Superhigh temperature graphitization furnace

A high-temperature graphitization and graphitization furnace technology, which is applied in the direction of inorganic chemistry, carbon compounds, chemical instruments and methods, etc., can solve the problems of time and energy consumption, large range of heating and cooling of ultra-high temperature furnaces, low efficiency, etc., and achieve improvement Efficiency and product quality, continuous and efficient process flow, and strong adaptability to product specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

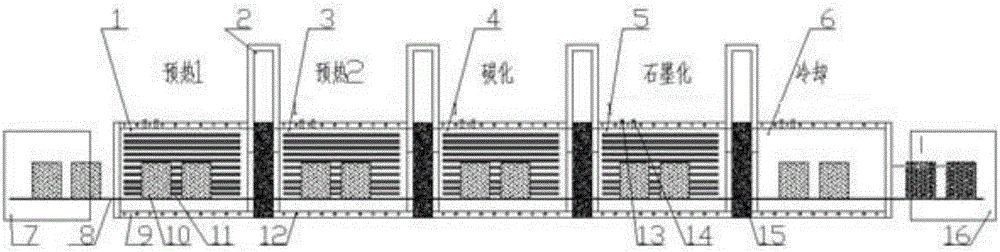

[0019] The core of the present invention is to provide an ultra-high temperature graphitization equipment in combination with the graphitization process, and the ultra-high temperature graphitization process of the ultra-high temperature graphitization equipment is relatively continuous and efficient.

[0020] In order to enable those skilled in the art to better understand the solutions of the present invention, specific implementations will be further described in detail below in conjunction with the accompanying drawings.

[0021] The graphitized sample 10 of the present invention is fed by the feeding system 7, and reaches the primary preheating furnace 1 through the material passage 8 of the feeding track. The heating rod 11 is arranged in the furnace, and the primary preheating furnace 1 is closed. Heating in the primary preheating furnace 1 from room temperature to 1200°C, and then opening the heat preservation and sealing system 2; entering the secondary preheating furn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com