Grinding device for inner wall and outer wall of pipe opening of steel pipe

A technology of inner and outer walls and steel pipes, which is applied to grinding drive devices, grinding/polishing safety devices, grinding machines, etc. The effect of avoiding the impact phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

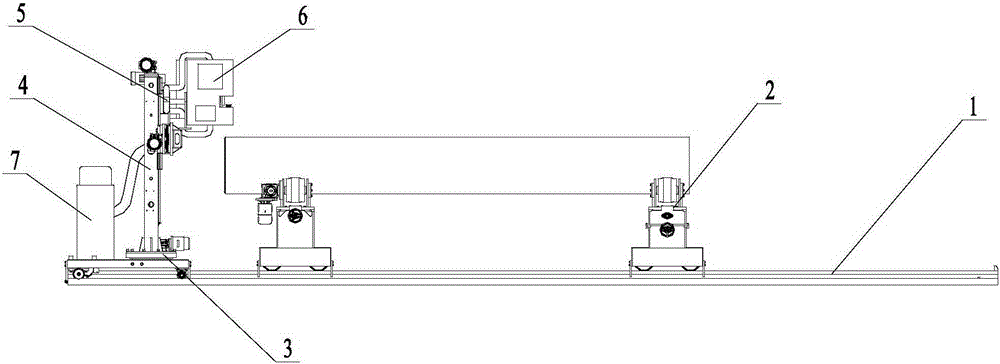

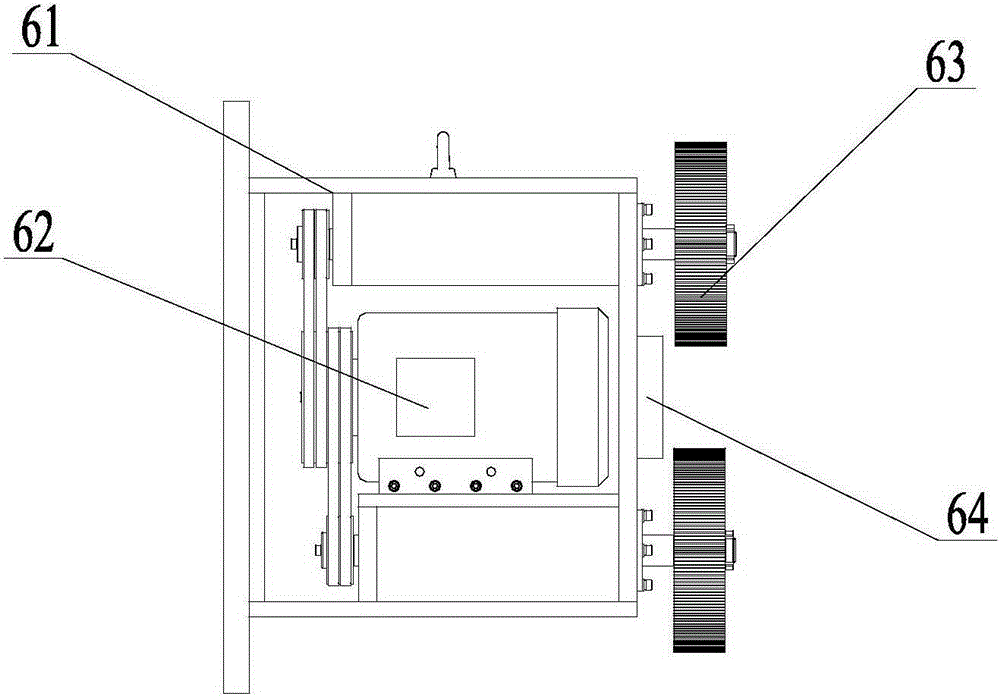

[0021] This embodiment provides a grinding device for inner and outer walls of a steel pipe nozzle, including a base 1 , a steel pipe support 2 , a mobile platform 3 , a rotary lifting assembly 4 , a rotating assembly 5 and a grinding assembly 6 . Among them, the steel pipe support 2 is fixed on the base 1 for supporting and rotating the steel pipe; the mobile platform 3 moves back and forth along the axial direction of the steel pipe placed on the steel pipe support 2; the rotating assembly 5 and the grinding assembly 6 are fixed by the rotary lifting assembly 4 On the mobile platform 3, the rotary lifting assembly 4 includes two parts: a rotary mechanism and a lifting mechanism. The rotary mechanism includes a rotary arm and a rotary motor. One end of the rotary arm is connected to the grinding assembly 6, and the other end is connected to the lifting structure; the lifting mechanism includes The fixed seat, the lifting motor and the screw mandrel are fixed on the mobile plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com