Metal rotating member constant-pressure grinding control device and method

A technology of a control device and a control method, which is applied in the direction of automatic grinding control device, workpiece feed movement control, metal processing equipment, etc., can solve the problems of unstable grinding pressure of automatic and semi-automatic grinding equipment, and achieve compensating grinding efficiency. Decreased, guaranteed grinding quality, good convergence effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

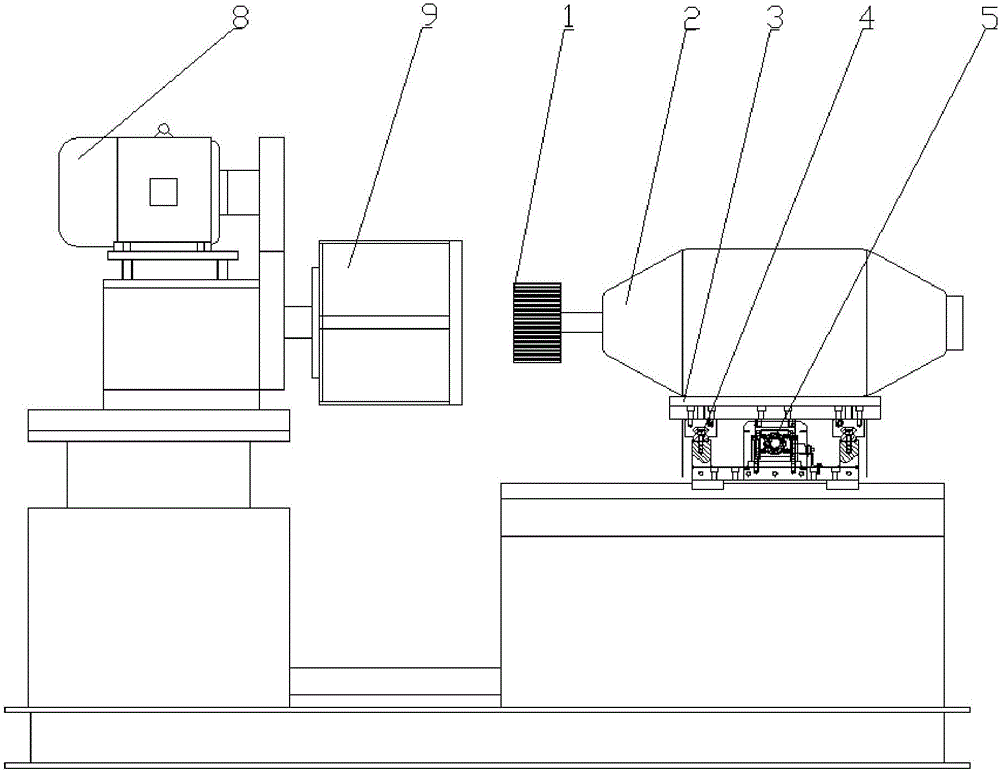

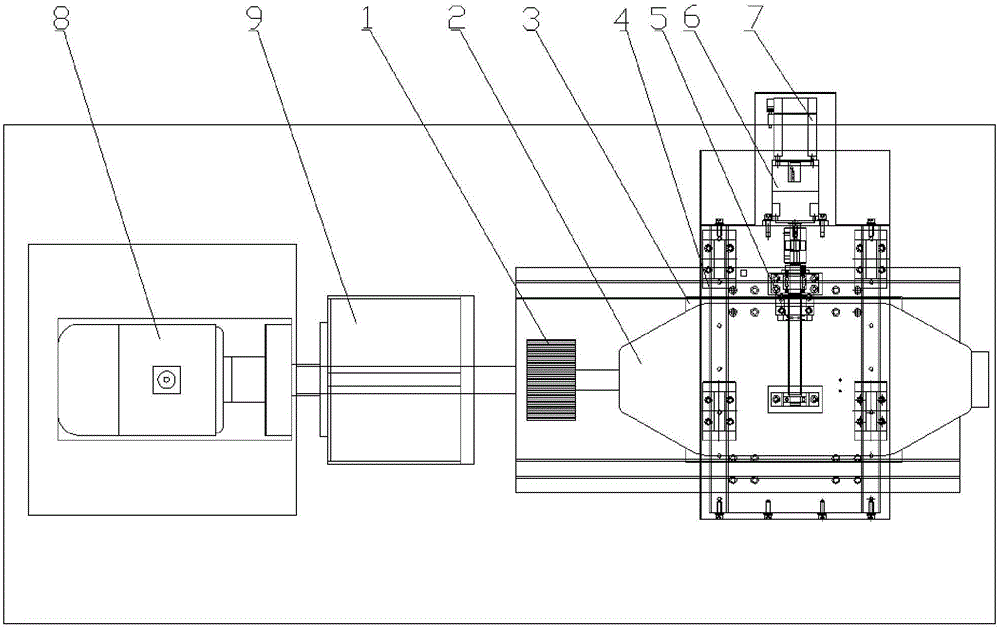

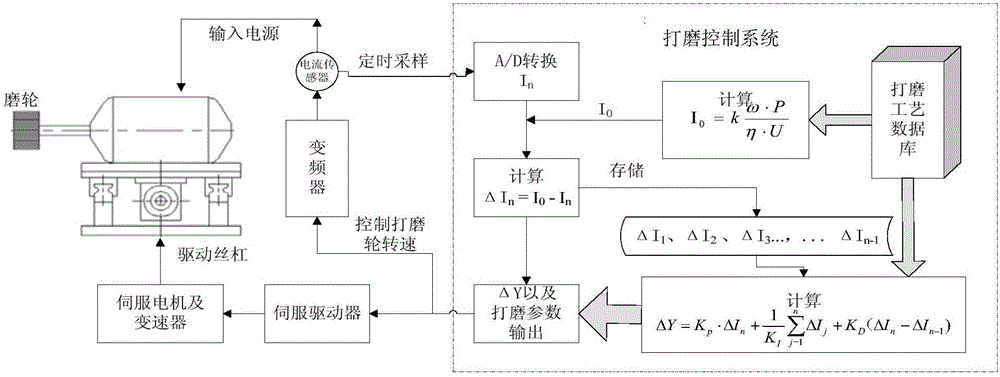

[0035] Such as figure 1 , figure 2 , image 3 As shown, a constant pressure grinding control device for metal rotary parts in this embodiment includes a grinding wheel 1, a grinding wheel driving motor 2, a workbench 3, a servo motor 7, a reducer 6 and a frequency converter; the grinding wheel 1 is driven by the grinding wheel driving motor 2 direct drive, the grinding wheel drive motor 2 is installed on the workbench 3, the worktable is installed on the two linear guide rails 4, and the nut of the screw nut transmission pair 5 is connected under the workbench 3, and the screw nut transmission pair The lead screw is driven by the servo motor 7 and the reducer 6, and the rotation of the servo motor is transmitted to the workbench through the lead screw nut pair; A current sensor is also installed, and the current sensor samples the working current of the grinding wheel driving motor at a set time period. The grinding control system is composed of a touch screen, a dedicated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com