Double-side double-station force control belt sander and polishing work station thereof

A technology of double station and belt machine, applied in the field of belt machine, can solve the problems of high belt replacement frequency, difficulty in belt replacement, and high energy consumption of driving motor, so as to reduce labor intensity and work risk, and quickly The effect of convenient replacement of abrasive belts and improved market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

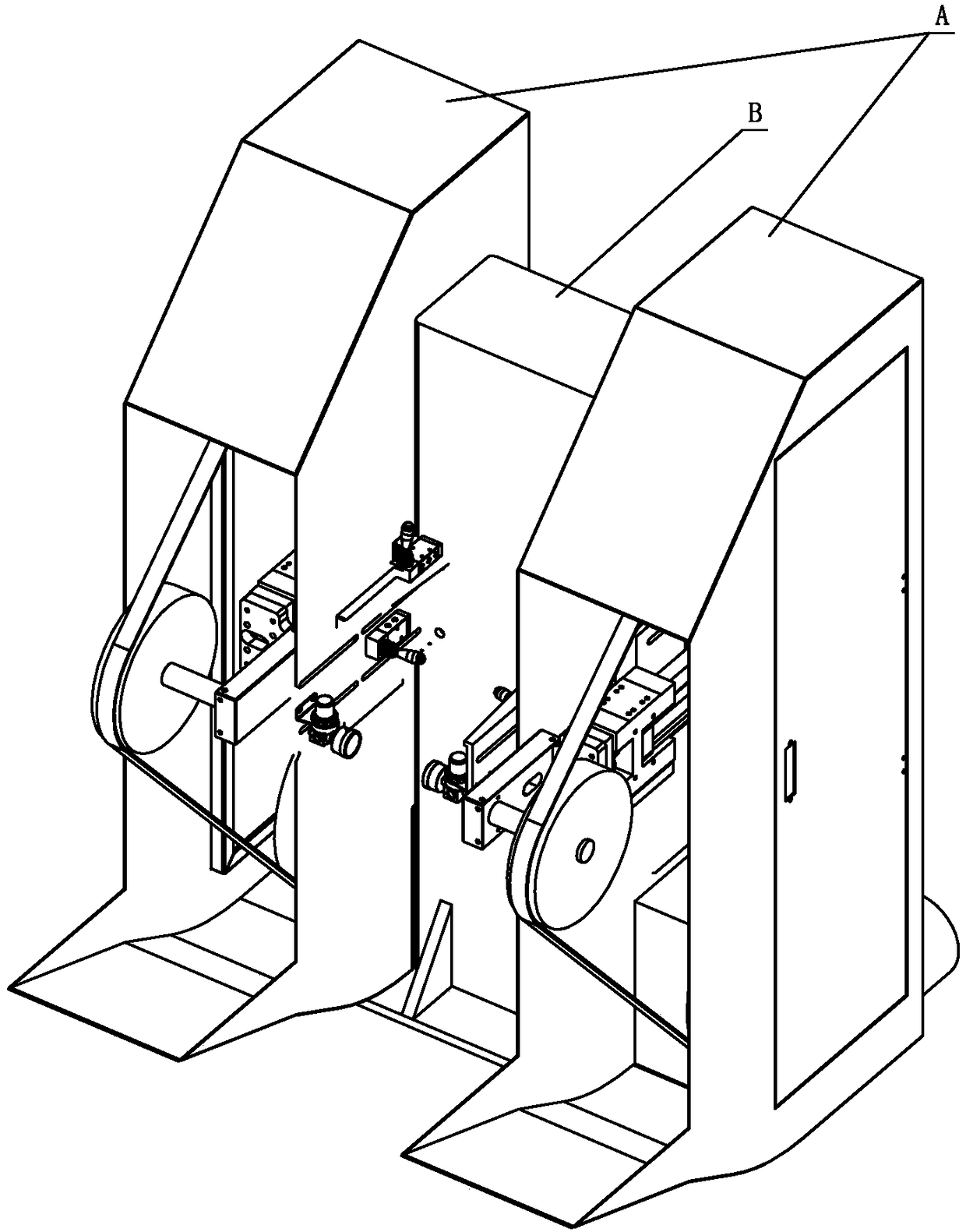

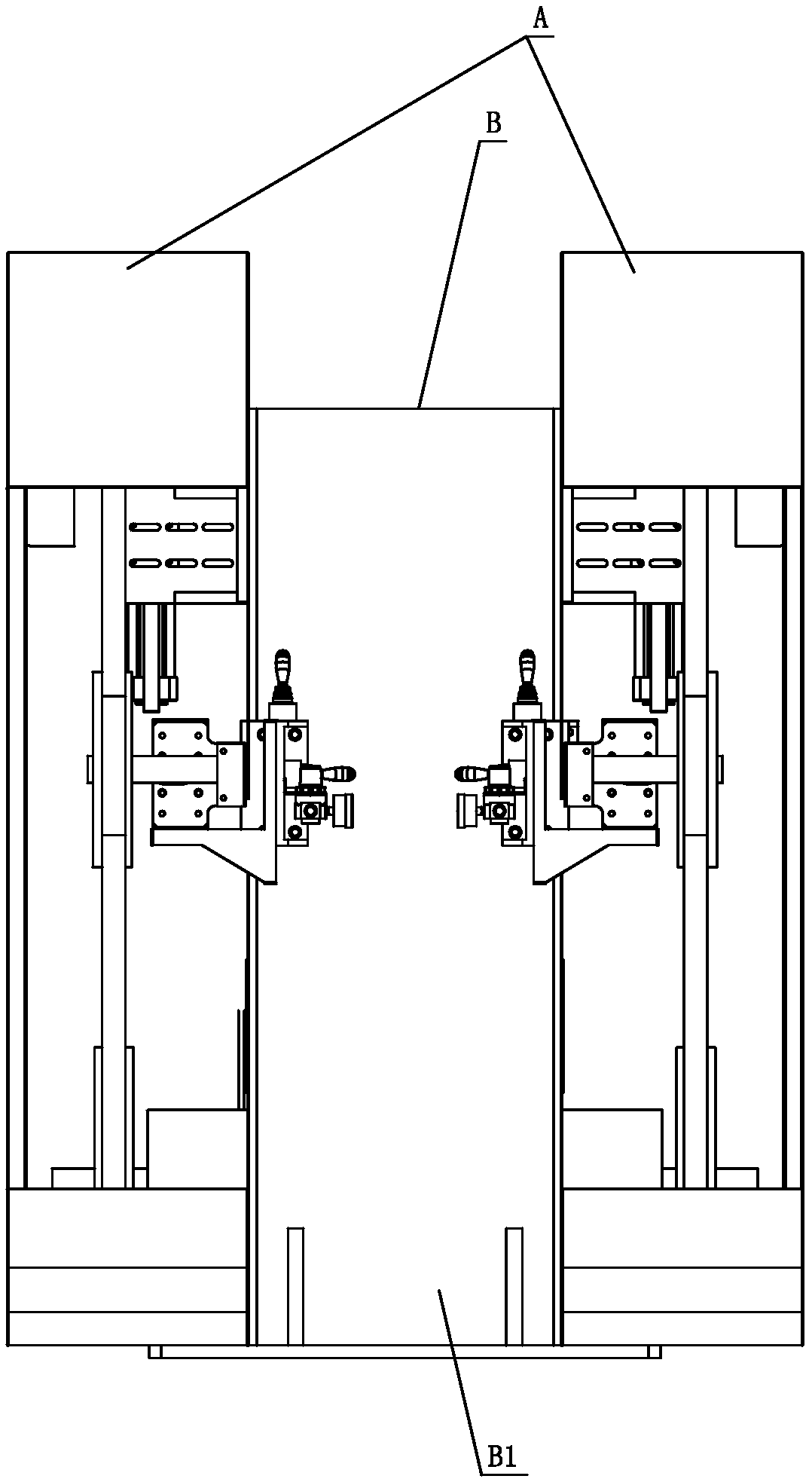

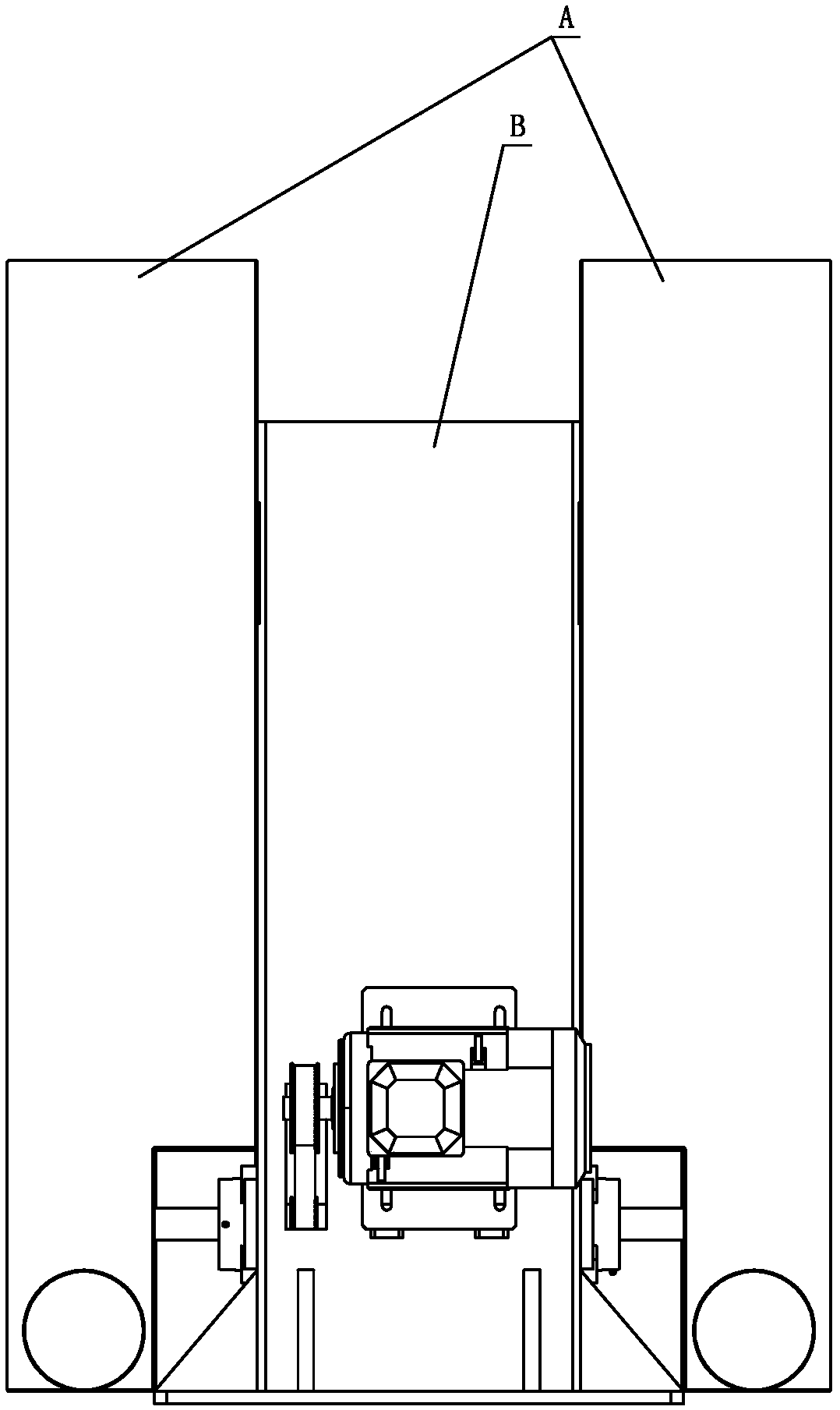

[0036] see Figure 1-Figure 7 , this bilateral double-station force-controlled belt machine includes a single-station grinding cabinet A and a power output cabinet B, in which two sets of single-station grinding cabinet A are arranged symmetrically on the left and right, and the power output cabinet B is set in two sets of simplex A bit between sanding cabinets. The single-station grinding cabinet A includes a grinding system composed of a grinding driving wheel 6, a grinding wheel 8, a grinding driven wheel 9, and a grinding belt 7. The grinding belt 7 is wound around the grinding driving wheel 6, the grinding wheel 8 and the grinding driven wheel 9, so that they are connected in transmission, and the grinding wheel 8 at least partially exposes the grinding cabinet body A1 on the single-station grinding cabinet A, so that the products Implement the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com