Moisture-conducting quick-drying weft-knitted fabric and processing technology thereof

A processing technology and fabric technology, used in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of high price, functional additives are not washable, and cannot be printed at high temperature, and achieve low cost of raw materials and moisture-conducting functions. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

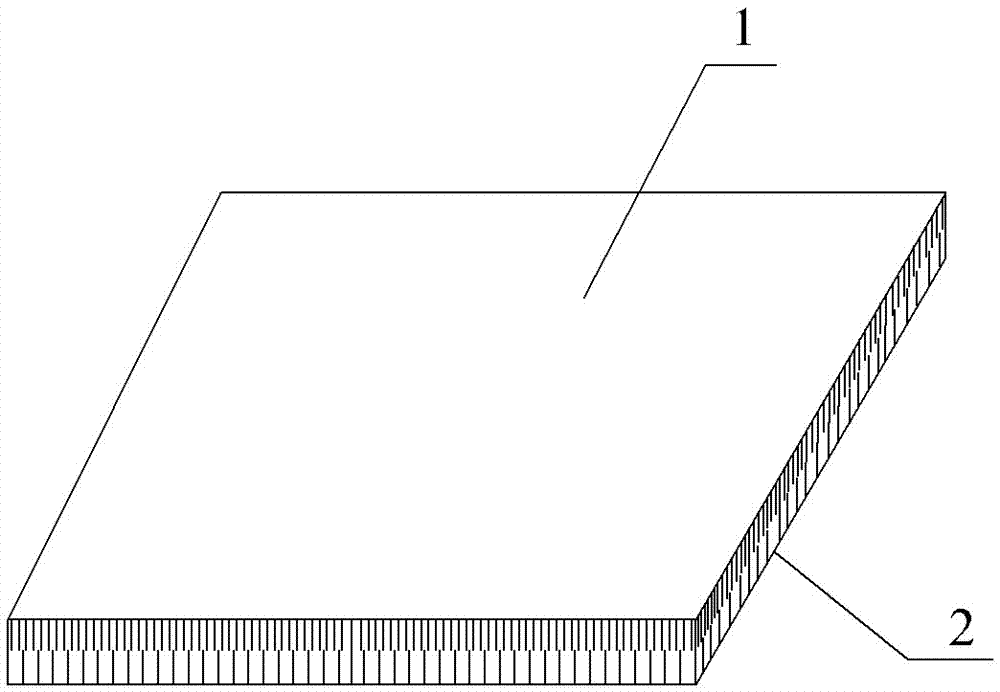

Image

Examples

Embodiment 1

[0026] The processing technology of moisture-conducting and quick-drying knitted weft-knitted fabric of the present invention comprises the following process steps: gray cloth weaving→pretreatment→dyeing→reduction washing→high temperature setting→reduction washing→finished product setting→embossing.

[0027]Among them, when weaving gray cloth, two kinds of yarns with different DPF are selected, among which the yarn with small DPF is 75D / 144F ordinary semi-gloss low-elastic light mesh polyester yarn, and the yarn with large DPF is 75D / 36F ordinary semi-gloss low-elasticity light mesh Net polyester yarn, put them on a 34"28G102F large circular machine to weave dobby fabric, and use double yarn feeding to make a single-sided jersey with a silk-covered silk structure. For 75D / 144F, the feeding yarn goes up the hole; the reverse side has an even number of paths, and the yarn frame is 75D / 36F, and the feeding yarn goes down the hole. 100% of the area, the loop forming area of the ...

Embodiment 2

[0039] The processing technology of the moisture-conducting and quick-drying knitted weft-knitted fabric of the present invention comprises the following process steps: gray cloth weaving→pretreatment→dyeing→reduction washing→high temperature setting→reduction washing→finished product setting→embossing.

[0040] Among them, when weaving gray cloth, two kinds of yarns with different DPF are selected, among which the yarn with small DPF is 75D / 144F ordinary semi-gloss low-elastic light mesh polyester yarn, and the yarn with large DPF is 75D / 36F ordinary semi-gloss low-elasticity light mesh Net polyester yarn, put them on a 34"28G102F large circular machine to weave dobby fabric, and use double yarn feeding to make a single-sided jersey with a silk-covered silk structure. For 75D / 144F, the feeding yarn goes up the hole; the reverse side has an even number of paths, and the yarn frame is 75D / 36F, and the feeding yarn goes down the hole. 95% of the area, and the loop forming area o...

Embodiment 3

[0050] The processing technology of the moisture-conducting and quick-drying knitted weft-knitted fabric of the present invention comprises the following process steps: gray cloth weaving→pretreatment→dyeing→reduction washing→high temperature setting→reduction washing→finished product setting→embossing.

[0051] Among them, when weaving gray cloth, two kinds of yarns with different DPF are selected, among which the yarn with small DPF is 75D / 144F ordinary semi-gloss low-elastic light mesh polyester yarn, and the yarn with large DPF is 75D / 36F ordinary semi-gloss low-elasticity light mesh Net polyester yarn, put them on a 34"28G102F large circular machine to weave dobby fabric, and use double yarn feeding to make a single-sided jersey with a silk-covered silk structure. For 75D / 144F, the feeding yarn goes up the hole; the reverse side has an even number of paths, and the yarn frame is 75D / 36F, and the feeding yarn goes down the hole. 90% of the area, and the loop forming area o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com