High modulus graphite fiber and its manufacturing method

A technology of graphite fiber and manufacturing method, applied in the field of high modulus graphite fiber and its manufacturing, can solve the problems of difficult to quantify the production of large bundles of fibers, failing to achieve high modulus, and increasing the difficulty of the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

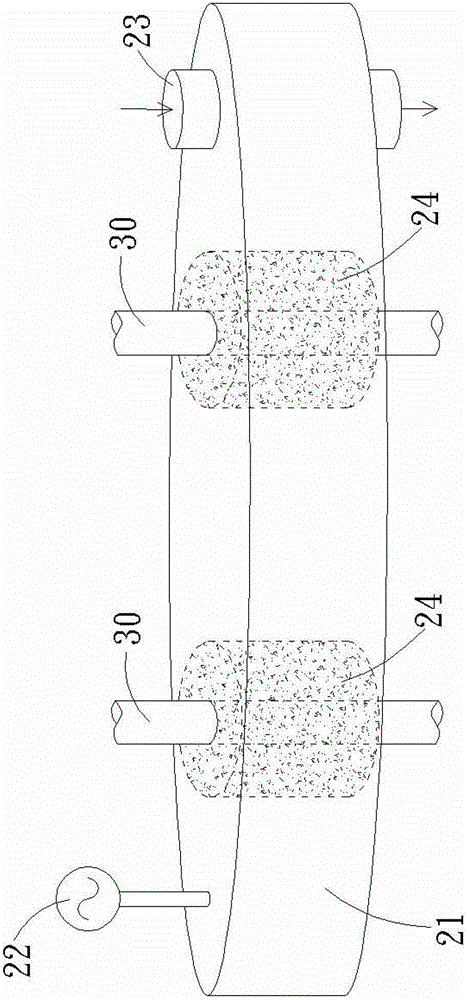

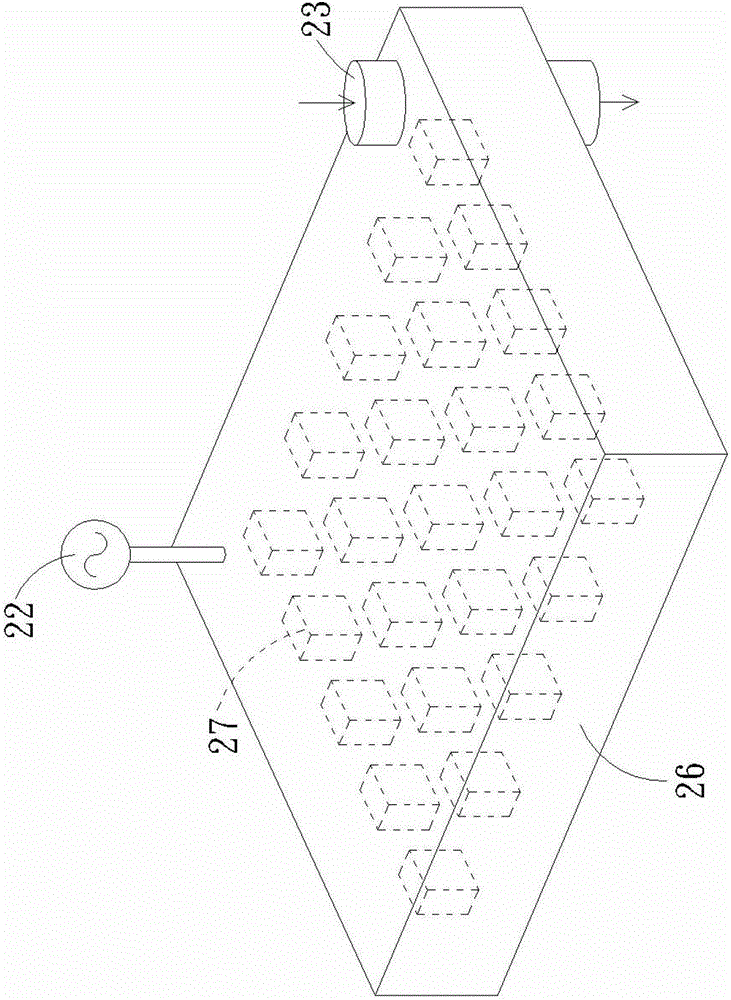

Method used

Image

Examples

Embodiment 1

[0061] Example 1: Using microwave focus to heat graphitize Toray’s T700 carbon fiber with a power of 10KW and graphitization time of 1 minute; Example 2: Using microwave focus to heat graphitize Toray’s T700 carbon fiber with a power of 20KW, graphite The heating time is 1 minute; the third embodiment uses microwave focusing to heat graphitize the M40 carbon fiber of Toray Japan, the power is 20KW, and the graphitization time is 1 minute; the fourth embodiment uses the microwave focus heating to graphitize the M40 carbon fiber of Toray Japan , The power is 30KW, the graphitization time is 1 minute; the comparative examples one to six are T700 carbon fiber, T7800 carbon fiber, T1000 carbon fiber, M40 carbon fiber, M50 carbon fiber and M60 carbon fiber of Toray.

[0062] The mechanical property test results (using ASTM D4018-99 standard, the number of samples × 30 take the average value) are shown in Table 2 below.

[0063]

Tensile strength / GPa

Tensile modulus / GPa

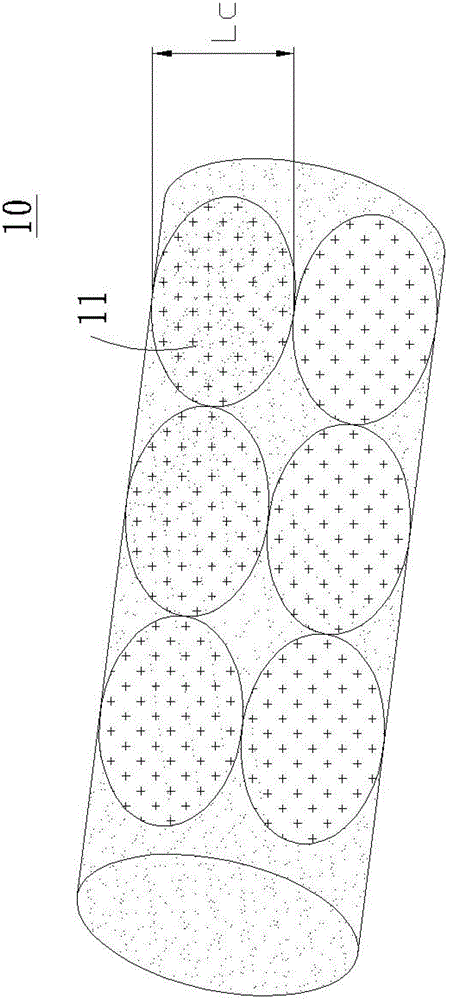

Lc / Angstrom

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com