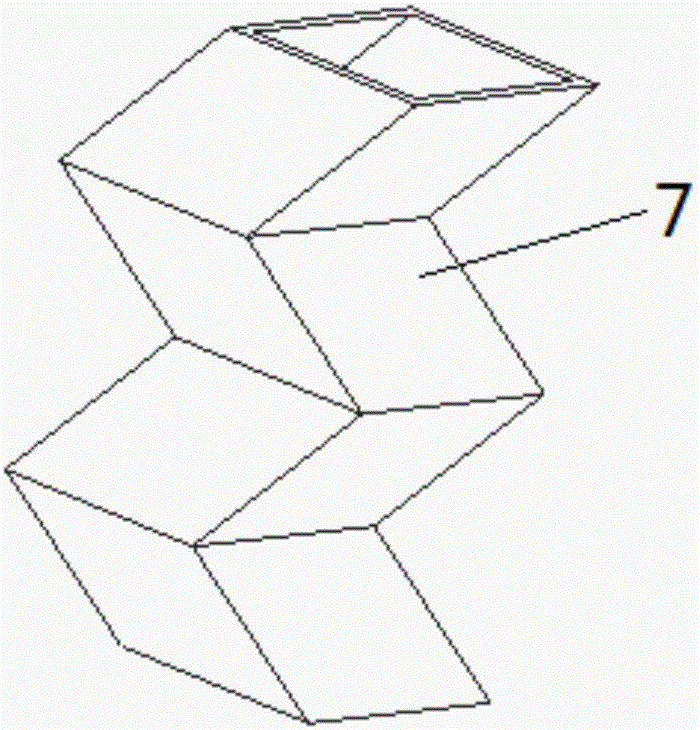

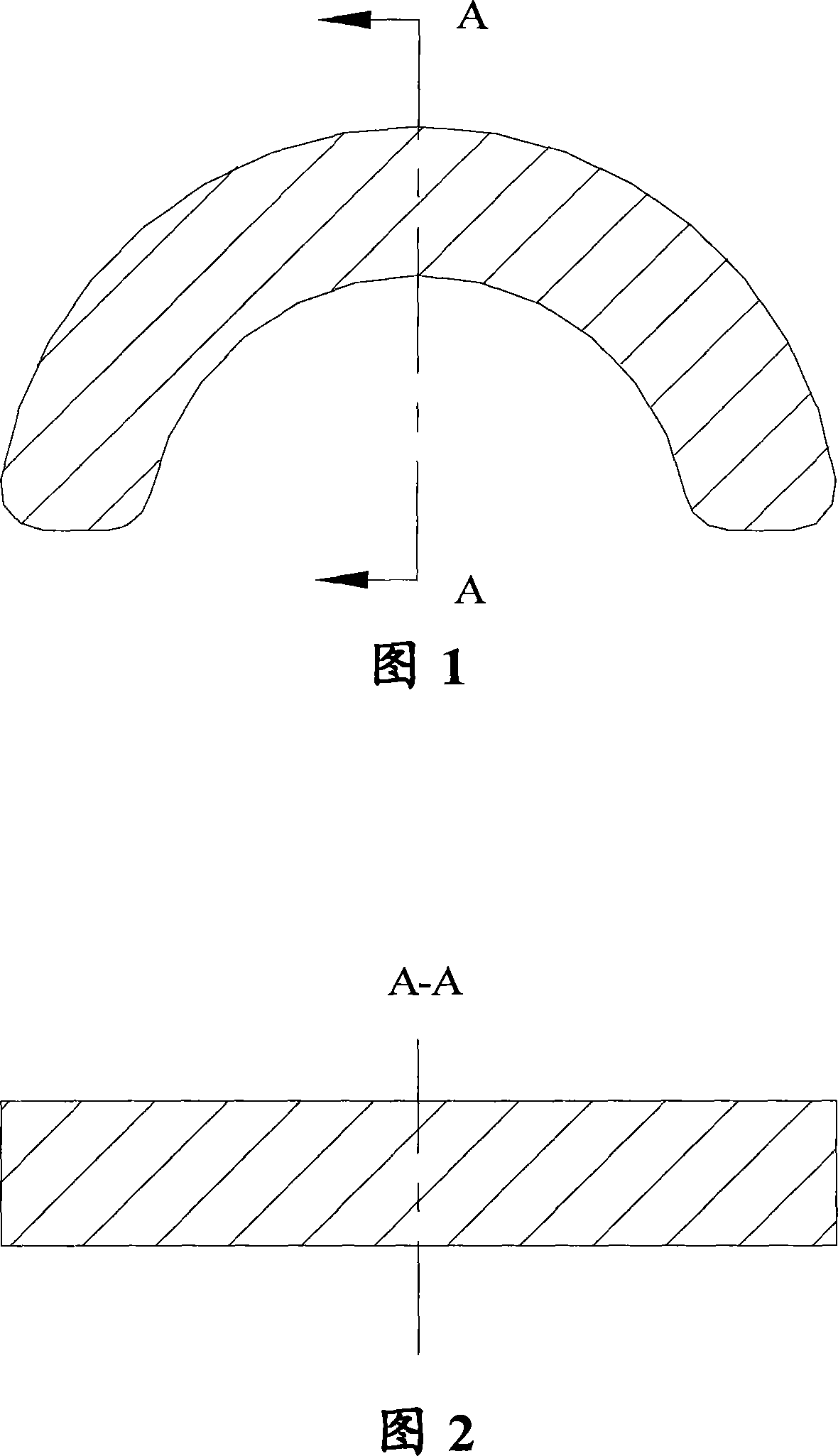

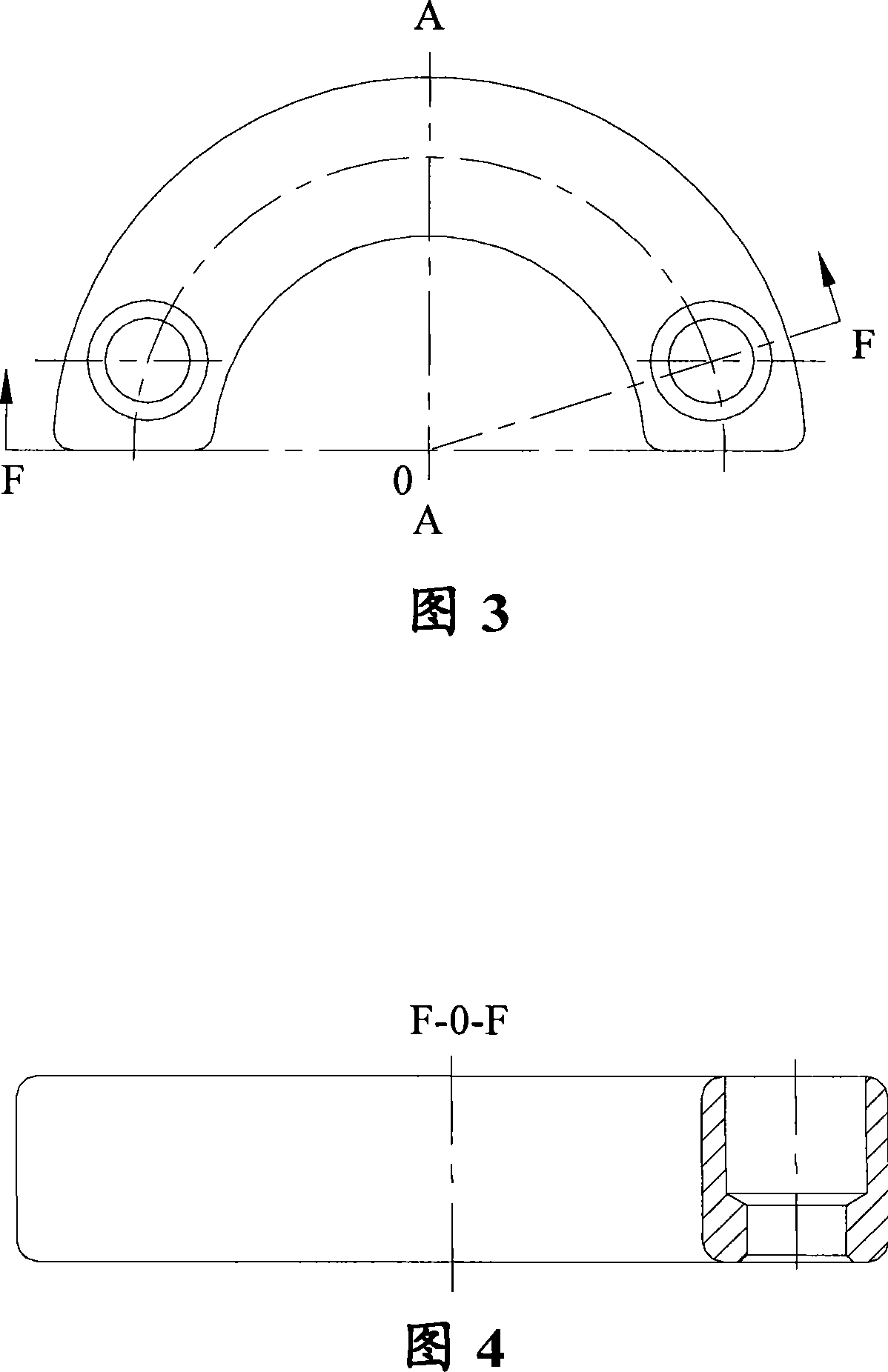

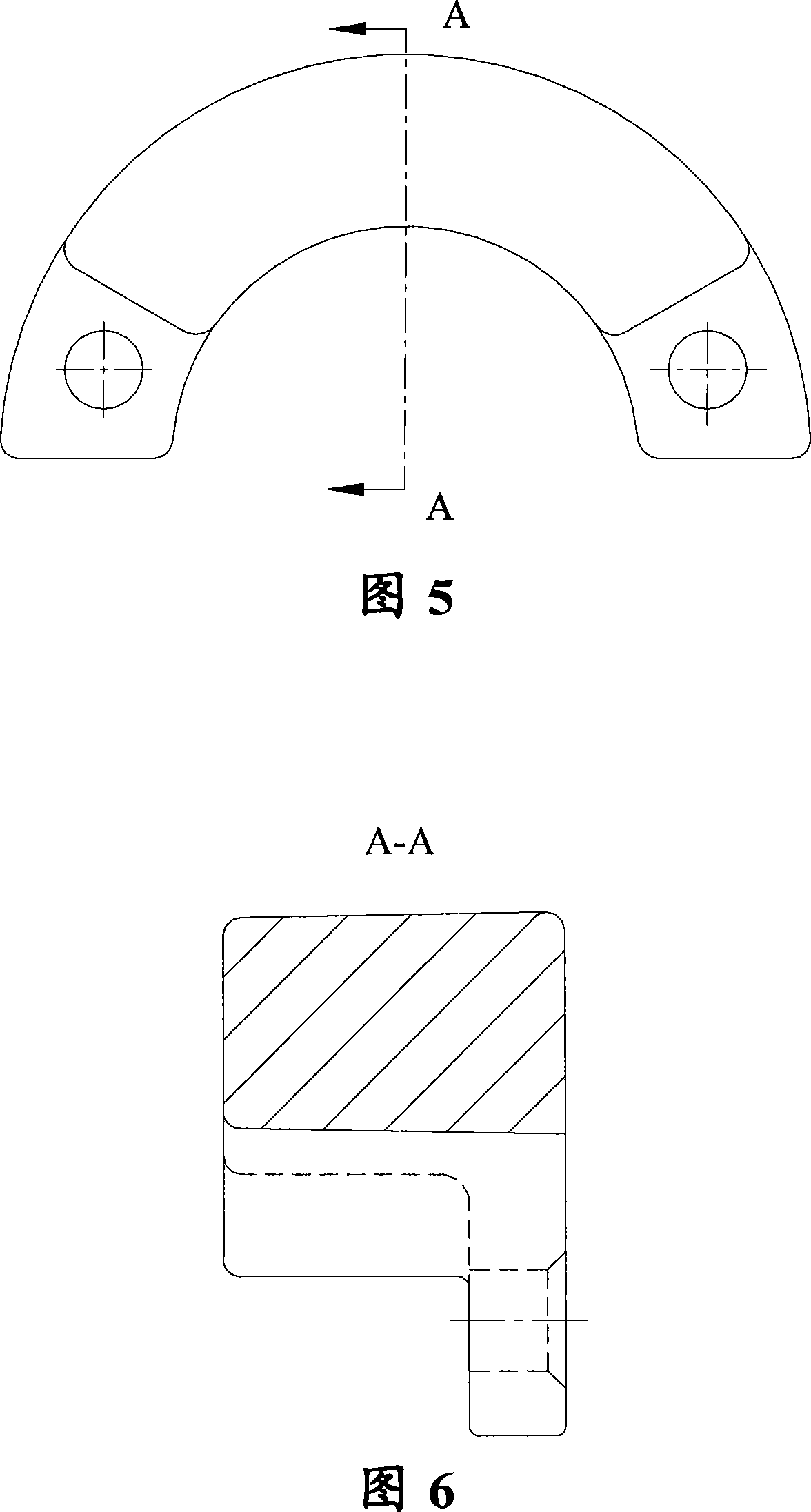

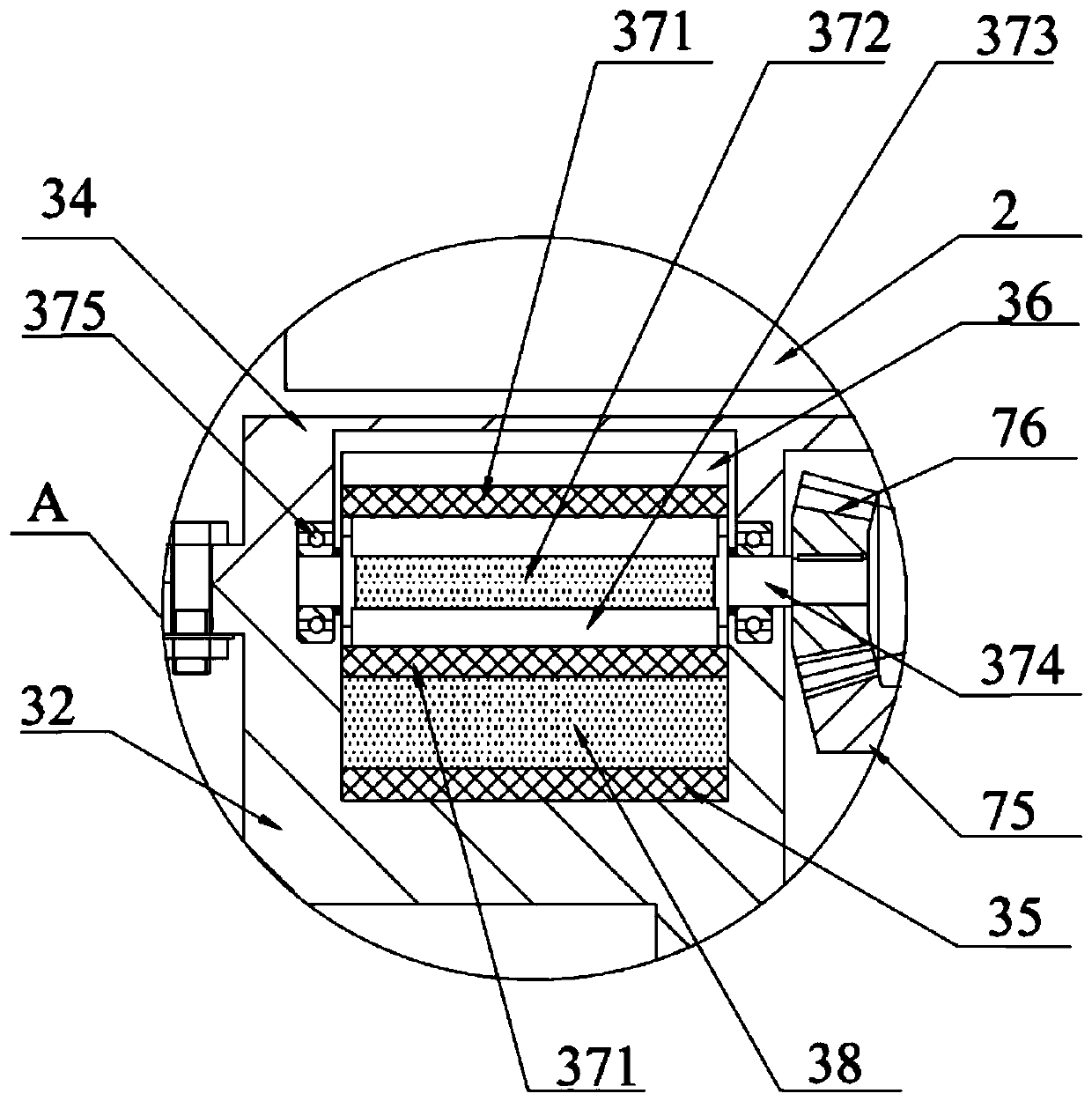

Energy dissipation type buckling constraint support with symmetrical initial imperfection unit at end

ActiveCN105971356AOptimize layoutFlexible layoutProtective buildings/sheltersShock proofingManufacturing technologyBuckling-restrained brace

The invention discloses an energy dissipation type buckling constraint support with a symmetrical initial imperfection unit at the end. The energy dissipation type buckling constraint support is characterized in that the support is composed of an end constraint segment, an energy dissipation segment and a support straight segment; and the two ends are connected with beams or column components or nodes to form a whole through bolt connection so as to achieve the purpose of improving of the resistant-lateral rigidity of components. The energy dissipation type buckling constraint support with the symmetrical initial imperfection unit at the end is adopted, and thus under the action of a small earthquake, the buckling constraint support keeps elasticity; and under the action of a medium earthquake or a severe earthquake, the buckling constraint support enters a yield stage, and the effect of a damper can further be achieved through the good hysteretic energy dissipation performance of the buckling constraint support. Compared with traditional buckling constraint supports, according to a manufacturing technology of the energy dissipation type buckling constraint support, the processes of adding a sleeve outside a core energy dissipation component, grouting and the like in the traditional manufacturing process are avoided in the manufacturing technology, so that manufacturing is convenient. The energy dissipation type buckling constraint support can be prefabricated and formed in a factory, the quality of the components is ensured, the workload of site operation is reduced, and energy conservation and environment protection are achieved.

Owner:SOUTHEAST UNIV

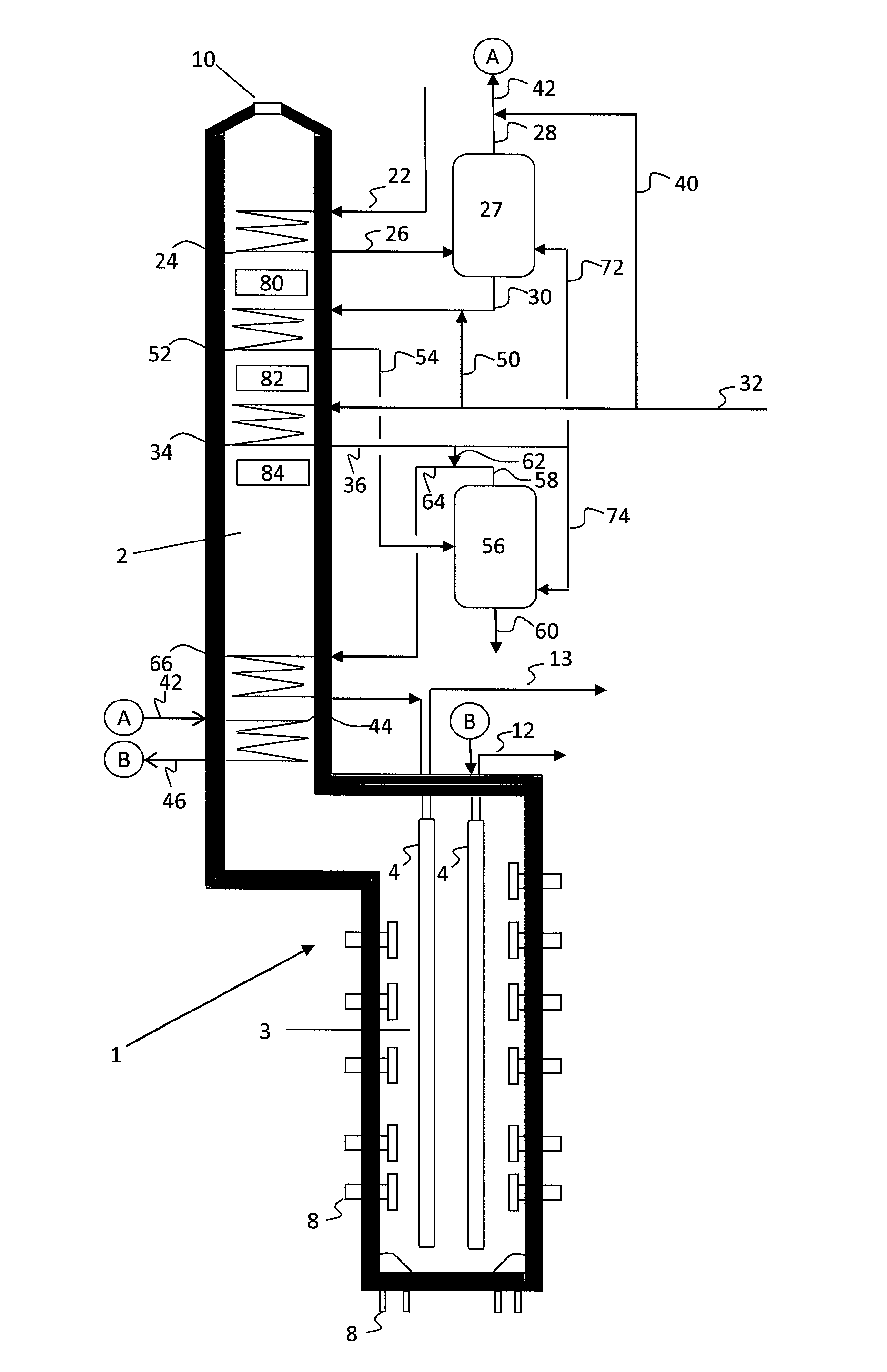

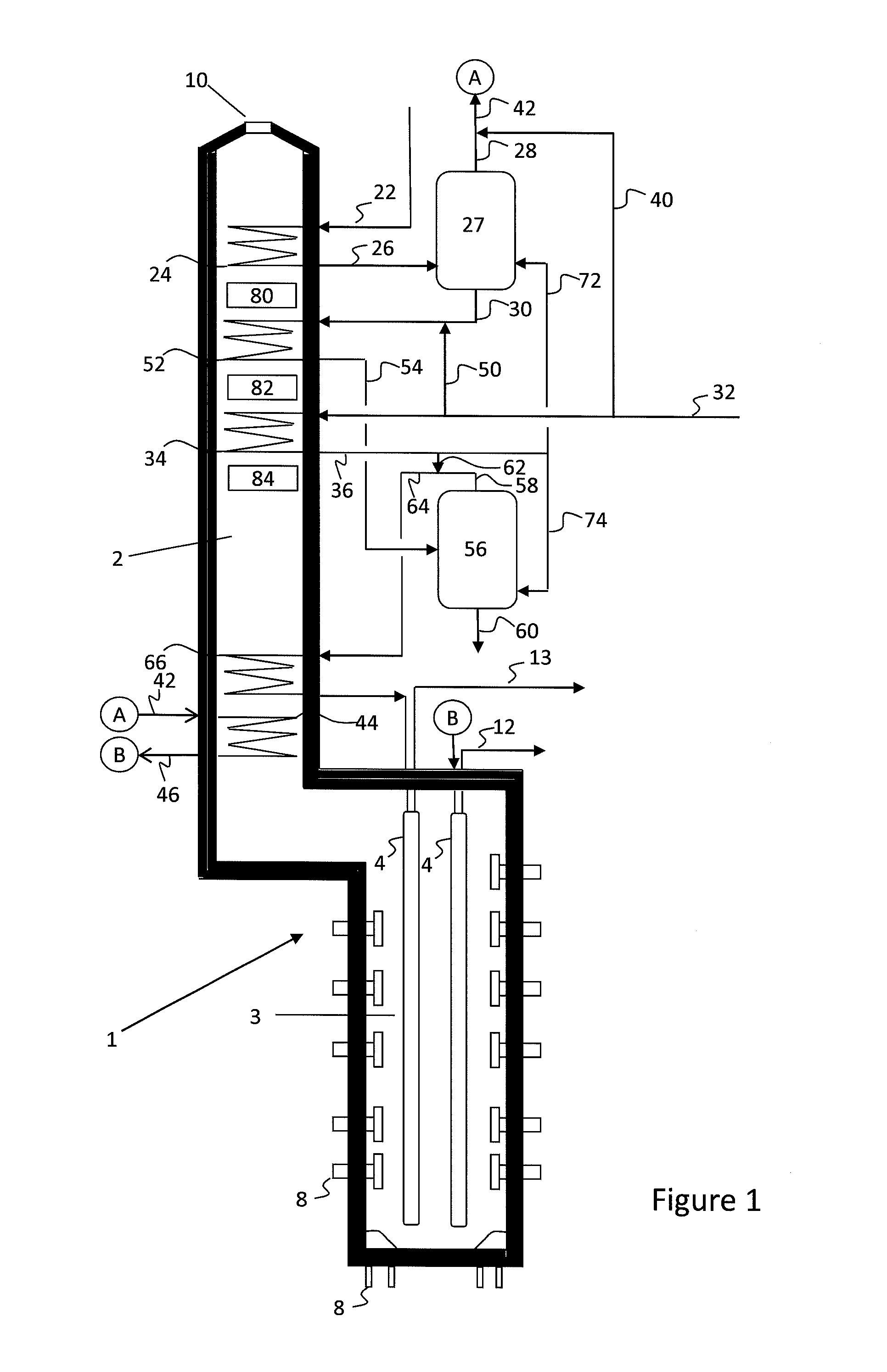

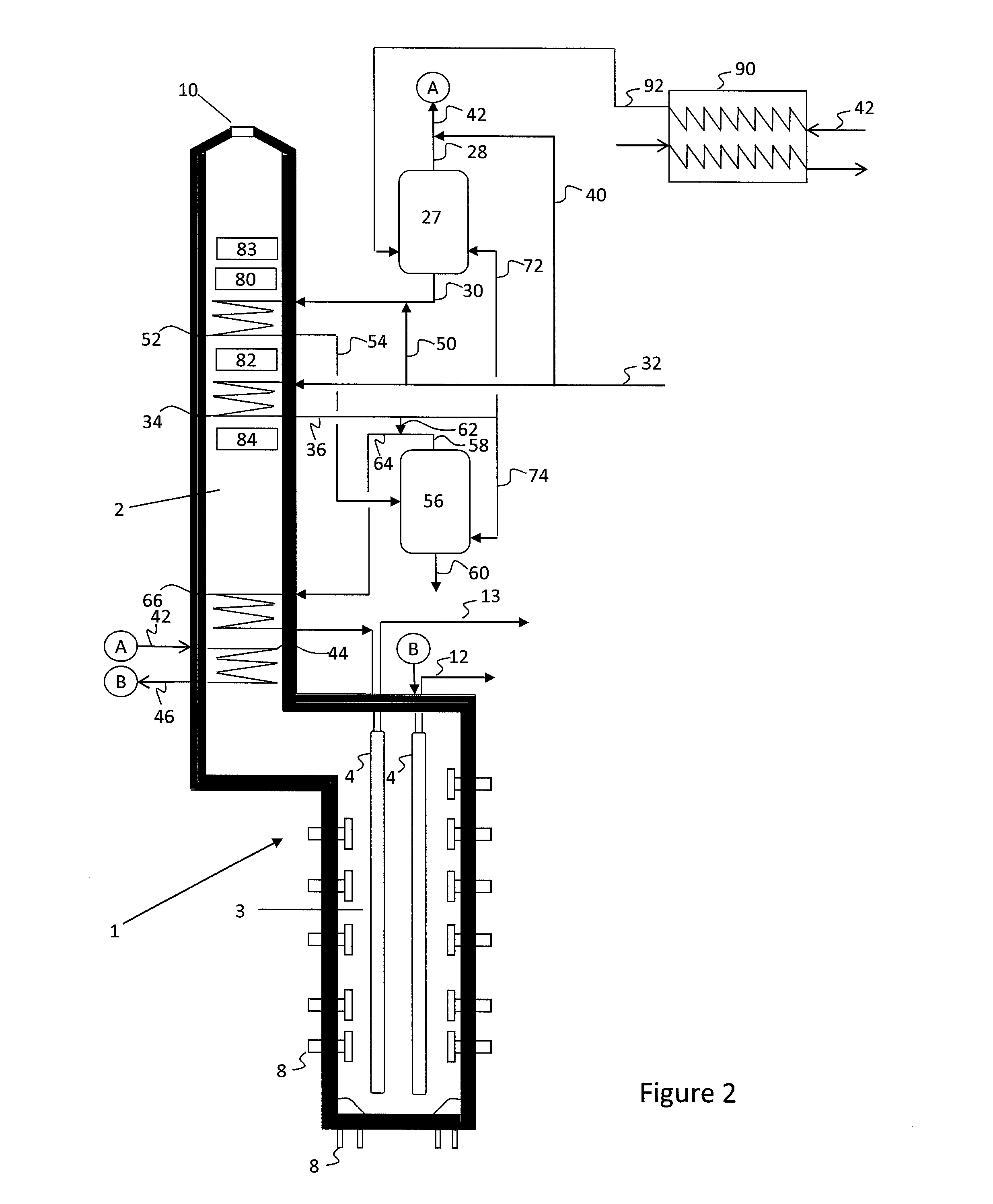

Thermal cracking of crudes and heavy feeds to produce olefins in pyrolysis reactor

ActiveUS20160097002A1Alleviate cokingReduce foulingThermal non-catalytic crackingTreatment with plural serial stages onlyHydrocarbon mixturesReactor system

Systems and processes for efficiently cracking of hydrocarbon mixtures, such as mixtures including compounds having a normal boiling temperature of greater than 450° C., 500° C., or even greater than 550° C., such as whole crudes for example, are disclosed.

Owner:LUMMUS TECH LLC

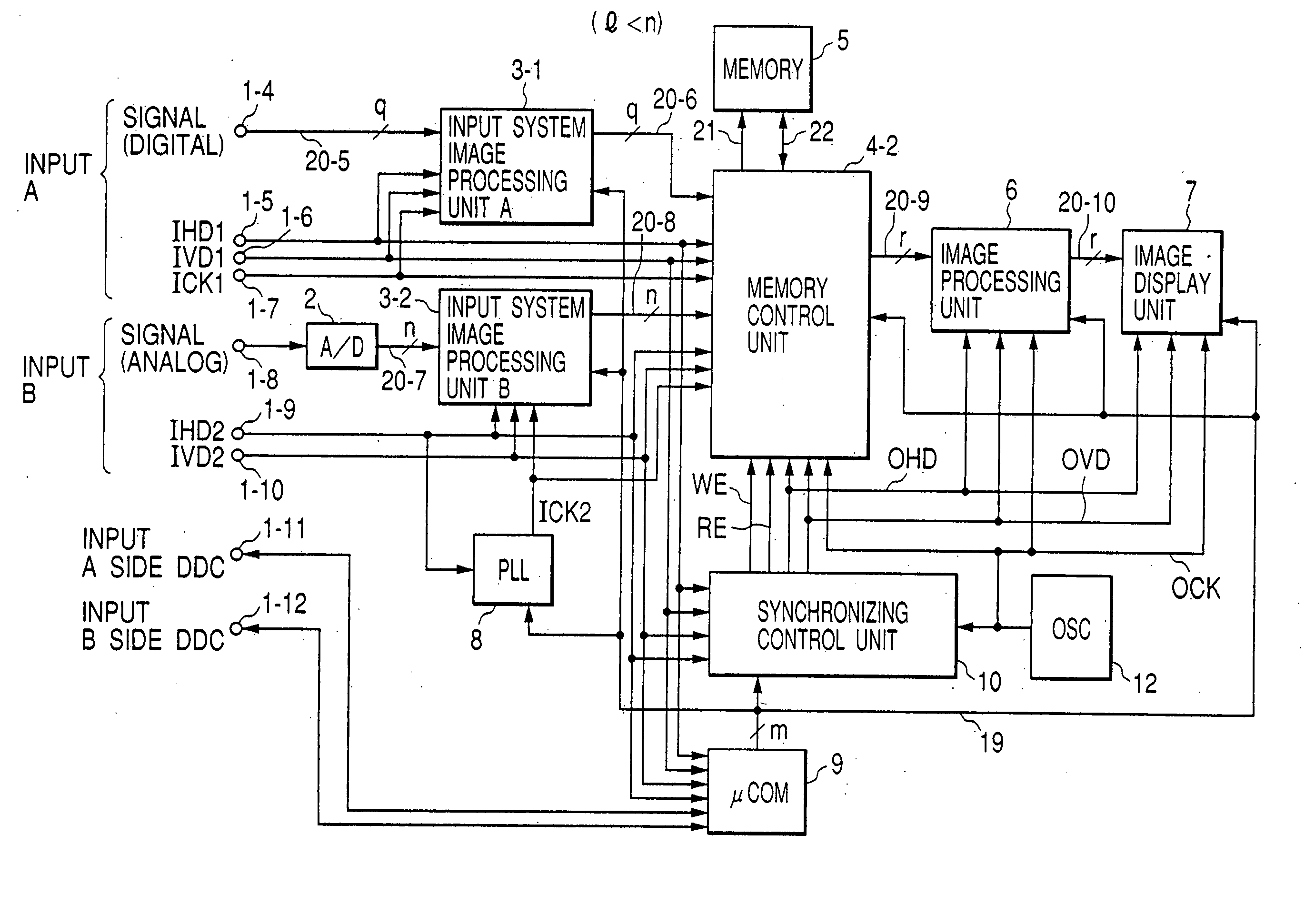

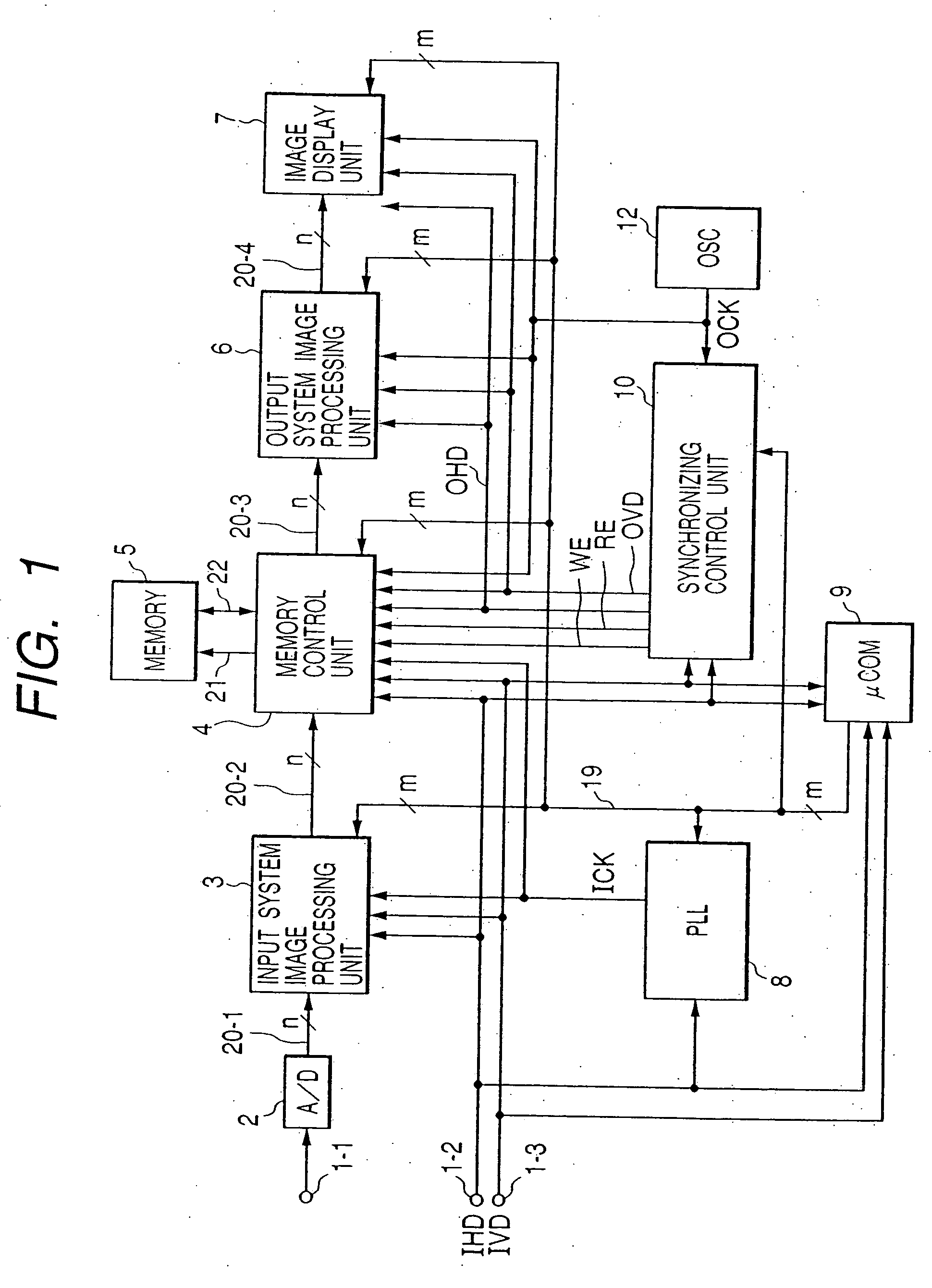

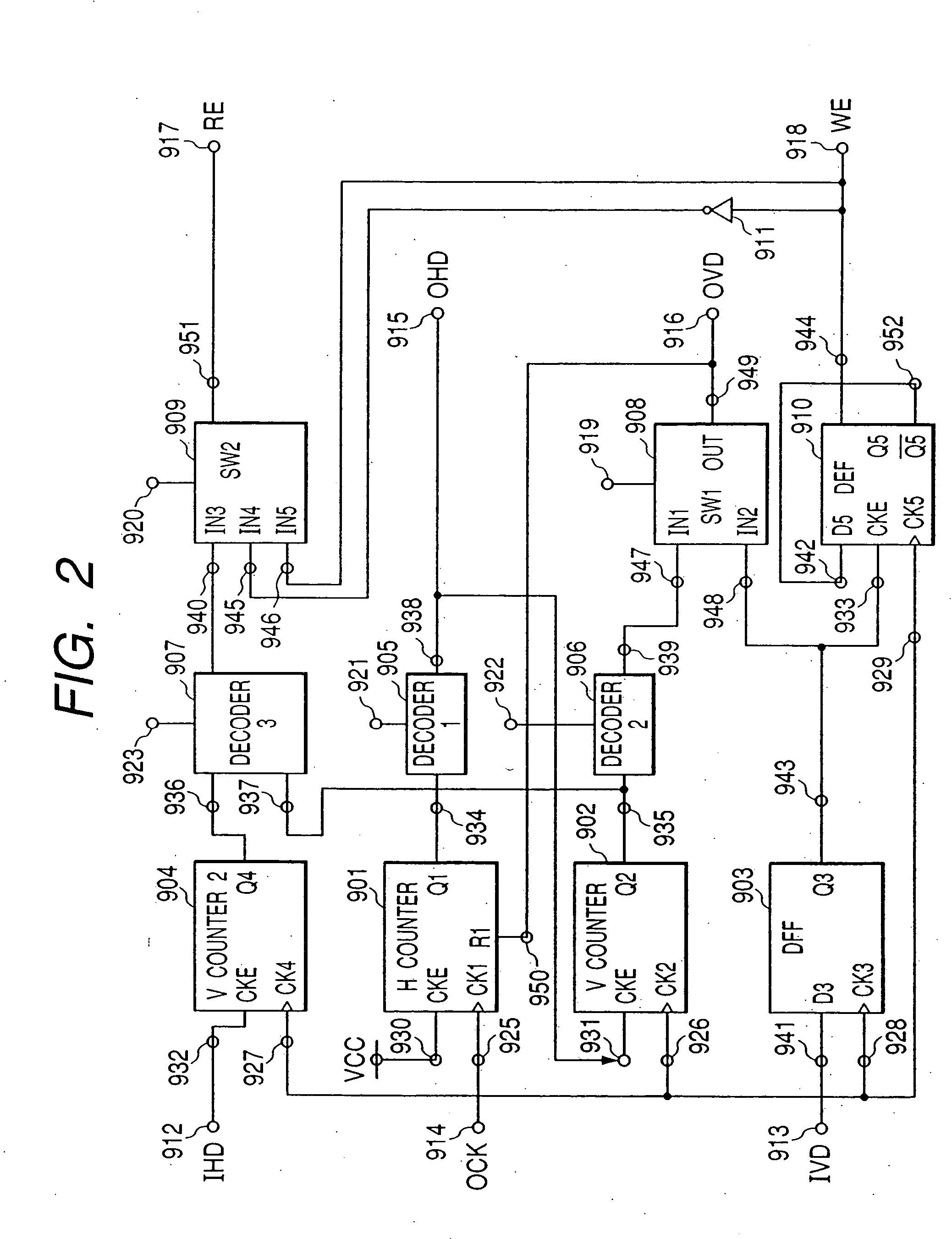

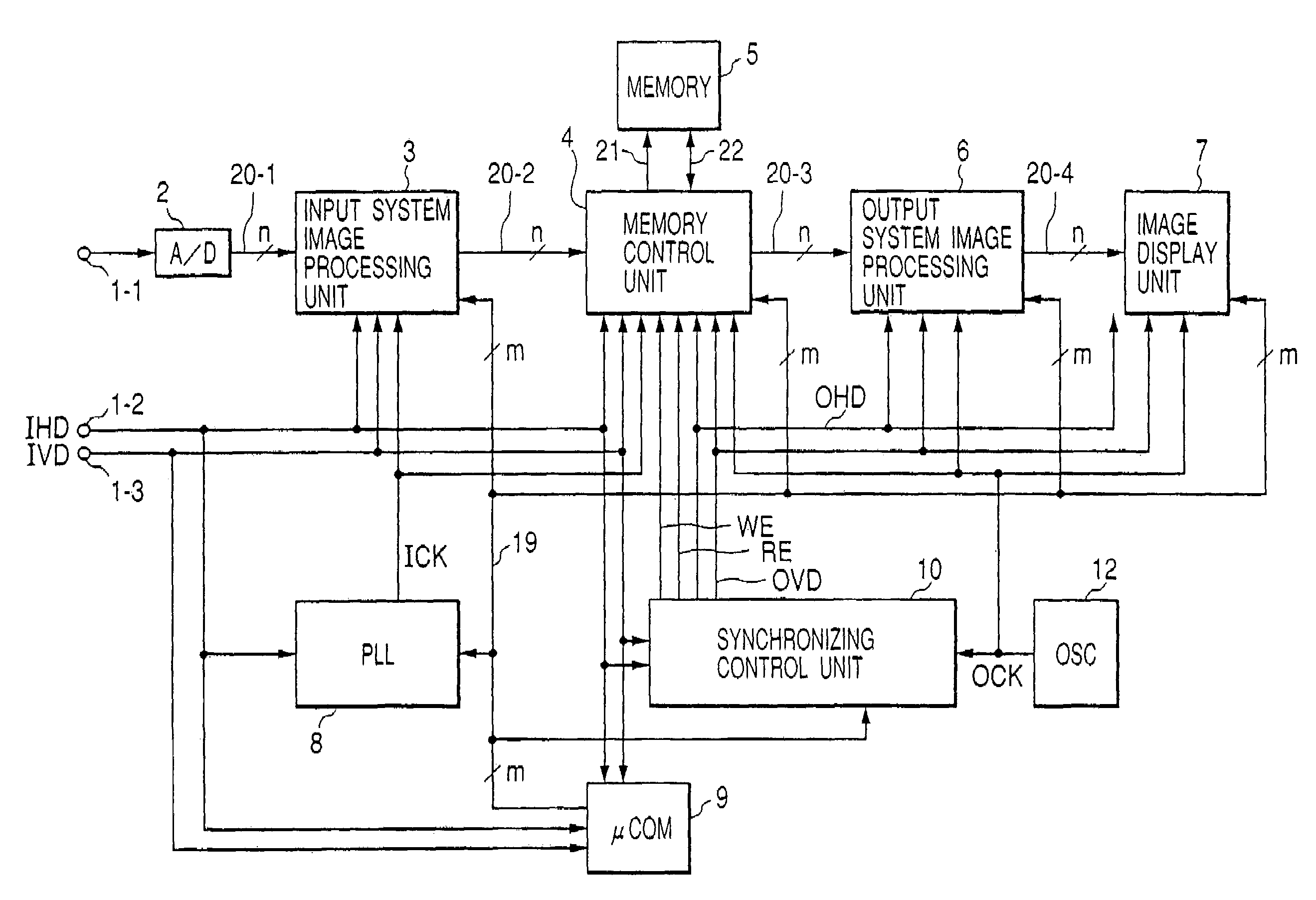

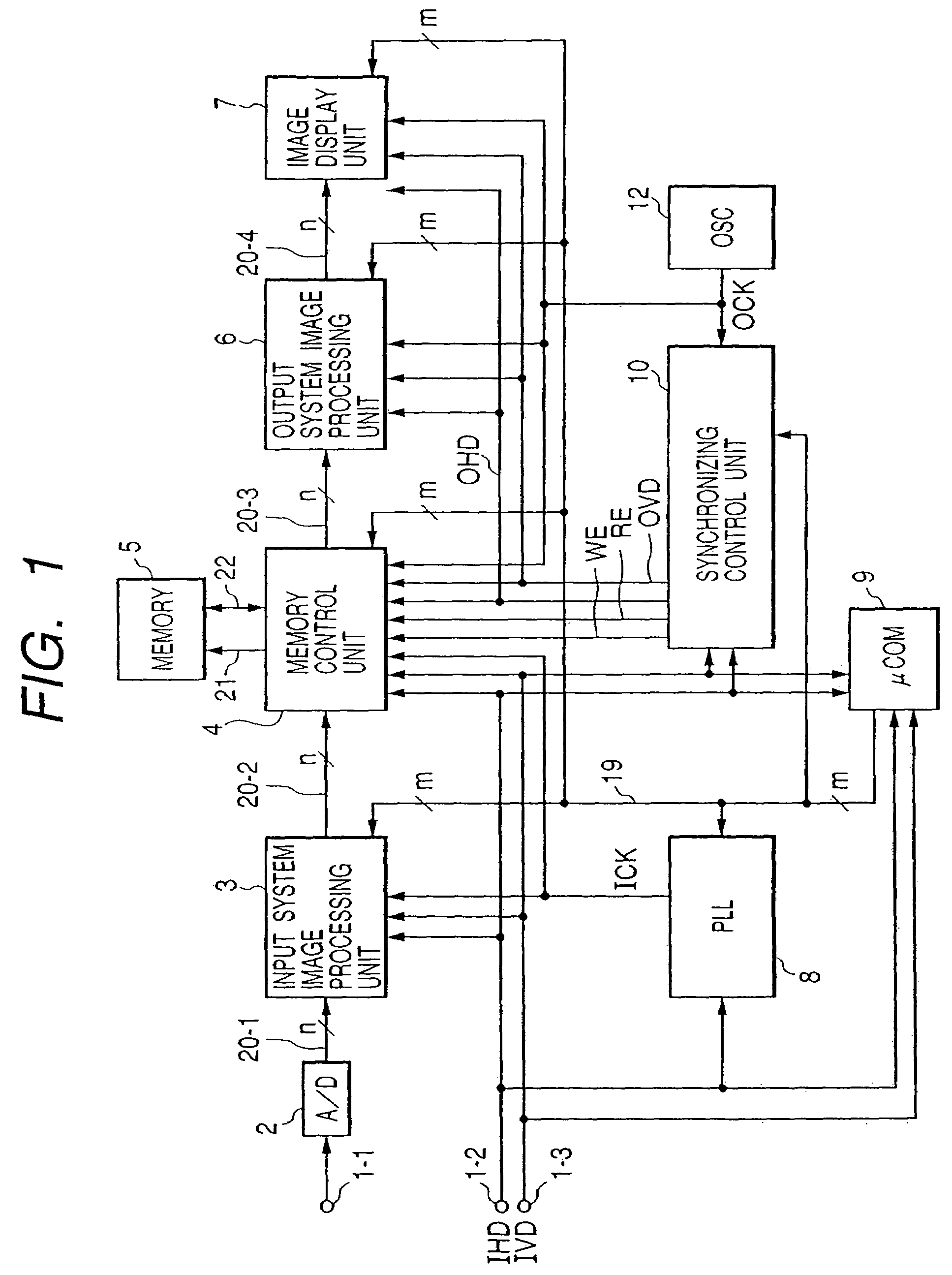

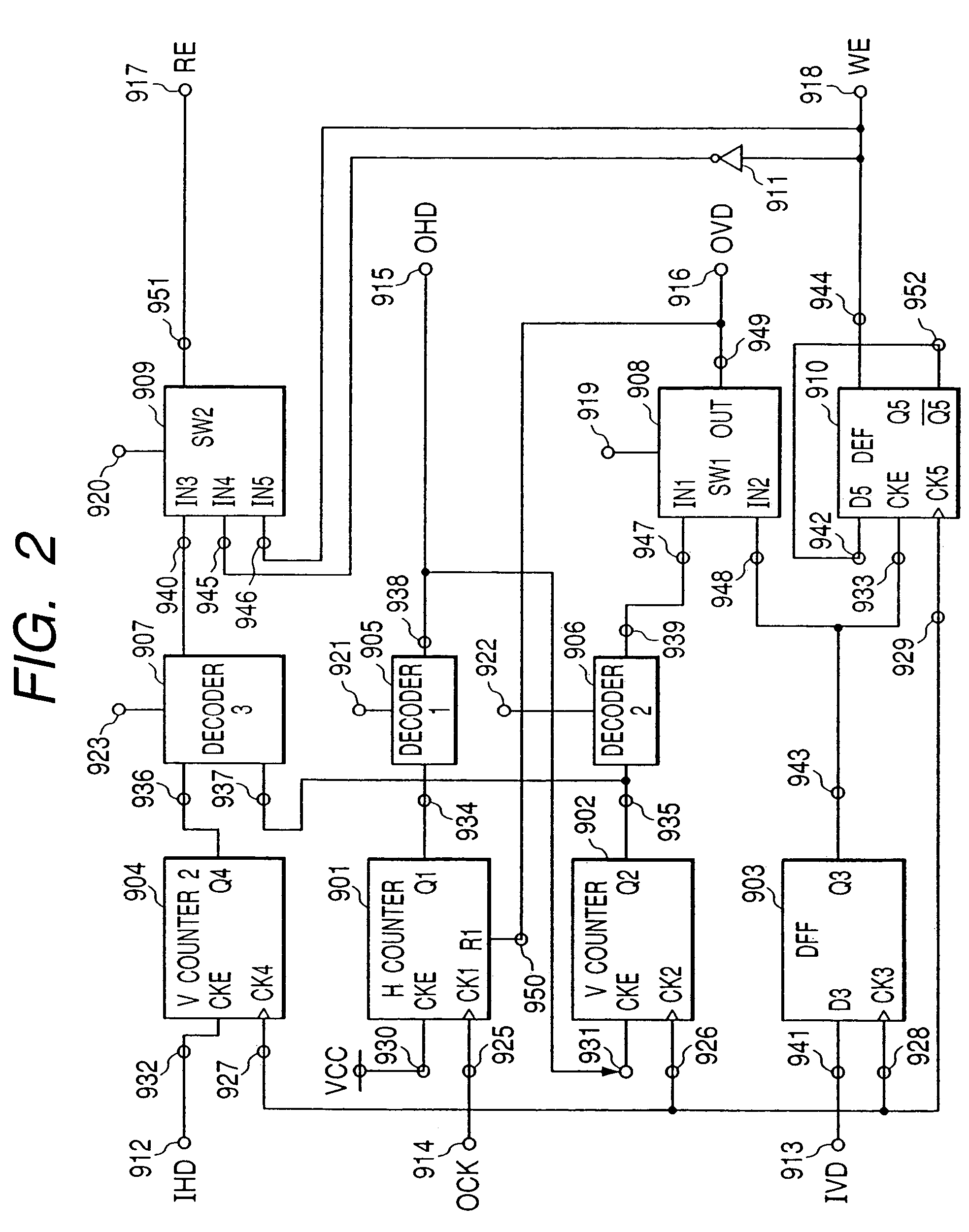

Image processing device

InactiveUS20050078101A1Simple and inexpensive circuit configurationImprove dynamic qualityTelevision system detailsHybrid switching systemsImaging qualityMultiple input

An inexpensive and simple circuit for improving the quality of a dynamic image, with appropriate, flexible dynamic image qualities processing, even with plural input signal sources. A memory unit has a region for storing images of at least one screen, and a memory control unit for writing image data to the memory unit on the basis of a first clock and a first image synchronizing signal and for outputting image data read out from the memory unit on the basis of a second clock and a second image synchronizing signal. A clock generating unit provides the second clock, and a synchronizing control unit inputs the second clock and outputs the second image synchronizing signal. The synchronizing control unit generates one signal asynchronous to the first image synchronizing signal, by dividing the second clock, and another that is and synchronized with the first synchronizing signal, by using the second clock, and selects one of the signals it has produced to be output as the second image synchronizing signal. In a case of multiple input signals, then such fourth image synchronizing signals equal in number to the input signals are produced.

Owner:CANON KK

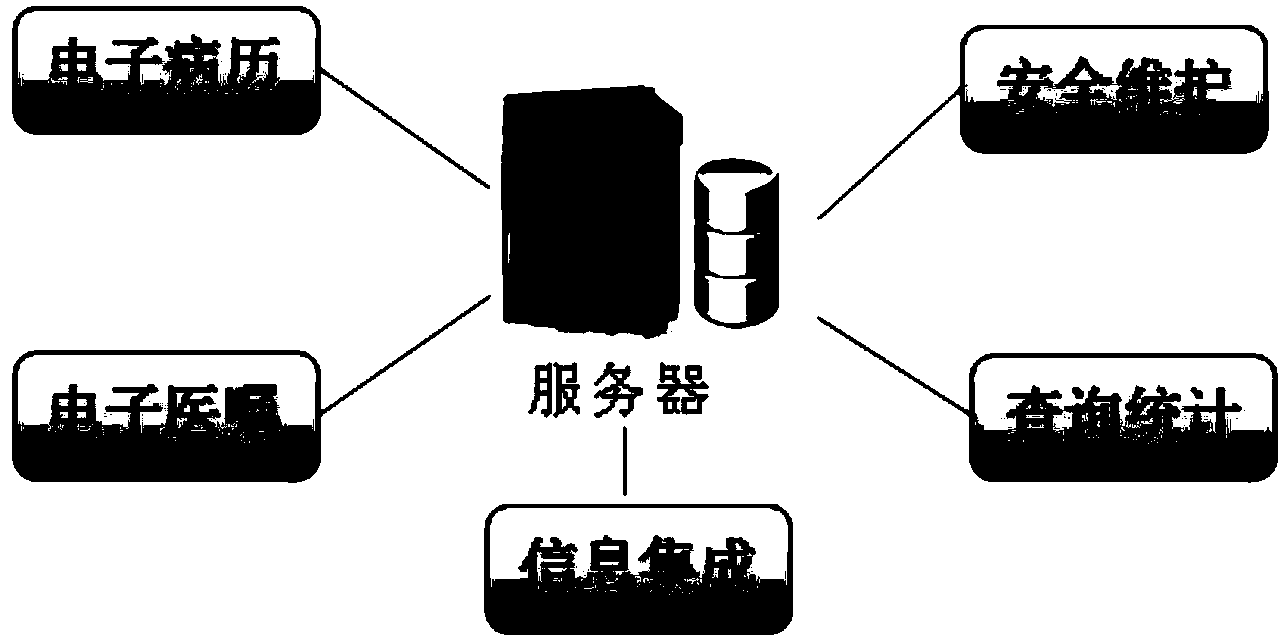

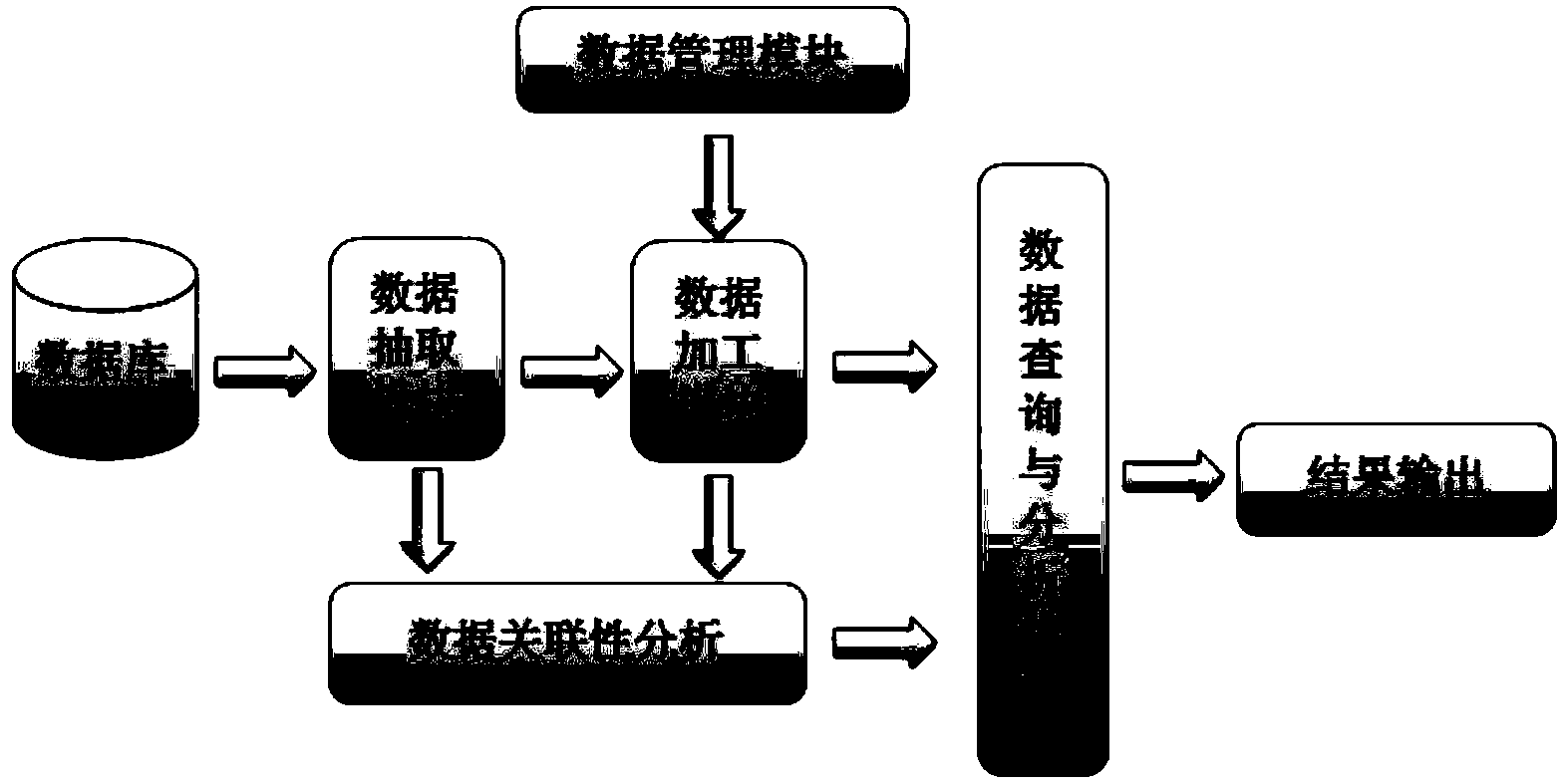

Emergency treatment electronic medical record system and information processing method thereof

InactiveCN103617343AQuick buildQuick releaseSpecial data processing applicationsInformation processingMedical record

The invention discloses an emergency treatment electronic medical record system and an information processing method thereof. The emergency treatment electronic medical record system comprises a server, an electronic medical record module, an electronic medical advice module, a safety maintenance module, an information integrating module and an inquiry counting module. By building, saving and calling templates, an electronic medical record can be built fast, electronic medical advices can be given fast, an inspection sheet, an check list and a prescription list can be prescribed, the characteristics of emergency treatment is adapted to, precious time can be saved for emergency rescuing, medical record input speed can be increased evidently, and prescriptions can be generated automatically according to the medical advices.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY +1

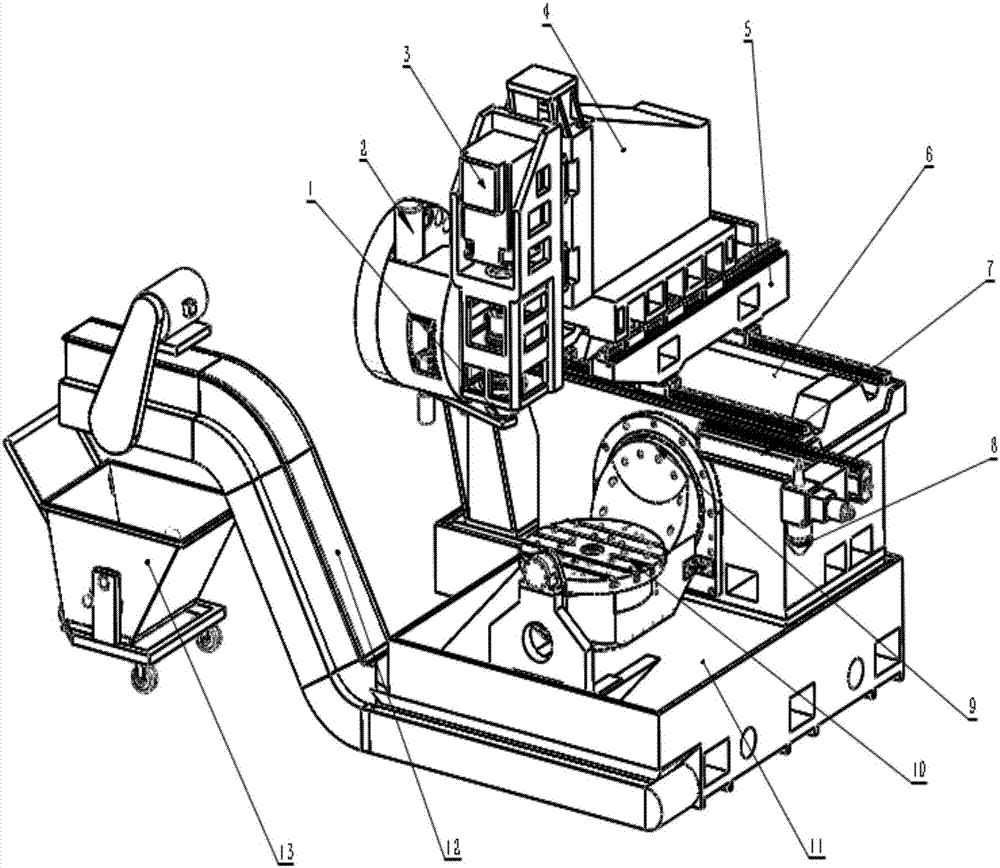

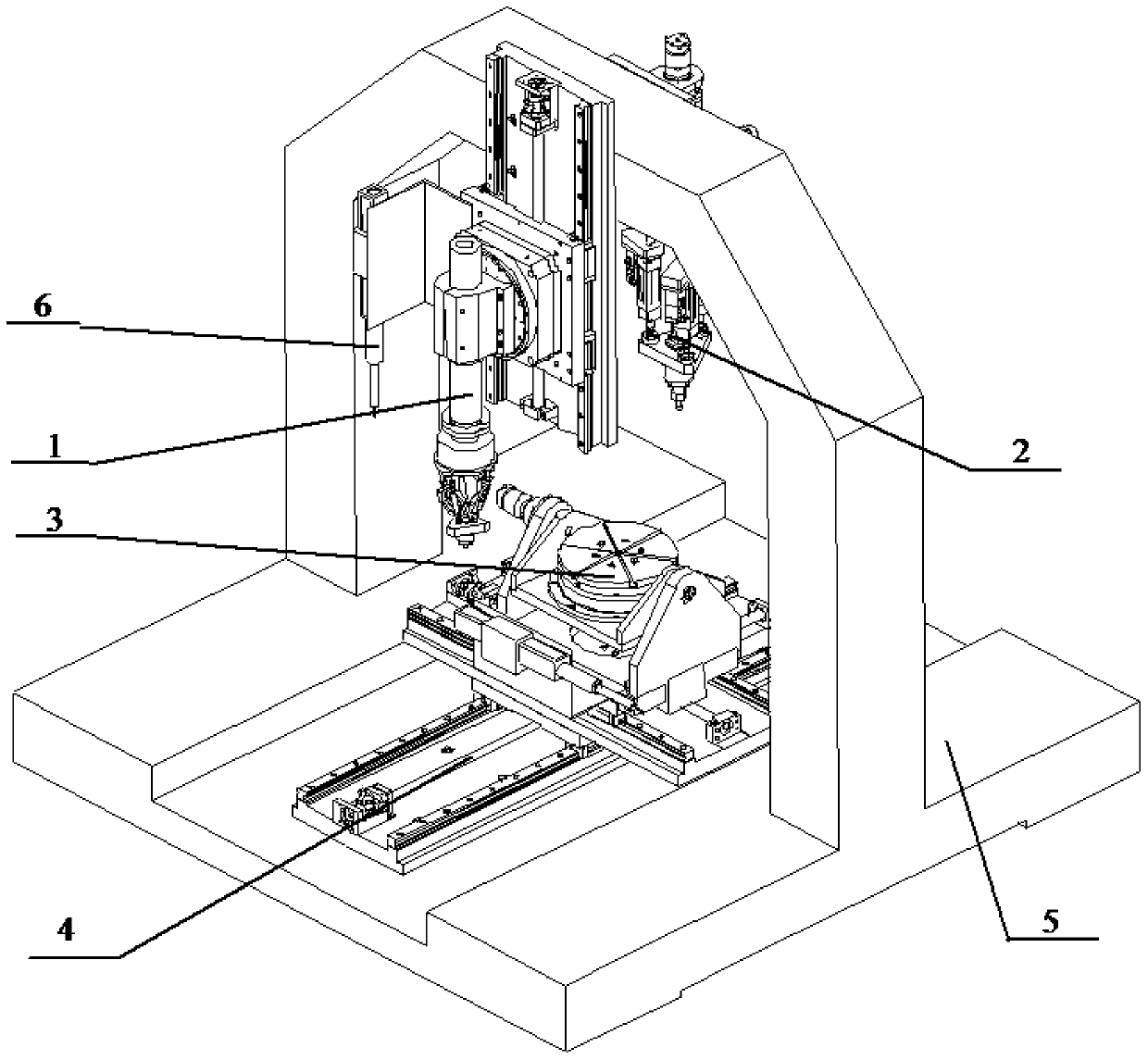

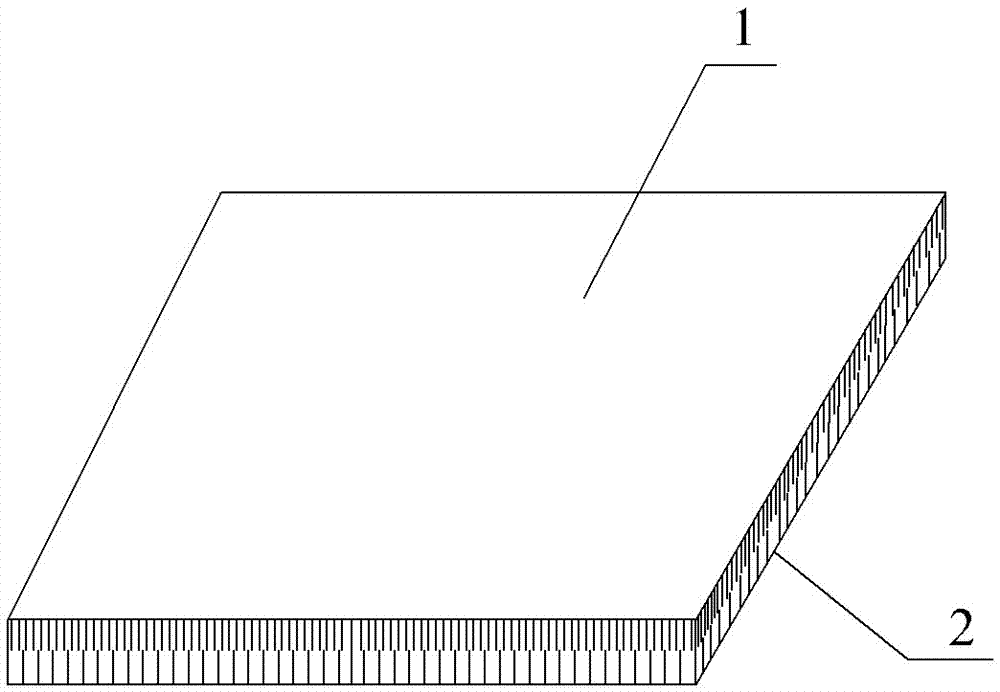

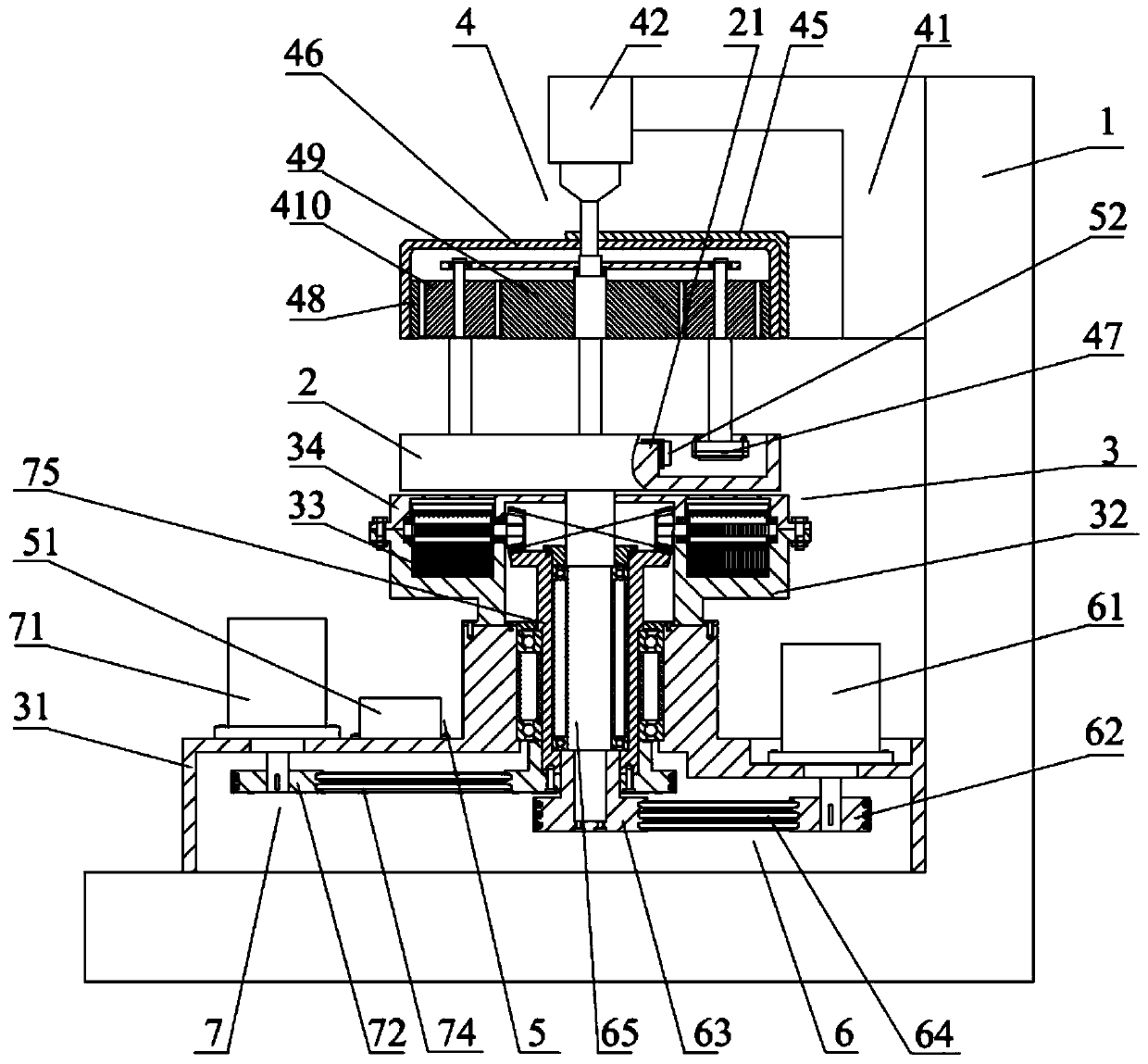

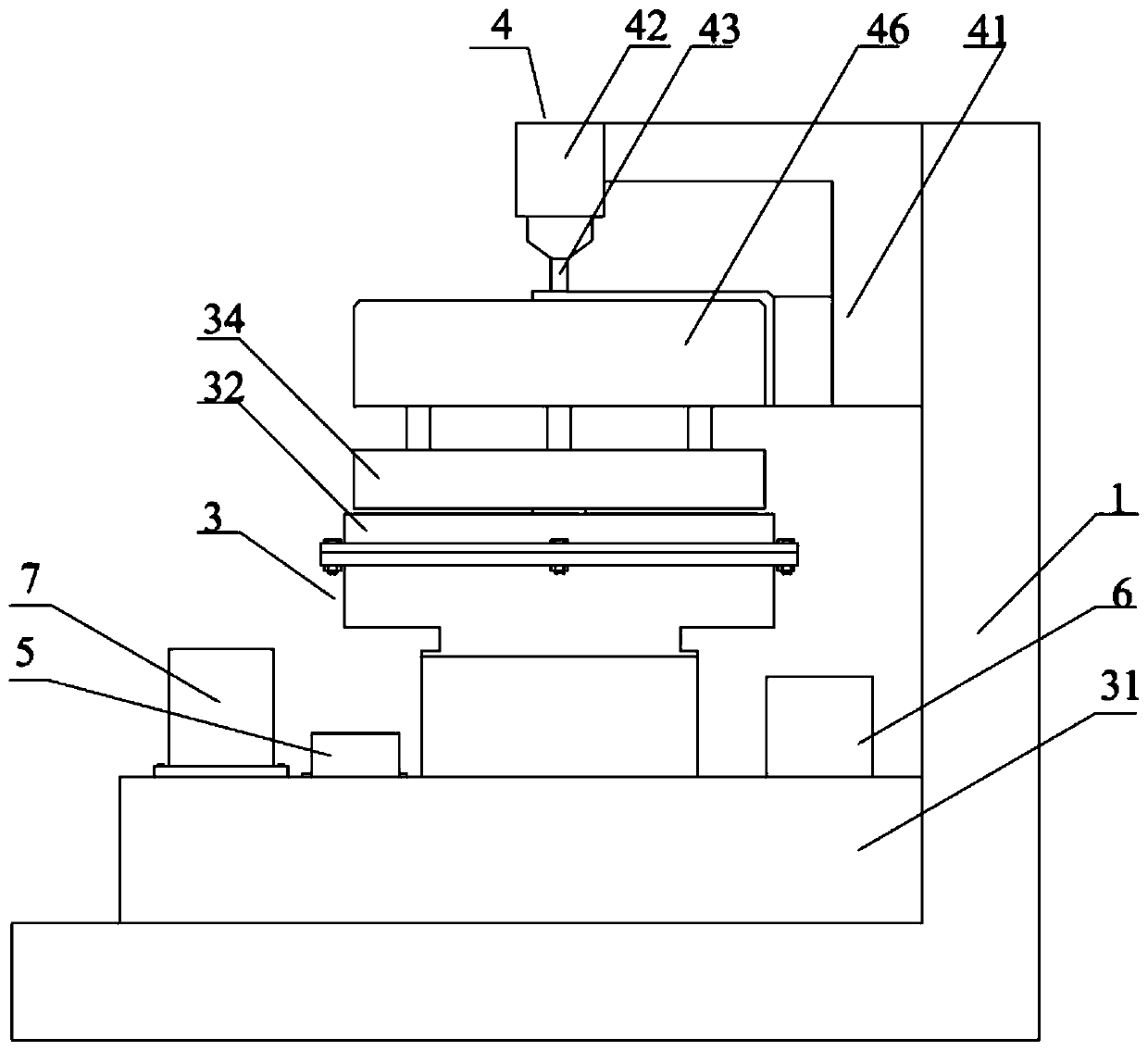

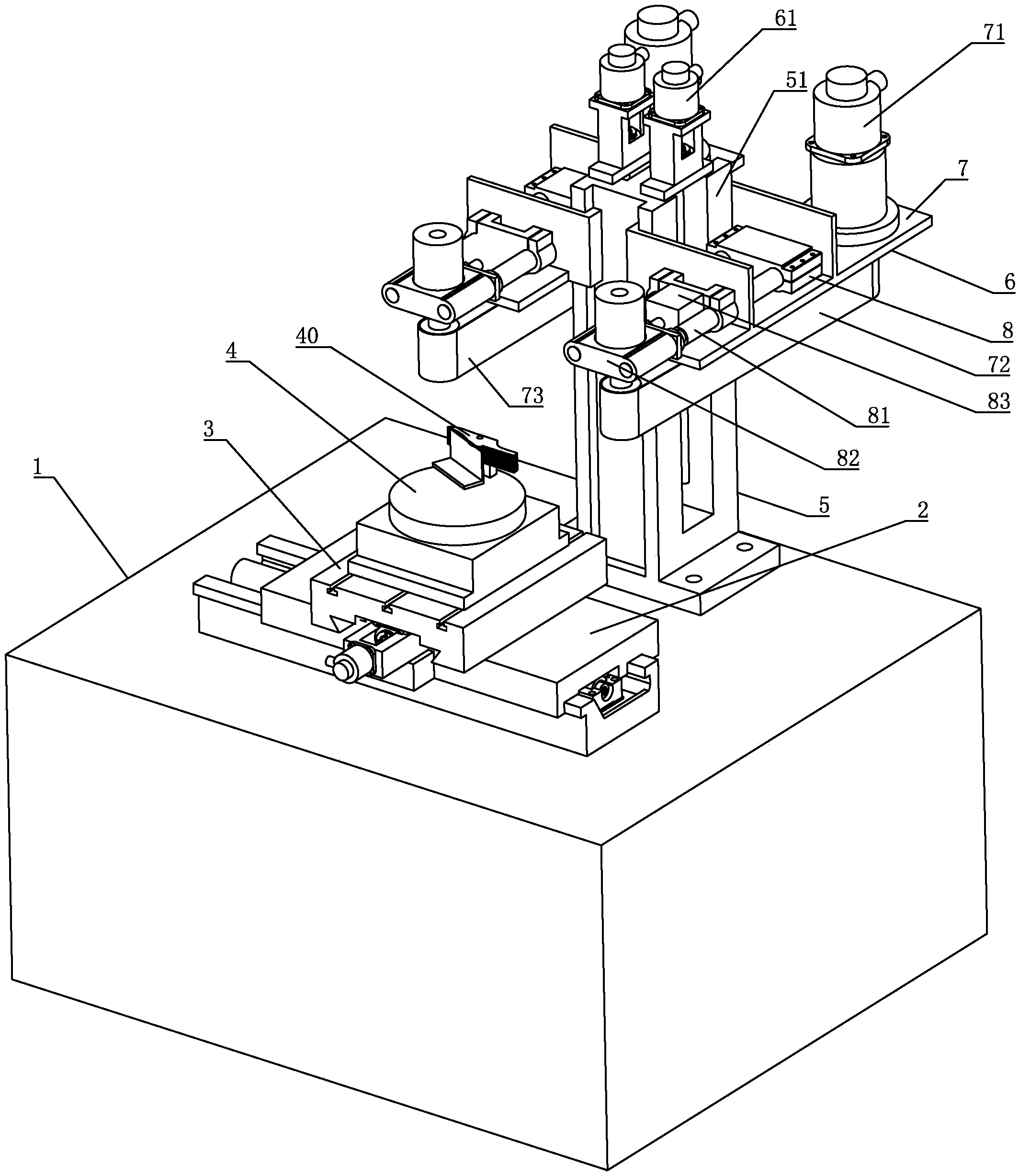

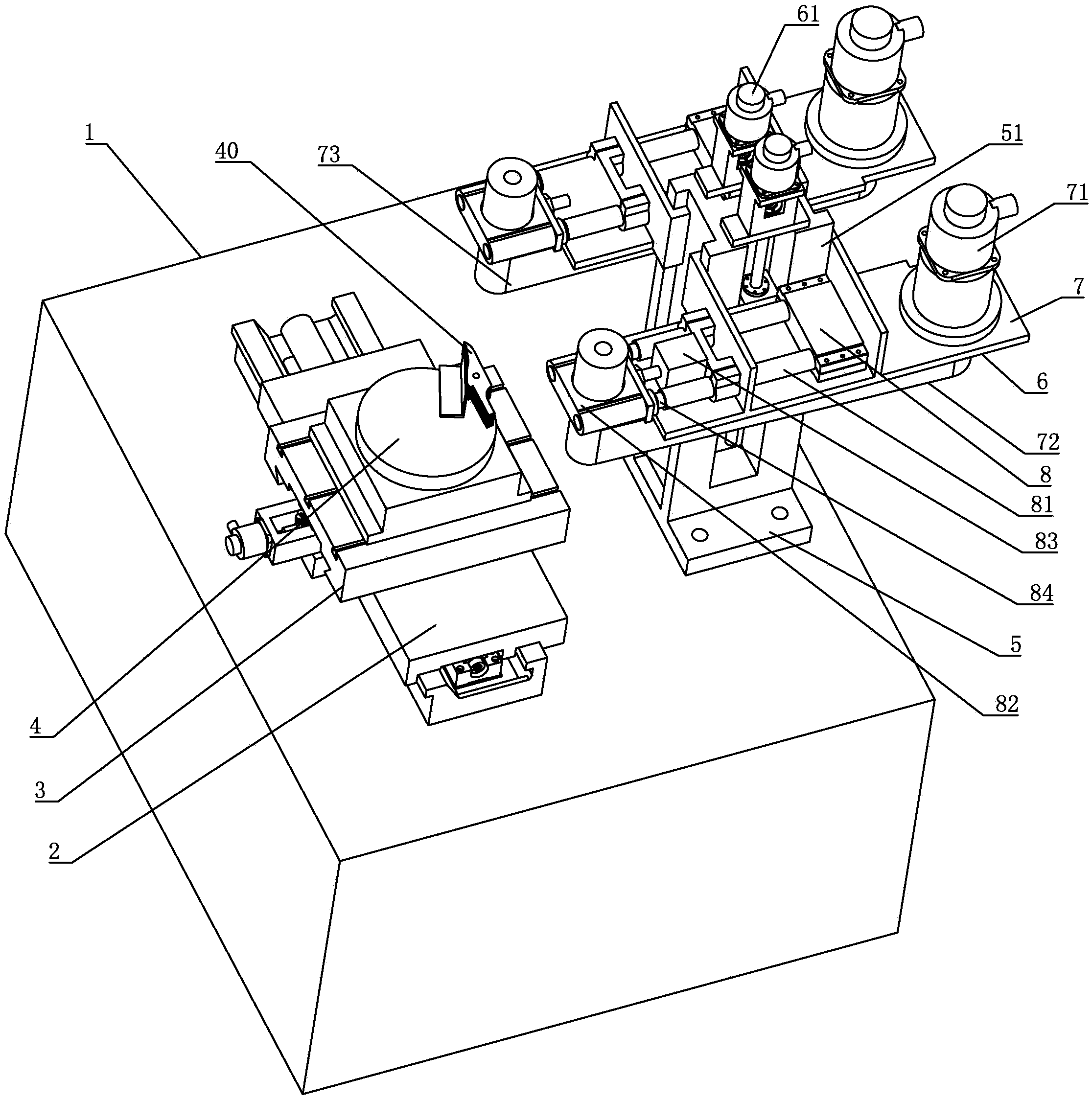

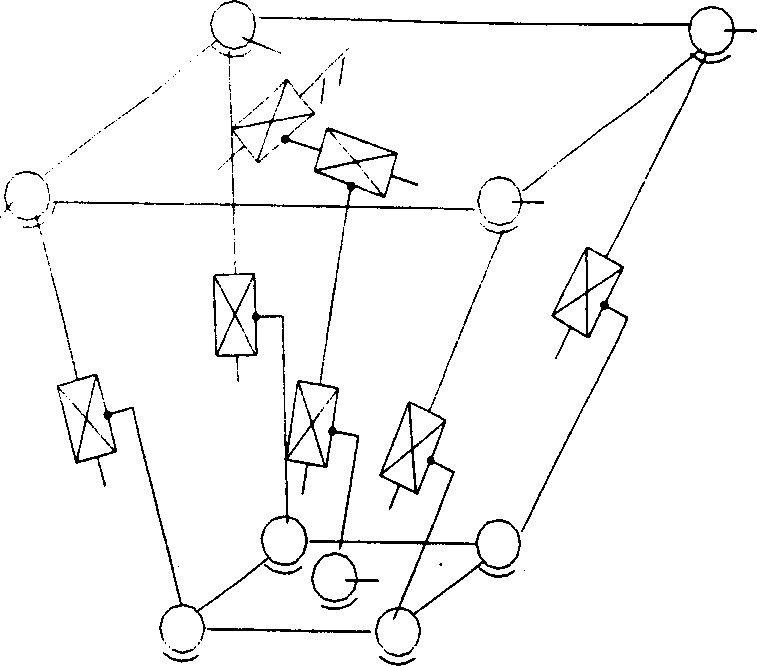

Addition and reduction material composite machining center

ActiveCN107336023ASmall error in positionFlexible processingIncreasing energy efficiencyOther manufacturing equipments/toolsStructural engineeringMachining

The invention discloses an addition and reduction material composite machining center which comprises a five-axis reduction material machining center and a laser addition material printing device. The five-axis reduction material machining center comprises a base, a bed body arranged on the rear portion on the top face of the base, a saddle erected on the bed body through a guide rail, a sliding pillow erected on the saddle through the guide rail, a main shaft box erected on the front side of the sliding pillow through the guide rail, a main shaft arranged in the main shaft box, and a tool magazine arranged on the left side face of the main shaft box. A clamping table is arranged between the front side of the bed body and the portion above the base. The clamping table is provided with a revolution shaft C. The clamping table is movably connected with the front side face of the bed body through a revolution shaft B. The laser addition material printing device comprises a laser printing head movably erected on the bed body. The laser printing head is connected with the bed body through an installing module which can be controlled to move and controlled to be disassembled. A clamping handle matched with the main shaft is arranged on the top of the laser printing head. Dual use of one machine is achieved, the space coordinate system of one position degree is shared, errors of the position degree are small, machining is flexible, machining quality is good, and efficiency is high.

Owner:HAIXI (FUJIAN) INST CHINA ACAD OF MASCH SCI&TECH GRP

Image processing device

InactiveUS7079129B2Simple and inexpensive circuit configurationImprove dynamic qualityTelevision system detailsHybrid switching systemsImaging qualityMultiple input

An inexpensive and simple circuit for improving the quality of a dynamic image, with appropriate, flexible dynamic image qualities processing, even with plural input signal sources. A memory unit has a region for storing images of at least one screen, and a memory control unit for writing image data to the memory unit on the basis of a first clock and a first image synchronizing signal and for outputting image data read out from the memory unit on the basis of a second clock and a second image synchronizing signal. A clock generating unit provides the second clock, and a synchronizing control unit inputs the second clock and outputs the second image synchronizing signal. The synchronizing control unit generates one signal asynchronous to the first image synchronizing signal, by dividing the second clock, and another that is and synchronized with the first synchronizing signal, by using the second clock, and selects one of the signals it has produced to be output as the second image synchronizing signal. In a case of multiple input signals, then such fourth image synchronizing signals equal in number to the input signals are produced.

Owner:CANON KK

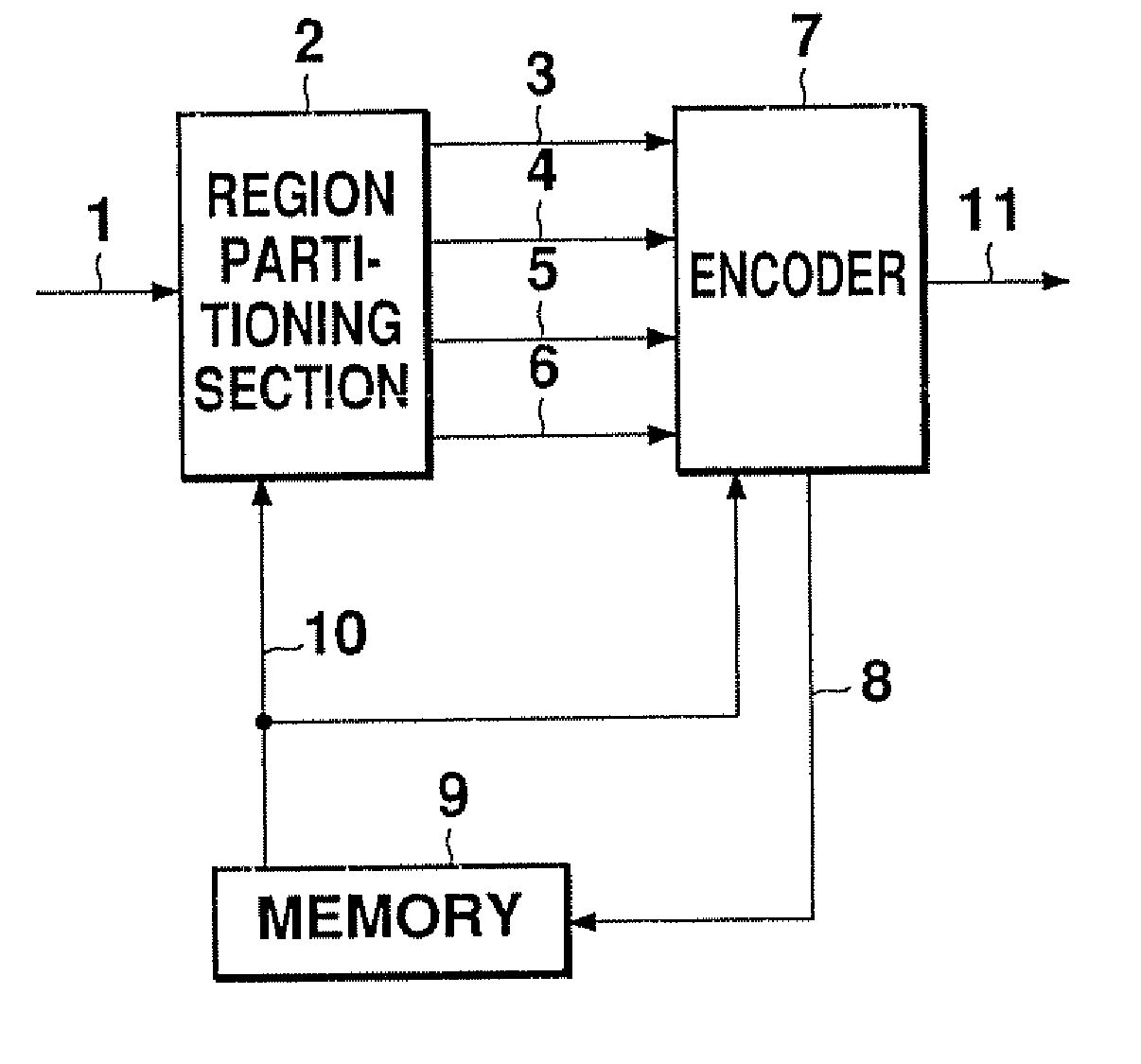

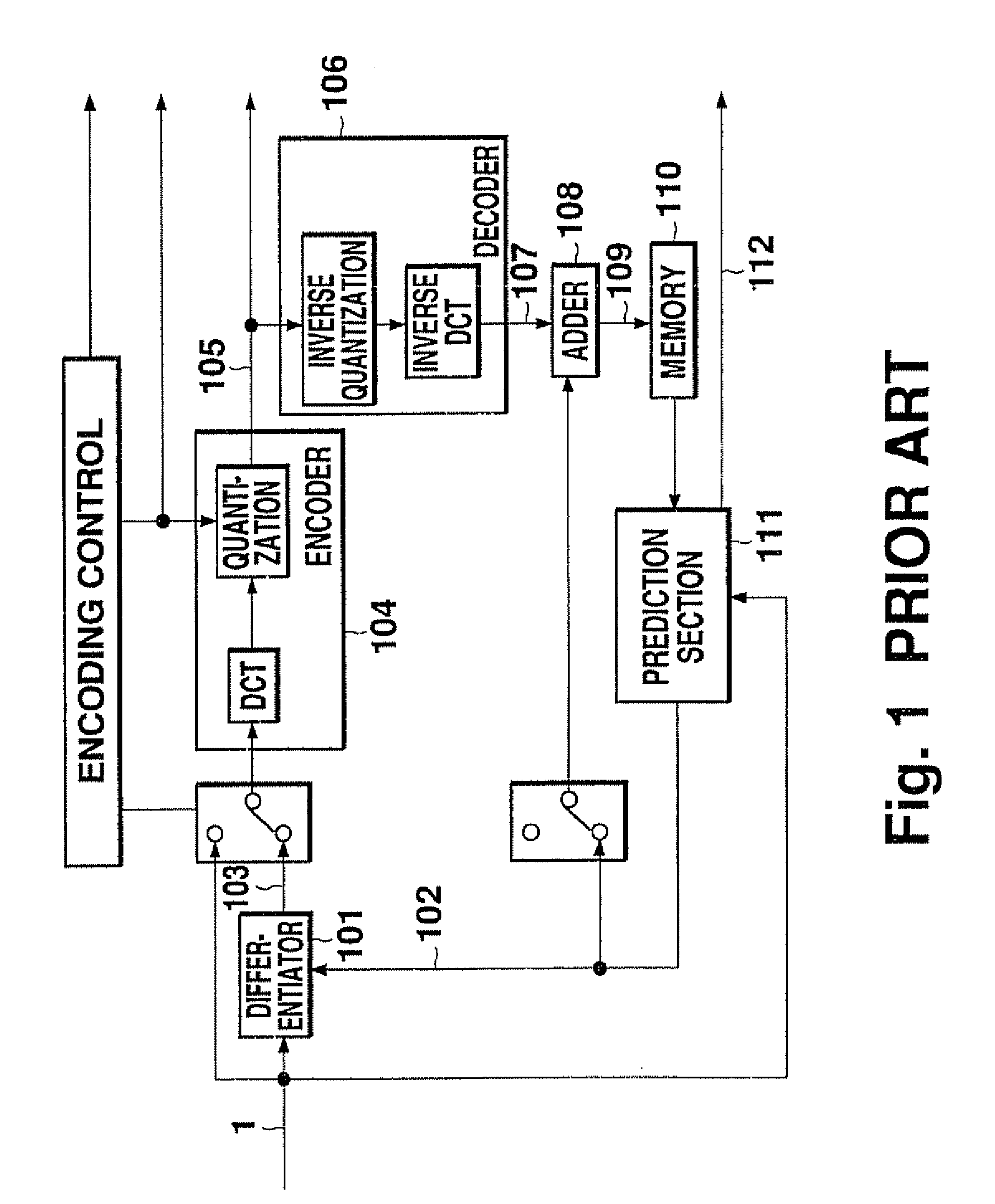

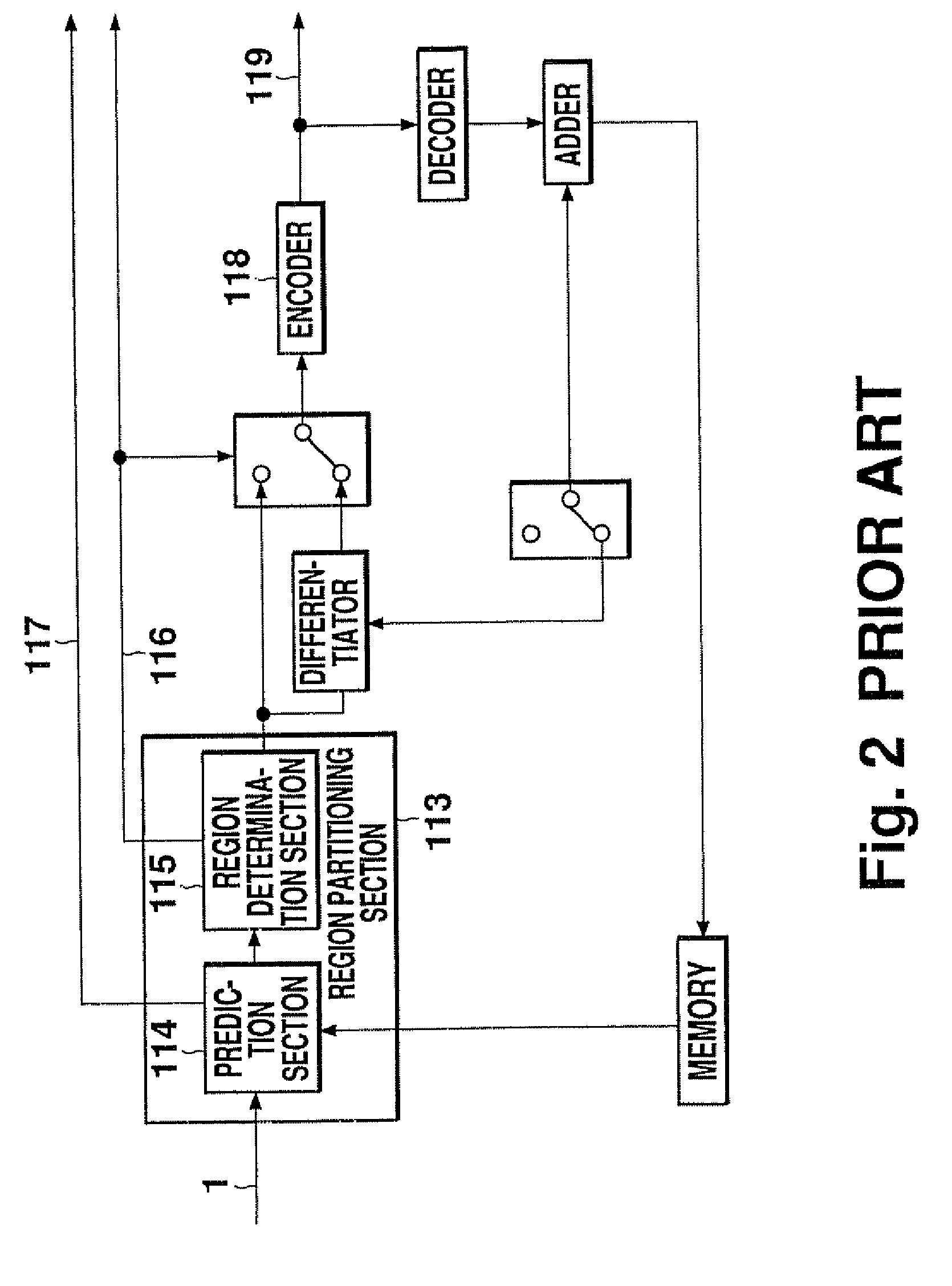

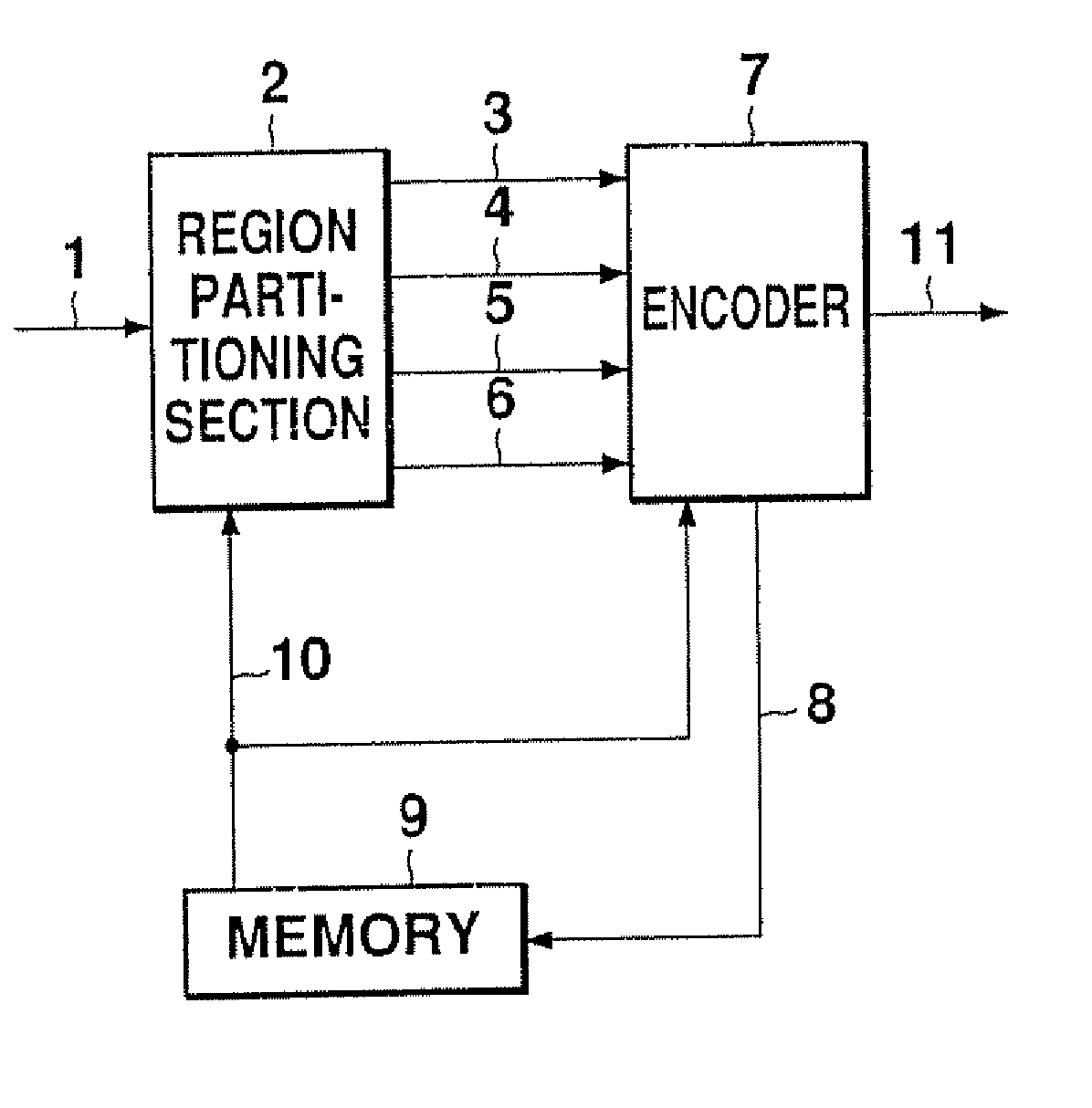

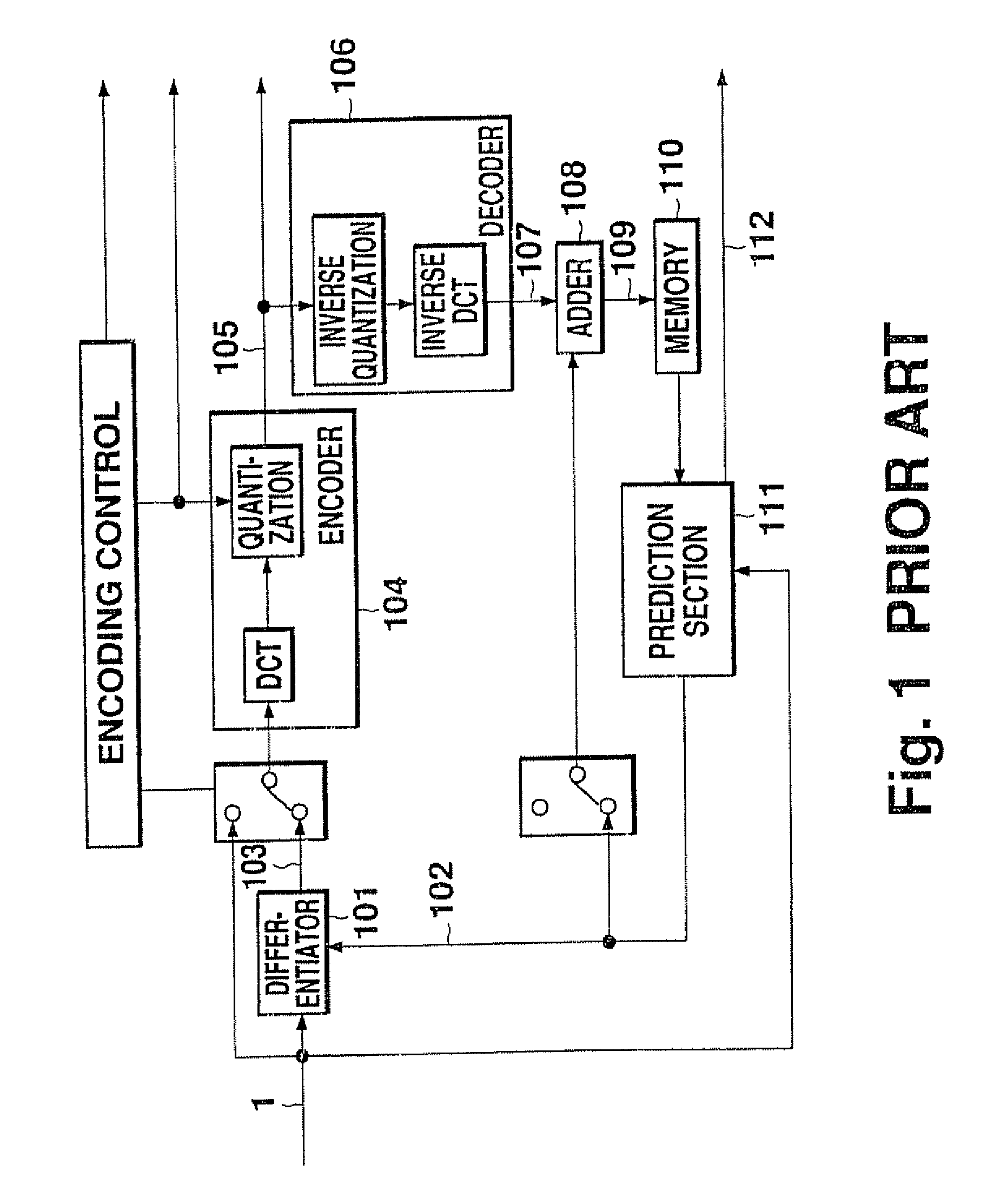

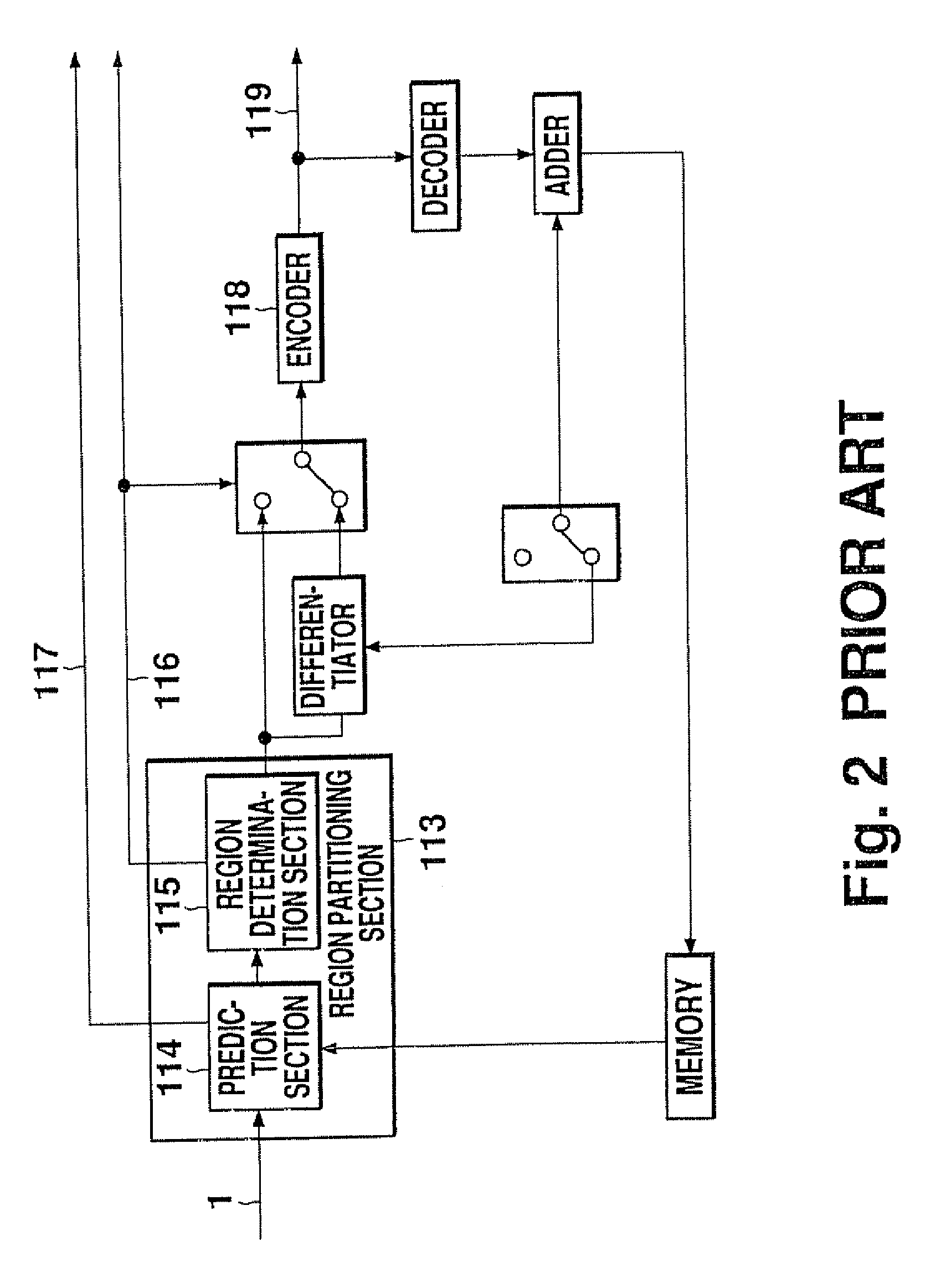

Method and apparatus for region-based moving image encoding and decoding

InactiveUS20070263727A1Accurate processingFlexible processingPulse modulation television signal transmissionPicture reproducers using cathode ray tubesImage segmentationDegrees of freedom

In partitioning and encoding an image into multiple regions, the degree of freedom of the region shape has generally been low and setting regions based on image features was difficult. A moving image encoding apparatus includes a region partitioning section, an encoder, and a memory for motion-compensated prediction. The region partitioning section includes a partitioning processing section and a integration processing section. The partitioning processing section partitions the input image based on a criterion relating to the state of partition. The integration processing section integrates mutually close regions based on a criterion relating to the state of integration. Thereafter, each region is encoded. A large variety of region shapes can be produced by the integration processing section.

Owner:SEKIGUCHI SHUNICHI +2

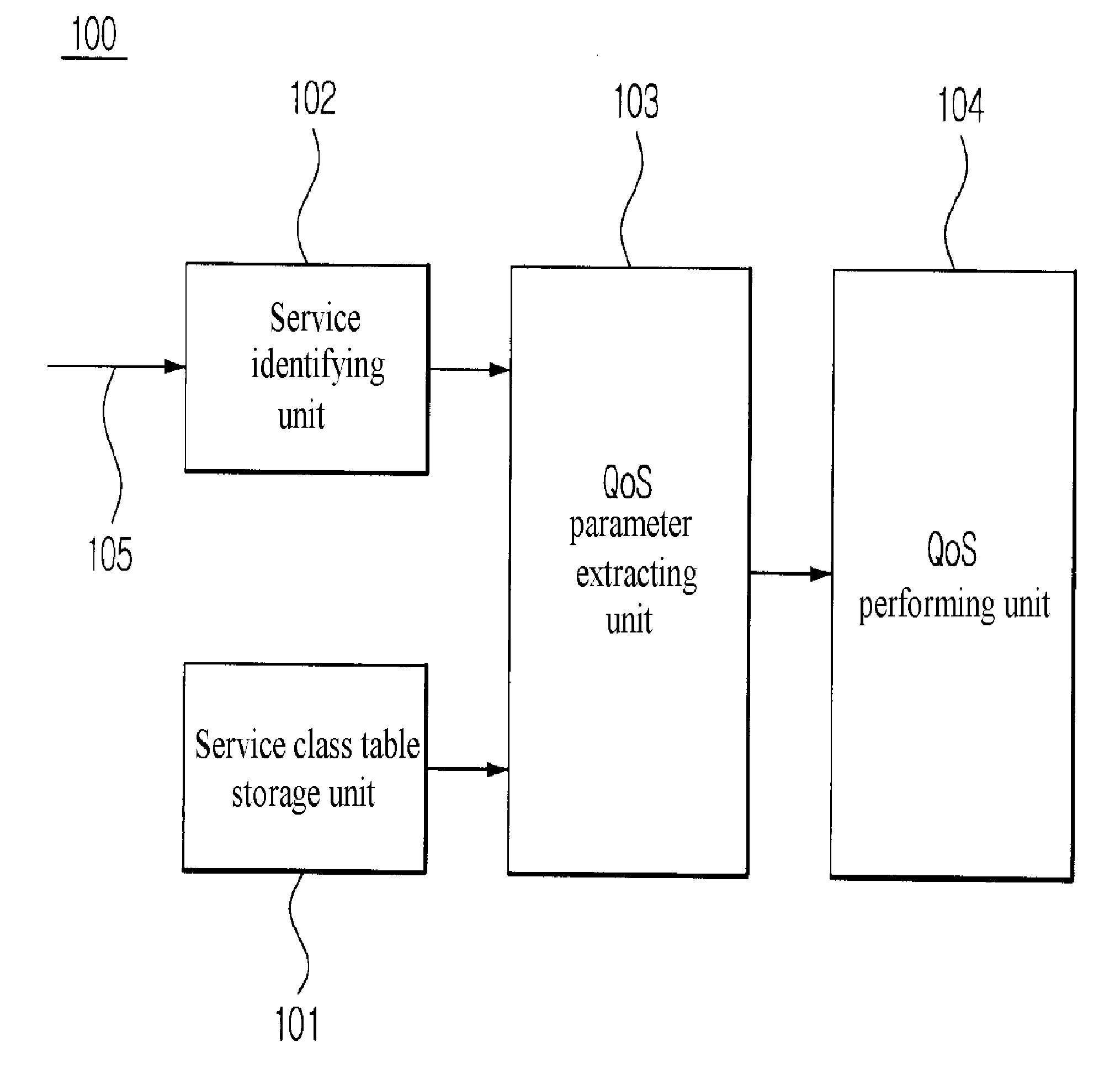

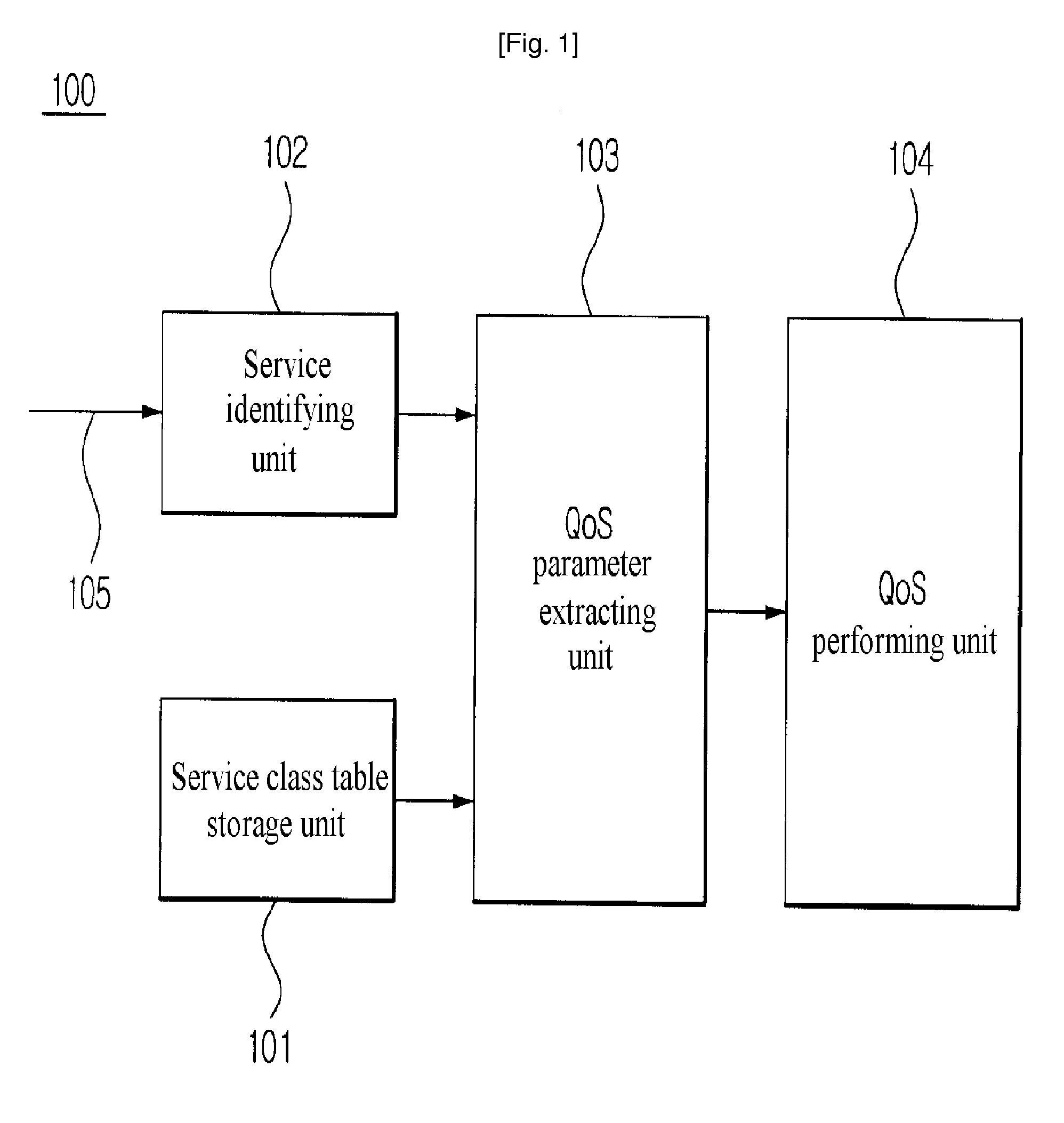

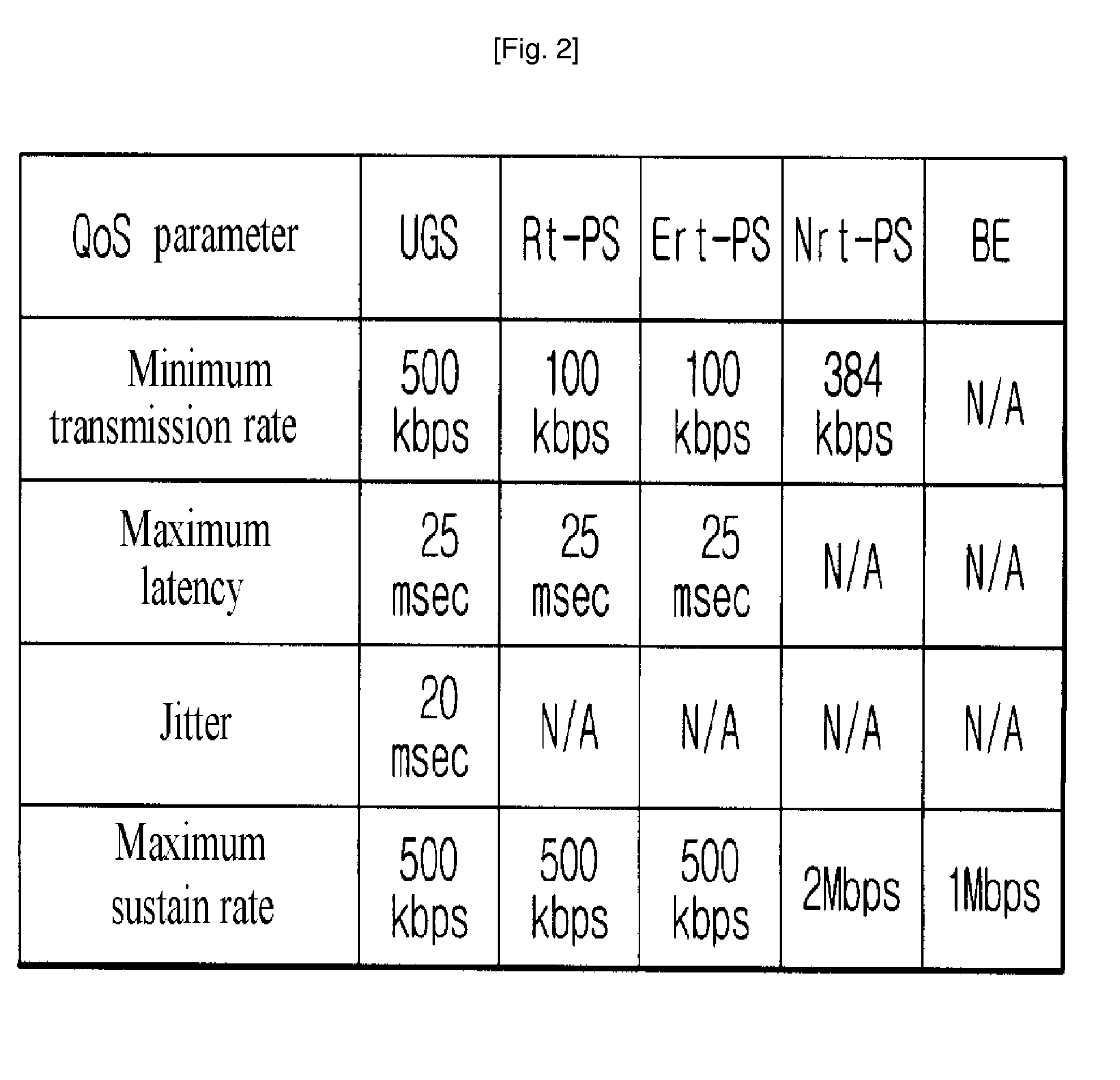

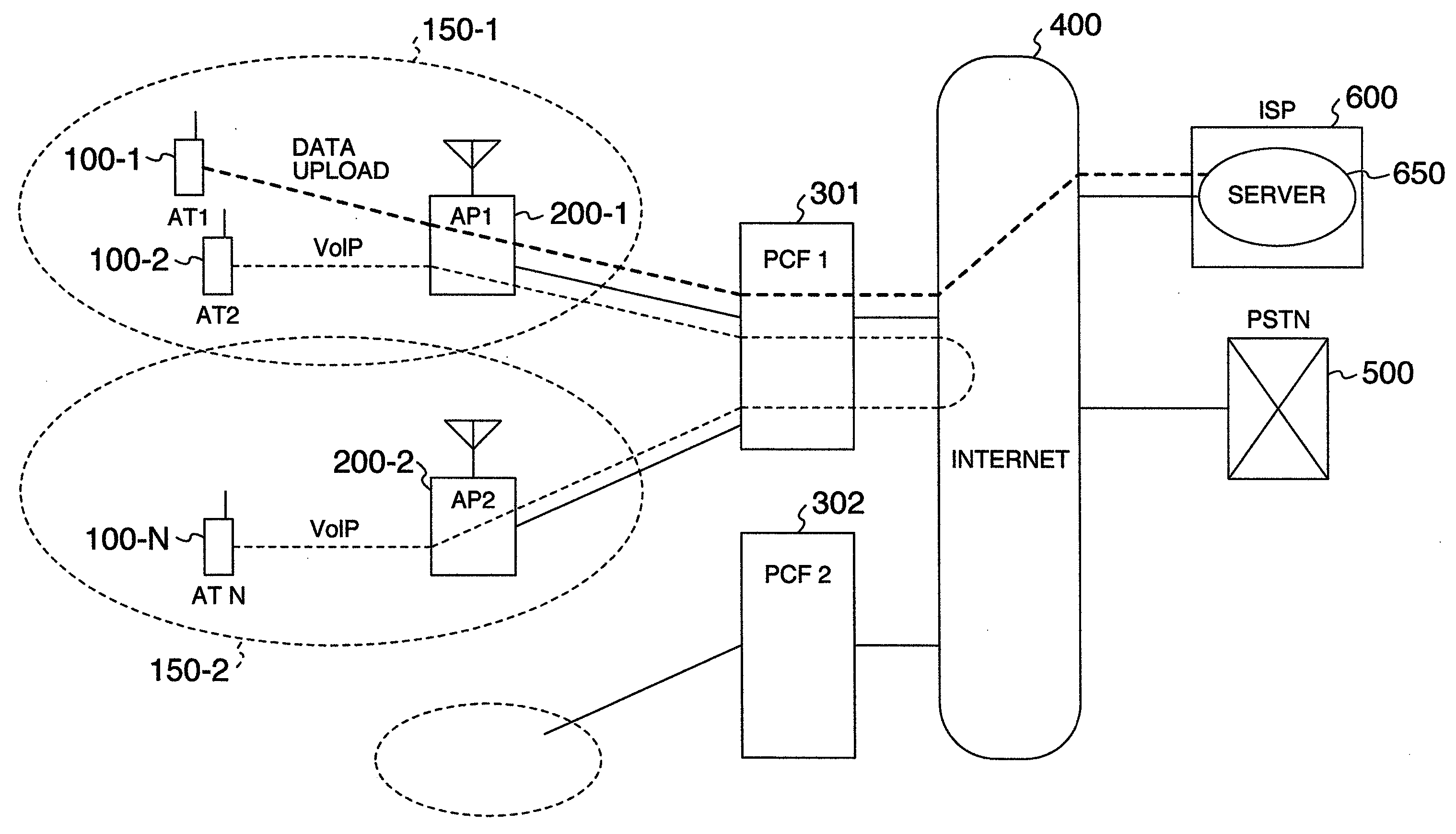

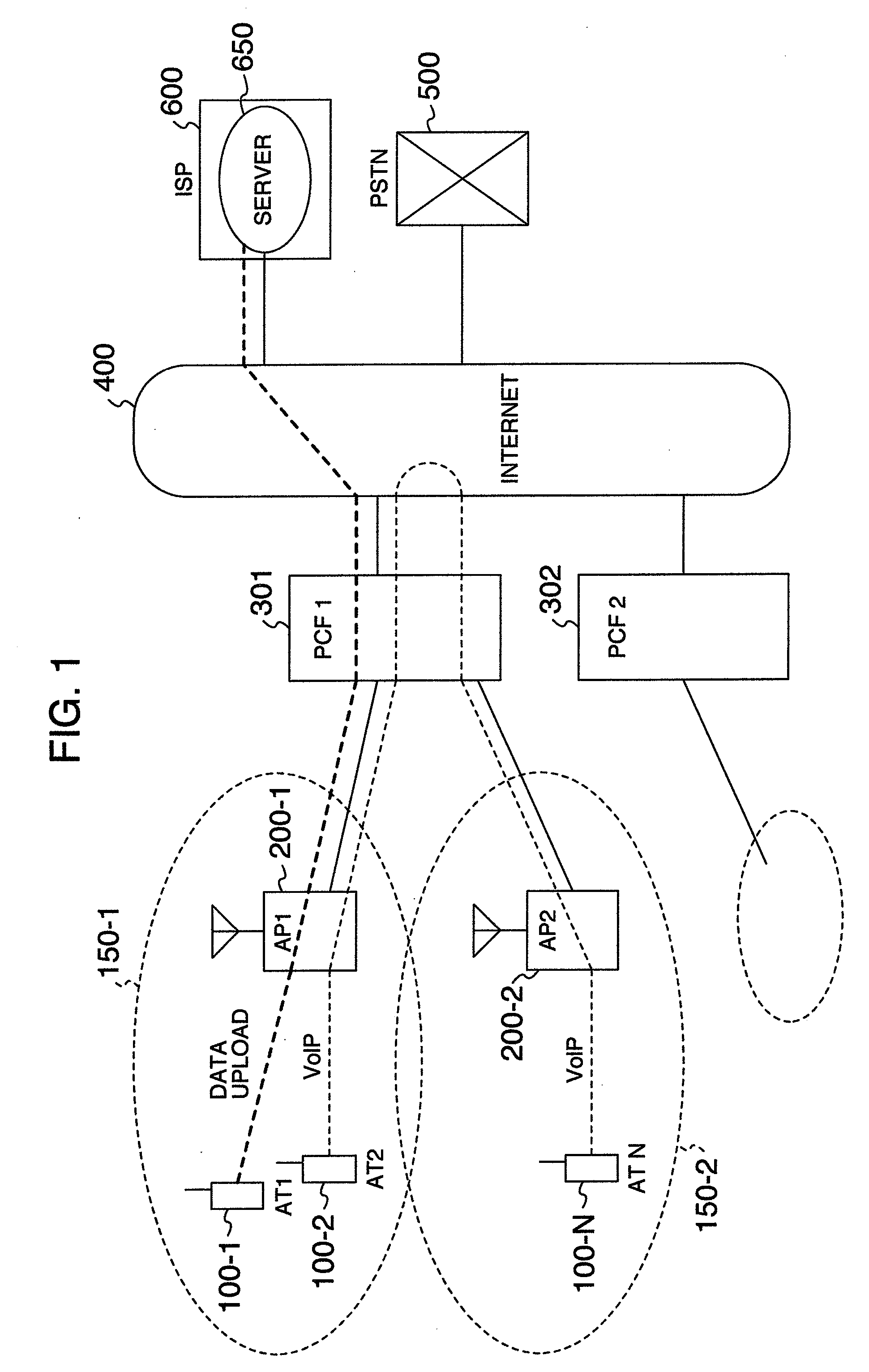

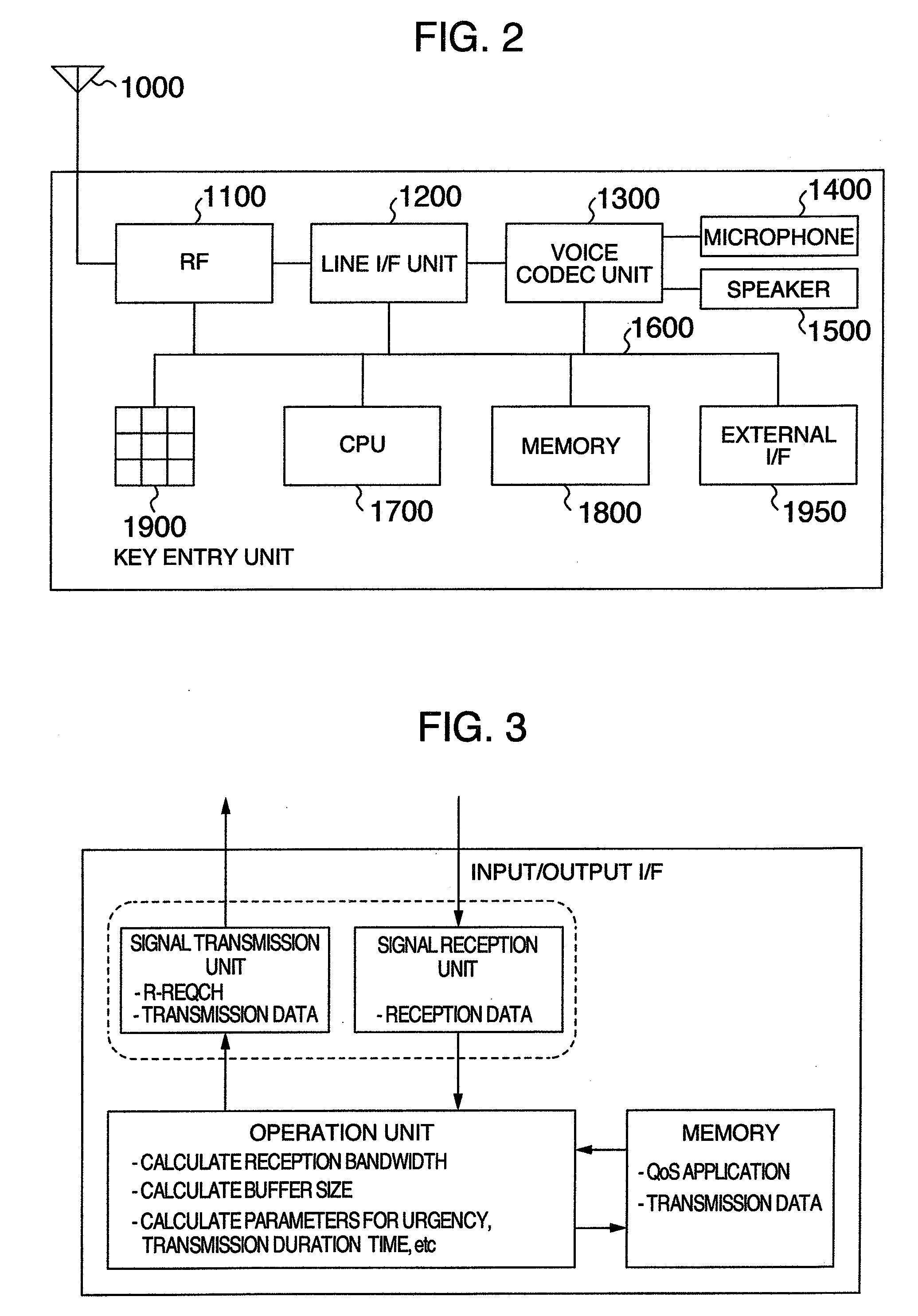

Method and system for providing QOS for mobile internet service

InactiveUS20090034428A1Effective performanceEffectively perform qosError preventionTransmission systemsType of serviceInternet network

Disclosed are a QoS (Quality of Service) providing system that manages service quality of a mobile Internet system, and an apparatus and method that apply QoS according to the class of a mobile Internet service provided over a mobile Internet network. The QoS providing system includes a service class table storage unit for storing at least one QoS parameter value for a plurality of mobile Internet services; a service identifying unit for identifying a QoS service class of a mobile Internet service requested over the mobile Internet network; a QoS parameter extracting unit for extracting QoS parameters of the identified mobile Internet service by referring to the service class table; and a QoS performing unit for performing QoS on the requested mobile Internet service according to the extracted QoS parameters. Thus, several types of services can be provided simultaneously and smoothly according to a requested service characteristic in a mobile Internet network in which real-time competition for resources occurs.

Owner:POS DATA CO LTD

Non-magnetic alloy and counterbalance produced thereby

InactiveCN101117685AEasy to manufactureImprove balanceRotary/oscillating piston pump componentsLiquid fuel engine componentsMetal alloySlag

The present invention provides a non-magnetic metal alloy used for the balancing weight of a compressor, with a weight percentage of components as follows: Mn 5-20 percent, chromium 5-20 percent, sulfur 0.05-1.5 percent and the remainders are Fe and trace. The alloy can also contain Cu 0.4-3 percent and / or nickel less than or equal to 1.5 percent. The balancing weight used for a compressor can be made by adopting the materials with a method of forging and pressing. Advantages of the method are that the working procedure is simplified, the pollution is lowered and the processing is flexible. Simultaneously, the adoption of forging and pressing rids the product of pores and slag inclusions, and improves the balancing capacity of the balancing weight.

Owner:NANCHANG ZHONGHAO MACHINERY

Gantry type rough and finish composite five-axis precision machine tool and processing method thereof

PendingCN110548908AQuick removalEnsure complete removalMilling machinesFeeding apparatusMilling cutterEngineering

The invention relates to a gantry type rough and finish composite five-axis precision machine tool and a processing method thereof and belongs to the field of precision machine tools. A rack is horizontally arranged; an X-Y feeding component is installed on the rack; a two-axis turntable component is installed on the X-Y feeding component through a Y-direction sliding plate; a sharp knife processing component and a fast removing component are installed on the two sides of a middle cross beam in a gantry shape through a guide rail seat and a vertical plate respectively; and a detector is installed on a sliding plate of the sharp knife processing component. The gantry type rough and finish composite five-axis precision machine tool has the characteristics of high processing efficiency and processing precision and can meet the processing precision requirement for rough milling semi-finish milling; by adopting a five-axis linkage processing method, multi-angle flexible processing can be realized, and the processing process from a blank to a finished product can be completed at one time; as a two-axis turntable is compact in structure, high in rotation precision and good in rapid response characteristic, the gantry type rough and finish composite five-axis precision machine tool has better use reliability; and with three-direction rotation and one sharp knife feeding system moving in a longitudinal feeding direction, multi-dimensional adjustment of a milling cutter processing angle is realized.

Owner:JILIN UNIV

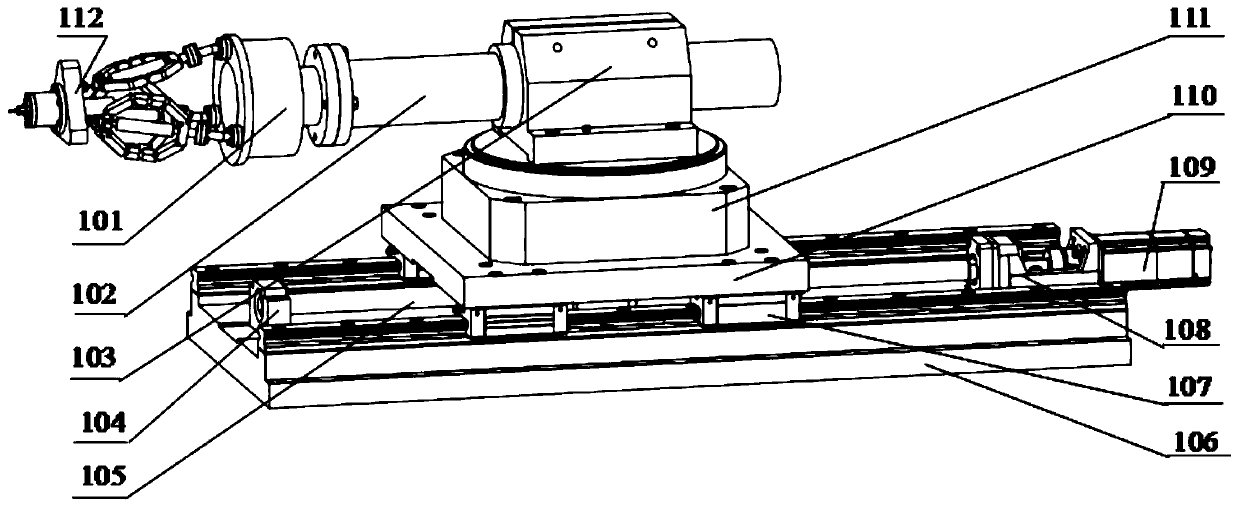

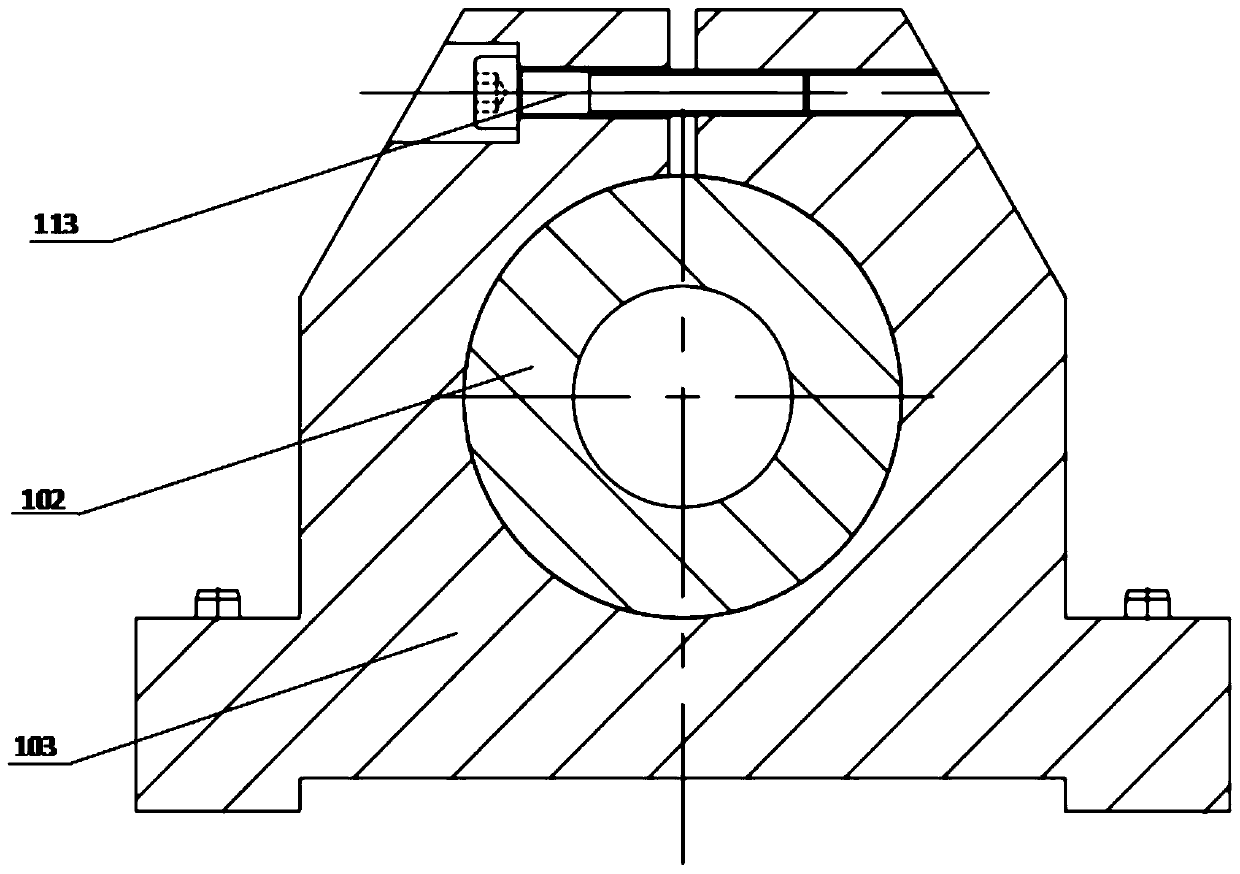

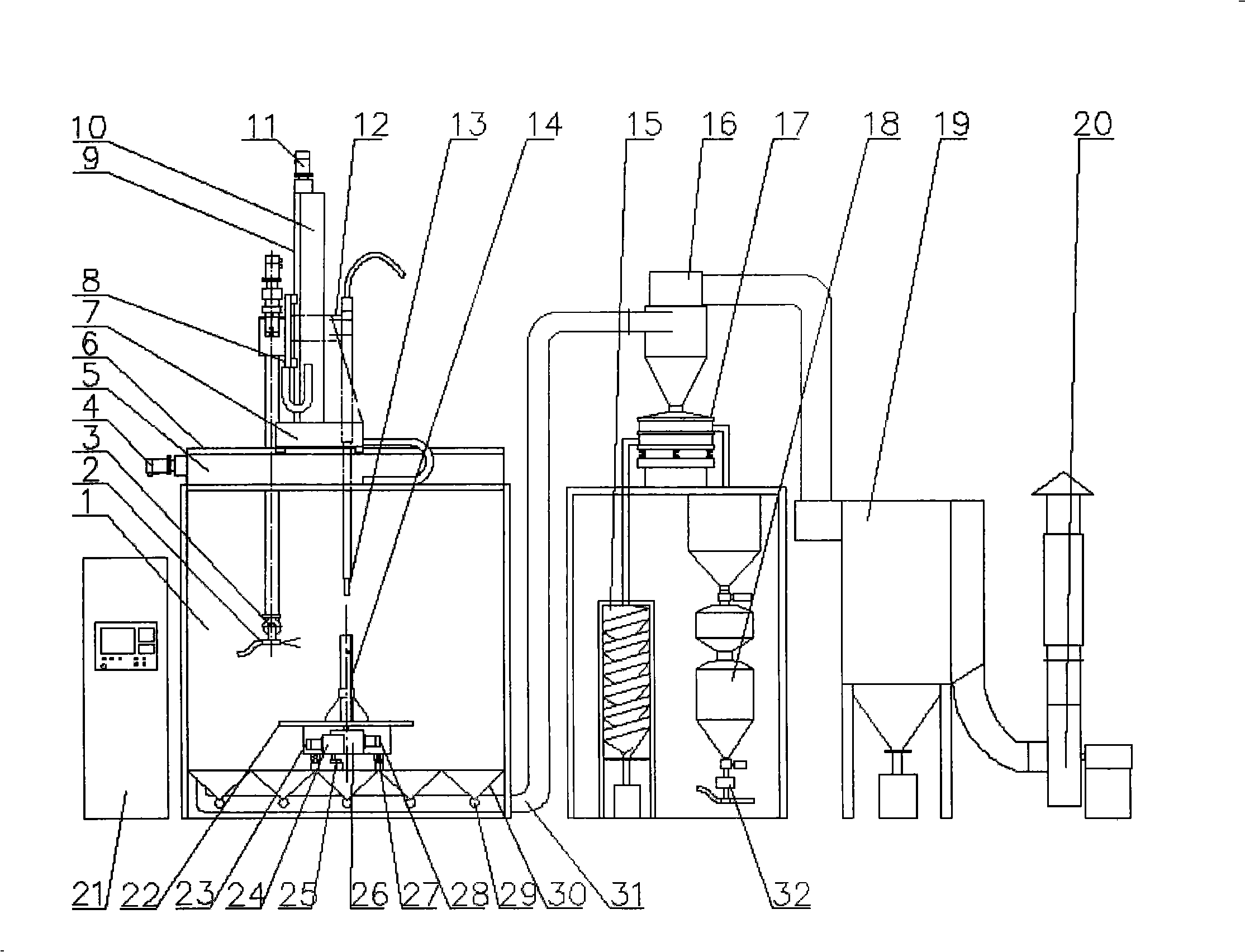

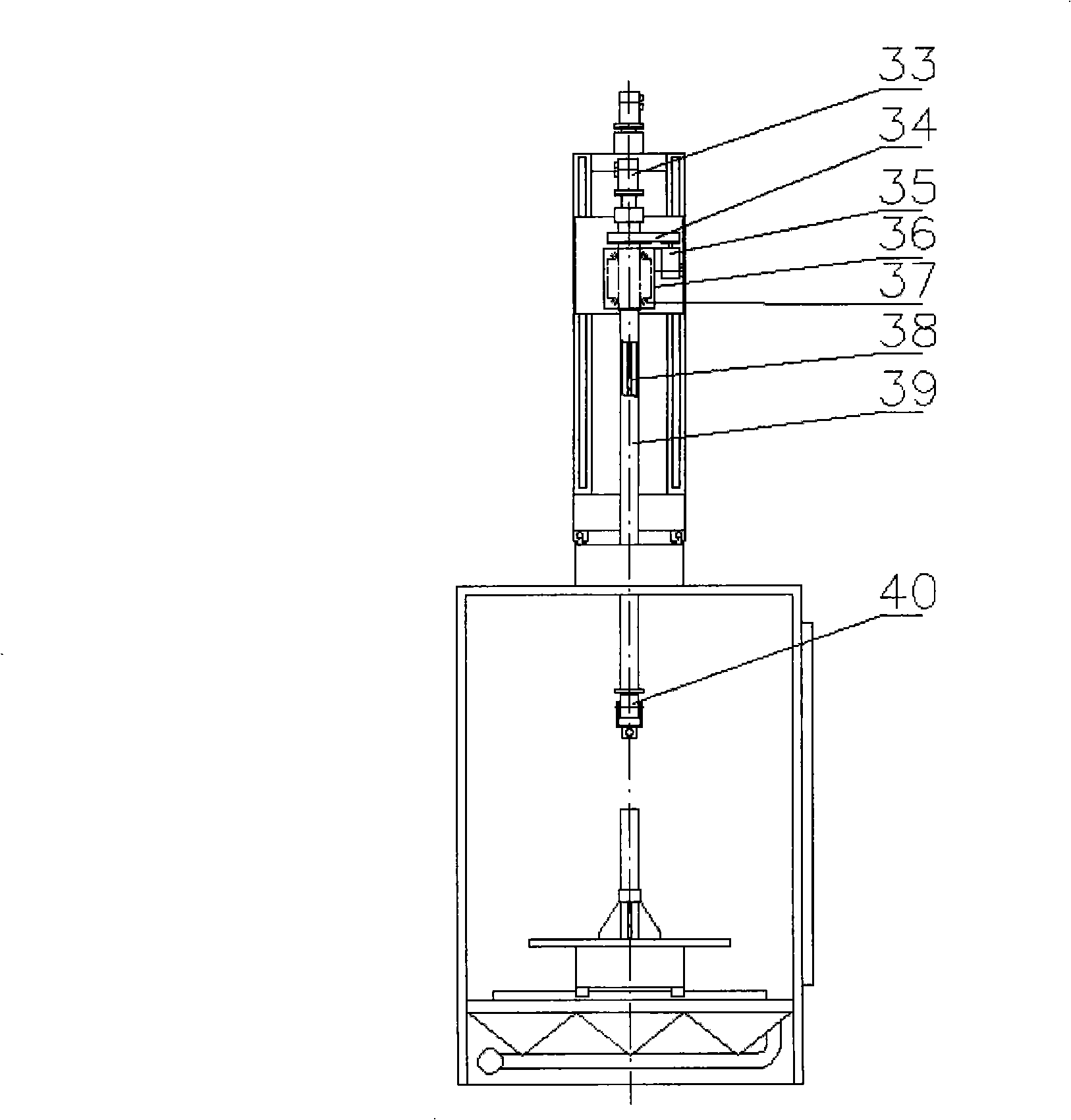

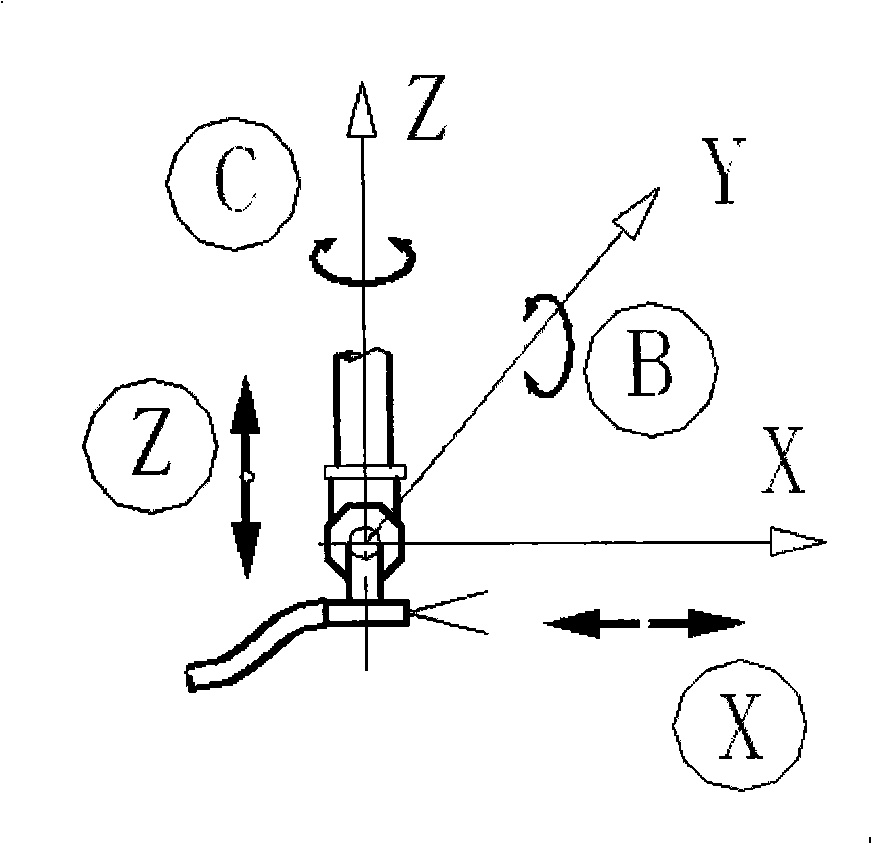

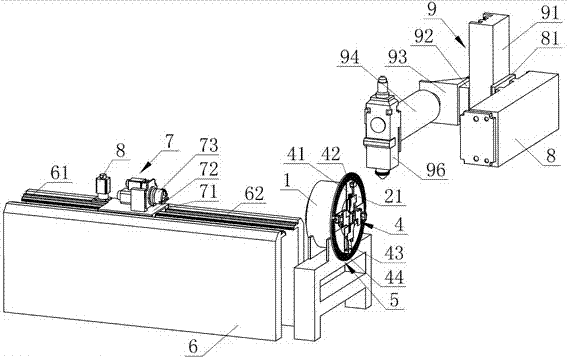

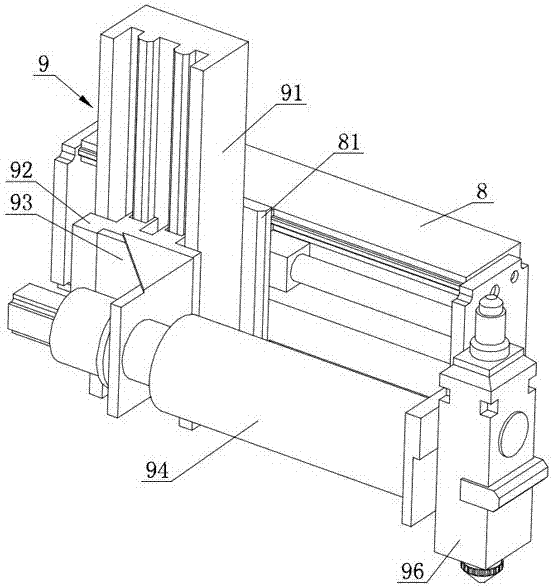

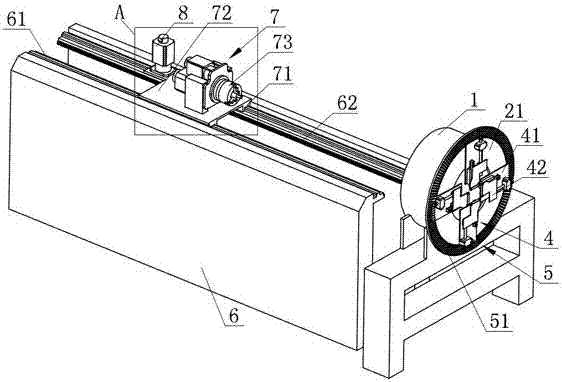

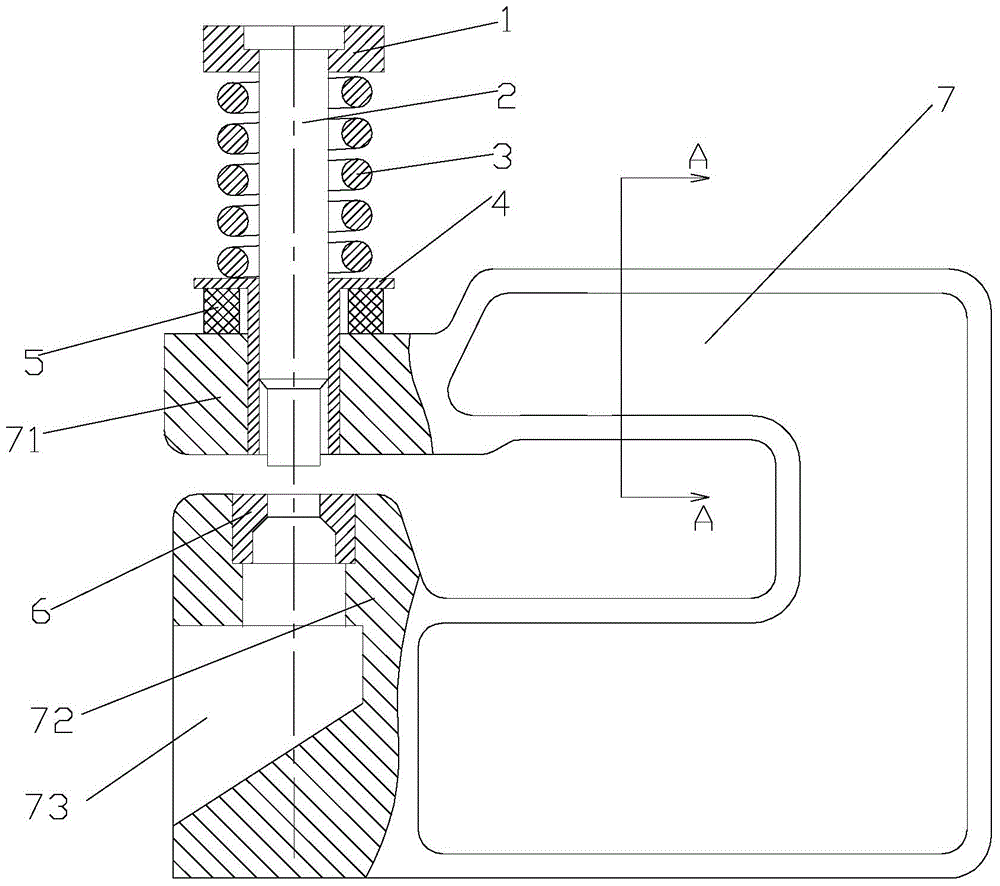

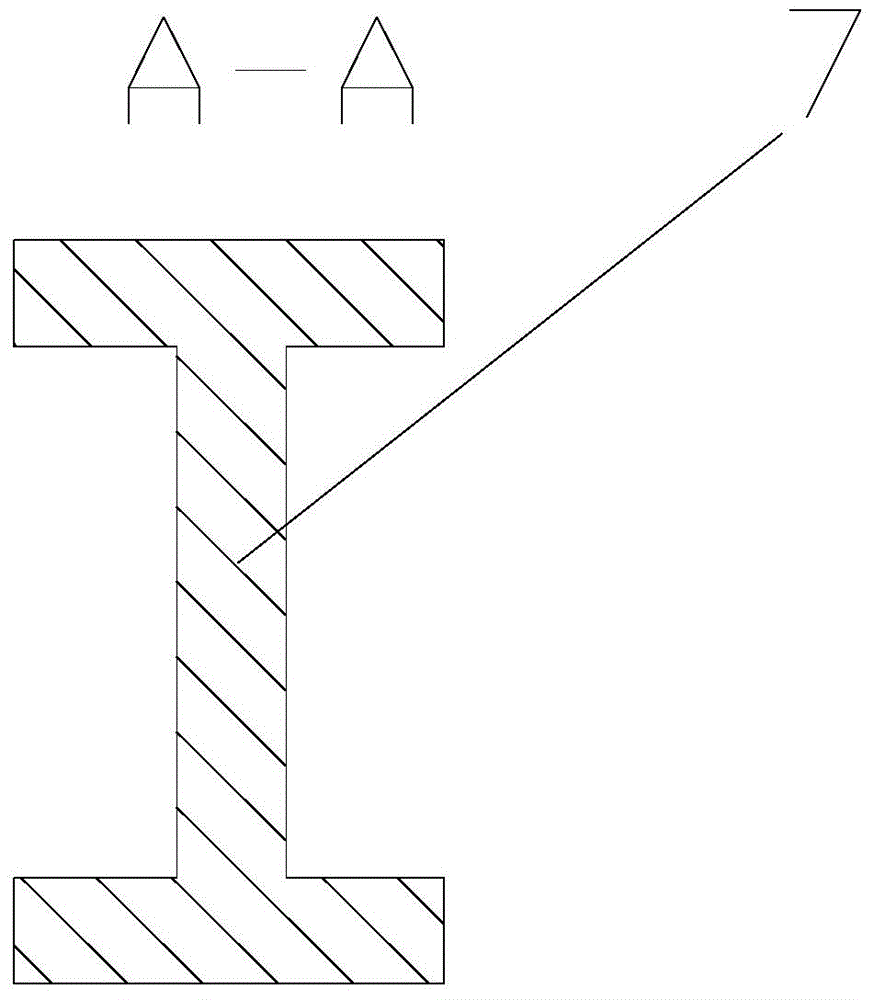

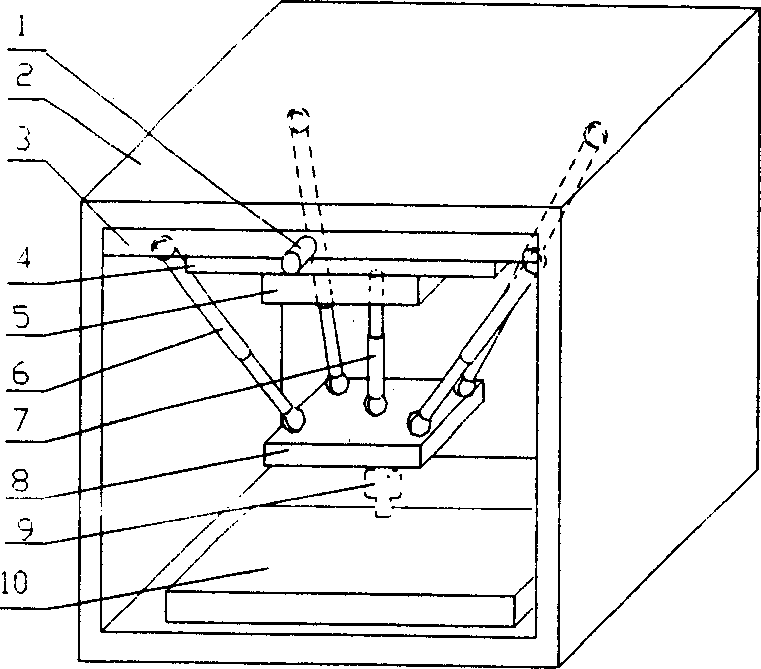

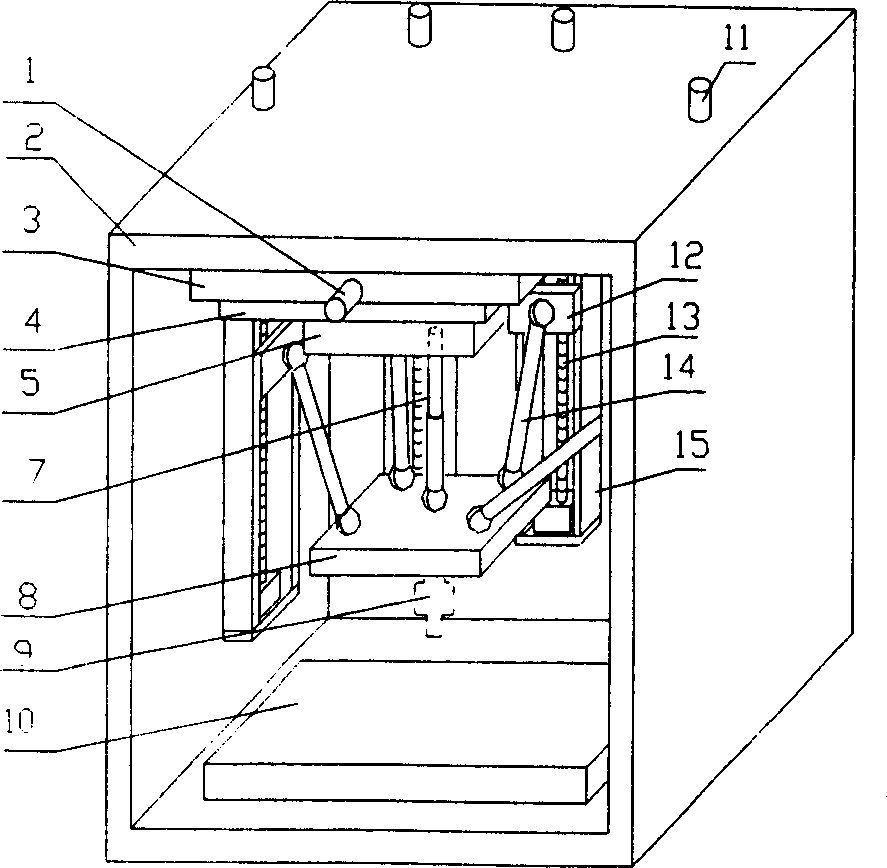

Pneumatic numerical control shot blasting strengthen machine

The invention discloses a numerical control shot peening strengthening machine; the shot peening chamber of the numerical control shot peening strengthening machine is provided with a numerical control rotating working platform which is controlled by CNC and is provided with two freedoms with C-direction rotation and Y-direction moving; a numerical control mechanical arm which is provided with four freedoms of B and C-direction rotation as well as X and Y-direction moving. A workpiece is clamped on the working platform; an outer wall lance is clamped by the numerical control mechanical arm to carry out shot peening strengthening on the outer surface of the workpiece. The Z-direction trailing bar of the moving mechanism of the numerical control mechanical arm is vertically provided with a dismountable inner hole lance which can carry out shot peening strengthening on the surface of the inner hole of the workpiece. Aiming at the programming processing procedure of different parts, the invention can carry out accurate and uniform shot peening strengthening processing on each shape of surface thereof. Compared with the prior art, the numerical control shot peening strengthening machine of the invention has high automatization degree and can realize precious control on the position and the angle as well as the moving speed of a spot flow and the flux of the spot. The numerical control shot peening strengthening machine of the invention solves the defect that the shot peening strengthening on the parts with complex surface shapes can not preciously control the distance between a lance and the surface of the part, the spot angle as well as the flow and the speed of the spot.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

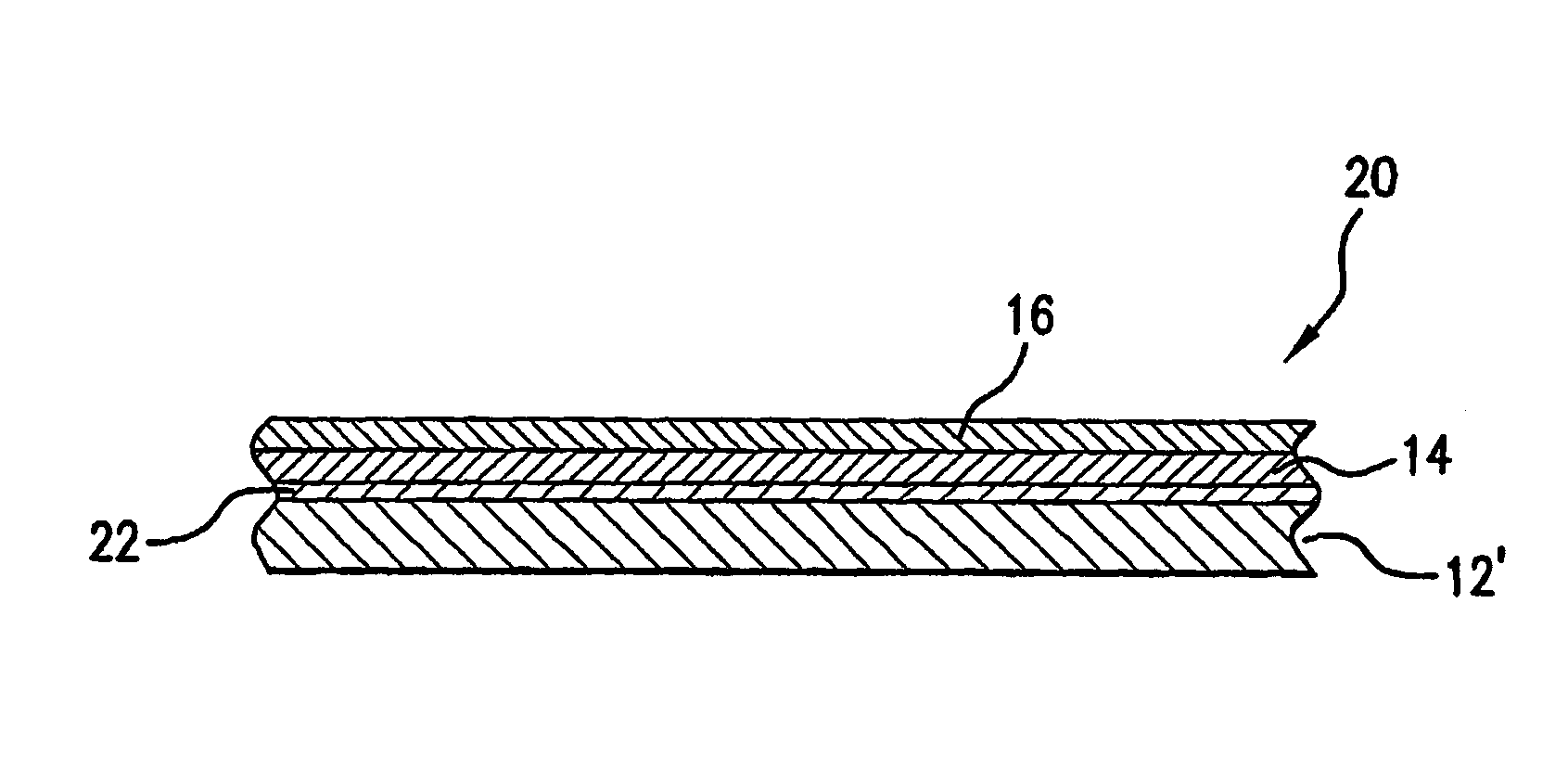

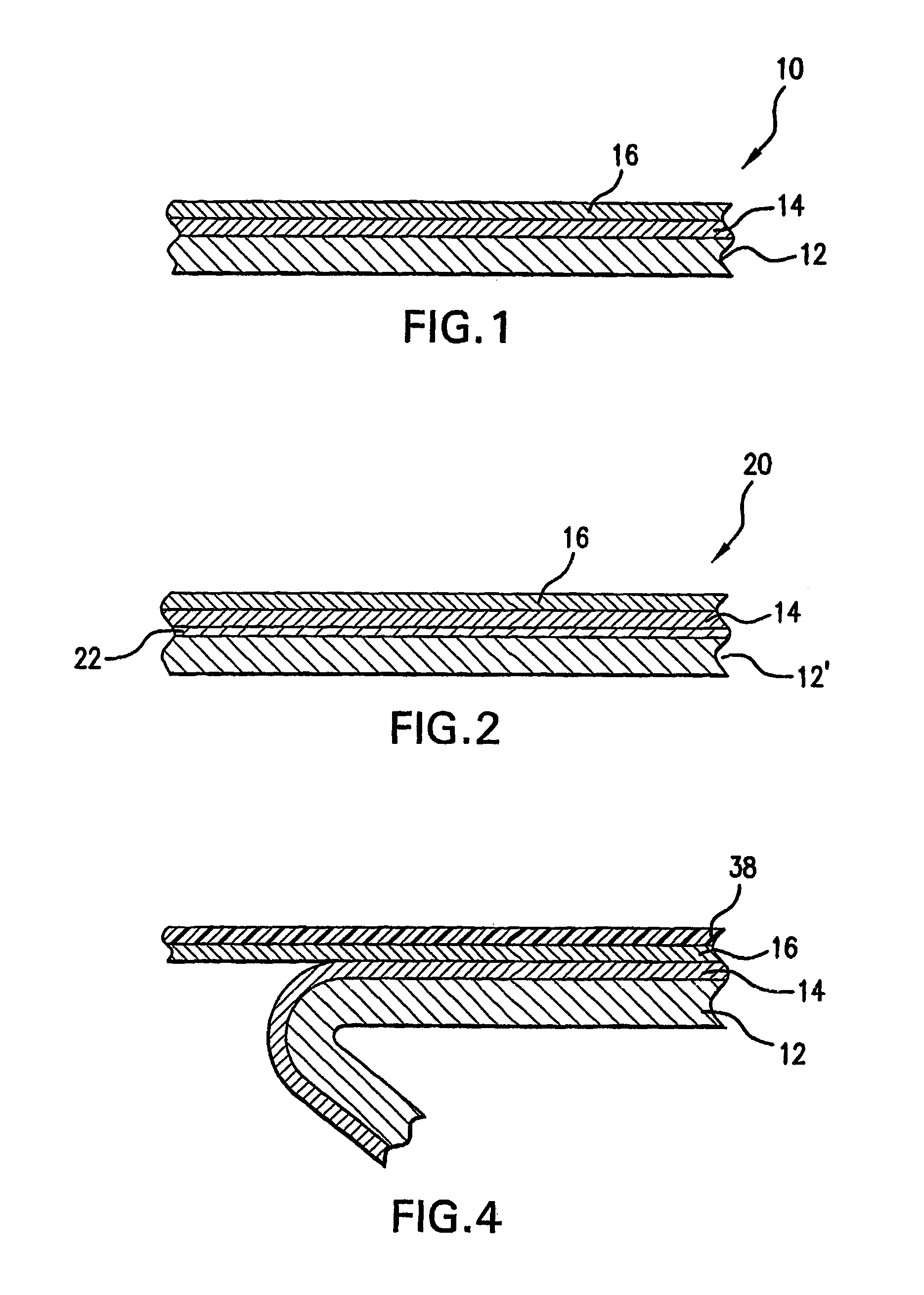

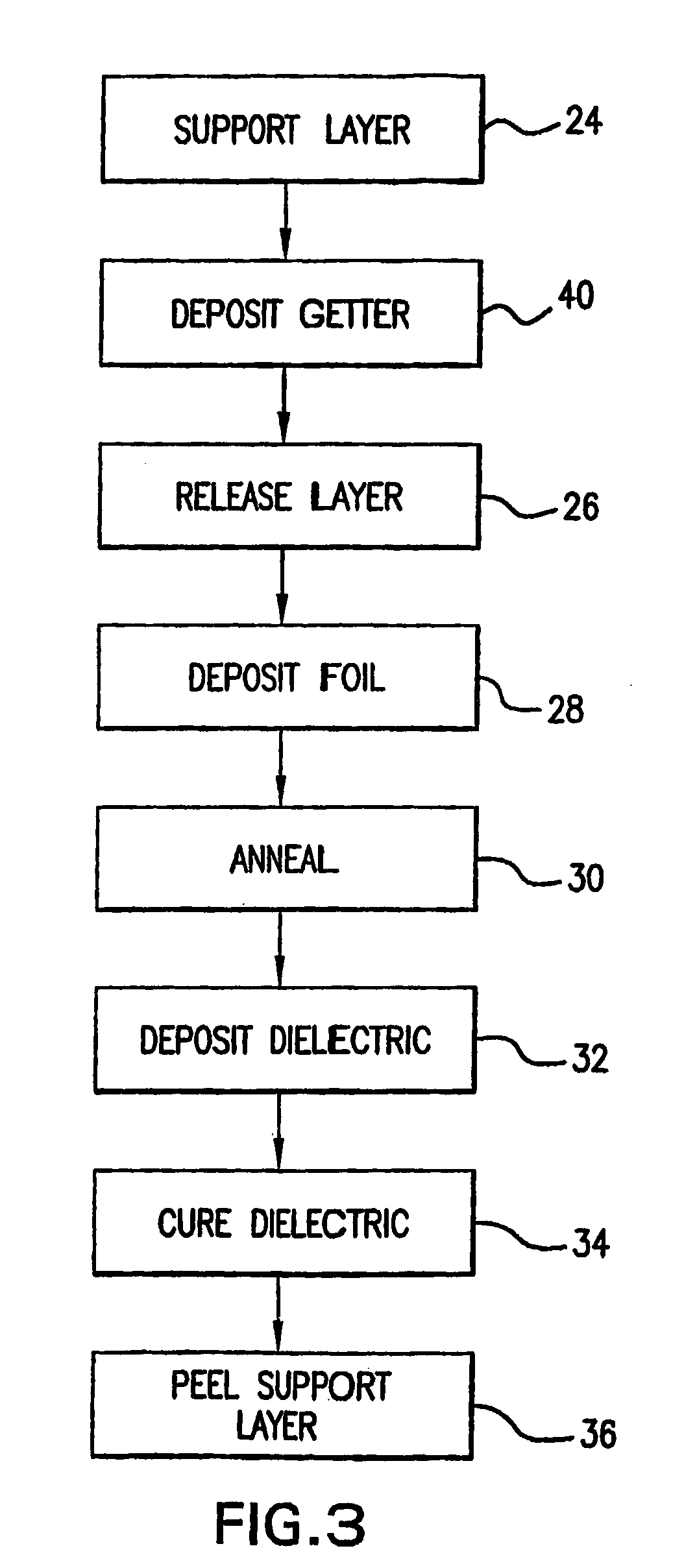

Support layer for thin copper foil

InactiveUS7132158B2Reduce in quantityHigh tensile strengthPig casting plantsThermometers using material expansion/contactionGaseous elementMetal foil

Owner:GBC METALS LLC

Production method of paper RFID hot stamping label

ActiveCN105893890ALow costEasy to recycleDigital marking by photographic/thermographic registrationHot stampingAntenna substrate

The invention belongs to the technical field of information, and in particular relates to a production method of a paper RFID hot stamping label. A paper substrate is used as an antenna substrate, wherein variable or invariable barcode information or a LOGO pattern is printed on one side of the antenna substrate, the other side of the antenna substrate is subjected to alignment printing to form an electronic label antenna surface, and then the electronic label antenna surface is compounded and compacted with a PET film coated with an isolation layer to obtain an antenna; a chip is bound to the compounded antenna to be manufactured into an electronic label inlay layer; an adhesive film is coated on an inlay surface bound with the chip; then the hot stamping electronic label is cut into a single label or single-row labels by a positioning die, and the single label or the single-row labels are rolled up to obtain a product. The production method of the paper RFID hot stamping label disclosed by the invention realizes a dual-information safety guarantee of visual information and electronic label information, and is environment-friendly and pollution-free, and the prepared electronic label has non-transferability, high anti-counterfeiting strength, fast hot stamping speed and high efficiency.

Owner:SHANDONG TAIBAO PREVENTING COUNTERFEIT

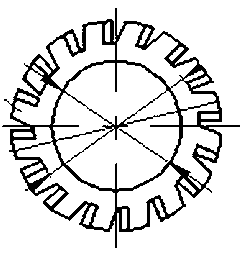

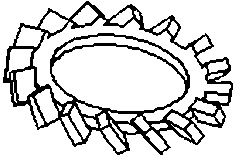

Processing crafts and tools of serrated lock washers external teeth

ActiveCN102974689AEasy loading and unloadingPrecise positioningShaping toolsTooth partManufacturing engineering

The invention discloses processing crafts and tools of serrated lock washers external teeth. According to the tools, a middle guide pillar mould base is adopted, and forming of parts is achieved by utilizing a manner that mold inserts provided with sawteeth are pressed mutually, wherein the mold inserts are arranged on end heads of an upper mold and a lower mold. In the process of machining of serrated lock washers external teeth part products, once tooth-pressing forming of the part products can meet the requirements of size and a performance test, and technological process is optimized by utilizing the crafts and the tools. And quality of the products machined by the crafts is guaranteed, and part-taking process is very convenient. The tools are simple in structure, flexible in machining method, accurate and reliable in positioning, and high in production efficiency, and the parts are convenient to assemble and disassemble. Guiding functions and valve of use for reference can also be provided for those internal serrated washer products which are large in types and varieties and specifications, small in batch and short in production cycle. And new product development of other similar structures can also be enlightened, and the processing crafts and the tools of the serrated lock washers external teeth are worthy of being popularized.

Owner:GUIZHOU AEROSPACE PRECISION PRODS

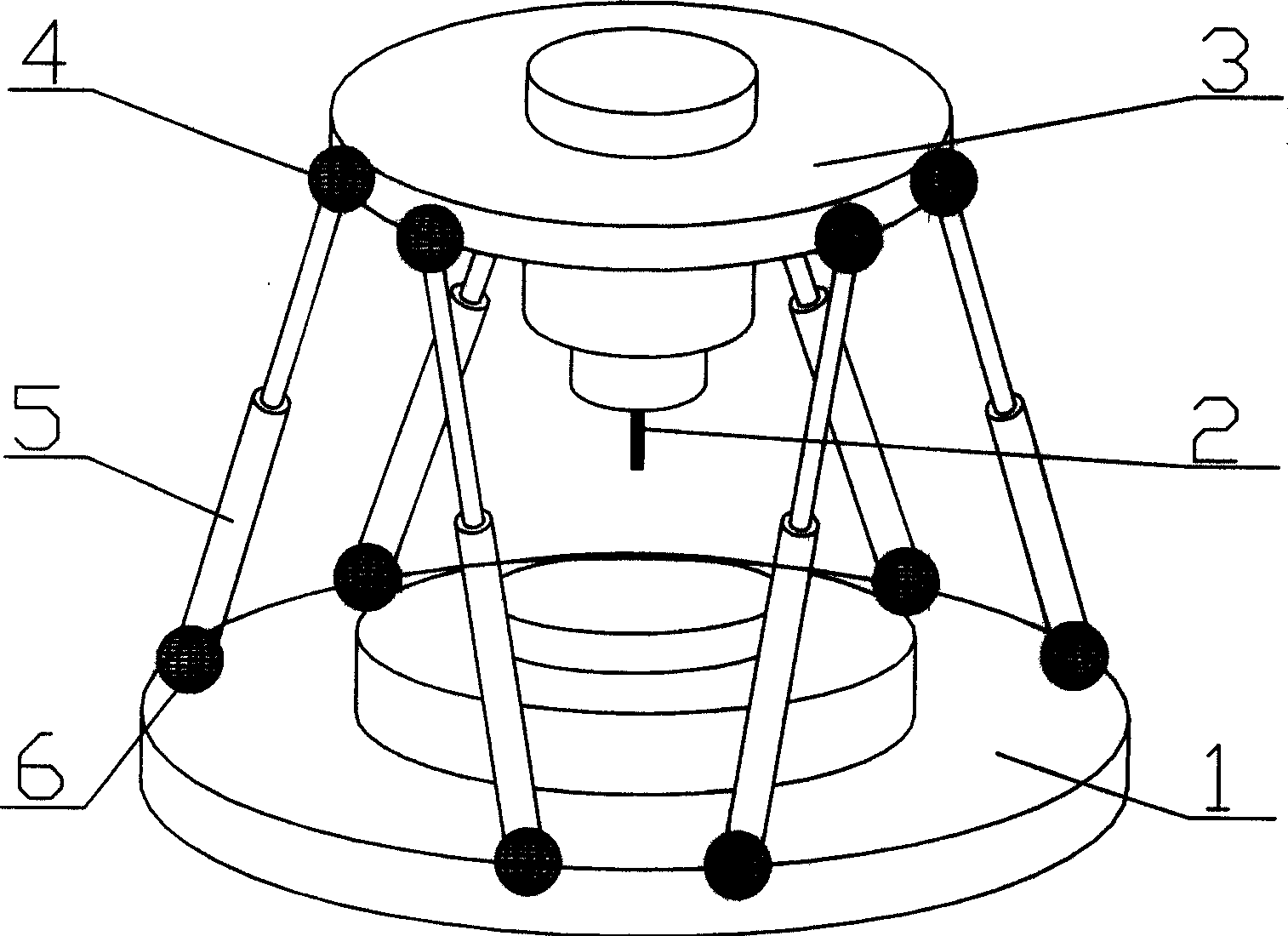

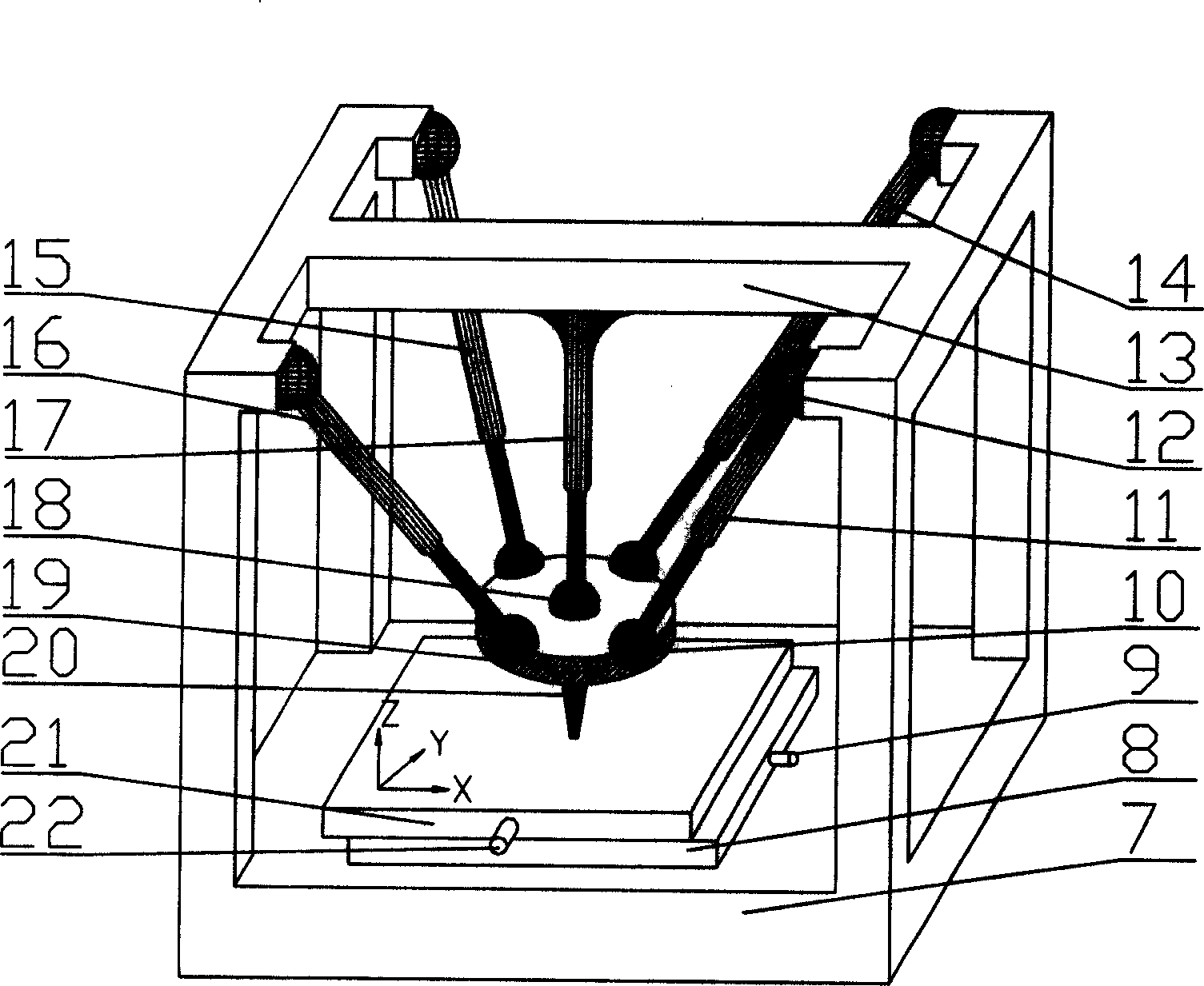

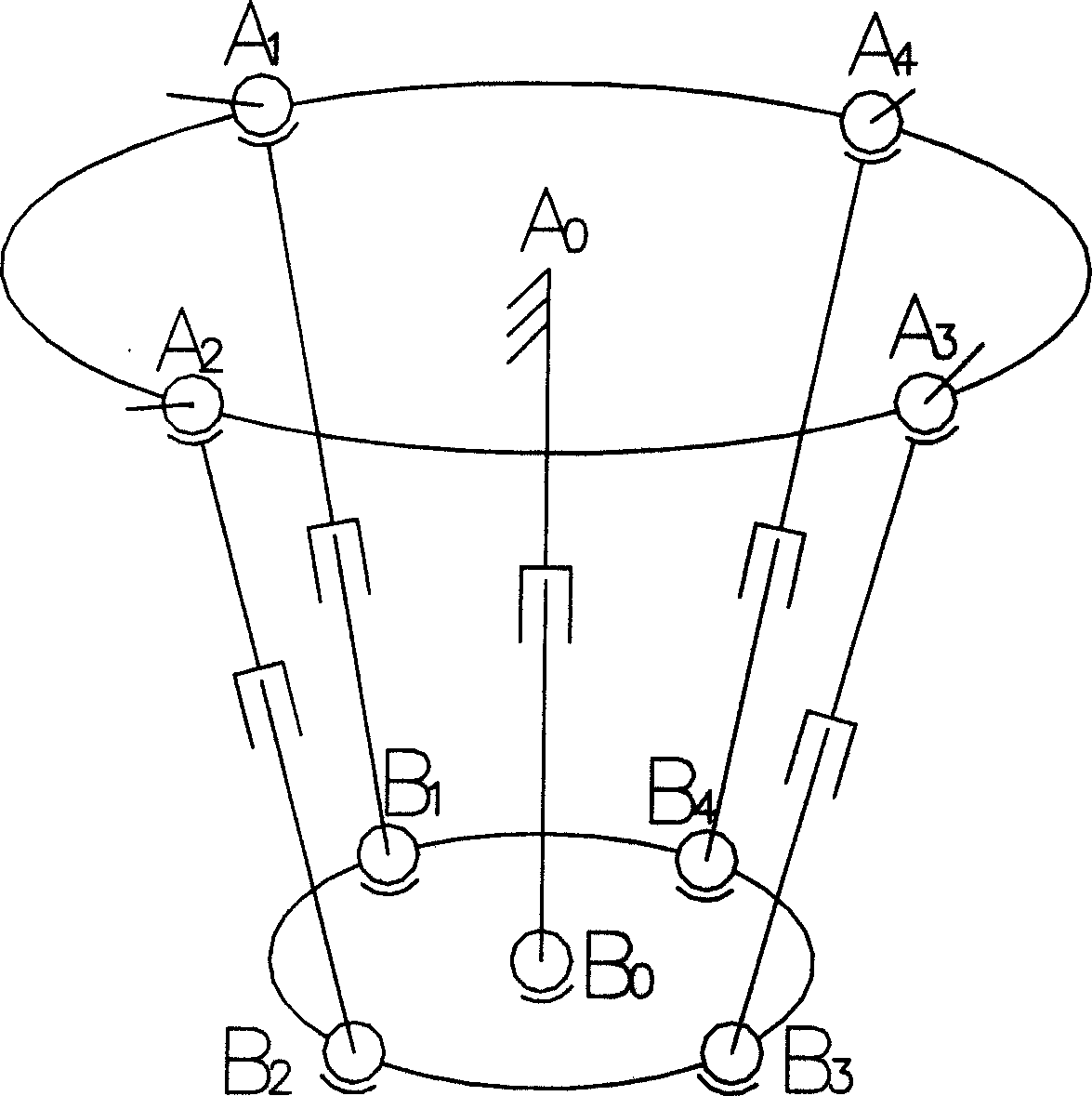

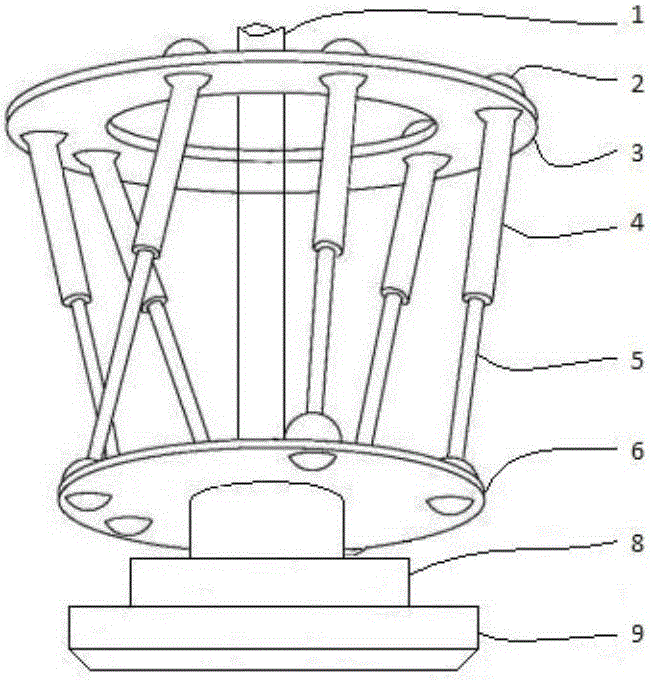

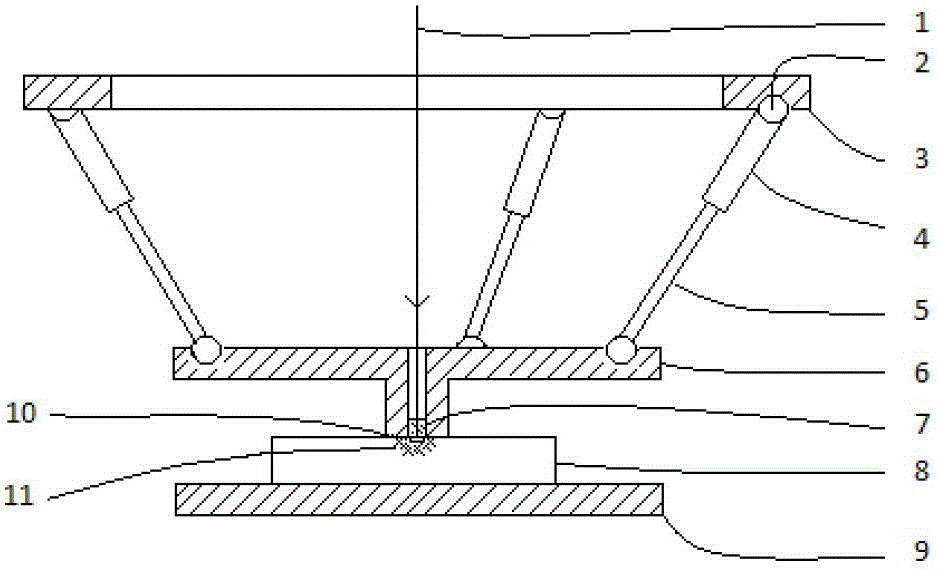

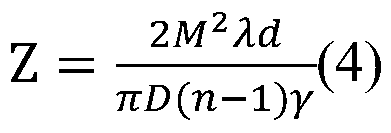

One-dimensional moving three-dimensional rotating parallel machine tool

InactiveCN1593846ASimple structureFlexible processingMetal working apparatusShunt DeviceCrooked face

The invention relates to a kind of shunt machine table which moves in one-dimensional and rotates in three-dimensional. It sets a space shunting device on the horizontal moving flat on which is fixed cutter. The space shunting device is made of five legs which connect to the moving flat through their tops. One end of the center leg is fixed firmly to the center of five legs connecting device, the other end of it connects to the moving flat through round hinge. The other four driving legs connect to the moving flat through round hinges. The device has advantages such as simple structure, flexible process, high precision, high process speed, high performance, decouple and digit controlling expediently. So it can meet the customer's demand of multi-shaft controlling digitally the big accessory that has many crooked faces.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

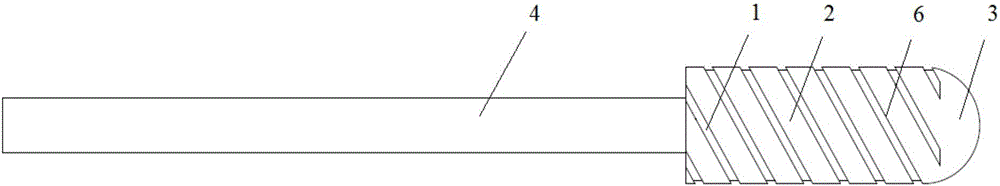

Method for machining narrow groove system impeller, grinding head and preparation method of grinding head

The invention provides a method for machining a narrow groove system impeller, a grinding head and a preparation method of the grinding head. The grinding head is a cylinder. The top end of the grinding head is in the shape of a spherical surface, and a spiral groove is formed in the side wall of the grinding head. The preparation method includes the steps that materials for use are calculated; ingredients are weighed; wetting and material mixing are performed; pressing of grinding head sand blocks is performed; drying is performed; the firing link is performed; and the grinding head sand blocks which are qualified through checking are selected and enter an adhesion processing procedure of a cutter handle, the cutter handle is bonded, after adhesives are cured and stabilized, laser dressing is performed, grooving is performed, and acceptance check of the grinding head is performed, and therefore preparation of the grinding head is completed. The method for machining the narrow groove system impeller through the grinding head includes the steps that fluttering stability analysis is performed, and a stable lobe graph of a grinding system is established; the technological parameter selecting range of stable grinding is determined; and technological parameters of stable grinding are selected, and the grinding head is installed for grinding machining. By means of the grinding head, the grinding temperature is effectively lowered, the adhesion and abrasion effects of cuttings on the grinding head are reduced, the machining surface burning problem is reduced, and better machining surface quality is acquired.

Owner:NORTHEASTERN UNIV

Moisture-conducting quick-drying weft-knitted fabric and processing technology thereof

PendingCN107354564AStable moisture-wicking functionLow raw material costWeft knittingTextile/flexible product manufactureChemistryProcess engineering

The invention provides a moisture-conducting quick-drying weft-knitted fabric. The fabric can solve the problems that an existing moisture-conducting quick-drying fabric is not washable when treated with a functional additive, is not resistant to high temperature when water-repellent fibers serve as the inner layer, and is expensive and not easy to process when waterproof yarn serves as the inner layer. A grey fabric of the fabric is formed through weft knitting of at least two kinds of yarn different in DPF, wherein the looping area of the yarn, with the minimum DPF, in the at least two kinds of yarn different in DPF on the front side of the grey fabric accounts for 60-100% of the total area of the front side; the looping area or the floating thread area of the yarn, with the maximum DPF, in the at least two kinds of yarn different in DPF on the reverse side of the grey fabric accounts for 60-100% of the total area of the reverse side; the DPF value of the yarn with the maximum DPF is at least 0.3 larger than that of the yarn with the minimum DPF. The invention provides a processing technology of the moisture-conducting quick-drying weft-knitted fabric. The technology comprises the following steps of grey cloth weaving, pre-treatment, dyeing, reduction washing, high-temperature setting, reduction washing and finished product shaping.

Owner:WUXI HANUO TEXTILE TECH

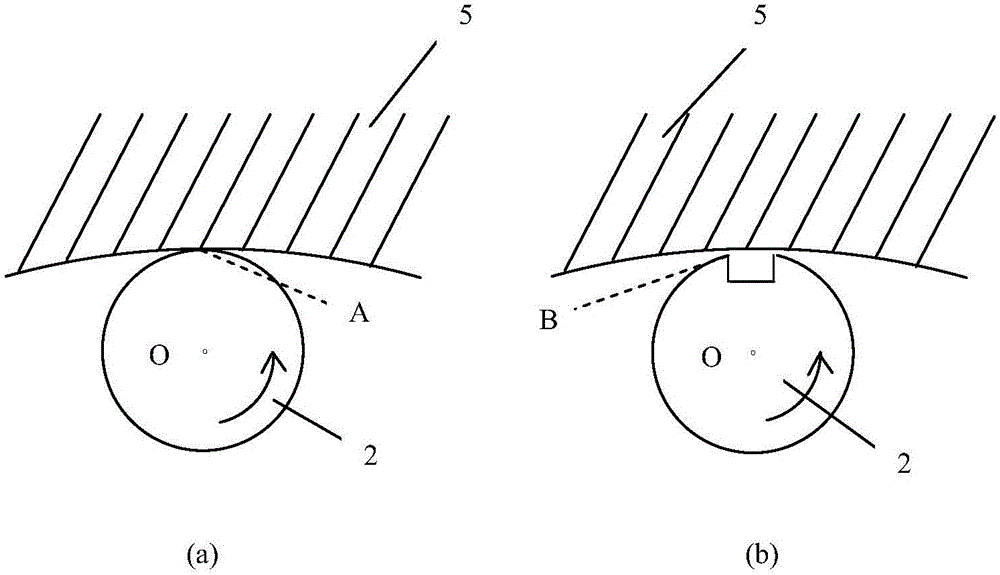

Magneto-rheological polishing device and polishing method for dynamic magnetic field

PendingCN111069984AImprove polishing effectEnhanced chemistryPolishing machinesGrinding drivesPhysicsGrinding

The invention relates to the technical field of ultraprecision machining, in particular to a magneto-rheological polishing device and polishing method for a dynamic magnetic field. The magneto-rheological polishing device for the dynamic magnetic field comprises a base, a polishing disk, a dynamic magnetic field generation assembly, a workpiece clamping assembly, an ultrasonic assembly, a first driving assembly and a second driving assembly, wherein the workpiece clamping assembly is mounted on the base and is arranged above the polishing disc, the polishing disc is connected to the first driving assembly, the dynamic magnetic field generation assembly is connected to the second driving assembly and is arranged below the polishing disc, the first driving assembly and the second driving assembly are mounted on the base, the ultrasonic assembly is mounted on the lateral part of the polishing disc, and a magneto-rheological polishing solution is contained in the polishing disc. A magneticchain string is rearranged by means of the dynamic magnetic field, so that a grinding material is updated and self-sharpened. A chemical reaction is fuller by means of an ultrasonic assistant chemical reaction. As a clamping disc revolves and rotates, a workpiece is in full contact with the magneto-rheological polishing solution, so that the polishing efficiency is improved.

Owner:GUANGDONG UNIV OF TECH

Radio base station, radio communication terminal and radio communication system

InactiveUS20080119181A1Effective resourcesSuppression delayNetwork traffic/resource managementRadio/inductive link selection arrangementsExpiration TimeCommunications system

A radio base station, a radio communication terminal, and a radio communication system that can efficiently utilize broadband resources even if many packets of different sizes and different QoS requirements are mixed when sent and received. When a data transmission request is sent from a radio terminal to a base station, at least one of a data transmission duration time, a transmission data transmission interval, and an expiration time is included in the data transmission request. The base station receives data transmission requests from multiple radio terminals, schedules the data transmission requests from multiple radio terminals, assigns bandwidths to the multiple radio terminals based on the duration time, transmission interval, and expiration time included in each of the data transmission requests and continues the assignment of bandwidths to the radio terminals during the duration time based on the received duration time.

Owner:HITACHI LTD

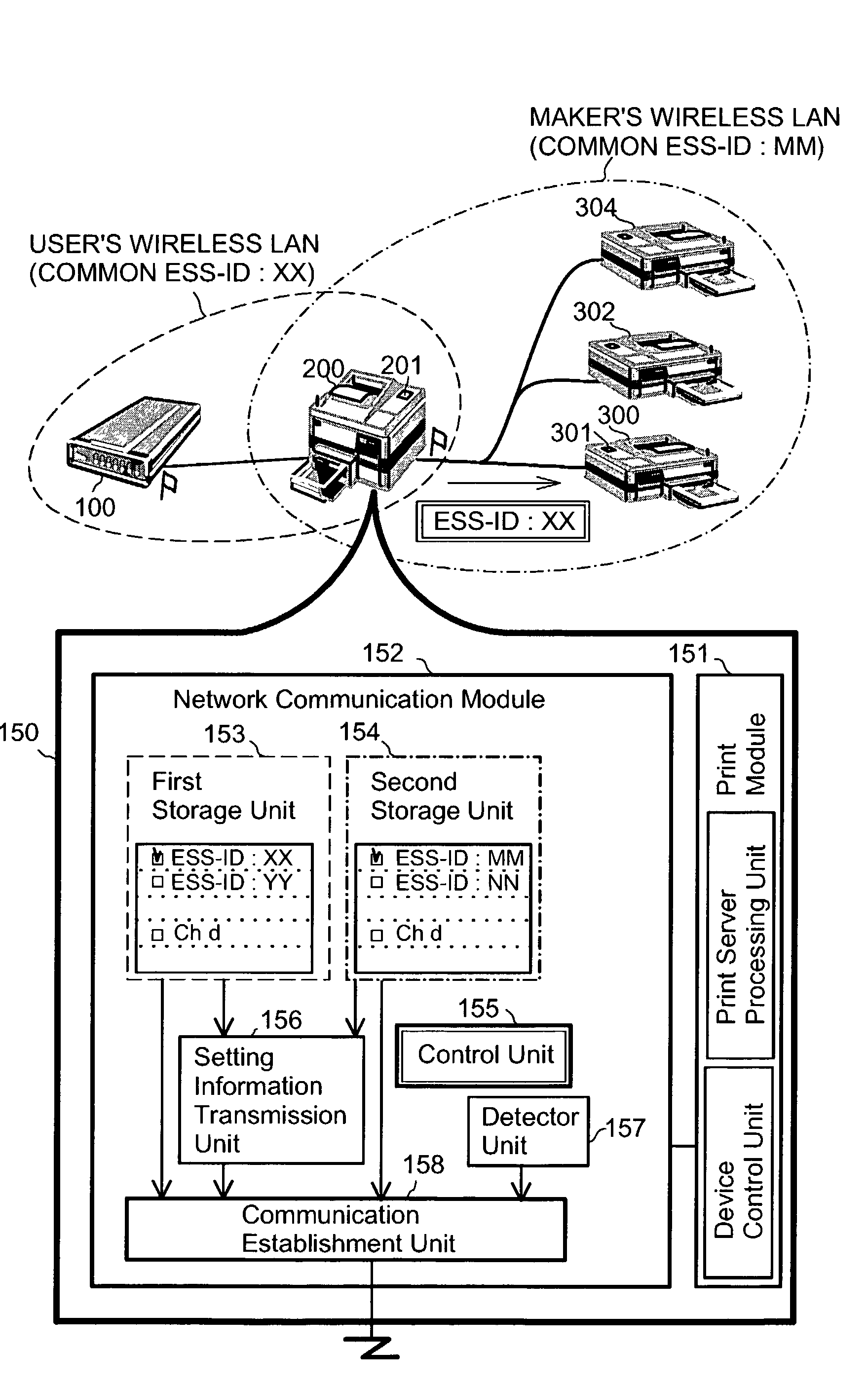

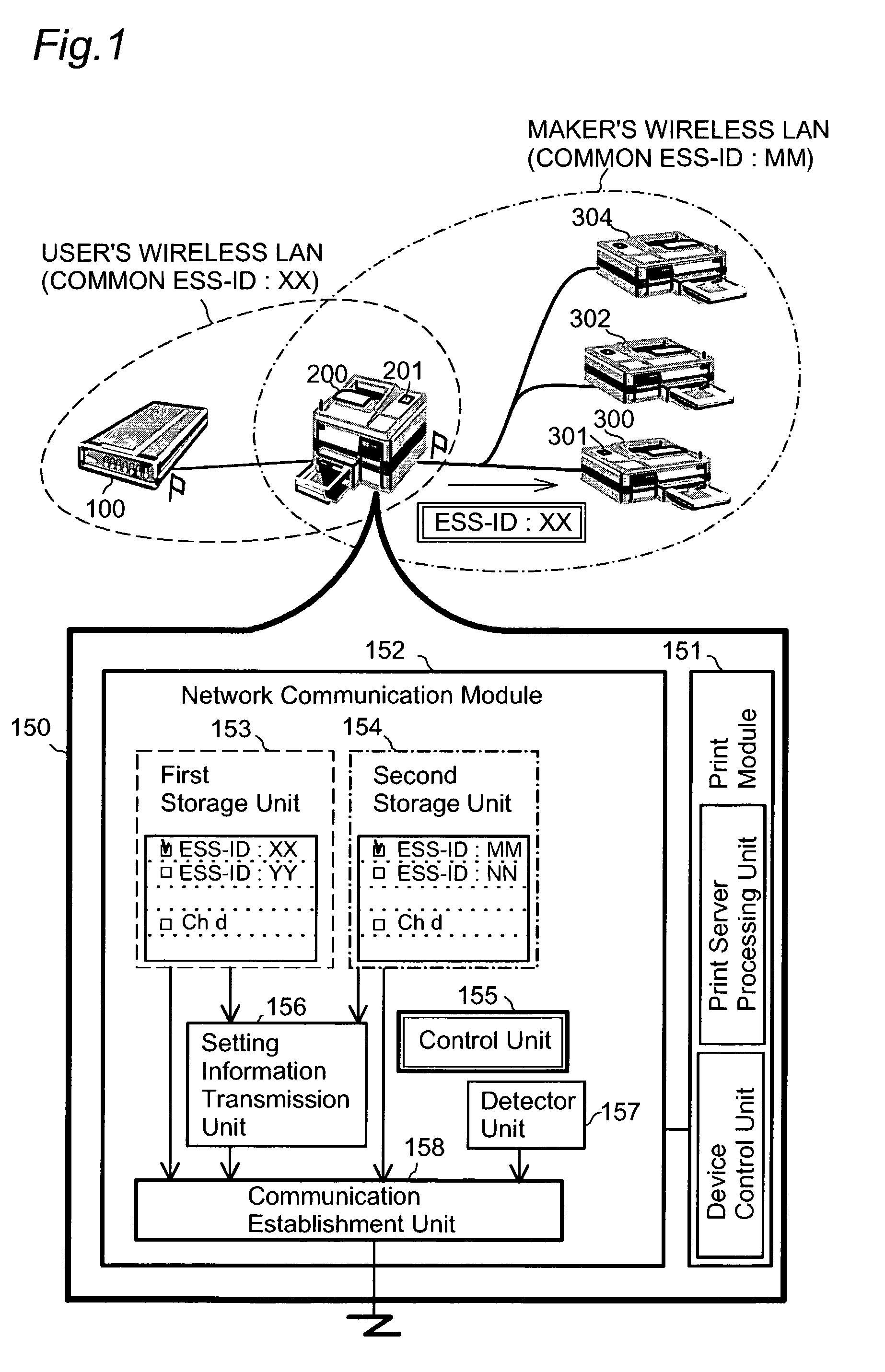

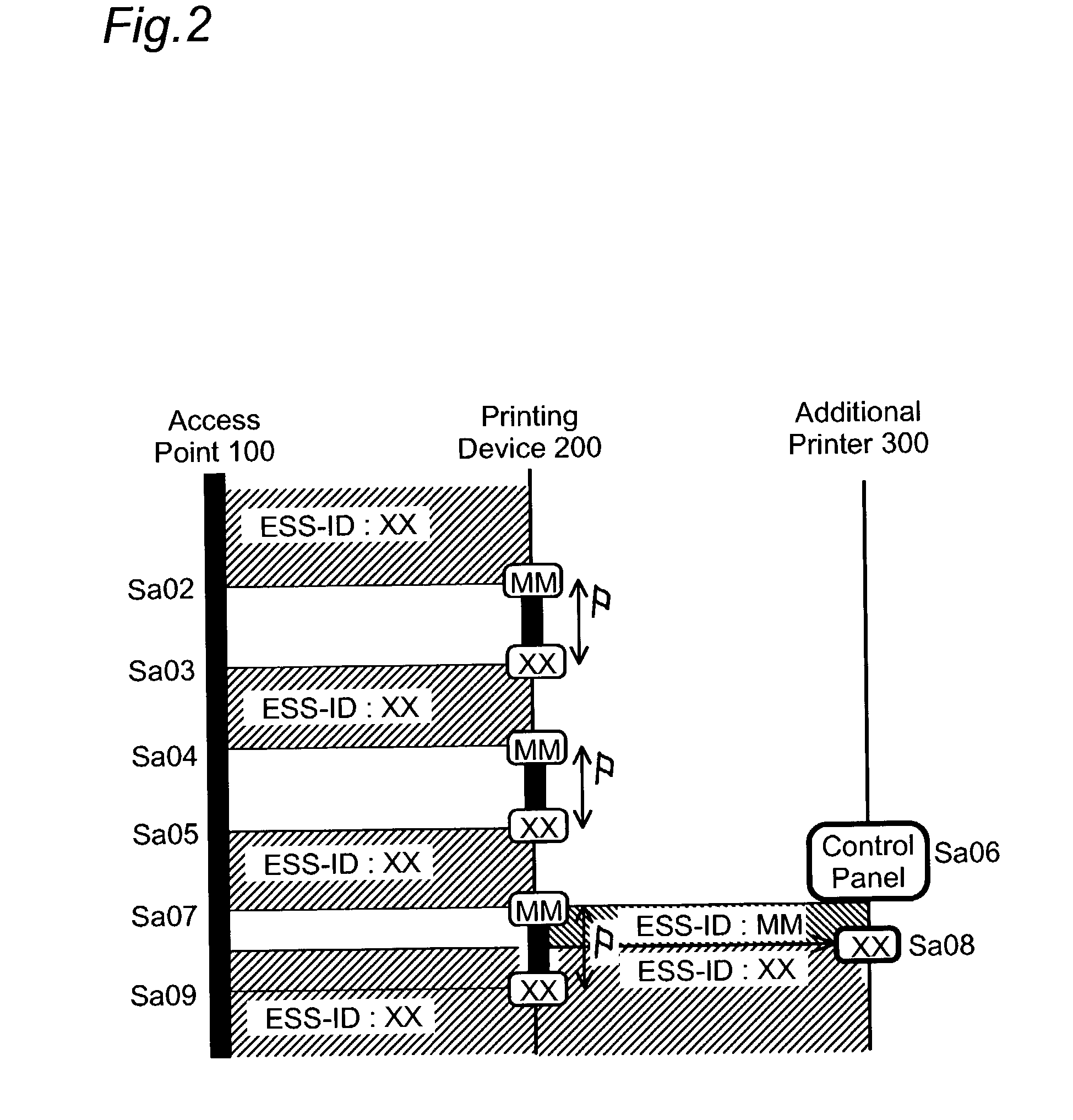

Adaptor for wireless network

InactiveUS7672278B2Facilitate settingEasy to carryBroadcast transmission systemsData switching by path configurationWireless mesh networkWireless sensor network

A printing device of the present invention has an additional function of switching over connection with two wireless networks. The printing device enters a user's wireless LAN based on first setting information, while establishing connection with a maker's wireless LAN based on second setting information to communicate with a printer, which is one of additional devices newly entering the user's wireless LAN. In response to a requirement from the printer, the printing device temporarily disconnects from the user's wireless LAN and enters the maker's wireless LAN to transmit setting information relating to the user's wireless LAN to the printer. This arrangement desirably relieves the labor of the user for settings in the additional devices to establish connection with the wireless network.

Owner:138 EAST LCD ADVANCEMENTS LTD

Belt sander

ActiveCN103659477AQuick grindingGuaranteed grinding qualityBelt grinding machinesOther manufacturing equipments/toolsCircular discSander

The invention discloses a belt sander. The belt sander comprises a base, wherein an X-axis workbench and a Y-axis workbench are arranged on the base, a rotating disk used for fixing a workpiece is arranged on the Y-axis workbench, more than one station is arranged on the rotating disk, a Z-axis support is arranged on the base, more than one sliding rail is vertically arranged on the Z-axis support, a Z-axis machining device is further installed on the Z-axis support and comprises a servo motor installed on the Z-axis support and a supporting table driven by the servo motor to move up and down on the sliding rail, a motor, a driving wheel driven by the motor, and a driven wheel driven by the driving wheel are installed on the supporting table, and the driven wheel is driven to rotate by the driving wheel through a sand belt. According to the belt sander, four-shaft linkage can be achieved, workpieces can be flexibly machined, a large part of side faces of the workpieces can be machined, machining efficiency is high, and the workpieces can be machined very conveniently.

Owner:江门杰能刀剪装备科技有限公司

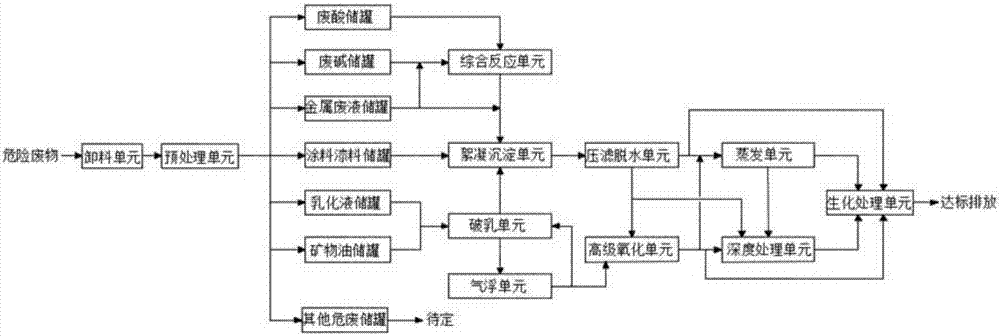

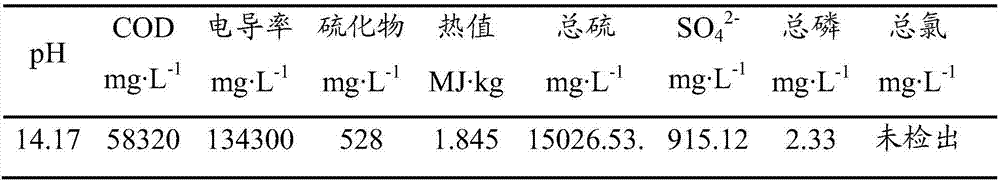

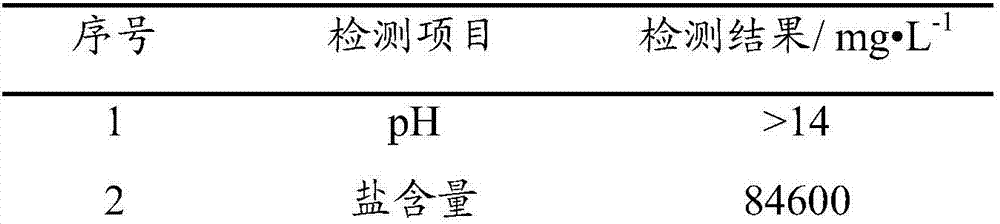

Physicochemical treatment system and physicochemical treatment method for hazardous wastes

PendingCN107572718AImprove adaptabilityReduce processing costsSludge treatment by de-watering/drying/thickeningWater contaminantsTreatment systemTreatment unit

The invention relates to the technical field of hazardous wastes, in particular to a physicochemical treatment system and a physicochemical treatment method for the hazardous wastes. The physicochemical treatment system for the hazardous wastes comprises a storage unit, a comprehensive reaction unit, a flocculent settling unit, a demulsification unit, an air flotation unit and a pressure filtration dehydration unit. The system also comprises an advanced oxidation unit, a deep treatment unit, an evaporation unit and a biochemical processing unit.

Owner:ENN ENVIROTECH CO LTD

Method and apparatus for region-based moving image encoding and decoding

InactiveUS20070263718A1Accurate processingFlexible processingPulse modulation television signal transmissionPicture reproducers using cathode ray tubesImage segmentationDegrees of freedom

Owner:SEKIGUCHI SHUNICHI +2

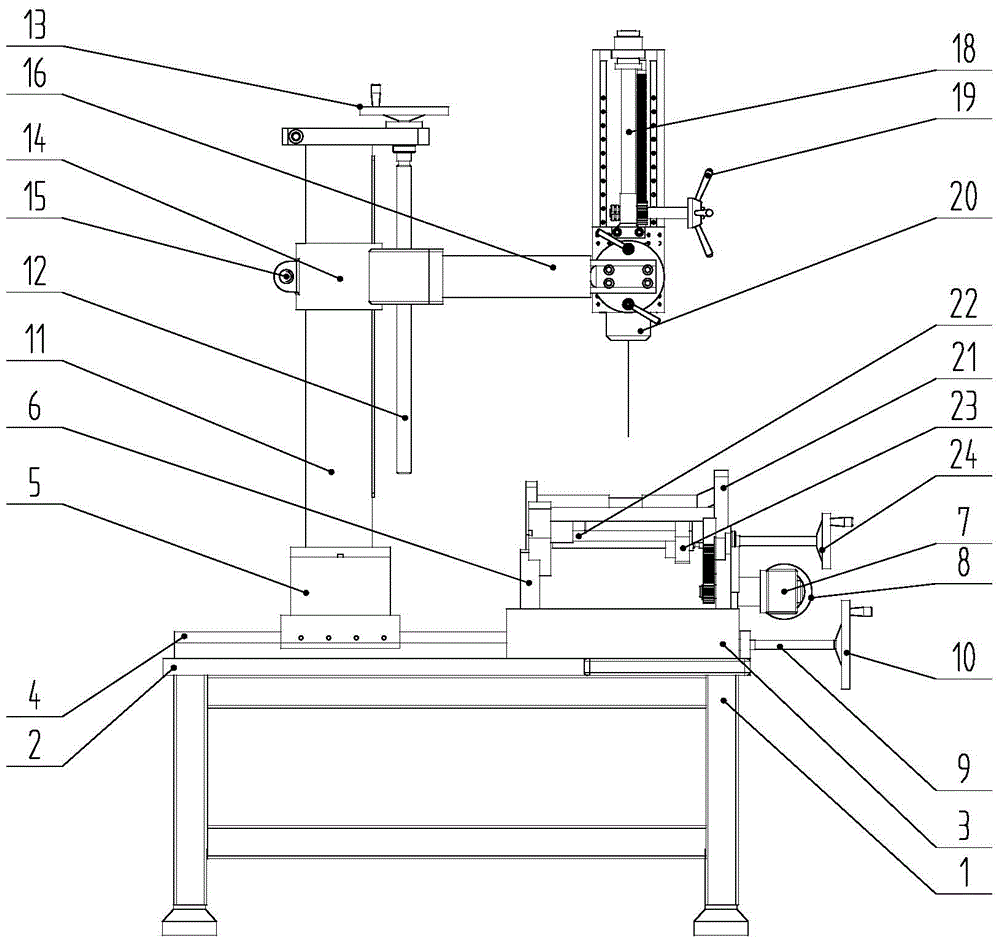

Pattern block air hole drilling machine

InactiveCN104985220AFlexible processingMeet the needs of drillingMetal working apparatusPositioning apparatusEngineeringMachining

The invention discloses a pattern block air hole drilling machine. The drilling machine comprises a machine frame, wherein a base is arranged above the machine frame, a small base is arranged above the base and located at the right side, and a rail is arranged above the base and located at the left side; a sliding block is arranged on the upper side of the rail, a fixing mechanism is arranged above the small base, and a rotary mechanism is arranged at the right side of the fixing mechanism; a Y-axis hand wheel is connected to the rotary mechanism, an X-axis lead screw is arranged at the right side of the small base, and an X-axis hand wheel is connected to the X-axis lead screw; a stand column is arranged on the upper side of the sliding block, a lifting lead screw is arranged at the right side of the stand column, and a Z-axis hand wheel is connected to the top end of the lifting lead screw; a lifting sleeve is connected to the lifting lead screw and the stand column in a chained mode, a locking bolt is arranged at the left side of the lifting sleeve, and a cross beam is arranged at the right side of the lifting sleeve; a spindle mechanism is connected to the right side of the cross beam, and a spindle penetrates through the center of the spindle mechanism. The drilling machine has the beneficial effects that machining is flexible, the requirement for drilling in different directions can be met, clamping is convenient, and due to the fact that a rotary mechanism is used for adjusting a workpiece, repeated fixation and calibration are not needed and working efficiency is improved.

Owner:ZHUCHENG ZHIXIN MOLD EQUIP

Externally-clamping type full-automatic pipe cutting machine

InactiveCN107052547AEasy alignmentFlexible processingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMachining process

The invention relates to the technical field of pipe cutting machines, in particular to an externally-clamping type full-automatic pipe cutting machine. A rotary rotating cylinder is arranged in a fixing sleeve. A rack is provided with a first drive mechanism used for driving the rotating cylinder to rotate. A rotating disc is fixed to the front end of the rotating cylinder. The rotating disc is provided with at least three clamping claw devices uniformly arranged in a ring shape. Each clamping claw device comprises an installing plate fixed to the rotating disc, a radial moving claw movably arranged on the installing plate, a lead screw connected with the radial moving claw, and a tensioning gear fixed to the outer end of the lead screw. The rotating cylinder is provided with a second drive mechanism used for driving the tensioning gears to rotate. Each radial moving claw is provided with a rolling sleeve. In the machining process, a workpiece can be moved front and back, and therefore the workpiece can follow rotation of the rotating cylinder and is fed and propelled conveniently, a plasma cutting part located on one side of the fixing sleeve is located to the place where cutting is needed through flexible moving of a supporting arm, and the externally-clamping type full-automatic pipe cutting machine can clamp and flexibly machine long-strip-shaped workpieces with triangular or rectangular sections, improves production efficiency and production quality and is very practical.

Owner:东莞友联钣金科技有限公司

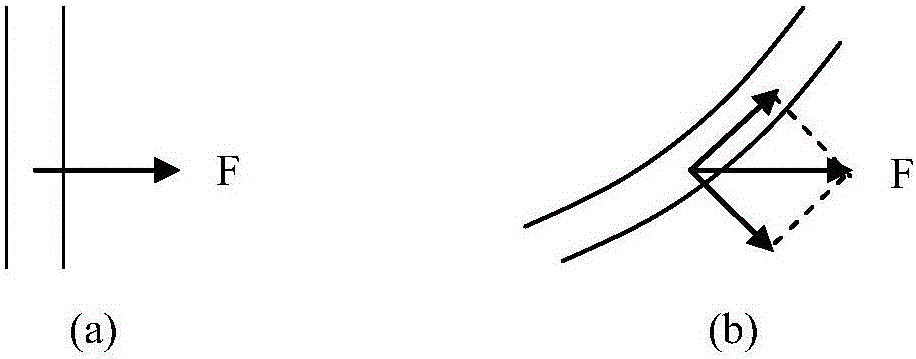

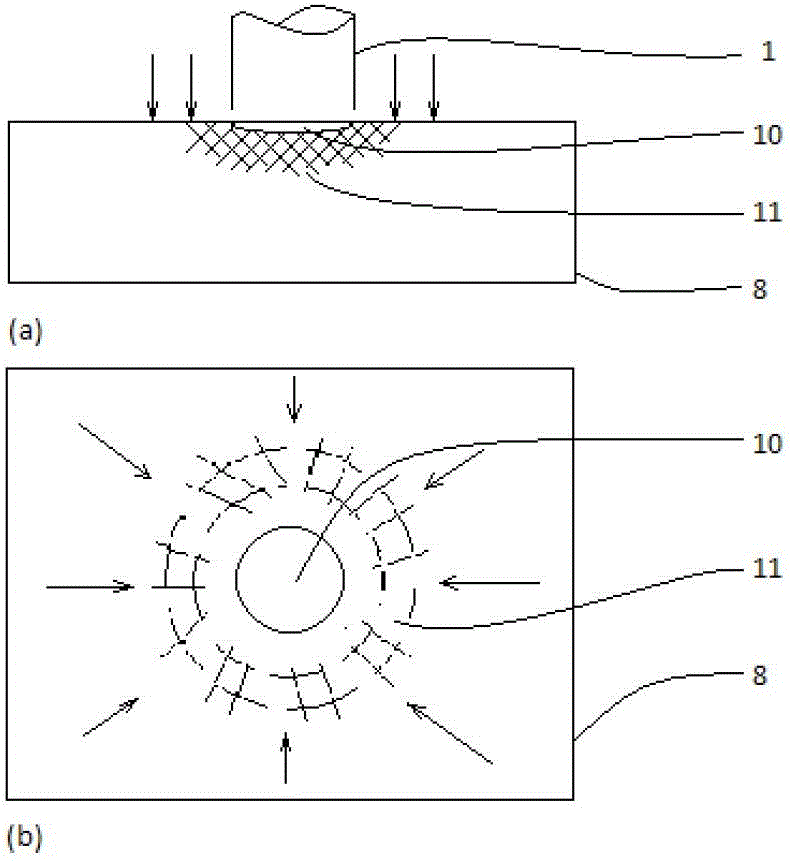

Method and device for improving room temperature plasticity of block amorphous alloy and structural member of block amorphous alloy

The invention relates to a method and a device for improving room temperature plasticity of block amorphous alloy and the structural member of the block amorphous alloy. The method comprises the following steps of: polishing and smoothening the surface of an amorphous alloy body and placing the polished amorphous alloy body on a rigid cushioning plate; introducing short-pulse laser beams to the surface of the polished amorphous alloy body through a boss with a center hole to generate explosion plasma impact waves which act on the amorphous alloy body so that an irradiated region generates trace high-strain-rate plastic deformation and compact shearing zone and residual compressive stress are formed. According to the invention, multiple mechanical and materialogical mechanisms for improving the room temperature plasticity of the amorphous alloy are compressively utilized, thus the plasticizing effect is obvious, and the method and the device are suitable for various amorphous alloy materials.

Owner:SHANDONG UNIV

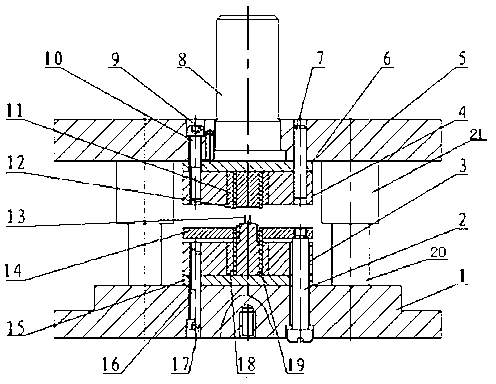

Punching blanking die

InactiveCN104550435AQuick changeSimple structurePerforating toolsStripping-off devicesPunchingEngineering

The invention discloses a punching blanking die. The punching blanking die comprises a die holder, an embedding cavity die, a punch assembly and a return spring; the die holder is provided with a punch supporting portion and a cavity die supporting portion; a plate arranging area is formed between the punch supporting portion and the cavity supporting portion; the embedding cavity die is installed on the cavity die supporting portion; the punch assembly is provided with a punch; the punch penetrates a punch supporting portion of the die holder; the punch can move relative the punch supporting portion; the punch is matched with the embedding cavity die to enable plate blanking to be convenient; the return spring is arranged between the punch assembly and the punch supporting portion. According to the punching blanking die, the punch can be rapidly replaced, the structure is simple, the operation is simple, the machining is flexible, costs are reduced, products in various types can be punched, the efficiency is high, and the costs are low.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

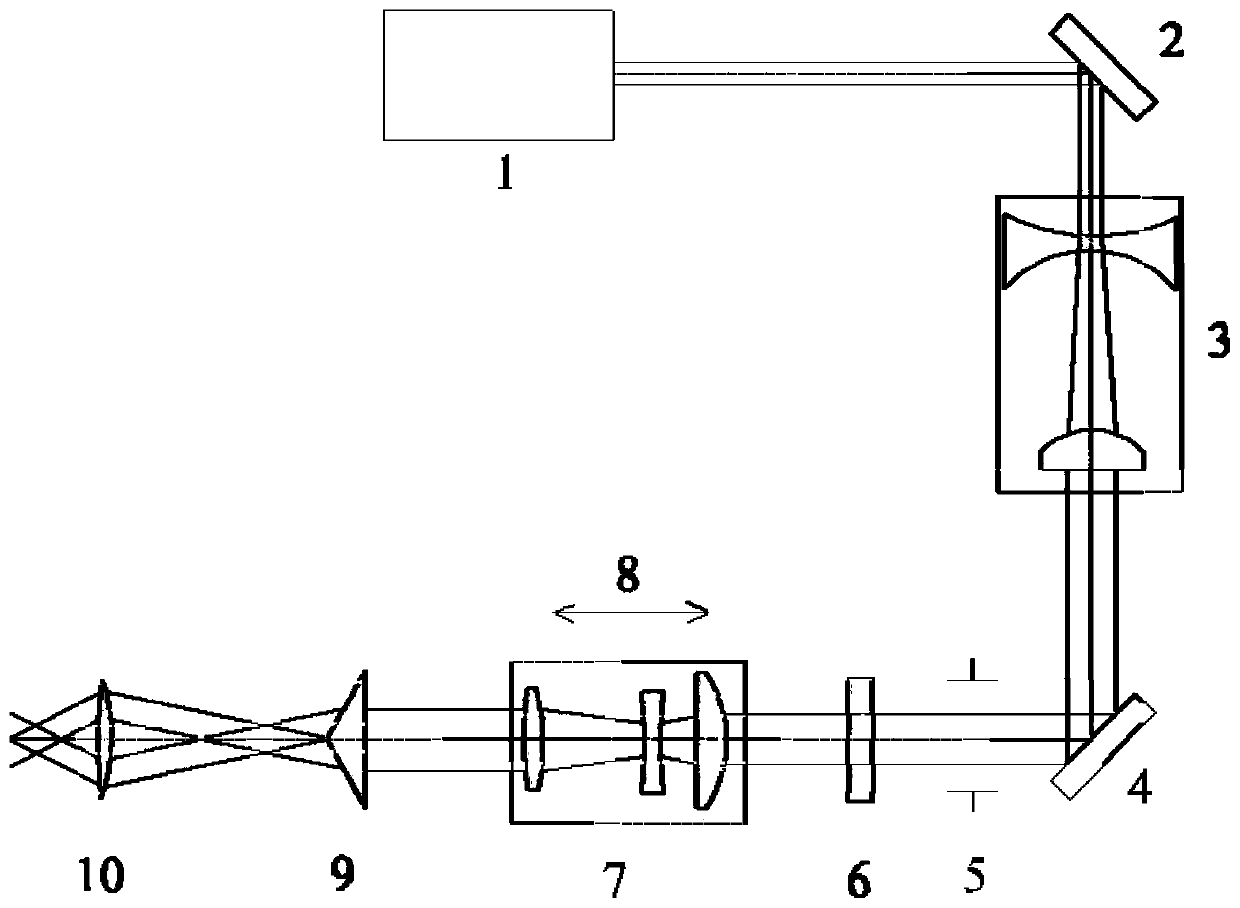

Focal spot-and-focal depth-variable Bessel beam laser processing system and method

ActiveCN111505831AMeet processing needsFlexible switchingLaser beam welding apparatusOptical elementsBeam expanderLaser processing

The invention belongs to the field of laser precision manufacturing and to a focal spot-and-focal depth-variable Bessel beam laser processing system and method and aims to solve the problem that an existing Bessel beam laser processing system cannot be suitable for processing different hole patterns and material thicknesses. The system comprises a laser, a beam expander, a diaphragm, a wave plate,a zoom lens, a positive axis pyramid and a lens, wherein the beam expander, the diaphragm, the wave plate, the zoom lens, the positive axis pyramid and the lens are sequentially arranged in the emergent light path of the laser; a light beam emitted from the laser is expanded and homogenized by the beam expander; the laser beam enters the diaphragm to be subjected to stray light filtering; after the filter laser beam reaches the wave plate and then enters the zoom lens, the focal length of the zoom lens and the distance between the zoom lens and the positive axis pyramid are adjusted, so thatthe focal spot and focal depth of the generated Bessel beam can be changed, and therefore, a required processing light beam is obtained; the light beam acts on the surface of a workpiece after being focused by the lens. By means of the system, the focal spot and focal depth changes of the processing Bessel beam can be realized, the multi-purpose processing of large-depth-diameter-ratio micropores,transparent materials and the like is achieved, and guarantees are provided for high-precision micropore pattern manufacturing, high-quality transparent material cutting and the like.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

New type two dimension moving two dimension rotating parallel machine tool

A 3D moving and 2D rotation parallel machine-tool is composed of fixed platform, moving platform for installing cutting tool, and bench. Said fixed and moving platforms are linked via 5 leg containing moving set. The central one of said legs contains 3 moving sets and Hooke pivot. One moving set is linked to the fixed platform. Other 4 legs are linked with fixed platform via Hooke pivots and with moving platform via ball-and-socket unit. Changing the extensions of 5 legs can realize 5-axle machining. Its advantages are high precision, stability and flexibility and low cost.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com