Plate surface polishing and flattening device for building construction

A surface polishing and building construction technology, which is applied in the direction of surface polishing machine tools, grinding drive devices, grinding/polishing equipment, etc., can solve the problems of small grinding area and inability to realize linear movement, etc., and achieve full grinding and polishing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

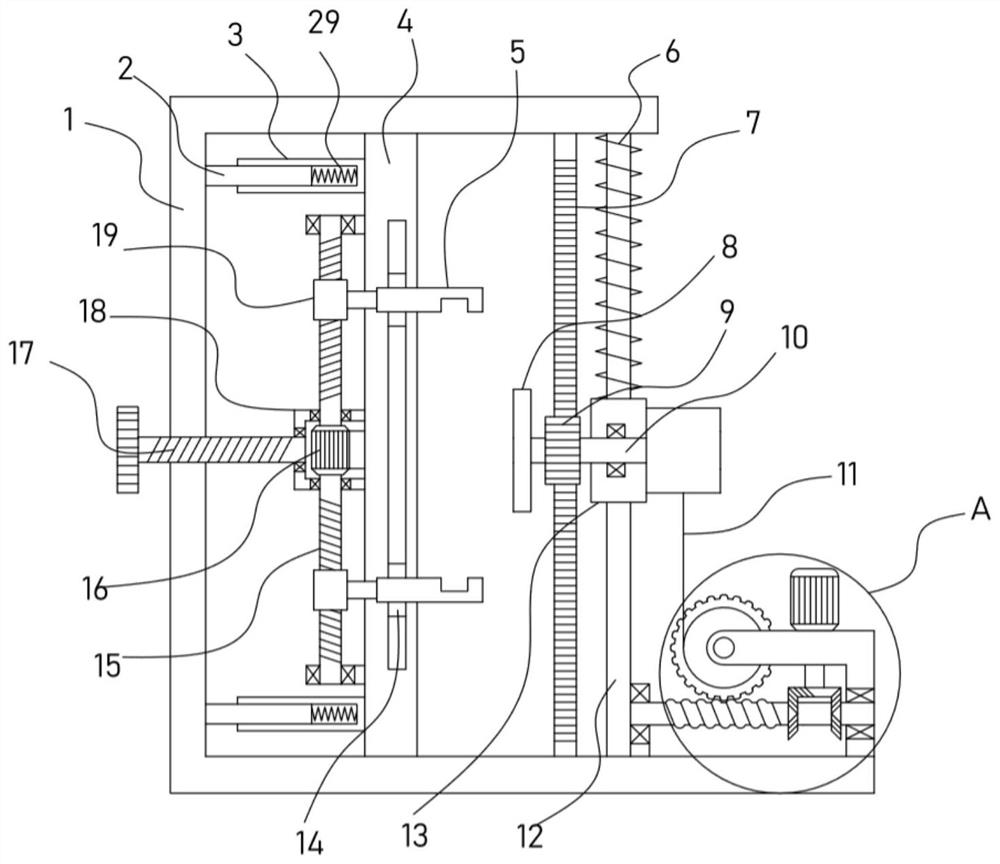

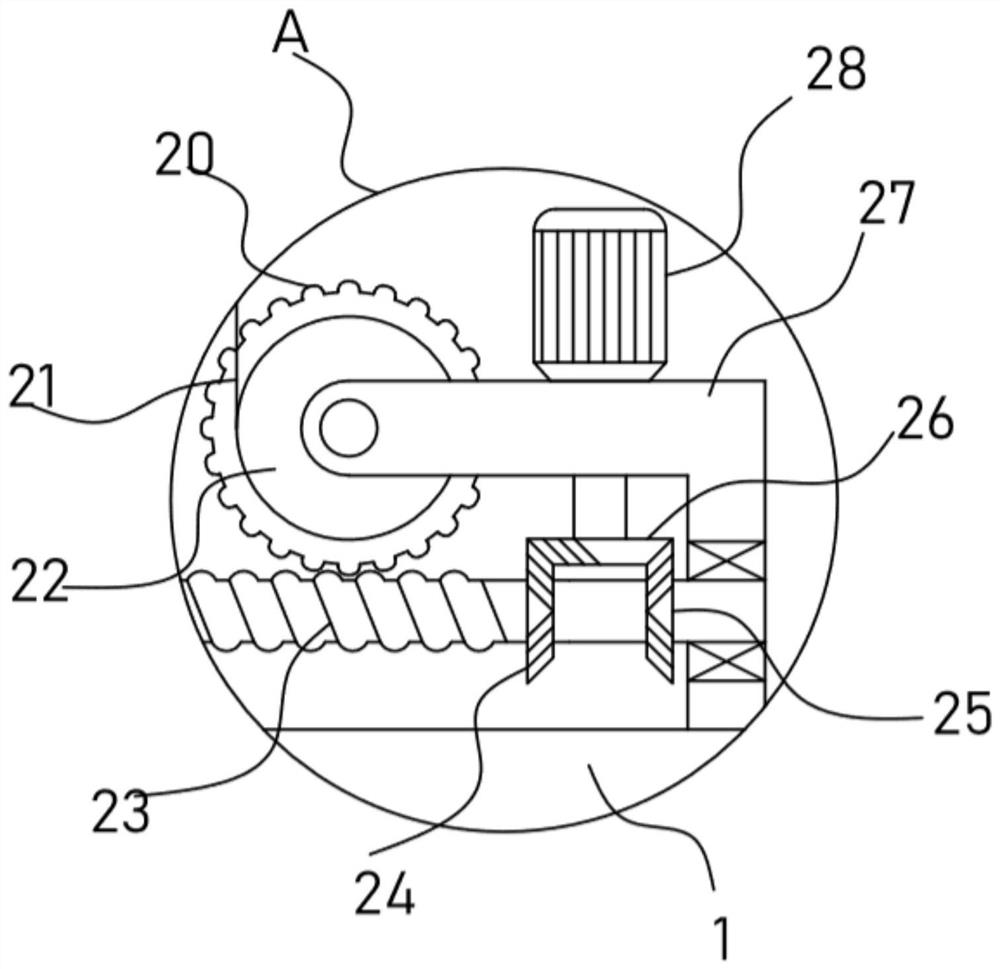

[0022] see Figure 1-3 , a device for polishing and leveling the surface of a plate for building construction, comprising a fixed frame 1, a vertical plate 4 is vertically arranged on the fixed frame 1, a connecting frame 18 is fixed on the vertical plate 4, and a biaxial motor is fixed on the connecting frame 18 16. The biaxial motor 16 is driven and connected with a limit mechanism for clamping the plate, the fixed frame 1 is provided with an adjustment mechanism for adjusting the lateral movement of the vertical plate 4, and the fixed frame 1 is provided with a vertical The guide block 13 of straight sliding is provided with a polishing mechanism for polishing the plate on the guide block 13, and the mounting frame 27 is fixed on the fixed frame 1, and the servo motor 28 is fixed on the mounting frame 27, and the servo motor 28 is driven A forward and reverse mechanism is connected, and a translation mechanism for driving the vertical movement of the guide block 13 is conne...

Embodiment 2

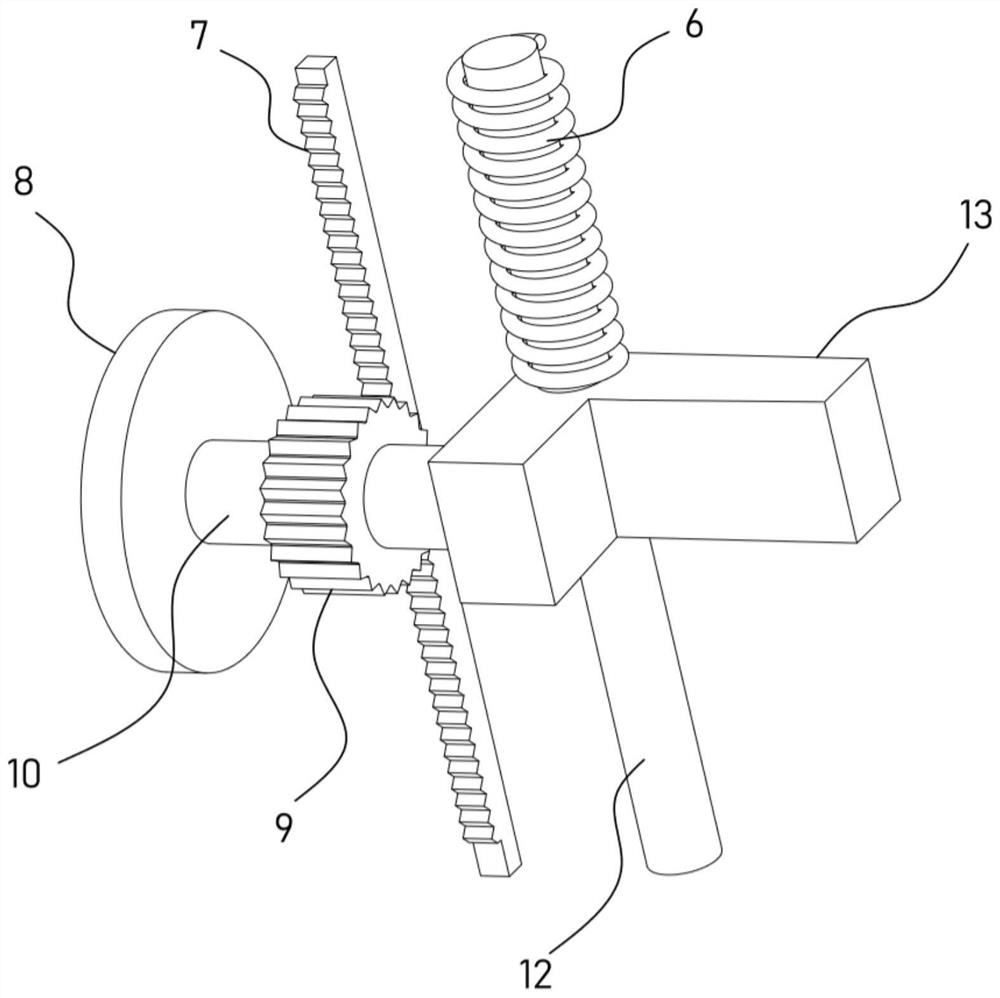

[0029] On the basis of Embodiment 1, in addition, the polishing mechanism of the device includes a horizontal drive shaft 10 that is rotatably installed on the guide sleeve block 13, and the end of the drive shaft 10 is coaxially fixed with a grinding disc parallel to the vertical plate 4 8. When the drive shaft 10 rotates, the drive shaft 10 drives the grinding disc 8 to rotate, so as to realize the polishing and smoothing of the surface of the plate.

[0030] Further, the translation mechanism of the device includes a winding wheel 22 that is rotatably installed on the mounting frame 27. The winding wheel 22 is wound with a stay rope 11 whose upper end is fixed to the guide block 13. The fixed frame 1 is vertically A vertical rack 7 is fixed, and the vertical rack 7 is meshed with a transmission gear 9 fixed coaxially with the drive shaft 10. The translation mechanism also includes a vertical rod 12 that vertically passes through the guide block 13, and the vertical rod 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com