Patents

Literature

156results about How to "Grinding stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

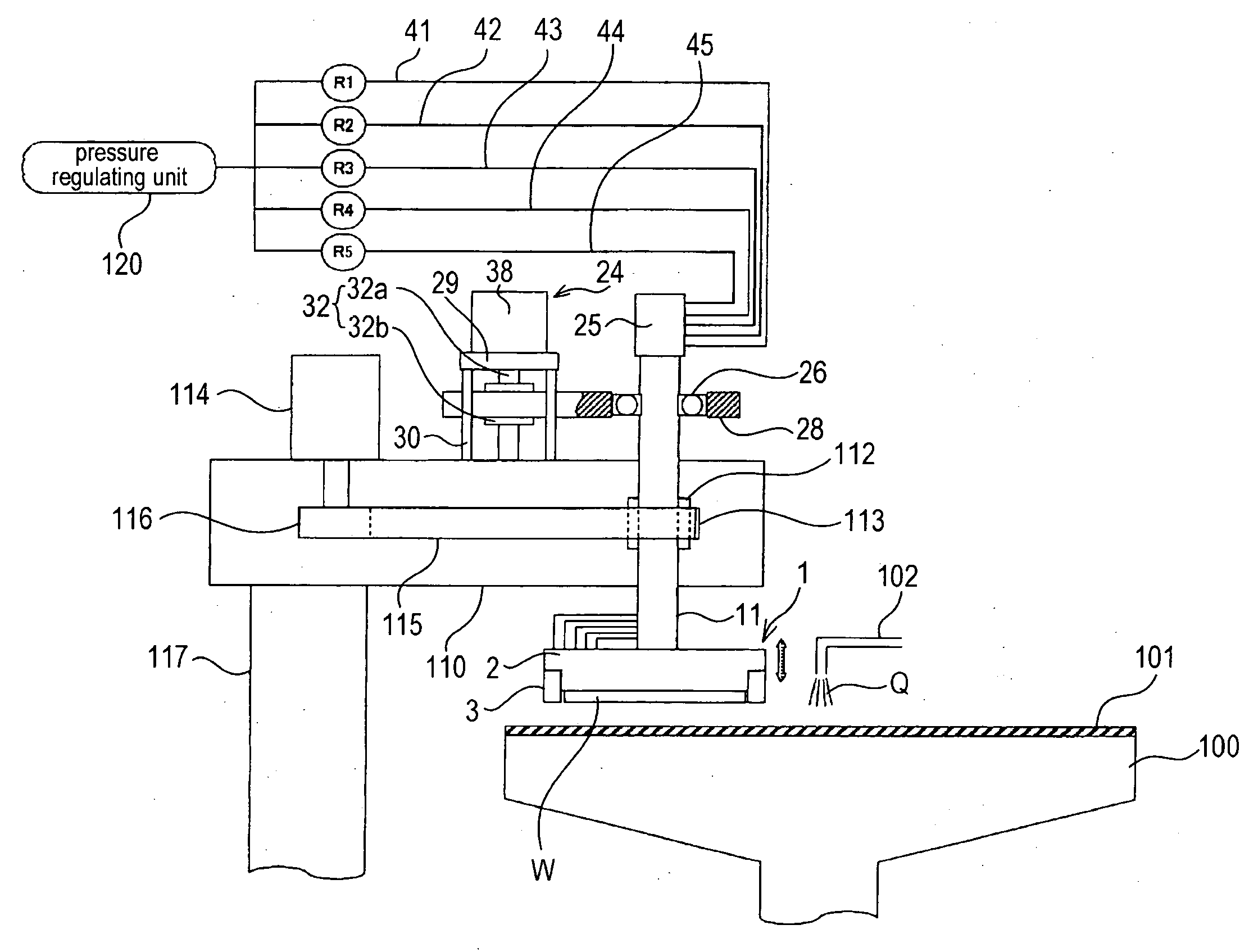

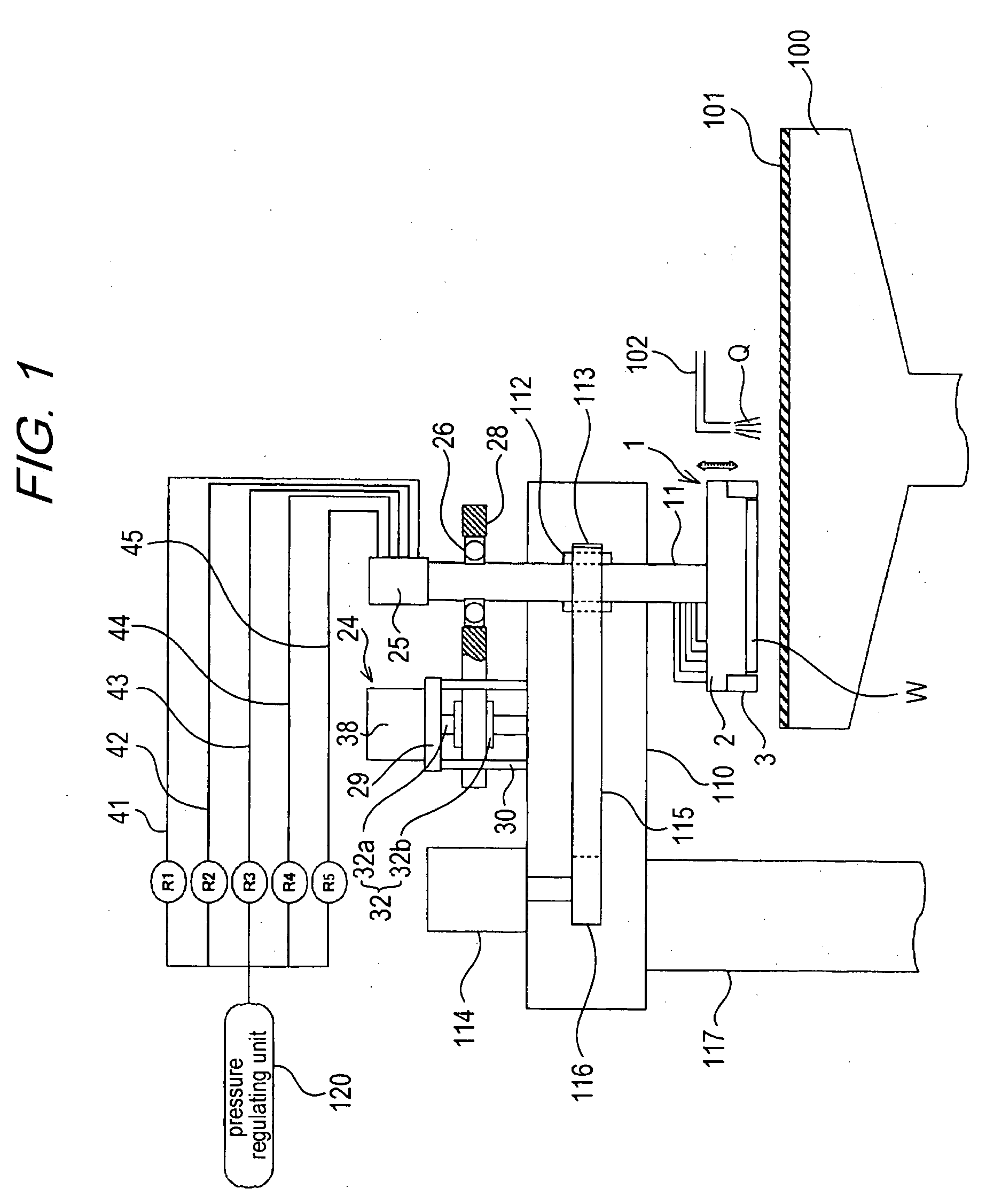

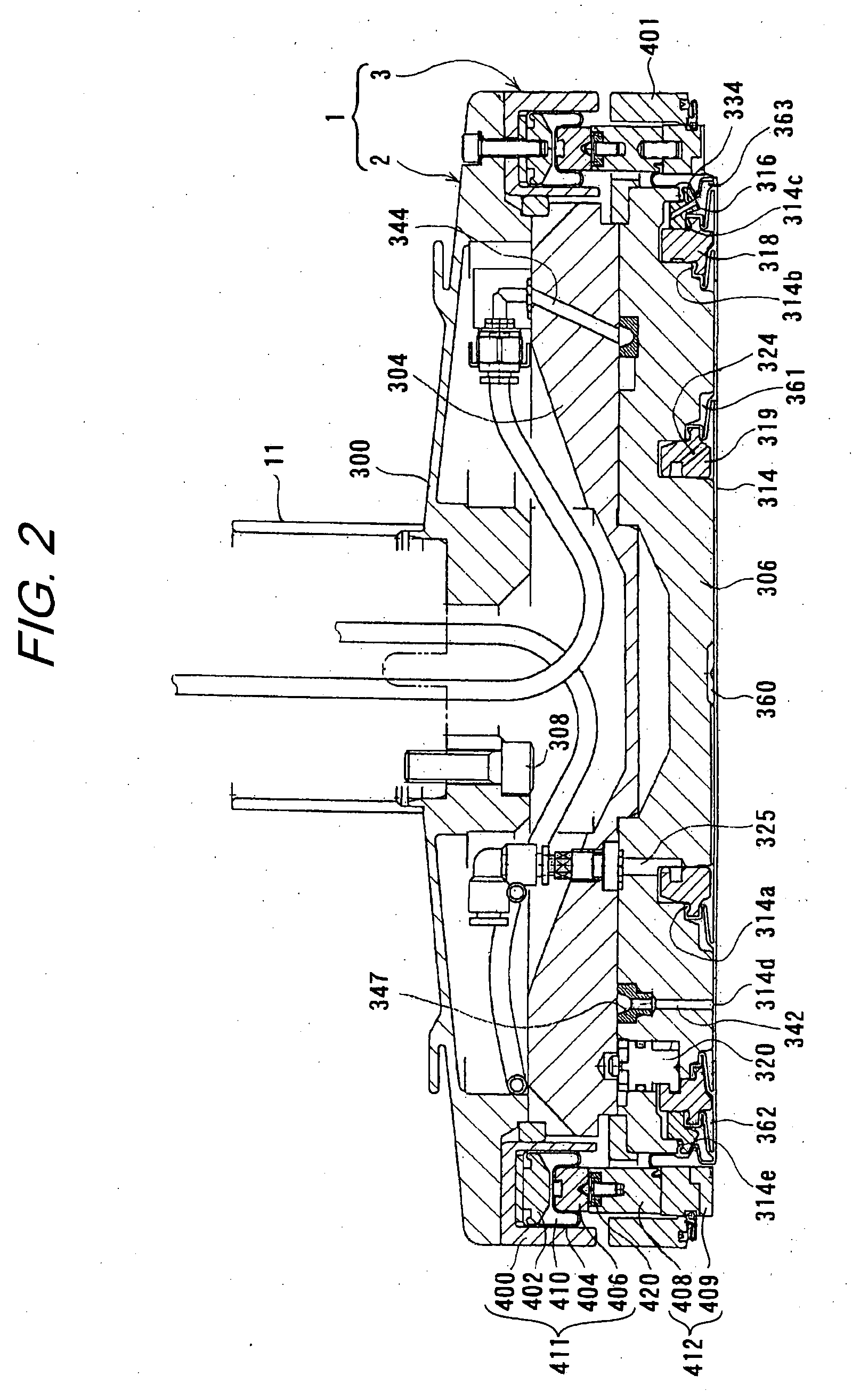

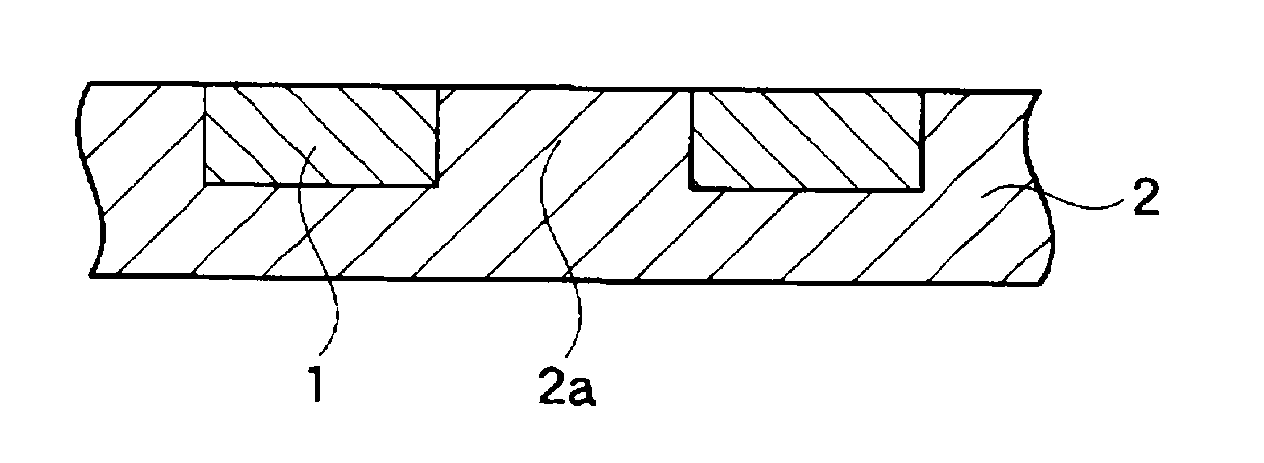

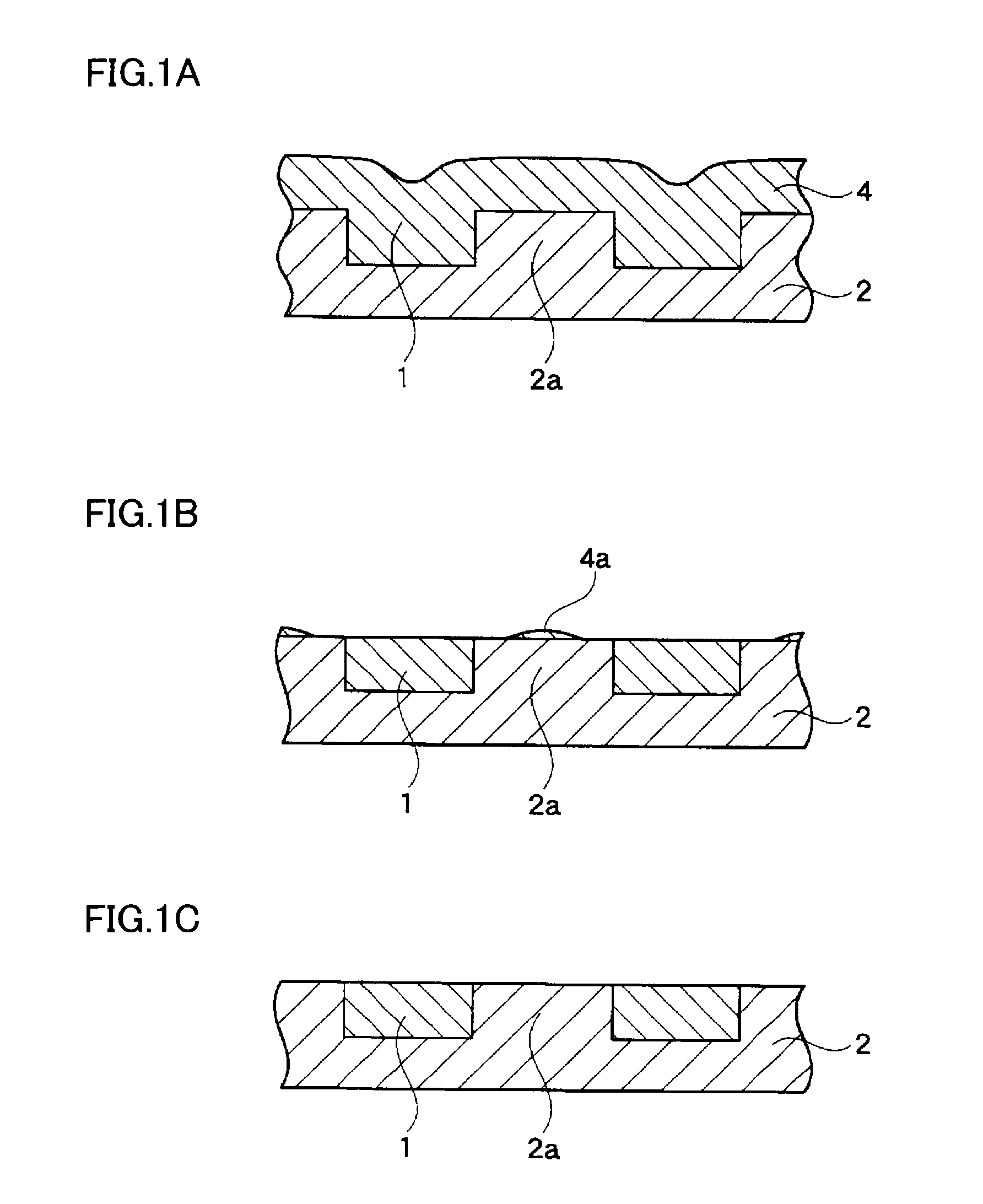

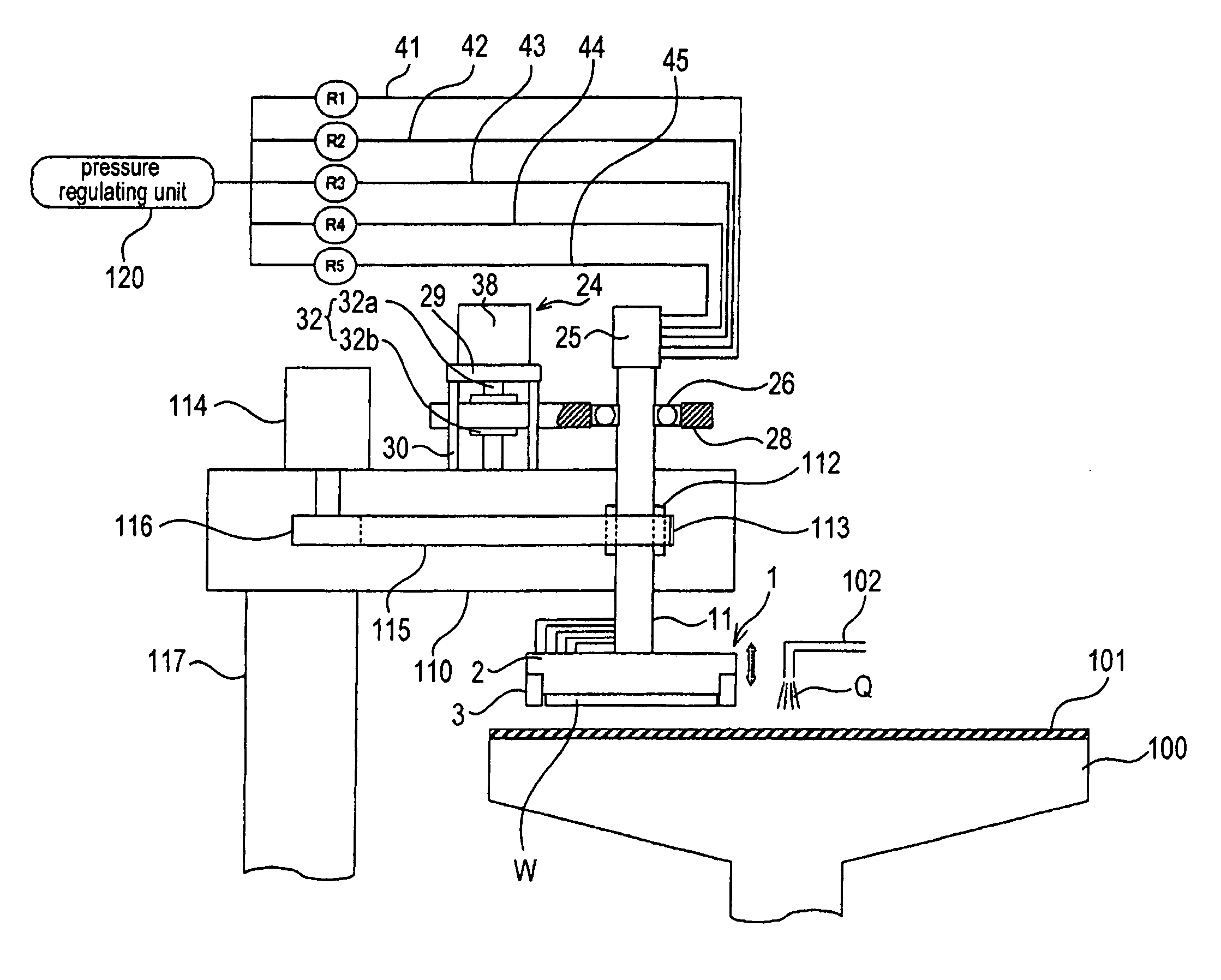

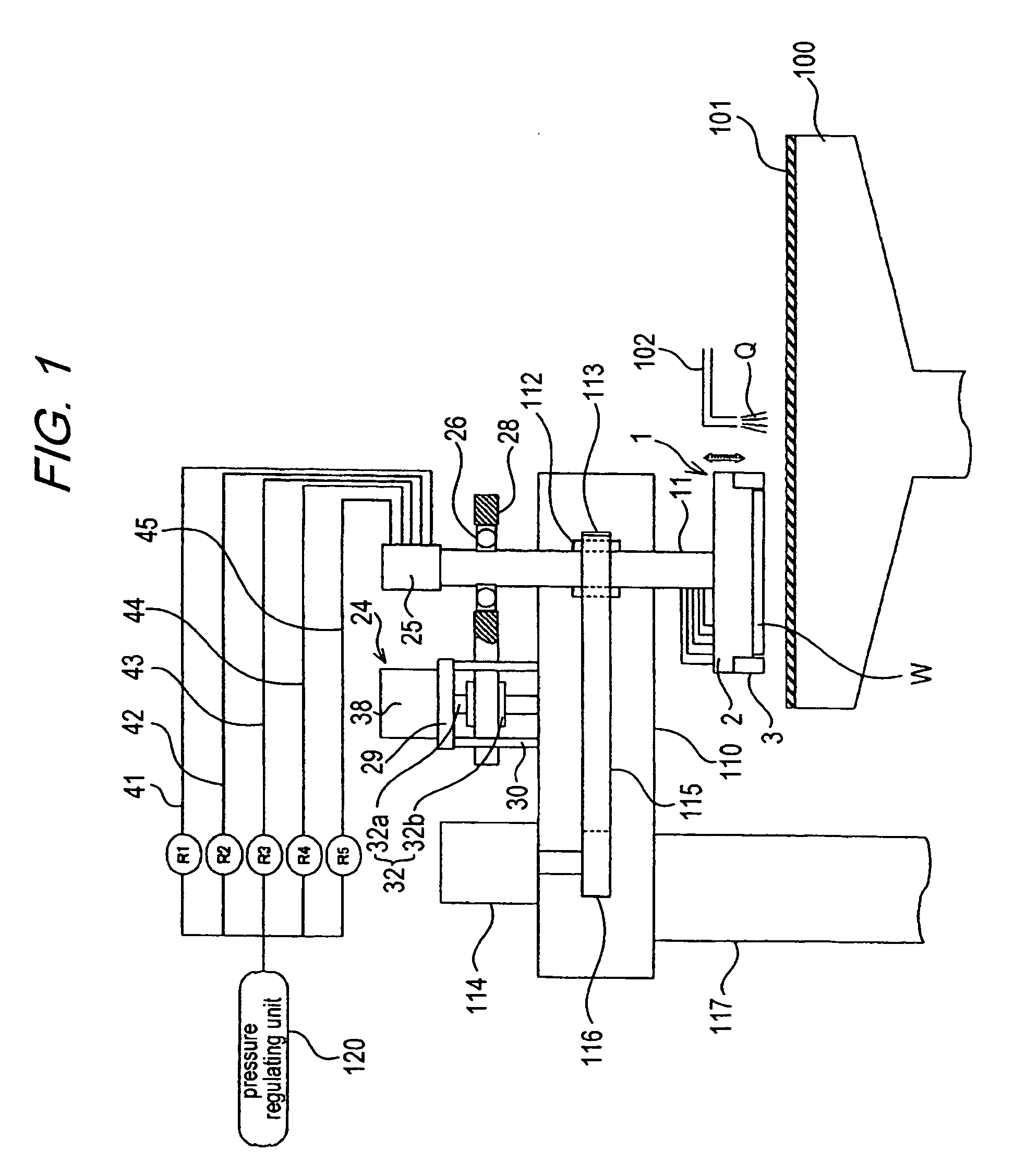

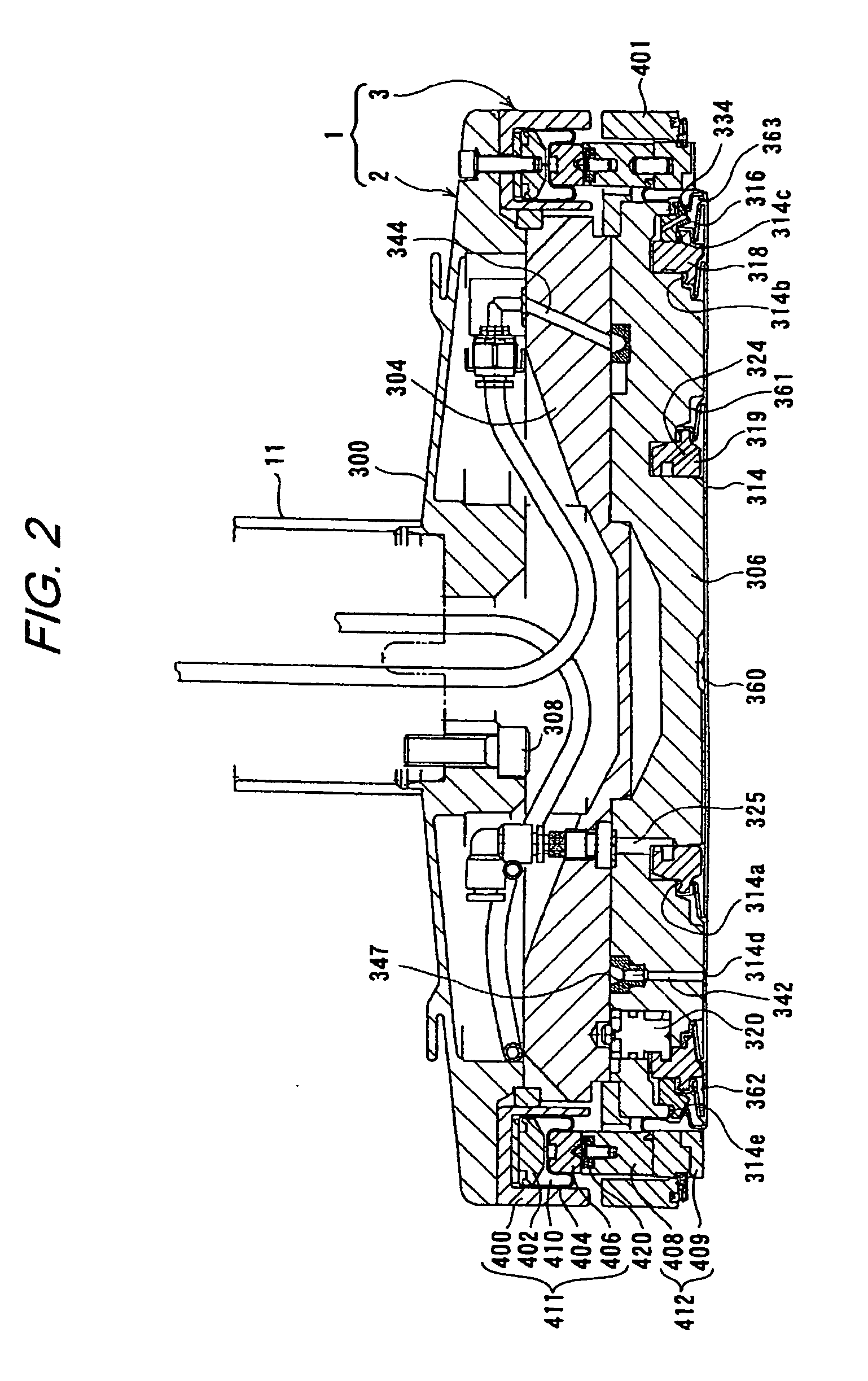

Substrate holding apparatus, polishing apparatus, and polishing method

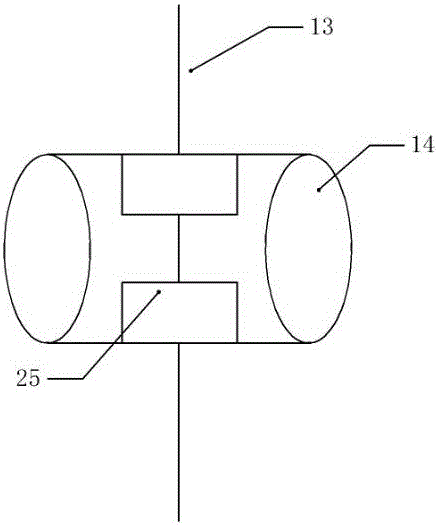

ActiveUS20070232193A1Substrate to be polished stablyEffective preventionPolishing machinesRevolution surface grinding machinesEngineeringMagnet

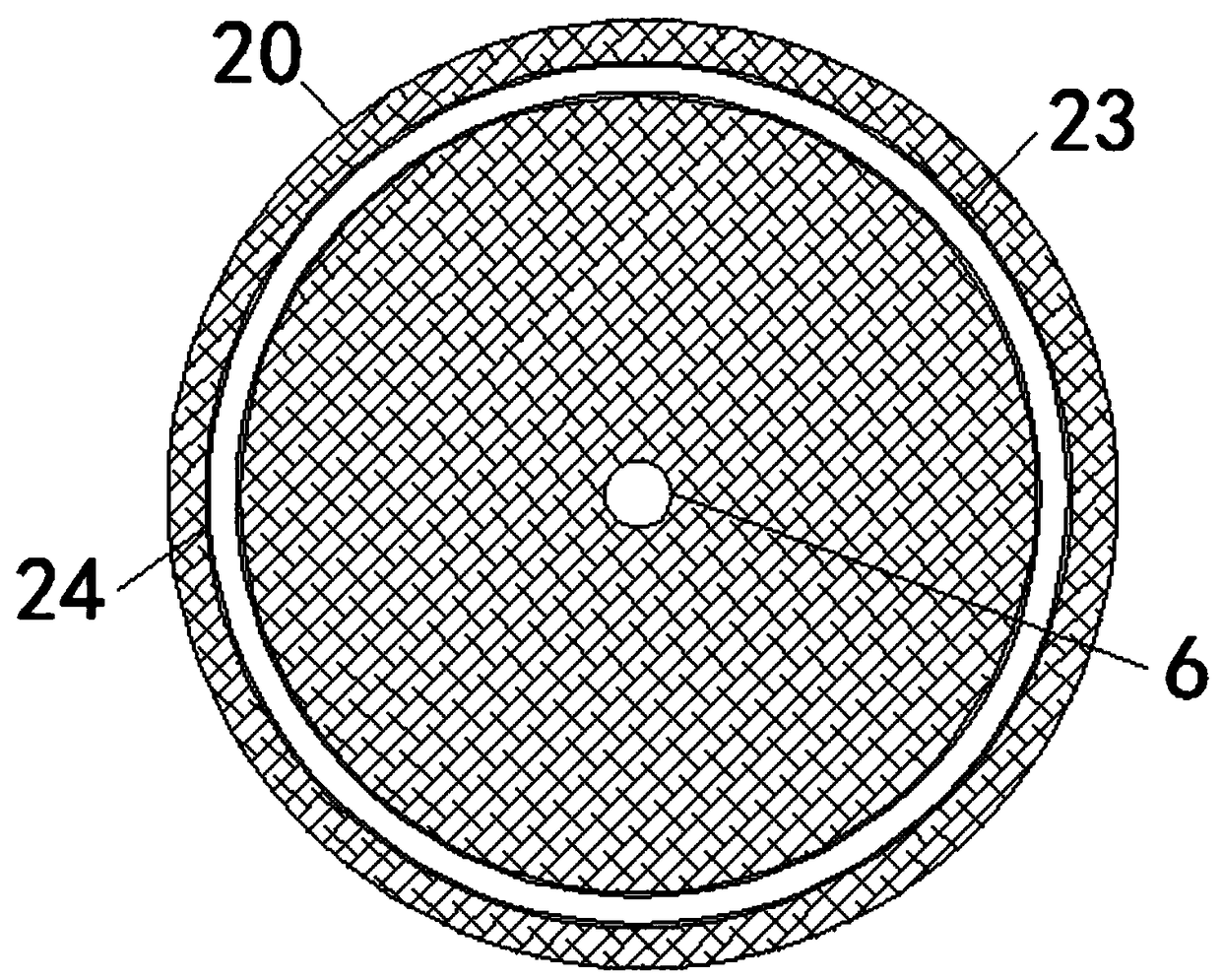

A substrate holding apparatus prevents a substrate from slipping out and allows the substrate to be polished stably. The substrate holding apparatus has a top ring body for holding and pressing a substrate against a polishing surface, and a retainer ring for pressing the polishing surface, the retainer ring being disposed on an outer circumferential portion of the top ring body. The retainer ring comprises a first member made of a magnetic material and a second member having a magnet disposed on a surface thereof which is held in abutment against the first member.

Owner:EBARA CORP

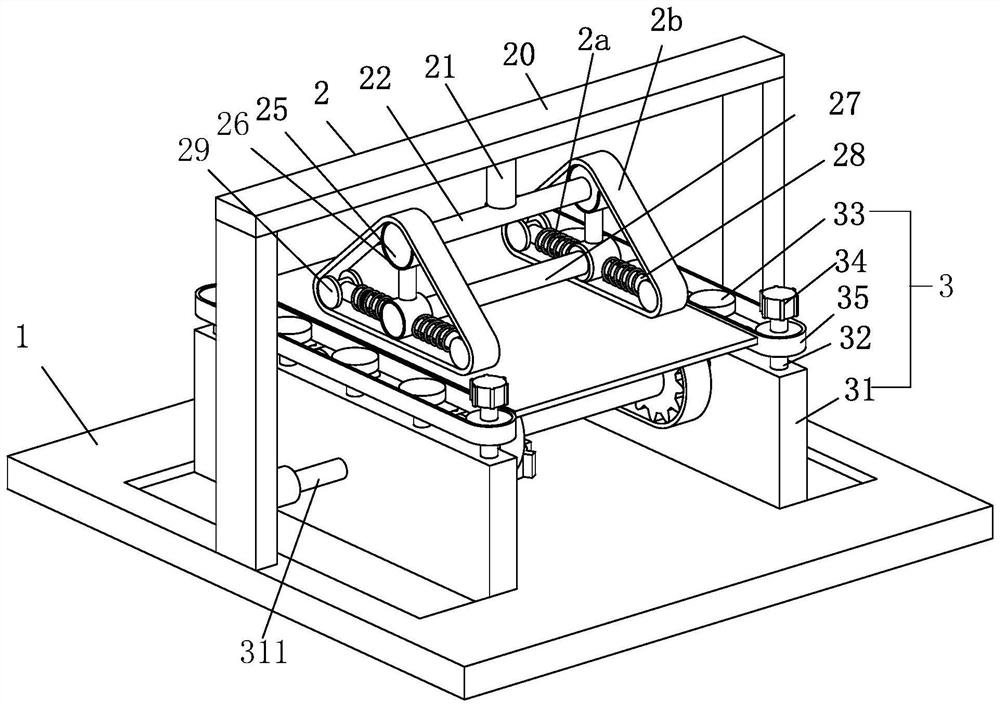

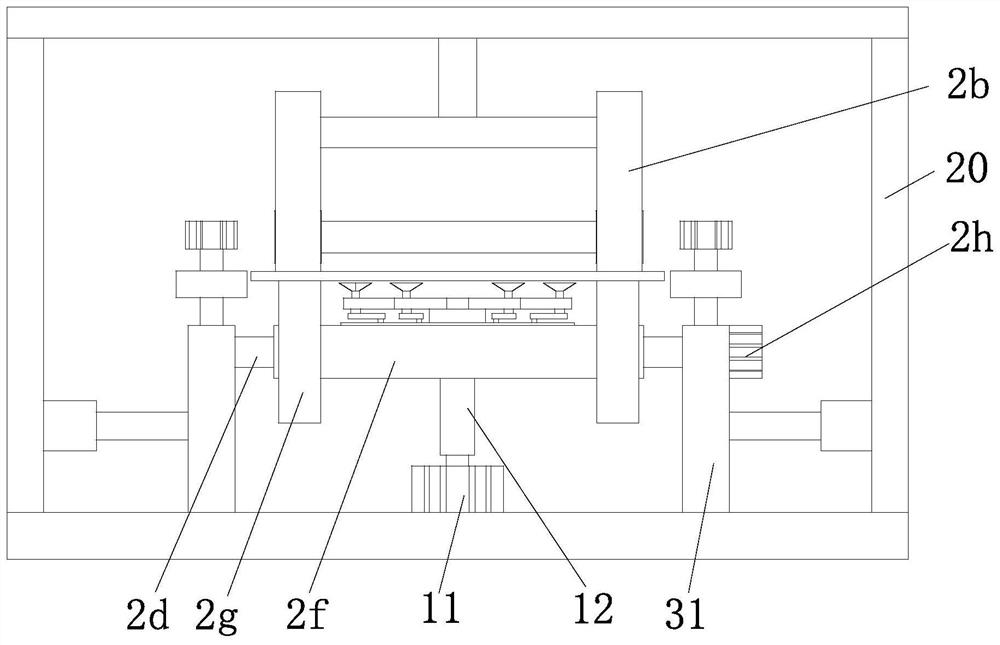

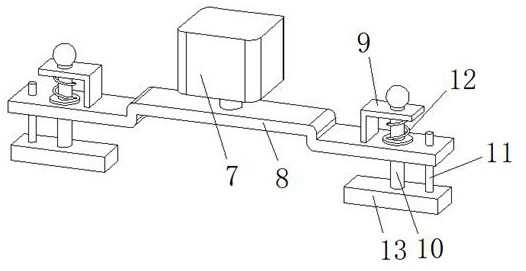

Mechanical plate grinding device with overturning function

InactiveCN111300185ARealize clamping and fixingRealize the grinding effectGrinding drivesGrinding feedersEngineeringMachining

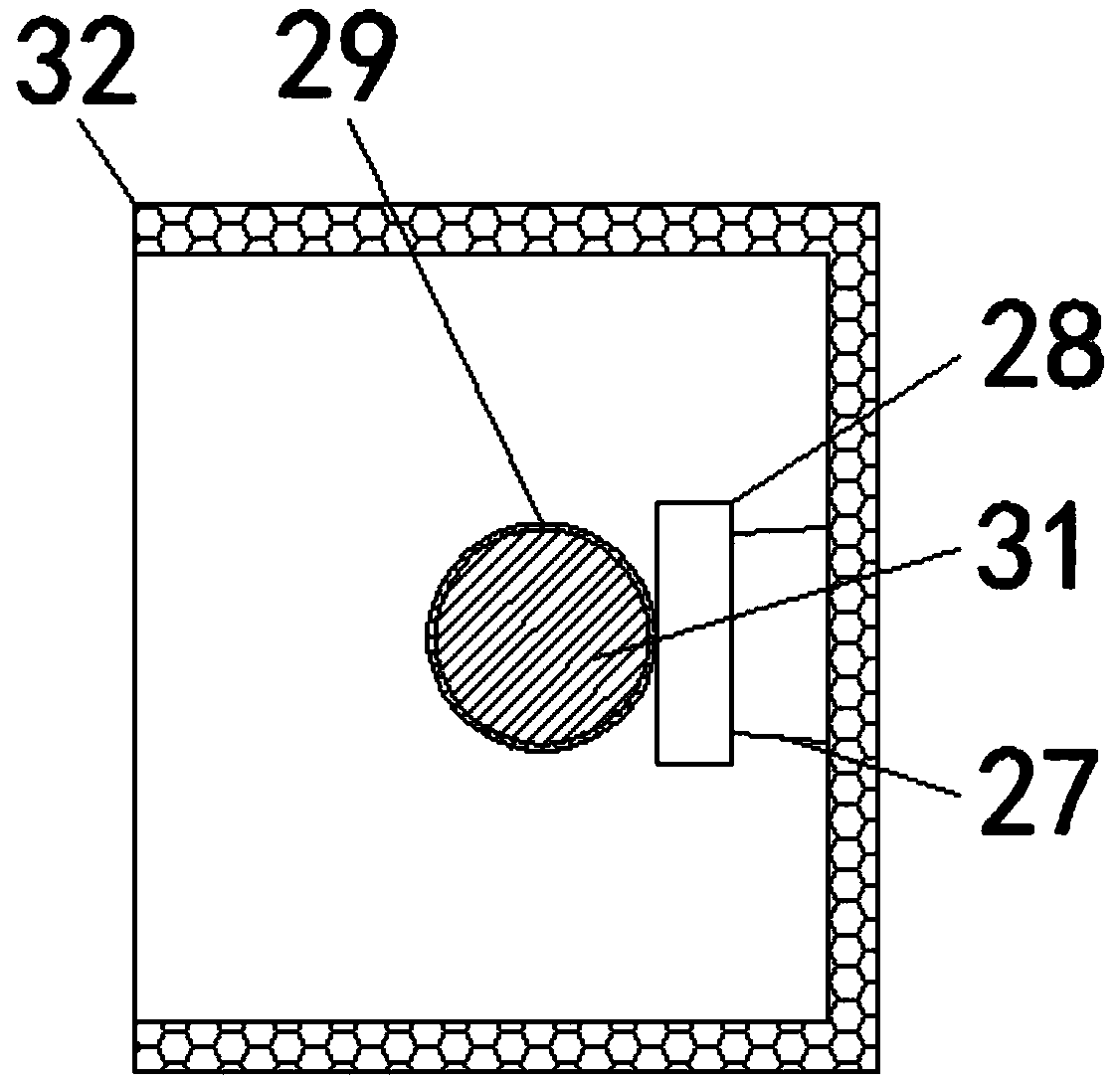

The invention discloses a mechanical plate grinding device with an overturning function, and relates to the technical field of machining. The mechanical plate grinding device comprises a supporting frame, wherein an electric push rod is vertically fixed at the inner top of the supporting frame; a translation mechanism for driving a grinding mechanism to move transversely is arranged in a steeringbox; an adjusting mechanism for driving two clamping plates to move oppositely is arranged on the supporting frame; and the supporting frame is provided with an overturning mechanism used for drivingthe clamping plates to rotate. According to the mechanical plate grinding device with the overturning function, the two clamping plates are driven by the arranged adjusting mechanism to move oppositely to clamp and fix a plate, so that stability of the plate in the grinding process is guaranteed, and a grinding effect is guaranteed; a grinding plate in the arranged grinding mechanism rotates to achieve grinding effects on the surface of the plate, and the translation mechanism can drive the grinding plate to transversely move relative to the plate, so that the grinding range of the plate is greatly widened, and the working efficiency is improved; and the arranged overturning mechanism can overturn the plate, so that sufficient double-face grinding effects of the grinding plate are achievedon the surface of the plate.

Owner:武文家

Chemical mechanical polishing aqueous dispersion, chemical mechanical polishing method using the same, and method of recycling chemical mechanical polishing aqueous dispersion

InactiveUS20110117821A1Improve polishing effectGrinding stabilityOther chemical processesSemiconductor/solid-state device manufacturingOrganic acidCu2 ions

A chemical mechanical polishing aqueous dispersion includes (A) abrasive grains, (B) an organic acid, and (C1) copper ions or (C2) at least one kind of metal atoms selected from Ta, Ti, and Rb, the chemical mechanical polishing aqueous dispersion including the copper ions (C1) at a concentration of 1×101 to 2×105 ppm, or including the at least one kind of metal atoms (C2) selected from Ta, Ti, and Rb at a concentration of 1×10−1 to 1×103 ppm.

Owner:JSR CORPORATIOON

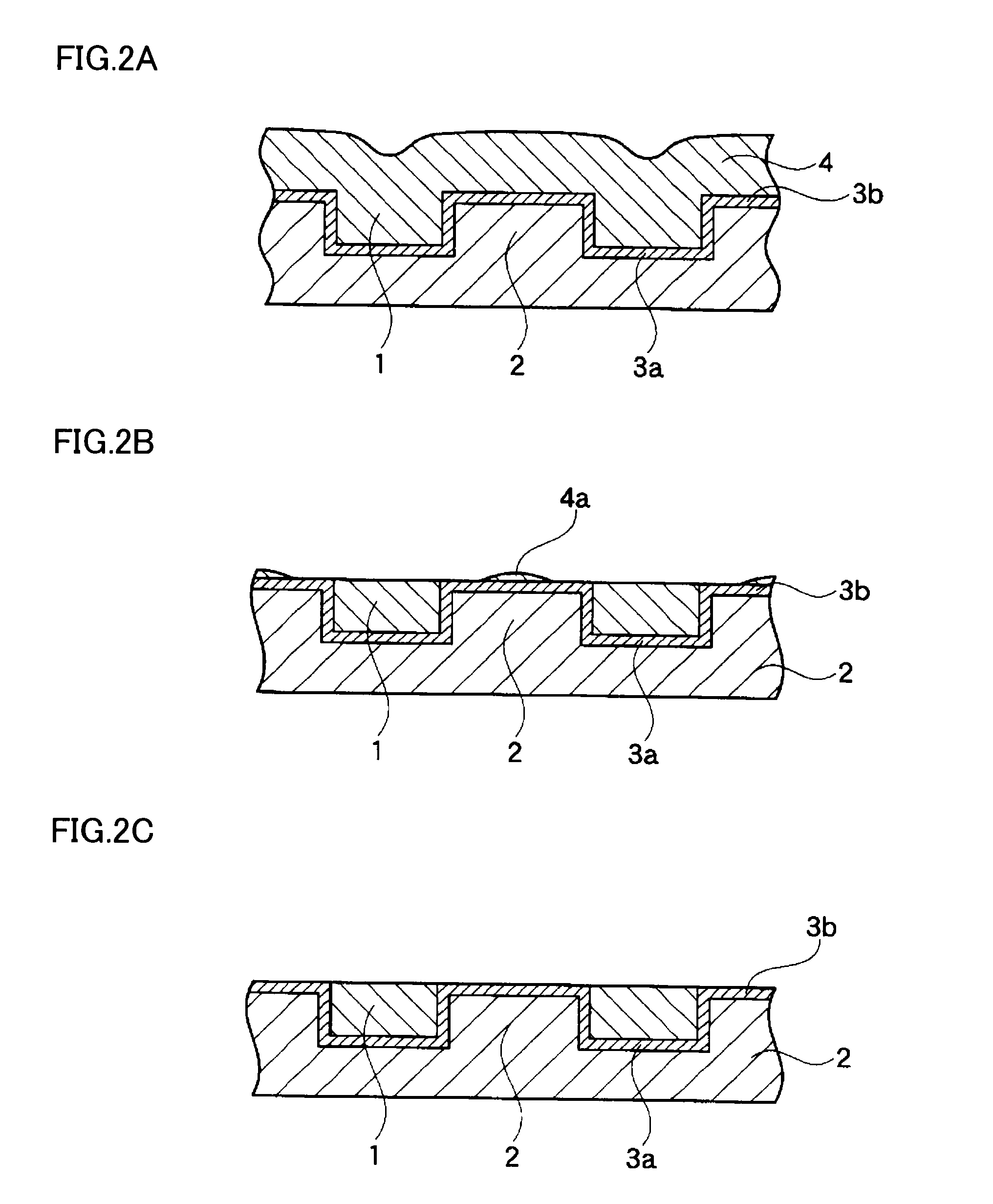

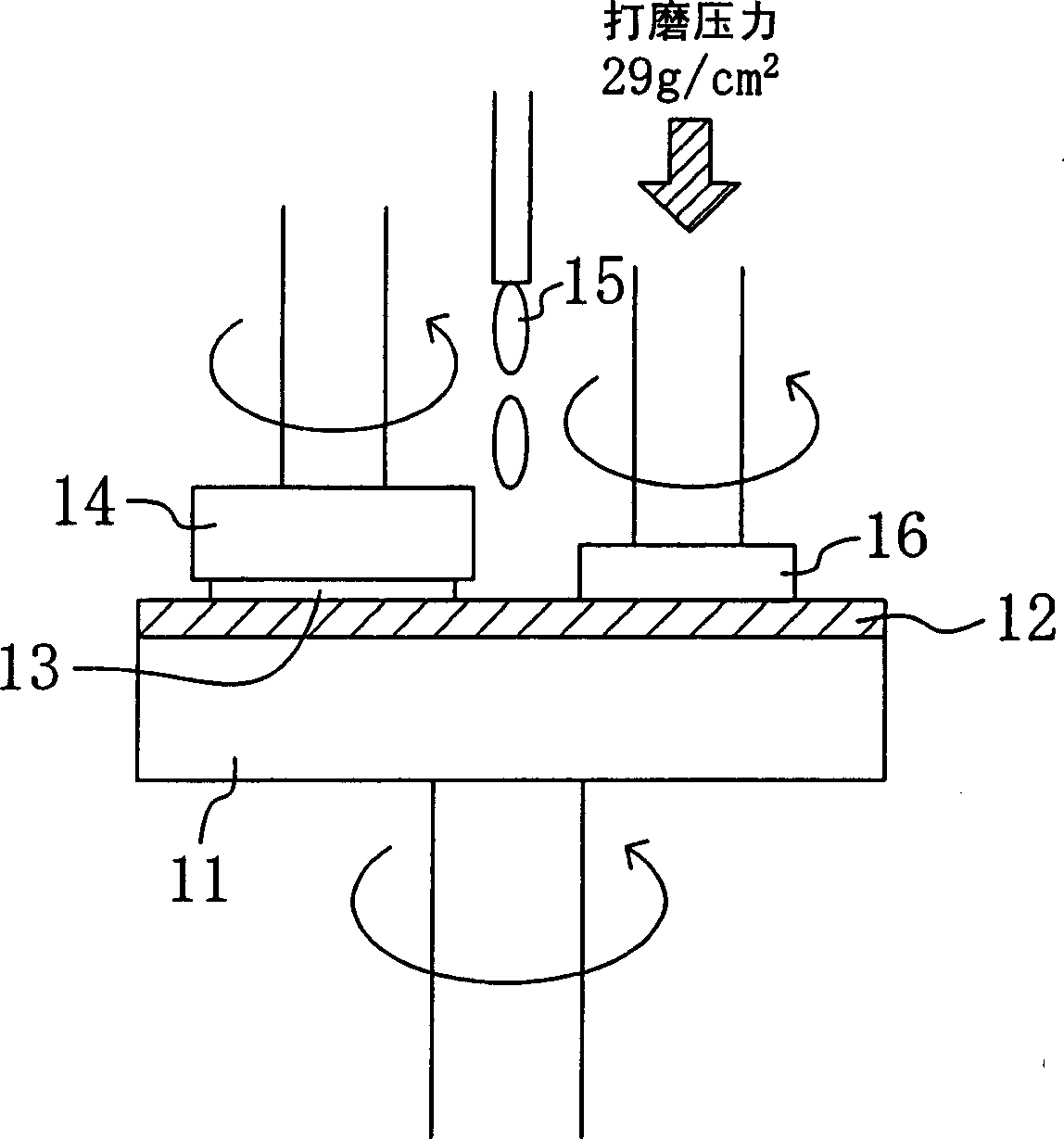

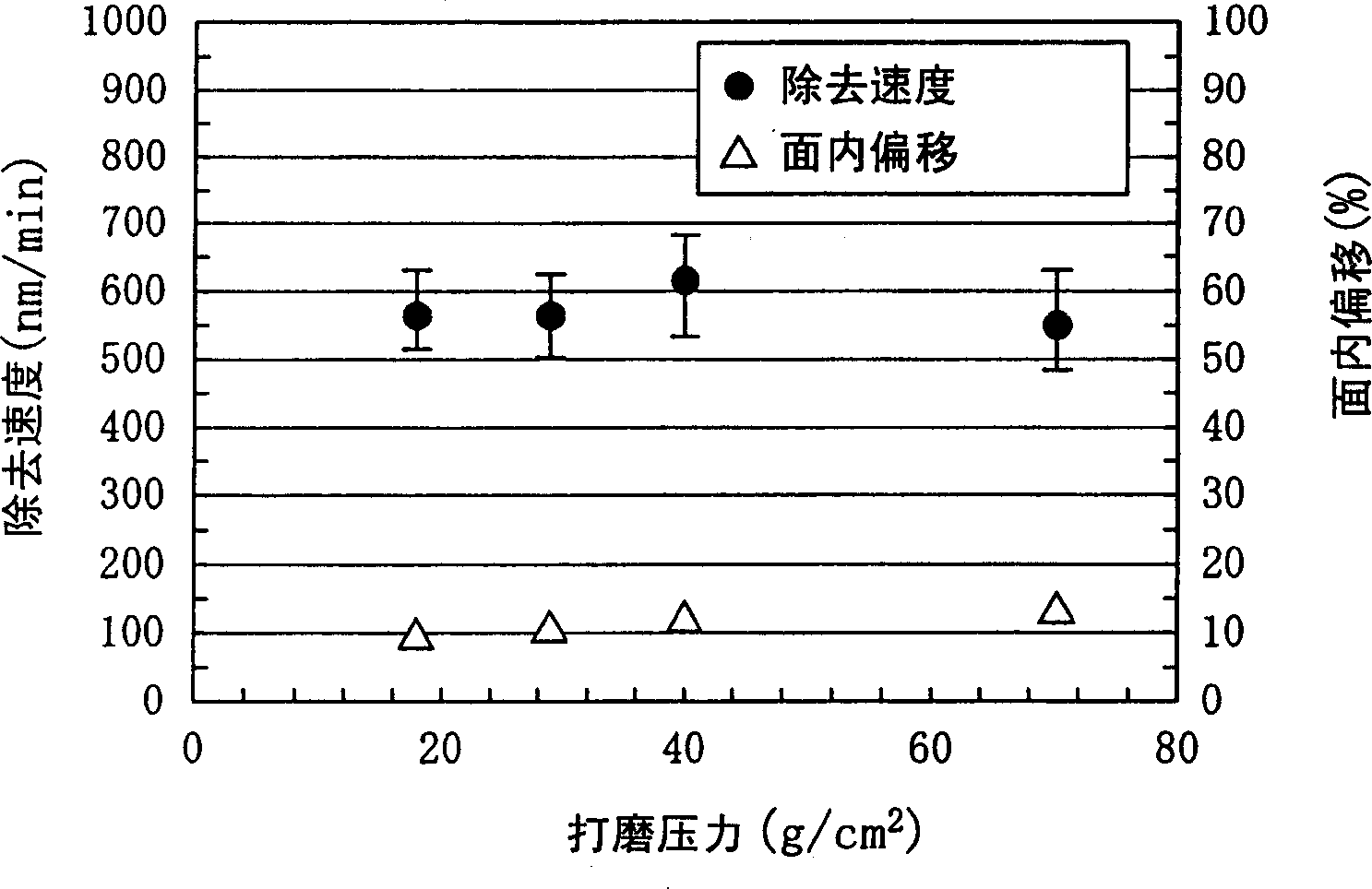

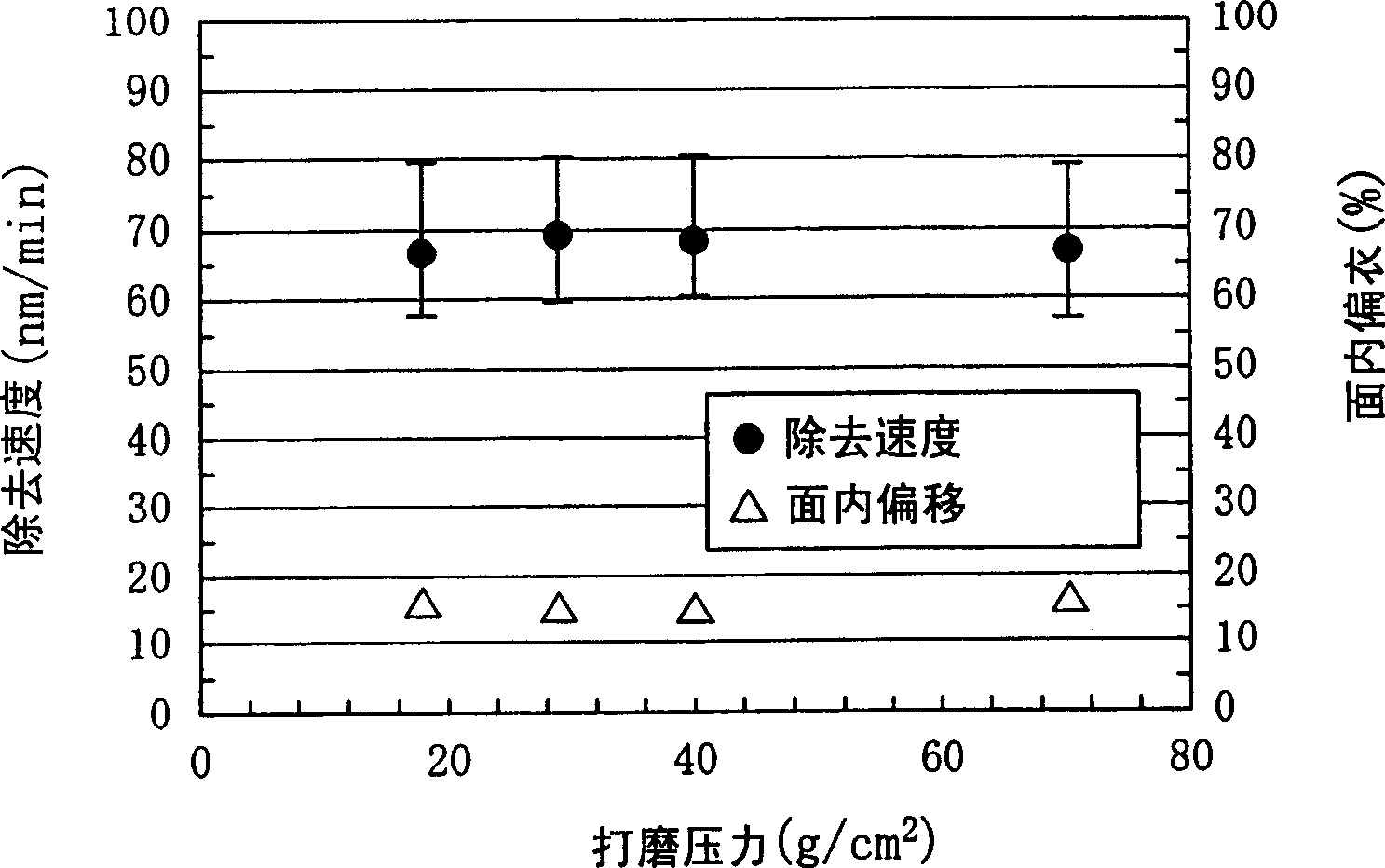

Chemical mechanical polishing method and apparatus

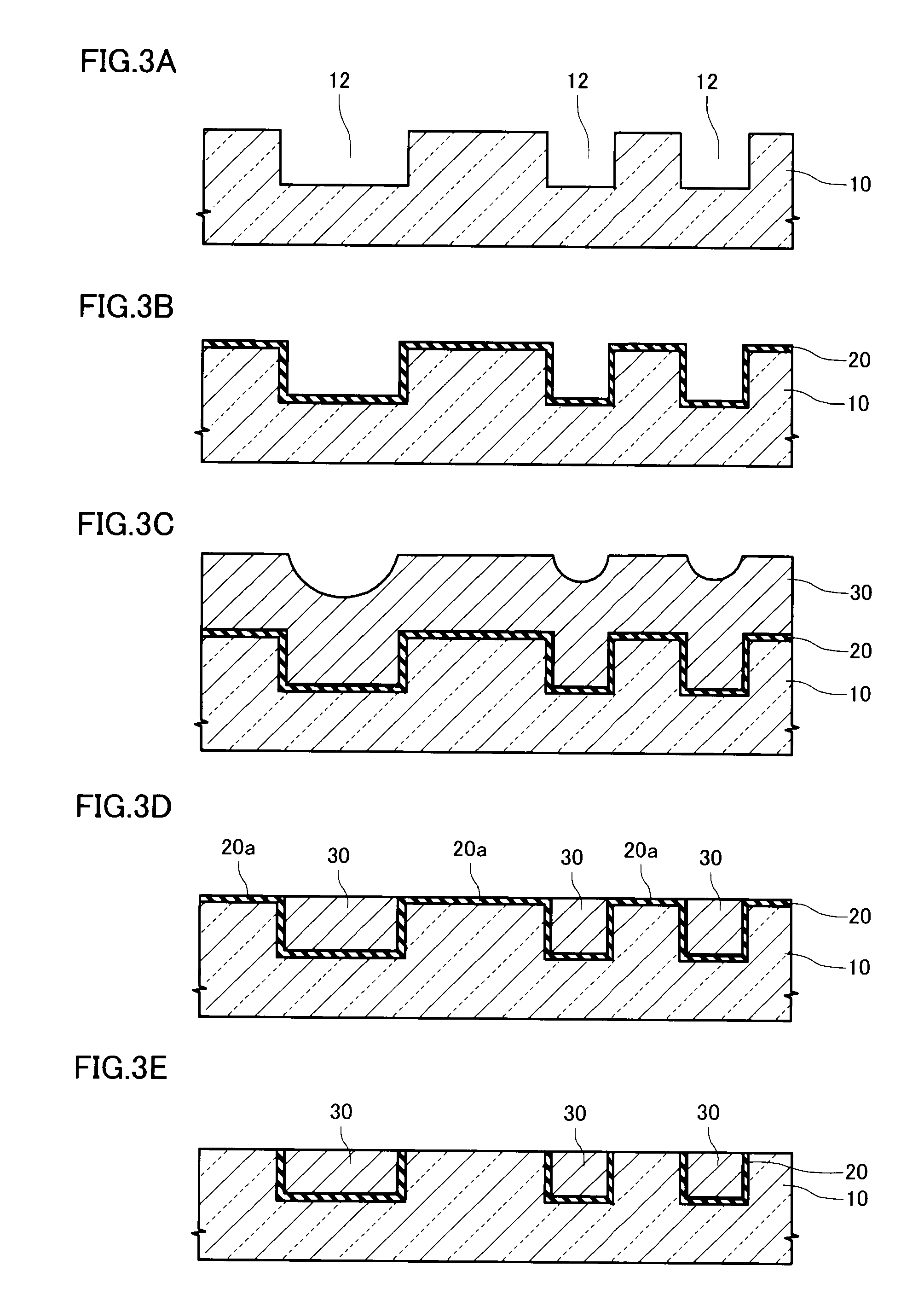

InactiveCN1505110AGrinding stabilityReduce embeddingSemiconductor/solid-state device manufacturingLapping machinesCopper interconnectMetallurgy

In a CMP process for polishing copper and a barrier metal formed on a substrate to form a buried copper interconnect, a polishing pad is subjected to dressing under a dressing pressure of 29 g / cm<2 >so that the surface roughness of the polishing pad becomes 3 mum to 5 mum inclusive. Thereby, dishing of the copper interconnect can be reduced as compared with a known method without reducing the removal rate of the copper and barrier metal.

Owner:PANASONIC CORP

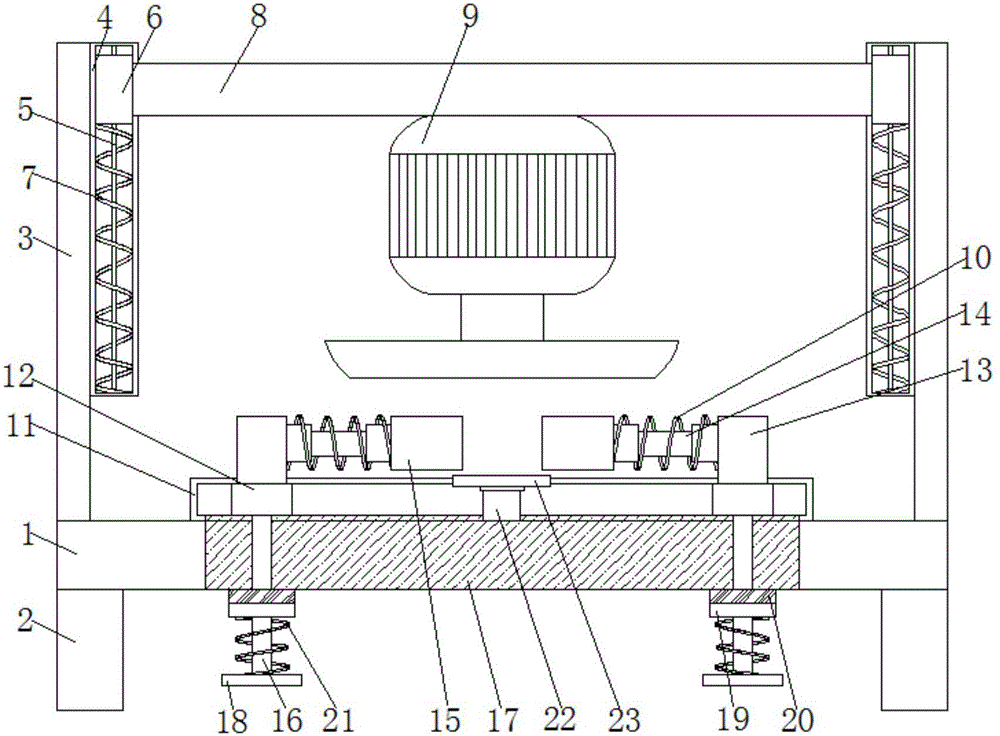

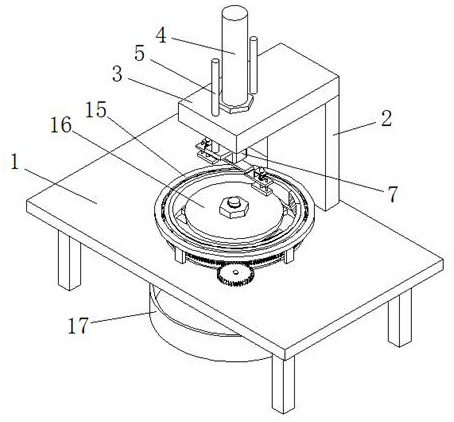

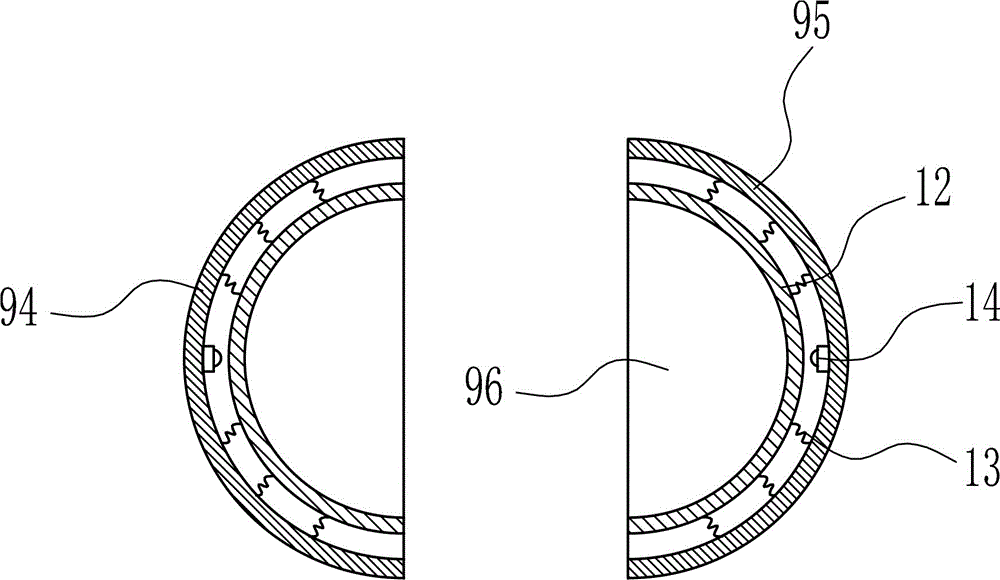

Hub polishing device convenient to use

InactiveCN107433498AImprove stabilityGrinding stabilityGrinding carriagesRevolution surface grinding machinesEngineering

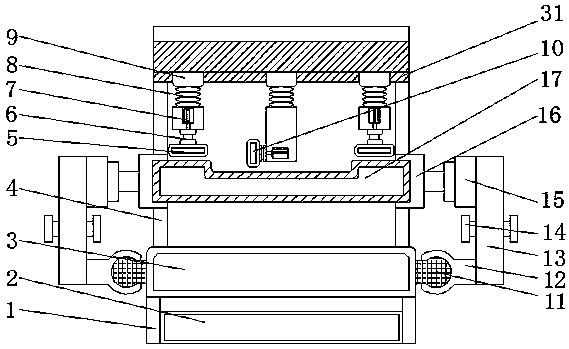

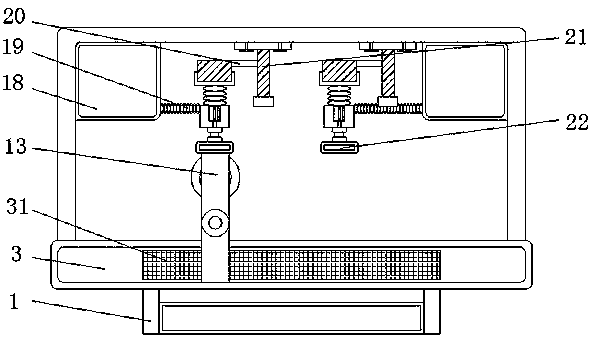

The invention discloses an easy-to-use hub grinding device, which comprises a base plate, support legs are fixedly connected to both sides of the bottom of the base plate, vertical plates are fixedly connected to both sides of the upper surface of the base plate, and two vertical plates The opposite side is fixedly connected with a vertical slide rail, the top and bottom of the inner wall of the vertical slide rail are connected by a slide bar, and a slide block is slidably connected in the vertical slide rail, and the slide block is sleeved on the slide On the rod, a return spring is sleeved on the sliding rod and below the slider. Through the improvement of the grinding machine, when the lifting plate is pressed down, the grinding disc of the grinding machine can be brought into contact with the wheel hub. After the lifting plate is released, the grinding machine can be returned to its position under the action of the return spring. The use of the spring can stably clamp the wheel hub, thereby facilitating the grinding of the wheel hub. When the two movable blocks are rotated in the annular slide rail at the same time, the wheel hub can be driven to rotate, thereby facilitating grinding of other positions of the wheel hub.

Owner:孙永丽

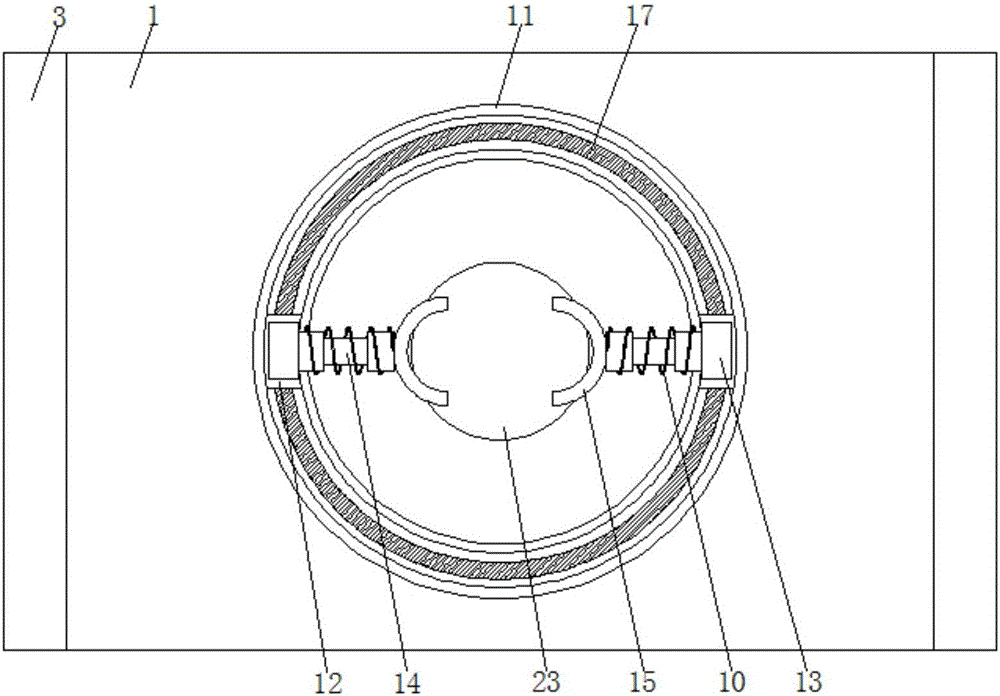

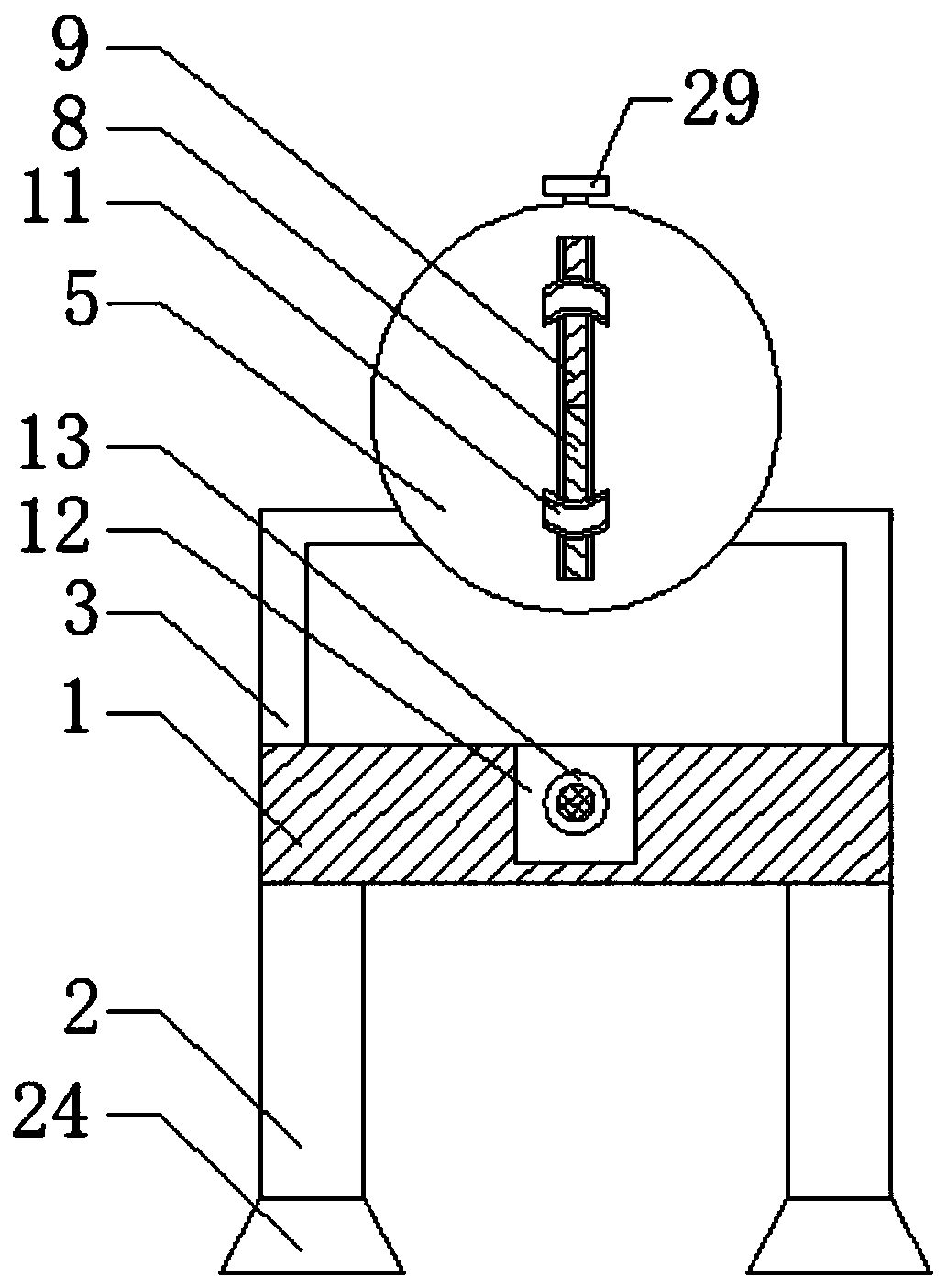

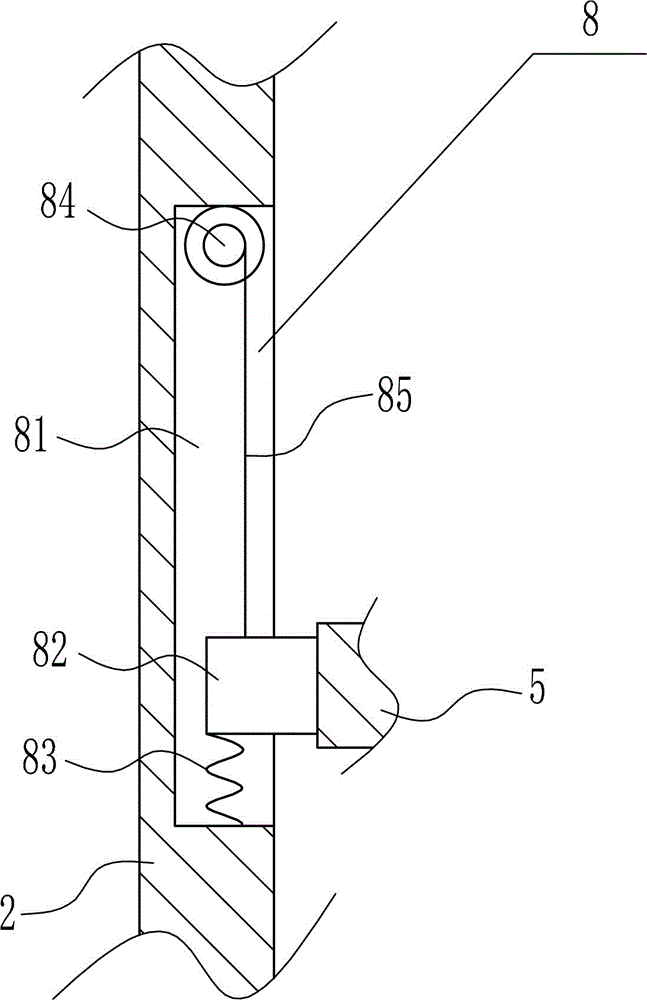

Bearing inner and outer ring grinding device

InactiveCN110421418AEasy to fixGrinding stabilityGrinding carriagesRevolution surface grinding machinesEngineeringThreaded rod

The invention discloses a bearing inner and outer ring grinding device. The device comprises a supporting platform and supporting legs, the supporting legs are welded to the bottom of the supporting platform, a first groove is formed in a round plate, the inner wall of one side of the first groove is embedded with a first bearing, the inner part of the first bearing is in interference connection with a first threaded rod, a rectangular supporting plate is welded to the top surface of a T-shaped sliding block, a third bearing is inlaid at one end of the top surface of the rectangular supportingplate, the inner part of the third bearing is in interference connection with a fourth threaded rod, a second n-shaped mounting frame is welded to the top surface of the rectangular supporting plate,sliding grooves are formed in the inner walls of the two sides of the second n-shaped mounting frame, sliding blocks are arranged in the sliding grooves in a sliding mode, and a rectangular movable plate is integrally formed between the sliding blocks. According to the device, the inner rings and the outer rings of bearings with different sizes can be fixed conveniently, the grinding can be stabler, the use is flexible and convenient, the grinding is more sufficient, and the grinding quality is guaranteed.

Owner:安徽千禧精密轴承制造有限公司

Grinding device for paint equipment

InactiveCN107803733AGrinding stabilityImprove stabilityGrinding carriagesGrinding machinesPistonEngineering

The invention discloses a grinding device for paint equipment. The grinding device for paint equipment comprises a bottom board; vertical boards are fixedly connected to the two sides of the upper surface of the bottom board, and sliding grooves are formed in the opposite sides of the two vertical boards; the top and the bottom of the inner wall of each sliding groove are connected through a sliding rod; sliding blocks are slidably connected in the sliding grooves and connected to the sliding rods in a sleeving mode; the sliding rods are sleeved with damping springs which are located below thesliding blocks; the two ends of the damping springs are fixedly connected with the bottoms of the inner walls of the sliding grooves and the bottoms of the sliding blocks; and the opposite sides of the two sliding blocks are connected through sliding boards. Through improvement on a grinding machine, when two poking rods slide oppositely, two pistons can move in two circular grooves back to back,at the moment, clamping teeth can disengage from pressing rods, after the poking rods are released, the clamping teeth on the piston can be pushed to abut against the pressing rods again under the action of resilience force of an extrusion spring, and thus the grinding machine can be kept at the adjusted height stably.

Owner:高峰

Carton cutting device

The invention belongs to the technical field of packaging, and particularly relates to a carton cutting device. The carton cutting device comprises a rack. A conveying belt is arranged on the rack. A driving wheel and a driven wheel are arranged above the conveying belt. The driving wheel and the driven wheel are connected through a belt. A plurality of rubber balls are mounted on the belt. Fur is arranged above the rubber balls. A cutting knife is arranged below the rack and provided with a plurality of cutting knife blades. A draught fan is arranged on the outer side of the cutting knife. A draught fan rotating shaft is arranged in the center of the draught fan. A cutting knife rotating shaft is arranged in the center of the cutting knife and provided with through holes. The through holes are formed in the spaced positions of the cutting knife blades. The cutting knife rotating shaft is connected with the draught fan rotating shaft through the belt. An air extraction channel is connected to the end, close to a workbench, of the draught fan, and a water pool is connected to the end, away from the workbench, of the draught fan through a pipeline. The upper portion of the water pool is connected with an exhaust pipe, and the end, away from the water pool, of the exhaust pipe is opposite to the through holes. The problem that in the corrugated paper cutting process, generated paper scraps are directly discarded, and consequently resource waste is caused is solved.

Owner:CHONGQING JINSHAFENG PACKAGING CO LTD

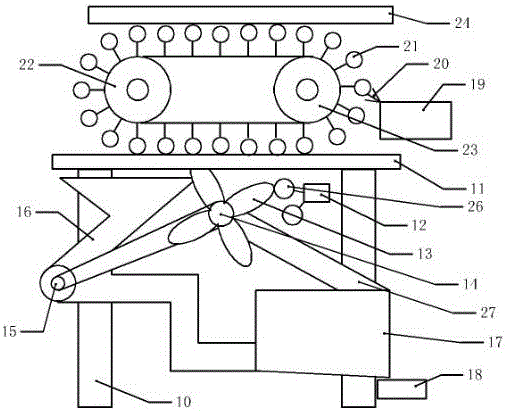

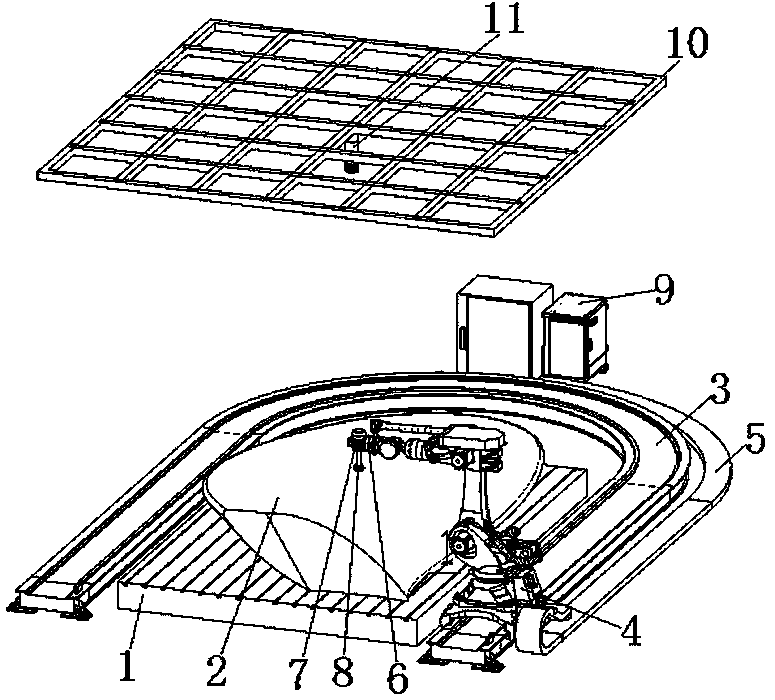

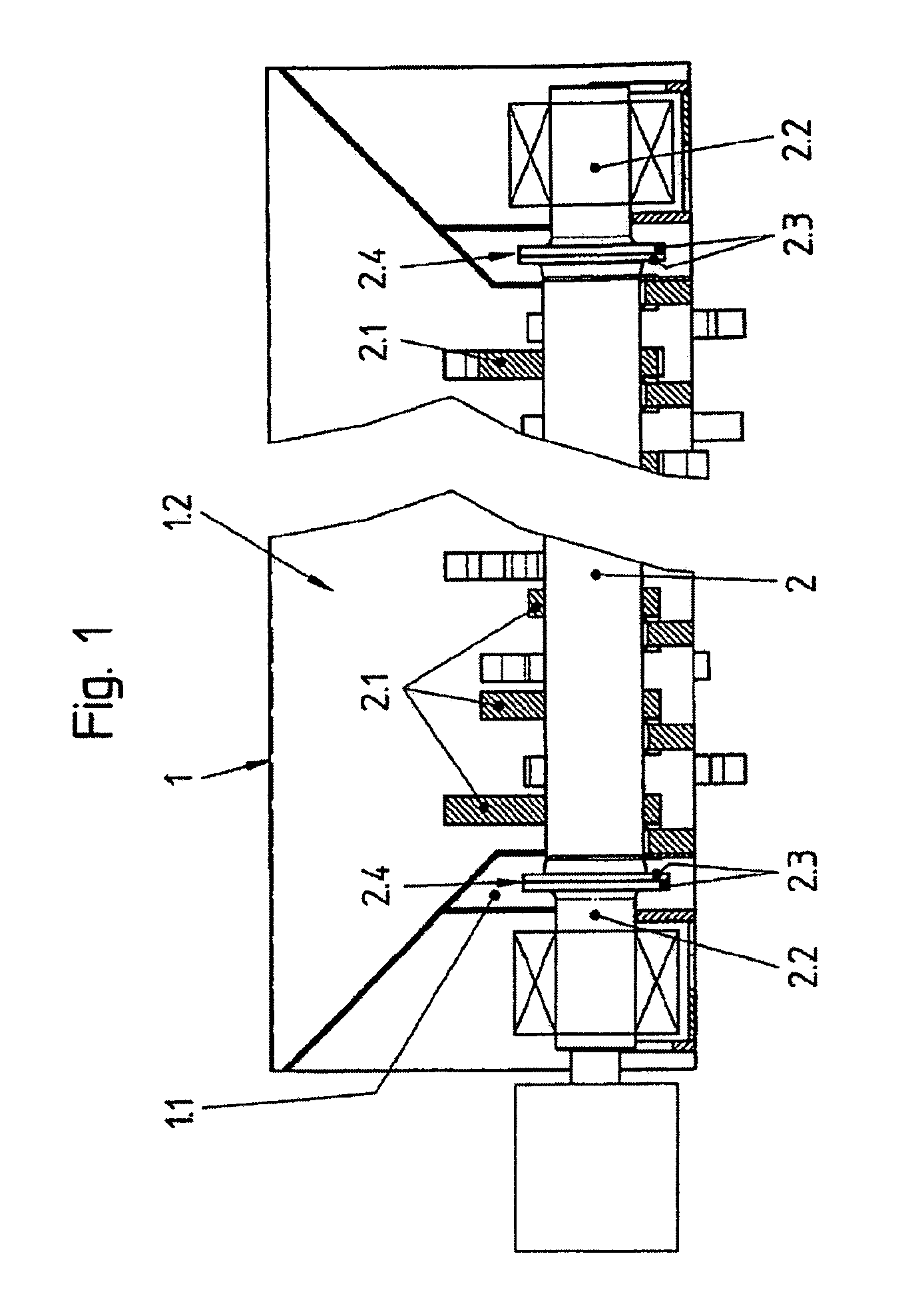

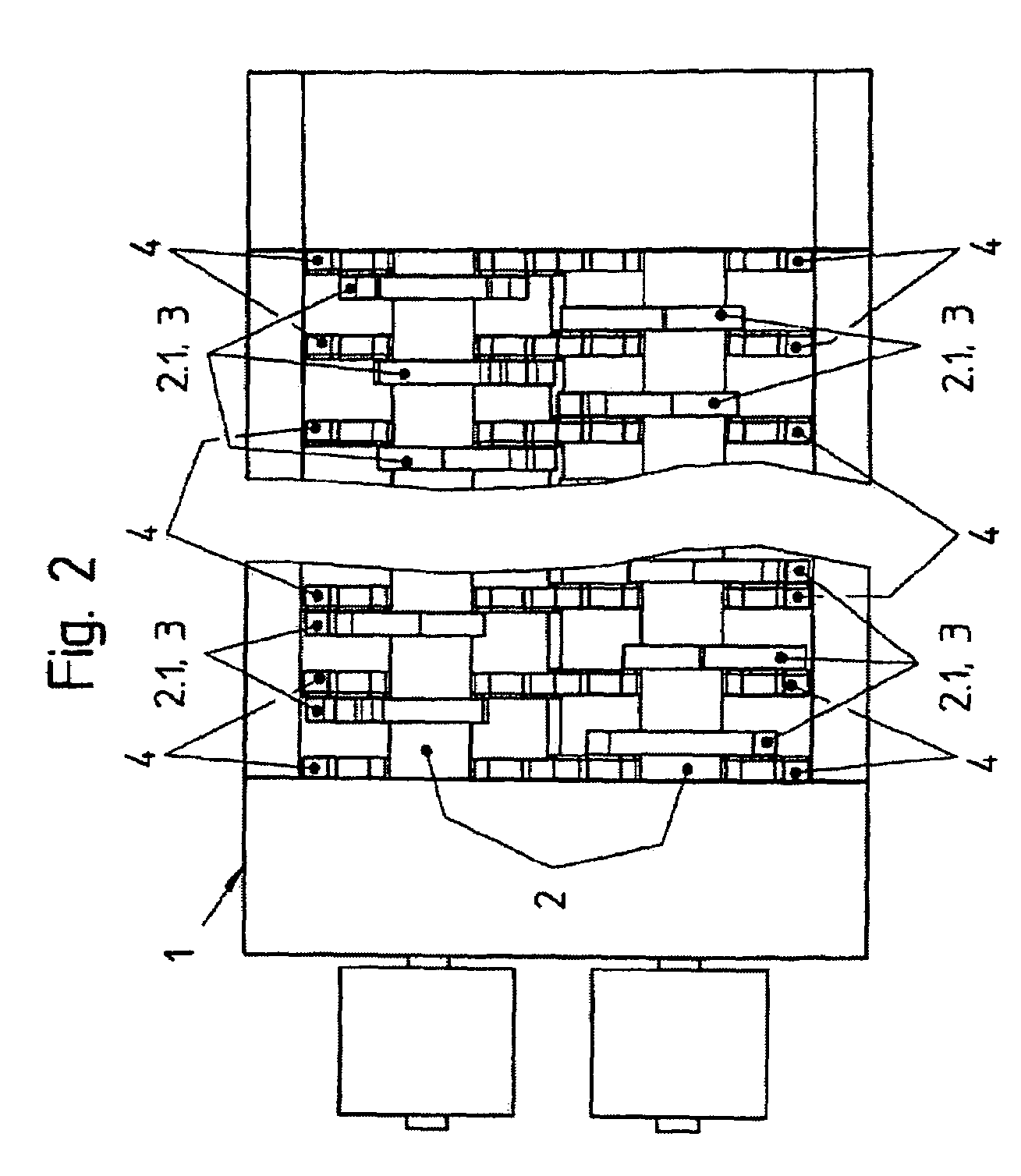

Automatic polishing system for water turbine blades

InactiveCN107866717AEffective sandingImprove sanding qualityAutomatic grinding controlGrinding machinesWater turbineControl system

The invention discloses an automatic polishing system for water turbine blades. The automatic polishing system for the water turbine blades comprises a clamping platform, an industrial robot, a polishing control system and a visual image system, and wherein the clamping platform is used for positioning and clamping the water turbine blade to be polished; the industrial robot is provided with a polishing mechanism, and the industrial robot is controlled by a polishing control system and is used for polishing the blade clamped on the clamping platform; and the polishing control system directs atthe current polishing surface of the blade to be polished and is used for planning a corresponding polishing path, then the planned polishing path is converted into a polishing action control programof the industrial robot and is conveyed to the industrial robot, and the visual image system is used for detecting the polishing quality and feeding back the polishing quality to the polishing control system. According to the automatic polishing system for the water turbine blades, the surface of the impact-type water turbine blade formed by precision casting can be provided with an automatic, intelligent and unified polishing treatment; and thus the polishing quality of the surface of the blade can be improved accurately and reliably.

Owner:SICHUAN ENG TECHN COLLEGE

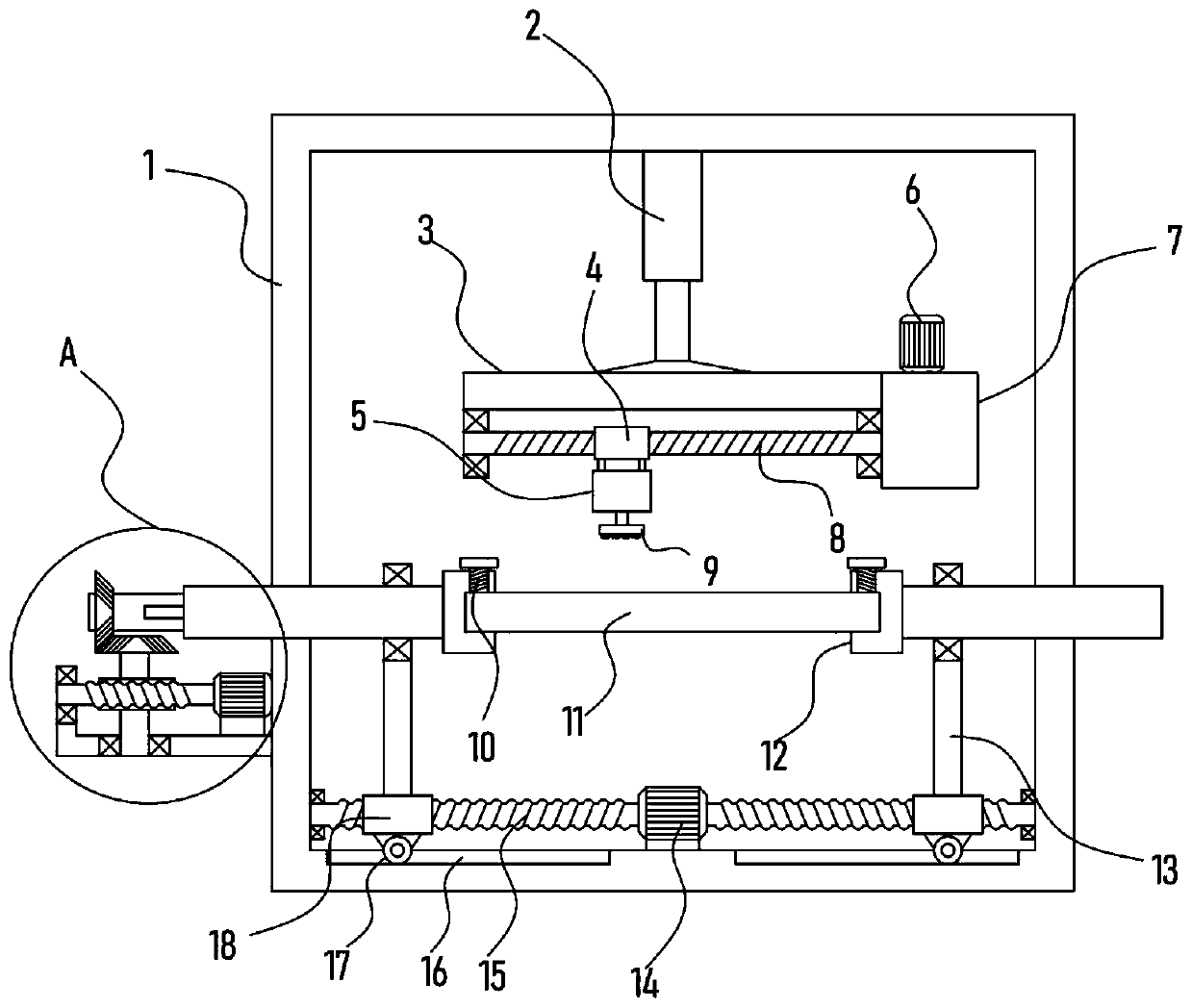

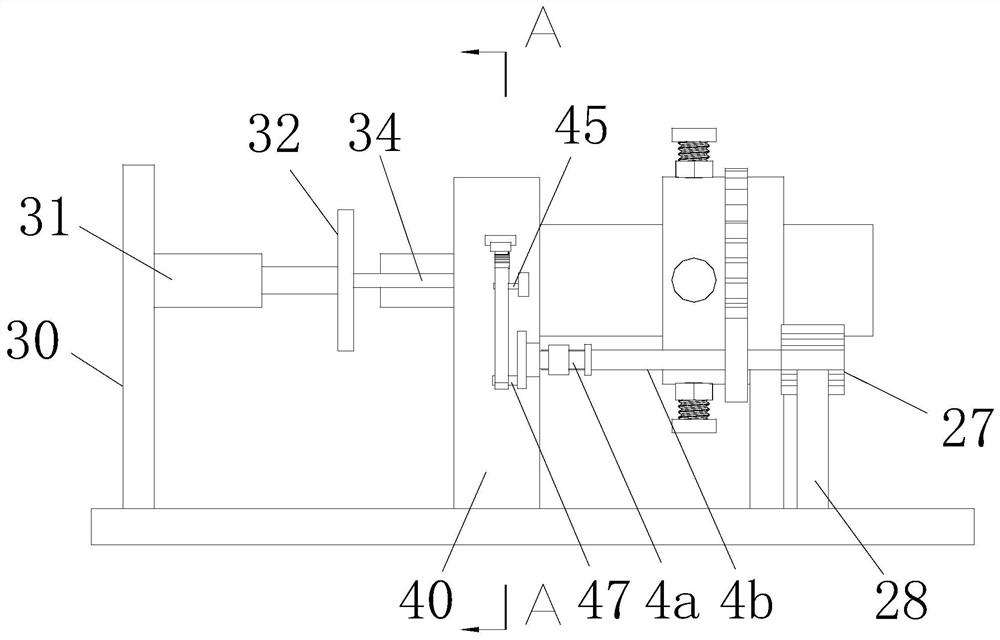

Grinding machine

InactiveCN103991019AHigh precisionGrinding stabilityGrinding machinesGrinding work supportsEngineeringMechanical engineering

The invention discloses a grinding machine. The grinding machine comprises a workpiece adjusting mechanism, a clamping part, a grinding mechanism and a base, wherein the grinding mechanism is installed on the base and comprises a grinding wheel, and the workpiece adjusting mechanism comprises a rotating column, a sliding rail and a sliding block. The top end of the rotating column is fixedly connected to the middle portion of the bottom of the sliding rail, the bottom end of the rotating column is rotatably installed on the base, the sliding rail can be driven by the rotating column to be close to or away from the grinding wheel, the sliding block is installed on the sliding rail in a slidable mode, and the clamping part is arranged on the sliding block and used for clamping a workpiece. The grinding machine has the advantages of being high in accuracy and easy to operate.

Owner:WUHU QIUJING FASTENER

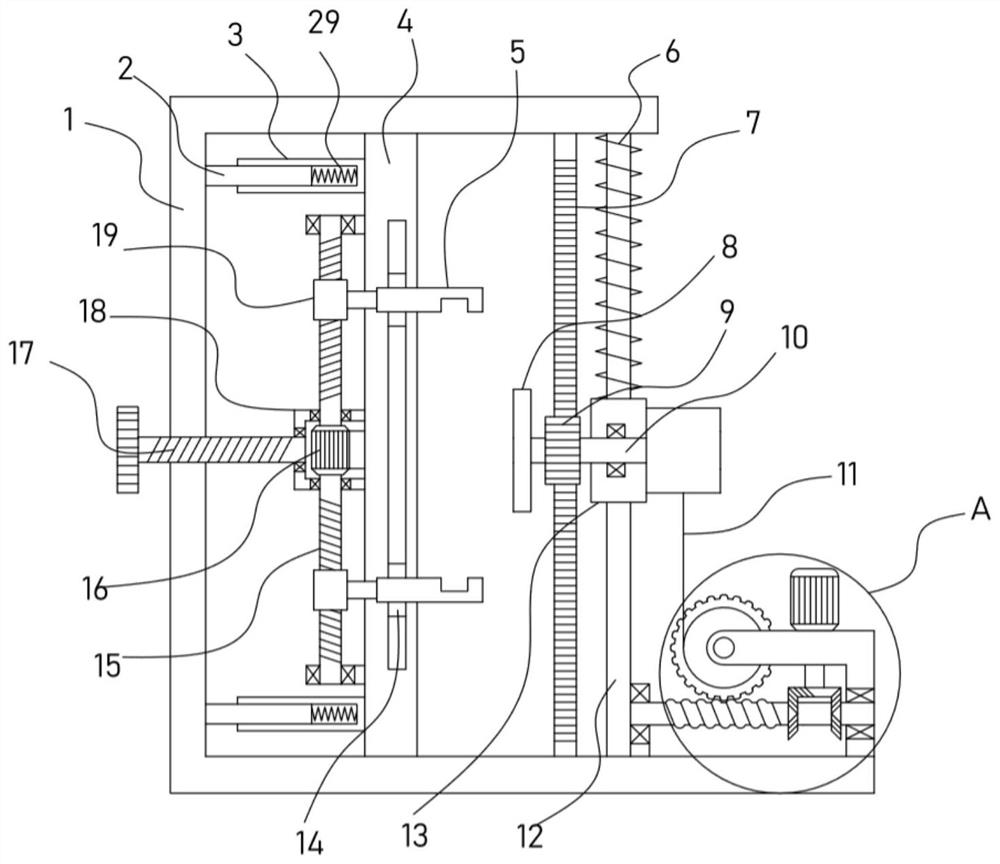

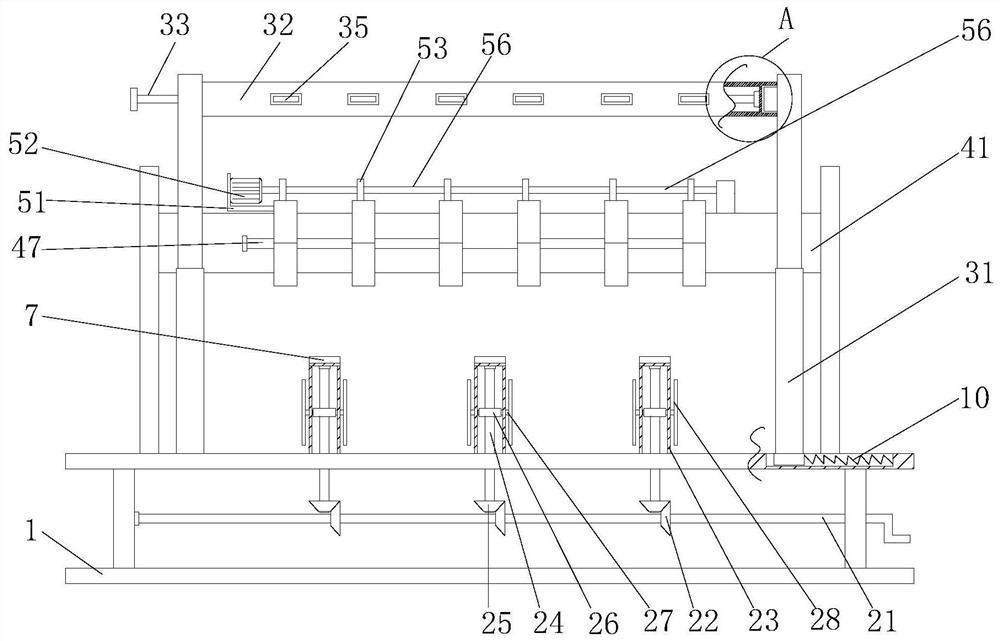

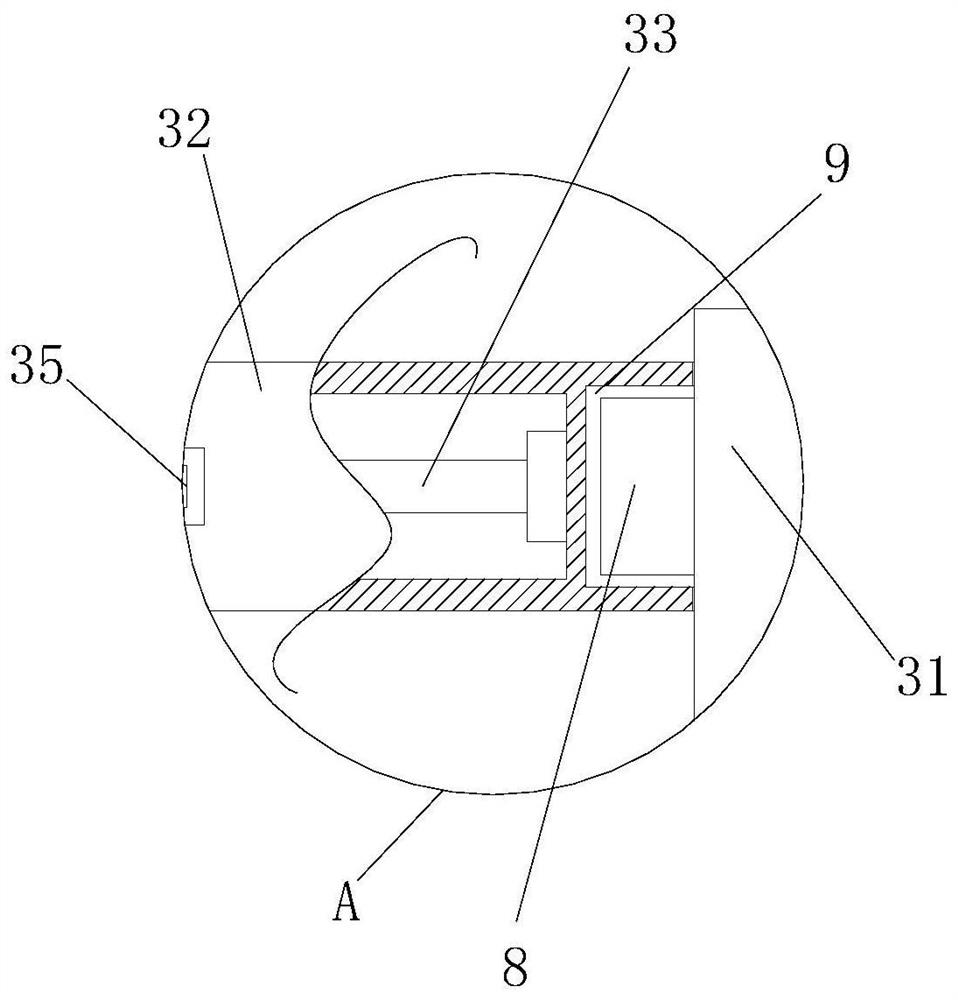

Plate surface polishing and flattening device for building construction

InactiveCN111872827AFully polishedGrinding stabilityGrinding carriagesPolishing machinesPolishingManufacturing engineering

The invention discloses a plate surface polishing and flattening device for building construction, and relates to the technical field of building construction machineries. The plate surface polishingand flattening device comprises a fixing frame, a polishing mechanism for polishing a plate is arranged on a guide sleeve block, a mounting frame is fixed on the fixing frame, a servo motor is fixed on the mounting frame, and a forward and reverse rotating mechanism is in driving connection with the servo motor; and the forward and reverse rotating mechanism is in driving connection with a translation mechanism for driving the guide sleeve block to vertically move; by means of a limiting mechanism, two clamping plates are used for clamping and fixing the plate, the stability of the plate grinding process is guaranteed, a grinding disc in the polishing mechanism rotates to achieve rotary polishing treatment on the surface of the plate, and the arranged forward and reverse rotating mechanismcan drive a winding wheel to rotate clockwise and anticlockwise alternately; and a steel wire rope can pull the guide sleeve block to do vertical reciprocating motion under the elastic effect of a spring ring, the rotating grinding disc can do vertical reciprocating motion relative to the plate, and efficient and sufficient grinding and polishing of the plate are achieved.

Owner:刘灿明

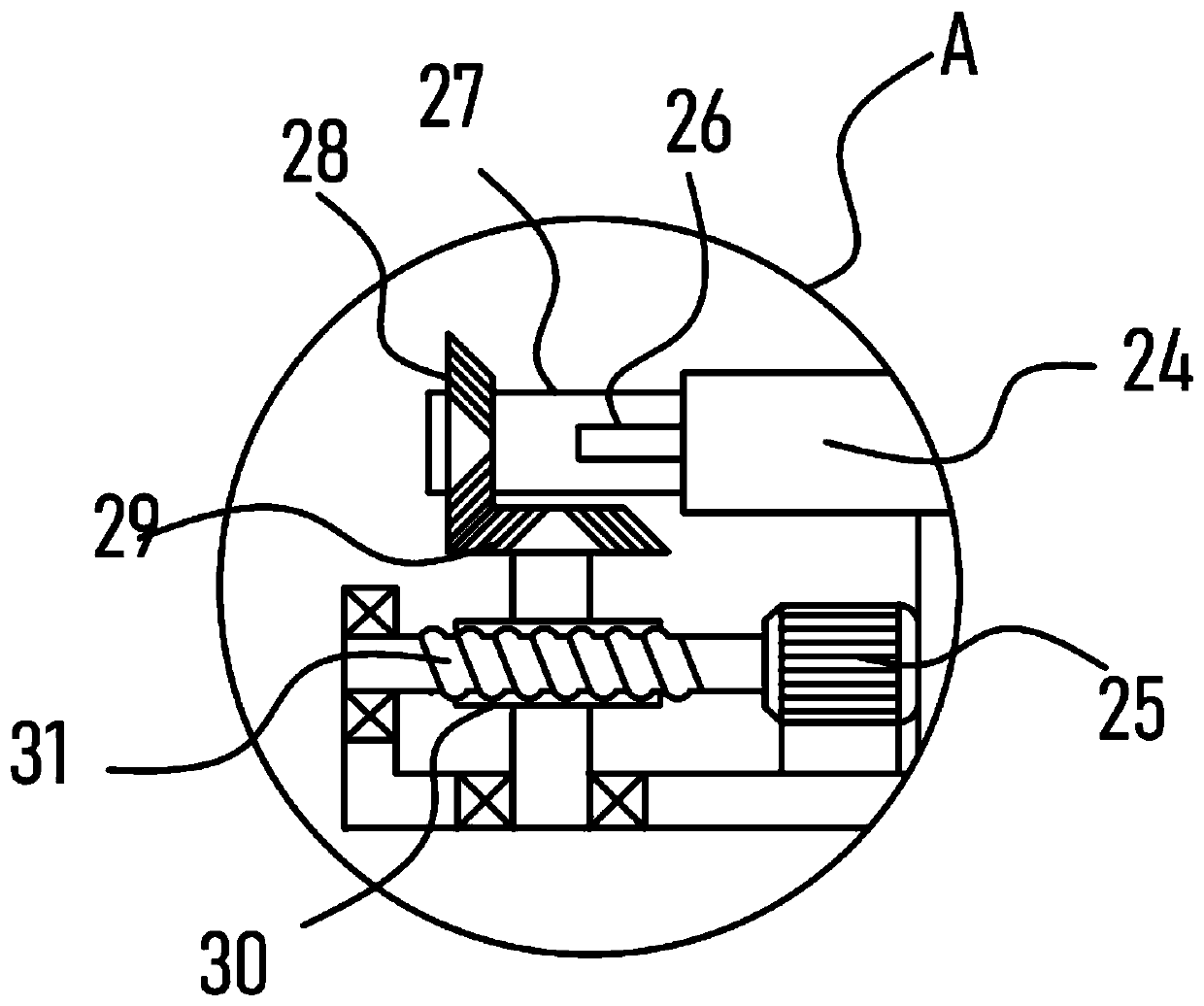

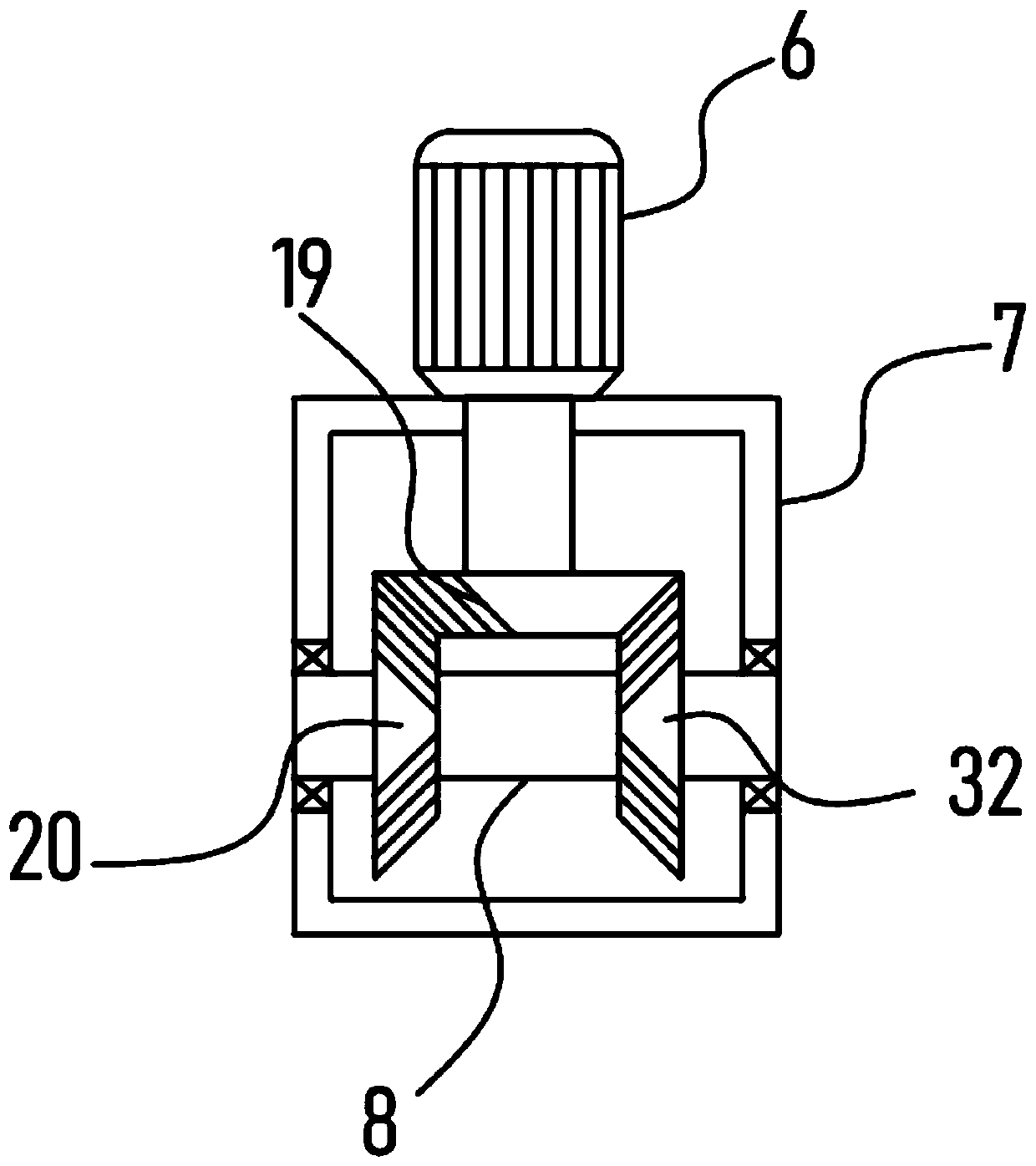

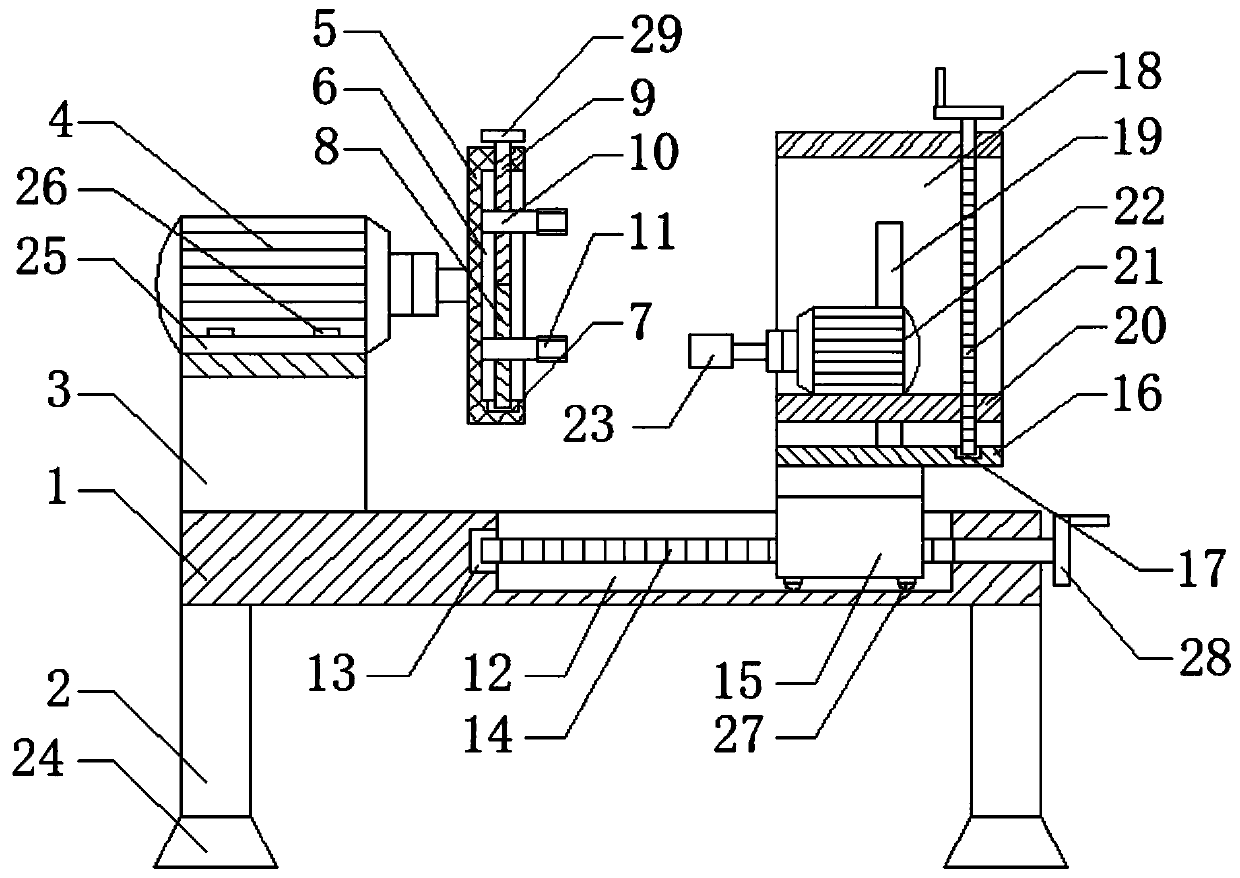

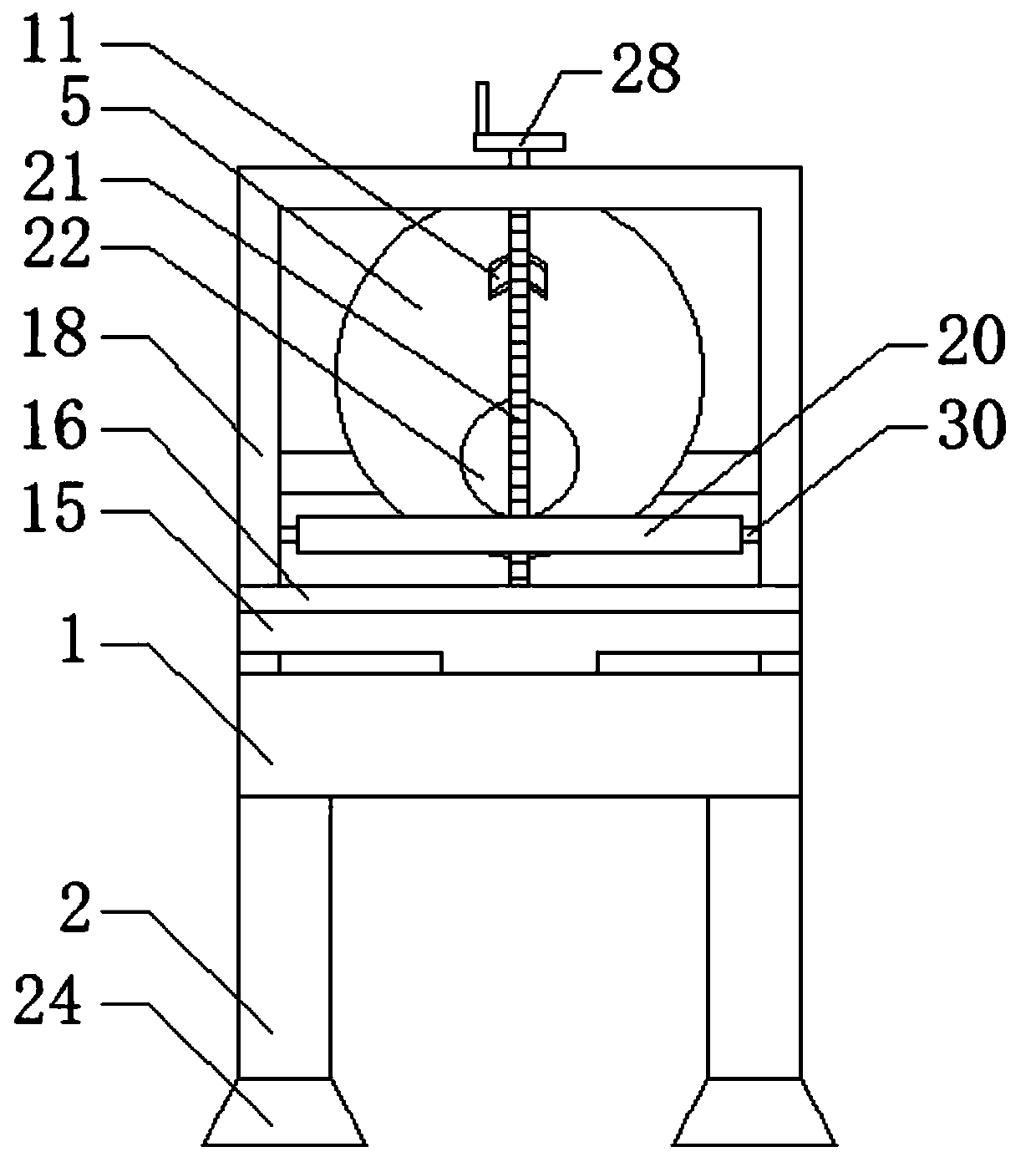

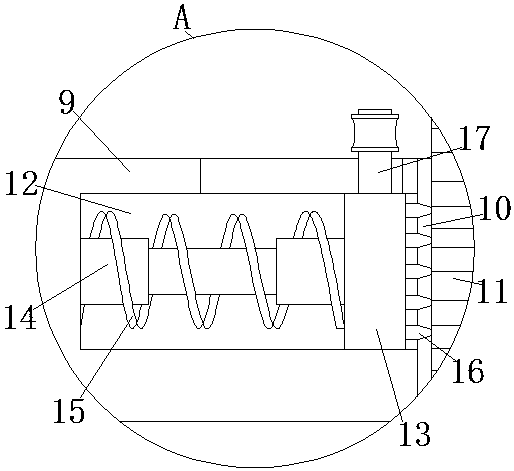

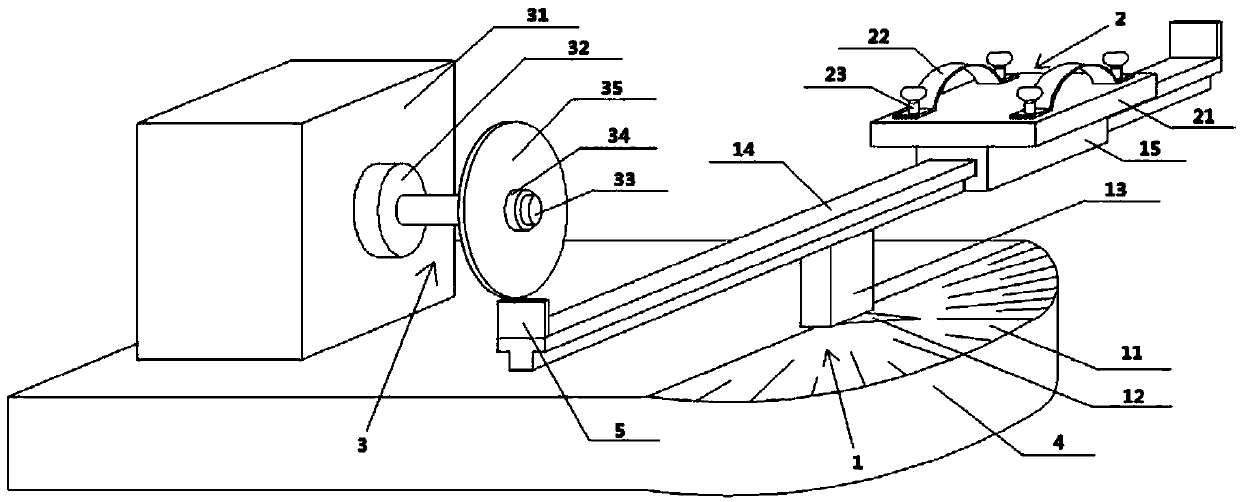

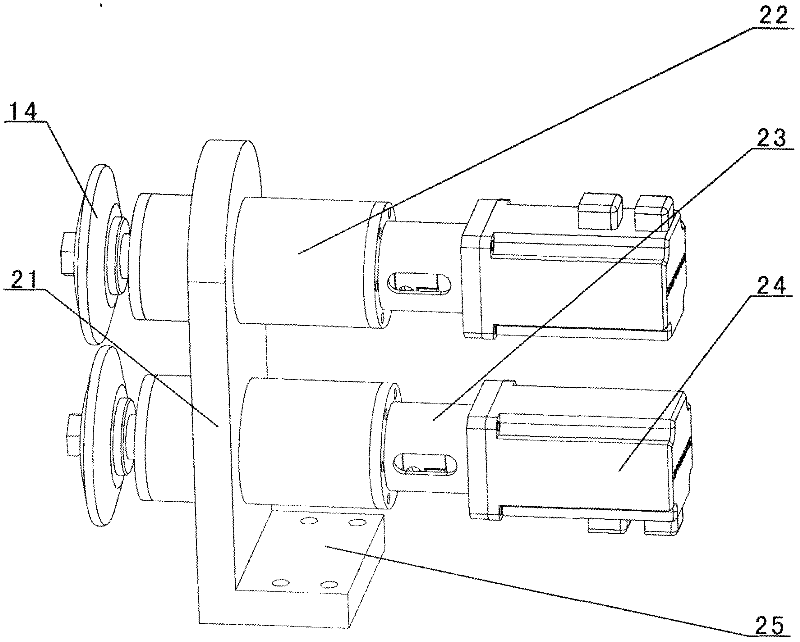

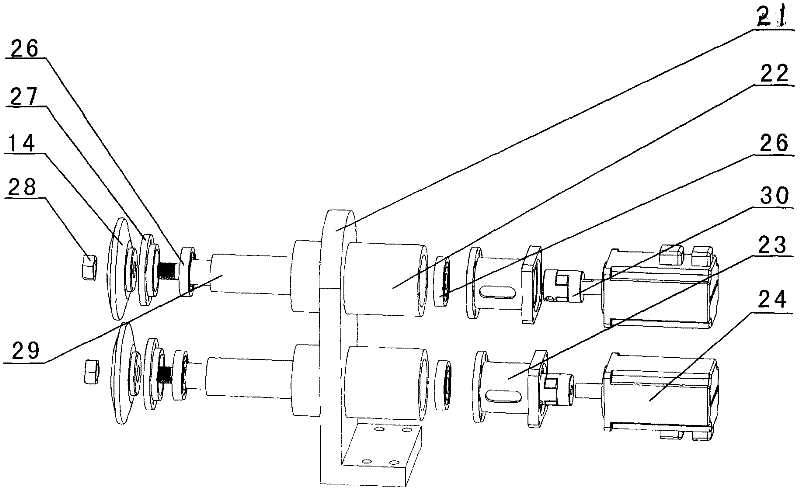

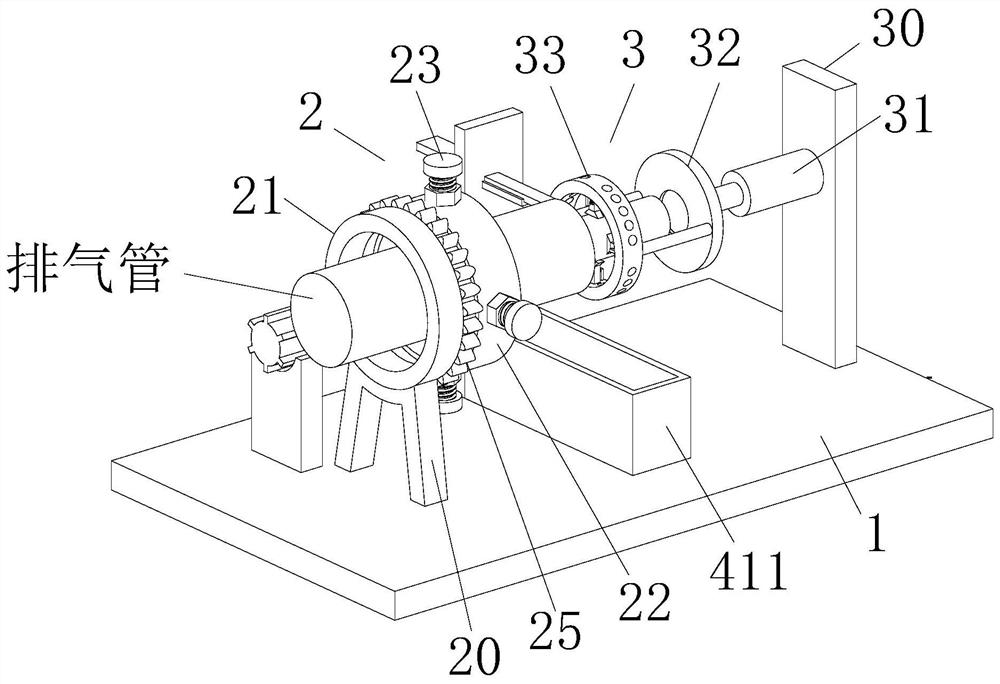

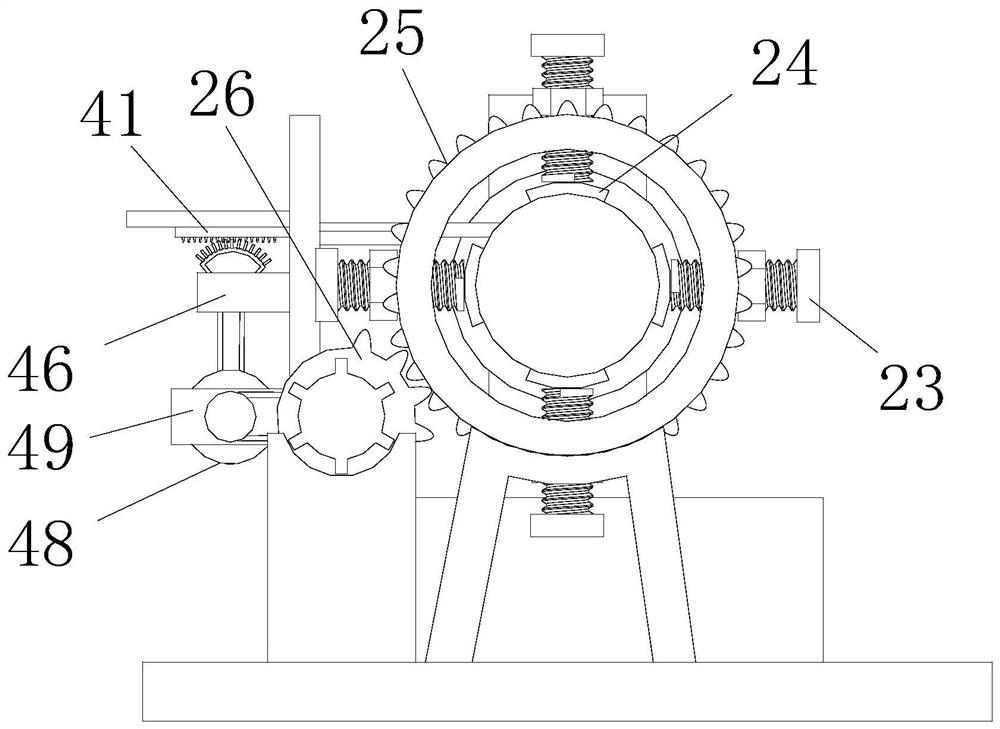

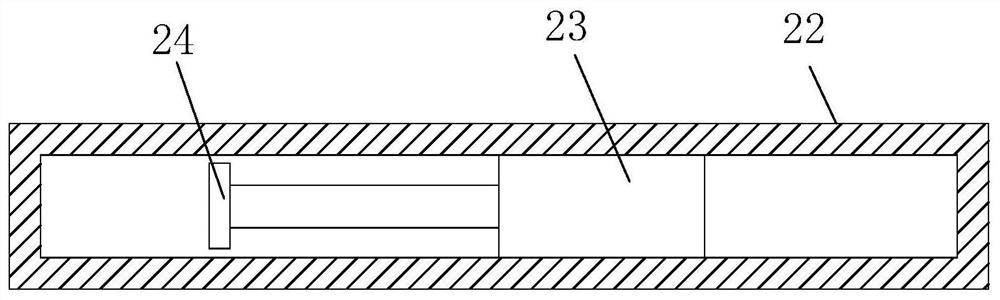

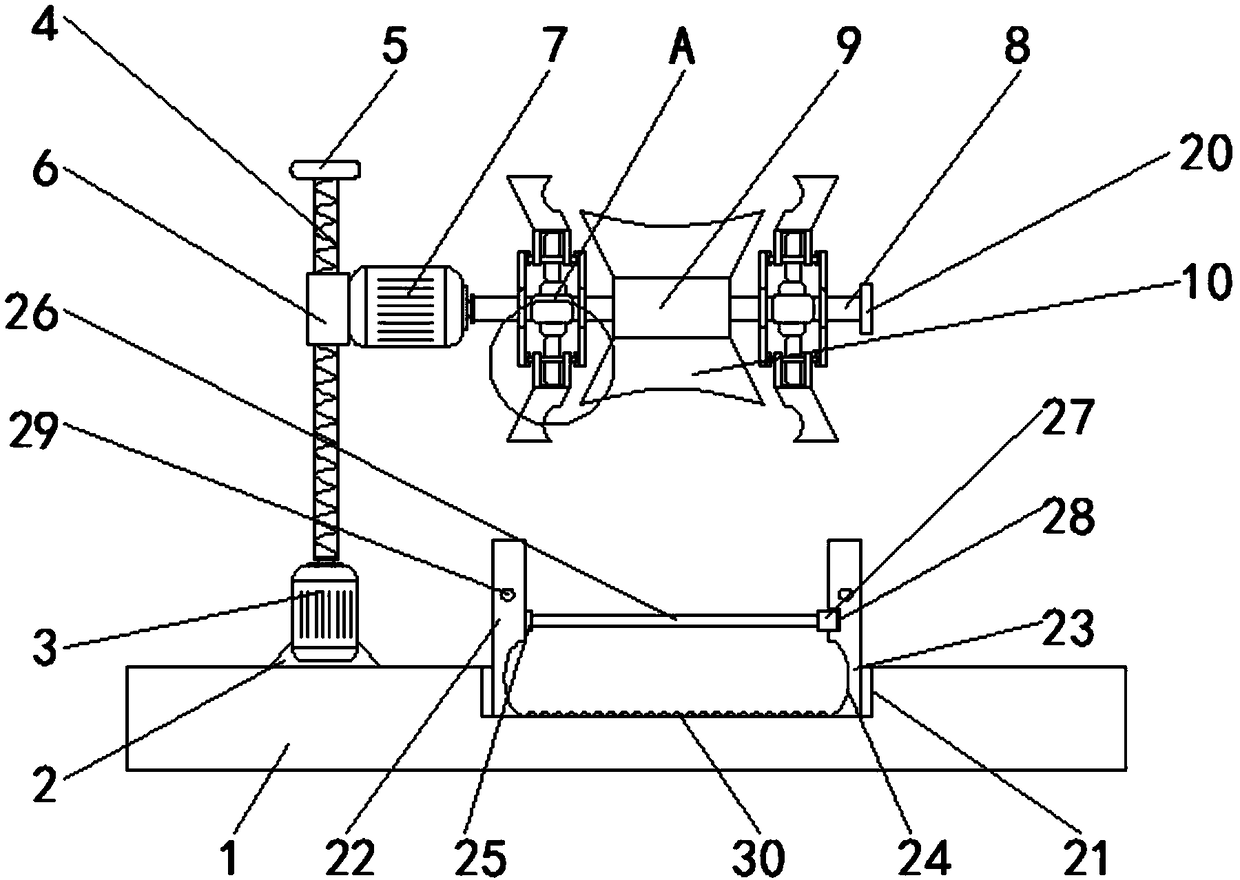

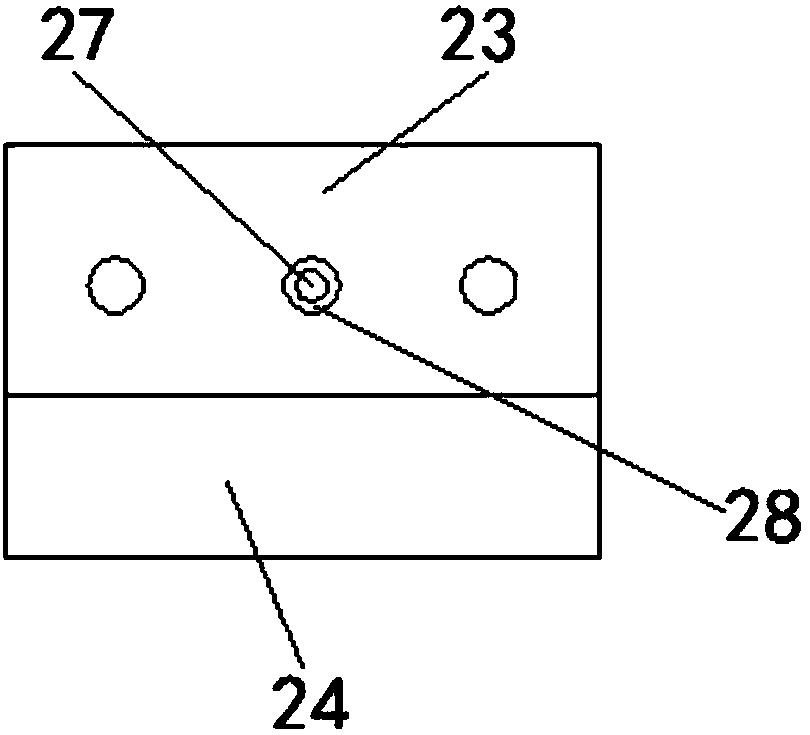

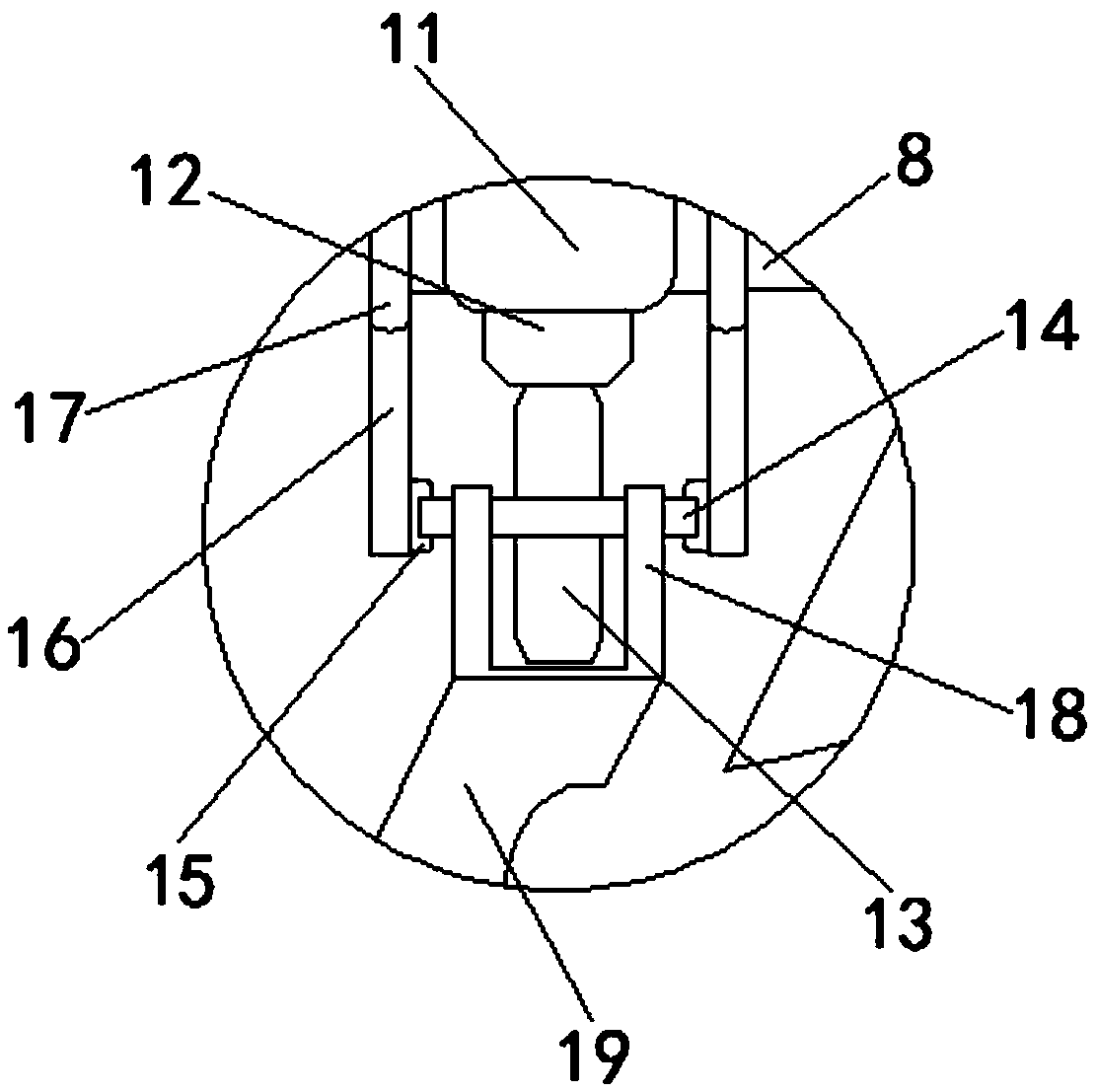

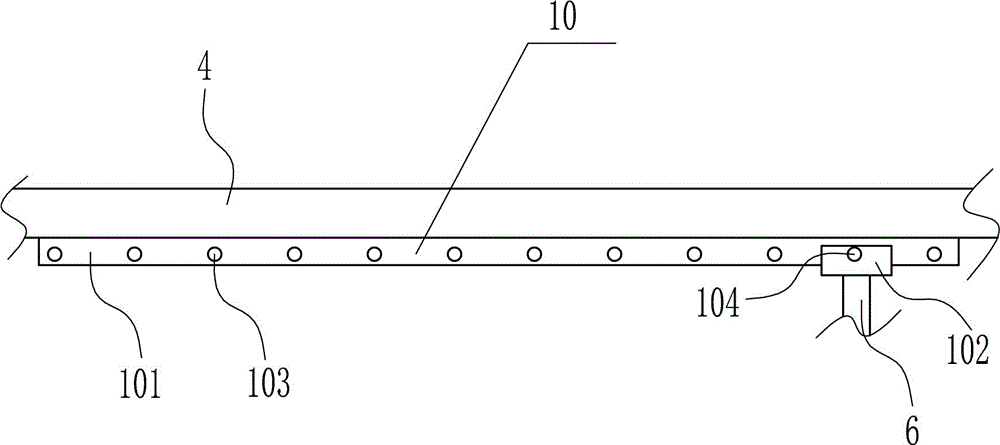

Bridge type crystal material double head grinder

ActiveCN102267073AGrinding stabilityHigh degree of mechanizationPlane surface grinding machinesCrystalline materialsBridge type

The invention provides a double-headed bridge type crystalline material grinding machine and relates to crystalline material machining equipment. The double-headed bridge type crystalline material grinding machine is characterized in that the middle of a crystal bar (18) is clamped by a crystal bar clamping mechanism, two grinding wheels (14) of a grinding mechanism at one end of the crystal bar respectively correspond to two sides of one end of the crystal bar, the crystal bar is ground at intervals respectively by the two grinding wheels on a base (21), and the rear parts of the two grinding wheels are respectively and externally connected with a power mechanism or a motor (24); and two grinding wheels of the grinding mechanism at the other end of the crystal bar respectively correspond to two sides of the other end of the crystal bar, the crystal bar is ground at intervals respectively by the two grinding wheels on the base, and the rear parts of the two grinding wheels are respectively and externally connected with a power mechanism or a motor. The use of the double-headed bridge type crystalline material grinding machine realizes the purpose of stably grinding the crystal bar, effectively improves the mechanical degree for machining the crystal bar, and overcomes the defect of necessity to pull a silicon core ball in the prior art.

Owner:LUOYANG JINNUO MECHANICAL ENG

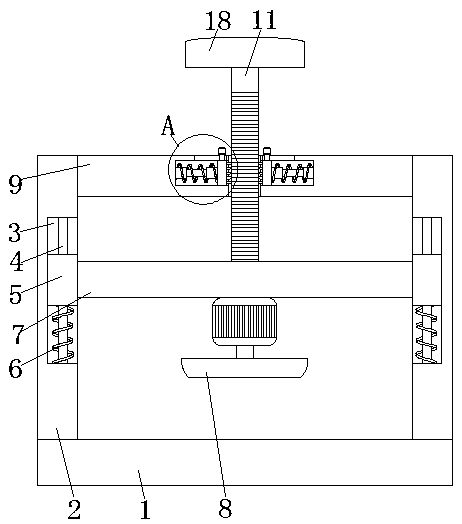

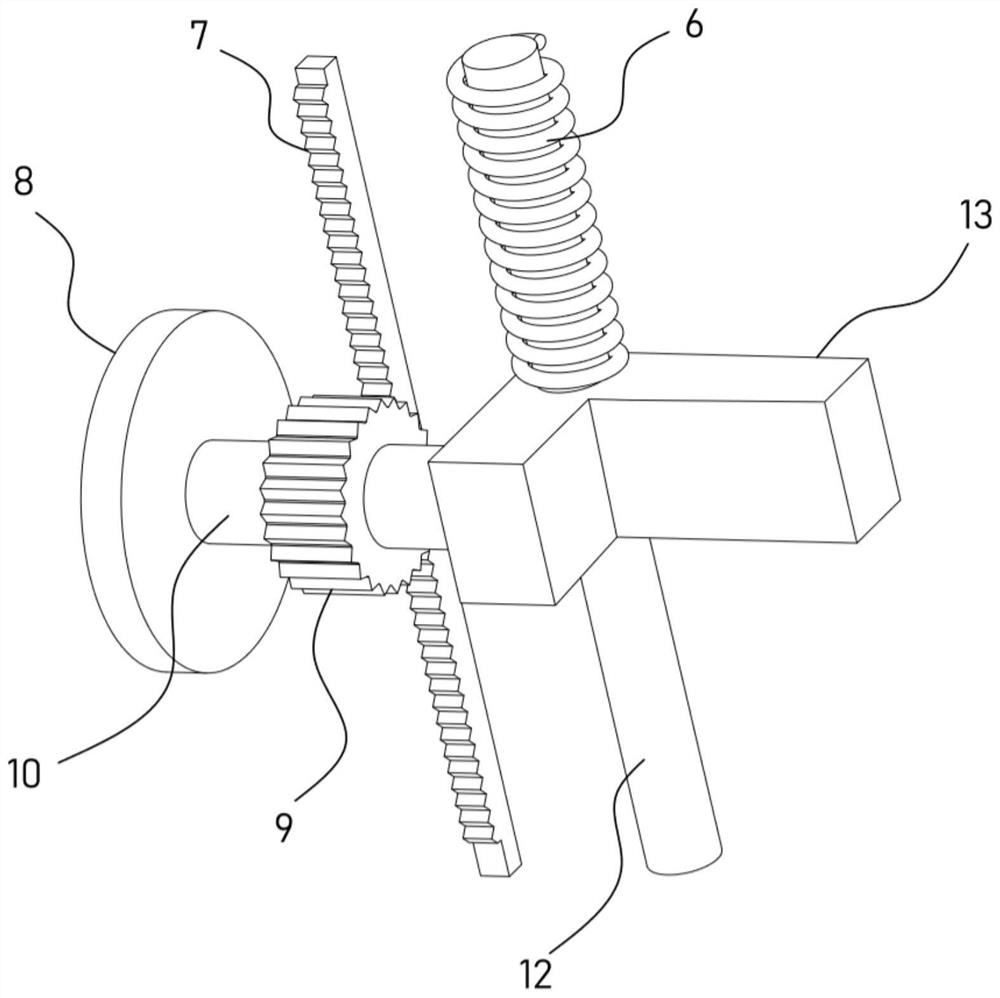

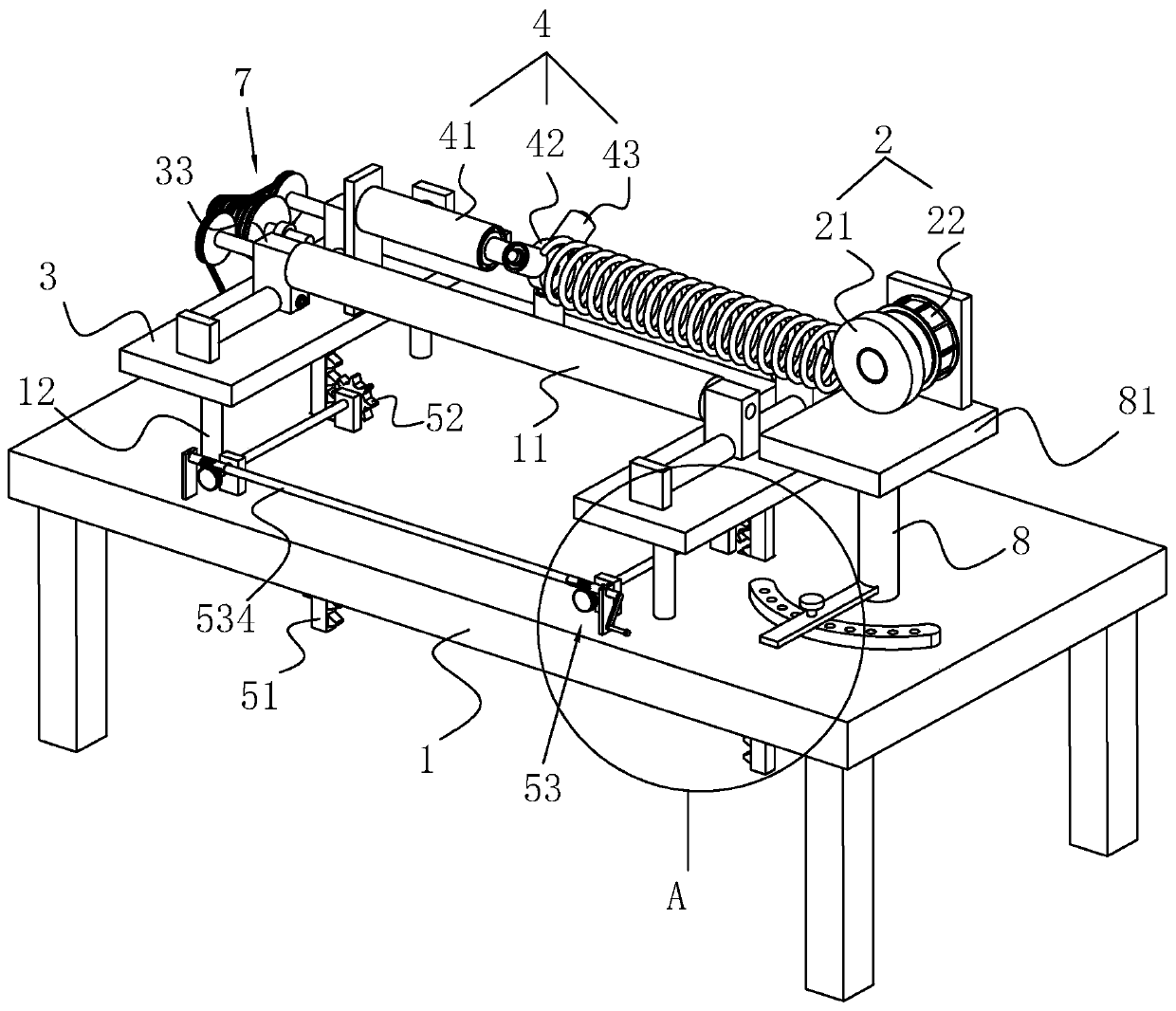

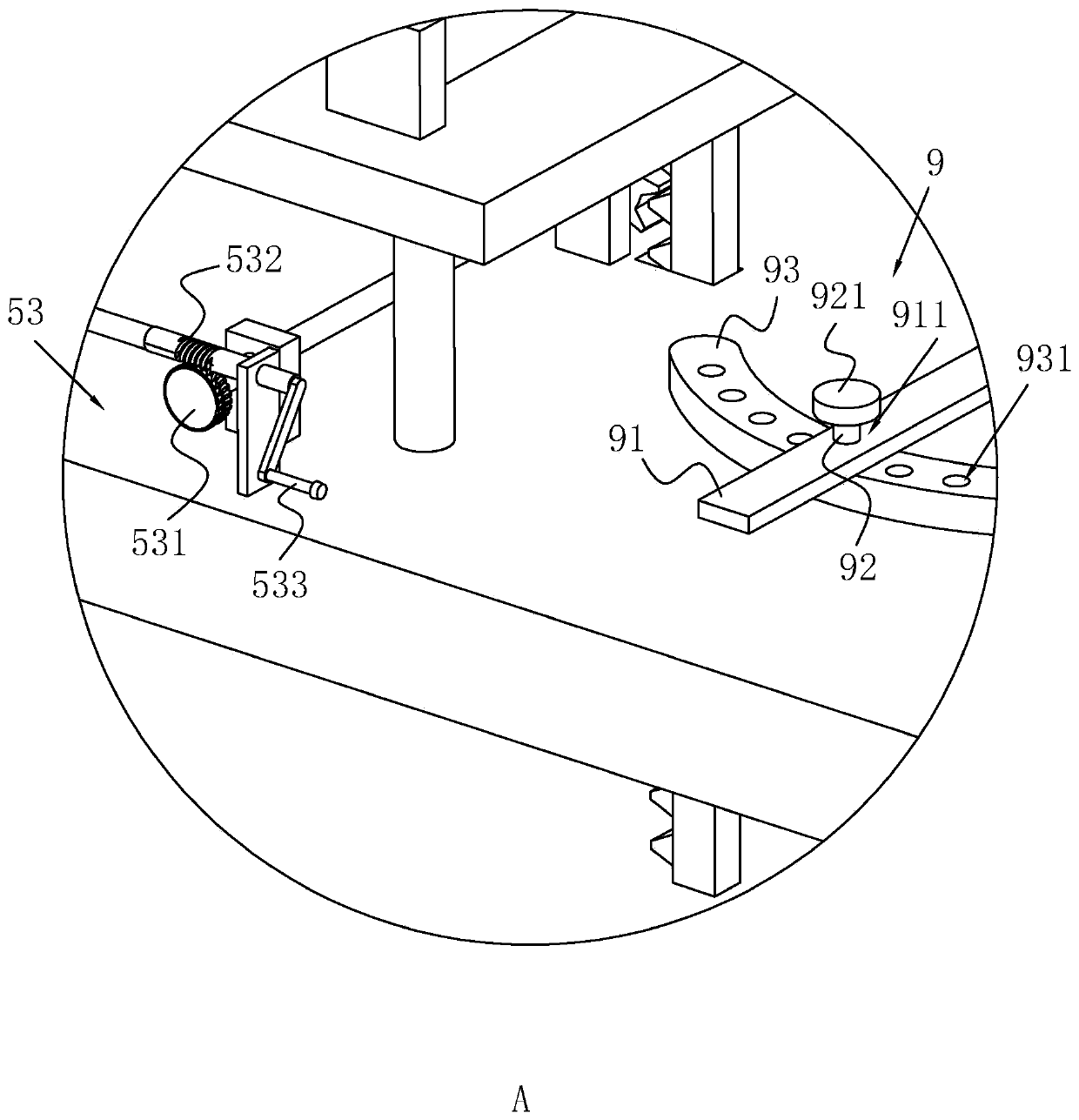

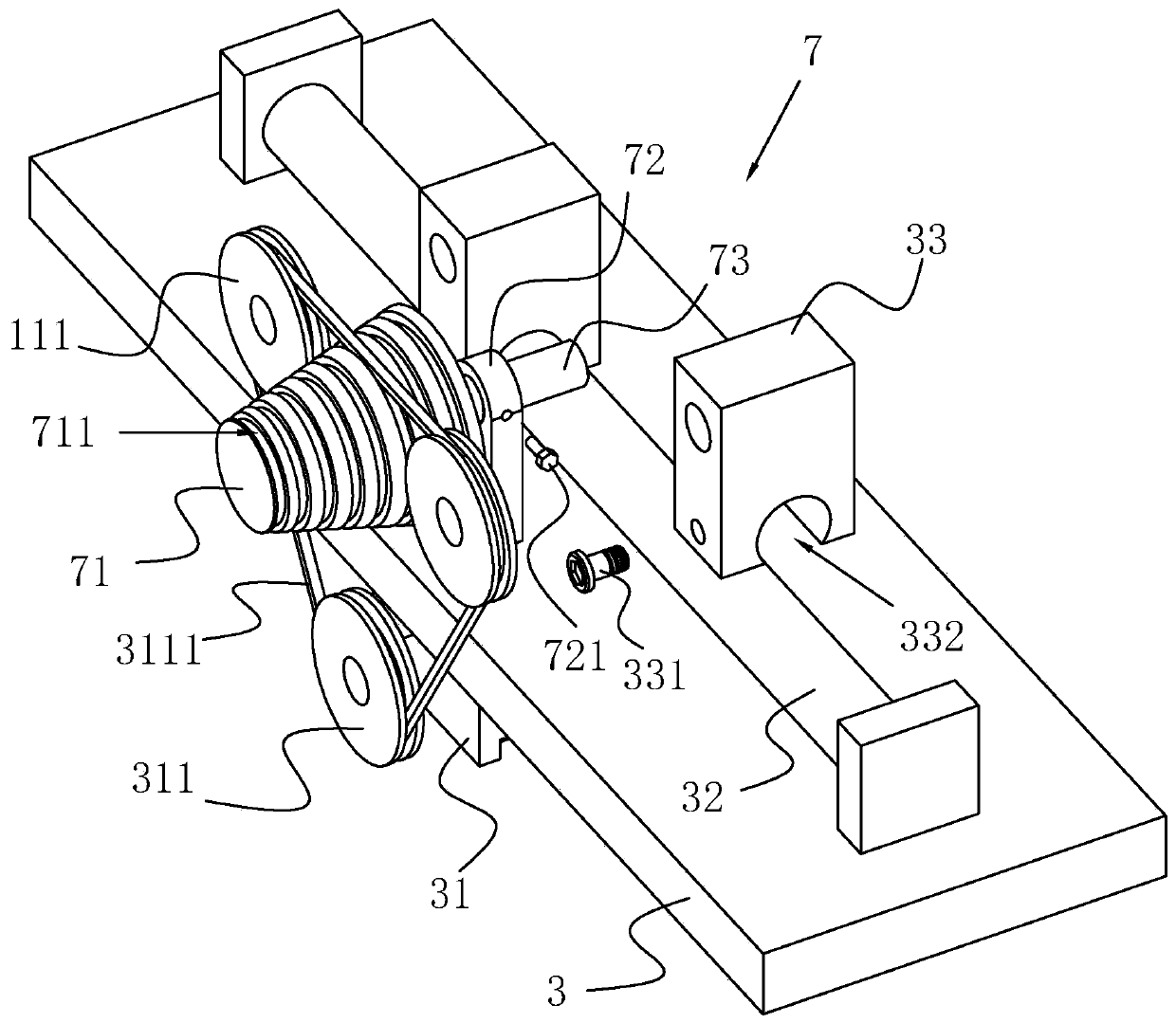

Spring end face grinding device and grinding method thereof

InactiveCN111037389ALower the altitudeImprove grinding performanceGrinding carriagesGrinding drivesElectric machineryEngineering

The invention relates to a spring end face grinding device and a grinding method thereof, and belongs to the technical field of spring grinding. The spring end face grinding device comprises a bottomplate, wherein a grinding assembly used for grinding a spring is arranged on the bottom plate, and the grinding assembly comprises a grinding wheel and a rotating motor; a mounting plate is arranged on the bottom plate, an abutting assembly used for abutting against one end, away from the grinding assembly, of the spring is arranged on the mounting plate, two rotating rollers are horizontally arranged on the mounting plate, and a driving source for driving the rotating rollers to rotate is arranged on the mounting plate; and a lifting assembly used for driving the mounting plate to ascend anddescend is arranged on the bottom plate. When a larger spring is polished, the mounting plate is driven to move downwards through the lifting assembly to reduce the height of the spring, and then theabutting assembly abuts against the spring; and the height of the spring is adjusted, so that the grinding position of the spring and the center of the grinding wheel are on the same horizontal line,the grinding effect of the grinding wheel on the spring is improved, radial jumping of the spring in the grinding process is reduced, and the grinding quality is effectively improved.

Owner:CHENGDU CHENHUI SPRING MFG

Handheld pipeline groove bionic polishing device

InactiveCN108747748ARealize front and rear stretchingLarge turning diameterEdge grinding machinesPortable grinding machinesHand heldEngineering

The invention discloses a handheld pipeline groove single-face polishing device which comprises a power device, a polishing device body and a tight-supporting device. The power device is fixedly connected with the tight-supporting device through a fixing pipeline. A rotating shaft I is arranged on the fixing pipeline in a sleeving mode and connected with the polishing device body through a bracket. The power device is in driving connection with the rotating shaft I. The polishing device body comprises a frame, a movable plate I, a movable plate II, a polishing piece, an inflation pipe I and two airbags I. The polishing device body is partially fixed to the rotating shaft and can rotate along with the rotating shaft to form revolution, and in this way, a pipe orifice of the whole pipeline can be polished at a time; through an adjustable telescopic rod arranged at the front end of a transverse rod, the polishing assembly can extend and retract in the front-rear direction, and the applicable range is expanded; and the bracket further be positioned in an up-down extending and retracting mode, and the revolution diameter of a polishing assembly is increased, so that the handheld pipeline groove single-face polishing device is applied to different pipeline diameters, and practicability and universality are improved.

Owner:潍坊高航机械科技有限公司

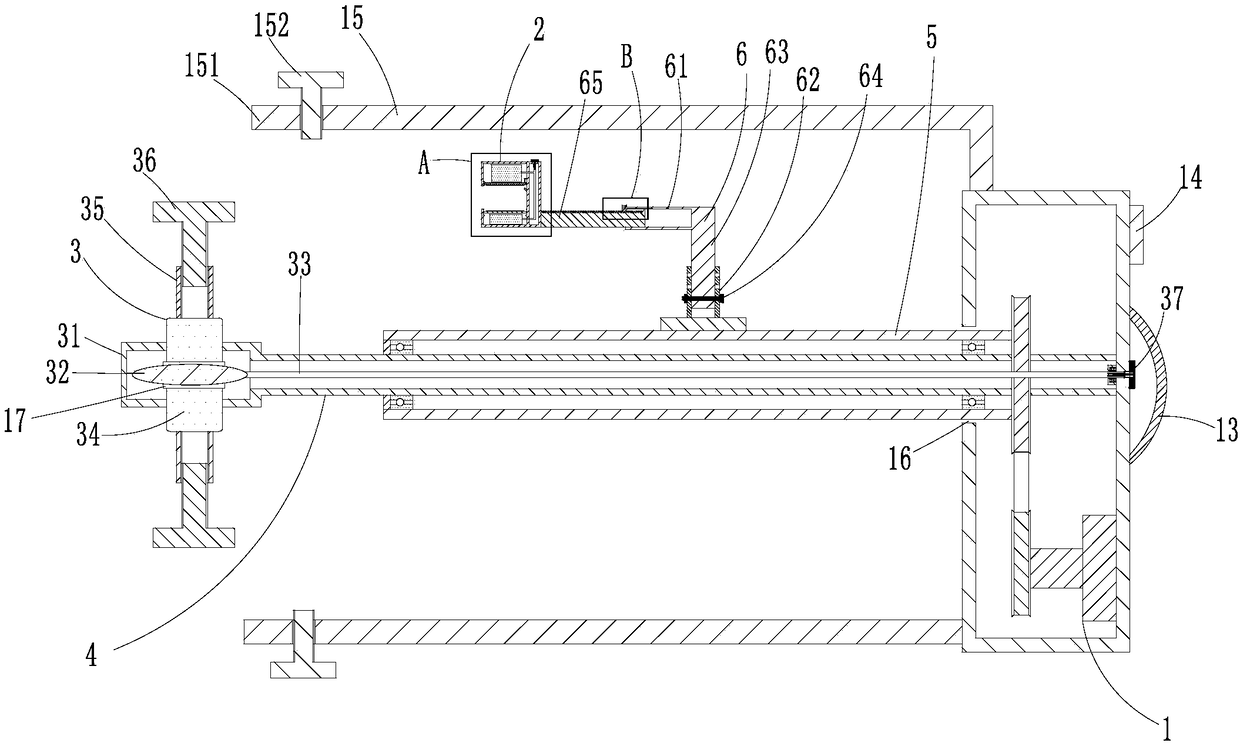

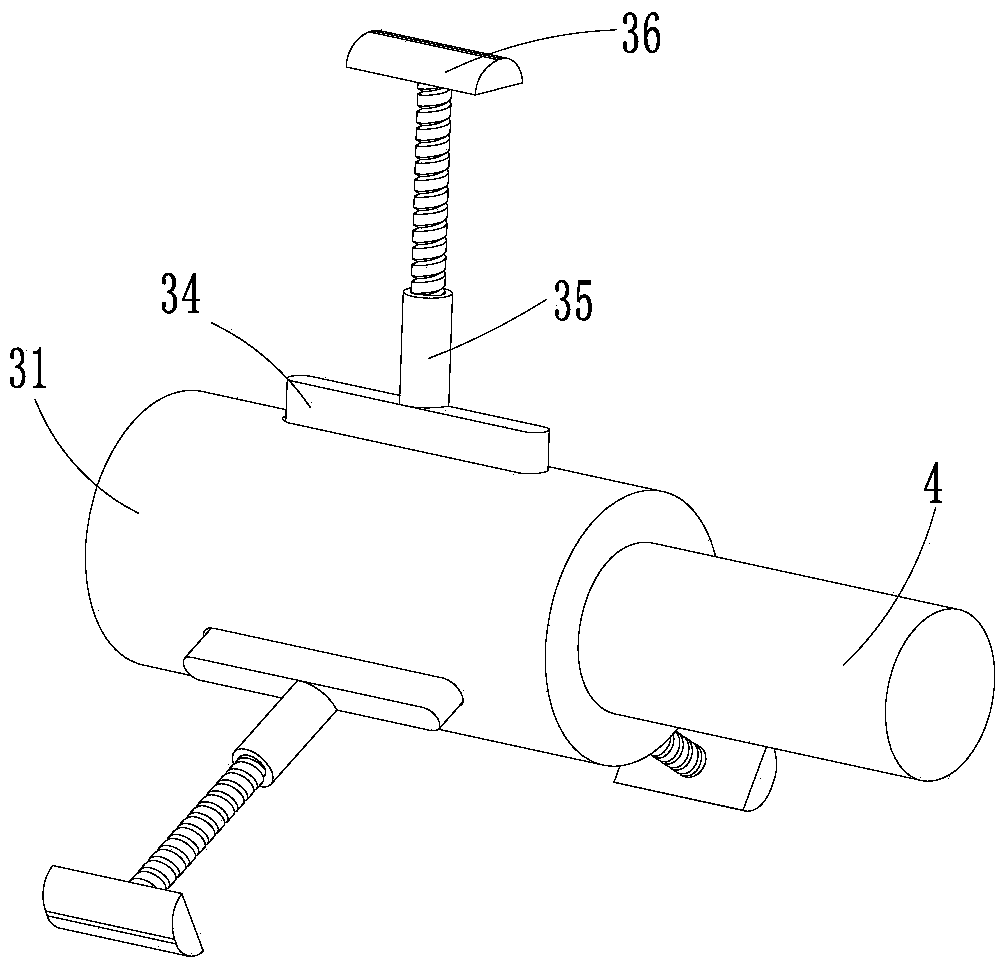

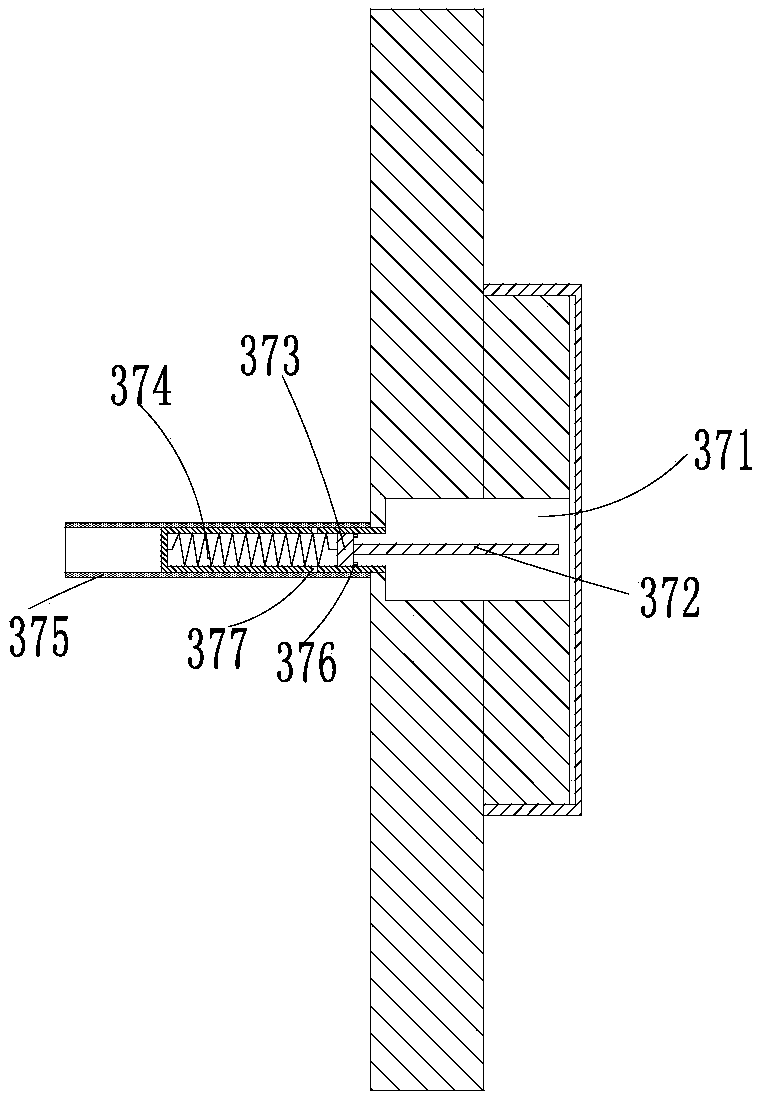

Automobile exhaust pipe welding forming post-processing equipment and post-processing method

InactiveCN113103082ARealize the function of secondary fine grindingRealize the function of preliminary grindingPolishing machinesRevolution surface grinding machinesMechanical engineeringExhaust pipe

The invention relates to automobile exhaust pipe welding forming post-processing equipment and a post-processing method. The automobile exhaust pipe welding forming post-processing equipment comprises a base, a fixing device and a polishing device, the lower end of the base is connected with the existing ground, and the fixing device and the polishing device are sequentially installed at the upper end of the base from front to back. Through cooperation of fixing rings, limiting bolts and arc-shaped blocks, automobile exhaust pipes can be fixed, the situation that the welded and formed automobile exhaust pipes deviate and shake in the polishing process is avoided, and the distance between the arc-shaped blocks can be adjusted by adjusting the limiting bolts, so that the equipment can fix the exhaust pipes with different diameters, and then the exhaust pipes with different diameters can be polished.

Owner:王小前

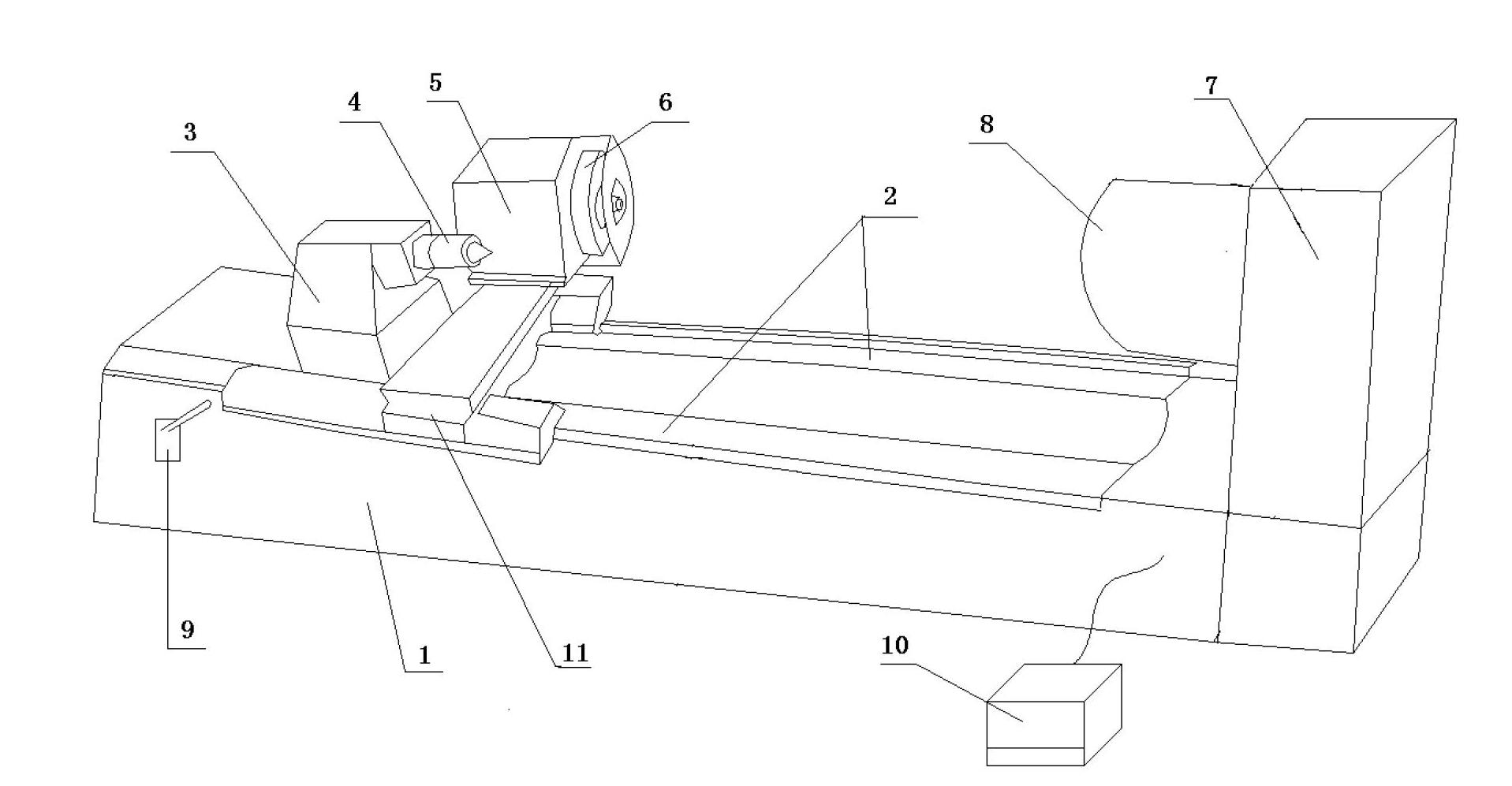

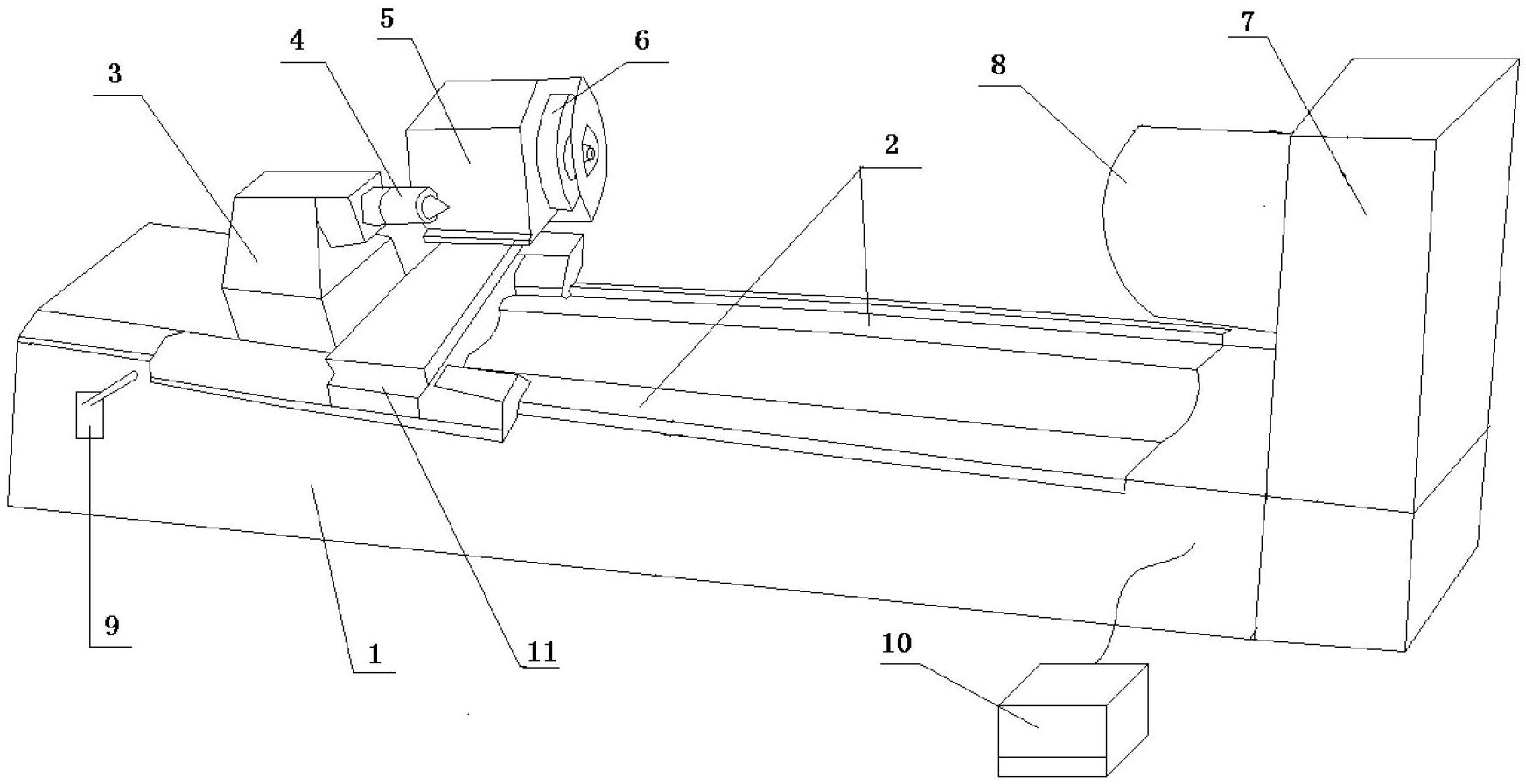

Rubber roll grinding device

InactiveCN102632439ASimple structureEasy to useRevolution surface grinding machinesSlide plateBench grinder

The invention provides a rubber roll grinding device, which comprises a machine seat, wherein two sides of the machine seat are provided with sliding rails, the front end of the machine seat is provided with a machine head front seat, a rotating shaft is arranged on the machine head front seat, a sliding plate is arranged on the sliding rails, one end of the sliding plate is provided with a grinding wheel machine, a grinding belt is arranged on the grinding wheel machine, the back end of the machine seat is provided with a machine head back seat, a rubber roll fixing device is arranged on the machine head back seat, and a part of the machine seat side surface near the sliding rails is provided with an emergency switch. The rubber roll grinding device has the beneficial effects that a rubber roll is ground in the mode of the autoroatation of the rubber roll and the forward and backward movement of the grinding wheel machine, after the grinding wheel machine completes the movement along the length of the rubber roll, the sliding plate touches the emergency switch, the grinding is stopped, and when accidents occur in the grinding process, workers can pedal a foot pedal switch by feet to stop the machine operation. The rubber roll grinding device has the advantages that the structure is simple, the use is convenient, the maintenance is convenient, the grinding is stable, the precision is high, the grinding efficiency is improved, and the like.

Owner:COMC TIANJIN CO LTD

Substrate holding apparatus, polishing apparatus, and polishing method

ActiveUS20080318499A1Substrate to be polished stablyEffective preventionPolishing machinesRevolution surface grinding machinesAbutmentMagnet

Owner:EBARA CORP

Tempered glass forming processing system

InactiveCN112171464AIncrease contact areaGrinding stabilityGrinding drivesBelt grinding machinesStructural engineeringToughened glass

The invention provides a tempered glass forming processing system. The tempered glass forming processing system comprises a bottom plate, a fixing device and a grinding device. The lower end face of the bottom plate is fixed to the existing ground, the fixing device is arranged on the upper end face of the bottom plate, and the grinding device is arranged below the fixing device. According to thetempered glass forming processing system, through mutual cooperation of a cylinder, a piston, I-shaped air bags and a ventilation pipe, the I-shaped air bags can deform; and through mutual cooperationof the I-shaped air bags, movable rods, I-shaped wheels and rubber belts, the I-shaped air bags can drive the I-shaped wheels and the rubber belts to expand and deform towards the two ends when expanding, so that the contact area between the rubber belts and the surface of glass is increased, the friction force between the rubber belts and the surface of the glass is increased, the glass is morestable in the grinding process, and the tempered glass forming processing system can adapt to glass of various specifications by changing the expansion degree of the I-shaped air bags.

Owner:李阳

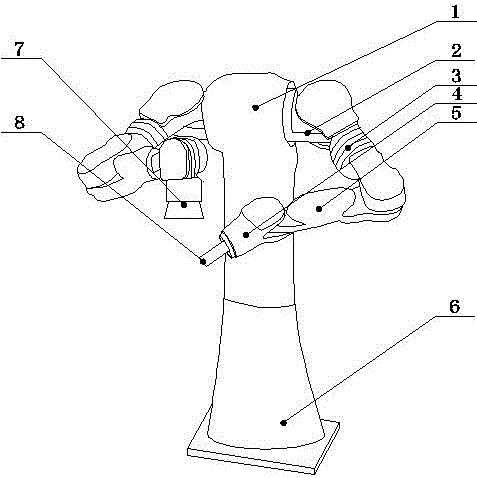

Grinding robot

InactiveCN106113060AExtended service lifeImprove grinding efficiencyManipulatorGrinding/polishing safety devicesCold airEngineering

The invention discloses a grinding robot which comprises a base and a waist seat; a left mechanical arm and a right mechanical arm are arranged on the two sides of the upper part of the waist seat respectively; each of the left mechanical arm and the right mechanical arm comprises a first main arm, a second main arm, a third main arm and an operation head; the first main arms are hinged to the second main arms; the second main arms are hinged to the third main arms; the third main arms are hinged to the rear ends of the operation heads; the front end of the operation head of the left mechanical arm is connected with a grinding disc; and an air nozzle is formed in the front end of the operation head of the right mechanical arm. The grinding robot can remove chips generated by grinding immediately, so that the grinding efficiency can be improved, the service life of the grinding disc can be increased effectively, daily loss can be reduced, and the expenditure can be lowered. Refrigerating equipment is arranged in the waist seat, and a cold air outlet pipe of the refrigerating equipment communicates with the air nozzle, cold air jetted by the air nozzle can blow away the scattered chips, and can cool to-be-ground goods, and damage of high temperature, generated by high-speed friction of the grinding disc, to the to-be-ground goods is avoided.

Owner:弘毅天承知识产权股份有限公司

Efficient glass edge grinding device with protection function

InactiveCN109500687AWith protective functionGrinding stabilityEdge grinding machinesGrinding drivesSlagEngineering

The invention relates to the technical field of glass processing, and discloses an efficient glass edge grinding device with a protection function. The efficient glass edge grinding device comprises aworking table, wherein a cross column is fixedly arranged at the top of the working table, the top of the cross column is fixedly provided with a slag groove, the top of the cross column is fixedly connected with a machine case, a first motor is fixedly installed inside the machine case, and an output shaft of the first motor is fixedly connected with a rotating shaft. The efficient glass edge grinding device with the protection function effectively improves the stability of glass clamping, the glass can be adjusted according to the glass with different thicknesses, the application range is widened, the grinding of the glass is finer, so that the grinding quality of the glass is improved, the grinding efficiency is greatly improved, the safety performance of the grinding device can be improved, so that the self protection performance is improved, and accidental damage to workers caused by unstable potential safety hazards is avoided.

Owner:ANHUI HUAYAO GLASS

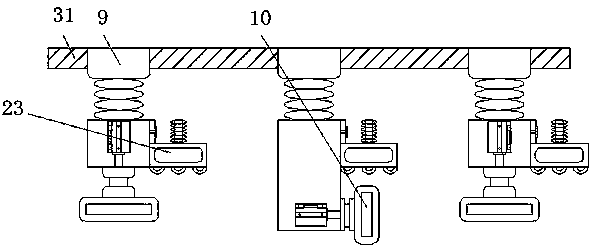

Automatic grinding and polishing device for high speed rail sleeper production

InactiveCN108406516ASave human effortGrinding speed is fastGrinding carriagesGrinding machinesEngineeringWater spray

The invention relates to an automatic grinding and polishing device for high speed rail sleeper production. The device comprises a supporting foot and a second transverse grinding stone; a waste box is arranged on the right side of the supporting foot, a containing table is arranged at the upper end of the supporting foot, a supporting frame is fixed to the two sides of the upper end of the containing table, water tanks are arranged on the two sides of the upper end of the interior of the supporting frame, telescopic water pipes are connected to the lower ends of the right sides of the water tanks, water spraying heads are embedded on the lower ends of the telescopic water pipes, and the second transverse grinding stone is arranged on the right sides of first transverse grinding stones. Transverse sliding blocks slide on a second transverse sliding rail, three first transverse grinding stones and a longitudinal grinding stone are driven to slide on the second transverse sliding rail left and right, the first transverse grinding stones and the longitudinal grinding stone can carry out sliding grinding on a sleeper on the second transverse sliding rail, sliding of the first transverse grinding stones and the longitudinal grinding stone does not need to be manually controlled, manpower is saved, the grinding speed is increased, and grinding is more uniform.

Owner:DONGGUAN UNIV OF TECH

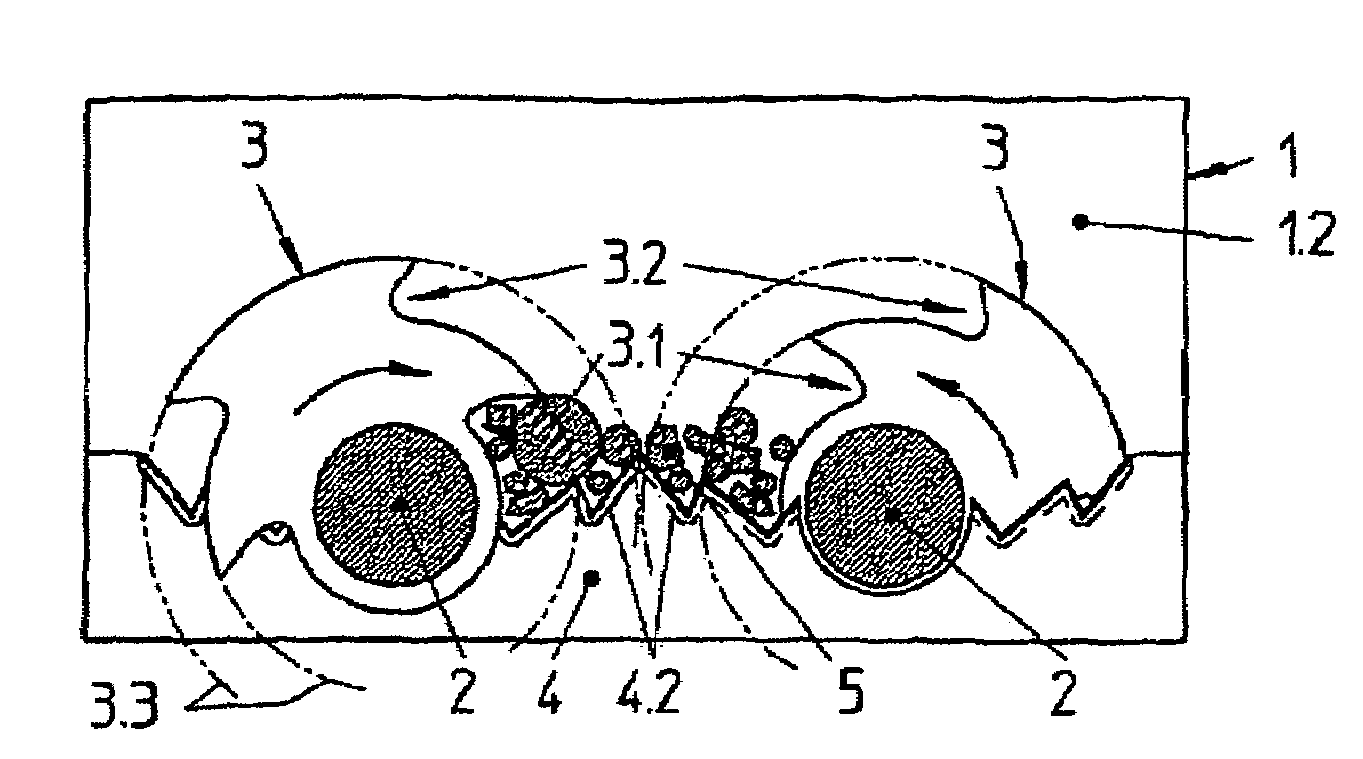

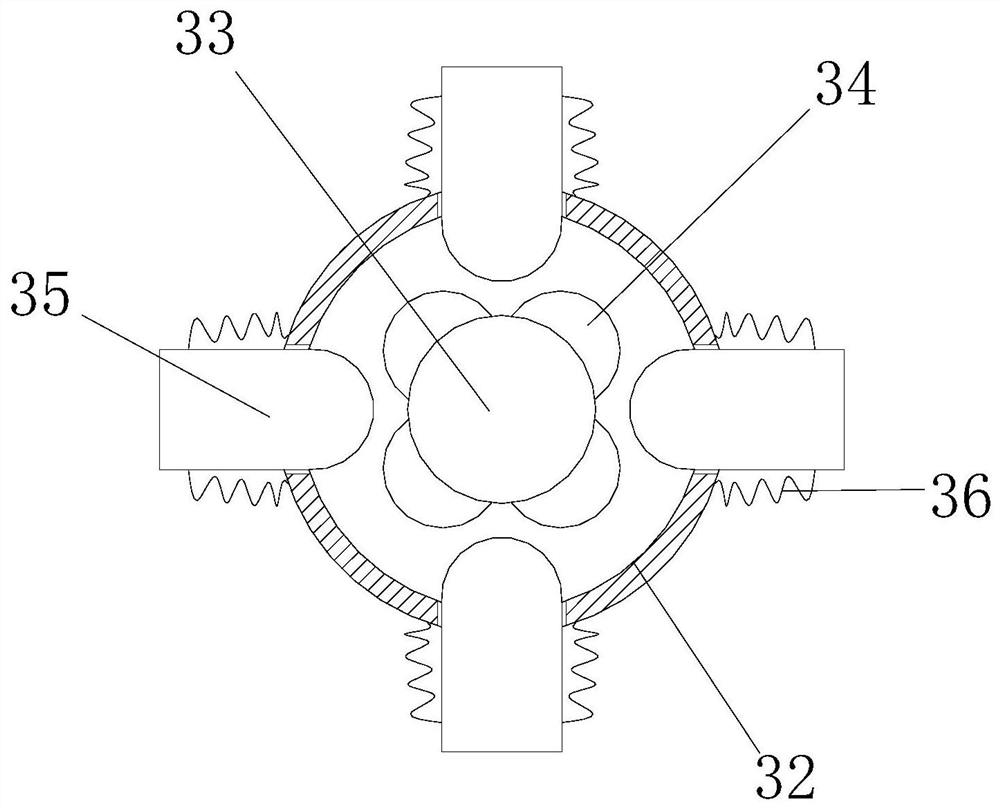

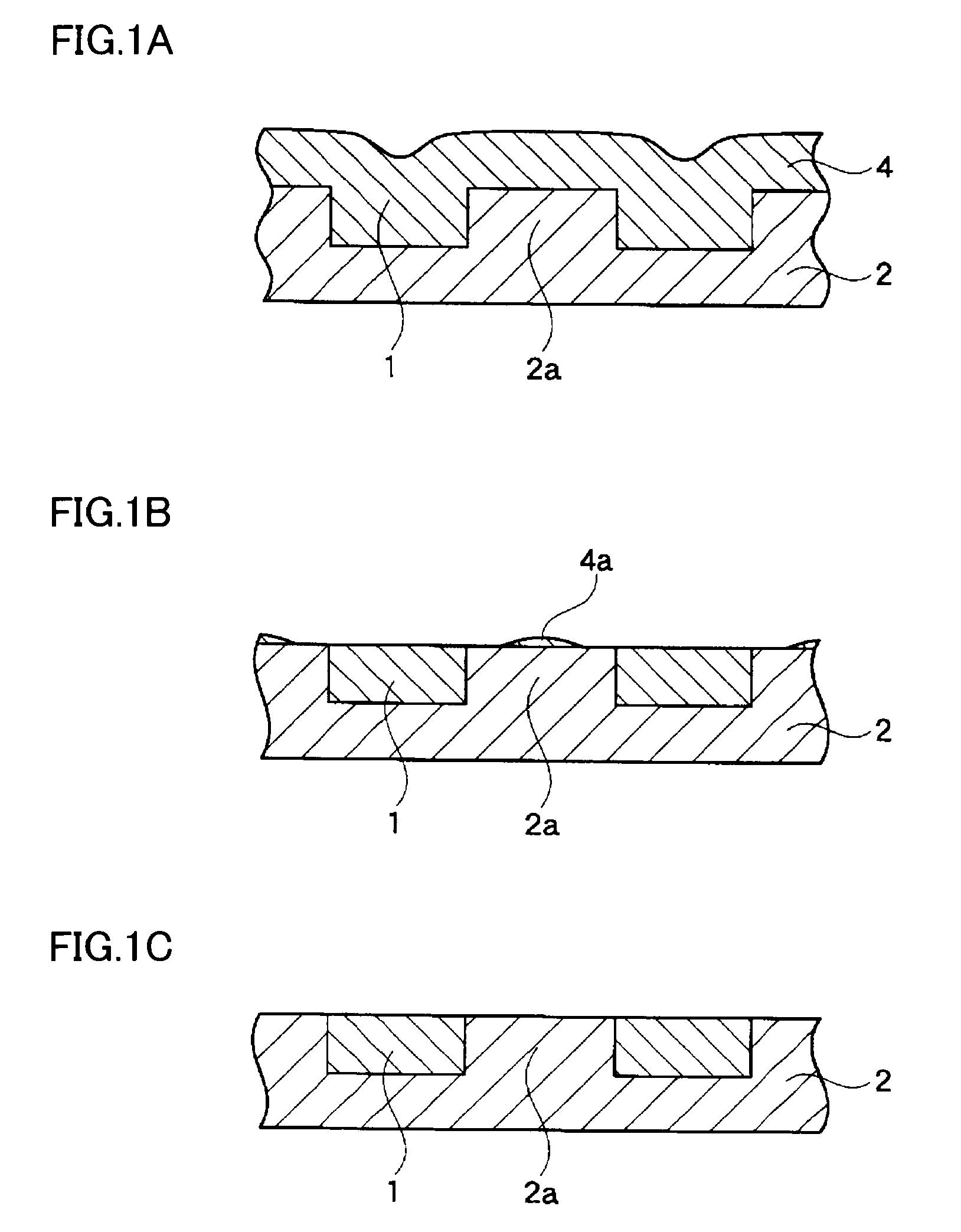

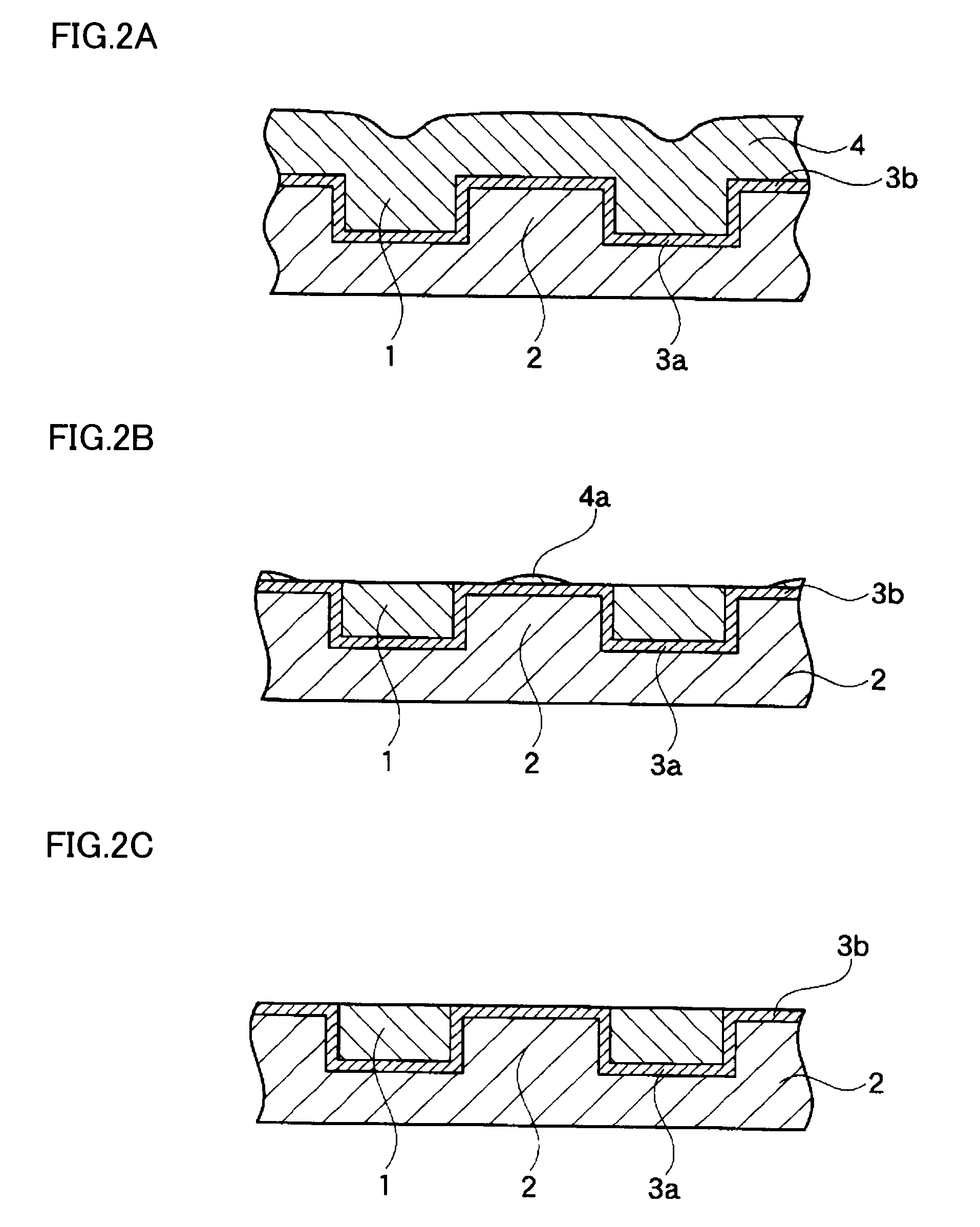

Grinding machine and method of grinding material

InactiveUS7237739B2Grinding stabilityReduce power consumptionCocoaGrain treatmentsEngineeringMechanical engineering

The invention relates to a grinding machine for all kinds of material, the machine comprising: a receiving element for the material (5); at least one shaft (2) positioned in the housing (1) and provided with grinding tools (3); rigid cutting tools (4) which are arranged in the housing (1) and against which the grinding tools (3) operate, grinding the material (5) with specifically low forces. To this end, the grinding tools (3) comprise cutting regions (3.1, 3.2) within which an inner cutting region (3.1) can take a large amount of material (5) to be ground and grind the same, thus comprising a small lever arm, and an outer cutting region (3.2) can take a smaller amount of material (5) to be ground and grind the same, thus comprising a large lever arm. According to the invention, the rigid cutting tools (4) are provided with teeth (4.2) having profiles (4.3) which cooperate with one of the cutting regions (3.1, 3.2), a first transversal edge (3.4) of the grinding tools (3) being oriented towards a second transversal edge (4.4) of a tooth (4.2) of the rigid cutting tools (4) in such a way that it cuts past the same.

Owner:METABO LINDEMANN GMBH

Grinding machine

InactiveCN105945725AImprove sanding qualitySimple structureGrinding work supportsBarrel ShapedEngineering

The invention relates to a grinding machine which comprises a base and a grinding machine body installed on the base. A motor is arranged in the grinding machine body. An output shaft of the motor stretches out of the grinding machine body, and a grinding wheel is fixed to the output shaft of the motor. A support is fixed to the base and comprises a vertical rod and a horizontal rod. The horizontal rod is in threaded connection with a stand rod. The bottom end of the stand rod is detachably connected with a clamp assembly. The clamp assembly comprises a support seat and a clamp seat connected with the support seat. The clamp seat comprises a circular truncated cone shaped seat and a barrel-shaped seat which are integrally formed and arranged up and down. At least two adjusting bolts are arranged on the circumference of the barrel-shaped seat. According to the grinding machine, a workpiece is installed in the barrel-shaped seat, and the height of the stand rod can be adjusted by rotating the stand rod, so that pressure between the workpiece and the grinding wheel is adjusted to guarantee the smooth proceeding of grinding. The outer diameter of a first cylindrical seat is greater than that of a second cylindrical seat; when the workpiece in the barrel-shaped seat needs to be replaced, the first cylindrical seat is supported by a replacement platform by rotating the barrel-shaped seat, supporting is stable and firm, and shaking is avoided.

Owner:SUZHOU BOLAIXI ELECTRICAL APPLIANCE CO LTD

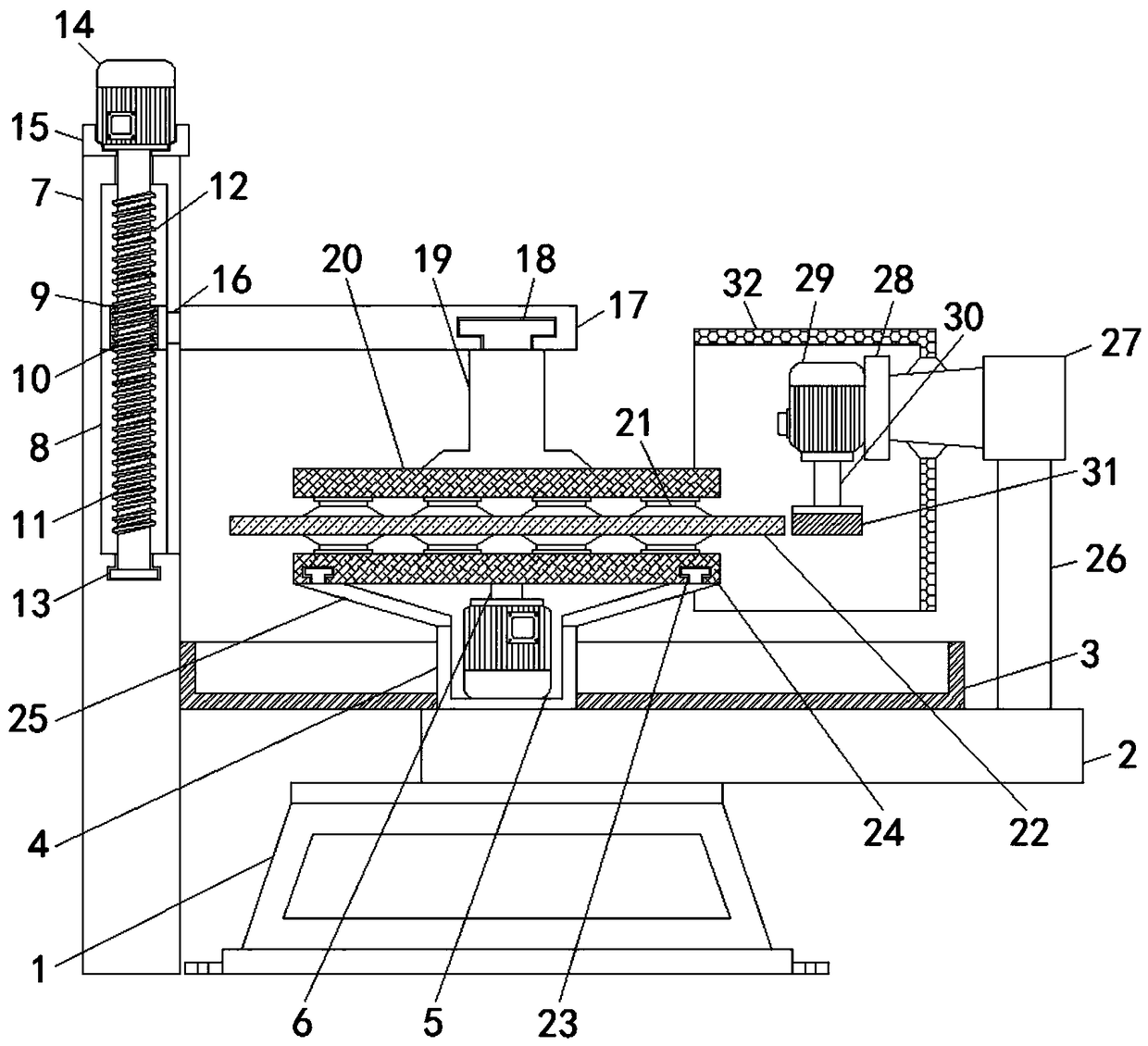

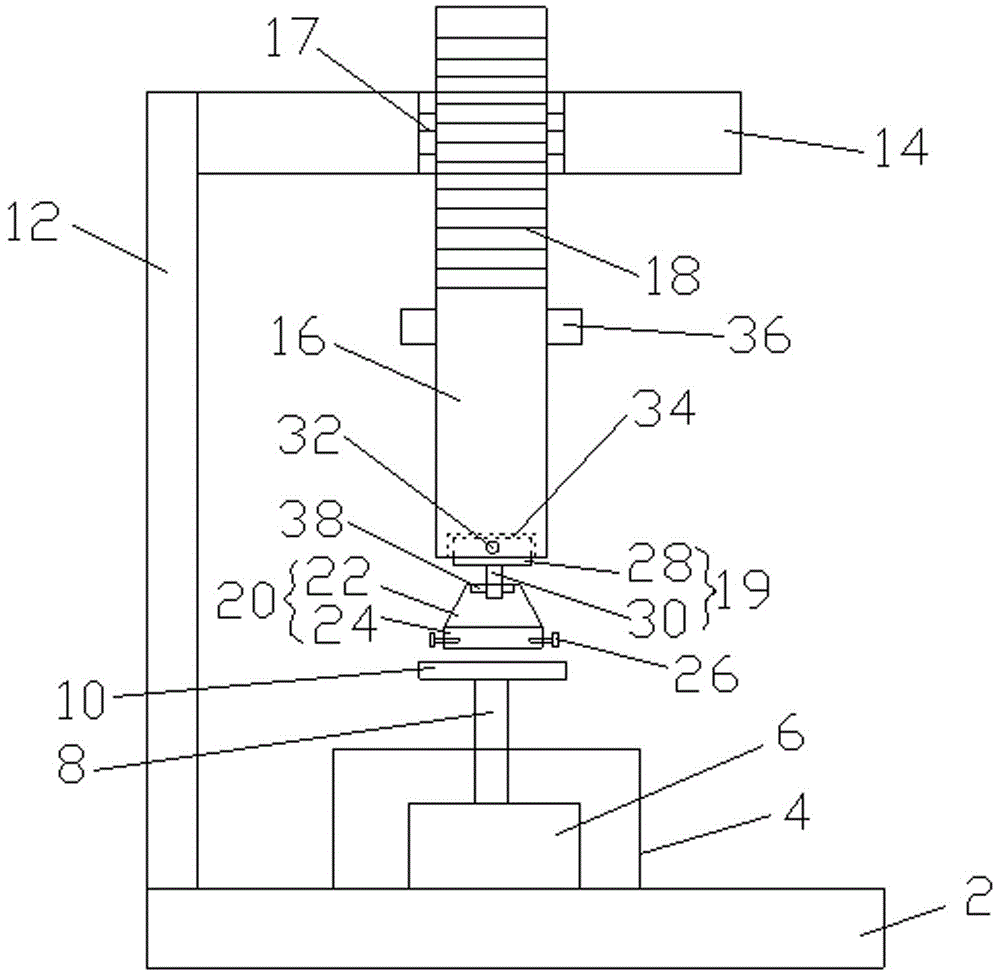

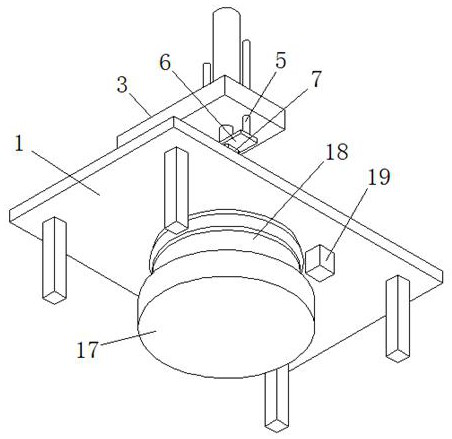

Numerical control device for flexible constant-pressure grinding of top part of cylinder block casting

InactiveCN110125779AGrinding pressure controllableStable grinding processGrinding carriagesGrinding drivesEngineeringCylinder block

The invention discloses a numerical control device for flexible constant-pressure grinding of the top part of a cylinder block casting. The numerical control device comprises a base; the base is provided with an X-axis sliding table; the X-axis sliding table is provided with a Y-axis sliding table; the Y-axis sliding table is provided with a numerical control rotary table; the numerical control rotary table is fixedly provided with a to-be-ground workpiece; the base is further provided with pillars; a cross beam is arranged on the pillars; the cross beam is provided with pulleys; a pull rope passes across the pulleys; one end of the pull rope is connected with a weight; the weight is put on a weighing sensor; the weighing sensor is arranged on the pillar through a sliding table; the otherend of the pull rope is connected with a grinding head sliding table; the grinding head sliding table is provided with a grating ruler; the grinding head sliding table is fixedly provided with a grinding head motor; an output shaft of the grinding head motor is connected with a grinding head; and the grinding head is located above the to-be-ground workpiece. The device disclosed by the invention is controllable in grinding pressure, is capable of realizing constant-pressure grinding, has a stable grinding process and is high in quality; and a grinding allowance can be set, so that even if castings of the same workpieces are greatly different in size, the same grinding allowance can be guaranteed.

Owner:CHANGZHOU INST OF TECH

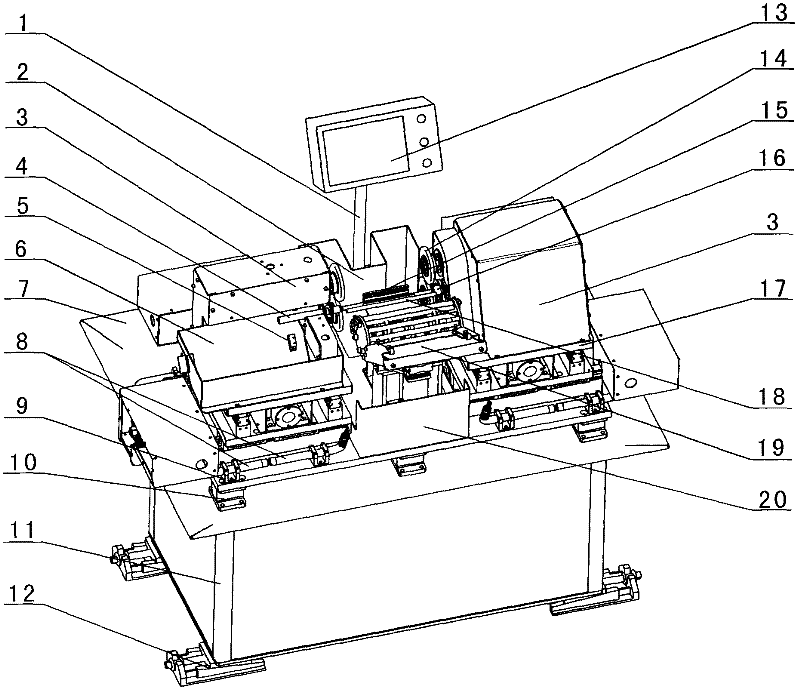

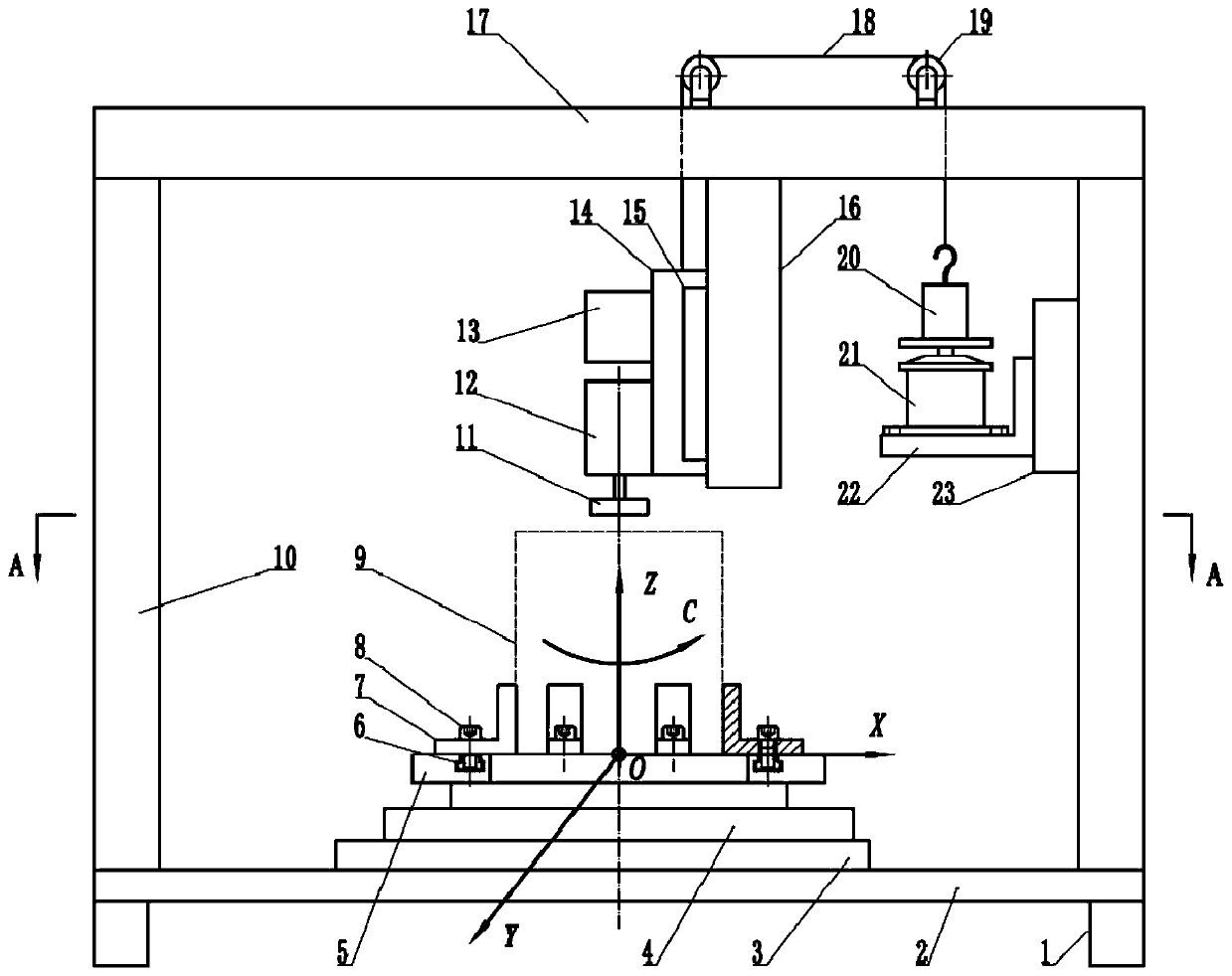

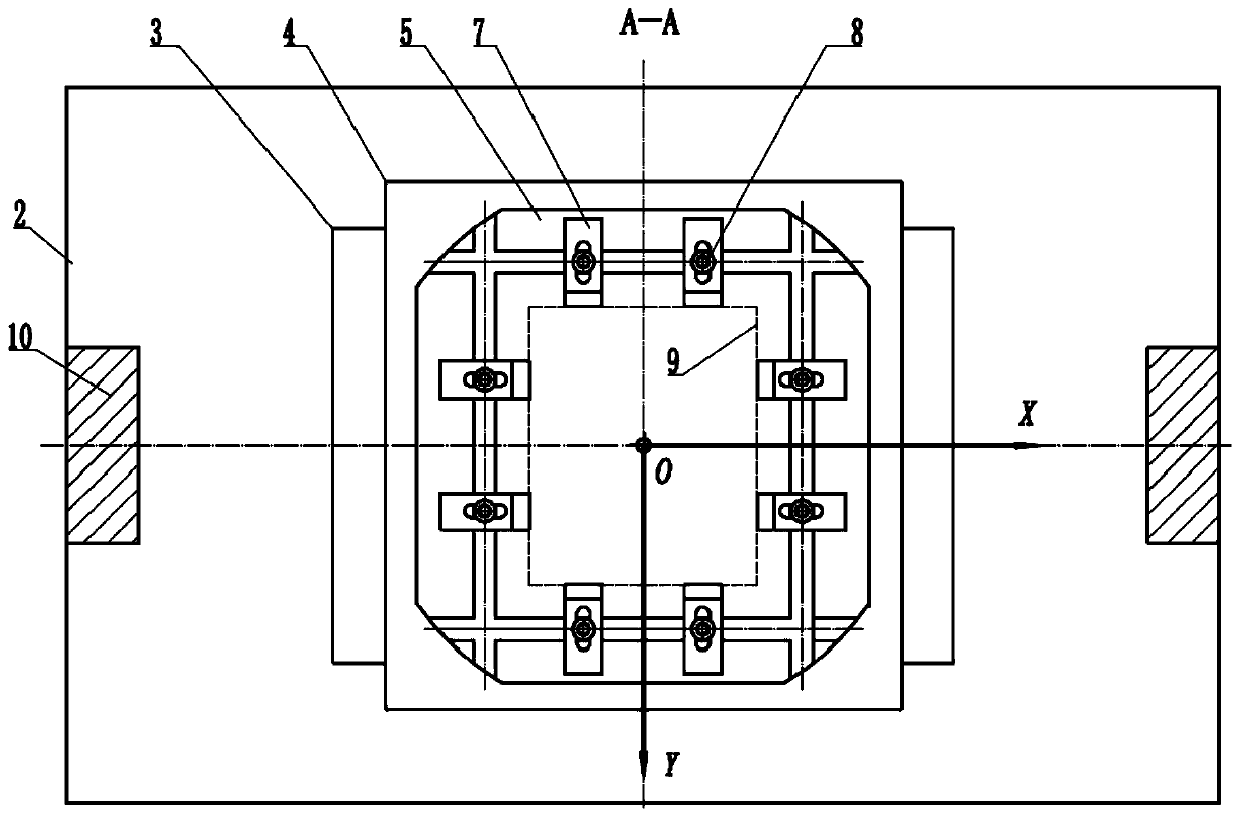

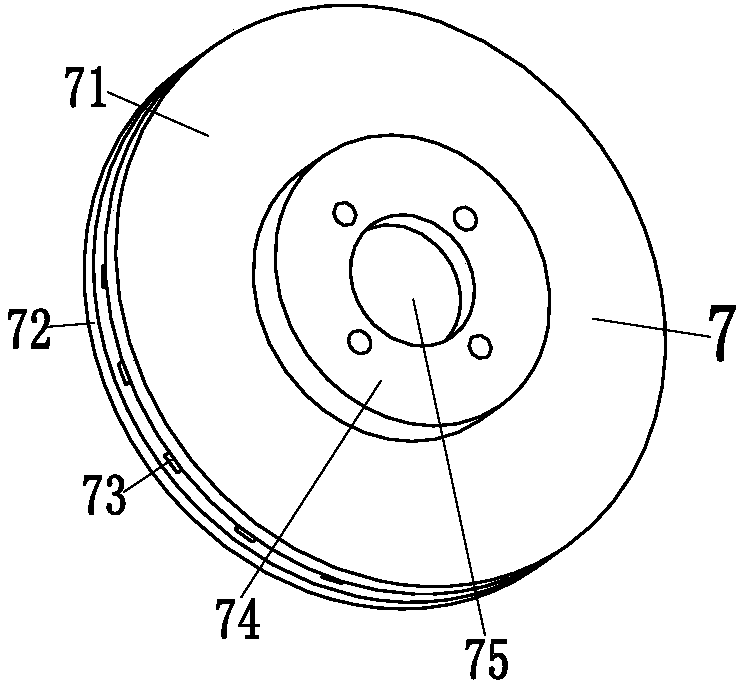

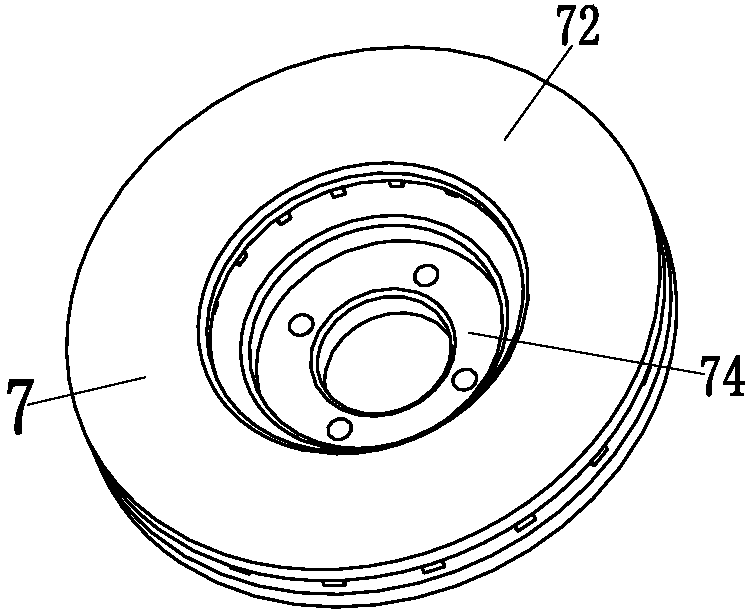

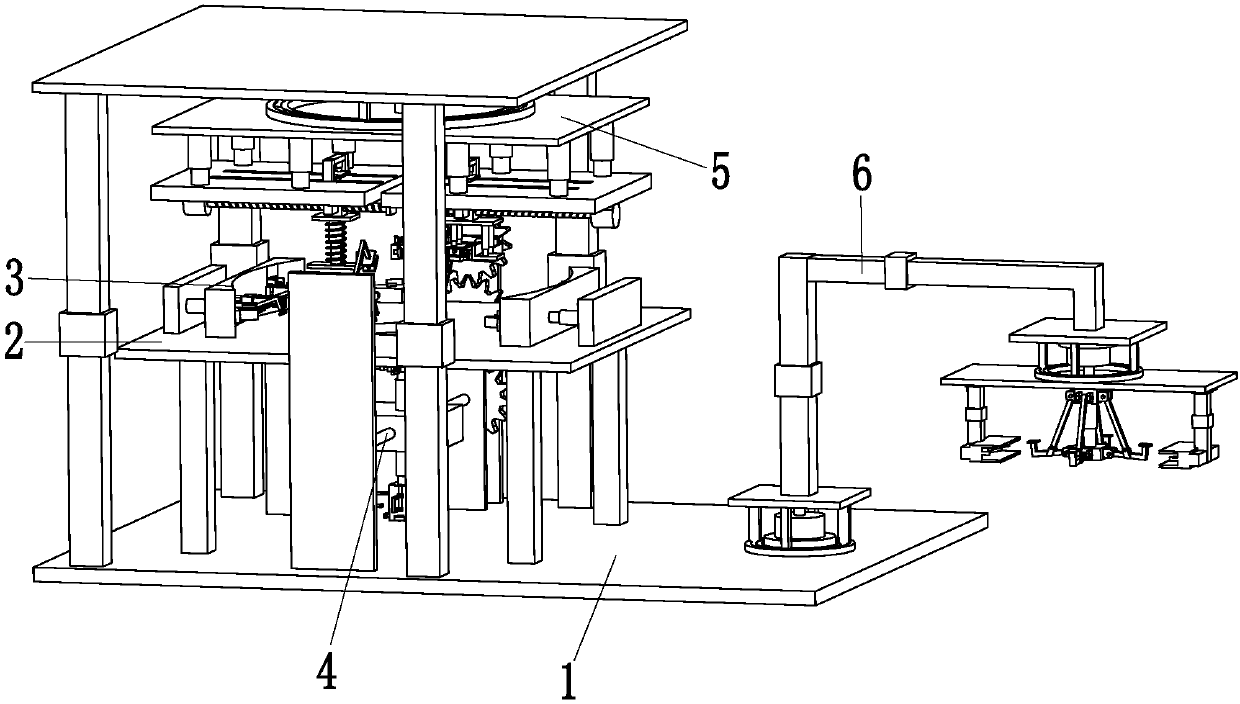

Brake disc machining machine with hoisting, fixing and grinding functions for electric automobile brake system

InactiveCN108098542AGrinding stabilityEasy to fixEdge grinding machinesGrinding carriagesEngineeringMachining

The invention relates to a brake disc machining machine with hoisting, fixing and grinding functions for an electric automobile brake system. The brake disc machining machine comprises a supporting bottom plate, a supporting connecting frame, fixing devices, a transposition device, a grinding device and a hoisting device; the supporting connecting frame is installed on the top part of the left endof the supporting bottom plate; the left side and the right side of the top part of the supporting connecting frame each are provided with one fixing device; the transposition device is located on the outer sides of the fixing devices, and the transposition device is connected with the supporting bottom plate; the grinding device is located above the fixing devices, and the grinding device is installed on the top part of the supporting bottom plate; and the top part of the right end of the supporting bottom plate is provided with the hoisting device. According to the brake disc machining machine, the problems that fixing of a brake disc is not stable, fixing cannot be carried out on different types of brake discs, the brake disc needs to be transposed manually, potential hazards exist when the ground brake disc is taken manually, the grinding effect is poor, and the brake disc needs to be carried manually when the electric automobile brake disc is ground in an existing factory can besolved.

Owner:刘秀娟

Dust treatment device for automobile brake disc grinding

InactiveCN113601365AEasy to handleSolve the phenomenon of random flyingGrinding carriagesGrinding drivesBrakeElectric machinery

The invention provides a dust treatment device for automobile brake disc grinding, and relates to the field of automobiles. The dust treatment device comprises a supporting frame, a fixing plate is fixedly mounted on the upper surface of the supporting frame, a supporting plate is fixedly mounted at the top end of the fixing plate, a telescopic device is fixedly mounted on the upper surface of the supporting plate, the bottom end of the telescopic device penetrates through the supporting plate, a mounting plate is fixedly mounted at the bottom end of the telescopic device, and two movable columns are fixedly mounted on the upper surface of the mounting plate. According to the dust treatment device for automobile brake disc grinding, a motor A, a connecting plate, L-shaped plates, movable rods, limiting rods, springs and grinding blocks are used in cooperation, the connecting plate can be driven to rotate by starting the motor A, under the elastic effect of the springs, the grinding blocks can make better contact with the grinding face of a brake disc body, and therefore in the polishing process that the polishing blocks make contact with the polishing surface of the brake disc body, the brake surface of the brake disc body is evenly stressed, and smooth grinding can be conducted.

Owner:杭州安存环保科技有限公司

Surface treatment system for three-way pipe fitting after cast molding

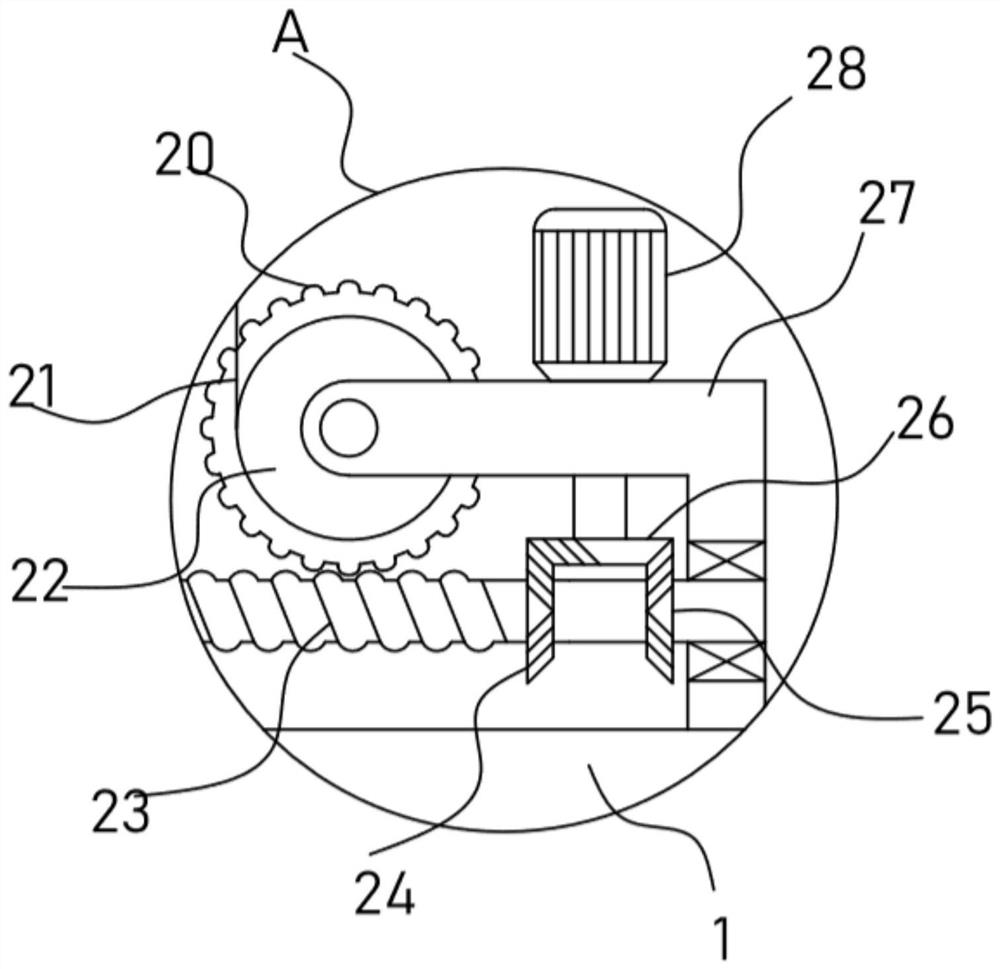

ActiveCN112223023AAchieve fixationGrinding stabilityGrinding carriagesGrinding drivesPipe fittingGear wheel

The invention relates to a surface treatment system for a three-way pipe fitting after casting molding. The surface treatment system for the three-way pipe fitting after casting molding comprises a supporting base, a grinding device, a fixing device, an inner supporting device and an adjusting device, wherein the supporting device is arranged in the middle of the upper surface of the supporting base, the inner supporting device fixedly connected with the supporting base is arranged on the upper side of the supporting device, the adjusting device fixedly connected with the supporting base is arranged on the rear portion of the inner supporting device, and the grinding device is arranged on the front portion of the adjusting device. According to the surface treatment system for the three-waypipe fitting after casting molding, arc-shaped supporting plates can be controlled to be adjusted through the arranged fixing device, so that three-way pipes of different sizes can be fixed; according to the arranged supporting device, attaching plates can slide, so that threads at the upper ends of the attaching plates can be matched with threads on the two sides of the pipe inner walls of the transverse parts of the three-way pipes, and the three-way pipes are more stable in the grinding process; and each driving gear rotates to drive two corresponding half gears to rotate, a correspondingadjusting operation ring is controlled to be opened or closed, and therefore the two sides of each three-way pipe can be conveniently tightly held before grinding.

Owner:徐州志恒伟创仪器包装有限公司

Convenient-to-adjust lifting type vamp polishing device

The invention relates to the technical field of shoes, and discloses a convenient-to-adjust lifting type vamp polishing device. The device comprises a work platform, the left end of the top of work platform is fixedly connected with a mounting base, a driving motor is fixedly mounted on the top of the mounting base, the output shaft of the driving motor is fixedly connected with a screw rod, the surface of the screw rod is in threaded connection with a screw rod sleeve, the right side surface of the screw rod sleeve is fixedly connected with a polishing motor, the output shaft of the polishingmotor is fixedly connected with a rotating shaft, the middle of the surface of the rotating shaft is sleeved with a rotating roller, and the surface of the rotating roller is fixedly connected with afirst polishing block. The convenient-to-adjust lifting type vamp polishing device has the advantages of simple structure and convenient use, and can not only adjust the polishing positions accordingto the different heights of shoes to be polished, so that the polishing effect is better, and the polishing is more convenient, but also better fix a shoe body, the polishing is more stable, and damage to the shoes caused by the case of sliding is prevented from occurring.

Owner:湖南顺康鞋业有限责任公司

Grinding device for producing brake clutch disc

ActiveCN106826477AGrinding stabilityPrevent movementGrinding machinesGrinding work supportsEngineeringBolt connection

The invention relates to a grinding device for production, in particular to a grinding device for producing a brake clutch disc. According to the technical aim, the grinding device for producing the brake clutch disc saves time and labor and is easy to operate, and workers are not likely to be hurt in the grinding process. In order to achieve the technical aim, the grinding device for producing the brake clutch disc comprises a bottom plate, a left side plate, a right side plate, a top plate, a cross plate, a vertical rod and the like. The left side of the top of the base is provided with the left side plate in a bolt connection mode, the right side of the top of the base is provided with the right side plate in a bolt connection mode, lifting devices are arranged on the lower portion of the right side of the left side plate and the lower portion of the left side of the right side plate, and the lifting devices are symmetrically arranged. Plug pins are inserted into a second plug pin hole and a first plug pin hole, a third sliding block can be fixed, then a first motor does not move, and the cross plate can rotate more stably.

Owner:靖江市华信科技创业园有限公司

Chemical mechanical polishing aqueous dispersion, chemical mechanical polishing method using the same, and method of recycling chemical mechanical polishing aqueous dispersion

InactiveUS8652350B2Improve polishing effectGrinding stabilityPigmenting treatmentOther chemical processesOrganic acidCompound (substance)

A chemical mechanical polishing aqueous dispersion includes (A) abrasive grains, (B) an organic acid, and (C1) copper ions or (C2) at least one kind of metal atoms selected from Ta, Ti, and Rb, the chemical mechanical polishing aqueous dispersion including the copper ions (C1) at a concentration of 1×101 to 2×105 ppm, or including the at least one kind of metal atoms (C2) selected from Ta, Ti, and Rb at a concentration of 1×10−1 to 1×103 ppm.

Owner:JSR CORPORATIOON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com