Method for adjusting spindle axis of hydraulic turbine generator set

A hydro-generator, spindle axis technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of grinding direction grinding area and the difficulty of determining the grinding amount of each area, so as to ensure the grinding quality and axis Adjustable and easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

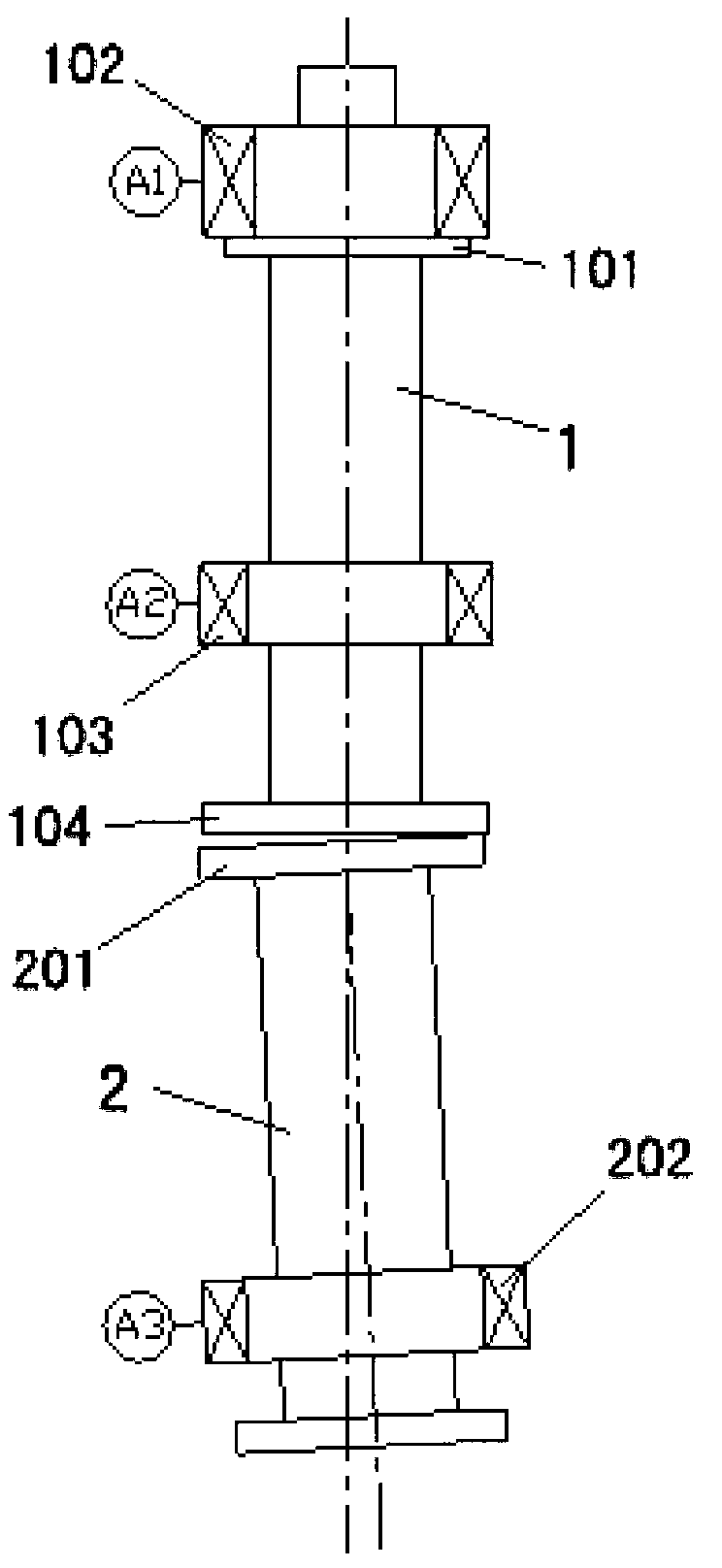

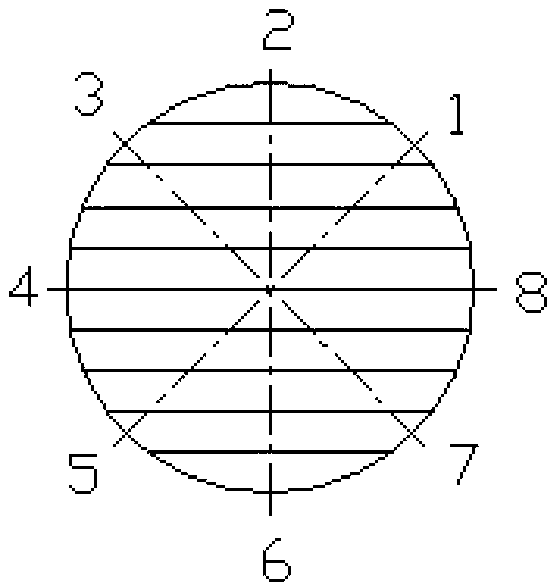

[0042] figure 1 is the structural schematic diagram of the main shaft of the hydro-generator unit, figure 2 It is a schematic diagram of the cranking point and flange surface division of the main shaft axis adjustment method of the hydro-generator set according to the present invention. In the figure, 1 is the shaft of the generator, 2 is the shaft of the water turbine, 101 is the shaft shoulder of the generator, and 102 is the upper guide bearing, 103 is the lower guide bearing, 104 is the generator shaft flange, 201 is the water turbine shaft flange, 202 is the water guide bearing, and A1, A2 and A3 are dial gauges. As can be seen from the figure, the method for adjusting the main shaft axis of the hydro-generator unit according to the present invention includes the following steps:

[0043] S1: Adjust the lead verticality of the generator shaft

[0044] S11: Set up a horizontal datum under the shoulder of the generator shaft;

[0045] S12: Set the mirror plate, push sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com