Pneumatic numerical control shot blasting strengthen machine

A technology of shot peening and shot peening chamber, which is applied in the field of surface shot peening treatment equipment, which can solve the problem that the shot peening machine cannot accurately control the speed of the shot, and achieve simplified programming, low dust concentration, and good adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

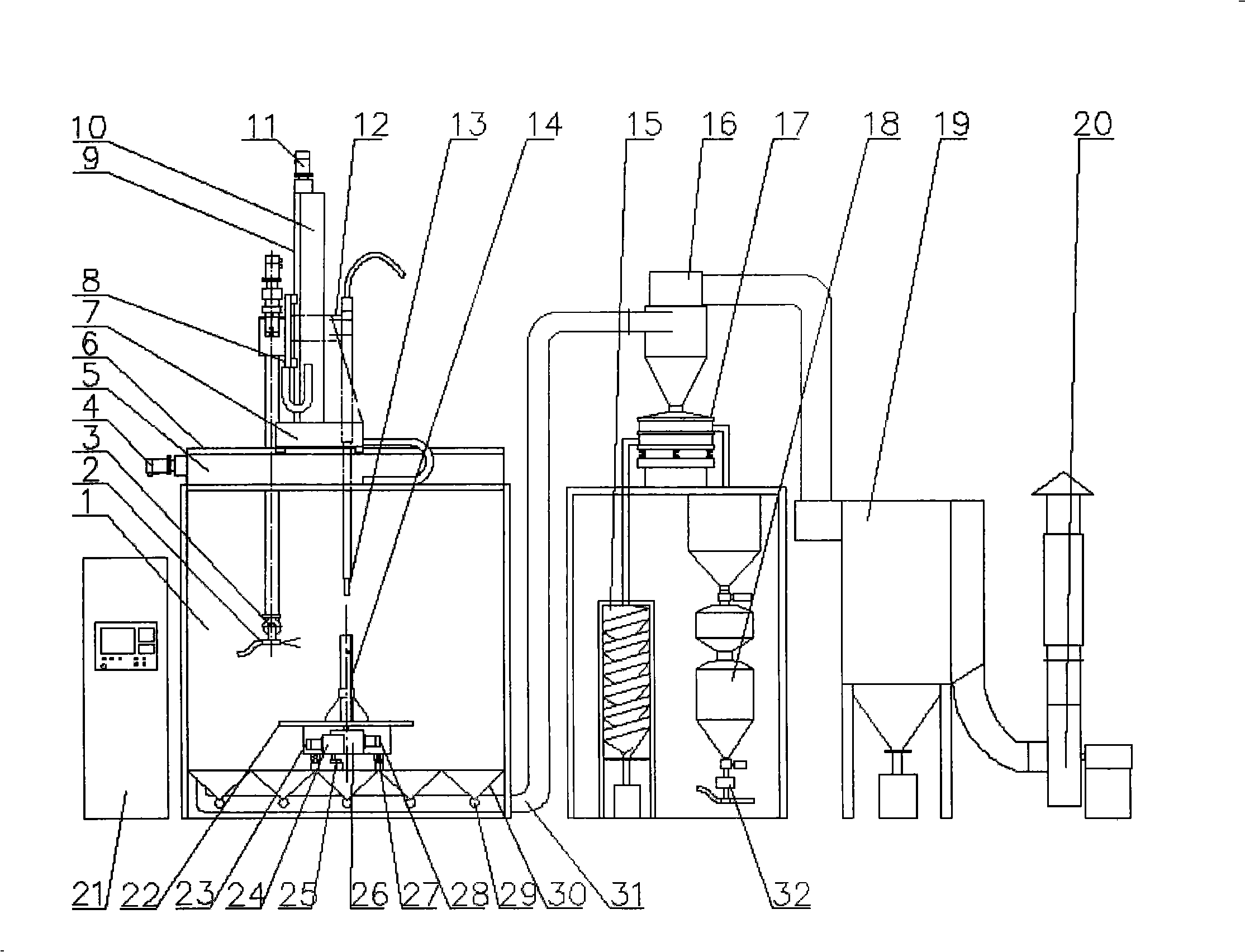

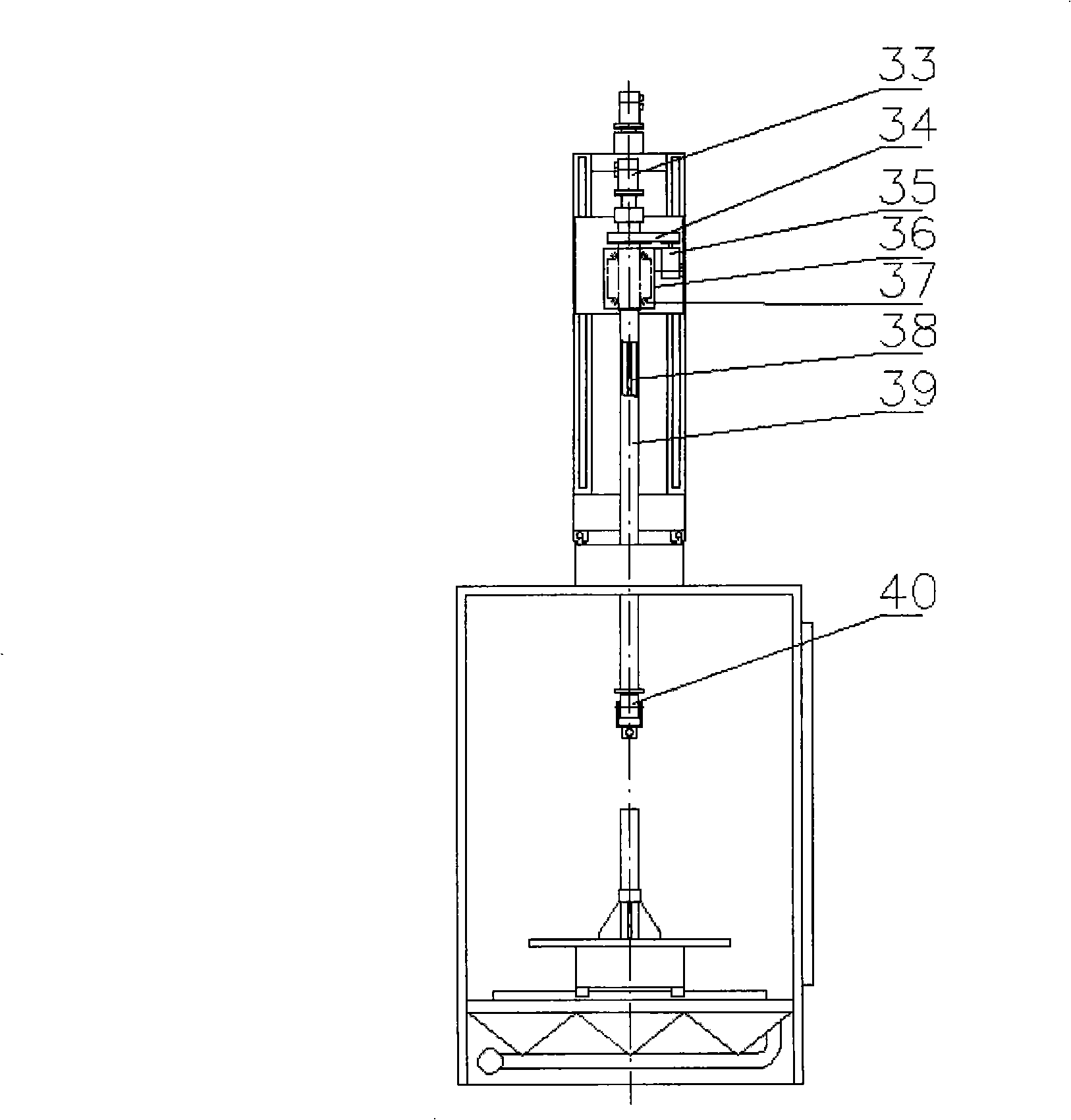

[0019] figure 1 , figure 2 It describes the shot blasting chamber 1, shot blasting tank 18, CNC rotary table 22, CNC manipulator 3, spiral circle selector 15, separator 16, vibration screening machine mainly controlled by CNC (the abbreviation of Computer number control) 17. A best embodiment of a numerically controlled shot peening machine composed of a dust collector 19, a centrifugal fan 20, an electric control device 21, and the like.

[0020] The workpiece 14 is clamped on the numerically controlled rotary table 22, and the outer wall spray gun 2 is clamped by the numerically controlled manipulator 3 to perform shot peening on the outer surface of the workpiece.

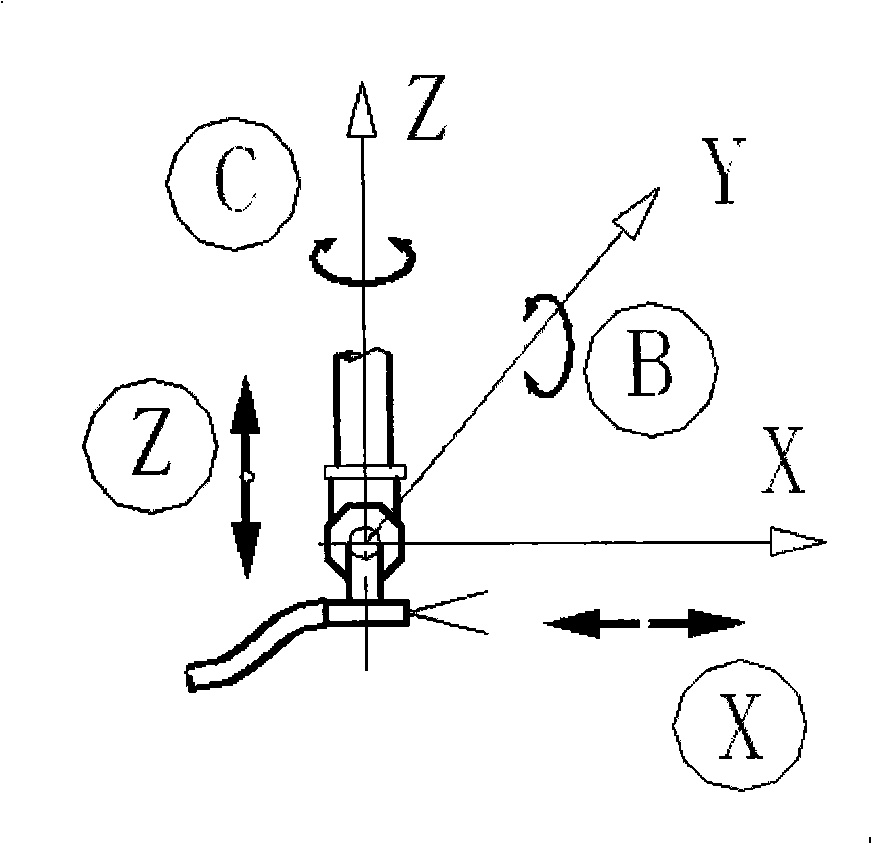

[0021] The degree of freedom of rotation and the degree of freedom of movement of the CNC rotary table 22 are driven by servo motors. Among them, the C-direction rotation and positioning are driven by the worktable C-direction servo motor 28 and right-angle reducer 26 installed in it; the Y-direction moving f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com