Automatic grinding device

A technology of equipment and grinding mechanism, applied in grinding/polishing equipment, metal processing equipment, grinding machine, etc., can solve the problems of inconvenient adjustment of grinding machine, poor grinding effect, easy to wear through materials, etc., to achieve simple structure and improve grinding Quality, ensure the effect of grinding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

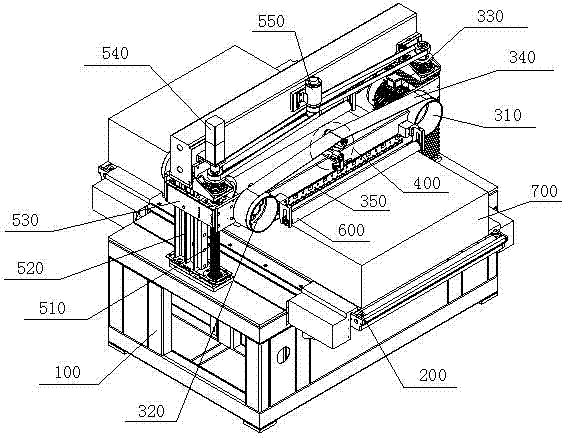

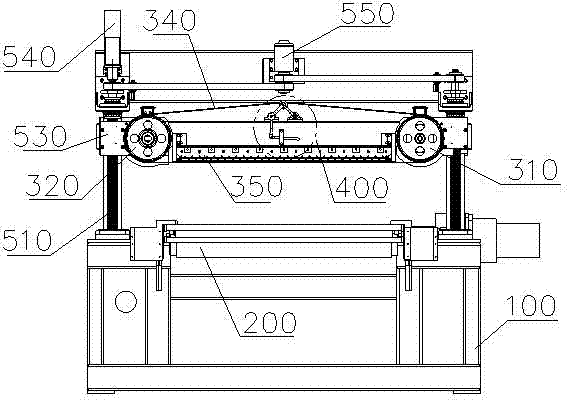

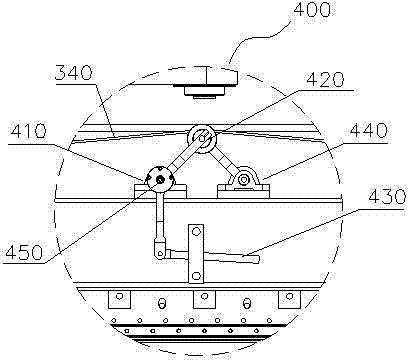

[0020] The invention discloses an automatic grinding equipment, such as figure 1 and figure 2 As shown, it includes a workbench 100, a conveyor belt 200 arranged on the workbench 100, and at least one grinding mechanism arranged above the conveyor belt 200. The grinding mechanism includes driving wheels 310 and driven wheels respectively arranged on both sides of the conveyor belt 200. 320, the grinding motor 330 that is connected with the driving wheel 310 and provides power for the driving wheel 310 and the abrasive belt 340 wound on the surface of the driving wheel 310 and the driven wheel 320; the abrasive belt 340 is wound to connect the driving wheel 310 and the driven wheel 320, Form a grinding plane; in actual use, the axis cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com