Diamond surface chemical mechanical combined machining method and device thereof

A surface chemical and diamond technology, applied in the field of mechanical processing, can solve the problems of low processing quality, complicated polishing technology equipment, low efficiency, etc., to achieve the effect of ensuring the grinding quality, improving the efficiency of grinding and polishing, and improving the efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] specific implementation plan

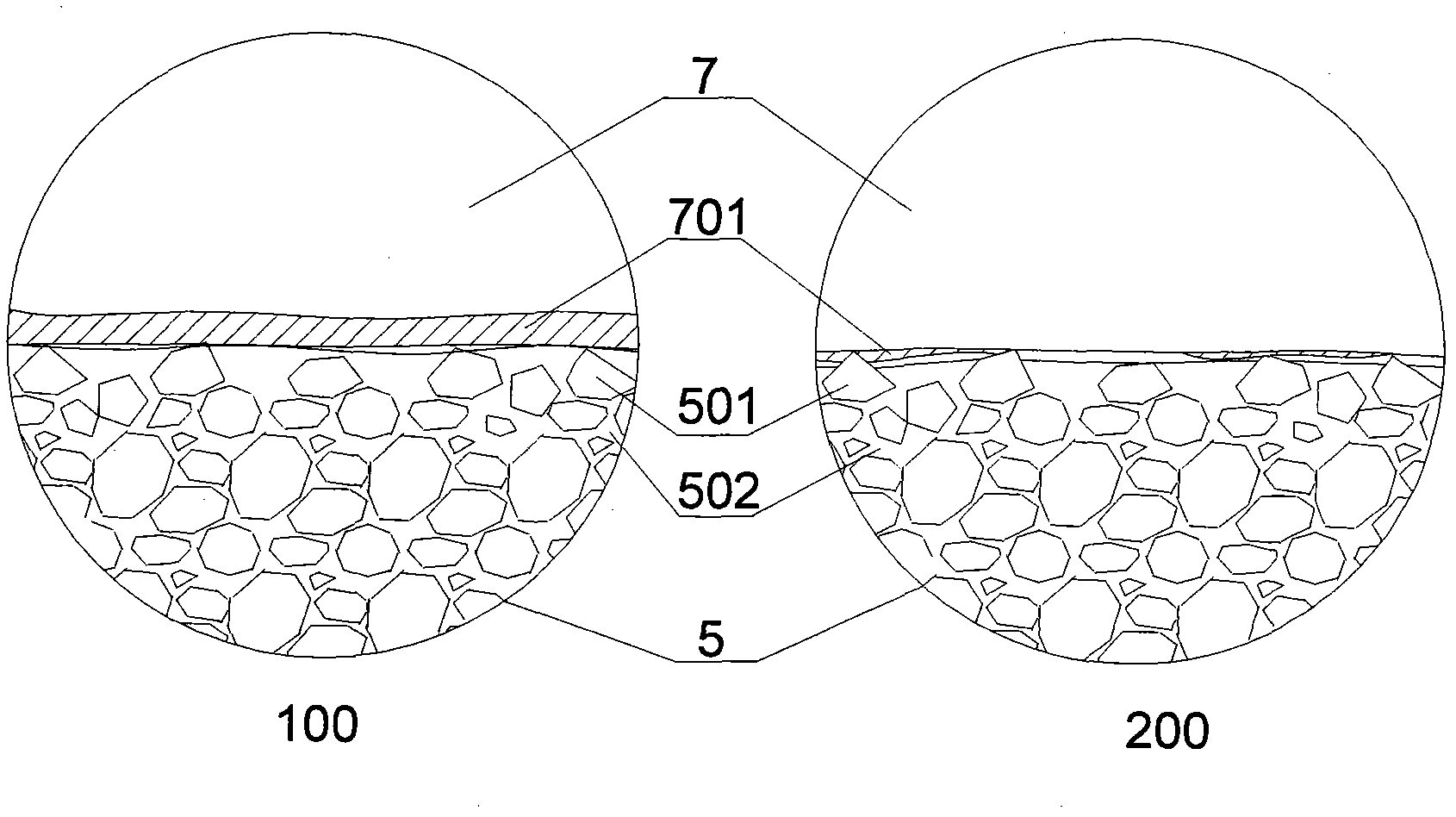

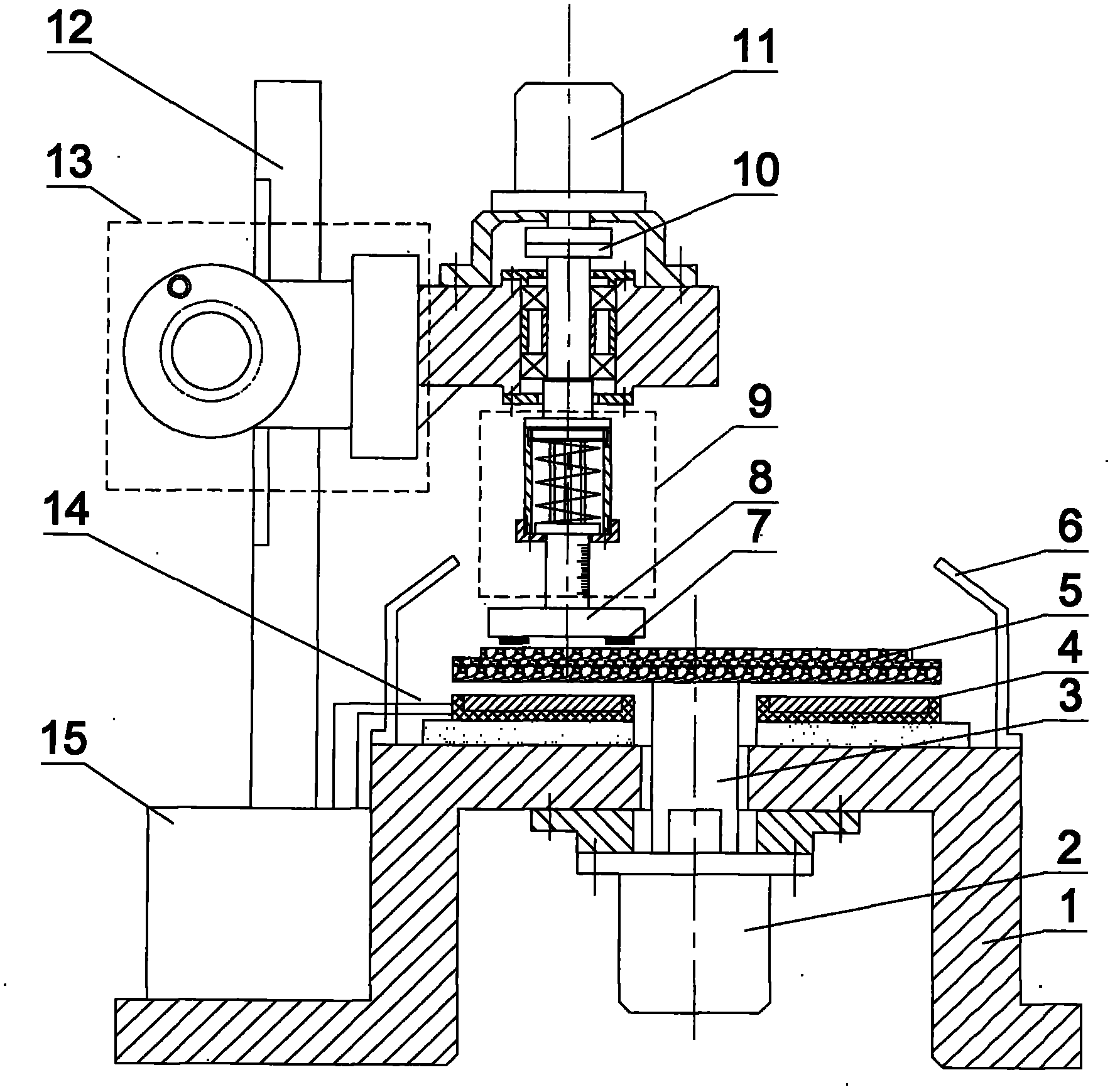

[0024] The invention relates to a chemical-mechanical composite grinding and polishing method for diamond surfaces, which is especially suitable for grinding and polishing the surface of single crystal diamond, PCD (polycrystalline diamond) composite sheet, and CVD diamond film. It is characterized in that composite materials are used as grinding, The polished tool grinding disc is heated to an appropriate temperature and then rotated at a high speed; the diamond film / block to be processed is pressed against the surface of the grinding disc with a certain pressure to cause high-speed friction with the grinding disc surface, and the chemical-mechanical Composite cycle effect realizes high-efficiency grinding and polishing of diamond surface.

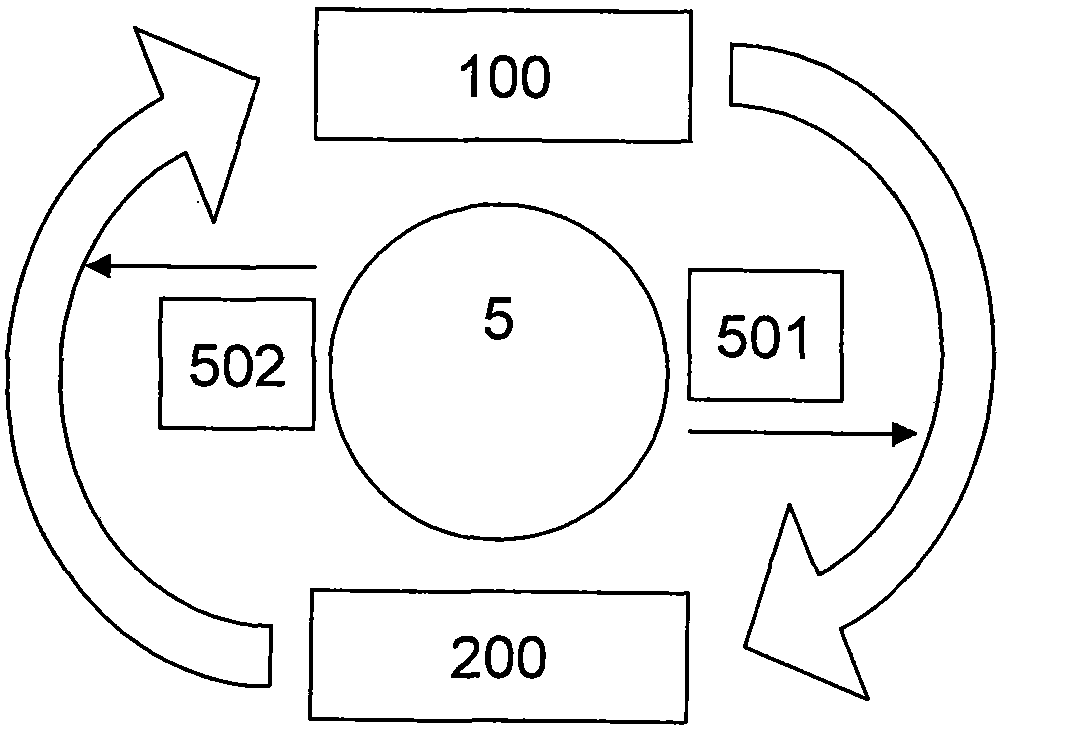

[0025] The chemical-mechanical composite cycle action refers to: the grinding and polishing process includes the soft phase (copper) catalyzed diamond surface graphitization process (100) and the hard...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com