Physicochemical treatment system and physicochemical treatment method for hazardous wastes

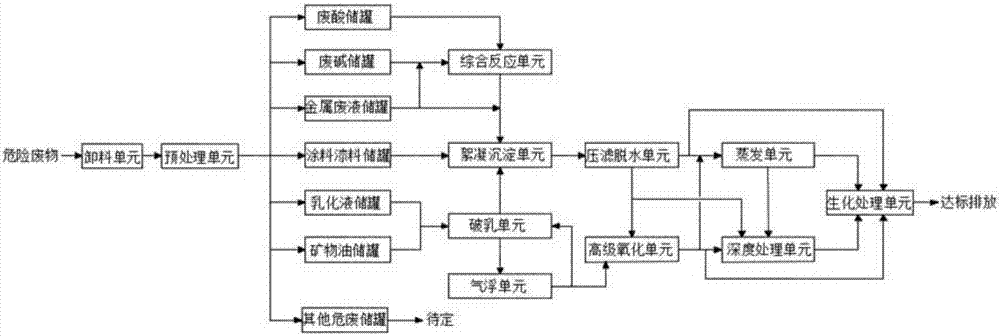

A hazardous waste and treatment system technology, applied in the field of hazardous waste physical and chemical treatment system, can solve problems such as poor adaptability, achieve strong impact load resistance, improve safety and stability, and achieve standard discharge or reuse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

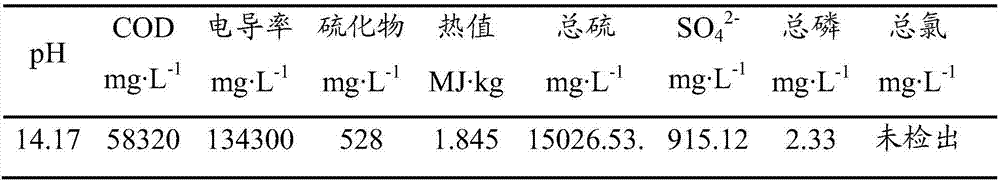

[0081] The organic waste lye was obtained from the petrochemical gasoline and diesel desulfurization process, and its water quality detection index data are shown in Table 1.

[0082] Table 1 Organic waste lye water quality detection index data

[0083]

[0084] Due to the high pH value of the organic waste lye, first use waste acid to adjust the pH value of the organic waste lye. When the pH of the organic waste lye drops to neutral, a large number of flocs are found, so flocculation precipitation is used. The agent uses polyaluminum chloride (PAC) and anionic polyacrylamide (APAM). The effluent after flocculation and precipitation enters the filter press dehydration unit for solid-liquid separation. Due to the high COD of the filtrate, the waste acid was used to continue to adjust the pH value to acidity for Fenton oxidation treatment. For each ton of organic waste lye, the dosage of PAC is 2kg, the dosage of APAM is 0.01kg, the dosage of ferrous sulfate is 16.68kg, and...

Embodiment 2

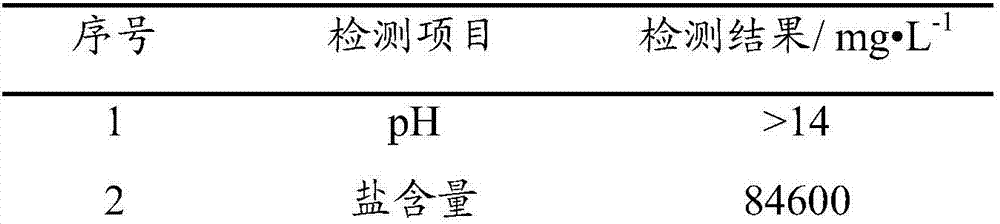

[0086] The organic waste lye is taken from the MTO project workshop. The main characteristics of the waste lye are high pH value, high COD value, high salt content, heavy odor, and reddish brown. The main detection index data are shown in Table 2.

[0087] Table 2 Organic waste lye detection index data

[0088]

[0089]

[0090] Use waste to treat waste, use waste acid to adjust the pH of the solution to neutral, and add polyferric sulfate (PFS) and cationic polyacrylamide (CPAM) for flocculation and precipitation to reduce the color, turbidity and organic matter of the solution. The effluent after flocculation and precipitation enters the filter press dehydration unit for solid-liquid separation. Due to the high COD and salt content of the filtrate, use waste acid to continue to adjust the pH value to acidity, add Fenton reagent for deep oxidation, degrade COD, sulfide and other refractory substances, and enter the evaporation unit to remove them after two Fenton oxidat...

Embodiment 3

[0092] The main characteristics of waste paint water are large chroma and turbidity, many suspended solids, heavy odor, pungent odor, and high COD. The mixed centralized treatment of three kinds of paint dye hazardous wastes from Langfang, Table 3 is the water quality detection index data of three kinds of paint dye hazardous wastes.

[0093] Table 3 Three kinds of coating dye hazardous waste water quality detection index data

[0094]

[0095]

[0096] Classification and centralized treatment are adopted. After mixing the three hazardous wastes of paint and dyes in Langfang, they will be treated in one batch. After mixing, flocculants are first added to decolorize and remove turbidity. The effluent after flocculation and precipitation enters the filter press dehydration unit for solid-liquid separation. Due to the high COD of the filtrate, use waste acid to continue to adjust the pH value to acidity, then add Fenton's reagent to degrade toxic and refractory substances,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com