Damage-free detection special pipeline automatic oxide skin polishing device and method thereof

A non-destructive testing and oxide skin technology, applied in the field of engineering applications, can solve the problems of pipeline wall damage and low efficiency, and achieve the effects of reducing labor intensity, ensuring grinding quality, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

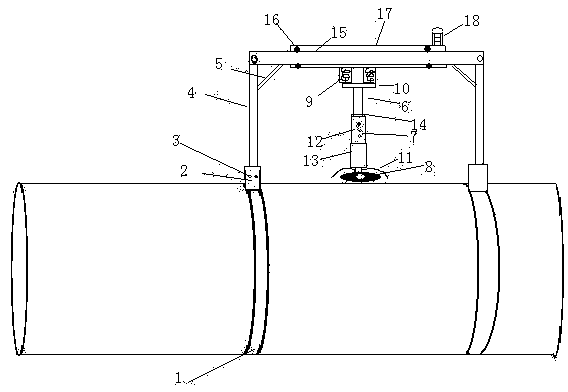

[0034] An automatic grinding device for non-destructive testing of pipeline oxide scales. The automatic grinding of pipeline scales for non-destructive testing is performed by a special grinding device designed for grinding, such as figure 1 , figure 2 As shown, the device includes an electromagnet rail holder, a ring rail, a spring loading device, a propulsion device, a frame, a sliding device, a motor, a regulator, a grinding device, and a controller.

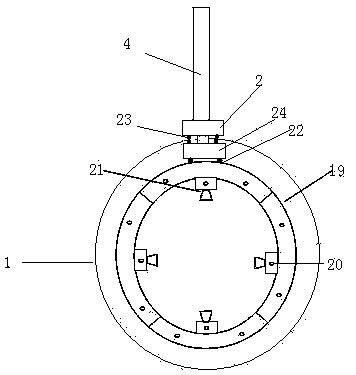

[0035] The electromagnet guide rail fixer is composed of 4 identical parts spliced together and connected by pins, and respectively includes a circular guide rail fixer, a size telescopic adjuster, and an electromagnet. The telescopic regulator can be telescopically adjusted according to different pipe diameters, and the electromagnet is energized to make the magnet and the pipe wall adsorb and fix.

[0036] The circular guide rail is composed of two identical parts spliced together and connected by pins, and is compose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com