Patents

Literature

503results about How to "Guaranteed grinding quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

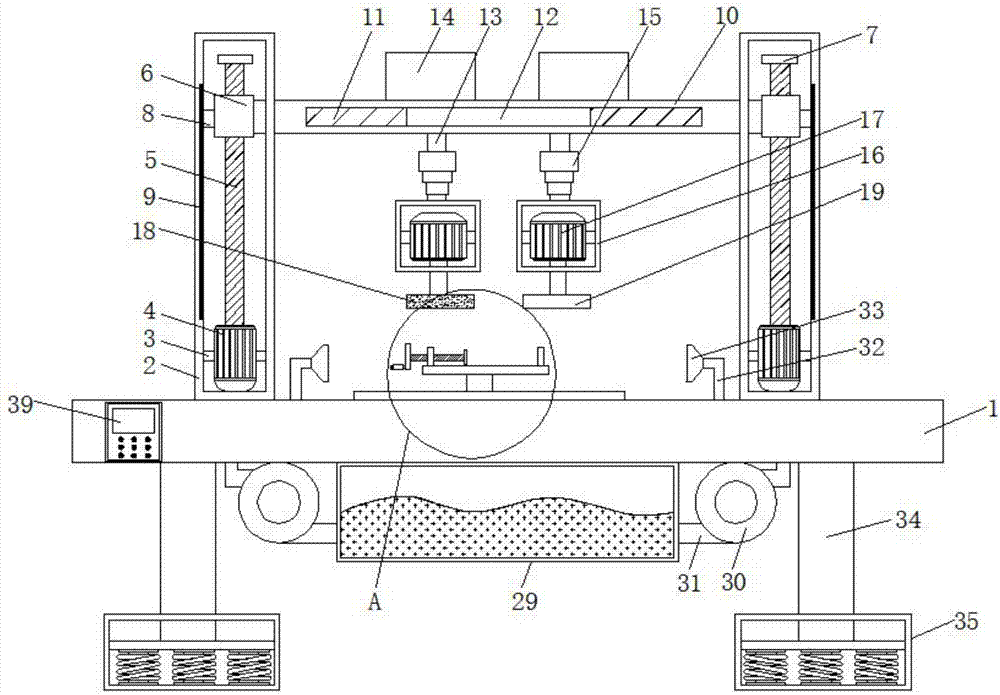

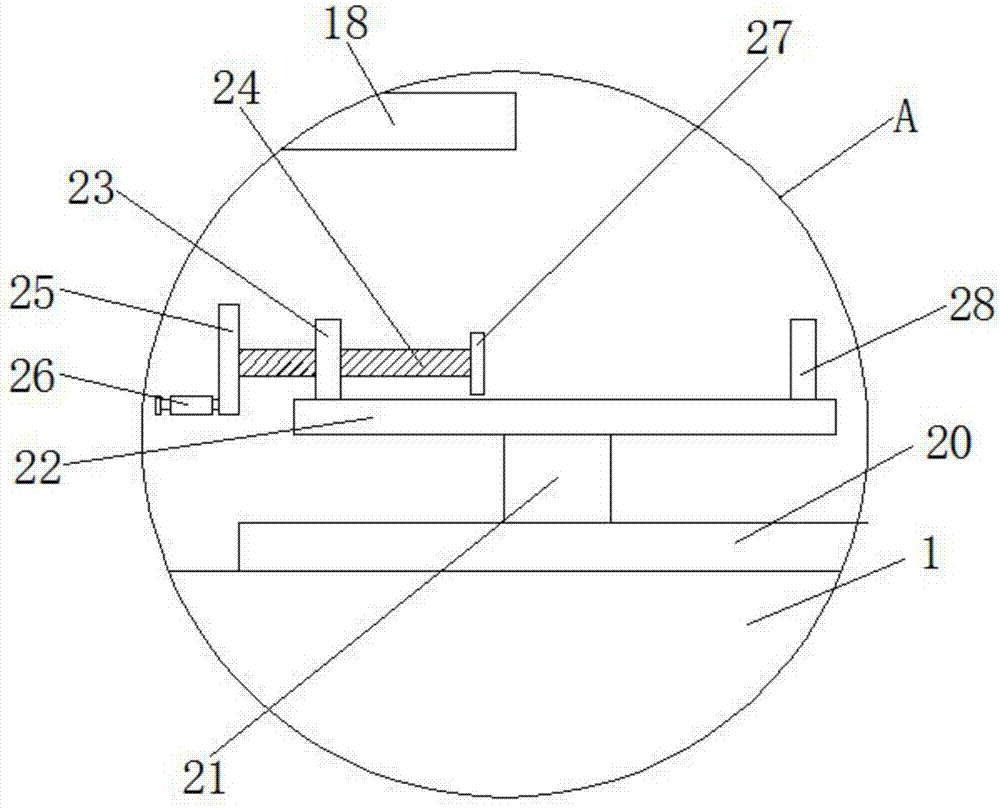

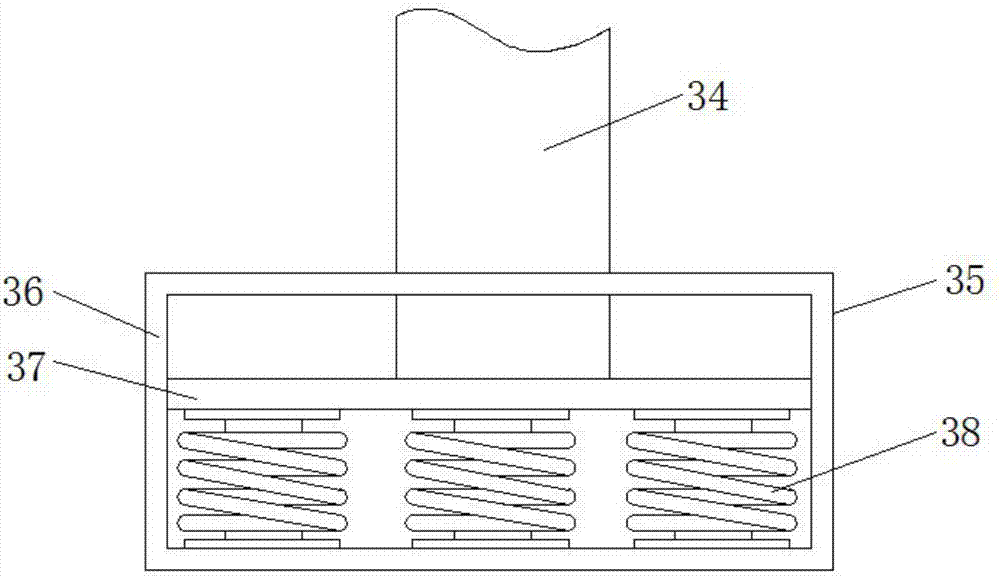

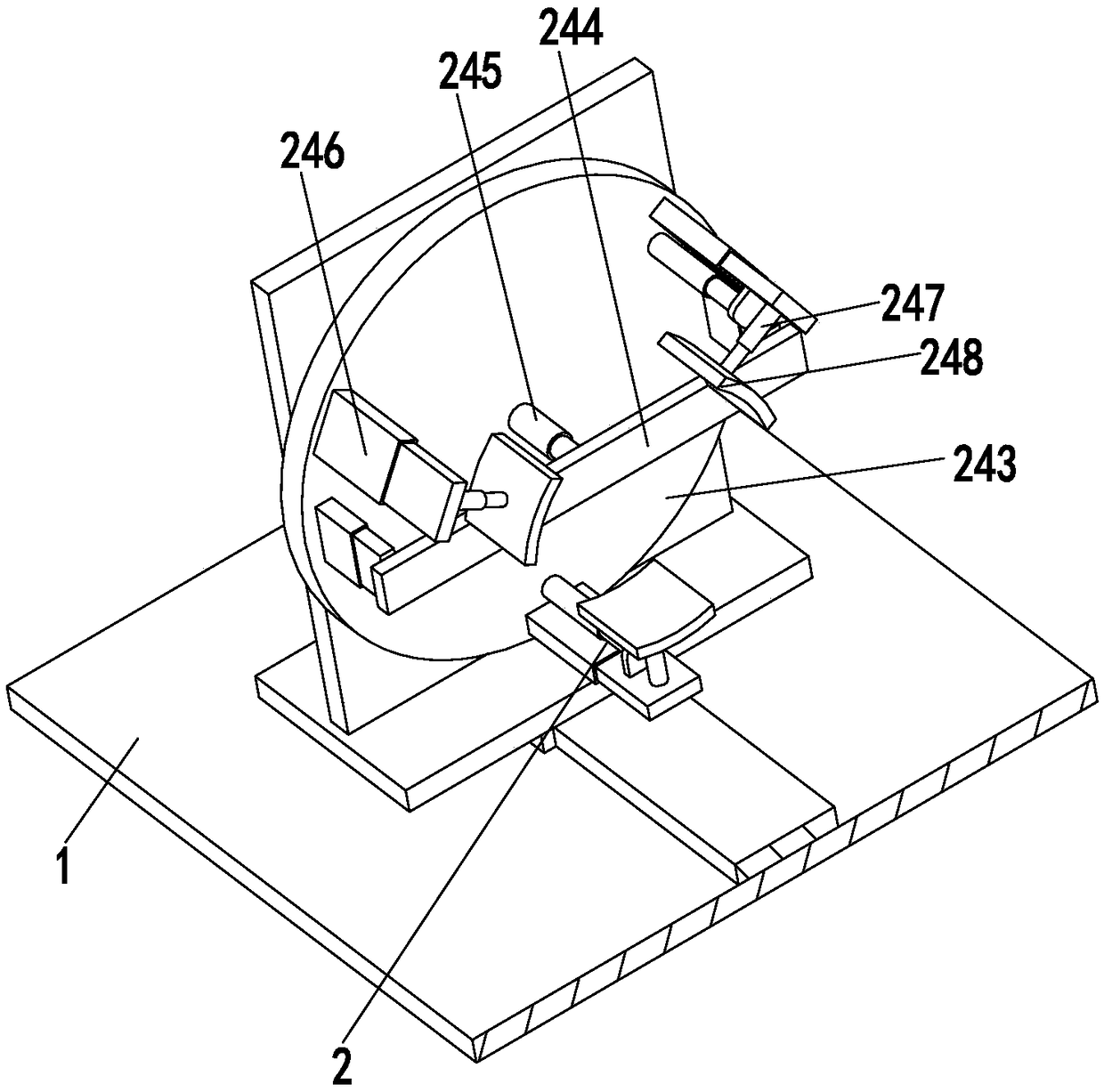

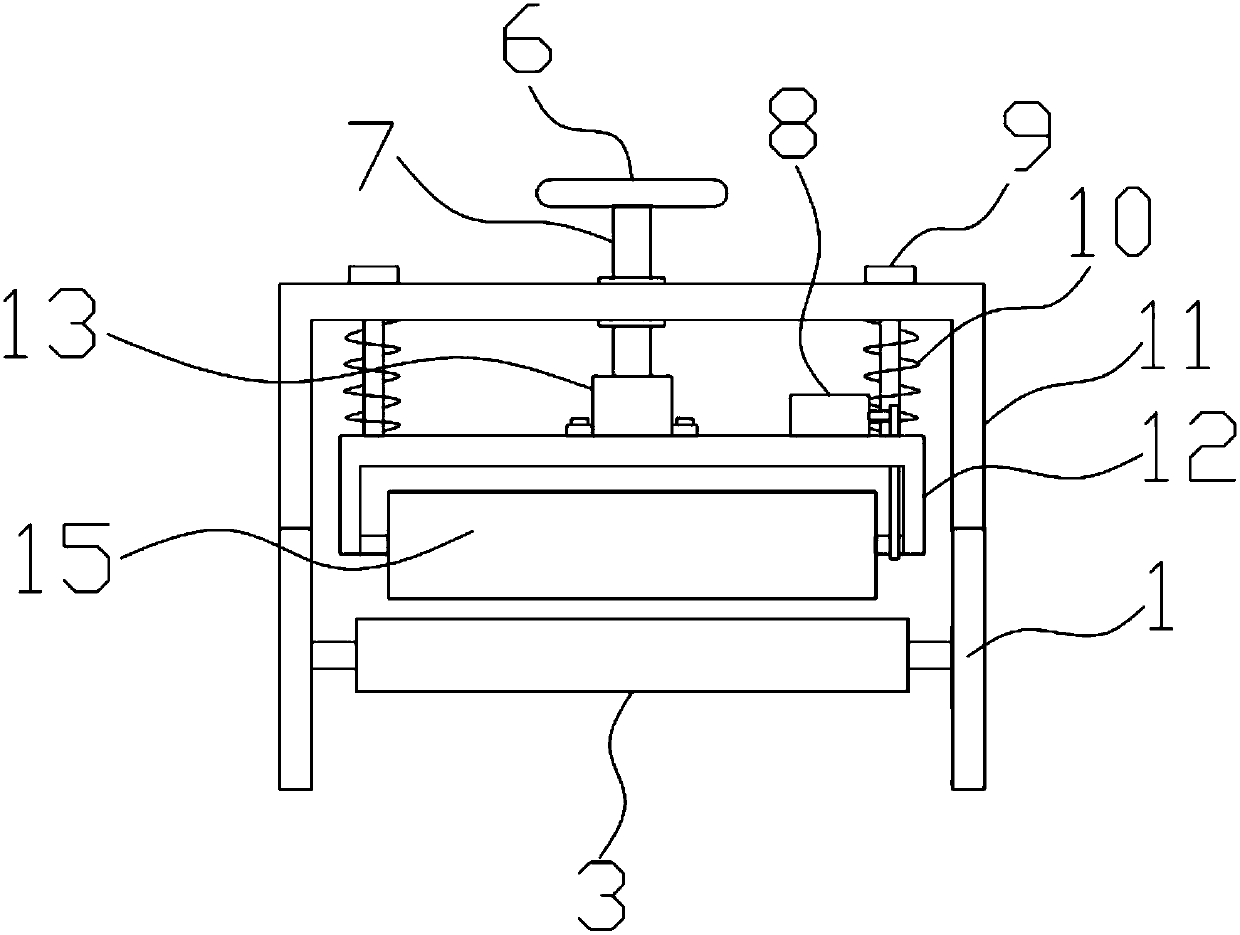

Automobile gear end surface polishing device

InactiveCN107336096AQuality improvementEasy to polishGrinding carriagesGrinding work supportsGear wheelEngineering

The invention provides an automobile gear end surface polishing device, and relates to the technical field of automobile gear polishing. The automobile gear end surface polishing device comprises a working table, standing columns are fixedly installed on both sides of the top of the working table, and motor mounting blocks are fixedly installed on both sides of the inner wall of each standing column. According to the automobile gear end surface polishing device, through arrangement of telescopic motors, threaded rods, telescopic blocks, sliding rods, a strip-shaped sliding groove and a cross plate, a polishing device body on the bottom of the cross plate can vertically move between the two standing columns under driving of the telescopic motors; through arrangement of the cross plate, the sliding groove and supports, the polishing device body on the bottom of the cross plate can transversely move on the bottom of the cross plate; through arrangement of a polishing table, a rotating rod and a clamping base, a gear to be polished which is fixed to the top of the clamping base in a clamped mode can conduct circular motion on the bottom of a polishing motor under driving of the rotating rod. In sum, by means of the automobile gear end surface polishing device, the effect that adjustment is convenient is achieved, it is convenient for people to polish the end surface of the gear from different angles, and the quality of the gear after polished is better.

Owner:姚飞

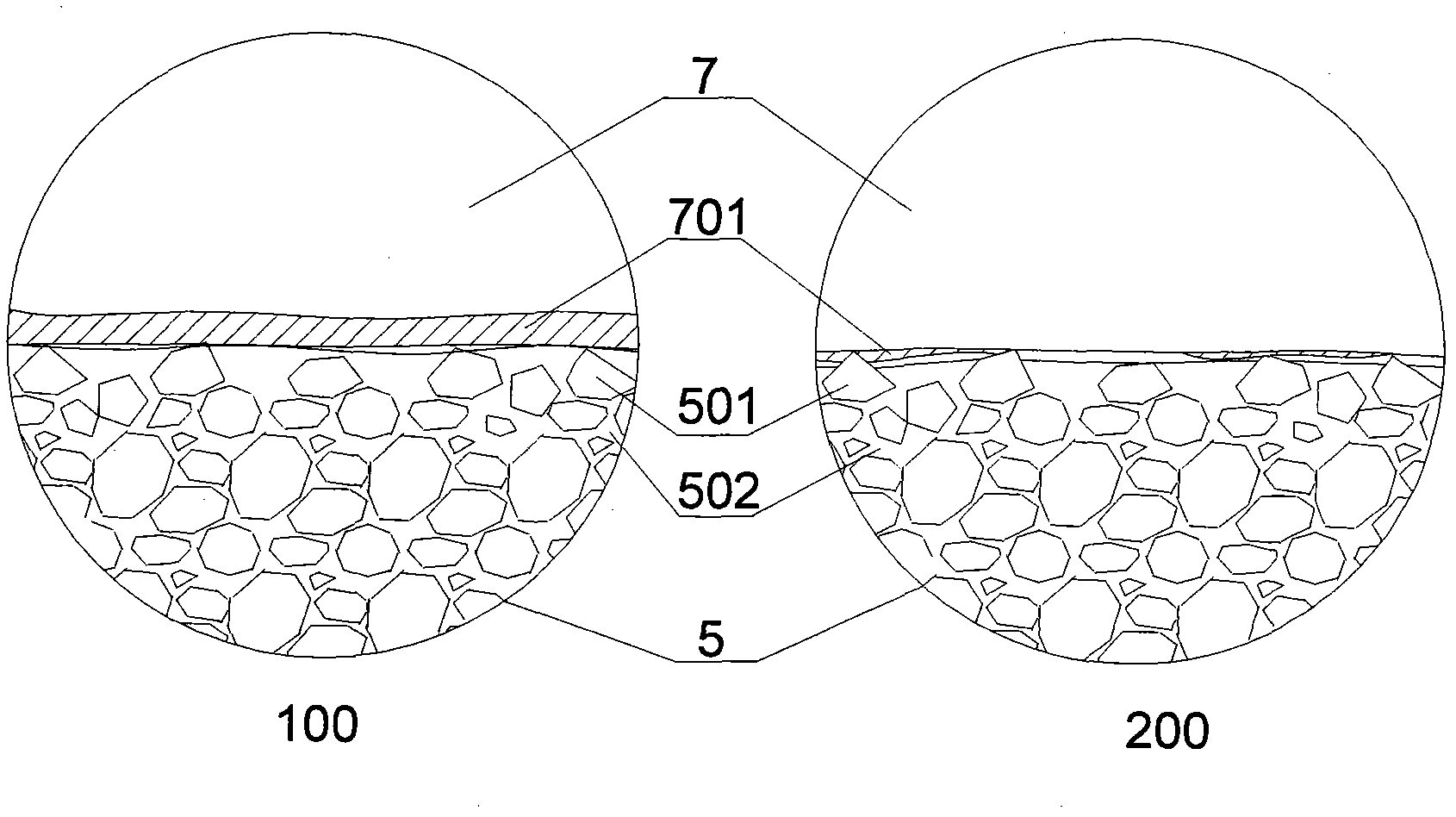

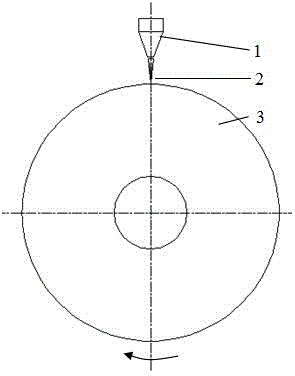

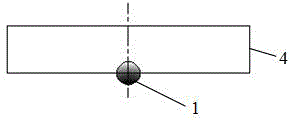

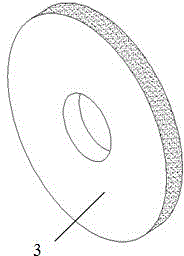

Diamond surface chemical mechanical combined machining method and device thereof

InactiveCN101972979AImprove the efficiency of graphitizationGuaranteed grinding qualityLapping machinesGraphiteAdamite

The invention relates to a diamond surface chemical mechanical combined grinding and polishing method. Composite material is adopted as a tool millstone used for grinding and polishing, the tool millstone is heated to appropriate temperature, and then high speed rotational motion is carried out; certain pressure is utilized to press a diamond film / block to be processed onto the surface of the millstone, so that high speed friction is produced between the diamond film / block and the surface of the millstone, and high efficiency grinding and polishing on the surface of the diamond is realized under the chemical-mechanical combined circulation action of friction region. The method adopts a chemical-mechanical combined way, and the grinding process includes a catalytic surface graphitizing process and a mechanical graphite scraping process. In the combined circulation process of chemical action and mechanical action, diamond surface material is efficiently removed. The related device integrates heating and loading functions, a combined millstone is used as a tool millstone, and the beneficial effects include that processing efficiency is high, mechanical acting force is small and processing quality is good. The invention also relates to a diamond surface chemical mechanical combined grinding and polishing device.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

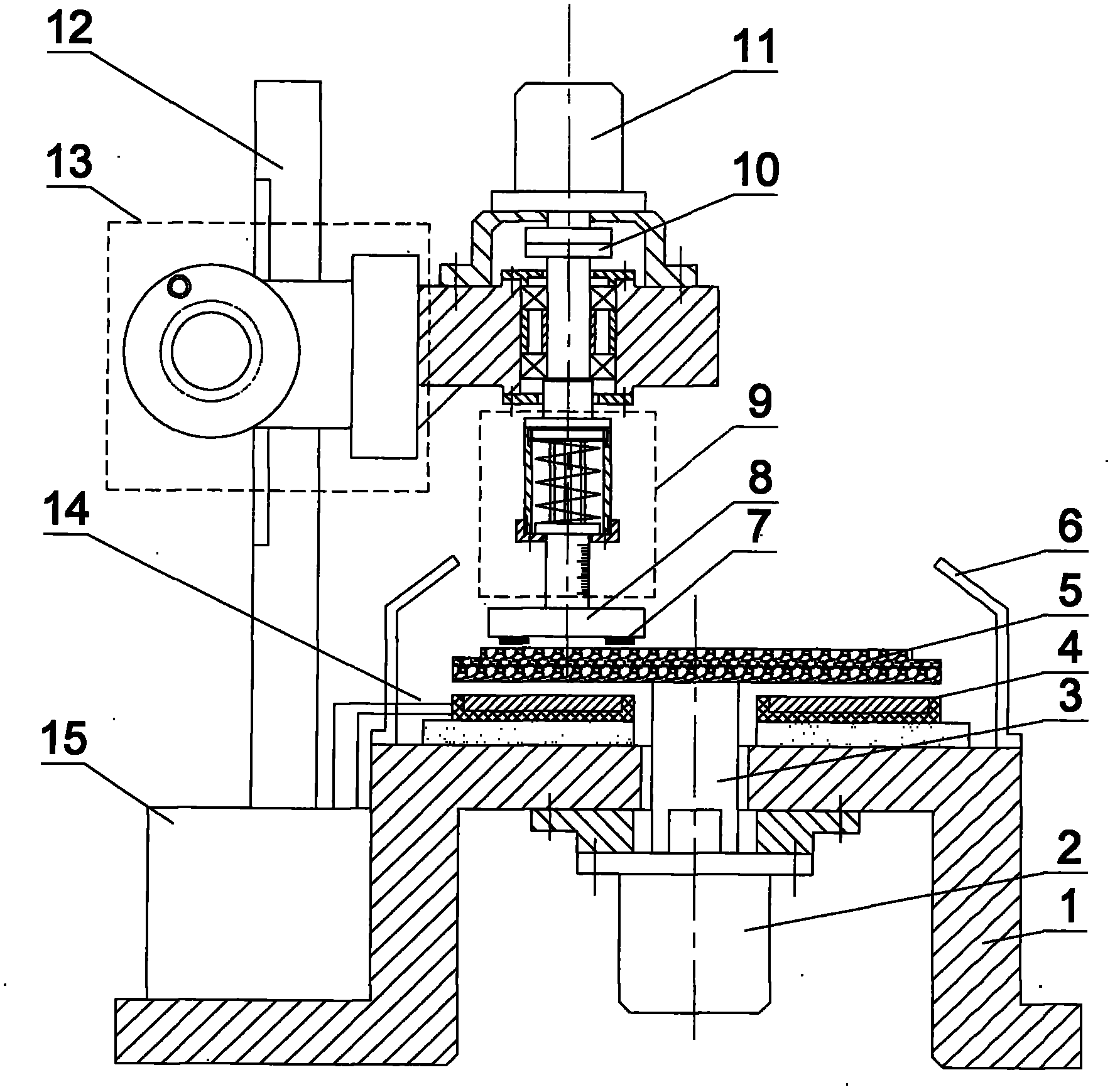

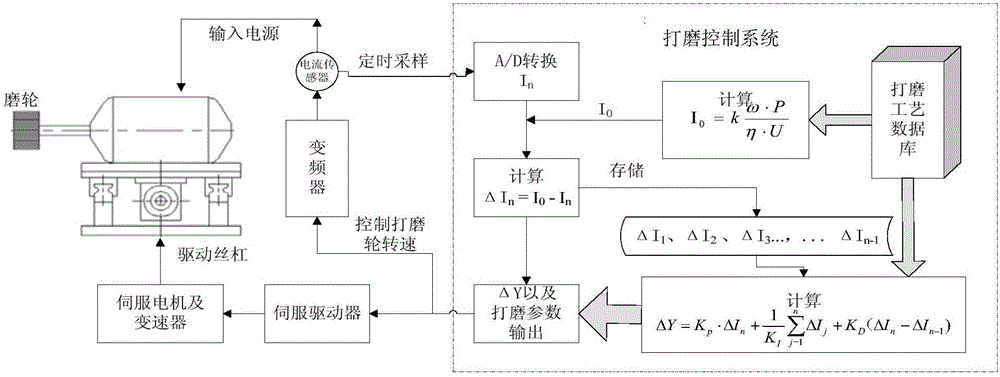

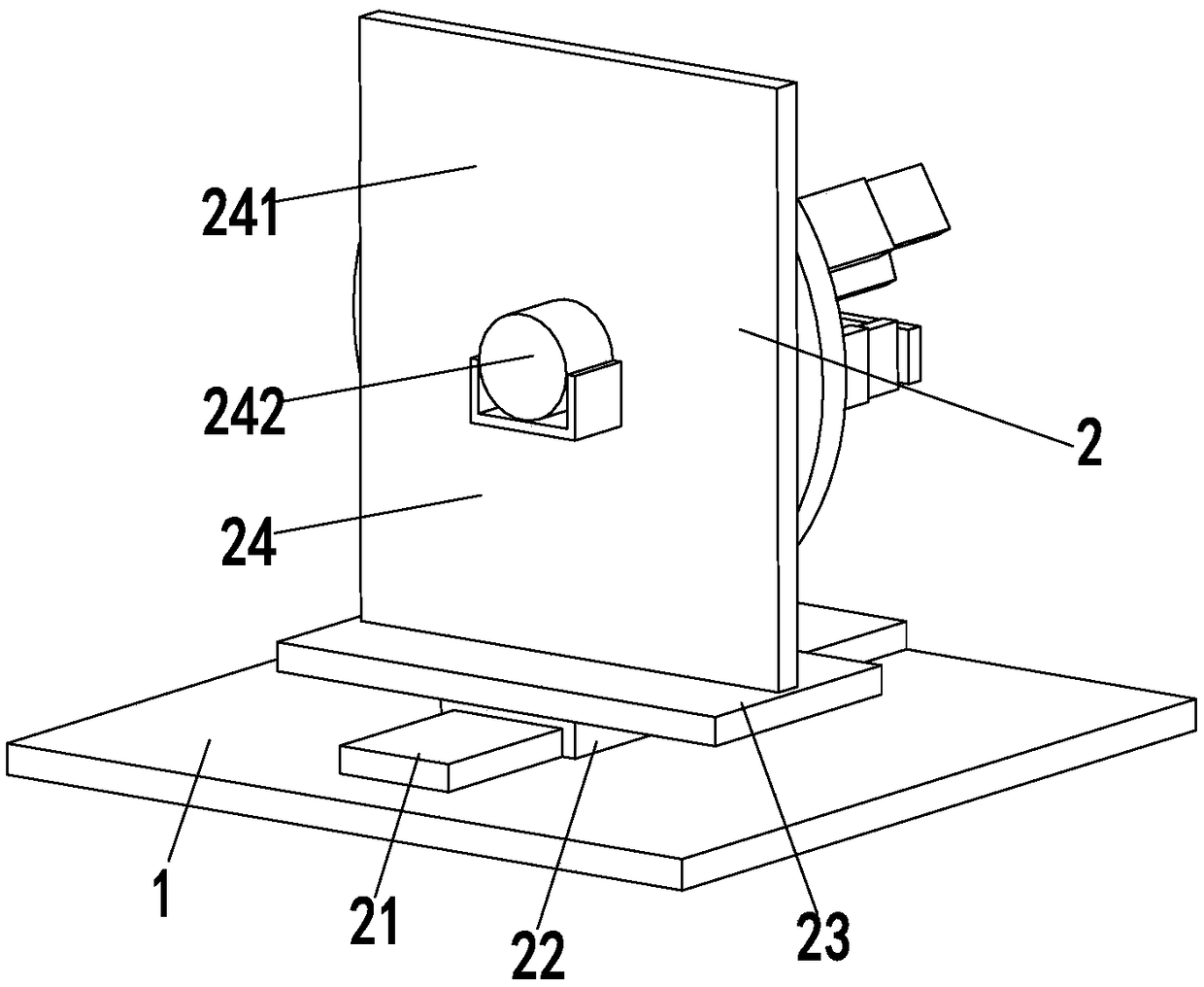

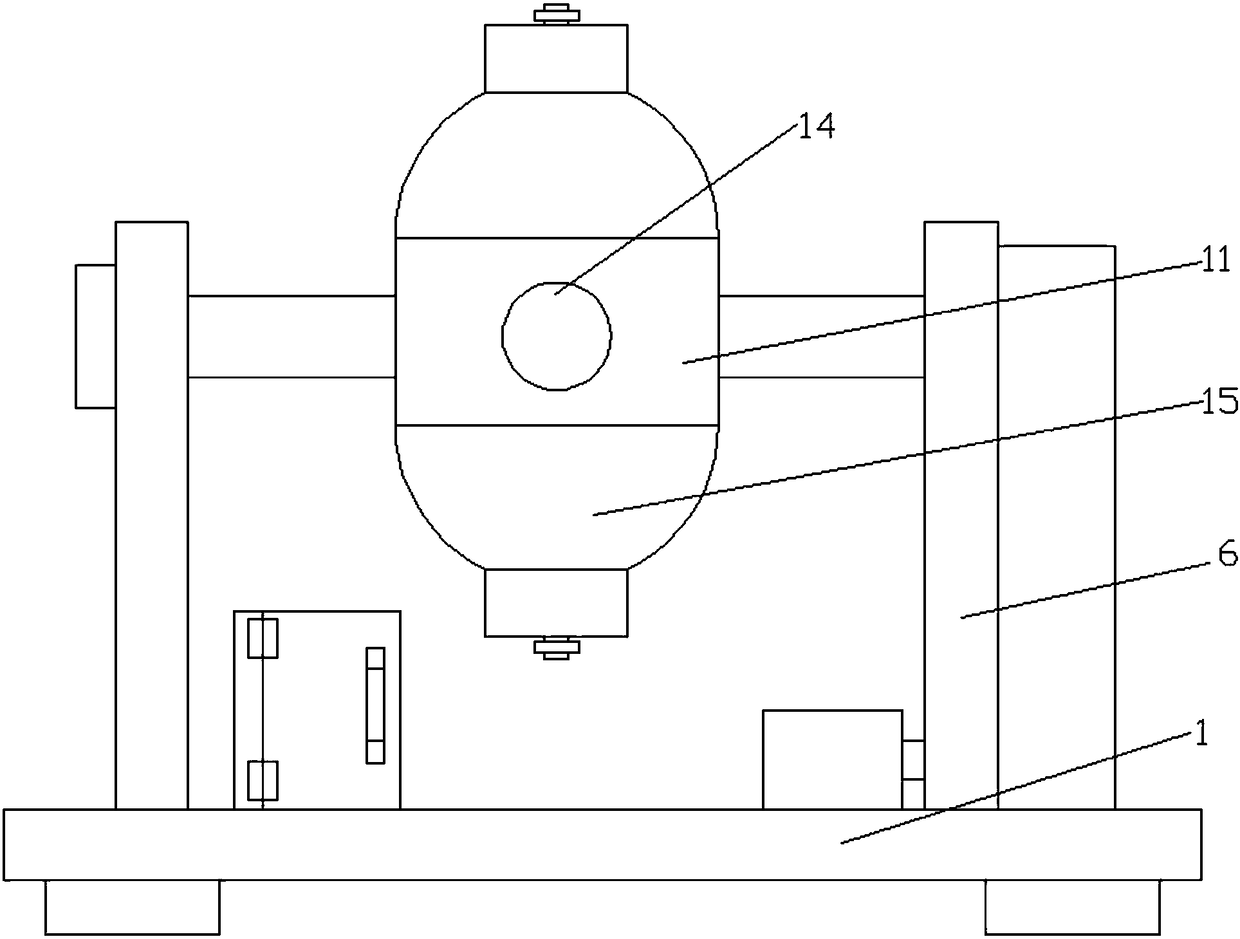

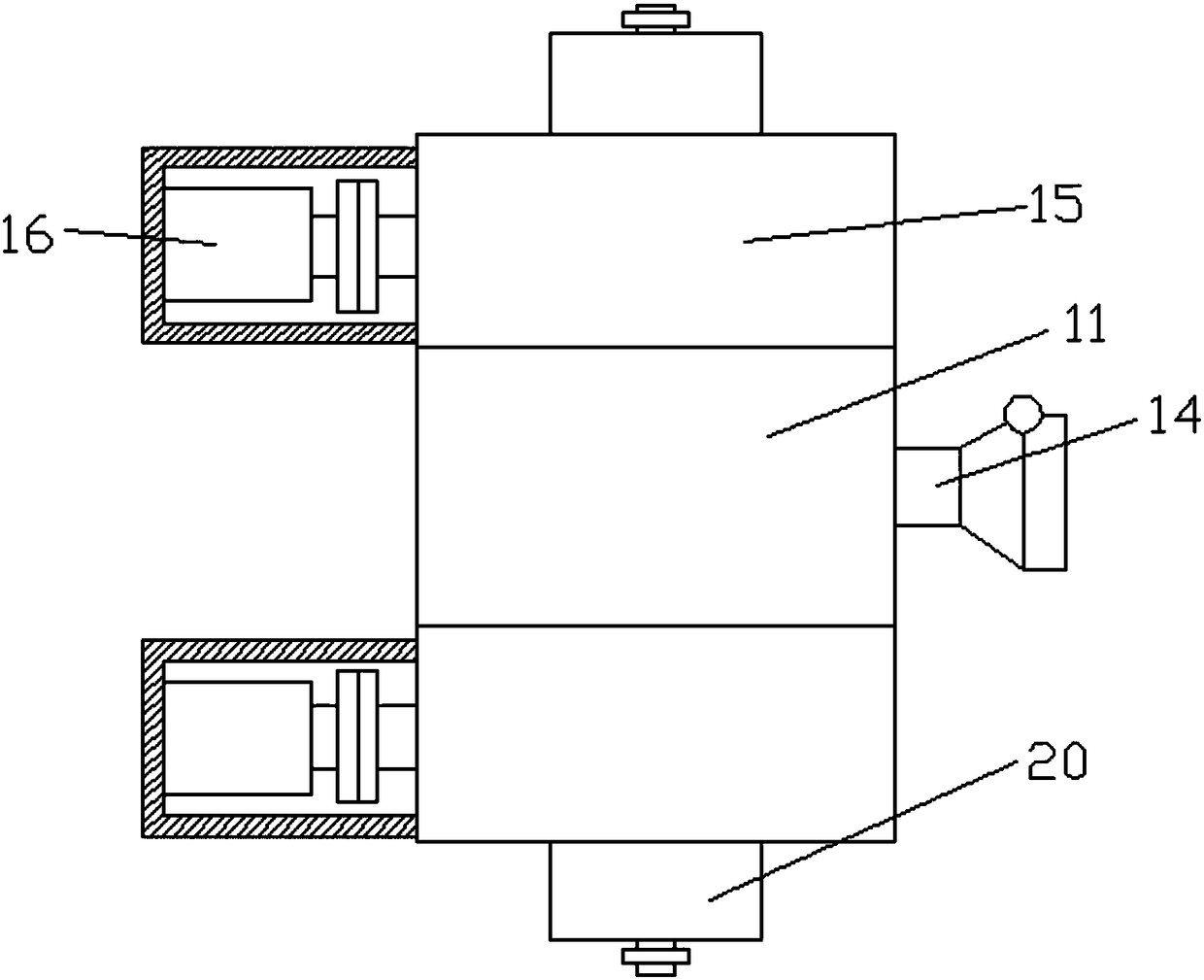

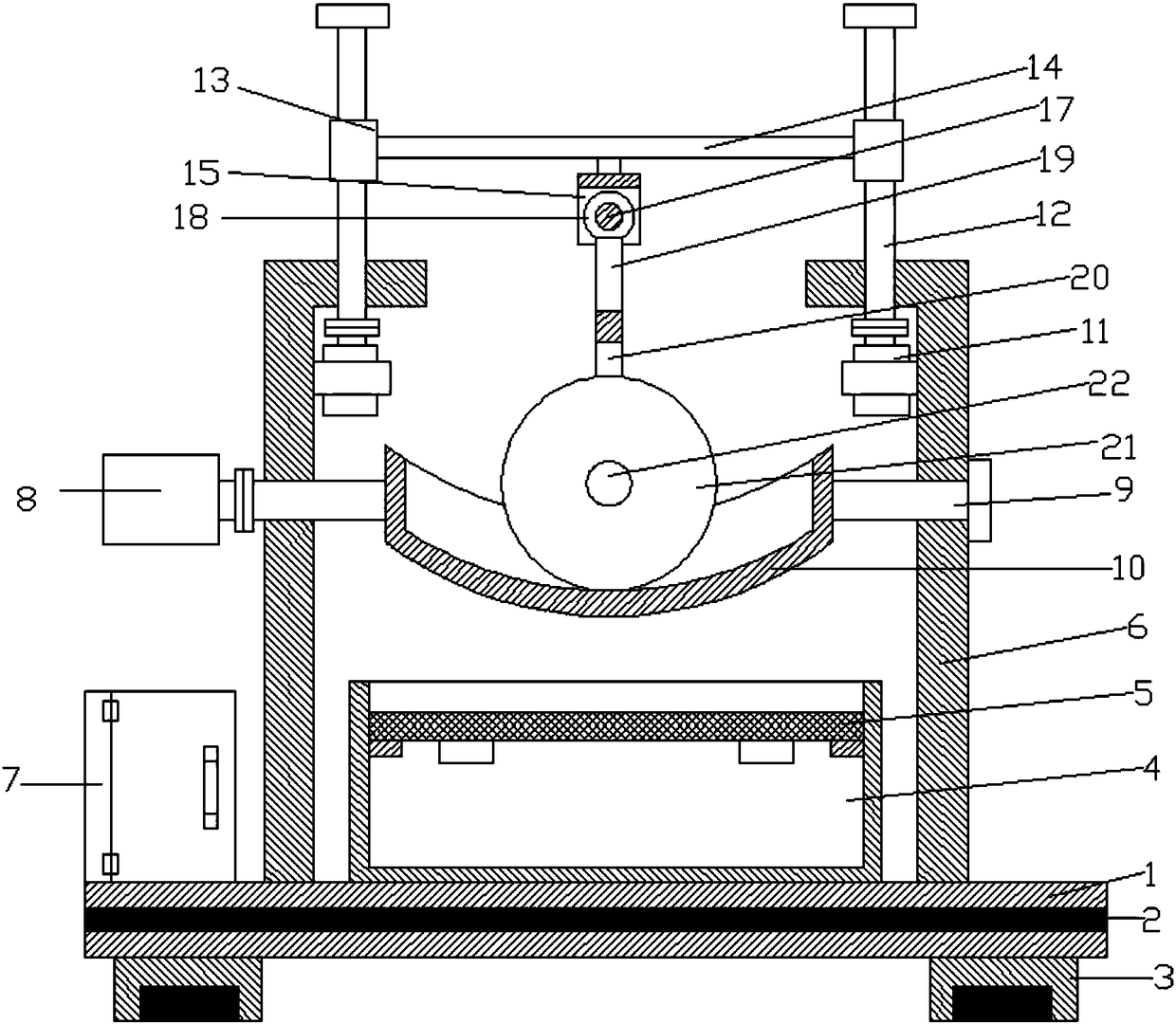

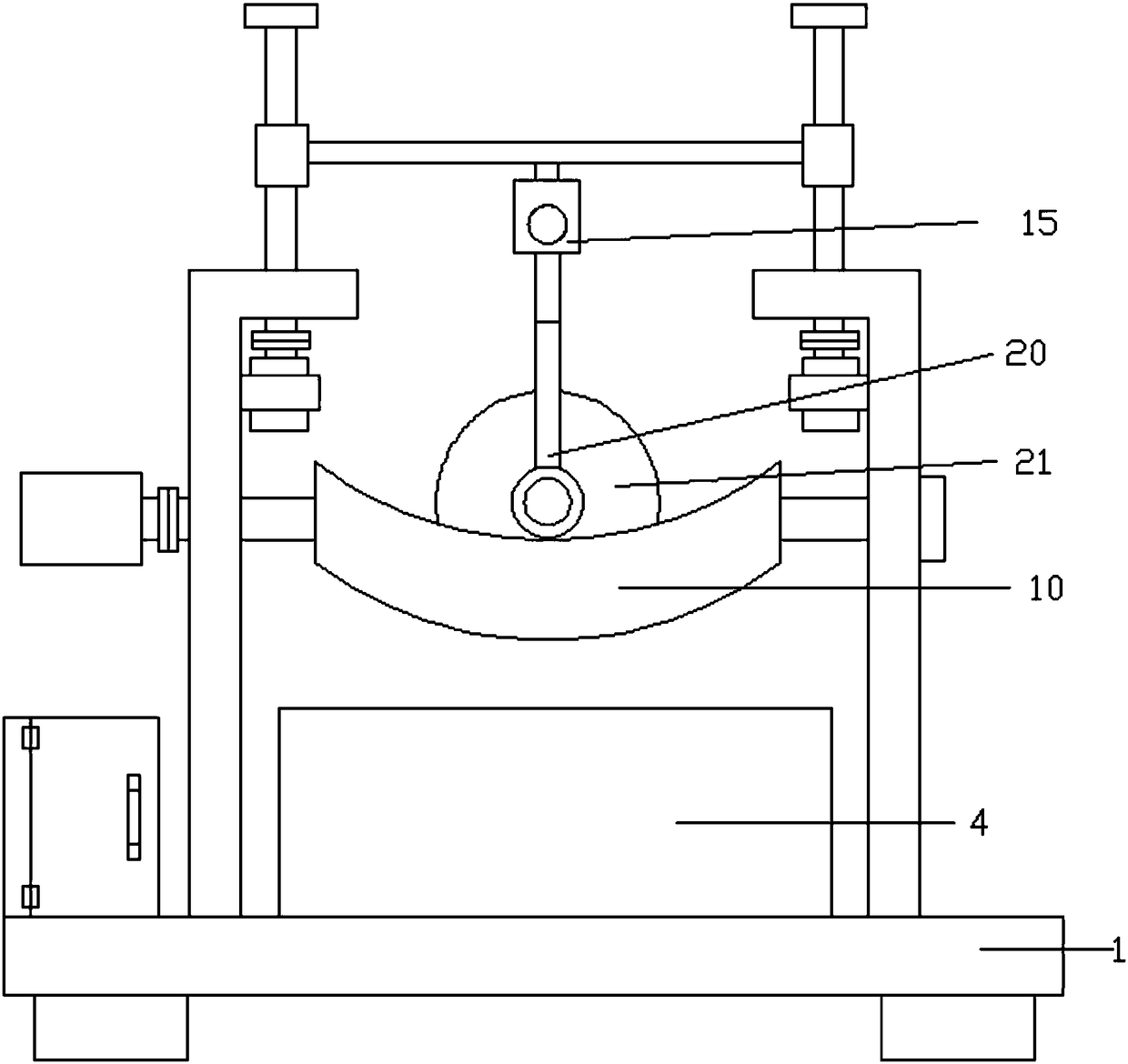

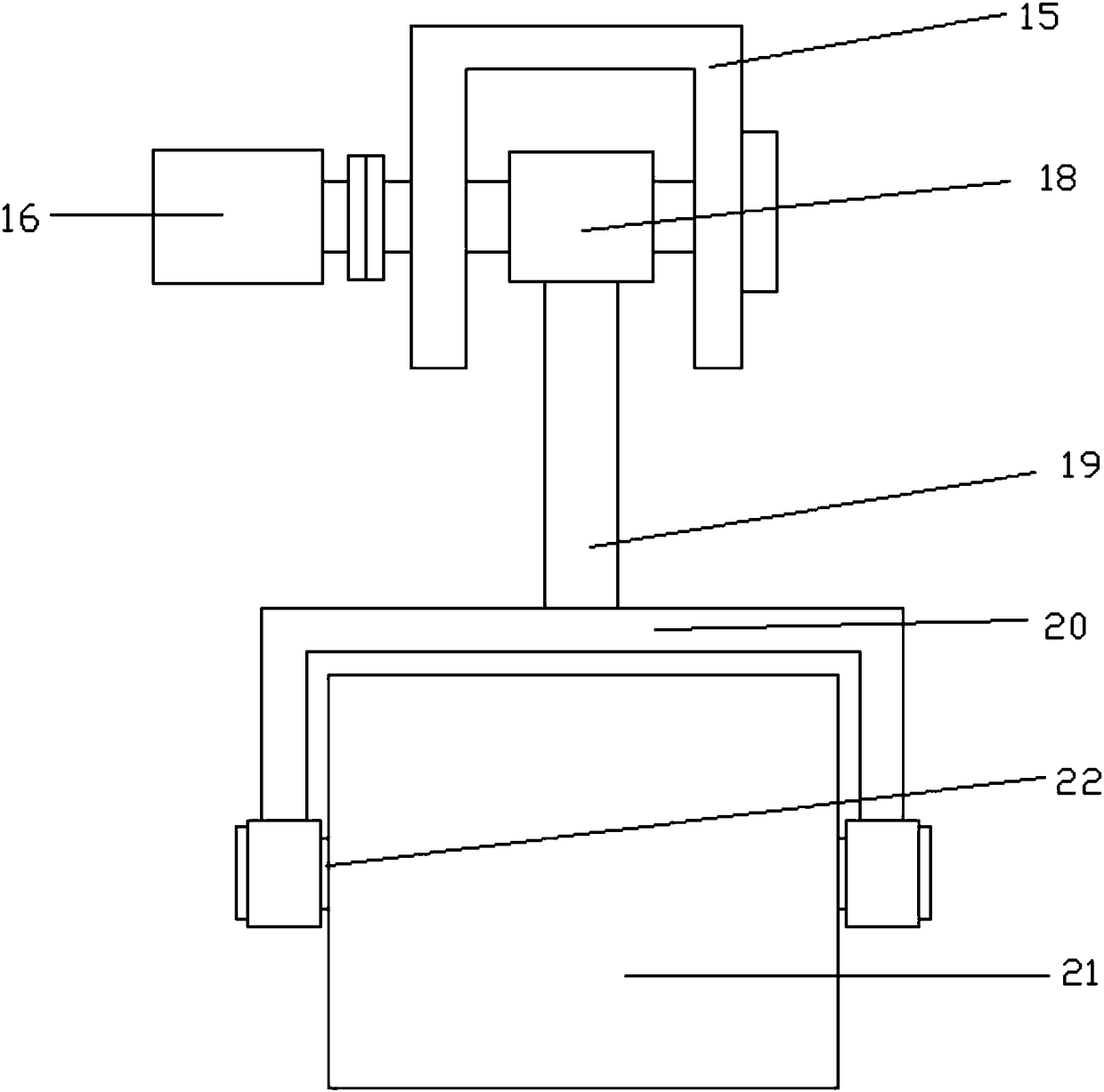

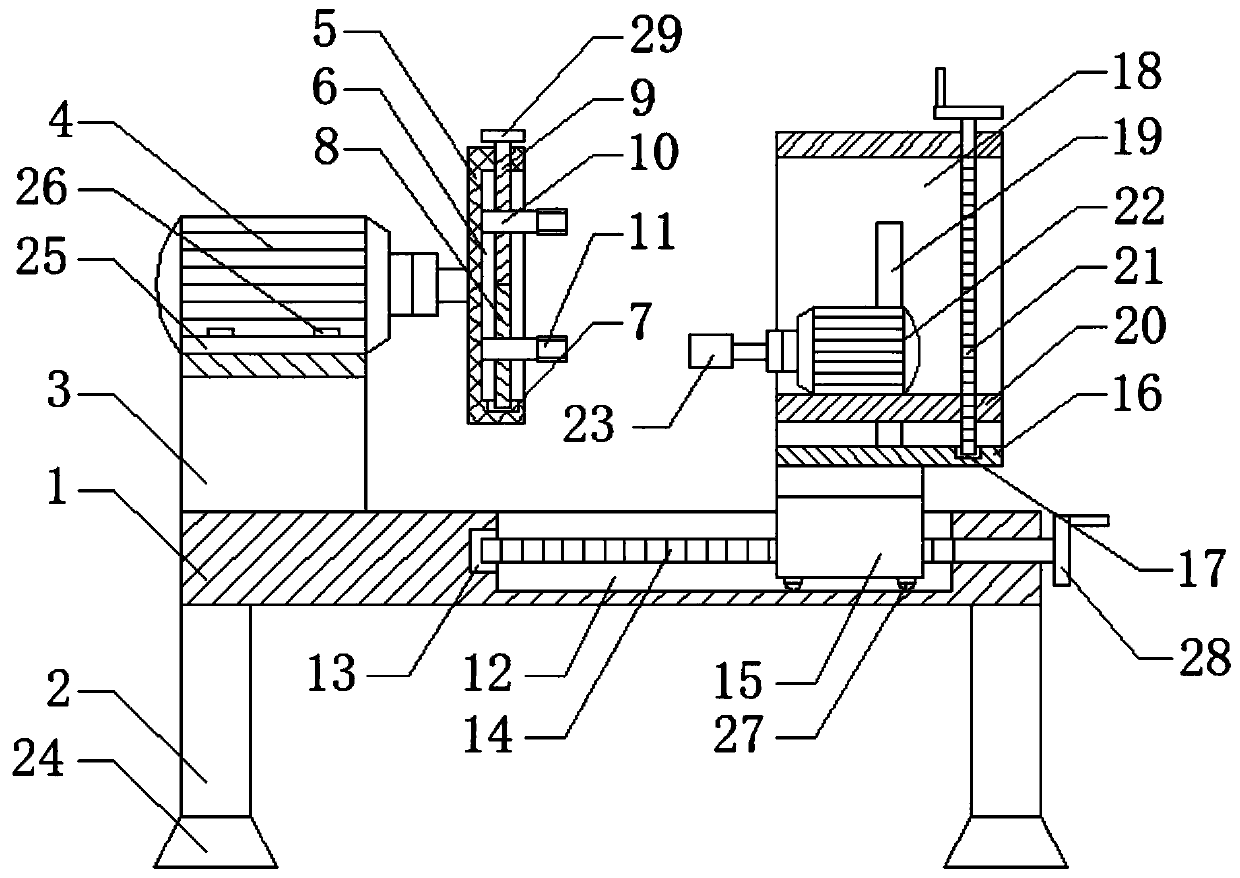

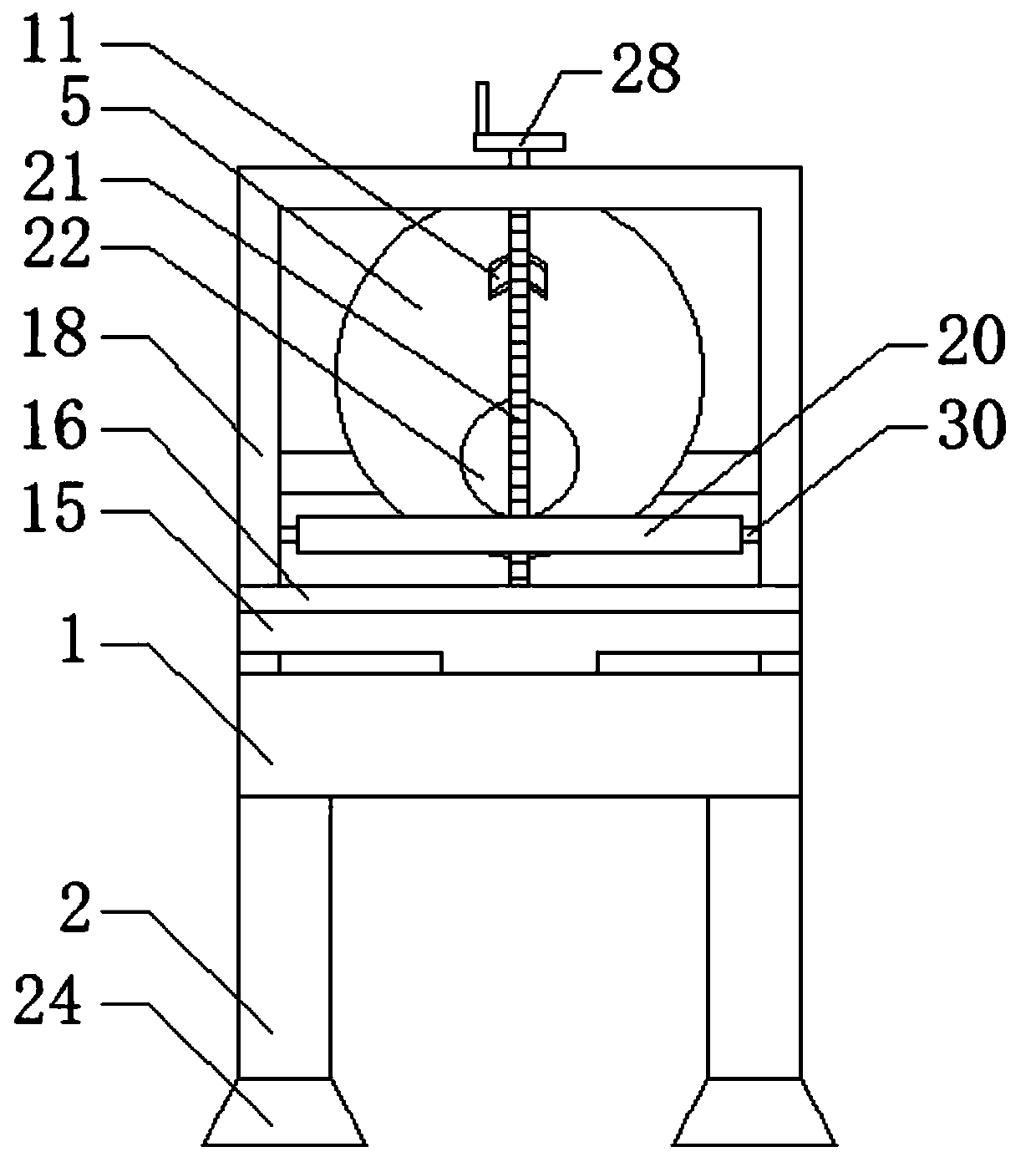

Metal rotating member constant-pressure grinding control device and method

InactiveCN105945729AQuality improvementStable controlGrinding feed controlAutomatic grinding controlReduction driveControl system

The invention discloses a metal rotating member constant-pressure grinding control device and method. The device comprises a grinding wheel, a grinding wheel driving motor, a workbench, a servo motor, a reducer, a frequency converter and a grinding control system. The grinding wheel is directly driven by the grinding wheel driving motor which is arranged on the workbench. The workbench is mounted on two linear guide rails. The lower portion of the workbench is further connected with a nut of a lead screw-nut transmission pair. A lead screw of the lead screw-nut transmission pair is driven by the servo motor and the reducer, and rotation of the servo motor is transmitted to the workbench through the lead screw-nut transmission pair. The frequency converter is connected with the grinding wheel and controls the rotation speed of the grinding wheel. A current sensor is arranged in the position of an input power source of the grinding wheel driving motor and samples working current of the grinding wheel driving motor according to a set time period. The convergence of parameters can be better controlled, and meanwhile the device and method have the advantages of being more stable in control and better in grinding quality.

Owner:GUANGDONG UNIV OF TECH +1

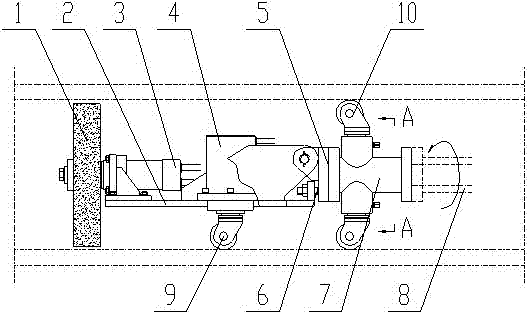

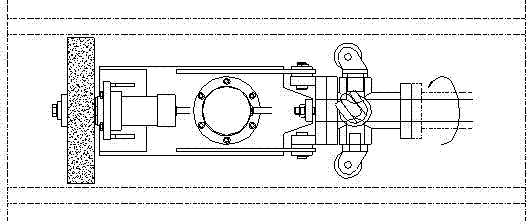

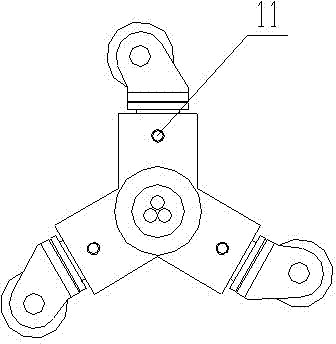

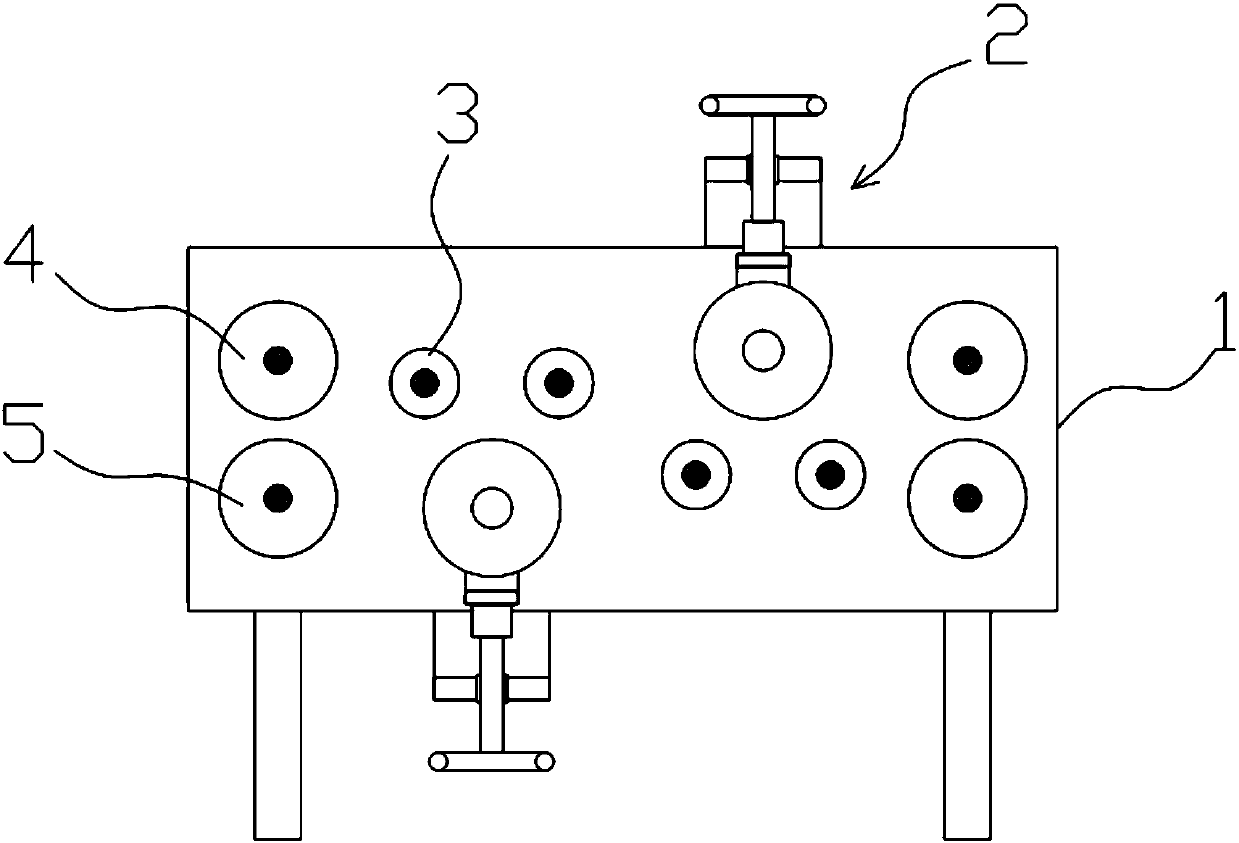

Pipe inner wall grinding and polishing device

InactiveCN103506903AControl the pressing forceImprove work efficiencyRevolution surface grinding machinesEngineeringGrinding wheel

The invention relates to a pipe inner wall grinding and polishing device. The pipe inner wall grinding and polishing device comprises a drawing rod (8), wherein a centering bracket (7) is arranged at the front end of the drawing rod (8); three second adjustable wheels (10) are arranged at the periphery of the centering bracket (7) uniformly; a bracket seat (5) is arranged on the centering bracket (7); the front end of the bracket seat (5) is hinged to a swinging bracket (2); a power part (3) is arranged at the front end of the swinging bracket (2); a grinding wheel (1) is arranged at the output end of the power part (3); a jacking part (4) is arranged in the middle of the swinging bracket (2); a first adjustable wheel (9) is arranged at the output end of the jacking part (4); a swinging bracket swinging angle limiter (6) is fixedly arranged at the rear end of the swinging bracket (2). The pipe inner wall grinding and polishing device provided by the invention improves the grinding or polishing efficiency and can effectively control the pressing force to the pipe inner wall so as to guarantee the final grinding or polishing quality.

Owner:江苏乐基重工机械有限公司

Ceramic cutting device

InactiveCN105014802AEnsure consistencyGuaranteed grinding qualityEdge grinding machinesWorking accessoriesCutting selfEngineering

The invention discloses a ceramic cutting device, and belongs to the technical field of cutting equipment. The ceramic cutting device comprises a support, a plurality of supporting feet, a cutting table, a guide rail, a cutting machine and a water spray device. The supporting feet are connected with the support and used for supporting the support to keep horizontal. The cutting table is fixed to the support. The guide rail is arranged above the cutting table. The cutting machine is arranged on the guide rail in a sleeving manner and can move left and right relative to the guide rail. Through the fixed guide rail and the cutting machine arranged on the guide rail in the sleeving manner, the cutting machine can only move along the guide rail, and the cutting quality is guaranteed; and meanwhile, a grinding wheel matched with a cutting wheel is arranged, and a cut cutting opening is ground in the cutting process. Due to the fact that the grinding wheel is fixedly arranged relative to the cutting wheel, the consistency of the grinding degree is guaranteed, and the grinding quality is guaranteed. The ceramic cutting device is simple in structure and convenient to operate, cutting and grinding can be achieved at the same time, the production efficiency is improved, and the production cost is lowered.

Owner:HUBEI AODIAO IND

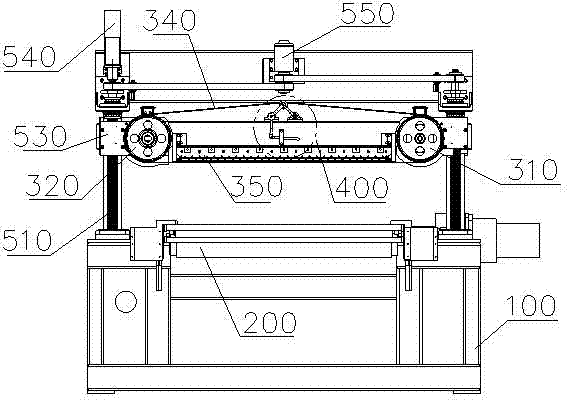

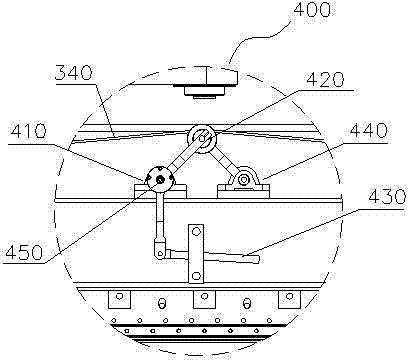

Automatic grinding device

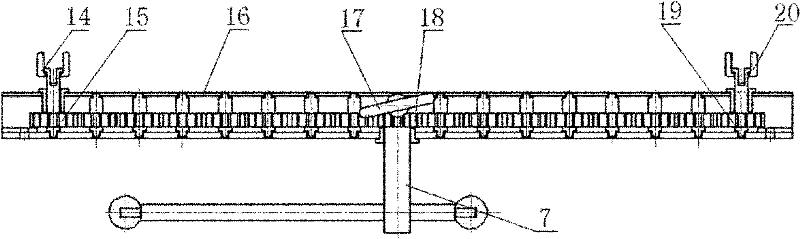

The invention discloses an automatic grinding device. The automatic grinding device comprises a working table, a conveyor belt and at least one grinding mechanism, wherein the conveyor belt is arranged on the working table, and the grinding mechanism is arranged above the conveyor belt. The grinding mechanism comprises a driving wheel, a driven wheel, a grinding motor and an abrasive belt, wherein the driving wheel and the driven wheel are arranged on the two sides of the conveyor belt respectively, the grinding motor is connected with the driving wheel and supplies power to the driving wheel, and the abrasive belt winds the surface of the driving wheel and the surface of the driven wheel. The abrasive belt winds the driving wheel and the driven wheel and makes contact with grinded materials to form a grinding plane. The automatic grinding device is high in grinding efficiency, good in grinding effect, high in accuracy, and especially suitable for grinding different materials.

Owner:徐成炳

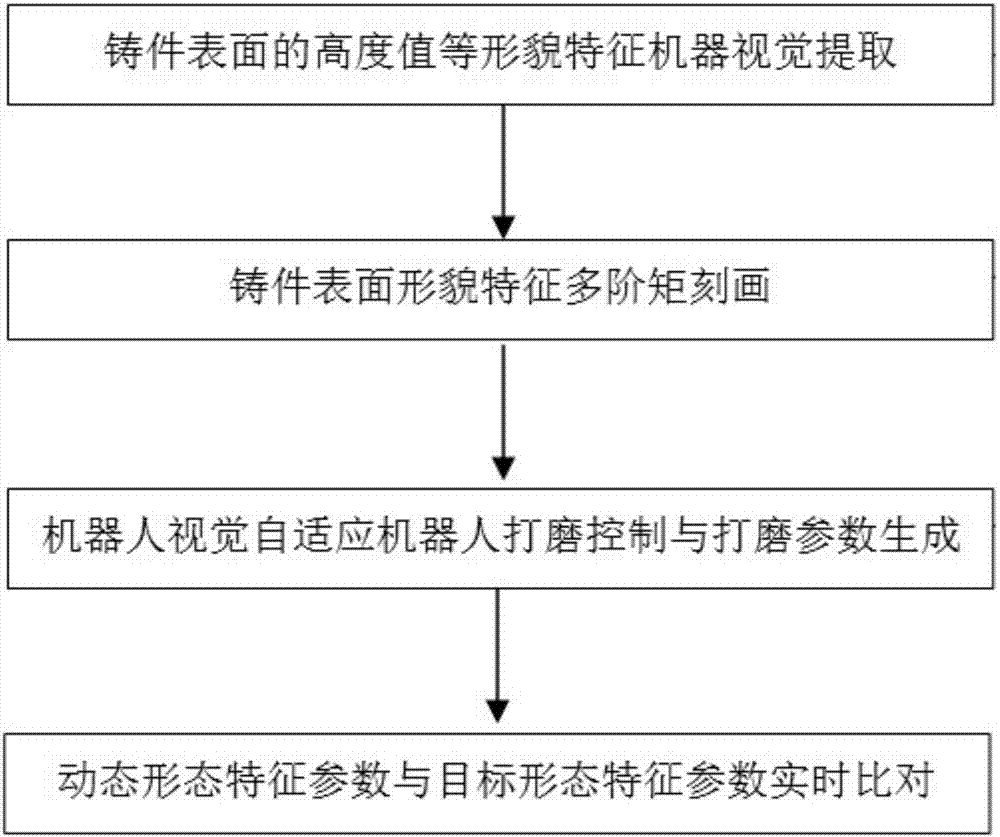

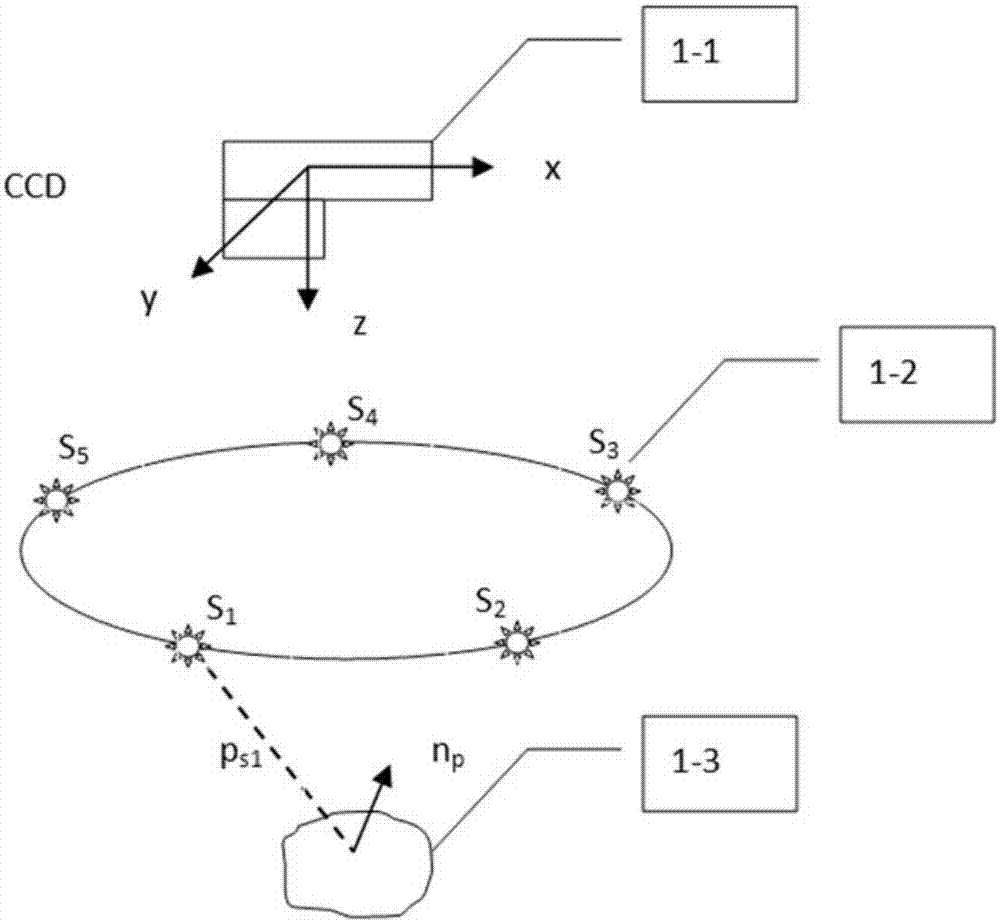

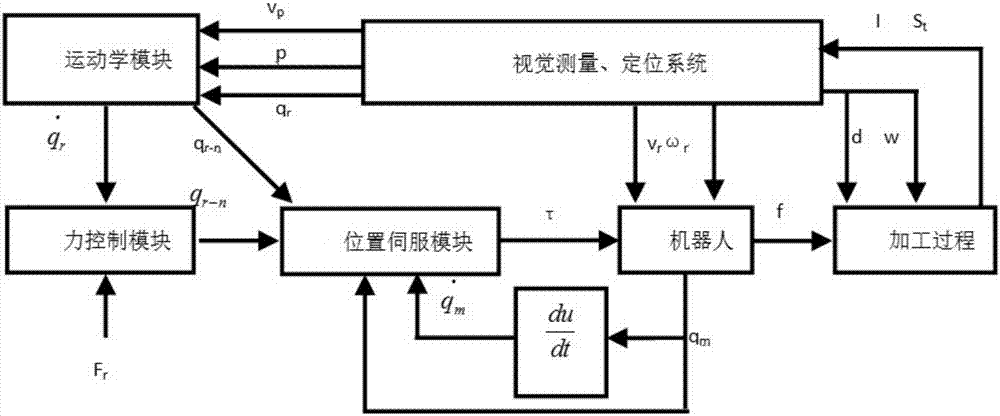

Robot casting grinding self-adaption method based on vision system

ActiveCN107378780AHigh precision measurementFully portrayedImage enhancementImage analysisVision basedFeature parameter

The invention provides a robot casting grinding self-adaption method based on a vision system. The robot casting grinding self-adaption method includes the following steps that casting surface morphology characteristics are extracted through machine vision; by means of a method for depicting the casting surface roughness, the first-moment characteristic, the second-moment characteristic, the third-moment characteristic and the fourth-moment characteristic of the casting height represent the casting surface average deviation degree, the standard deviation, the twisting degree and the kurtosis correspondingly; according to the casting surface roughness, by combining the vision measuring and positioning method, the kinematics analysis method, the force control method and the position control servo method, vision self-adaption robot grinding parameters are generated and a grinding execution element is controlled to conduct grinding; and in the grinding process, the workpiece surface real-time dynamic morphology characteristic parameter is compared with target morphology characteristic parameter in real time till the workpiece surface roughness reaches the target morphology characteristic parameter. According to the robot casting grinding self-adaption method, casting surface morphology characteristics can be more comprehensively and more finely depicted through the workpiece surface quality obtained by depicting the casting surface morphology characteristics through moments.

Owner:JIANGSU UNIV

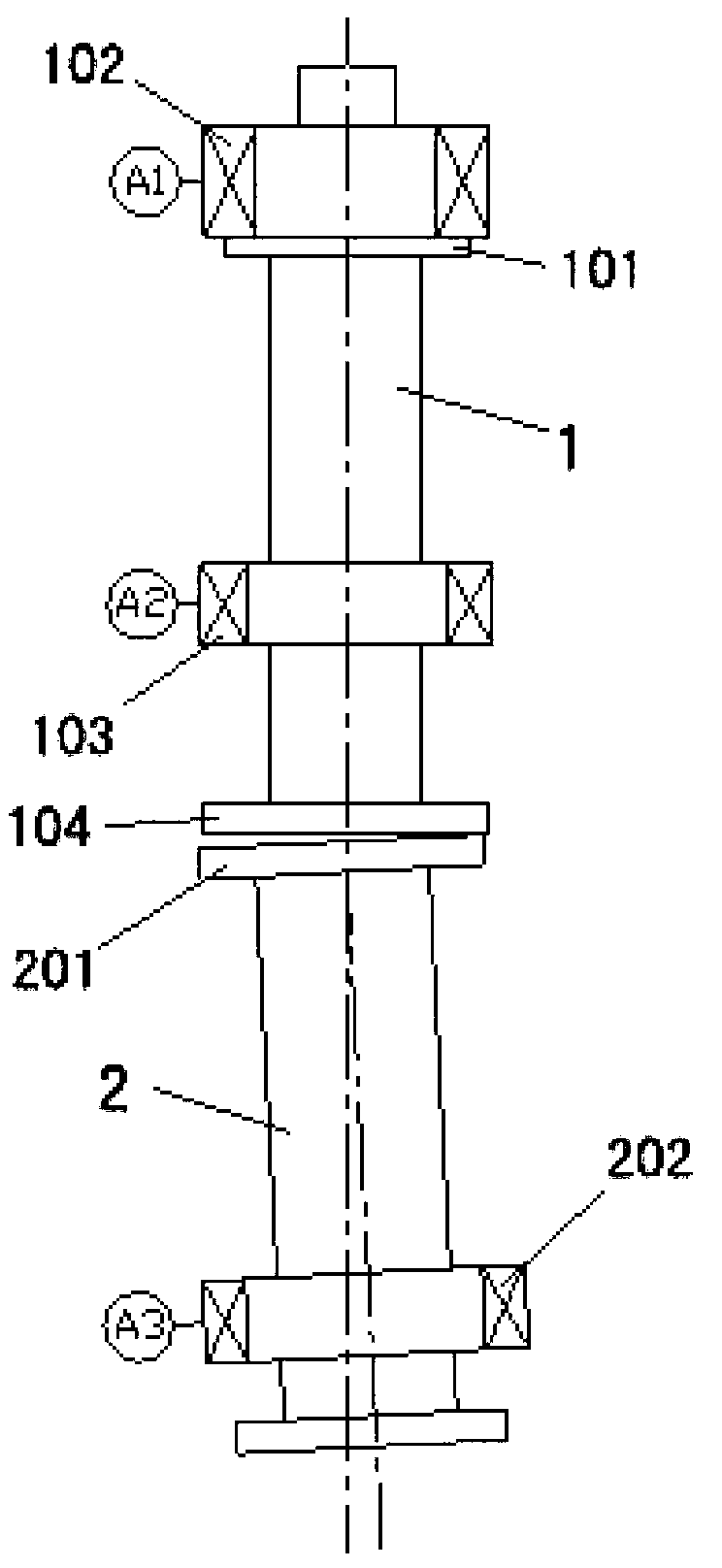

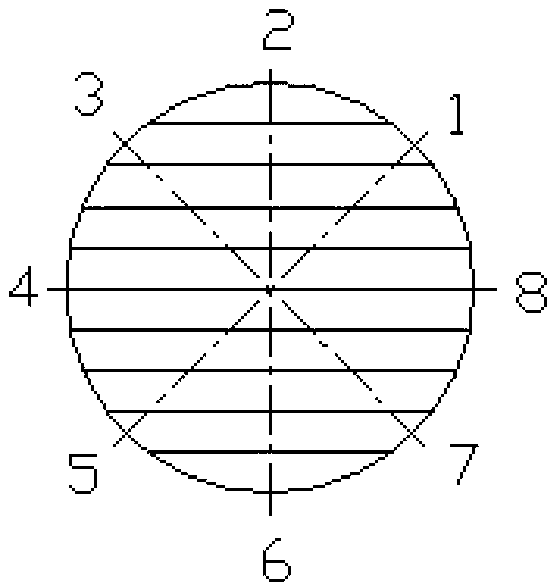

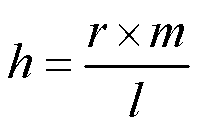

Method for adjusting spindle axis of hydraulic turbine generator set

ActiveCN103008973AEasy to adjustThe adjustment is validMetal working apparatusElectric generatorFlange

In order to solve problem that the grinding direction, the grinding area and the grinding quantity of each area are hard to determine in the method for adjusting a spindle axis of a hydraulic turbine generator set in the prior art, the invention provides a method for adjusting the spindle axis of the hydraulic turbine generator set. Whether a generator shaft of the set is bent and deformed or not by using absolute value of relative swing; a diameter direction represented by two turning points with maximum pure swing absolute values is used as the grinding direction; when the pure swing with maximum absolute value is a positive value, the grinding quantity is changed from small to large; and when the pure swing with maximum absolute value is a negative value, the grinding quantity is changed from large to small. The method has the advantages as follows: the grinding direction and the grinding quantity are determined through turning data and grinding a flange surface by using a regional step-by-step grinding method, the grinding quality is guaranteed and the axis is simply, conveniently and effectively adjusted.

Owner:CHONGQING WATER TURBINE WORKS

Efficient rotary grinding device

InactiveCN108067990ASmooth rotationGuaranteed sandingGrinding machinesGrinding work supportsAerospace engineering

The invention discloses an efficient rotary grinding device. The efficient rotary grinding device comprises a box; a first motor is disposed at the lower end of the interior of the box; a rotary shaftis disposed on the left side of the first motor; a rotary plate is disposed on the upper side of the rotary shaft; a supporting plate is disposed on the outer side of the rotary plate; a first sliding groove is formed in the right end of the upper side of the supporting plate; a first sliding block is disposed in the first sliding groove; a first connecting rod is disposed on the left side of thefirst sliding block; a first telescopic rod is disposed on the left side of the first connecting rod; a grinding roller is disposed on the left side of the first telescopic rod; a second sliding groove is formed in the upper end of the interior of the box; a second sliding block is disposed in the second sliding groove; a second telescopic rod is disposed on the lower side of the second sliding block; a powerful dust suction hood is disposed on the lower side of the second telescopic rod; a first connecting pipe, a connecting hose and a second connecting pipe are disposed on the upper side ofthe powerful dust suction hood; and a dust suction box is disposed on the left side of the second connecting pipe. By means of the efficient rotary grinding device, rotary grinding of equipment can be performed effectively and conveniently, therefore the grinding quality of the equipment can be effectively guaranteed, the working efficiency of the equipment is improved, and the cleanliness of theequipment is guaranteed.

Owner:ZHENGZHOU GUOZHI NETWORK TECH CO LTD

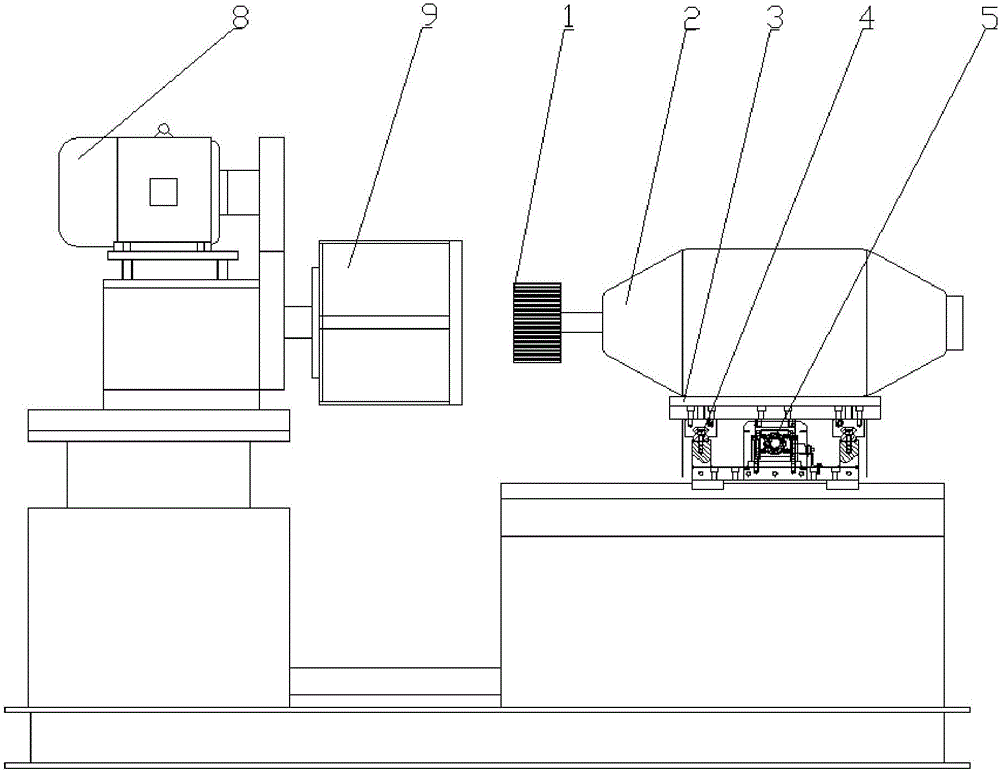

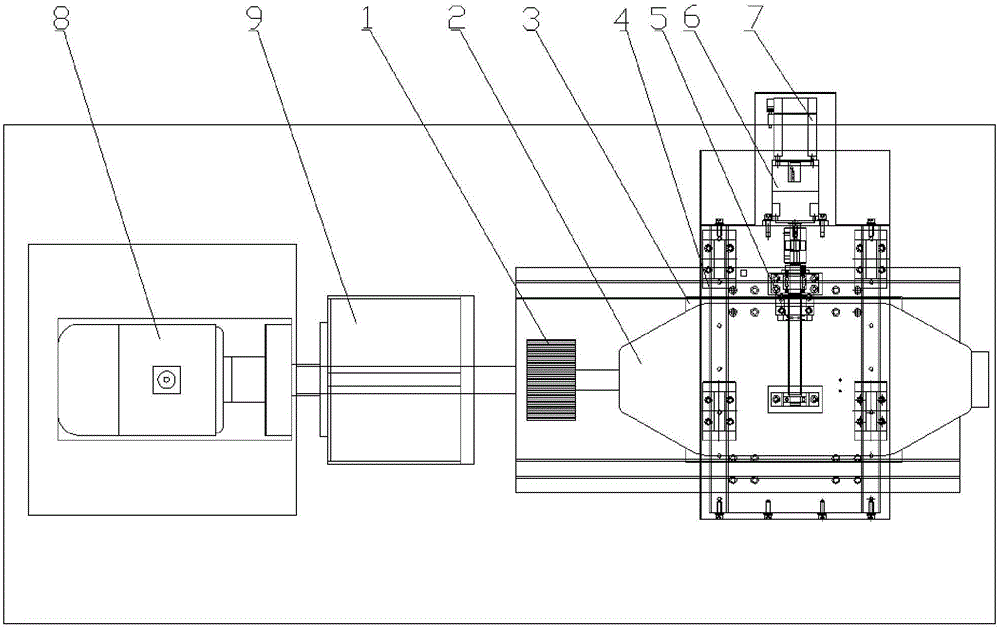

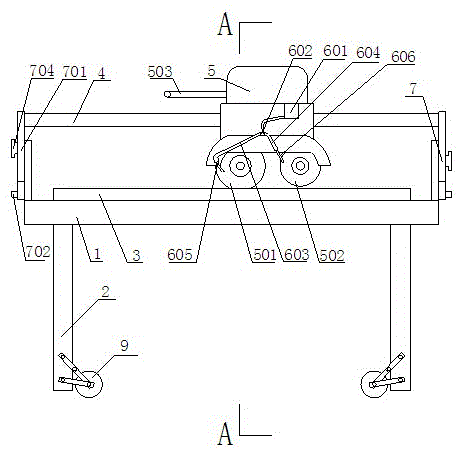

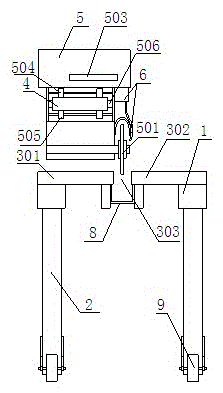

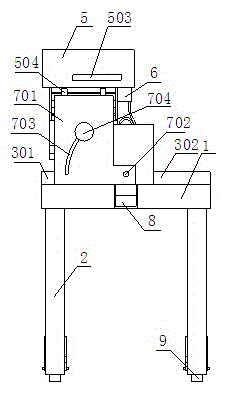

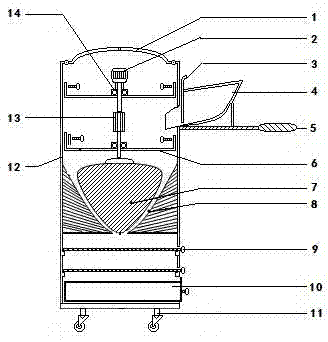

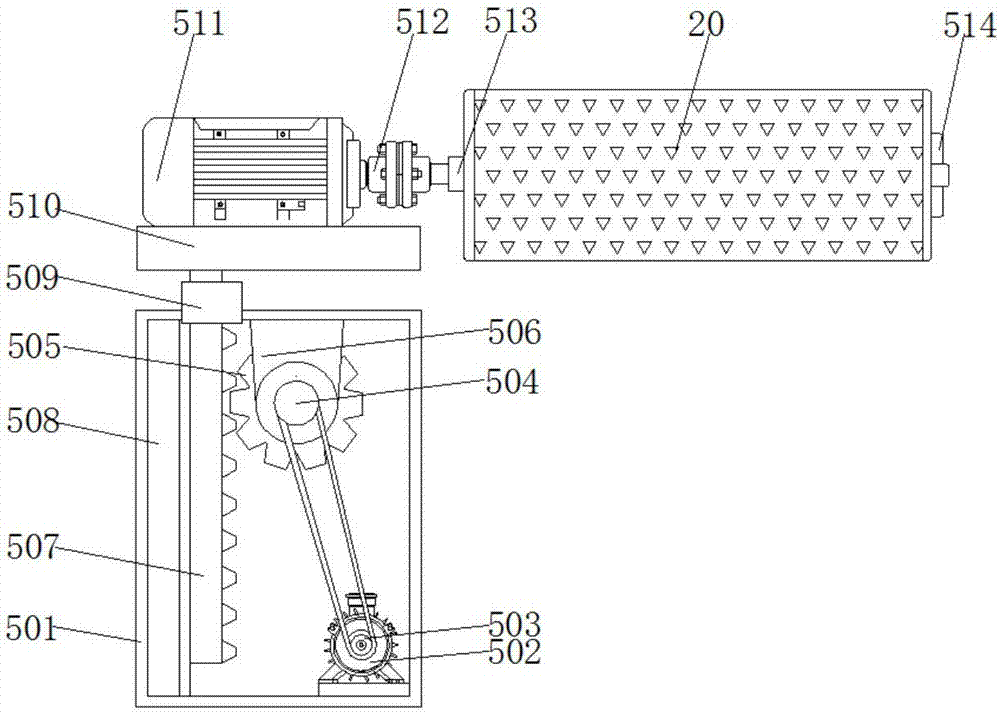

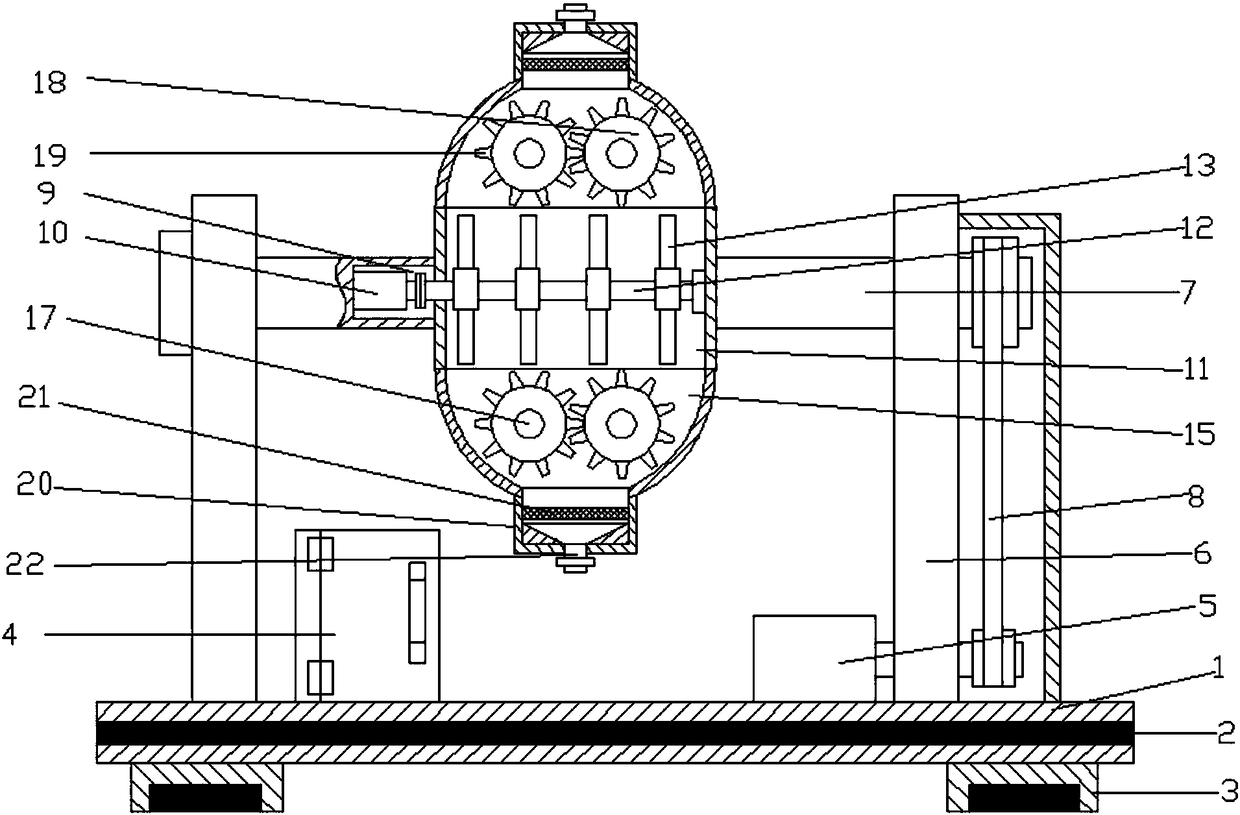

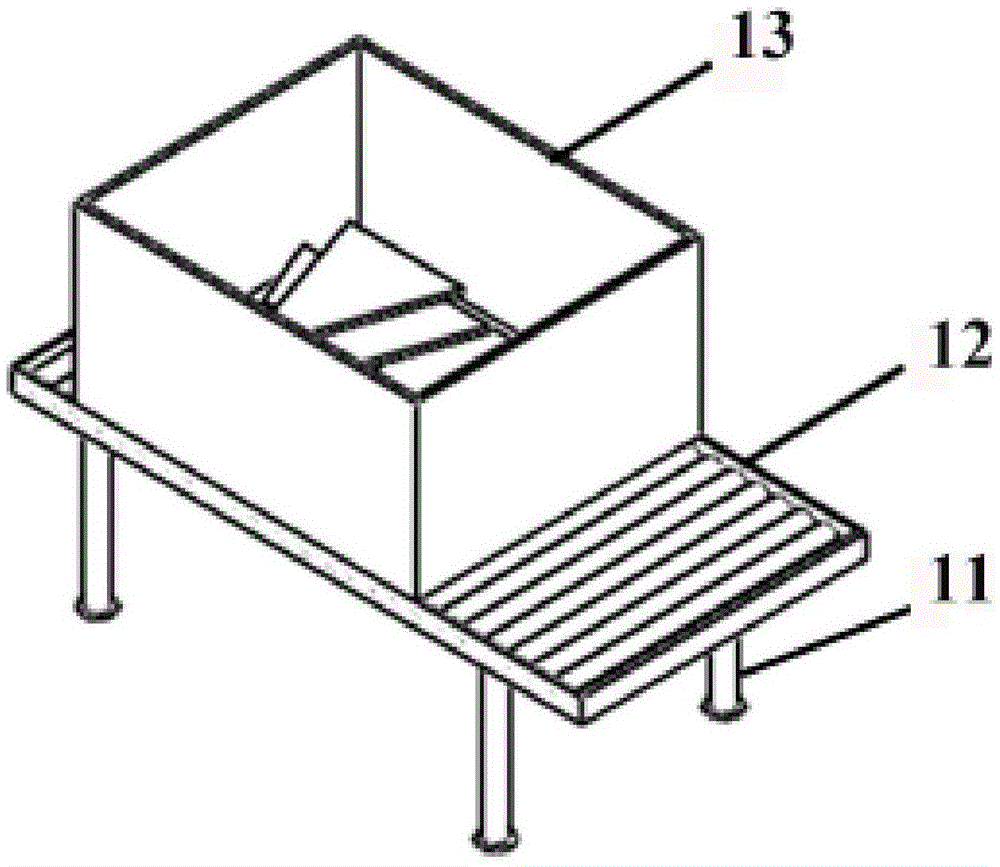

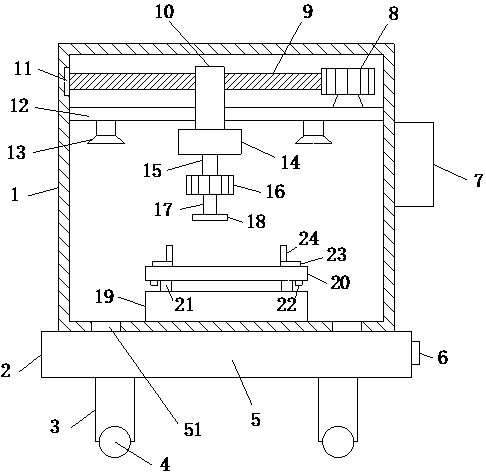

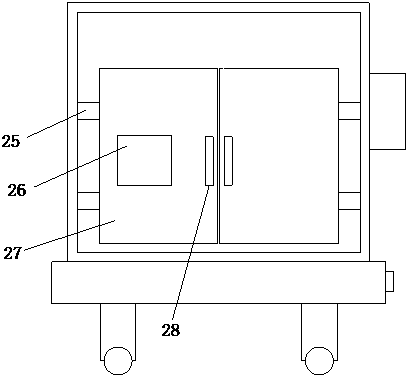

Soil analysis sample screening-grinding movable all-in-one machine

ActiveCN103487301AReduce workloadLow pricePreparing sample for investigationSoil scienceAgricultural engineering

The invention relates to the technical field of soil sample screening-grinding equipment, particularly to a soil analysis sample screening-grinding movable all-in-one machine for laboratory analysis. The technical scheme of the machine is that the movable all-in-one machine includes a machine body, a feeding treatment system, a grinding system and a classified screening system, wherein the machine body is formed by a cuboid box body; a feeding treatment system is arranged at the upper part of the side wall of the box body; the classified screening system is positioned at the middle lower part of the box body; the grinding system is positioned at the middle upper part of the box body and is arranged in the middle part. Tests show that the all-in-one machine can one-step pulverize soil into particles not larger than 2 mm in diameter and counting for 85% above, and one-step pulverize soil into particles not larger than 0.15 mm in diameter and counting for 65% above, and the screening yield is 100%. The machine has the advantages that the obtained materials are common, the operation is simple, high quality and efficiency are realized, no pollution to a soil sample is caused, and the result is reliable.

Owner:FUJIAN NORMAL UNIV

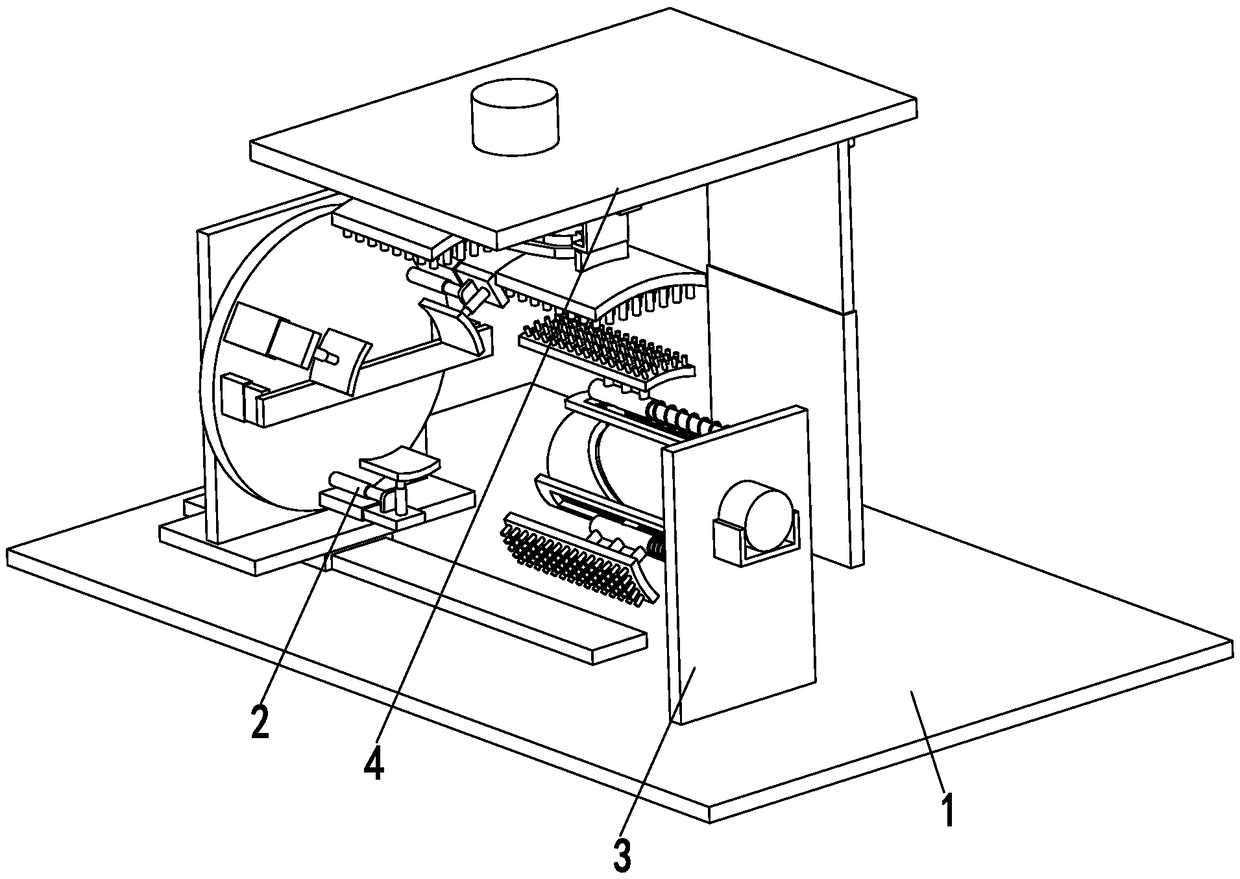

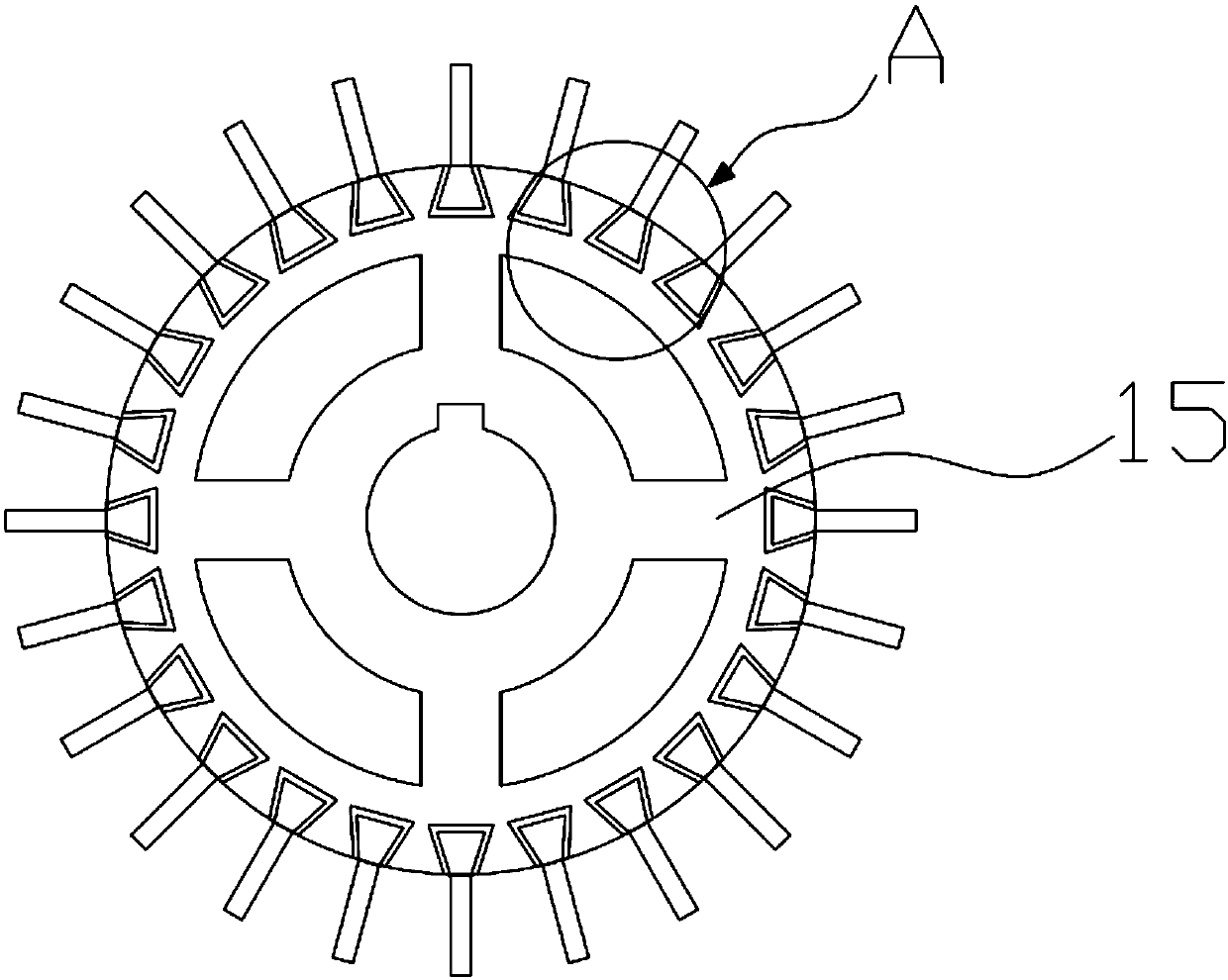

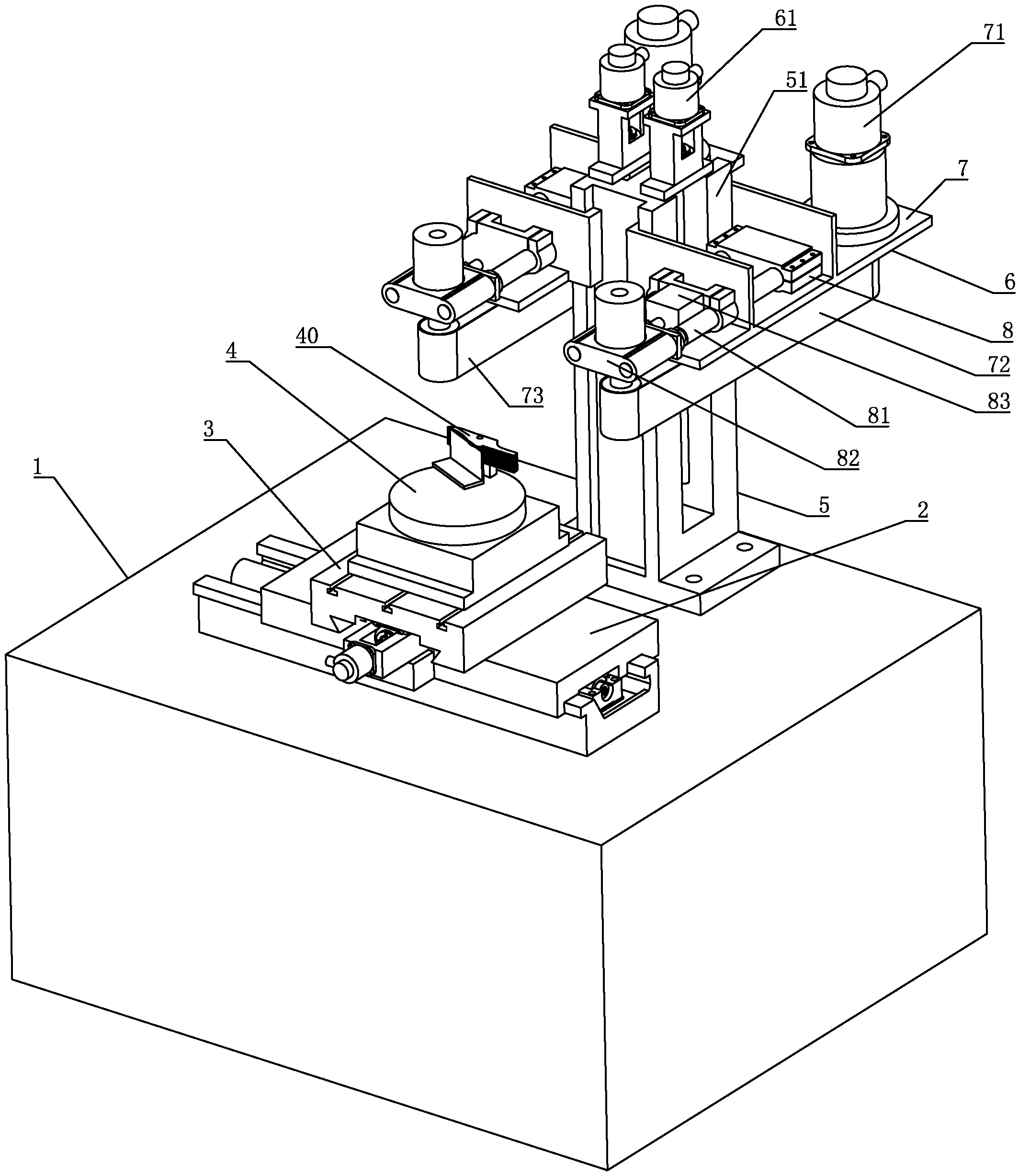

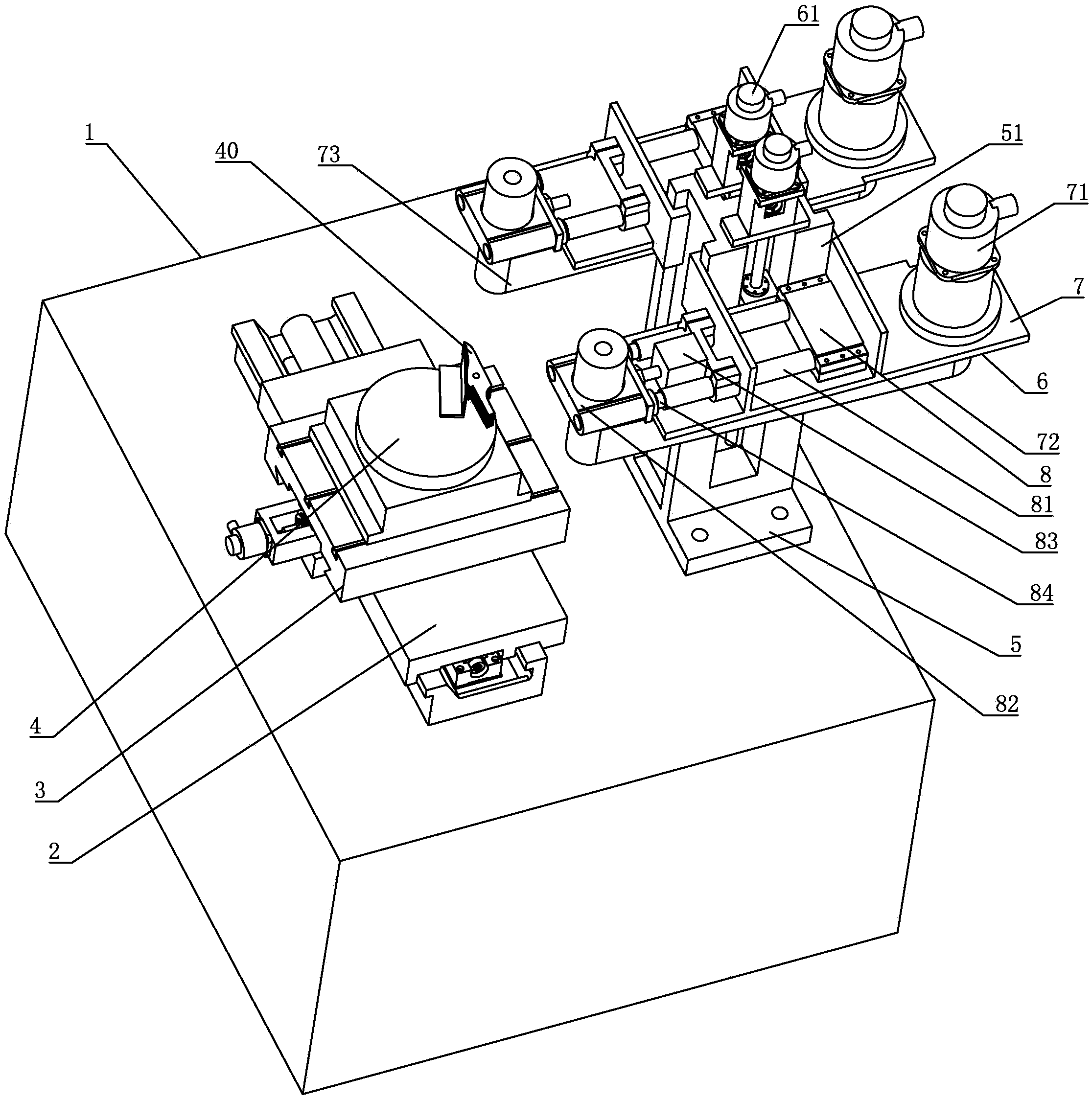

Workpiece grinding machine of numerical-control electric spark machine tool

InactiveCN108789046ASolve the costSolve labor intensityGrinding carriagesGrinding drivesNumerical controlEngineering

The invention relates to a workpiece grinding machine of a numerical-control electric spark machine tool. The workpiece grinding machine of the numerical-control electric spark machine tool comprisesa base plate, a fixing device, an inner wall grinding device and an outer wall grinding device. The fixing device and the inner wall grinding device are sequentially installed on the base plate from left to right. The outer wall grinding device is installed on the back side of the base plate. The inner wall grinding device comprises a fixing plate, a rotating motor, a rotating column, sliding blocks, limiting frames, telescopic rods, springs, adjusting air cylinders and first steel wire brushes. The outer wall polishing device comprises a lifting frame, a rotating motor, a rotating column, a cam, connection sliding blocks, connection frames, guide rails and second steel wire brushes. The workpiece grinding machine of the numerical-control electric spark machine tool can solve the problemsthat in an existing annular workpiece grinding process, the labor cost is high, the labor intensity is high, the work efficiency is low, the grinding difficulty is large, and the adjustability is poor; the automatic grinding function on the annular workpiece can be achieved; and the workpiece grinding machine of the numerical-control electric spark machine tool has the advantages of being low in labor cost, low in labor intensity, high in work efficiency, small in polishing difficulty, good in adjustability and the like.

Owner:浙江芊荷科技有限公司 +1

Manufacturing method of electroplated grinding wheel of ordered structure

The invention discloses a manufacturing method of an electroplated grinding wheel of an ordered structure. The method includes: adopting a pulse laser beam to process a fine spiral groove with the pitch of hundreds of micrometers and the notch size of dozens of micrometers in the working surface of the outer annulus of a grinding wheel base body made of metal, filling the groove with epoxy resin, and enabling the metal and the epoxy resin on the working surface of the outer annulus of the grinding wheel base body to be in spiral regularly-spaced layout; then electroplating the working surface of the outer annulus of the grinding wheel base body with abrasive grains by adopting an electroplating method. Since the groove is filled with the non-conductive epoxy resin, the region cannot be electroplated with the abrasive grains. By the steps, the electroplated grinding wheel with the abrasive grain layer and the epoxy resin being in spiral regularly-spaced layout can be obtained. The manufactured electroplated grinding wheel of the ordered structure is in favor of solving the problems that the grinding wheel is blocked easily during grinding and grinding fluid cannot enter the grinding region easily, workpieces can be prevented from being burnt, and the grinding quality is improved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Numerical control fine-grinding quality control method of rail welding joint

InactiveCN102535279AImprove straightnessImprove pass rateRailway track constructionNumerical controlProgrammable logic controller

The invention relates to a numerical control fine-grinding quality control method of a rail welding joint; longitudinal temperature and flatness data of a welding joint region are obtained through on-line actual measurement, a flatness curve measured actually is converted into the flatness curve corrected by temperature and removing temperature effect according to the relation of temperature change and rail flatness variation, and the parameters such as grinding position, range, feed rate and the like can be calculated by the corrected flatness curve, the fine-grinding process can be automatically and flexibly controlled by a programmable logic controller according to the calculated fine-grinding parameters, and the corrected flatness curve of the rail joint after each fine-grinding is measured again, the fine-grinding parameters are reset to perform next round of fine-grinding, until the measured corrected flatness curve meets the standard requirements. The method can perform automatic whole-course fine-grinding to the rail welding joint ground coarsely, the fine-grinding process has high automation degree and low fine-grinding cost, the welding joint ground finely has smooth appearance and good flatness, and no depressed joint can be ground; the method is convenient for data traceability, analysis and responsibility.

Owner:SOUTHWEST JIAOTONG UNIV

Grinding device for inner wall and outer wall of pipe opening of steel pipe

InactiveCN105215826AAdjust feedConsistent feedEdge grinding machinesGrinding drivesMachineGrinding wheel

The invention discloses a grinding device for the inner wall and the outer wall of the pipe opening of a steel pipe. The grinding device comprises a base, steel pipe supports fixed to the base and used for supporting and rotating the steel pipe, a grinding assembly and a rotating assembly, wherein the grinding assembly and the rotating assembly are arranged on one side of the steel pipe supports. The grinding assembly comprises a machine frame, a drive device arranged in the machine frame, a transmission mechanism arranged in the machine frame, and two grinding wheels arranged on the outer side wall of the machine frame and driven by the drive device and the transmission mechanism to rotate. The rotating assembly extends into the machine frame. The whole machine frame is driven by the drive device to rotate. The two grinding wheels are fed to the steel pipe placed on the steel pipe supports to grind the pipe opening of the steel pipe. The two grinding wheels are arranged, and therefore the inner wall and the outer wall of the steel pipe can be ground at the same time, and the work efficiency is greatly improved; and in addition, the rotating assembly is arranged, and therefore the two grinding wheels can make contact with the inner wall and the outer wall of the steel pipe at the same time, and the grinding quality can be ensured.

Owner:NANJING AUTO ELECTRIC

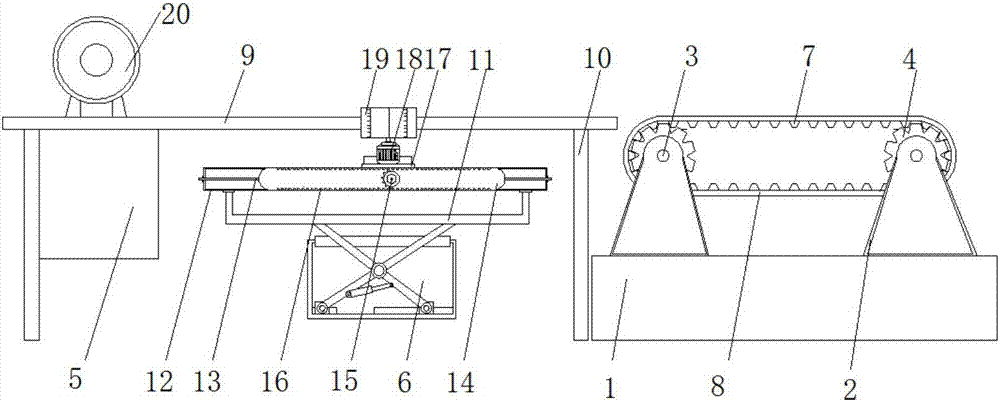

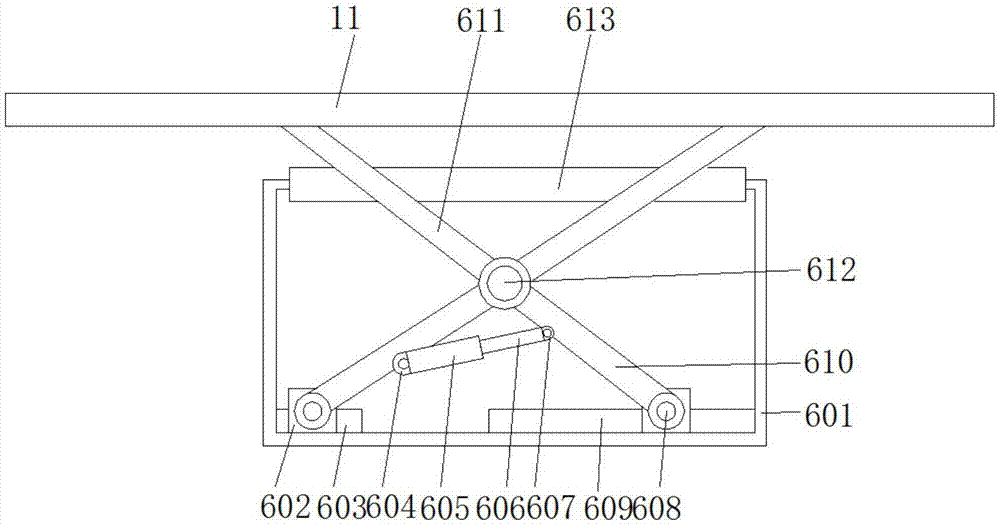

Automatic grinding machine for wood board processing

InactiveCN107263238AAchieve the purpose of moving up and downRealize moving up and downPlane surface grinding machinesEngineeringPulp and paper industry

The invention discloses an automatic grinding machine for wood board processing. The automatic grinding machine comprises a fixed installation base platform, wherein conveyor belt installation racks are fixedly connected to the top of the fixed installation base platform; a rotating shaft is rotatably connected to the top end of each of the conveyor belt installation racks; each of the rotating shafts is fixedly connected with a gear through a flat key; the gears are meshed and connected with a conveyor belt through a transmission toothed rack; a working platform is arranged on the left side of the fixed installation base platform; a grinding machine lifting device is arranged on one side of the inner wall of the working platform; and an up-down moving device is arranged at the position corresponding to the part below the middle of the working platform. The automatic grinding machine for wood board processing relates to the technical field of processing machinery. According to the automatic grinding machine for wood board processing, the following problems are solved: wood boards with different thicknesses can be ground by the grinding machine, the grinding quality and grinding efficiency are ensured, the production efficiency is improved, the production cost is reduced, the grinding efficiency and grinding quality are ensured through a reciprocating device, wood boards are prevented from improper grinding, and the life and property safety of workers is further ensured.

Owner:安吉县瑞旺竹木制品厂

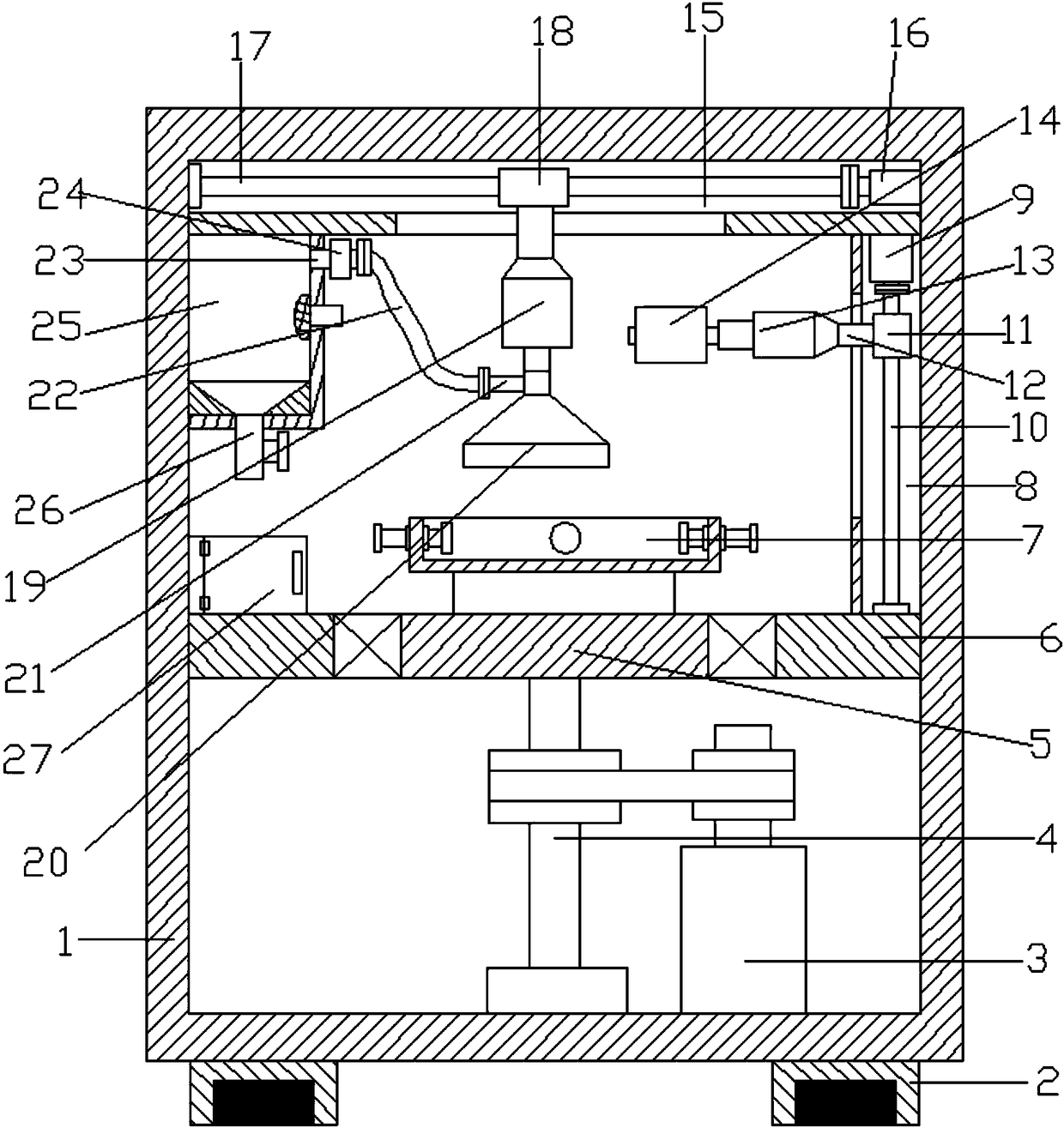

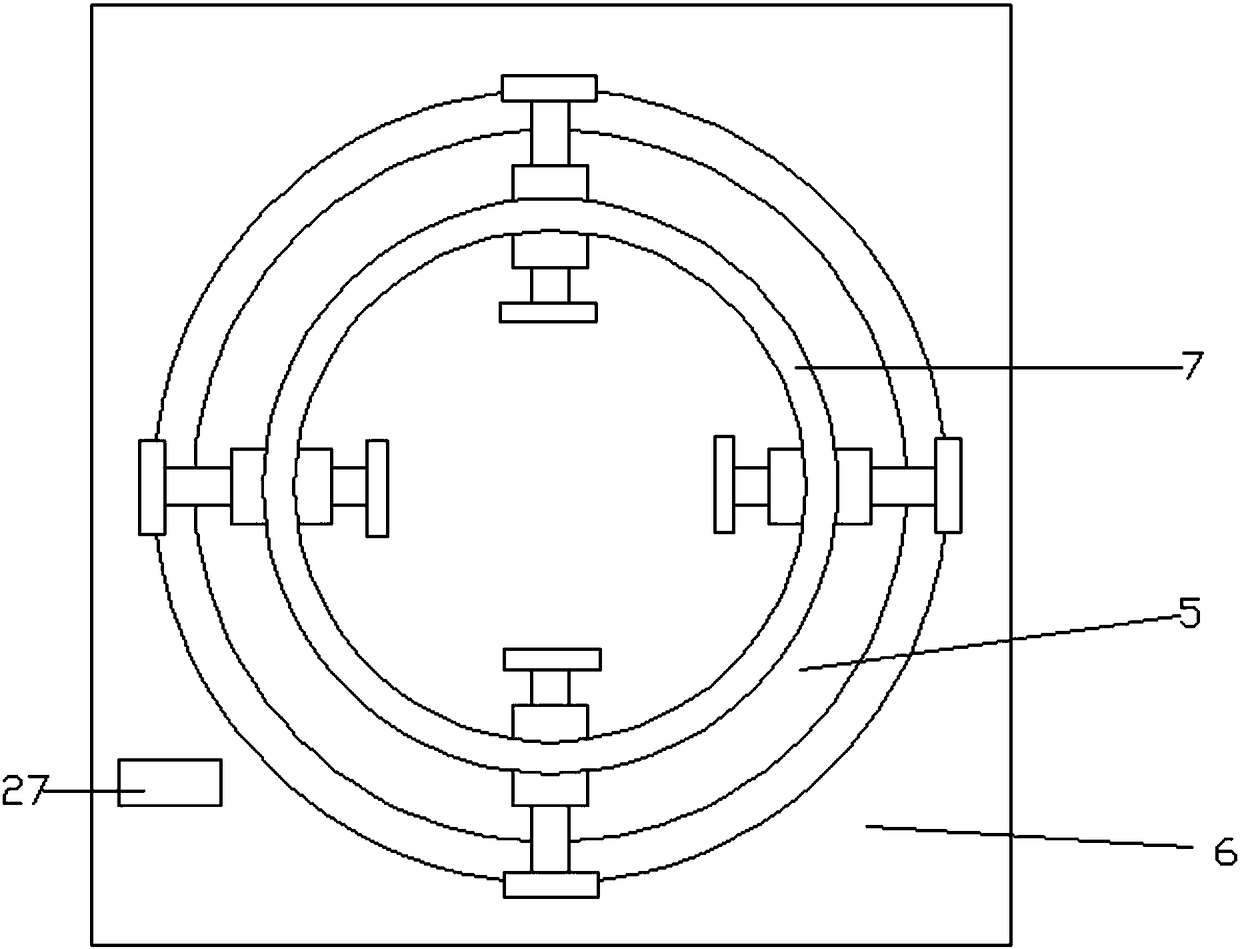

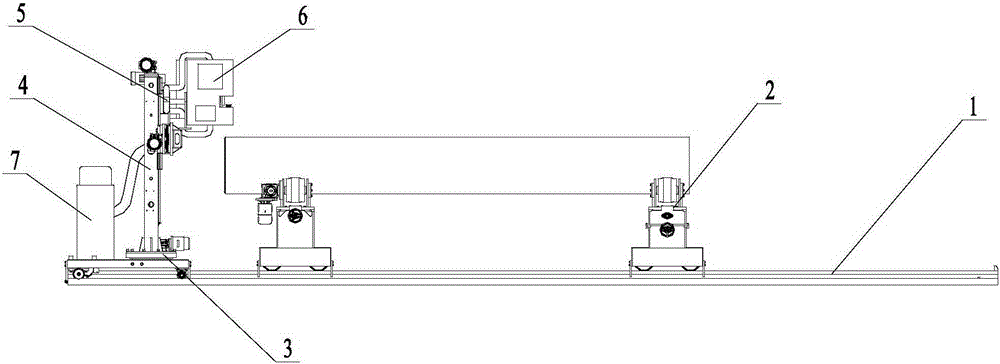

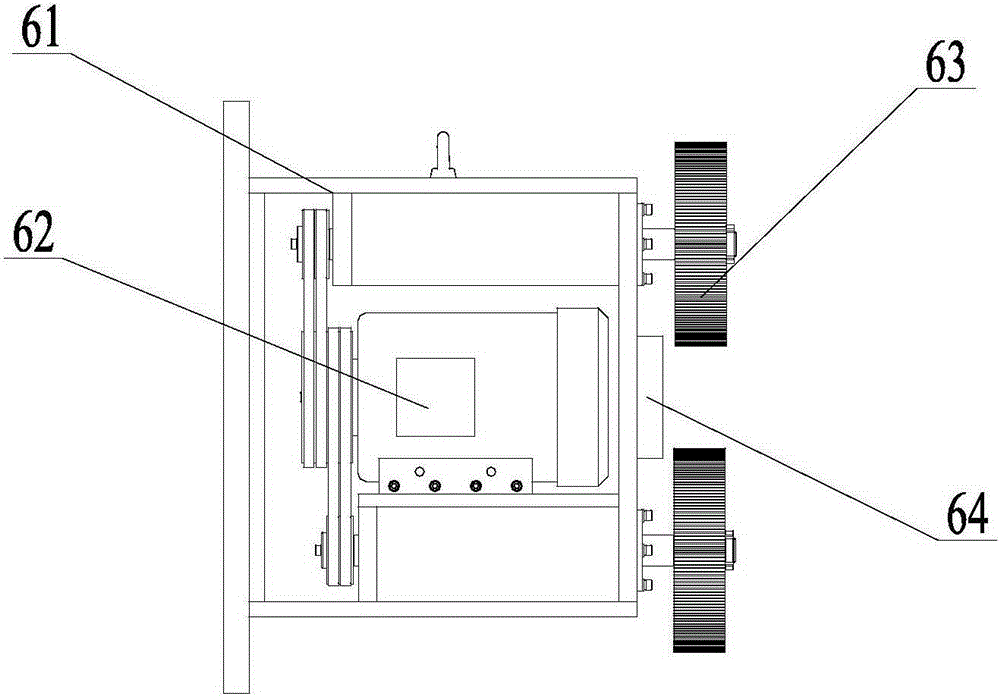

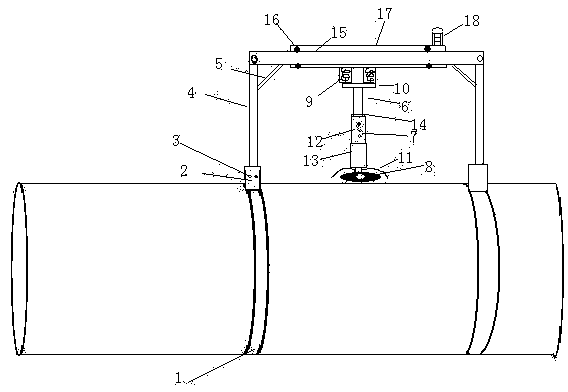

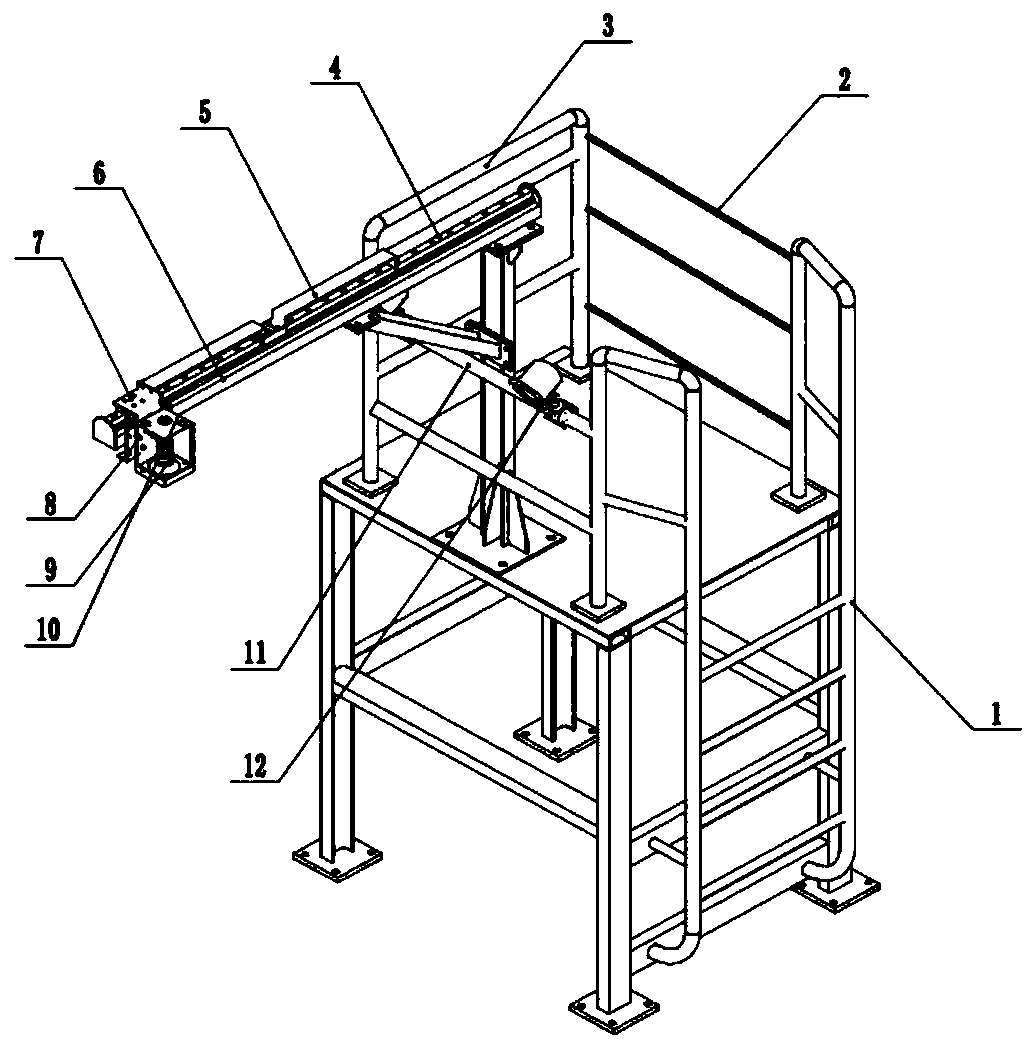

Damage-free detection special pipeline automatic oxide skin polishing device and method thereof

ActiveCN103465143AReduce labor intensityGuaranteed grinding qualityGrinding machinesElectric machineryBench grinder

The invention discloses a damage-free detection special pipeline automatic oxide skin polishing device and a method of the damage-free detection special pipeline automatic oxide skin polishing device. The problems that damage can be caused to a pipeline wall due to manual polishing and the efficiency is low are solved. The automatic oxide skin polishing device comprises at least two sets of annular guiding rails which are arranged outside a pipeline to be detected in a sleeved mode, a door-shaped polishing frame, a horizontal sliding device and a polishing machine. The door-shaped polishing frame is installed on the annular guiding rails and rotates in the circumferential direction along the pipeline to be detected. The horizontal sliding device which can move back and forth relative to a beam is installed on a beam of the door-shaped polishing frame. The polishing machine is installed on the horizontal sliding device through an elastic connecting part and driven by a motor. When the polishing machine works, the elastic connection part can make a polishing wheel of the polishing machine keep in contact with the face, to be polished, of the pipeline to be detected. According to the damage-free detection special pipeline automatic oxide skin polishing device and the method of the damage-free detection special pipeline automatic oxide skin polishing device, the pipeline can be polished automatically, polishing quality is ensured, potential safety risks are eliminated, labor intensity of workers is reduced and working efficiency is improved.

Owner:STATE GRID HUNAN ELECTRIC POWER +2

Chinese medicinal material repeated grinding device

InactiveCN108097405AEasy to GrindGuaranteed grinding qualityNon-rotating vibration suppressionGrain treatmentsCouplingGrinding teeth

The invention discloses a Chinese medicinal material repeated grinding device. The Chinese medicinal material repeated grinding device comprises a base. Supporting plates are arranged at the left andright ends of the base. The left end of the supporting plate at the right end and the right end of the supporting plate at the left end are provided with two connecting shafts correspondingly. The connecting shaft at the left end is provided with a notch. A second motor is arranged in the notch. A crushing cavity is arranged between the connecting shafts. A crushing shaft is arranged in the crushing cavity. The left side of the crushing shaft is connected with the second motor through a coupling. The upper and lower ends of the crushing shafts are provided with crushing blades. The front sideof the crushing cavity is provided with a feed port. The upper and lower sides of the crushing cavity are provided with grinding cavities. The left and right ends of each grinding cavity are providedwith third motors. The front side of each third motor is provided with a rotary shaft. A grinding roll is arranged on the outer side of each rotary shaft. The outer side of each grinding roll is provided with grinding teeth. A screening cavity is arranged on the outer side of each grinding cavity. A filter screen is arranged in each screening cavity. The outer side of each screening cavity is provided with a discharge port. The Chinese medicinal material repeated grinding device can effectively guarantee that Chinese medicinal materials are crushed and ground repeatedly and cyclically and accordingly, the grinding quality of the device can be effectively guaranteed.

Owner:ZHENGZHOU RENHONG PHARMA CO LTD

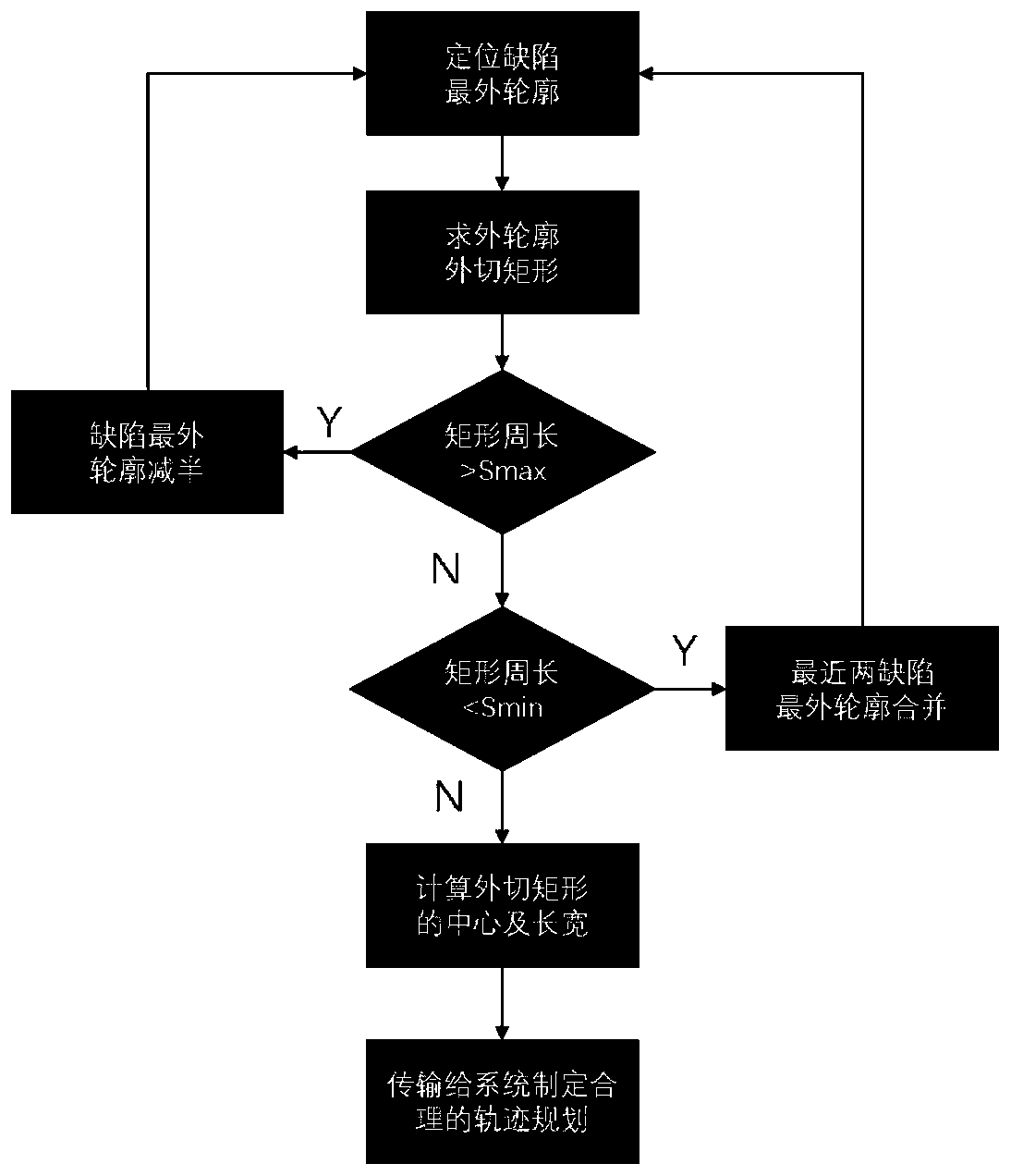

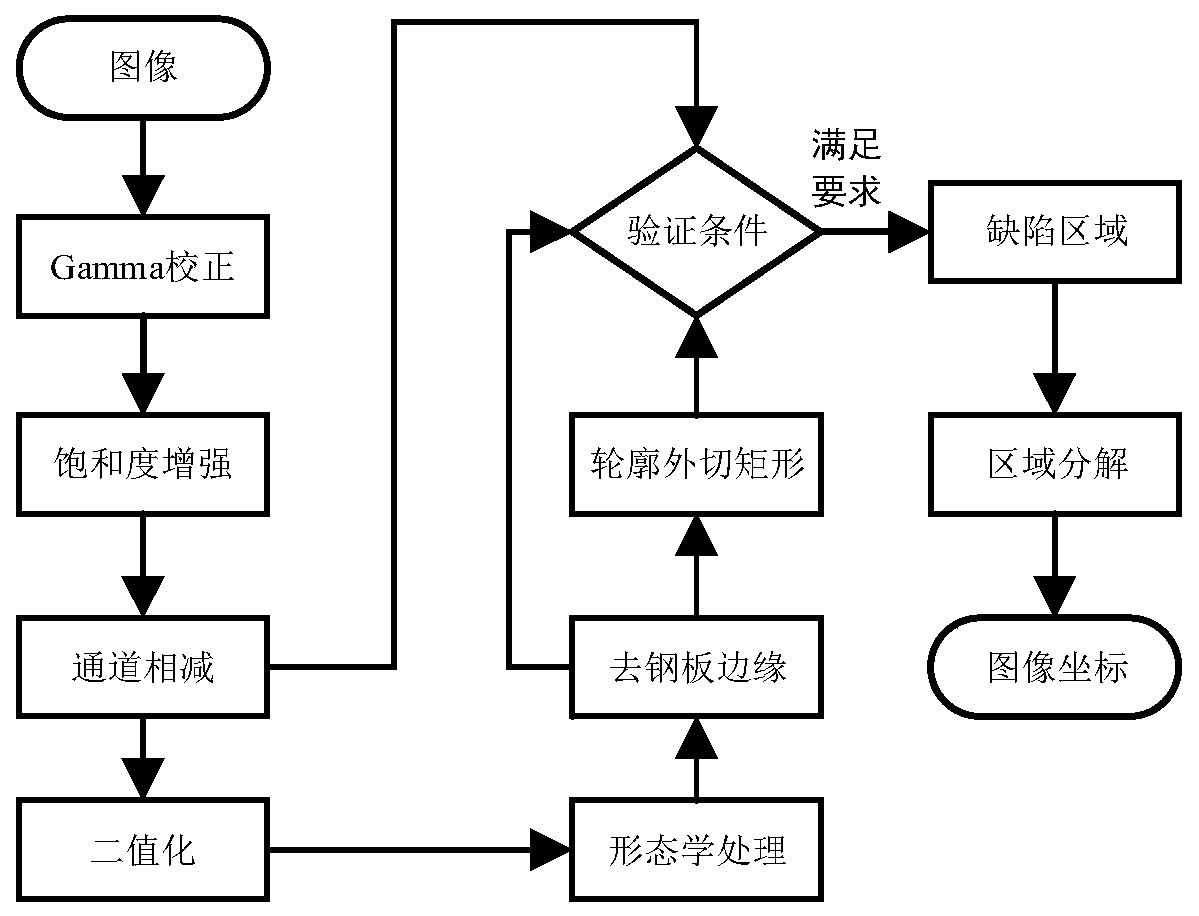

Metal surface grinding system based on industrial vision

ActiveCN111421425AAvoid grinding wasteImprove grinding efficiencyImage enhancementImage analysisVision processingProcess engineering

The invention belongs to the technical field of metal surface grinding, and discloses a metal surface grinding system based on industrial vision. The metal surface grinding system comprises a visual processing system, a grinding movement system and an auxiliary system, wherein the grinding movement system is combined with the visual processing system to finely divide a to-be-ground area, excessivegrinding waste is avoided, and the grinding efficiency is improved; a force balance device is combined with depth detection, the grinding force and the reasonable downward pressing amount are controlled in real time, and the grinding uniformity and the surface quality are guaranteed; and the grinding recognition rate and the grinding quality of the whole system are multiply guaranteed, and grinding personnel in severe environments can be greatly reduced or replaced in practical application.

Owner:NORTHEASTERN UNIV

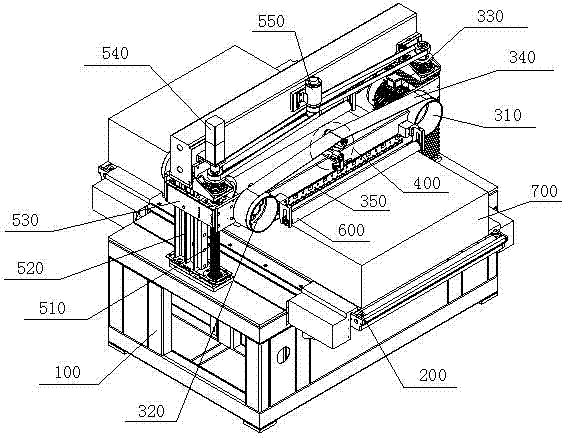

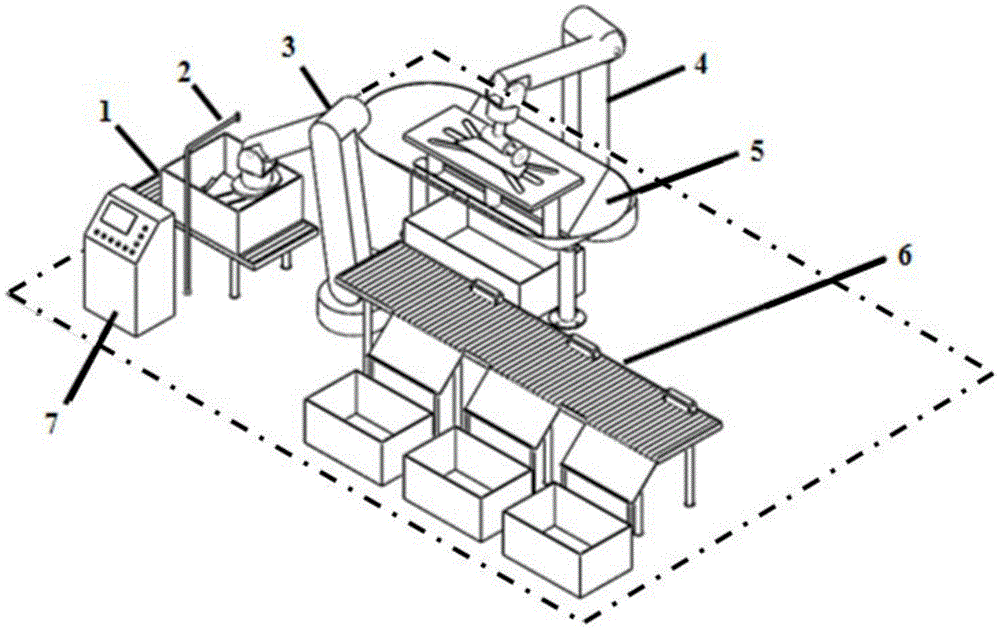

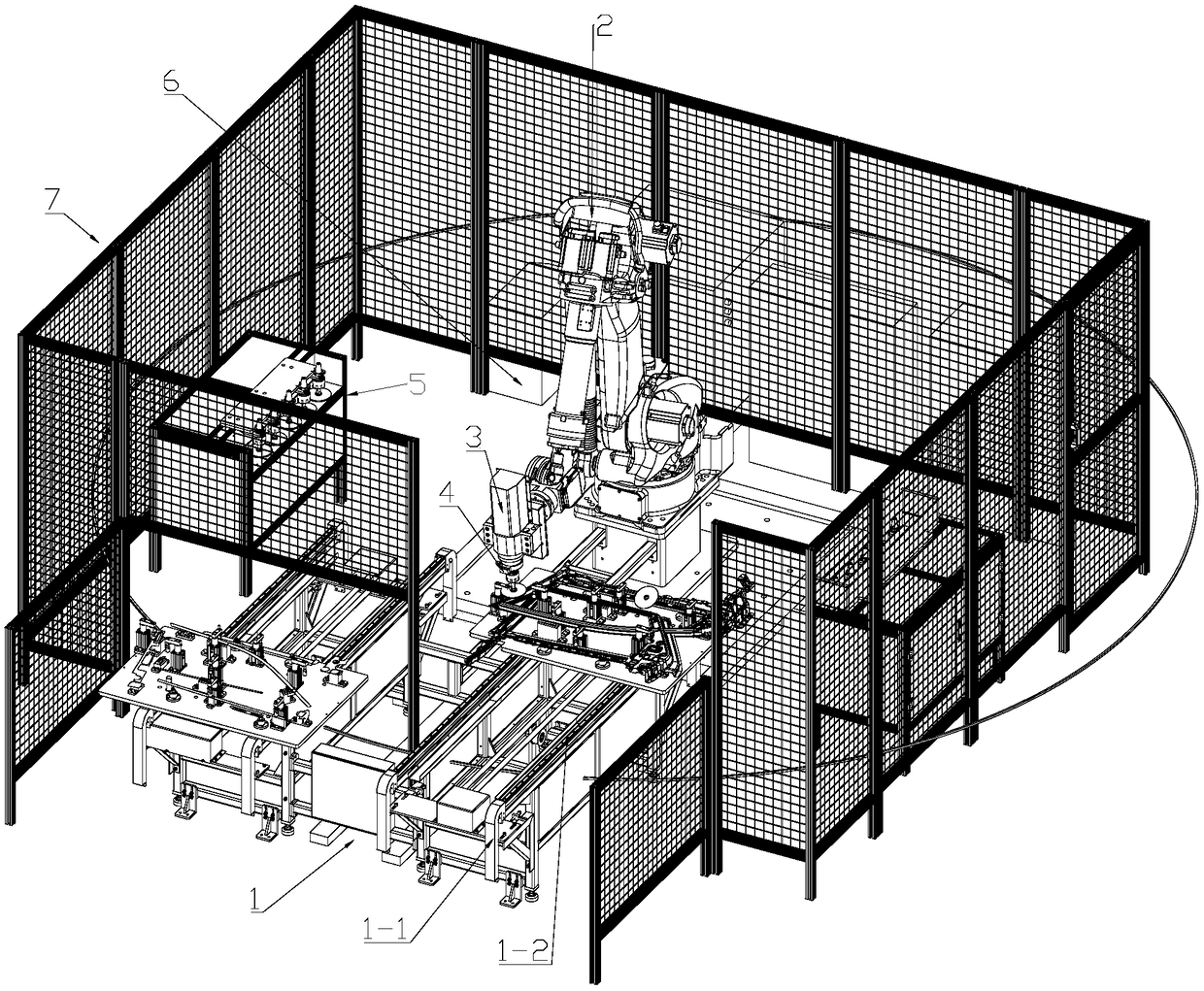

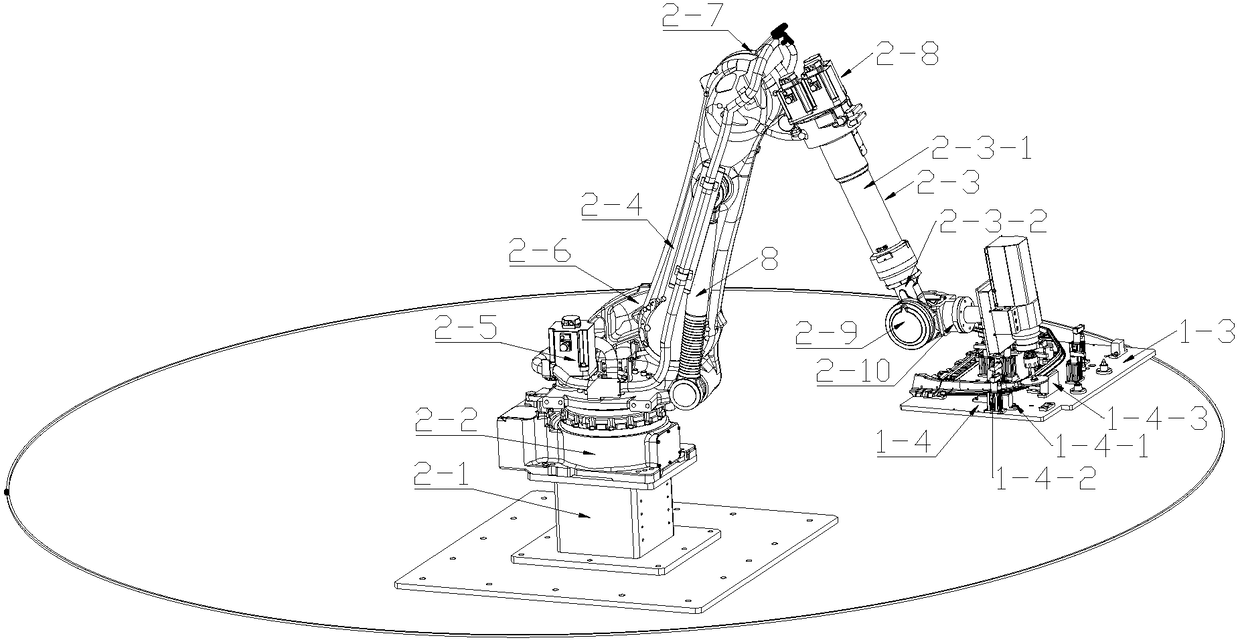

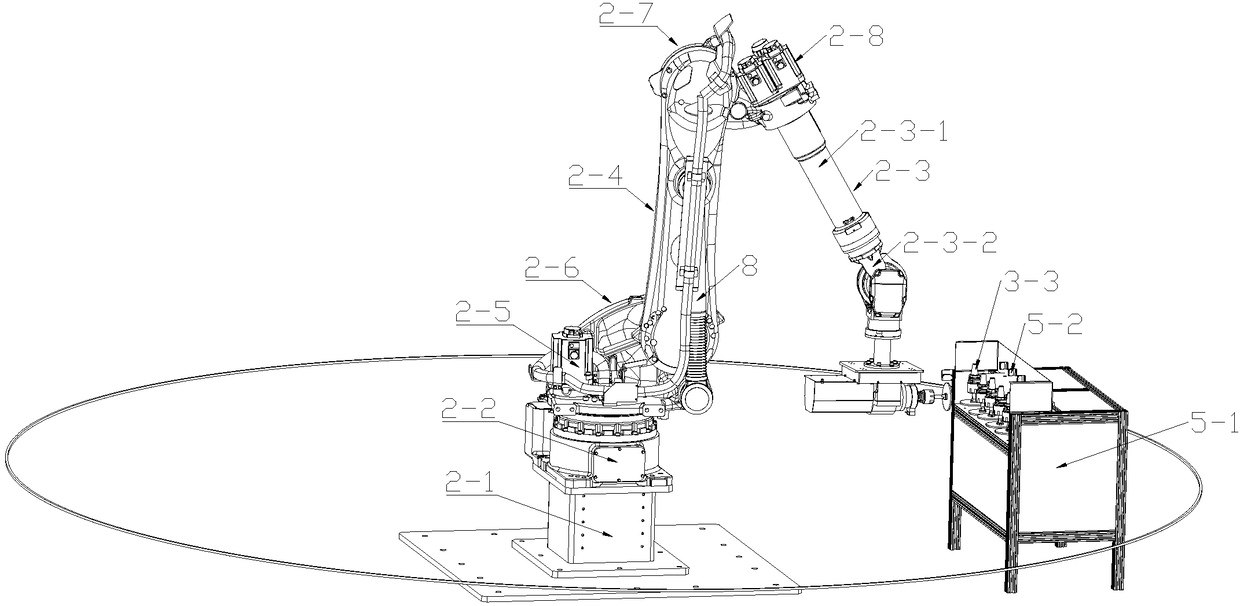

Robot polishing device

ActiveCN105643636AIncrease productivitySatisfy grinding requirementsProgramme-controlled manipulatorControl systemRobot

The invention discloses a robot polishing device. The robot polishing device comprises a feeding device, a vision device, a feeding / blanking robot, a polisher robot, a polishing platform, a classified conveying device and a control system, wherein the feeding device is used for conveying a work-piece to a working region of the vision device; the vision device acquires position information and outline information of the work-piece and conveys the position information and the outline information to the control system; the control system controls the feeding / blanking robot to place the work-piece on the polishing platform according to the position information, controls the polisher robot to polish the work-piece according to the outline information, and controls the feeding / blanking robot to move the polished work-piece to the classified conveying device; the classified conveying device classifies and outputs the polished work-piece. The robot polishing device disclosed by the invention is easy to control, and capable of realizing high-intelligent automatic polishing, high in production efficiency, and capable of guaranteeing the polishing quality and improving the production efficiency.

Owner:GUANGZHOU WENCHONG SHIPYARD CO LTD

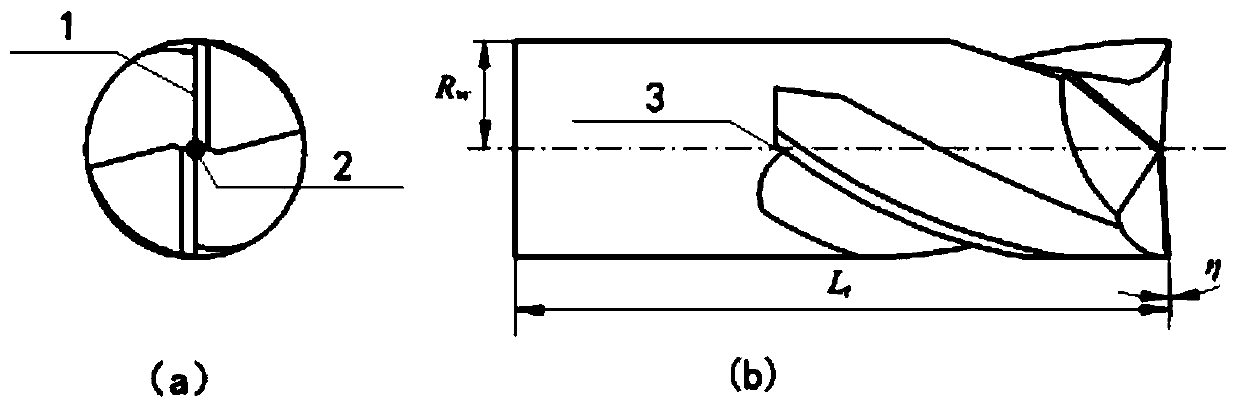

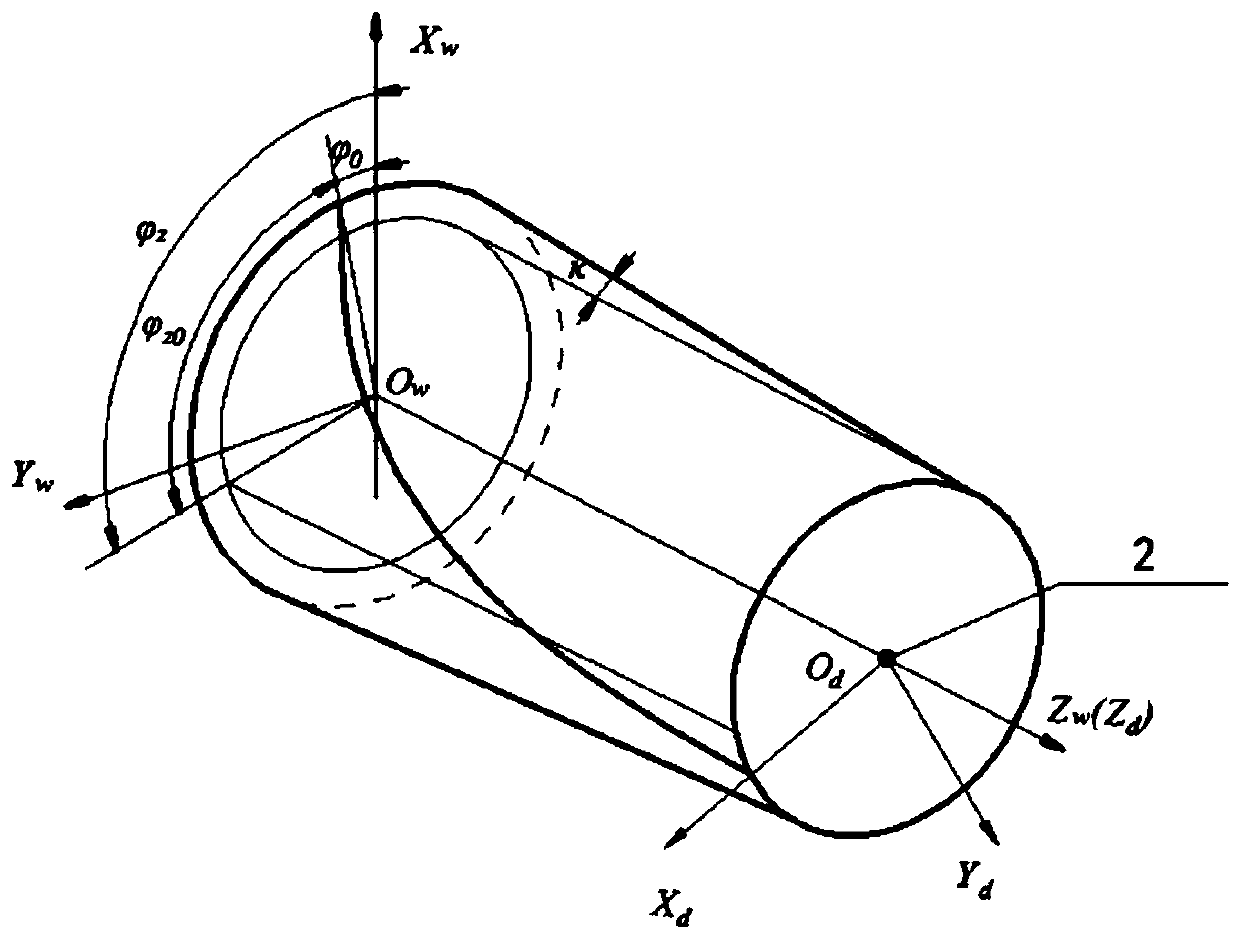

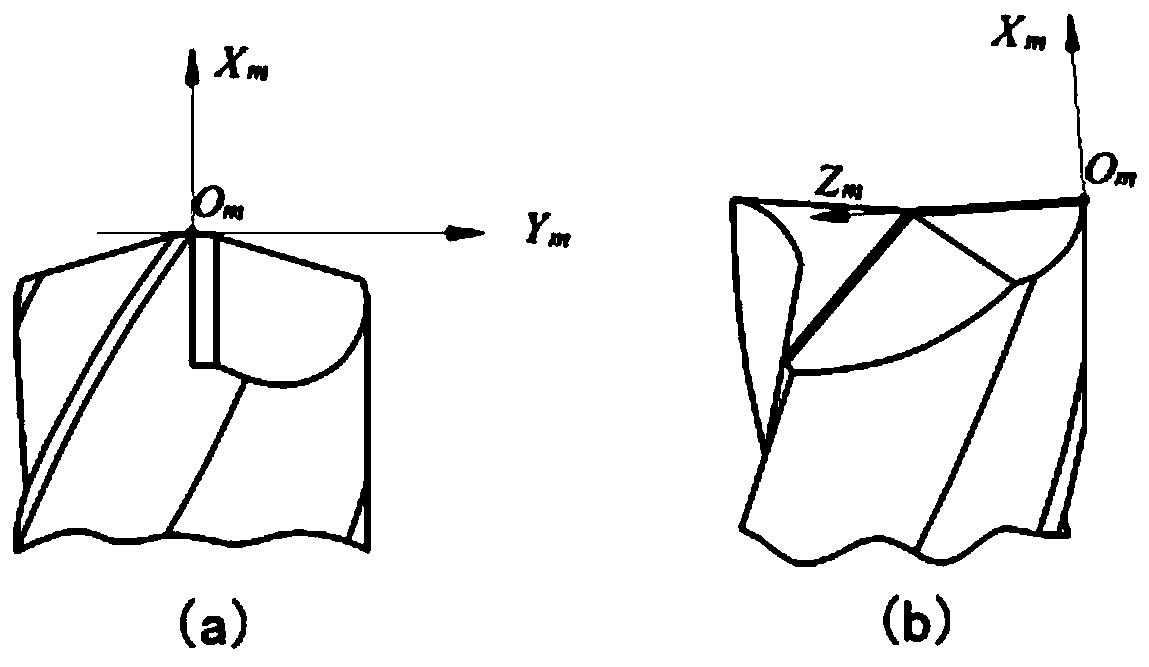

Method for solving grinding track of end tooth straight grain type flank face of integral flat-end end mill

ActiveCN111008441AGuaranteed grinding qualitySharpening achievedGeometric CADDesign optimisation/simulationStructural engineeringGrinding wheel

The invention discloses a method for solving a grinding track of an end tooth straight grain type flank surface of an integral flat-end end mill. The method comprises the following steps of: establishing the end tooth edge line of the integral flat-end end mill with tooth pass and tooth offset structural characteristics, and proposing an edge grinding model for the end tooth straight grain type flank surface. According to the model, the end face of the grinding wheel serves as a grinding face, the grinding quality can be guaranteed, the flexibility of grinding posture definition of the grinding wheel is achieved by adjusting technological parameters such as the swing angle and the lifting angle of the grinding wheel, and blade grinding interference is avoided.

Owner:SOUTHWEST JIAOTONG UNIV

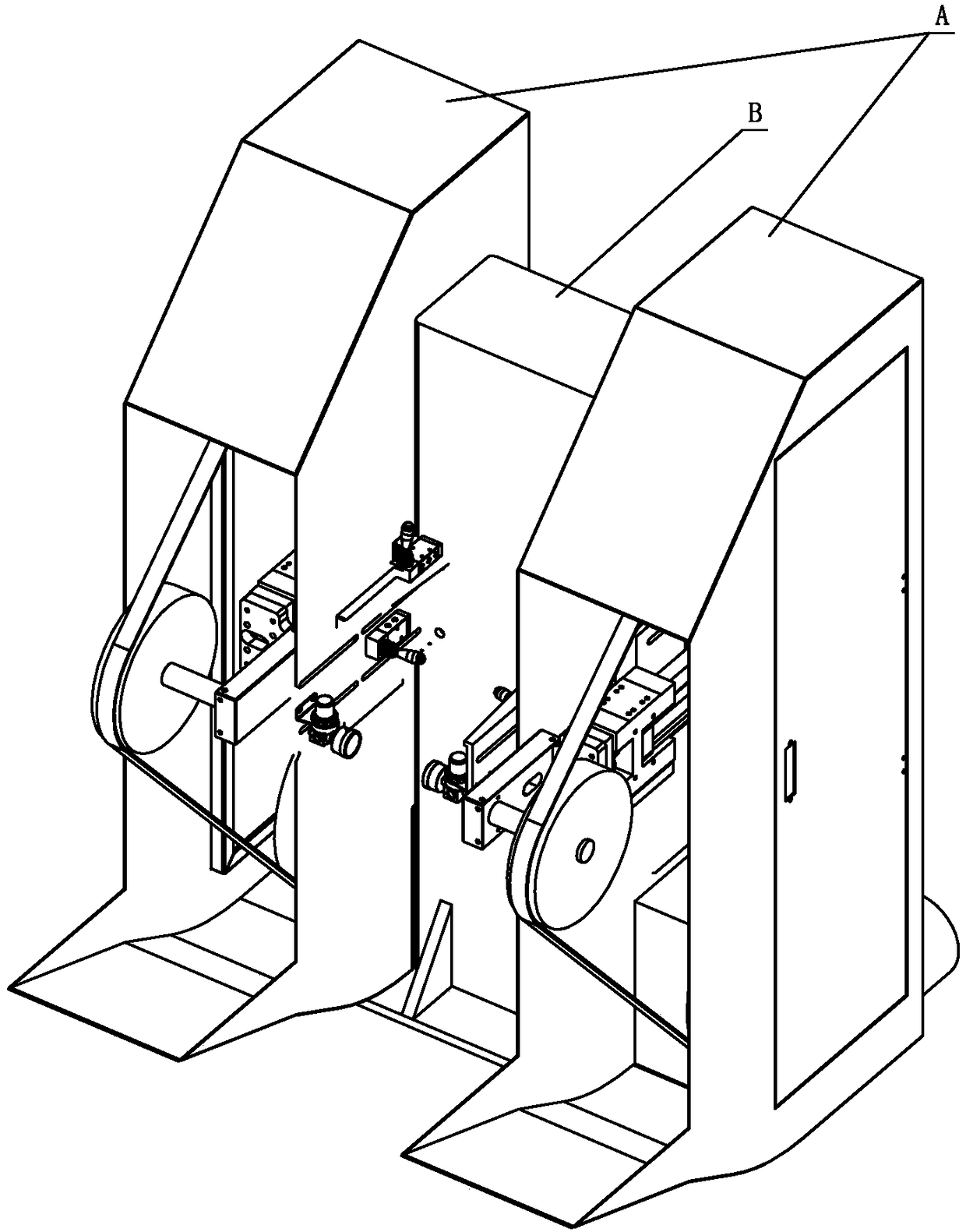

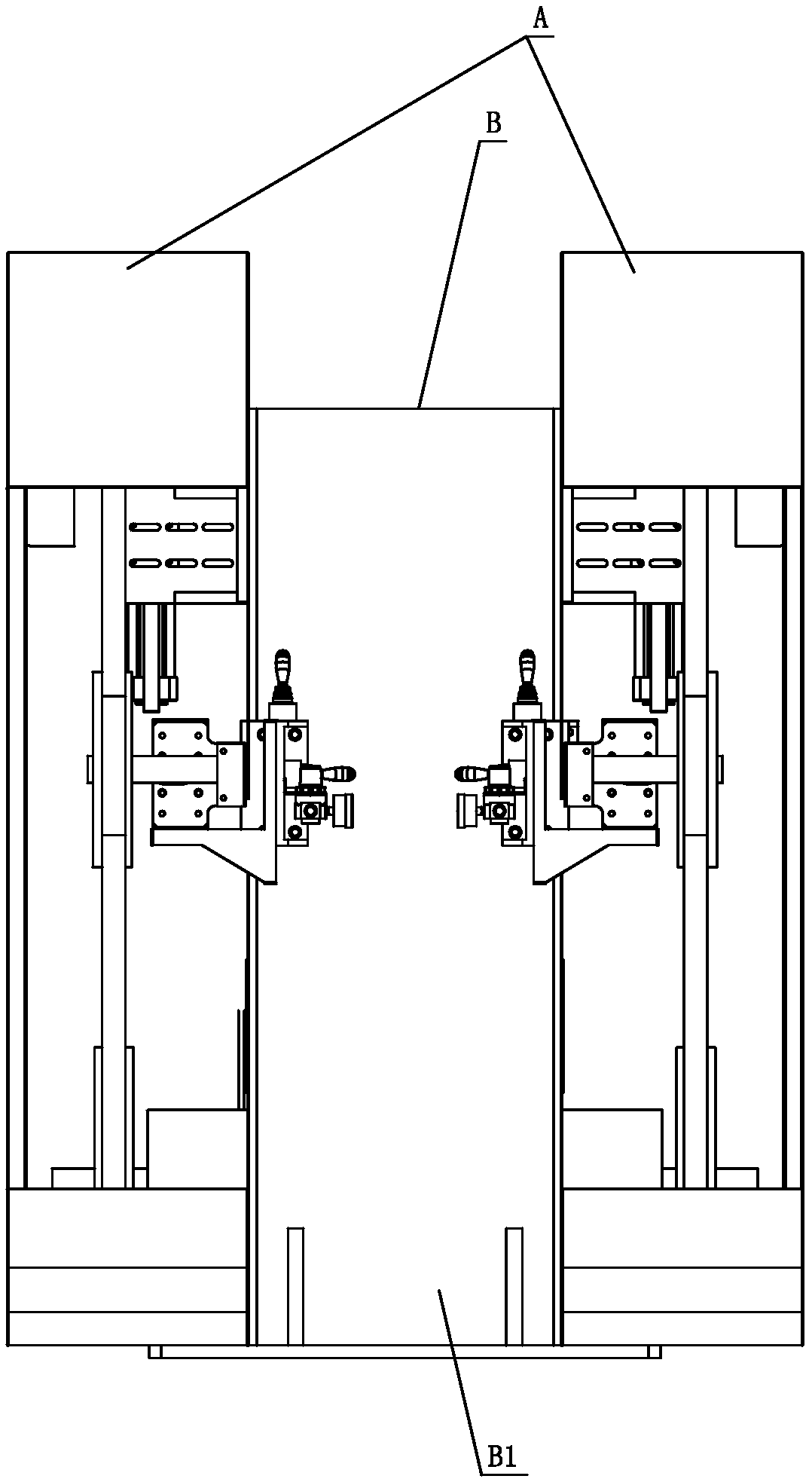

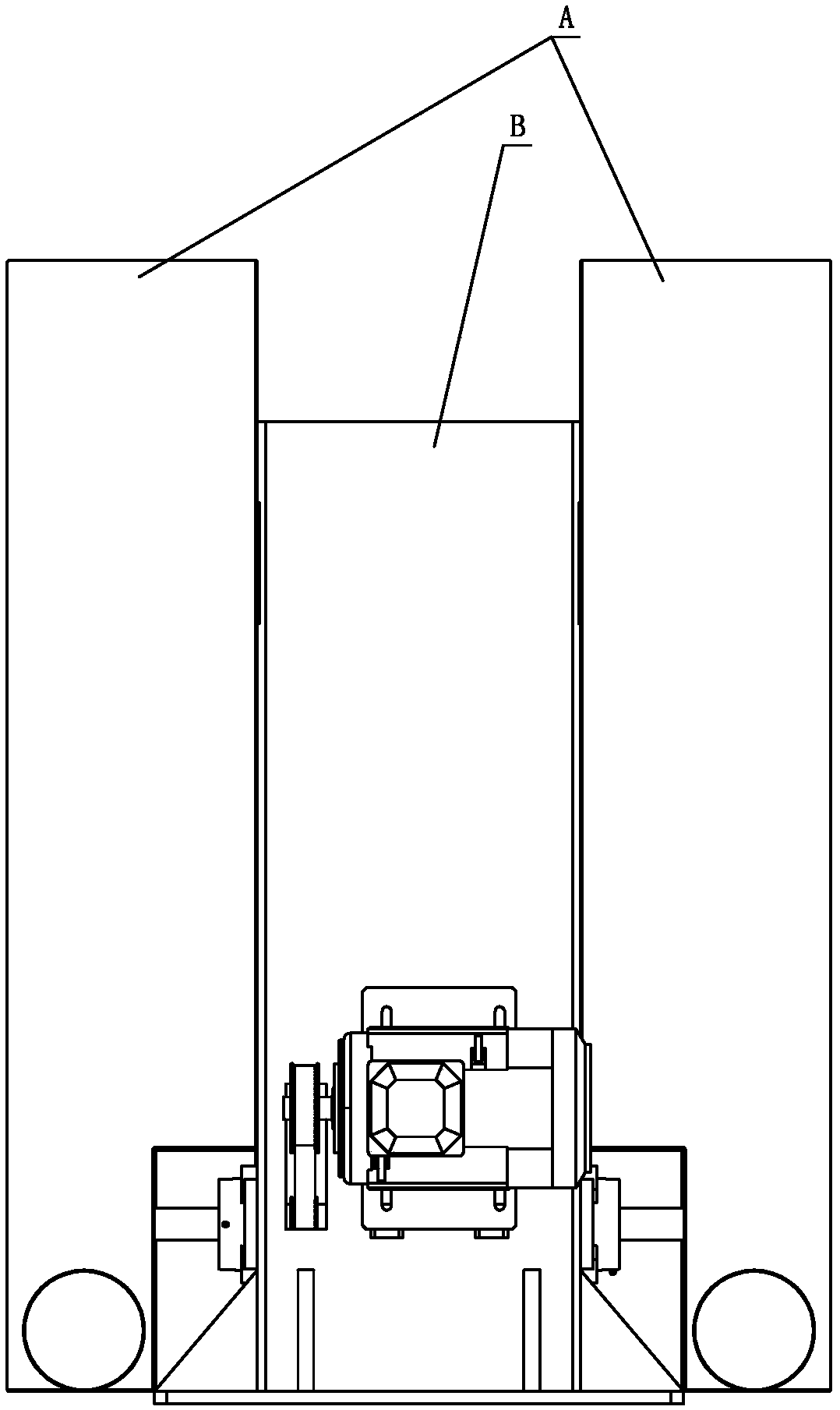

Double-side double-station force control belt sander and polishing work station thereof

ActiveCN108789060AReduce labor intensityReduce job hazardsBelt grinding machinesAutomatic grinding controlSanderDrive wheel

The invention provides a double-side double-station force control belt sander and a polishing work station thereof. The double-side double-station force control belt sander comprises single-station polishing cabinets and a power output cabinet. The two single-station polishing cabinets are arranged. The power output cabinet is arranged between the two single-station polishing cabinets. Each single-station polishing cabinet comprises a polishing system composed of a polishing driving wheel, a polishing abrasion wheel, a polishing driven wheel and a polishing abrasion belt, wherein the polishingabrasion belt is arranged on the polishing driving wheel, the polishing abrasion wheel and the polishing driven wheel in a winding manner. Each single-station polishing cabinet further comprises a force control mechanism and a deviation rectifying mechanism, wherein the force control mechanism drives the polishing abrasion wheel to move linearly, and the deviation rectifying mechanism drives thepolishing driven wheel to swing around one side. The power output cabinet comprises a polishing motor and a transmission shaft. The polishing motor drives the transmission shaft to rotate. The two ends of the transmission shaft are connected with the corresponding polishing driving wheels. The polishing quality and efficiency of the belt sander are improved, sensitivity of force control is high, the polishing applicability is high, the polishing performance is reliable, the abrasion belts are convenient and fast to replace, and the manufacturing cost is low.

Owner:GUANGDONG LXD ROBOTICS CO LTD

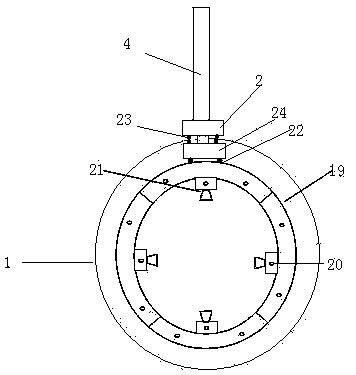

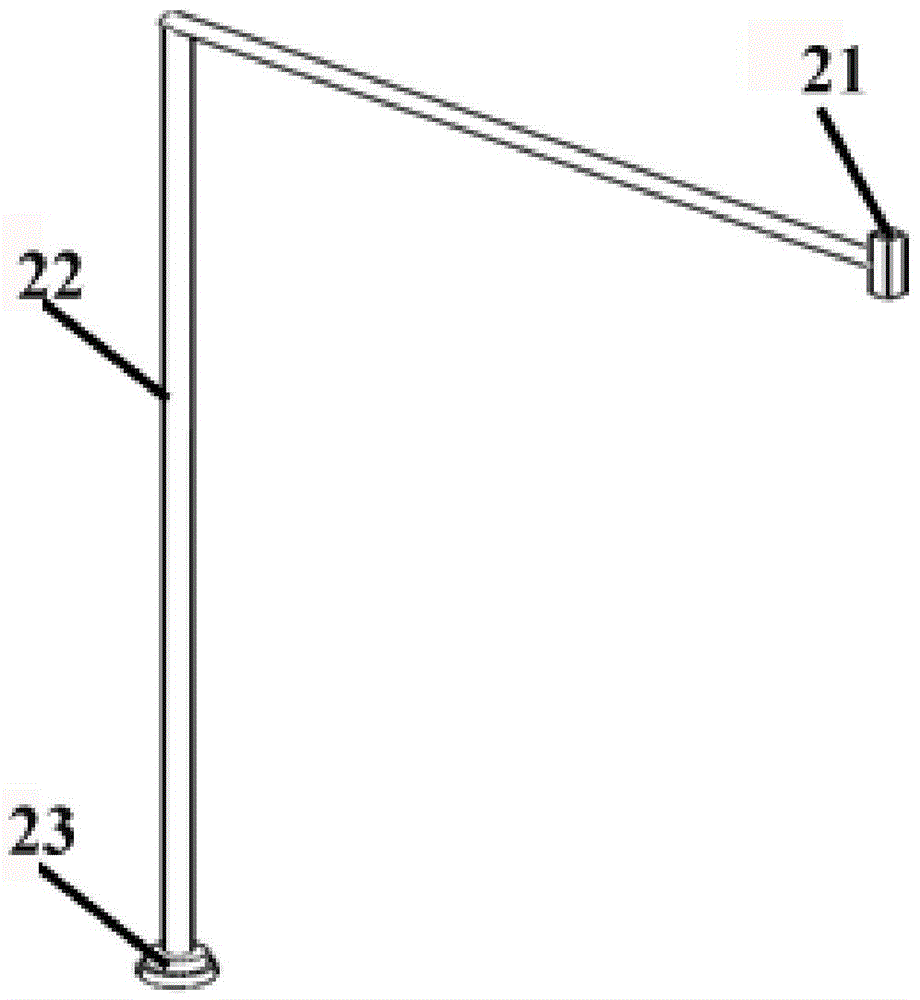

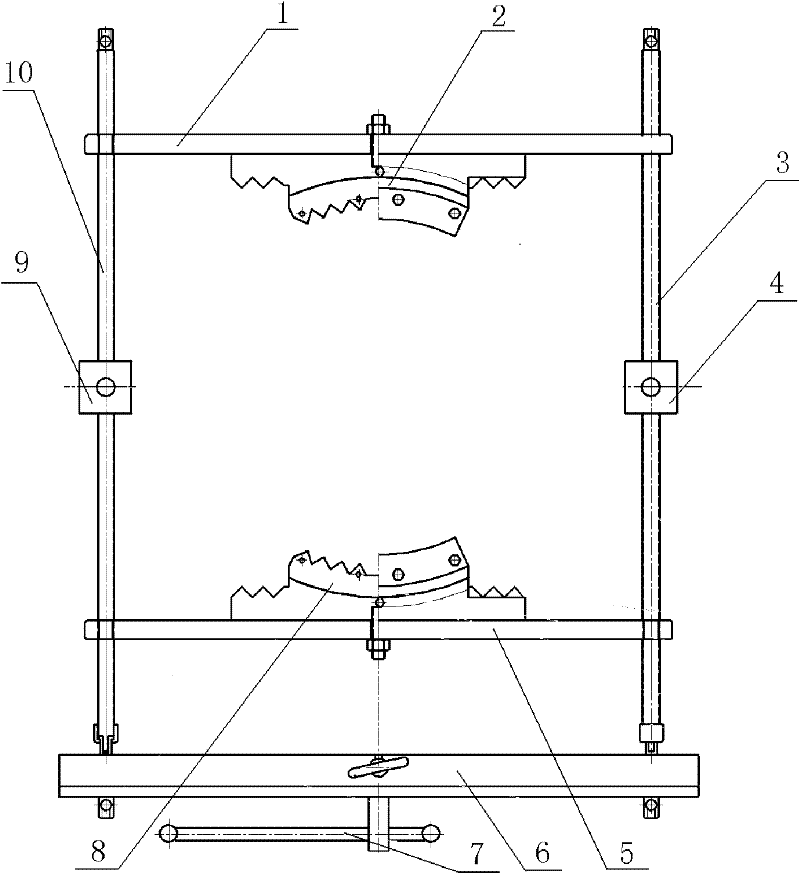

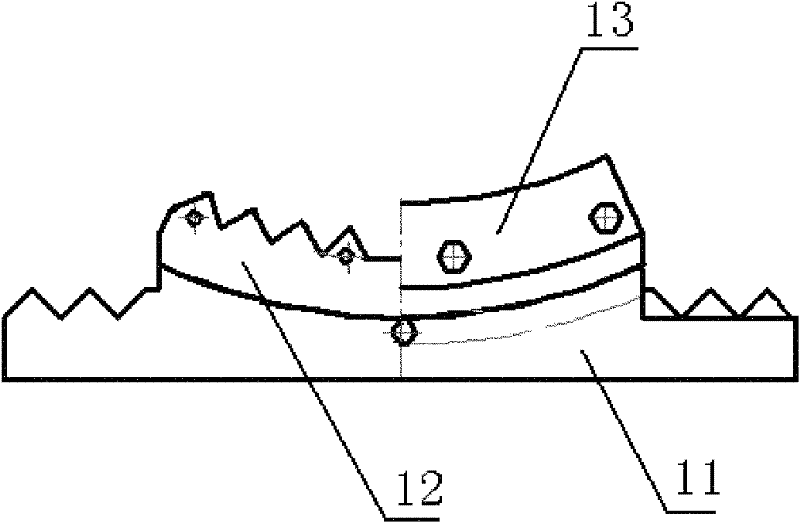

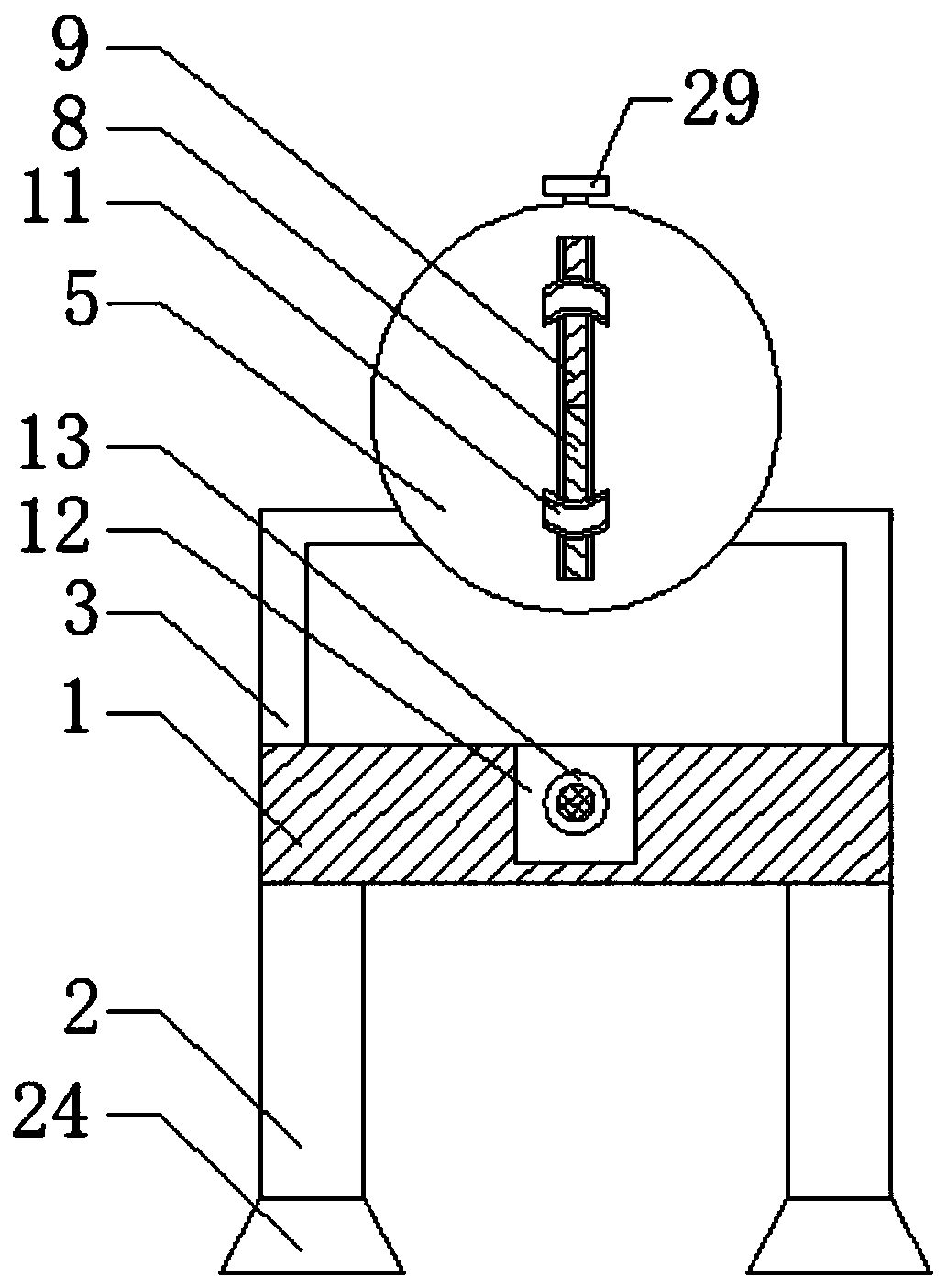

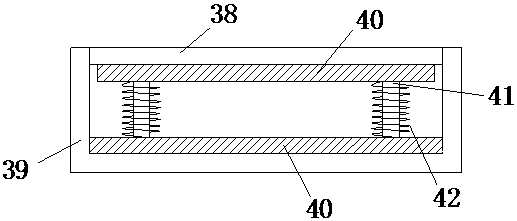

Clamping mechanism for seal surface grinding unit of valve

ActiveCN102049727AGuaranteed grinding qualityReduce maintenance workloadLapping machinesWork carriersEngineeringSurface grinding

The invention discloses a clamping mechanism for a seal surface grinding unit of a valve, which comprises an operating handle, a first screw, a second screw, a synchronous interlocking member driving the first screw and the second screw to rotate simultaneously with the operating handle, as well as a first blocking member and a second blocking member which displace oppositely along the first screw and the second screw and used for clamping a valve flange; the second screw and the first screw have same structure, and are mutually parallel; a first central fixing seat is fixedly arranged in the middle of the first screw; and a second central fixing seat is fixedly arranged in the middle of the second screw. When in use, the clamping mechanism for the seal surface grinding unit of the valve can guarantee the grinding quality, reduce the maintenance workload, and low the maintenance cost by employing the structure.

Owner:DHV VALVE & FOUNDRY

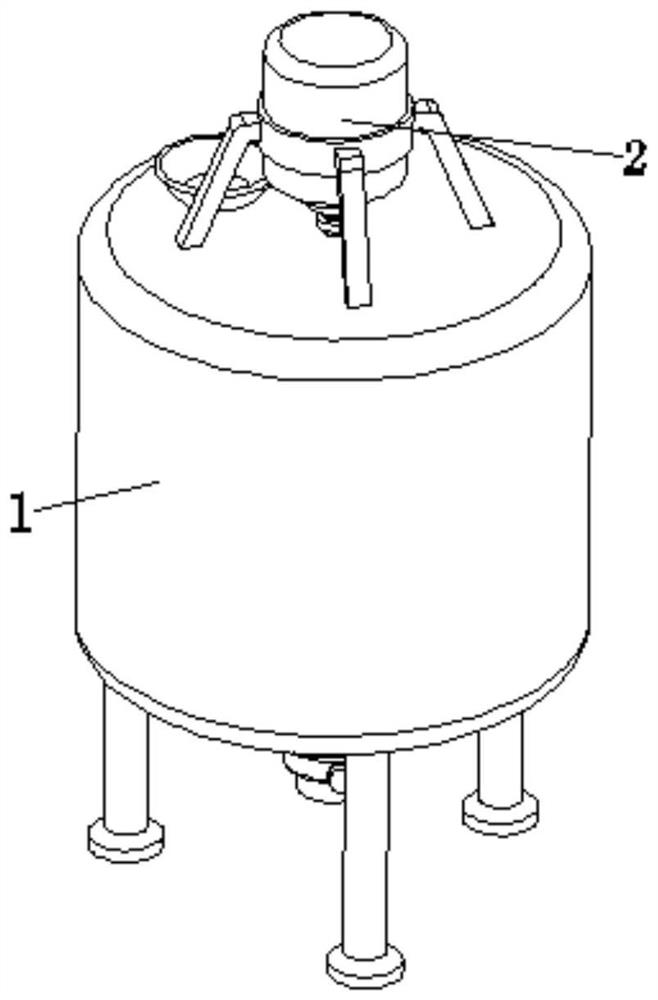

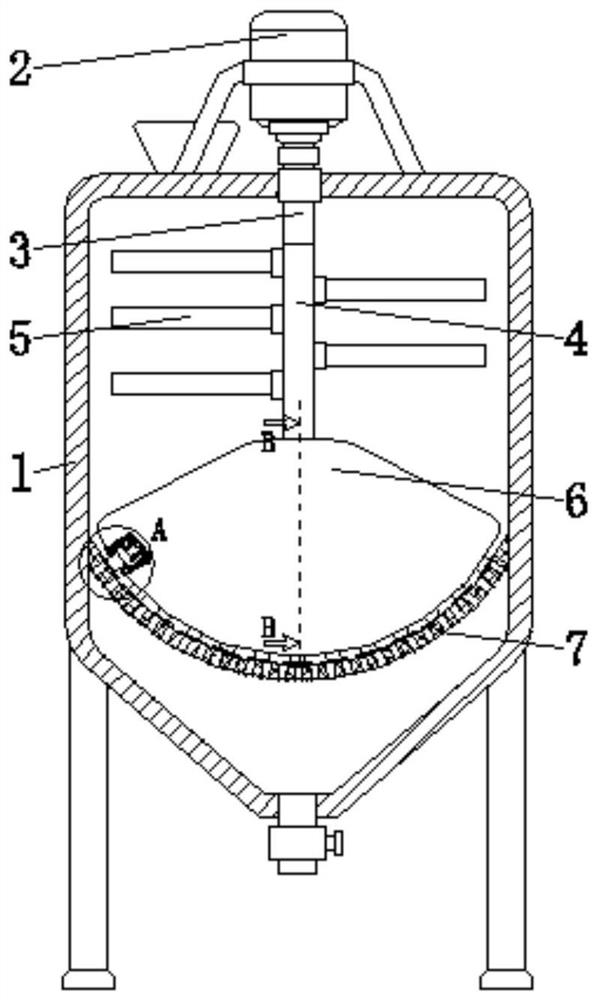

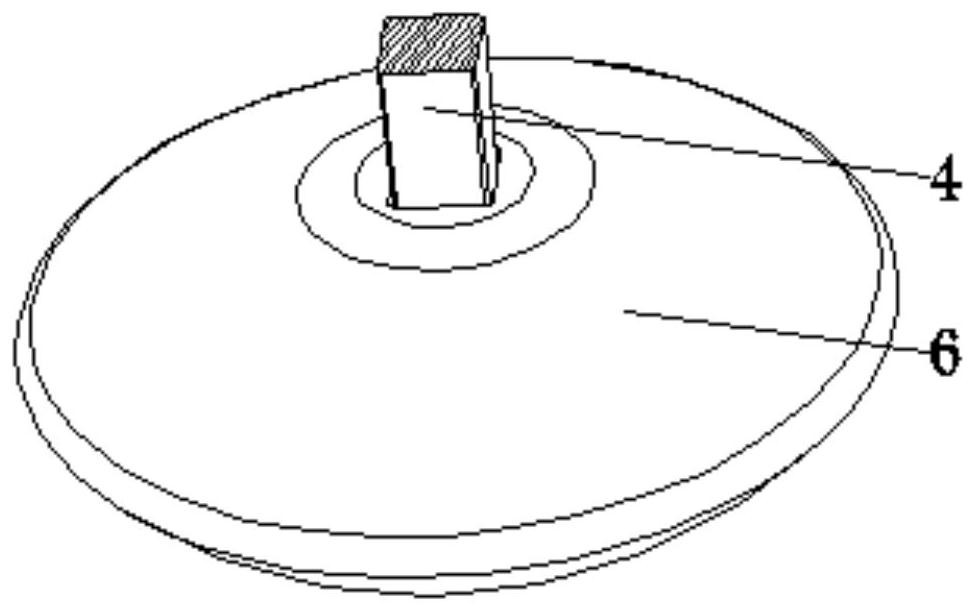

Feed processing equipment

The invention discloses feed processing equipment. The feed processing equipment comprises a grinding tank and a driving motor, wherein a rotating shaft is rotatably connected to the center of the topof the grinding tank; the top end of the rotating shaft is fixedly connected with an output shaft of the driving motor through a coupling; a square connecting rod is fixed to the bottom end of the rotating shaft and located in the center of the interior of the rotating shaft; deflector rods are fixed to the surface of the square connecting rod; a grinding device is arranged at the bottom end of the square connecting rod, the grinding device is in sliding connection with the square connecting rod; and a sieve plate is fixed to the position, close to the bottom of the grinding device, in the grinding tank. The invention relates to the technical field of feed processing. According to the feed processing equipment, the effects of uniform grinding and adhesion prevention are achieved; elasticpressing can be carried out, and the grinding space is automatically and moderately increased, so that large and small granular materials uniformly leak, and grinding is rapid and uniform; and meanwhile, sticky materials on the inner wall can be automatically scraped off, so that the working efficiency and the use performance are improved.

Owner:莱阳和美华饲料有限公司

High-efficiency Chinese medicinal material grinding device

InactiveCN108097375AGuaranteed grinding qualityEnsure stabilityGrain treatmentsElectric machineryStorage tank

The invention discloses a high-efficiency Chinese medicinal material grinding device. The high-efficiency Chinese medicinal material grinding device comprises a base. A storage tank is arranged on theupper side of the base. A filter screen is arranged at the upper end of the interior of the storage tank. Supporting plates are arranged at the left and right ends of the upper side of the base. A first motor is arranged in the middle portion of the left side of the supporting plate at the left end. A first connecting shaft is arranged on the right side of the first motor. A first connecting shaft is also arranged on the left side of the supporting plate at the right end. A grinding cavity is formed between the first connecting shafts. Second motors are arranged on the inner sides of the upper ends of the supporting plates. The upper side of each second motor is provided with a lead screw. A sliding block is arranged on each lead screw. A connecting cross rod is arranged between the sliding blocks. The lower side of the connecting cross rod is provided with a connecting frame. A connecting sleeve is arranged in the connecting frame. The lower side of the connecting sleeve is providedwith a connecting vertical rod. The lower side of the connecting vertical rod is provided with a connecting support. A grinding roll is arranged in the connecting support. The high-efficiency Chinesemedicinal material grinding device can be used for grinding Chinese medicinal materials effectively and conveniently, can effectively conduct vibratory screening and accordingly can effectively guarantee the grinding efficiency and the grinding quality.

Owner:ZHENGZHOU RENHONG PHARMA CO LTD

Quick polishing device for planks for machining

InactiveCN107584394AImprove grinding efficiencySave sanding timeGrinding carriagesGrinding feed controlPulp and paper industryMachining

The invention discloses a quick polishing device for planks for machining. The quick polishing device comprises a frame and two polishing components, wherein a driven roller and a driving roller are respectively mounted at the two ends of the frame; a support roller is arranged on the middle part of the frame; each polishing component comprises a portal gantry fixed on the frame; a screw rod is inthreaded connection with the portal gantry; the bottom end of the screw rod is moveably connected with the interior of a fixing sleeve; the bottom of the fixing sleeve is fixed on a bracket through abolt; a polishing roller is arranged on the bracket through a rotating shaft. According to the invention, the two sets of polishing components are used for respectively polishing the two surfaces ofthe plank at the same time, so that the polishing efficiency is greatly increased and the polishing time is reduced; a spring is utilized to drive the polishing roller to automatically adjust the acting force on the plank surface, the control on the polishing pressure of the polishing roller is benefited and the polishing quality is guaranteed; the polishing wire on the polishing roller is conveniently replaced and the use cost of the whole polishing roller is lowered.

Owner:WUXI ZHIGURUITUO TECH SERVICE CO LTD

Bearing inner and outer ring grinding device

InactiveCN110421418AEasy to fixGrinding stabilityGrinding carriagesRevolution surface grinding machinesEngineeringThreaded rod

The invention discloses a bearing inner and outer ring grinding device. The device comprises a supporting platform and supporting legs, the supporting legs are welded to the bottom of the supporting platform, a first groove is formed in a round plate, the inner wall of one side of the first groove is embedded with a first bearing, the inner part of the first bearing is in interference connection with a first threaded rod, a rectangular supporting plate is welded to the top surface of a T-shaped sliding block, a third bearing is inlaid at one end of the top surface of the rectangular supportingplate, the inner part of the third bearing is in interference connection with a fourth threaded rod, a second n-shaped mounting frame is welded to the top surface of the rectangular supporting plate,sliding grooves are formed in the inner walls of the two sides of the second n-shaped mounting frame, sliding blocks are arranged in the sliding grooves in a sliding mode, and a rectangular movable plate is integrally formed between the sliding blocks. According to the device, the inner rings and the outer rings of bearings with different sizes can be fixed conveniently, the grinding can be stabler, the use is flexible and convenient, the grinding is more sufficient, and the grinding quality is guaranteed.

Owner:安徽千禧精密轴承制造有限公司

Flexible polishing device and flexible polishing system

InactiveCN108481120AReal-time monitoring heightReal-time monitoring of the diameter change of the abrasive sheetEdge grinding machinesGrinding feed controlLaser rangingControl system

The invention relates to a flexible polishing device comprising a material supply assembly, a polishing mechanical arm assembly, a polishing head assembly, a laser range finder, an abrasive wheel replacing assembly, a control console and a protective separation net. According to the flexible polishing device, a laser measuring instrument and the laser range finder are adopted to monitor the weld joint height of a workpiece and the diameter change of an abrasive sheet in real time correspondingly, and meanwhile a PLC control system online reregulates the polishing path of the workpiece according to all information and controls and adjusts the angles of polishing branch arms and the abrasive sheet and the polishing depth at the same time; and in this way, a qualified polished product is obtained, and on the premise of guaranteeing the polishing quality, the polishing efficiency is improved.

Owner:NINGBO HUIZHIHENGDONG AUTOMATION TECH CO LTD

Belt sander

ActiveCN103659477AQuick grindingGuaranteed grinding qualityBelt grinding machinesOther manufacturing equipments/toolsCircular discSander

The invention discloses a belt sander. The belt sander comprises a base, wherein an X-axis workbench and a Y-axis workbench are arranged on the base, a rotating disk used for fixing a workpiece is arranged on the Y-axis workbench, more than one station is arranged on the rotating disk, a Z-axis support is arranged on the base, more than one sliding rail is vertically arranged on the Z-axis support, a Z-axis machining device is further installed on the Z-axis support and comprises a servo motor installed on the Z-axis support and a supporting table driven by the servo motor to move up and down on the sliding rail, a motor, a driving wheel driven by the motor, and a driven wheel driven by the driving wheel are installed on the supporting table, and the driven wheel is driven to rotate by the driving wheel through a sand belt. According to the belt sander, four-shaft linkage can be achieved, workpieces can be flexibly machined, a large part of side faces of the workpieces can be machined, machining efficiency is high, and the workpieces can be machined very conveniently.

Owner:江门杰能刀剪装备科技有限公司

Convenient and rapid environment-friendly stone polishing device

InactiveCN108326661AEasy to polishEasy to moveGrinding carriagesGrinding work supportsHydraulic cylinderSlide plate

The invention discloses a convenient and rapid environment-friendly stone polishing device. The convenient and rapid environment-friendly stone polishing device comprises a device body, the device body is fixedly connected with a base, and the bottom of the base is fixedly connected with supporting columns. Universal wheels are arranged at the bottoms of the supporting columns, a sealing door is arranged on the end face of the outer wall of the device body, and a control panel is fixedly mounted on the sealing door. A fixing plate is arranged on the upper portion in the device body, recoveringsucking heads of the lower end face of the fixing plate are connected with a dust collecting box through a recovering pipe, and a motor is fixedly mounted on the right side of the upper end face of the fixing plate. The output end of the motor is fixedly connected with a threaded rod, the threaded rod is in threaded connection with a sliding plate, and a hydraulic cylinder, a polishing motor anda polishing disc are arranged below the fixing plate. A damping table is fixedly mounted at the bottom of the device body, a first sliding groove is fixedly formed in the upper end face of the dampingtable, and a fixing table is arranged on the upper side of the first sliding groove. According to the convenient and rapid environment-friendly stone polishing device, the structure is simple, operation is convenient, to-be-polished stone is fixed through clamping plates, and the damping table can buffer impacting force generated when the stone is placed on the fixing table.

Owner:CHENGDU PUJIANG KEXIAN TECH

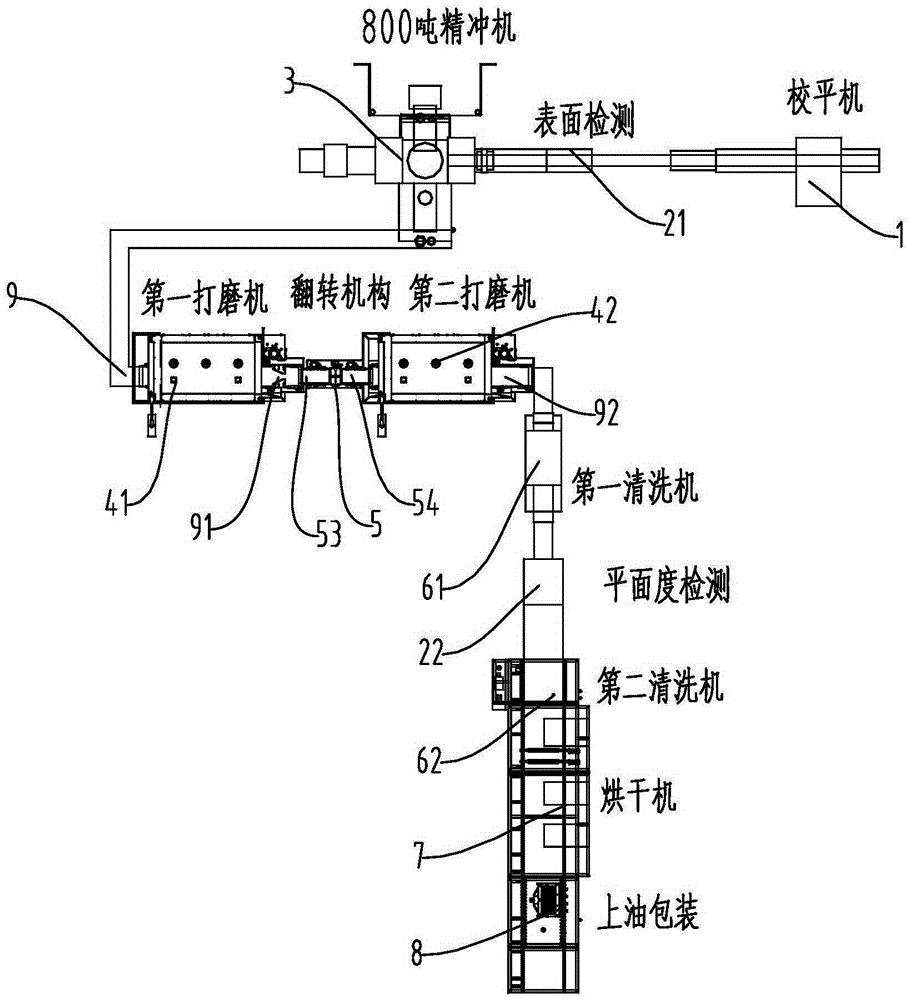

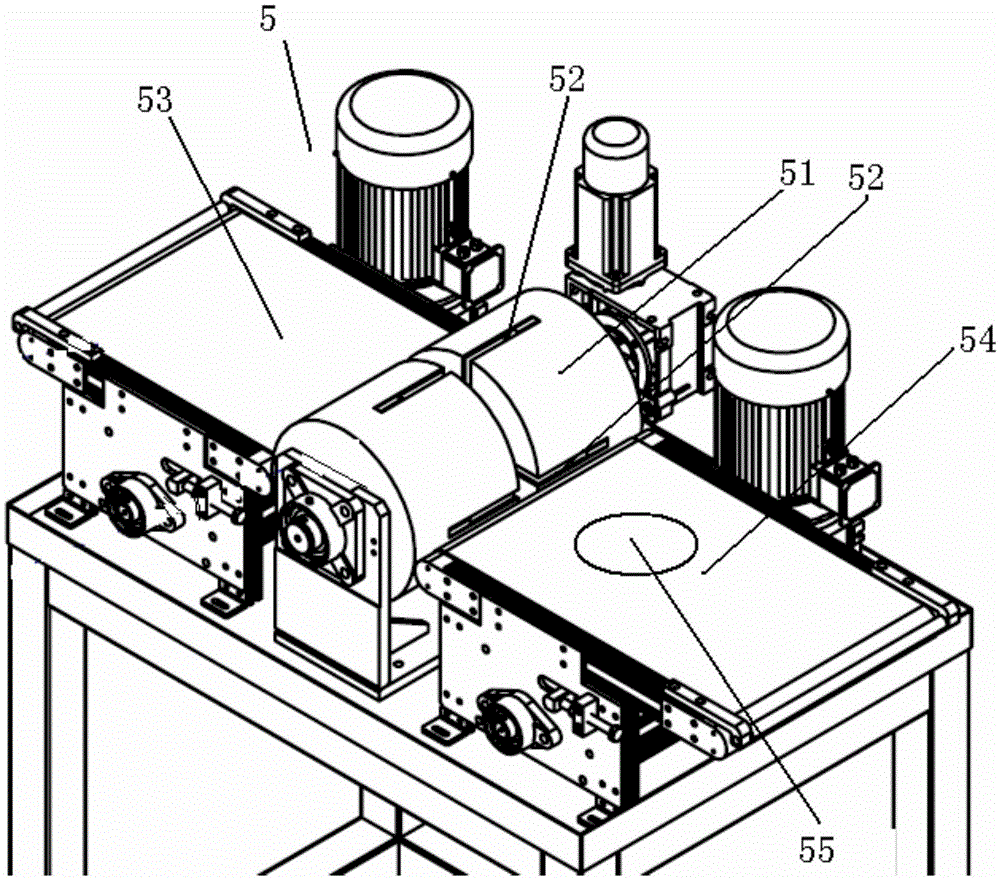

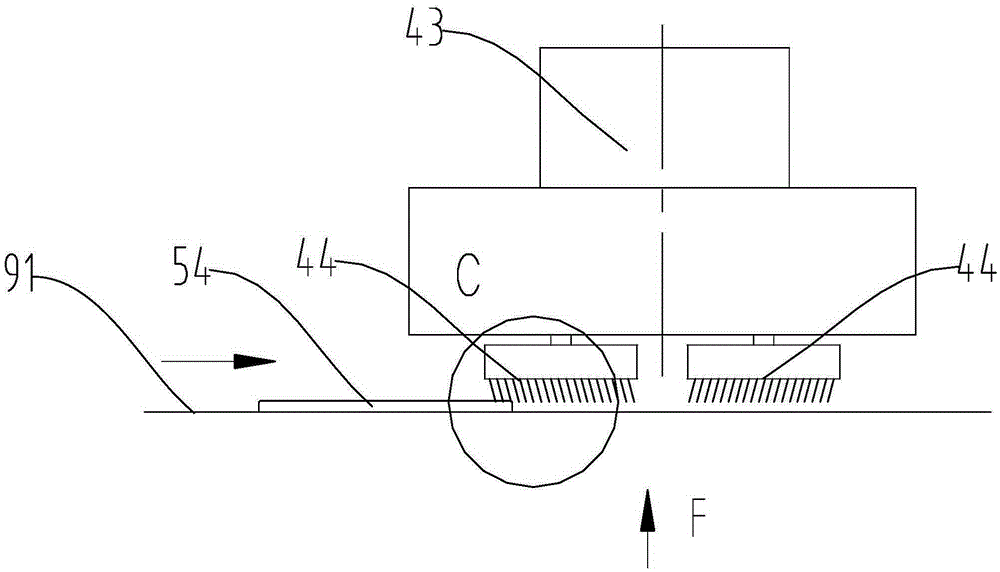

Manufacture equipment and manufacture method for steel friction plate of clutch

ActiveCN105397487APolished evenlyGrinder grinds evenlyOther manufacturing equipments/toolsVehicle componentsSanderEngineering

The invention provides manufacture equipment and a manufacture method for a steel friction plate of a clutch. The manufacture equipment comprises a punch, a first sander, a turnover mechanism and a second grinder which are sequentially arranged, wherein a first section of conveyor belt is arranged between the turnover mechanism and the first sander; a second section of conveyor belt is arranged between the turnover mechanism and the second sander; the first sander and the second sander each comprise a rotary brush; by utilizing the turnover mechanism, the friction plate sanded by the first sander can be turned over so that the surface which is not sanded by the first sander can be sanded by the second sander; the whole process is finished by the machine automatically, and the sanding quality and working tempo can be easily controlled, so that the sanding quality of the surface of the friction plate is ensured, and the manufacture efficiency can be improved; and the first sander and the second sander can sand the friction plate by adopting the rotary brushes; and during a sanding process, the rotary brushes rotate, and the sanding angle is changed continuously so that the surface of the friction plate can be uniformly sanded.

Owner:上海交运汽车精密冲压件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com